#PSA Oxygen Gas Generator

Explore tagged Tumblr posts

Text

How an Oxygen generator is used in manufacturing ...

In various manufacturing industries, oxygen plays a crucial role in enhancing product quality, reducing costs, and improving overall efficiency. PSA Oxygen Gas Generators have emerged as a game-changer, providing a reliable and cost-effective source of pure oxygen. Here's how manufacturing companies leverage oxygen generators to streamline their operations:

1. Cutting and Welding: Oxygen generators supply high-purity oxygen for cutting and welding applications, ensuring cleaner cuts, reduced oxidation, and improved weld quality.

2. Surface Treatment: Oxygen is used to enhance surface treatment processes like blasting, cleaning, and coating, resulting in improved product durability and appearance.

3. Chemical Processing: Oxygen generators support chemical reactions, oxidation processes, and water treatment, enabling companies to produce high-quality chemicals and materials.

4. Food Processing: Oxygen is used to preserve food freshness, extend shelf life, and maintain quality during packaging and storage.

5. Pharmaceutical Manufacturing: High-purity oxygen is essential for pharmaceutical production, ensuring the quality and stability of medicines.

By integrating oxygen generators into their operations, manufacturing companies can:

- Reduce reliance on costly oxygen cylinders

- Lower energy consumption and operating costs

- Increase productivity and efficiency

- Enhance product quality and consistency

- Improve workplace safety

In conclusion, oxygen generators have become a vital component in various manufacturing industries, driving growth, innovation, and sustainability. By adopting this technology, companies can stay competitive, reduce costs, and contribute to a cleaner and more efficient future.

For More Information –

. Contact Us - 8126173604

. Email Id - [email protected]

. Address - 493, Devlok Colony, Swarg Ashram Road, Hapur - 245101, Uttar Pradesh, India

#PSA Oxygen Gas Generator#PSA Oxygen Gas Generator Manufacturer#PSA Oxygen Gas Generator Supplier#PSA Oxygen Gas Generator Exporter

0 notes

Text

Onsite Oxygen | PSA Oxygen Generator - Airox Technologies

In PSA Oxygen generator oxygen is been produced at 4.5 bar pressure. To fill cylinders this oxygen need to be boost at 150 bar. This is possible by using oxygen booster. The oxygen is collected from PSA oxygen receiver tank, from there it is been boosted through oxygen booster and with the help of Manifold it is been filled in Cylinders.

Applications of Oxygen Gas Boosters

The following are a few well-known applications of oxygen gas boosters

Laser Cutting

Gas Transfer and Charging in Defence and Aviation

Life Support

Fire Fighting

Industrial Equipment Manufacturing

Medical Resuscitation

Diving

Oxygen bottle charging

For more information » on Airox Technologies Ltd, Visit us & give us a call now » at +91 9764634964 or mail us at [email protected] »

0 notes

Text

#nitrogen gas generator manufacturer#ammonia cracker unit manufacturer#oxygen gas generator manufacturer#psa oxygen gas plant manufacturer#psa nitrogen gas plant manufacturer#ammonia cracker manufacturer

0 notes

Text

#Medical oxygen gas plant Manufacturer#Oxygen gas Generator Manufacturer#Psa nitrogen gas plant Manufacturer#Nitrogen gas plant Manufacturer#Nitrogen gas generator Manufacturer#Ammonia cracker Manufacturer#Ammonia cracker Unit Manufacturer#Oxygen Gas Plant Manufacturer

0 notes

Text

How does Gruner Renewable convert municipal solid waste (MSW) into clean biogas?

In a world increasingly threatened by climate change and pollution, sustainable waste management has become a pressing need. One of the most promising solutions to urban waste problems lies in transforming municipal solid waste (MSW) into renewable energy. Gruner Renewable, a leader in clean energy solutions, has pioneered a revolutionary method for boldBio Gas Generation from MSWbold, helping cities manage their waste while generating clean, green fuel.

What is Municipal Solid Waste (MSW)?

Municipal Solid Waste (MSW) refers to the everyday garbage collected from households, commercial buildings, schools, and public spaces. It includes a mix of biodegradable waste (like food scraps, garden waste, and paper) and non-biodegradable components (like plastics, metals, and glass).

In India, millions of tons of MSW are generated daily, leading to overfilled landfills, foul odors, disease outbreaks, and greenhouse gas emissions. The conventional disposal methods — dumping and burning — not only waste valuable resources but also harm the environment.

This is where Gruner Renewable’s innovation comes in — offering a cleaner, smarter solution through Bio Gas Generation from MSW.

The Gruner Renewable Process: From Waste to Energy

Gruner Renewable’s process involves a well-structured, science-backed system that transforms organic fractions of MSW into high-quality biogas. Here’s a breakdown of the process:

1. Waste Collection and Segregation

The journey starts with the collection of municipal solid waste. However, not all MSW is suitable for biogas production. That’s why Gruner emphasizes the importance of waste segregation at the source. Biodegradable materials like food waste, agricultural residues, and paper are separated from plastics, glass, and metals.

Advanced mechanical and manual sorting processes ensure that only organic-rich fractions enter the digestion system.

2. Pre-treatment of Organic Waste

Once segregated, the organic material undergoes shredding to reduce its size and increase surface area for microbial action. Water may be added to create a slurry, improving the efficiency of the digestion process.

This pre-treatment ensures uniformity, removes contaminants, and sets the stage for optimal anaerobic digestion.

3. Anaerobic Digestion

This is the heart of Bio Gas Generation from MSW. The prepared organic slurry is fed into a large anaerobic digester — an oxygen-free chamber where naturally occurring bacteria break down the waste over several days.

During this biological process, the microbes digest the organic matter and release methane-rich biogas, along with a nutrient-rich residue called digestate.

4. Biogas Collection and Purification

The raw biogas produced contains impurities like carbon dioxide (CO₂), hydrogen sulfide (H₂S), and water vapor. Gruner Renewable uses advanced purification technologies like scrubbing, membrane separation, and pressure swing adsorption (PSA) to upgrade the biogas.

The result? Clean, high-purity biomethane that can be used as:

● Fuel for cooking

● Electricity generation

● Transportation (as CNG substitute)

● Industrial thermal applications

5. Utilization of Digestate

The leftover digestate is not waste — it’s a valuable by-product. Rich in organic nutrients, it is processed into organic manure or compost. This contributes to sustainable agriculture by reducing dependence on chemical fertilizers.

Why Gruner Renewable’s Model is a Game-Changer

Reduces Landfill Waste

By diverting a large portion of biodegradable MSW from landfills, Gruner helps reduce the strain on municipal waste systems and limits harmful emissions like methane.

Clean Fuel Production

Biogas is a clean, renewable fuel. It burns without producing harmful pollutants, making it ideal for sustainable energy use.

Decentralized Waste Management

Gruner Renewable’s plants can be set up near cities or industrial zones, reducing the need for long-distance waste transport and allowing localized energy production.

Job Creation and Economic Impact

Each plant creates jobs in waste collection, sorting, operations, and maintenance, supporting local communities and informal workers.

Environmental and Social Benefits

● Reduction in Greenhouse Gas Emissions: Methane captured from waste is used as fuel rather than escaping into the atmosphere.

● Improved Public Health: Cleaner surroundings and fewer open dumpsites help reduce diseases and foul air.

● Support for Circular Economy: Waste is transformed into resources — fuel and fertilizer — closing the resource loop.

Real-World Impact: Case Study Example

In one of the pilot projects in a Tier-2 city, Gruner Renewable installed a biogas plant capable of processing 50 tons of MSW per day. Within months:

● The city reported 30% less garbage reaching landfills.

● Biogas produced powered over 1,000 homes.

● Local farmers began using organic manure made from digestate.

This proves that Bio Gas Generation from MSW is not just theory — it’s a working, scalable solution.

Challenges and Gruner’s Solutions

While the concept is powerful, MSW-to-biogas systems do face real-world challenges:

Challenge

Gruner’s Approach

Unsegregated waste

Promoting awareness, partnering with municipalities for segregation drives

Odor management

Using sealed digesters, filters, and proper aeration systems

Space for setup

Offering modular plant designs suitable for urban peripheries

Fluctuating waste volume

Scalable tech that adapts to daily input variations

Conclusion

Gruner Renewable is not just creating energy — it’s creating a cleaner future. By converting waste into wealth, the company showcases the immense potential of Bio Gas Generation from MSW as a sustainable solution for India’s mounting waste crisis.

It’s time to reimagine garbage not as a burden, but as a resource waiting to be tapped. Gruner Renewable is leading that transformation — one biodegradable bag at a time.

0 notes

Text

What Is a Biogas Plant and How Does It Function?

Australia is at the forefront of transitioning to sustainable energy, and biogas plants are playing a critical role in that evolution. As concerns about fossil fuel dependence, greenhouse gas emissions, and landfill space mount, biogas plants in Australia offer a powerful, eco-friendly solution by converting organic waste into renewable energy.

Understanding a Biogas Plant

A biogas plant is a facility designed to convert organic material—such as food waste, animal manure, agricultural residues, and sewage—into biogas through a process known as anaerobic digestion. This biogas can then be used for electricity generation, heating, or even upgraded to biomethane to be injected into gas grids or used as a vehicle fuel.

Biogas plants operate in a closed system, ensuring minimal environmental disruption while producing valuable byproducts like digestate, which can be used as an organic fertilizer.

The Biogas Production Process

1. Feedstock Collection and Preparation

The process begins with the collection of organic waste from various sources:

Agricultural operations (livestock manure, crop residues)

Food processing industries (expired products, peels, pulp)

Municipal waste (household food scraps)

Sewage treatment facilities (sludge)

The feedstock is then pre-treated—this may include shredding, pulping, or mixing—to ensure consistency and enhance microbial digestion.

2. Anaerobic Digestion

The core of the biogas plant lies in the anaerobic digesters—airtight tanks where microorganisms break down organic matter in the absence of oxygen.

There are typically four phases in the digestion process:

Hydrolysis: Complex organic polymers (carbohydrates, fats, proteins) are broken into simpler molecules.

Acidogenesis: The simple molecules are converted into volatile fatty acids.

Acetogenesis: Fatty acids are transformed into acetic acid, CO₂, and hydrogen.

Methanogenesis: Methanogenic bacteria produce methane (CH₄) and carbon dioxide (CO₂), forming the main components of biogas.

This process typically occurs over 15 to 30 days, depending on the system design and feedstock.

3. Biogas Collection and Utilisation

The biogas produced is a renewable energy source containing approximately:

50–70% methane

30–40% carbon dioxide

Trace amounts of hydrogen sulfide, ammonia, and water vapour

The gas is collected, purified, and directed toward different energy applications:

Electricity and heat generation via combined heat and power (CHP) units

Biomethane production through upgrading processes (water scrubbing, PSA, or membrane separation)

Fuel for vehicles using compressed biogas (CBG)

4. Digestate Management

A crucial byproduct of the biogas process is digestate, the nutrient-rich slurry left after digestion. It can be separated into:

Liquid fraction used as liquid fertilizer

Solid fraction processed into compost or soil conditioner

This supports sustainable agriculture, returning nutrients to the land and closing the nutrient loop.

Types of Biogas Plants in Australia

Australia utilises different types of biogas plant configurations, each suited to specific waste streams and operational goals.

1. Wet Digesters

These systems process slurry-based feedstock with a high moisture content. Common in livestock farms and municipal waste plants, wet digesters are cost-effective for substrates with low solid content.

2. Dry Digesters

Ideal for solid waste like food scraps or crop residues, dry digesters operate with less water, making them suitable for arid regions in Australia.

3. Continuous vs. Batch Systems

Continuous systems are fed daily and offer stable gas production—common in large-scale operations.

Batch systems are filled and sealed until digestion completes—more suitable for small-scale or seasonal use.

Benefits of Biogas Plants in Australia

1. Renewable Energy Generation

Biogas offers a consistent and reliable energy source that can supplement wind and solar. It supports grid stability and reduces reliance on fossil fuels.

2. Waste Reduction

By diverting organic waste from landfills, biogas plants help Australia manage municipal solid waste, reduce methane emissions, and extend landfill lifespan.

3. Agricultural Sustainability

Farmers benefit from waste-to-energy systems that process manure while generating power and high-value fertilizer, thus improving soil health and crop yield.

4. Carbon Emissions Reduction

Methane is a potent greenhouse gas—biogas systems capture and utilise it instead of releasing it into the atmosphere, contributing to climate change mitigation.

5. Energy Independence

Local production of biogas reduces Australia's reliance on imported fuels, promoting regional development and energy security.

Challenges and Opportunities in the Australian Context

Despite its advantages, biogas adoption in Australia faces some challenges:

High initial investment and infrastructure costs

Regulatory complexities and approval processes

Lack of awareness among stakeholders

However, the Australian Renewable Energy Agency (ARENA) and state governments are actively funding biogas projects, especially in sectors like agriculture, wastewater, and food manufacturing.

Incentives such as carbon credits, feed-in tariffs, and renewable gas targets are expected to increase the viability of biogas plants across the nation.

Real-World Applications of Biogas in Australia

1. Farms and Livestock Operations

Dairy farms in Victoria and Queensland have implemented anaerobic digesters to handle cow manure, producing both electricity and reducing odour problems.

2. Food Processing Plants

Several Australian food manufacturers are turning waste products—like whey, vegetable peelings, and spent grains—into biogas for energy and process heat, reducing their operational carbon footprint.

3. Municipal Waste Facilities

Cities like Sydney and Melbourne are integrating anaerobic digestion into waste treatment, using biogas to power wastewater treatment plants and municipal buildings.

4. Biomethane Injection Projects

Pilot projects are underway to upgrade biogas into biomethane and inject it into the natural gas grid, creating opportunities for clean gas utilities and carbon-neutral fuel.

Future of Biogas Plants in Australia

With growing demand for renewable energy, carbon neutrality, and circular economy solutions, biogas plants are poised to become a key part of Australia’s energy landscape.

Emerging technologies like advanced microbial consortia, high-rate digesters, AI-based monitoring, and mobile biogas units will further drive adoption, especially in remote communities and off-grid areas.

0 notes

Text

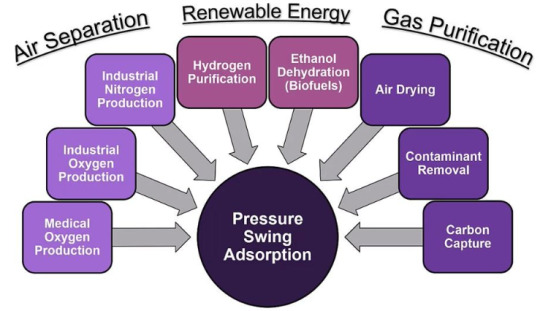

Understanding Pressure Swing Adsorption (PSA) Technology: A Game-Changer in Gas Separation by Gas Processing

In today's rapidly evolving industrial landscape, the demand for efficient, cost-effective, and environmentally friendly gas separation techniques is higher than ever. One of the most trusted and widely used technologies in this domain is Pressure Swing Adsorption (PSA). At Gas Processing, we specialize in delivering advanced PSA systems designed to meet diverse industry needs, from nitrogen and oxygen generation to hydrogen purification and biogas upgrading.

0 notes

Text

CMS for Nitrogen Purification and PSA Applications

Sorbchem India's Carbon Molecular Sieve offers an efficient solution for nitrogen purification in PSA systems. By selectively adsorbing oxygen, the CMS ensures high-purity nitrogen gas at the outlet. Its robust performance under various conditions guarantees a consistent nitrogen output with minimal regeneration time. Ideal for diverse industrial applications, Sorbchem CMS ensures the best nitrogen generation performance, maintaining efficiency and purity.

For more information

Contact +91 9879203377,

Email us- [email protected]

Website- https://www.sorbchemindia.com/products/carbon-molecular-sieve

#CarbonMolecularSieve#CMSForNitrogenProduction#MolecularSieve#SorbchemIndia#AirSeparation#PSANitrogenSystems#CMS#NitrogenGeneration#OxygenAdsorption#PressureSwingAdsorption#GasPurification

1 note

·

View note

Text

How Medical Oxygen Plant Manufacturers Are Expanding Into Nitrogen Generator Solutions

The global demand for on-site gas generation systems has seen a significant uptick in recent years, driven by the increasing needs of healthcare, manufacturing, and food processing sectors. Among the most notable trends is the expansion of medical oxygen plant manufacturers into the domain of nitrogen generator solutions. This diversification is not only strategic but also logical, considering the technological overlap and growing market synergy between these two essential gases.

Shared Technologies and Infrastructure

Medical oxygen and nitrogen generators often rely on similar core technologies, particularly Pressure Swing Adsorption (PSA) and cryogenic air separation. These technologies are capable of separating different components from atmospheric air, and manufacturers who have perfected oxygen generation systems find it relatively straightforward to adapt their designs and production lines for nitrogen generation.

For example, PSA-based systems can be reconfigured with different adsorbent materials and operating pressures to shift from oxygen to nitrogen output. This allows oxygen plant manufacturers to leverage their existing R&D, supply chain, and production infrastructure while tapping into an adjacent and rapidly growing market.

Rising Demand Across Industries

While oxygen is primarily critical in the healthcare sector for life support and surgical applications, nitrogen generator manufacturers plays an essential role in industries such as electronics, pharmaceuticals, metallurgy, and food packaging. The increased industrialization across emerging economies has led to a surge in demand for on-site nitrogen generation. Manufacturers already supplying oxygen plants to hospitals during the COVID-19 pandemic now see a natural opportunity to serve a broader clientele by offering nitrogen generator systems.

Dual Expertise, One Manufacturer

Companies that previously specialized in oxygen plants are now branding themselves as comprehensive gas solution providers. These manufacturers offer complete system integration, including compressors, dryers, storage tanks, and monitoring panels, for both oxygen and nitrogen generators. Their deep understanding of purity levels, gas safety standards, and regulatory compliance gives them a competitive edge when entering the nitrogen generator market.

By expanding into nitrogen solutions, these manufacturers provide added value to clients in industries that use both gases—for instance, pharmaceutical companies that require medical-grade oxygen for certain processes and nitrogen for inerting or blanketing applications.

Customization and Scalability

Another advantage for oxygen plant manufacturers entering this space is their existing experience with customization and scalable systems. Just as hospitals require oxygen generators tailored to patient volume and infrastructure, factories need nitrogen systems that match their production scale and safety requirements. Experienced manufacturers are well-positioned to design modular systems that can be upgraded or reconfigured easily, depending on the client’s operational needs.

This versatility has made these dual-capable manufacturers attractive to industries that prefer a single vendor for multiple gas systems, reducing their dependency on multiple suppliers and simplifying maintenance and compliance.

Competitive and Strategic Benefits

From a business perspective, expanding into nitrogen generation diversifies product offerings and reduces dependency on one vertical. This move also enables manufacturers to withstand market fluctuations—for instance, if hospital oxygen demand dips post-pandemic, rising industrial nitrogen demand can balance the scale.

Furthermore, it opens doors to international markets, where nitrogen generators are in high demand in remote manufacturing zones or areas lacking a reliable gas supply chain. Manufacturers with a proven track record in medical equipment are more likely to be trusted for sensitive industrial applications as well.

Conclusion

The transition of medical oxygen plant manufacturers into nitrogen generator solutions marks a strategic evolution driven by technology, demand, and opportunity. This shift is not only filling critical gaps across industries but also enhancing the versatility, competitiveness, and global footprint of these manufacturers.

By offering both oxygen and nitrogen systems, these companies position themselves as full-spectrum gas generation partners—meeting the growing need for safe, efficient, and on-site gas supply solutions across healthcare and industry alike.

0 notes

Text

What Are the Steps in the Oxygen Pressure Swing Adsorption Process?

Introduction to Oxygen Pressure Swing Adsorption

Oxygen pressure swing adsorption (PSA) is a widely used technology for separating oxygen from air to produce high-purity oxygen gas. This process is efficient, cost-effective, and environmentally friendly, making it ideal for industries such as medical, chemical, and metallurgy. Unlike cryogenic distillation, which is energy-intensive, oxygen pressure swing adsorption leverages the selective adsorption properties of materials to isolate oxygen at ambient temperatures. This article outlines the key steps involved in the oxygen pressure swing adsorption process, providing a clear and objective understanding of its mechanics and applications.

What is Pressure Swing Adsorption?

Pressure swing adsorption is a gas separation technique that uses adsorbent materials, such as zeolites or activated carbon, to selectively capture specific gases from a mixture. In the context of oxygen pressure swing adsorption, the goal is to separate oxygen (O₂) from nitrogen (N₂) and other trace gases in atmospheric air. The process operates by cycling between high-pressure adsorption and low-pressure desorption phases, exploiting differences in the adsorption affinities of gases under varying pressures.

The oxygen pressure swing adsorption process is highly efficient because it can be performed in compact systems, making it suitable for both large-scale industrial applications and smaller, on-site oxygen generators. Companies like Hangzhou Z-Oxygen Intelligent Device Co., Ltd utilize this technology to provide tailored solutions for oxygen generation across various industries.

Key Steps in the Oxygen Pressure Swing Adsorption Process

The oxygen pressure swing adsorption process involves a series of well-defined steps that ensure the continuous production of high-purity oxygen. These steps are typically performed in two or more adsorption columns to maintain a steady output. Below, we break down the process into its core stages.

1. Air Compression and Pre-Treatment The oxygen pressure swing adsorption process begins with the compression of ambient air. Atmospheric air, which contains approximately 21% oxygen, 78% nitrogen, and trace amounts of other gases (e.g., argon, carbon dioxide, and water vapor), is drawn into the system and compressed to a pressure typically between 4 and 10 bar. This compression increases the concentration of gas molecules, facilitating effective adsorption.

Before entering the adsorption columns, the compressed air undergoes pre-treatment to remove impurities that could damage the adsorbent material or reduce efficiency. This involves:

Filtration: Removing dust, oil, and particulate matter using compressed air filters.

Moisture Removal: Using dryers to eliminate water vapor, as moisture can degrade the performance of adsorbents like zeolites.

Carbon Dioxide Reduction: In some systems, additional filters reduce CO₂ levels to prevent competition with oxygen during adsorption.

Pre-treatment ensures that the air entering the oxygen pressure swing adsorption system is clean and dry, optimizing the performance of the adsorbent material.

2. Adsorption Phase In the adsorption phase, the pre-treated, compressed air is directed into an adsorption column filled with a selective adsorbent, typically a zeolite molecular sieve. Zeolites are highly porous materials with a strong affinity for nitrogen due to their molecular structure. In oxygen pressure swing adsorption, the zeolite preferentially adsorbs nitrogen molecules while allowing oxygen and other non-adsorbed gases (e.g., argon) to pass through.

During this high-pressure phase, the following occurs:

Nitrogen molecules are trapped on the surface of the zeolite, reducing the nitrogen content in the gas stream.

Oxygen, which has a lower adsorption affinity, flows through the column and is collected as the product gas.

The output gas typically achieves an oxygen purity of 90–95%, suitable for most industrial and medical applications.

The adsorption phase continues until the zeolite becomes saturated with nitrogen, at which point the column can no longer effectively separate oxygen. To maintain continuous operation, the system switches to a second adsorption column while the first undergoes regeneration.

3. Depressurization and Desorption Once the adsorbent in the first column is saturated, the oxygen pressure swing adsorption process transitions to the depressurization and desorption phase. The column is isolated from the compressed air feed, and the pressure is rapidly reduced, often to near-atmospheric levels. This pressure drop causes the adsorbed nitrogen to be released from the zeolite, a process known as desorption.

Depressurization is critical because it regenerates the adsorbent, preparing it for the next adsorption cycle. The released nitrogen, along with other trace gases, is vented to the atmosphere or, in some systems, collected for further use (e.g., in nitrogen PSA systems). The desorption phase ensures that the zeolite regains its capacity to adsorb nitrogen, making the oxygen pressure swing adsorption process cyclical and sustainable.

4. Purge and Pressure Equalization To enhance efficiency, many oxygen pressure swing adsorption systems include a purge and pressure equalization step. During the purge phase, a small portion of the high-purity oxygen produced from the active column is redirected to the regenerating column. This oxygen flow helps "purge" residual nitrogen from the zeolite, ensuring thorough regeneration.

Pressure equalization is another optimization technique. Before fully depressurizing, the high-pressure gas from the saturated column is transferred to another column that is about to begin adsorption. This reduces energy losses and stabilizes the pressure across the system, improving the overall efficiency of the oxygen pressure swing adsorption process.

5. Cycle Repetition The oxygen pressure swing adsorption process is cyclical, with each column alternating between adsorption and regeneration. In a typical two-column PSA system, while one column is adsorbing nitrogen and producing oxygen, the other is depressurizing and regenerating. The cycle time is carefully controlled, often lasting only a few minutes, to ensure continuous oxygen production.

Advanced oxygen pressure swing adsorption systems may use multiple columns or sophisticated control algorithms to optimize cycle timing and energy consumption. This ensures a steady supply of oxygen with minimal downtime or fluctuations in purity.

Advantages of Oxygen Pressure Swing Adsorption

The oxygen pressure swing adsorption process offers several benefits, making it a preferred choice for oxygen generation:

Energy Efficiency: Compared to cryogenic distillation, PSA requires less energy, as it operates at ambient temperatures and moderate pressures.

Compact Design: PSA systems are compact and scalable, suitable for both large industrial plants and portable oxygen generators.

Cost-Effectiveness: The use of durable adsorbents like zeolites reduces maintenance costs, and on-site generation eliminates the need for oxygen transportation.

High Purity: Oxygen purity levels of 90–95% meet the requirements of most applications, including medical oxygen supply.

Applications of Oxygen Pressure Swing Adsorption

Oxygen pressure swing adsorption is employed across diverse industries due to its versatility and reliability. Key applications include:

Medical Oxygen Supply: PSA systems provide medical-grade oxygen for hospitals and clinics, especially in remote or resource-limited areas.

Industrial Processes: Oxygen is used in chemical manufacturing, metal cutting, and wastewater treatment.

Aerospace and Defense: PSA systems supply oxygen for high-altitude operations and emergency response.

Environmental Applications: Oxygen enhances combustion efficiency in incinerators and supports ozone generation for water purification.

Challenges and Considerations

While oxygen pressure swing adsorption is highly effective, it has some limitations. The process typically produces oxygen with a purity of up to 95%, which may not suffice for applications requiring ultra-high purity (e.g., semiconductor manufacturing). Additionally, the performance of PSA systems depends on the quality of the adsorbent and the precision of cycle control. Regular maintenance, such as replacing filters and monitoring adsorbent degradation, is essential to ensure consistent performance.

Conclusion

Oxygen pressure swing adsorption is a robust and efficient technology for producing high-purity oxygen from atmospheric air. By cycling through compression, adsorption, depressurization, and regeneration, PSA systems deliver a reliable oxygen supply for diverse applications. Its energy efficiency, compact design, and cost-effectiveness make it an attractive solution for industries worldwide. Understanding the steps of the oxygen pressure swing adsorption process highlights its technical elegance and practical value in meeting global oxygen demands.

#asexual#easter#margot robbie#michael cera#across the spiderverse#artists on tumblr#donald trump#barbie#rwby#ryan gosling

0 notes

Text

0 notes

Text

#ammonia cracker unit manufacturer#nitrogen gas generator manufacturer#nitrogen gas plant manufacturer#oxygen gas plant manufacturer#ammonia cracker manufacturer#medical oxygen gas plant manufacturer#psa oxygen gas plant manufacturer#psa nitrogen gas plant manufacturer#oxygen gas generator manufacturer

0 notes

Text

Oxygen Prices: Market Analysis, Trend, News, Graph and Demand

The oxygen market has witnessed significant changes in recent years, driven by rising industrial demand, evolving healthcare needs, and global supply chain dynamics. Oxygen, a critical industrial gas, plays a vital role in sectors such as healthcare, metallurgy, chemicals, water treatment, and energy. With its indispensable use across multiple industries, fluctuations in oxygen prices have become a subject of growing interest to businesses, analysts, and policymakers.

From an industrial perspective, oxygen is a crucial component in processes such as steel manufacturing, welding, cutting, and chemical synthesis. The metallurgy industry, one of the largest consumers of oxygen, relies heavily on high-purity oxygen to enhance combustion efficiency and reduce energy consumption. As global construction and infrastructure development activities continue to grow, especially in emerging economies, the demand for industrial oxygen has increased proportionately. This industrial demand has a direct impact on the oxygen price trend, with regional market dynamics playing a significant role in shaping pricing strategies. Countries with abundant production capacities and established distribution infrastructure tend to offer more stable prices, while others dependent on imports may face cost volatility due to logistics and geopolitical factors.

Get Real time Prices for Oxygen: https://www.chemanalyst.com/Pricing-data/oxygen-1575

Technological advancements in oxygen production, including cryogenic distillation and pressure swing adsorption (PSA), have also influenced market pricing. While traditional cryogenic processes remain dominant for large-scale production, PSA technology has gained traction due to its cost-effectiveness and ease of deployment in smaller setups, such as hospitals and remote industrial sites. The widespread adoption of PSA-based oxygen generators has contributed to cost optimization and reduced reliance on centralized supply chains. However, the capital investment required for high-capacity oxygen production facilities continues to influence the pricing structure, especially in developing regions where infrastructure development is ongoing.

Energy prices are another critical factor influencing oxygen market prices. Since oxygen production, particularly through cryogenic air separation, is energy-intensive, fluctuations in electricity and fuel costs have a direct bearing on operational expenses. In regions where energy costs are high or volatile, oxygen prices tend to reflect this increase, creating challenges for industries operating on thin profit margins. Additionally, the push for sustainable and energy-efficient production methods has led to innovation in oxygen manufacturing, with some producers exploring renewable energy integration to offset energy costs and reduce their carbon footprint. These shifts, while promising in the long term, may initially lead to varied pricing outcomes depending on the scalability and regional adoption of such green technologies.

Government regulations and health safety standards also contribute to the pricing and availability of oxygen. In many countries, oxygen is classified as a medical product and subject to stringent quality controls. Compliance with these regulations entails added costs for purification, packaging, and transportation, especially for medical-grade oxygen. These regulatory requirements, while essential for safety, add to the overall cost structure and influence market prices. In contrast, industrial oxygen, which does not require the same level of purity, is subject to less stringent standards, resulting in a slightly different pricing mechanism. Nonetheless, both grades often share the same production infrastructure, and any disruptions in the supply chain can cause cross-segment price ripple effects.

Geopolitical events and supply chain disruptions have also played a role in shaping oxygen prices globally. For instance, during periods of conflict or economic sanctions, the transportation and export of industrial gases, including oxygen, may be restricted or delayed, leading to localized shortages and price spikes. Furthermore, the COVID-19 crisis exposed vulnerabilities in global oxygen supply chains, prompting many governments to prioritize local production capabilities. This shift toward regional self-sufficiency has led to investments in domestic oxygen plants, which, while initially costly, are expected to stabilize prices over time by reducing import dependencies.

Looking at regional market trends, Asia-Pacific remains the largest and fastest-growing market for oxygen, fueled by robust industrialization, healthcare expansion, and population growth. Countries such as China and India are leading in both production and consumption, with government support playing a crucial role in expanding manufacturing capabilities. In North America and Europe, market maturity and stringent environmental policies have driven innovation in energy-efficient oxygen production, keeping prices relatively stable while supporting sustainability goals. Latin America and Africa, although smaller in scale, are witnessing growing demand, particularly in healthcare and water treatment, which is expected to contribute to moderate price growth in the coming years.

Future trends in the oxygen market suggest a steady rise in demand across both medical and industrial sectors. Innovations in hydrogen production, particularly green hydrogen, also present new avenues for oxygen use and may influence long-term price trajectories. As electrolysis becomes more mainstream in the energy sector, the by-product oxygen generated during hydrogen production could alter market dynamics by increasing supply. However, the economic viability of such processes remains under scrutiny, and their impact on pricing will depend on global energy transition policies and technological advancements.

In conclusion, oxygen prices are influenced by a complex interplay of factors including industrial demand, healthcare needs, energy costs, production technology, regulatory standards, and geopolitical conditions. While prices may exhibit short-term volatility due to supply chain challenges or global events, the long-term outlook for the oxygen market remains stable and growth-oriented. As industries evolve and new applications emerge, the need for efficient, cost-effective, and sustainable oxygen production will become increasingly critical. This ongoing evolution ensures that oxygen will continue to play a central role in both economic and public health landscapes, making its market performance a key indicator to watch in the coming years.

Get Real time Prices for Oxygen: https://www.chemanalyst.com/Pricing-data/oxygen-1575

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Oxygen Prices#Oxygen Price Trend#Oxygen News#Oxygen Monitor#India#united kingdom#united states#Germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

0 notes

Text

Biogas Treatment Solutions: Unlocking the Potential of Renewable Energy

Biogas, a renewable energy source derived from organic waste, has gained significant attention due to its ability to reduce greenhouse gas emissions and provide sustainable energy solutions. However, before biogas can be used effectively, it must undergo a treatment process to ensure its quality and usability. In this article, we will explore the different biogas treatment solutions, their importance, and how they contribute to a cleaner, more sustainable future.

What is Biogas?

Biogas is produced through the anaerobic digestion of organic materials, such as agricultural waste, food scraps, sewage sludge, and landfill waste. This process involves the breakdown of organic matter by microorganisms in the absence of oxygen, resulting in the production of methane (CH4), carbon dioxide (CO2), and trace gases. Biogas is an important renewable energy source, particularly in sectors like agriculture, waste management, and energy generation.

The Need for Biogas Treatment

Biogas in its raw form often contains impurities such as carbon dioxide (CO2), hydrogen sulfide (H2S), moisture, ammonia, and siloxanes. These impurities can reduce the efficiency of biogas use, damage engines and equipment, and contribute to air pollution when released into the atmosphere. Therefore, biogas treatment is a crucial step before it can be utilized for power generation, heating, or as a vehicle fuel.

Biogas treatment improves the quality of the gas by removing harmful impurities, increasing the methane concentration, and making it suitable for a wide range of applications. The treatment process ensures that the biogas meets the standards required for use in various energy systems.

Key Biogas Treatment Solutions

1. Desulfurization (Removal of Hydrogen Sulfide)

Hydrogen sulfide (H2S) is one of the most common contaminants found in raw biogas. It is corrosive and can damage equipment, including engines, turbines, and pipelines. Furthermore, when H2S is burned, it produces sulfur dioxide (SO2), a harmful air pollutant.

Treatment Methods:

Iron Oxide Scrubbing: This method involves passing biogas through a bed of iron oxide, which reacts with H2S to form iron sulfide. It is an effective and widely used method for desulfurization.

Chemical Scrubbing: Chemical scrubbing uses alkaline solutions, such as sodium hydroxide (NaOH), to absorb and neutralize H2S. It is a common treatment in large-scale biogas plants.

Biological Scrubbing: This method uses bacteria to break down H2S into sulfuric acid. It is an environmentally friendly approach but may require more complex systems.

2. Carbon Dioxide Removal (Upgrading)

The high concentration of carbon dioxide (CO2) in raw biogas reduces the energy content of the gas. Biogas upgrading is the process of removing CO2 and increasing the methane concentration to produce "biomethane" or "renewable natural gas" (RNG), which has similar properties to conventional natural gas.

Treatment Methods:

Water Scrubbing: In this process, raw biogas is passed through water, which absorbs CO2. Water scrubbing is cost-effective and widely used in small to medium-sized biogas plants.

Pressure Swing Adsorption (PSA): This method utilizes adsorbent materials, such as activated carbon or zeolites, to capture CO2 at high pressure. PSA is efficient and is typically used in large-scale biogas plants.

Membrane Separation: Membranes with selective permeability are used to separate CO2 from methane. This method is highly efficient but can be expensive for small-scale operations.

Chemical Absorption: A liquid solvent absorbs CO2 from the biogas. This method is highly effective and commonly used in commercial applications.

3. Moisture Removal

Biogas typically contains moisture in the form of water vapor, which can cause corrosion in pipelines, engines, and other equipment. Removing moisture ensures that the biogas is in a dry and stable state, preventing damage to infrastructure.

Treatment Methods:

Condensation: This process involves cooling the biogas to allow moisture to condense and separate from the gas.

Membrane Dehydration: Membranes are used to separate moisture from biogas, producing dry biogas suitable for use.

Chilled Water Scrubbing: In this method, biogas is passed through chilled water to remove moisture, making the gas dry and ready for use.

4. Ammonia Removal

Ammonia (NH3) is another contaminant that can be found in biogas, especially when derived from livestock waste or wastewater treatment. Ammonia can be toxic to biological systems and cause corrosion in equipment.

Treatment Methods:

Absorption in Acidic Solutions: Ammonia can be removed from biogas by passing it through acidic solutions, such as sulfuric acid, which neutralizes the ammonia.

Biological Treatment: Specific bacteria can be used to break down ammonia in biogas, making it safer for use.

5. Siloxane Removal

Siloxanes are silicon-based compounds commonly found in biogas, particularly in landfill and sewage treatment plant biogas. When burned, siloxanes form silicon dioxide (SiO2), which can cause wear and tear on engines and turbines.

Treatment Methods:

Activated Carbon Filtration: Activated carbon is highly effective at adsorbing siloxanes from biogas, preventing damage to equipment.

Silica Gel Adsorption: Silica gel can also be used to capture siloxanes and prevent them from causing operational issues.

Benefits of Biogas Treatment Solutions

Improved Energy Efficiency: By removing impurities like CO2 and moisture, biogas treatment increases the energy content of biogas, making it a more efficient fuel.

Protection of Equipment: Treatment solutions remove harmful contaminants that can damage equipment, ensuring the longevity of engines, turbines, and pipelines.

Environmental Impact: Biogas treatment reduces harmful emissions, such as H2S, CO2, and siloxanes, ensuring that the gas is cleaner and safer for the environment.

Compliance with Standards: Properly treated biogas meets the required standards for use in power generation, heating, and transportation, opening up a wide range of applications.

Sustainability: By upgrading biogas to biomethane, it can be injected into the natural gas grid or used as a vehicle fuel, promoting sustainable energy solutions and reducing reliance on fossil fuels.

Conclusion

Biogas treatment solutions are a critical component of the renewable energy industry. By effectively removing impurities such as hydrogen sulfide, carbon dioxide, moisture, ammonia, and siloxanes, biogas treatment ensures that biogas can be safely and efficiently used for power generation, heating, and as a clean fuel source for transportation. As biogas continues to grow as a renewable energy resource, these treatment technologies will play an essential role in supporting the transition to a more sustainable and environmentally friendly energy future.

0 notes

Text

PSA Nitrogen Generator – Efficient, Cost-Effective, and High-Purity Nitrogen Supply

A PSA Nitrogen Generator is an advanced solution for producing high-purity nitrogen gas used in various industries. Using a Carbon Molecular Sieve (CMS) and a twin-tower system, this technology efficiently separates nitrogen from atmospheric air, ensuring a continuous supply of nitrogen without relying on external gas cylinders. With easy installation, low maintenance, and automatic operation, PSA nitrogen generators offer an energy-efficient and cost-effective alternative for industrial nitrogen production.

How Does a PSA Nitrogen Generator Work?

The PSA (Pressure Swing Adsorption) technology operates with two towers filled with Carbon Molecular Sieve (CMS). The process includes:

Air Compression & Filtration – Atmospheric air is compressed and passed through an air dryer and filters to remove moisture and impurities.

Separation Process – The twin-tower system alternates between adsorption and regeneration. One tower extracts oxygen and other gases, while the other regenerates for continuous operation.

Nitrogen Collection – The purified nitrogen is stored in a surge vessel and delivered to industrial applications.

Pressure Regulation – A Back Pressure Regulator (BPR) maintains the required pressure level for efficient gas flow.

Purity Control – An Online Oxygen Analyzer ensures the nitrogen meets the desired purity levels before being supplied for use.

This fully automated process eliminates the need for manual intervention, ensuring low operating costs and high efficiency.

Key Features of PSA Nitrogen Plants

✔ Air Compressor (Screw Type) – Supplies compressed air for nitrogen separation ✔ Air Dryer & Filters – Removes moisture, dust, and impurities ✔ Twin-Tower CMS System – Ensures maximum nitrogen purity ✔ Surge Vessel & Control Panels – Maintains stable pressure and gas flow ✔ Oxygen Analyzer & Rota Meter – Monitors purity and gas flow rates

Advantages of PSA Nitrogen Generators

✅ Cost-Effective & Energy Efficient – Produces nitrogen at a lower cost compared to traditional gas cylinders ✅ Eliminates Cylinder Dependency – No need to purchase, store, or transport nitrogen gas cylinders ✅ Compact & Space-Saving Design – Occupies minimal space in industrial setups ✅ Automatic Operation – Works on demand and stops when the required nitrogen level is reached ✅ Low Maintenance – Requires minimal servicing and has a long operational life ✅ Fast Installation & Service Support – Comes with quick after-sales service and a warranty

Technical Specifications

ParameterDetailsCapacity5 NM³ to 1000 NM³/HrMaterial of ConstructionMS/SS (Based on application)Nitrogen Purity95% to 99.999%OperationFully Automatic

Industries That Use PSA Nitrogen Generators

✔ Food & Beverage – Prevents oxidation and spoilage ✔ Pharmaceuticals – Used in drug manufacturing and packaging ✔ Electronics – Protects components from oxidation ✔ Chemical & Petrochemical – Essential for inerting and blanketing applications ✔ Metal Processing – Used in laser cutting and heat treatment

Why Choose Trimech India?

At Trimech India, we specialize in manufacturing high-quality PSA Nitrogen Generators designed to meet industry-specific requirements. Our products are known for their durability, efficiency, and advanced technology. We provide:

✔ Pre-installation consultation ✔ On-site installation & setup ✔ Comprehensive user training ✔ Quick 48-hour service response ✔ Warranty & free maintenance support

Contact Us Today!

📩 Email: [email protected] 📞 Phone: +91-79-25840557

0 notes

Text

Understanding Pressure Swing Adsorption (PSA) Technology: A Game-Changer in Gas Separation by Gas Processing

In today's rapidly evolving industrial landscape, the demand for efficient, cost-effective, and environmentally friendly gas separation techniques is higher than ever. One of the most trusted and widely used technologies in this domain is Pressure Swing Adsorption (PSA). At Gas Processing, we specialize in delivering advanced PSA systems designed to meet diverse industry needs, from nitrogen and oxygen generation to hydrogen purification and biogas upgrading.

What is Pressure Swing Adsorption (PSA)?

Pressure Swing Adsorption is a physical process that separates specific gases from a mixture under pressure. The separation is based on the molecular characteristics and affinity of gases towards an adsorbent material such as zeolite, activated carbon, or molecular sieves. When the gas mixture is passed through the adsorbent at high pressure, certain components are retained while others pass through, resulting in purified output gas.

How Does PSA Work?

The PSA process operates in cycles and generally consists of the following steps:

Adsorption – The gas mixture is compressed and passed through an adsorption vessel. The target gas (like nitrogen or oxygen) is separated as the adsorbent traps other gases.

Depressurization (Swing) – The pressure is lowered to release the trapped gases, regenerating the adsorbent for the next cycle.

Purging – A portion of the purified gas is used to flush out remaining impurities from the adsorbent bed.

Repressurization – The bed is brought back to operating pressure to begin a new adsorption cycle.

This cyclic pressure variation makes the PSA method energy-efficient and capable of delivering high-purity gases continuously.

Applications of Pressure Swing Adsorption

At Gas Processing, our PSA systems are tailored to meet the specific requirements of various sectors, including:

Medical Oxygen Generation Hospitals rely on PSA-based oxygen plants for a consistent and on-site oxygen supply.

Nitrogen Generation for Food & Beverage PSA units produce food-grade nitrogen used in packaging, preservation, and storage.

Hydrogen Purification Refineries and chemical plants use PSA to purify hydrogen by removing CO, CO₂, CH₄, and other impurities.

Biogas Upgradation Converting raw biogas into biomethane by separating CO₂ and other contaminants through PSA technology.

Why Choose PSA from Gas Processing?

At Gas Processing, we bring industry-leading expertise and innovation to every PSA project. Here's why clients across industries trust our PSA systems:

Custom-Engineered Solutions We design systems tailored to specific flow rates, purity levels, and space constraints.

Energy-Efficient Design Our PSA units are optimized for low energy consumption and long service life.

High Purity Output We deliver gas purity up to 99.999% depending on application requirements.

Minimal Maintenance Robust construction and high-quality adsorbents ensure longer operational cycles and reduced downtime.

Turnkey Installation & Support From system design and installation to training and post-sales service, Gas Processing offers complete PSA solutions.

Conclusion

As industries increasingly demand efficient and eco-friendly gas separation techniques, Pressure Swing Adsorption continues to lead the way. At Gas Processing, we are committed to advancing PSA technology to meet modern challenges. Whether it's for oxygen, nitrogen, hydrogen, or biogas, our PSA systems ensure reliability, purity, and performance.

Get in touch with Gas Processing today to discover how our PSA solutions can power your operations with precision and efficiency.

Visit us https://gasprocessing.in/gas-processing/

0 notes