#PP Non Woven Bag

Explore tagged Tumblr posts

Text

Say No to Plastic: A Guide to Stylish Sustainable Bags

The image is all too familiar: overflowing landfills choked with plastic bags, a symbol of our disposable culture. Thankfully, the narrative is shifting. Consumers are demanding eco-friendly alternatives, and stylish, sustainable bags are leading the charge. This guide delves into the exciting world of reusable bags, empowering you to make conscious choices for your shopping and everyday needs.

Natural All-Stars: Cotton, Canvas, and Jute

Embrace the power of nature with these reusable wonders:

Cotton Bags: The classic tote bag. Soft, durable, and readily available, Cotton bags are perfect for everyday errands. They come in a variety of sizes and designs, allowing you to express your personality. For maximum eco-friendliness, choose organic cotton.

Canvas Bags: Need something a little more robust? Canvas bags are the answer! These sturdy companions can handle heavier loads and spills with ease. They come in various sizes and styles, making them ideal for everything from bustling farmers' markets to relaxing beach escapes.

Jute Bags: For a touch of rustic charm, look no further than jute bags. Derived from the jute plant, this natural fiber boasts incredible strength and biodegradability. Jute bags are excellent grocery bags or eco-friendly gift bags, adding a touch of earthy elegance.

Beyond the Ordinary: A World of Colors and Designs

Sustainable bags are no longer just plain and boring. Today, they are a canvas for creativity:

Express Yourself: Cotton, canvas, and jute bags often come in a variety of colors and prints. Choose a bag that reflects your style, or create your own design with fabric paint or embroidery.

Support Local Artists: Many local artists and businesses sell reusable bags featuring their unique artwork. This is a fantastic way to combine sustainability with supporting your community.

Statement Pieces: Make a statement with a bold slogan or image printed on your reusable bag. Raise awareness about environmental issues or simply show off your passion for a cause.

Matching Your Bag to Your Mission

The perfect sustainable bag depends on your needs:

Everyday Champions: Cotton or canvas totes are perfect for everyday errands like grocery shopping or carrying library books. Choose a comfortable design with sturdy handles.

Market Marvels: Canvas or jute bags are ideal for farmers' markets. They're spacious enough to hold all your fresh produce and sturdy enough to handle heavy items.

Stylish Shopper: A canvas bag with a bold design or a jute bag with a touch of rustic elegance can elevate your everyday shopping trip.

Beach Essentials: Canvas bags are perfect beach companions. They can hold your towel, sunscreen, and other beach essentials, and they're easy to clean if they get sandy.

By choosing sustainable bags, we can all contribute to a cleaner and healthier planet. Remember, the most sustainable bag is the one you'll use again and again! So ditch the plastic habit, embrace the sustainable revolution, and discover a world of stylish and reusable bags that work for you and the environment. Let's create a future where landfills are replaced by happy memories and a thriving planet.

#Sustainable Bags#Eco-friendly Bags#Cotton Bags#Canvas Bags#Jute Bags#PP Woven Bags#PP Non-Woven Bags#BOPP Bags#RPET Bags

1 note

·

View note

Text

What Are the Benefits of Using Non-woven Fabric?

You didn't know What Are the Benefits of Using Non-woven Fabric? Here, Shankar Packaging gave all info on Uses & Applications of Non Woven Fabric, and Benefits of Using Non Woven Fabrics, like Light Weight, Softness, Eco-friendly, etc. For more details on Non Woven Fabric Manufacturer in India, visit us!

#non woven fabric#non woven fabric bags#geotextile fabric manufacturers in Gujarat#non woven bags#non woven bag material#non woven fabric manufacturer in India#spunboud non woven material#PP cover manufacturers#filter material

0 notes

Text

What Are the Benefits of Using Non-Woven Fabric?

The non-woven fabrics are materials that are produced by thermal, mechanical and chemical processes. These are engineered fabrics that are used in various industrial and consumer products, by itself or with other materials. It is hygroscopic, UV resistant and flame retardant.

The non-woven fabrics have various benefits, including minimising solid wastes, and landfills and releasing no pollutants in the air and soil. In this blog, we will look into the various benefits of using non-woven fabrics that make them more practical and versatile than other traditional fabrics.

What is Non Woven Fabrics?

The non woven fabric is an engineered material manufactured from different fibers. These materials need not be converted to fibres into yarn, as the fibre yarns are bonded together due to inherent friction from one fibre to another.

Benefits of Using Non Woven Fabrics

Light Weight: The pp non-woven fabrics are the primary raw material for production. Its specific gravity is only 0.09, which is ⅗ of cotton. It is super-soft and pleasant to touch.

Softness: Its softness makes it ideal for non woven fabric bags. The bags are soft and comfy.

Eco-friendly: The reason why geotextile fabric manufacturers in Gujarat are in demand for its non-woven fabrics is its eco-friendly nature. This makes it applicable in different industries. With the rising concerns over environmental consciousness and sustainability, woven materials have gained immense popularity.

Air-Permeable: The non woven bags are made of fiber that exhibits excellent air permeability. This makes it easy to clean and maintain.

Non-Toxic and Non-irritant: The non woven bag material is non-toxic, non-irritant, odourless and stable. The manufacturers use food-grade materials, which makes it ideal for industries like pharmaceutical, personal care, cosmetics and other products.

Water Resistant: The non woven fabric manufacturer in India caters to different industries that need water-repellent materials. The non woven materials are made of polypropylene chips and are non-absorbent and water resistant properties. This makes the end-product exhibit excellent breathabilty and porous.

Excellent Physical Properties: As the material is made of PP spinning directly into the mesh and thermally bonded, it gives the products exceptional strength than other fibre materials.

Uses of Non Woven Fabric

The Non Woven Fabric is Used in a Variety of Applications, Such as:

Medical: The non-woven fabrics have gained a lot of popularity, especially during the pandemic. It is widely used in the manufacturing of various medical products like gloves, masks, surgical drapes, plastic, medical packaging, cleanroom wipes, disposal face masks and more.

Health & Hygiene: The spunboud non woven material has brought an evolution in the hygiene industry. It is used in producing various hygiene products like sanitary pads, diapers, make-up wipes, nail wipes, facial pads, and other products.

Geotextile and Construction: The PP cover manufacturers provide non-woven geotextiles that are used in various applications in the construction and engineering industry. It is primarily used for drainage systems, separation, canal construction, filtration, landfill lining and others.

Household: We are surrounded by non woven geotextiles. It is a part of everyday lives, ranging from water and air filters, household wipes, floor wipes, coffee filter material and much more. Shankar Packaging Ltd. is a prominent filtration fabric manufacturer. We offer a range of filtration materials in 100% multifilament, monofilament spun and other combinations.

Conclusion

Woven fabrics are used in different industrial sectors and play a pivotal role in the technical industry globally. Its soil stability, tear and puncture resistance, UV resistance, breathability, excellent weather ability and tensile strength make it a versatile material. Shankar Packaging Ltd. is a leading geotextile manufacturer and supplier in India.

We offer a comprehensive range of technical textiles, indu-tech, geo-tech, agro-tech and pack-tech products to clients across the globe. Our geotextile is also ideal for geo tubes and geo bags. At SPL, we provide technical textiles in 3 different yarns viz PES multifilament, PP tape yarns and PPMF. To know more about geotextiles and other products, contact us.

#non woven fabric#non woven fabric bags#geotextile fabric manufacturers in Gujarat#non woven bags#non woven bag material#non woven fabric manufacturer in India#spunboud non woven material#PP cover manufacturers#filter material

0 notes

Text

Enhance your logistics with EPP dunnage boxes. Maintain air quality with dust bag and activated carbon filters for refrigerators. Ensure purity with liquid bag filters.

#pet acoustic panel#pp + pet felt#breather fabric#non woven battery gaunlets#fiber glass felt#plastic extrusion profile#compressor felt#Activated air Carbon Filters#Liquid Bag Filters#Refrigerator air filter#Dust Bag Filters

0 notes

Text

SAMI Layer Pavement Fabrics: Boost Road Durability

SAMI Layer Pavement Fabrics: Boost Road Durability

Introduction:

In the ever-evolving landscape of road construction, innovations like SAMI layer pavement fabrics are transforming the way we approach durability and longevity in infrastructure. This blog post explores the key benefits and applications of SAMI layer fabrics, shedding light on how they play a crucial role in enhancing the resilience of our roads.

Understanding SAMI Layer Pavement Fabrics:

How SAMI Layer Fabrics Boost Road Durability

SAMI layer pavement fabrics strengthen the road in multiple ways:

Crack Prevention

Acting as a barrier, the SAMI fabric inhibits cracks from appearing and spreading across the road surface. This adds years to the pavement life. The bonded fabric intercepts cracks at the surface level preventing downward propagation into the base layers.

Enhanced Structural Stability

The integration of the high-modulus SAMI layer evenly distributes traffic loads over a broader pavement area. This reduces concentrated stresses and deformations leading to pavement failures. The outcome is improved stability and strength.

All-Weather Reliability

SAMI fabrics are engineered using polymers like polyester, polyethylene or glass fibers that can withstand diverse environmental conditions from freezing winters to scorching summers. This makes roads more reliable through changing seasons.

Extended Lifespan

The collective impact of crack prevention, load distribution and weather resistance provided by SAMI layers is a significantly extended road lifespan. The surface maintains integrity for longer periods without requiring repairs and rehab.

Sustainable Construction

Applications of SAMI Layer Pavement Fabrics

Some prominent applications that highlight the benefits of SAMI layers include:

Road Rehabilitation

Applying SAMI fabrics provide an economical overlay solution for rehabilitating aged, damaged road surfaces. The fabric strengthens the existing base while providing a new wearing course.

New Road Construction

Integrating a SAMI layer into new road construction leads to more crack-resistant, durable surfacing that extends the period between overlays.

Preventing Reflective Cracking

SAMI layers serve as effective crack retarders at the interface of old and new pavement sections. This addresses reflective cracking, a common issue in road overlays.

Bridge Deck Protection

In conclusion:

SAMI layer pavement fabrics are a game-changer in the realm of road construction, offering a sustainable and effective solution for enhancing the durability of our infrastructure. As we pave the way to the future, these innovative fabrics prove to be an indispensable asset in creating roads that can withstand the test of time.

#geotextile#pavement#non woven fabrics#woven mesh fabric#pp woven bags#woven#woven fabric manufacturers#fabrics

0 notes

Text

Non-woven geotextiles are an important category of geosynthetics used across a wide range of infrastructure and construction applications. This guide provides a deep dive into what non-wovens are, their types, key properties, manufacturing processes, installation methods, advantages, applications, and more.

Introduction to Non-Woven Geotextiles

Geotextiles refer to permeable, polymeric textile materials used in contact with soil or rock in civil engineering applications. They can be woven or non-woven.

Non-woven geotextiles are made by bonding polymeric fibers together through processes like needle punching, heat bonding or resin bonding. The random arrangement of fibres produces a strong, porous and flexible material.

Geotextiles that are non-woven are better than those that are woven. They are better at filtering, draining, and cushioning, and are easier to install. In addition, they are more budget-friendly. These characteristics make non-wovens ideal for many functions like filtration, drainage, separation, and reinforcement.

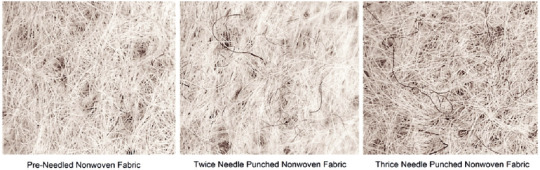

Needle Punched Non-Woven Geotextiles

Needle-punched non-wovens are a major type of non-woven geotextile produced by mechanically orienting and entangling fibers. Hundreds of fine needles repeatedly penetrate a fibre web to tangle the fibres into a strong, porous and stable fabric.

Compared to other non-wovens, needle-punched variants have high permeability and drainage capacity along with good puncture resistance. This makes them ideal for filtration and drainage applications.

Types of Needle-Punched Non-Woven Geotextiles

Needle-punched non-wovens can be categorized into three main types based on weight and fiber thickness:

Lightweight Needle Punched Wovens

Made from fine fibres and low fiber weights between 20-100 gsm. Mainly used in applications that do not require high strength.

Medium Weight Needle Punched Non Wovens

Heavier fibers and medium basis weights of 100-250 gsm. Provides moderate strength for functions like separation.

Heavyweight Needle Punched Non-Wovens

Very coarse, thick fibres and high basis weights above 250 gsm. Imparts maximum strength for reinforcement uses.

Selections depend on the target function. Non-woven fabrics can be categorized into lightweight and heavyweight variants.

Key Functions and Applications of Non-Woven Geotextiles

Non-woven geotextiles perform various functions that make them indispensable for major infrastructure and construction projects:

Filtration Applications

The porous structure allows water to pass through while blocking soil particles. This filtration ability is useful in:

Roadway drainage systems

Retaining walls

Landfill drainage

Water treatment plants

Drainage Applications

Nonwovens have high water flow rates in the principal direction. This makes them excellent for drainage purposes like:

Landfill drainage layers

Sports field drainage

Retaining wall and slope drainage

Separation Applications

The fabric physically separates dissimilar materials. Key applications include:

Roadway base and subbase separation

Railroad bed separation

Foundations separation

https://www.aakarperiwal.com/blogs/wp-content/uploads/2023/09/geotextile-500x500-3.webp

Reinforcement Applications

Non-wovens provide reinforcement for additional strength when wrapped around soil. Uses include:

Embankments over soft soils

Retaining walls with stacked blocks

Slopes requiring improved bearing capacity

Erosion Control Applications

The fabric acts as a permeable layer to protect against wind and water erosion while allowing water passage. Some uses are:

Covering slopes along railways and highways

Coastal embankments erosion control

Riverbanks and canal protection

Transportation Applications

Within road construction, non-wovens assist with filtration, separation, drainage and stabilization. Common applications:

Separation between sub-base and subgrade

Filtration in edge drains alongside pavements

Soil stabilization for improved load-bearing

Construction Applications

Foundations and walls drainage

Vapor barriers in concrete slabs

Flooring reinforcement and crack prevention

This demonstrates the versatility of non-woven geotextiles across diverse functions in C&I projects. Their adaptive properties drive widespread adoption.

Key Properties of Non-Woven Geotextiles

Non-woven geotextiles exhibit unique properties derived from their material composition, manufacturing method and overall structure:

Raw Materials

Most non-wovens use polypropylene as the raw material which is cost-effective and provides required properties. High-end variants use polyester or a polypropylene-polyester blend.

Basis Weight

Basis weight is the mass per unit area measured in g/m2. Heavier basis weights produce stronger fabrics with higher puncture resistance. Typical range is from 20 g/m2 to 300 g/m2.

Thickness

Thickness depends on fiber density and varies from 1mm to 15mm. Affects permeability, cushioning ability and separation effectiveness.

Hydraulic Properties

Non-wovens have high water permeability (normal to the plane) and adequate transmissivity. Allows swift drainage while blocking soil passage.

Mechanical Properties

Tensile strength, tear strength, puncture resistance and burst strength are key mechanical properties. Non woven selection depends on the required load capacity.

Endurance Properties

Long-term resistance against environmental exposure, chemicals, microbes and mechanical stresses comes under endurance properties. Requires proper polymer choice.

These characteristics directly impact the effectiveness and lifespan of the non-woven geotextile for its intended function.

Overview of Manufacturing Processes

Non-woven geotextile production involves specialized processes to achieve the desired fiber arrangement and properties:

Web Formation

The first step is creating a uniform web of fibres laid out in overlapping, random orientations using air, mechanical or wet-laid techniques.

Web Bonding

The fiber web undergoes thermal, chemical or mechanical bonding. This interlocks the fibres to impart strength, stability and thickness.

Finishing

Additional treatments enhance properties - for instance, calendering uses heated rollers to achieve smoothness. Fabric edges are trimmed to create rolls.

Testing and Inspection

Extensive testing under certified labs evaluates parameters like strength, permeability, opening size etc. This ensures compliance with specifications.

Keeping manufacturing consistent and monitoring variabilities is vital for non-woven quality assurance. Automation allows scalable production with minimal defects.

Design and Installation Factors for Non-Woven Geotextiles

Proper design, handling and deployment of non-wovens ensures successful project outcomes:

Site Preparation

The installation site must be graded uniformly and cleared of debris/rocks to avoid damage. Burial depth is determined. Subsurface drainage may be added.

Installation Techniques

Non wovens can be unrolled on site and placed loose or tense. Joints are sewn or bonded. Additional layers can be installed to enhance functioning. Fixings like sandbags or pegs may be used.

Seams and Overlaps

Adjoining rolls are overlapped for continuity. End overlaps depend on joint strength. Edges can be sewn, welded, glued or kept loose. Key consideration for soil retention uses.

Design Factors

Careful specifications of geotextile properties like strength, permeability, and opening size based on engineering requirements and testing. Survivability and performance lifetime also key.

Following recommended practices for non-woven deployment optimizes field performance and prevents failures.

Key Benefits and Advantages of Using Non-Woven Geotextiles

Non-woven geotextiles offer numerous benefits that make them advantageous over traditional materials:

Cost-Effectiveness

Made from polypropylene, non-wovens are an affordable alternative to CMP pipe drains or graded aggregates for drainage. Limited overlap joints also reduce the quantity required.

Rapid Drainage Performance

The high porosity provides greater flow capacity compared to sand filters or gravel layers. Useful in applications like retaining walls.

Good Puncture and Burst Resistance

The entangled fibrous structure provides better resistance against punctures during installation compared to woven geotextiles.

Ease of Installation

Flexible, lightweight non-wovens are simpler to install in field conditions compared to rigid materials. No special equipment needed.

Enhanced Properties

Specialized manufacturing processes like calendering and bonding create improved non-wovens with the right balance of filtration, separation, cushioning and strength.

Wider Widths

The ability to produce up to 5m wide rolls compared to just 1m for wovens leads to faster deployment with fewer joints.

These advantages have positioned non-wovens as a material of choice for major construction activities and geotechnical engineering applications.

Applications and Case Studies Demonstrating Non-Woven Geotextiles in Action

Non-woven geotextiles have delivered value across many real-world projects:

Landfill Construction - Needle-punched non-wovens used in leachate collection systems increased design life while reducing clogging through superior filtration compared to gravel layers.

Retaining Wall Drainage - Heat-bonded non-wovens used as wall wraps maintained water drainage and prevented soil washout, keeping 100km of critical rail walls safely stabilized through extreme weather.

Riverbank Protection - Durable non-woven wraps applied on embankments prevented erosion along highly flood-prone rivers through monsoons. Filtered runoff while retaining soil stability.

Roadway Improvement - Calendered non-wovens beneath motorway overpasses provided vital reinforcement to stabilize compressible soil while facilitating drainage and preventing pumping.

Coastal Reinforcement - Wide-width non-wovens encasing sandy coastal cliffs added shear strength and tensile reinforcement. Protected against collapse from rising sea levels and storm surges.

This demonstrates how non-wovens of different compositions can be adapted for specialized needs in infrastructure projects where performance and longevity are critical.

Industry Trends and Ongoing Innovations in Non-Woven Geotextiles

Several interesting trends, developments and innovations are shaping the non-woven geotextiles sector:

High Growth Potential - The non-wovens market is projected to grow steadily at 6% CAGR driven by major public infrastructure investments and demand from emerging economies.

Raw Material Advances - Enhanced polymers like high-density polypropylene and high-modulus polyester are creating improved non-wovens with greater functionality.

Manufacturing Improvements - Process enhancements and new techniques are allowing more fine-tuned manipulation of fiber properties during production.

Multifunctional Products - Combining non-wovens with drainage nets or reinforcing grids creates single products that provide filtration, separation and reinforcement together.

Application R&D - Ongoing research into novel uses for non-wovens like landfill caps, nuclear waste containment and offshore geotextiles to drive adoption across new domains.

Conclusion

Non-woven geotextiles have become an indispensable resource for civil engineering and infrastructure applications where their high permeability, strength, and versatility can enhance project outcomes and lifespan.

As materials and manufacturing continue evolving, non-wovens are poised to meet more specialized demands. With a thorough understanding of their capabilities, civil engineers can apply these adaptable fabrics for a sustainable future.

0 notes

Photo

PP Woven Packaging Bags | Bankey Bihari Packaging

0 notes

Text

Non Woven Bag Raw Material Cost: Factors, Pricing Guide, and Optimization Tips

Non-woven bags are an eco-friendly alternative to plastic bags, widely used in retail, grocery, and promotional sectors. The cost of raw materials for manufacturing these bags depends on several factors. Let’s explore key aspects of non-woven bag raw material costs, a pricing guide, and tips to optimize expenses.

Factors Affecting Non-Woven Bag Raw Material Cost

1️⃣ Material Type – Polypropylene (PP) is the most common raw material, with costs varying based on quality and GSM (grams per square meter). 2️⃣ GSM (Fabric Thickness) – Higher GSM means better durability but increases costs. 3️⃣ Fabric Color & Printing – Custom colors and multi-color printing impact pricing. 4️⃣ Market Demand & Supply – Prices fluctuate based on raw material availability. 5️⃣ Bulk Purchasing – Buying in bulk reduces per-unit costs.

Pricing Guide for Non-Woven Bag Raw Materials

Standard PP Non-Woven Fabric: ₹120 - ₹250 per kg (varies by quality & GSM)

Custom Printed Fabric: ₹150 - ₹300 per kg (depends on design & print type)

Laminated Non-Woven Fabric: ₹180 - ₹350 per kg (adds durability & water resistance)

Optimization Tips to Reduce Costs

✔ Choose Optimal GSM – Balance durability with cost efficiency. ✔ Buy in Bulk – Wholesale purchases lower material expenses. ✔ Use Efficient Printing Techniques – Opt for cost-effective methods like flexo or screen printing. ✔ Partner with a Reliable Supplier – Work with a trusted manufacturer like Favourite Fab for the best deals.

Conclusion

Understanding non-woven bag raw material costs helps businesses make informed purchasing decisions. By optimizing material selection and sourcing smartly, manufacturers can achieve cost efficiency without compromising quality.

Looking for affordable, high-quality non-woven bag materials? Contact Favourite Fab, your trusted supplier!

0 notes

Text

Affordable and Cost-Effective Solution

For businesses, non-woven PP bags from TLP Packaging provide an economical way to promote their brand while encouraging eco-friendly habits. Customizable with company logos and designs, these bags double as effective marketing tools. Their affordability ensures that businesses can make a sustainable choice without exceeding their budget.

0 notes

Text

Right Agencies: Setting the Benchmark for Excellence in Packaging

Packaging is more than just a necessity—it’s an essential element that bridges functionality, branding, and sustainability. For businesses, it’s the first impression, the protective shield, and the silent salesperson all rolled into one. Understanding the significance of packaging, Right Agencies,in Kondotty, Malappuram district, has positioned itself as a leader in the industry. With over two decades of expertise, Right Agencies is not just a packaging supplier; it’s a partner in innovation and quality.

Who We Are

Established with a vision to revolutionize the packaging industry, Right Agencies has become synonymous with reliability and excellence. As the best packaging company in the region, we pride ourselves on offering high-quality, customizable solutions that cater to a diverse clientele across industries, including food service, retail, agriculture, and more.

From polyplast items like round containers, hinged containers, and sauce cups to eco-friendly solutions such as non-woven and PP woven bags, Right Agencies ensures every product meets the highest standards of quality and sustainability.

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] Bivisen High Quality Black 128 Big Capacity CD/DVD Case WalletThis CD case does its job very well. Moisture and strong Nylon case design is durable enough to store it anywhere without worrying about your CDs being crushed and scrached. 1.CD CASE SIZE:11.4*6.4*3.5 inch2.Provides Maximum Protection from Dust, Scratches and other Disk Damage.3.Organizer holds 128 CDs,The already pulled out tabs make it easy for you to slide your discs right into the pockets.4.Transparent Sleeves for Improved Media Organization.5.Total: 1x Black 128 Large Capacity CD/DVD/VCD Case BagATTENTION: We have upgraded our CD Bags, it holds around 128 CDs, and the zipper can be closed easily and perfectly Ideal solution for music CDs, DVD & Blu-ray movies, and video game discs (In order to close the zipper better, we advise hold 128 CDs/DVDs) 【High Quality Material】Bivisen Black CD/DVD/VCD Case Wallet is made of durable, moisture & tear resistant Plastic +PP film + non-woven fabric material for long time use, protecting your CD/DVD well. 【Perfect Light Weight Design】Thin and lightweight, perfect size for traveling and home. It does not much room of your car. Modest size and portable for car, home and travel. 【Easy to Carry】With Hand strap, supplying a hand strap on the side of the case allows for quick transportation and easy grab. You can carry this CD case conveniently during exhibition or travel 【Humanized Design】New design upgraded CD Bags, it can holds around 128 CDs, and the zipper can be closed easily and perfectly. [ad_2]

0 notes

Text

The Conclusive Guide to Geotextiles

Shankar Packaging is an FIBC jumbo bags manufacturer in India that offers various technical textiles such as PP woven and non-geotextiles and geotextile fabric suppliers provide these products with high strength and durability, making them ideal for car parks and roads for more information visit our wbsite.

#geotextile fabricv#types of geotextile fabric#geotextile fabric suppliers#pp non woven geotextile#guide geotextile fabric#FIBC jumbo bags manufacturer in India

0 notes

Text

Sudarshan Addpack – Your Trusted Packaging Partner

Their versatility, reusability, and cost-efficiency make them an ideal choice for industries such as agriculture, pharmaceuticals, chemicals, and construction.

In today’s fast-paced industrial landscape, Flexible Intermediate Bulk Containers (FIBCs) have become an essential solution for bulk packaging needs across various sectors. fibc manufacturer in india versatile and cost-effective packaging option, FIBCs, also known as jumbo bags, big bags, or bulk bags, are widely used for storing and transporting large quantities of materials such as chemicals, food grains, pharmaceuticals, construction materials, and more. India, as a leading global manufacturing hub, is home to several reputed FIBC manufacturers, with us standing out as a trusted name in the industry.

What Are FIBCs?

Flexible Intermediate Bulk Containers (FIBCs) are industrial containers made of woven polypropylene (PP) fabric, designed to carry loads ranging from 500 kg to 2,000 kg. These lightweight, durable, and flexible bags are an efficient packaging solution for bulk materials. FIBCs are available in various designs, including single-loop, two-loop, and four-loop configurations, tailored to specific handling and storage requirements.

Their versatility, reusability, and cost-efficiency make them an ideal choice for industries such as agriculture, pharmaceuticals, chemicals, and construction.

Benefits of FIBCs

Cost-Effective SolutionFIBCs are a cost-effective alternative to rigid packaging options like metal drums or wooden crates. Their lightweight nature reduces transportation costs, while their robust construction ensures the safety of goods during transit.

High Durability and StrengthManufactured from high-quality polypropylene fabric, FIBCs are designed to withstand heavy loads and challenging environments. They are resistant to wear and tear, ensuring the safe handling of goods over long distances.

Customizable DesignsFIBCs can be customized to meet specific requirements, including different sizes, shapes, and lifting options. Features like liners, spouts, and discharge outlets can also be added to enhance functionality and convenience.

Eco-Friendly and SustainableMany FIBCs are reusable and recyclable, making them an environmentally friendly packaging option. By choosing FIBCs, industries can reduce their carbon footprint and contribute to sustainable business practices.

Versatile ApplicationsFIBCs are suitable for a wide range of materials, including fine powders, granules, liquids, and coarse aggregates. They are used across diverse industries, from food and pharmaceuticals to mining and construction.

Safe and HygienicFIBCs designed for food-grade and pharmaceutical applications adhere to stringent safety and hygiene standards. Specialized coatings and liners ensure that the contents are protected from contamination and moisture.

Types of FIBCs

Standard FIBCsIdeal for general-purpose use, these bags are suitable for handling and storing non-sensitive materials like construction aggregates, sand, and fertilizers.

Food-Grade FIBCsDesigned to meet stringent hygiene standards, food-grade FIBCs are widely used in the food and beverage industry for transporting grains, flour, sugar, and other edible products.

Conductive FIBCs (Type C)These bags are designed to safely transport flammable or electrostatically sensitive materials. Conductive FIBCs are made from fabrics with interwoven conductive threads, providing a safe pathway for electrostatic discharge.

Baffle BagsFeaturing internal baffles, these bags maintain a square shape even when filled, optimizing storage space and improving stability during stacking.

Ventilated FIBCsThese bags are specifically designed for materials that require airflow, such as fresh produce, firewood, or certain agricultural products.

UN-Certified FIBCsUN-certified bags meet international safety standards and are used for transporting hazardous materials that require strict handling guidelines.

Applications of FIBCs in Various Industries

Agriculture: Transportation of grains, seeds, fertilizers, and animal feed.

Chemicals: Safe handling of powders, granules, and hazardous materials.

Construction: Storage and transportation of sand, gravel, and cement.

Food Industry: Hygienic packaging of flour, sugar, and other food products.

Pharmaceuticals: Ensuring contamination-free handling of medicinal products.

Mining: Transporting ores, minerals, and other bulk materials.

Why India is a Leading FIBC Manufacturing Hubfibc manufacturer in india

India has emerged as a major player in the global FIBC market due to its cost-competitive manufacturing capabilities, skilled workforce, and access to high-quality raw materials. Indian FIBC manufacturers adhere to international quality standards, ensuring that their products meet the diverse needs of global clients.

Why Choose us?

As a leading FIBC manufacturer in India, Sudarshan Addpack is committed to delivering high-quality, durable, and cost-effective packaging solutions tailored to the unique needs of its clients. With a state-of-the-art manufacturing facility, cutting-edge technology, and a team of skilled professionals offers a comprehensive range of FIBCs, including food-grade, UN-certified, and custom-designed options.

The company adheres to the highest standards of quality and safety, ensuring that its products meet international benchmarks. Whether you're in agriculture, chemicals, or any other industry requiring bulk packaging, Sudarshan Addpack is your trusted partner for innovative and reliable FIBC solutions.

By choosing Sudarshan Addpack, you gain access to a dedicated team focused on providing exceptional products and services, ensuring that your packaging needs are met with precision and care. Let transform the way you package, store, and transport your materials.

0 notes

Video

youtube

Fasmpo-Non woven Factory In Vietnam

New Product Comeout from Fasmpo's factory PP, SS, SMS, SMMS NON-WOVEN FABRIC. - In the end 2024, we have invested in a non-woven fabric production line serving the following industries: Medical, Filter, Shopping Bags, Furniture, etc. - 2025 promises many new challenges and competitions and we will always accompany our customers on all fronts. - Products with GRS and EOKO-TEX certificates ensure global export standards. - Wherever there is non-woven fabric, there is FASMPO ===== FASMPO CO., LTD *P: +84938741145 *W: https://fasmpo.com/pp-spunbond-nonwoven-fabric *E: [email protected] *O: 52/51/1 Nguyen Sy Sach St, Ward 15, Tan Binh District, Ho Chi Minh Citi, Vietnam *F: Duc Hoa Dong Commune, Duc Hoa District, Long An province, Vietnam ===== #Nonwovenfabric #Nonwovenfactory #Nonwovensuplliers #nonwovencompany #nonwovenvendors #feltfactory #feltvendor #feltmaterial #feltfabrics #waddinginvietnam #madeinvietnam #acousticpannelsinvietnam #SS #SMS #SMMS #SSlaminatedPE #medicalprotective #PPfabric #wadding #acousticpanelfactory #soundproofmanufactory

0 notes