#PP Needle Fabrics

Explore tagged Tumblr posts

Text

Top Non Woven Fabric Suppliers in Coimbatore

Coimbatore, known as the "Manchester of South India," is a major hub for textile and fabric industries, including non-woven fabrics. These fabrics are widely used in industries like packaging, healthcare, agriculture, and automotive due to their eco-friendly and durable properties.

If you’re looking for reliable non-woven fabric suppliers in Coimbatore, this guide will help you explore the best suppliers, their product range, and where to buy them.

Why Choose Non-Woven Fabric?

Non-woven fabrics are gaining popularity due to their: ✔ Eco-friendliness – 100% recyclable and reusable ✔ Durability – Stronger and more tear-resistant than traditional fabrics ✔ Customizability – Available in various GSM (grams per square meter), colors, and patterns ✔ Cost-effectiveness – More affordable compared to woven alternatives

Top Non-Woven Fabric Suppliers in Coimbatore

1. Favourite Fab

🔹 Products: Spunbond, PP non-woven fabric, BOPP laminated non-woven fabric 🔹 Industries Served: Shopping bags, medical textiles, packaging, agriculture 🔹 Why Choose? High-quality, customizable options, and bulk supply 🔹 Contact: Website

2. SRV Fabrics

🔹 Products: Polypropylene (PP) non-woven, melt-blown fabric, SMS fabric 🔹 Industries Served: Healthcare, hygiene products, and industrial applications 🔹 Why Choose? Superior strength, lightweight, and UV-resistant fabrics 🔹 Location: Peelamedu, Coimbatore

3. Sree Kaderi Ambal Mills

🔹 Products: Spunbond non-woven fabric, stitch-bond fabric 🔹 Industries Served: Mattress manufacturing, industrial textiles 🔹 Why Choose? High tear resistance and flame-retardant options available 🔹 Location: Mettupalayam Road, Coimbatore

4. Coimbatore Non-Woven Solutions

🔹 Products: Agricultural non-woven, disposable medical fabrics 🔹 Industries Served: Horticulture, geotextiles, medical sector 🔹 Why Choose? Cost-effective and bulk supply options 🔹 Location: Avinashi Road, Coimbatore

5. Ayyappa Textiles

🔹 Products: Needle punch non-woven fabric, felt fabrics 🔹 Industries Served: Automotive, filtration, furniture 🔹 Why Choose? High-density and water-resistant fabrics 🔹 Location: Ganapathy, Coimbatore

6. United Non-Wovens

🔹 Products: PP spunbond, thermal bond non-woven fabrics 🔹 Industries Served: Medical, packaging, personal hygiene 🔹 Why Choose? Eco-friendly options with antibacterial properties 🔹 Location: Sundarapuram, Coimbatore

Factors to Consider When Choosing a Non-Woven Fabric Supplier

Before selecting a supplier, consider these key factors: ✔ Fabric Quality: Check for GSM, strength, and breathability ✔ Customization: Availability of different colors, sizes, and printing options ✔ Pricing: Compare bulk prices for cost-effectiveness ✔ Delivery & Availability: Ensure timely supply and sufficient stock ✔ Eco-Friendly Certifications: Prefer suppliers offering biodegradable and recyclable options

Where to Buy Non-Woven Fabric in Coimbatore?

You can purchase non-woven fabric from: 📌 Direct Manufacturers: Visit factory outlets for bulk orders 📌 Wholesale Markets: Check local textile markets in Coimbatore 📌 Online Platforms: Amazon, Indiamart, TradeIndia, Favourite Fab

Conclusion

Coimbatore is home to some of the best non-woven fabric manufacturers and suppliers, catering to diverse industries. Whether you need PP non-woven, spunbond, melt-blown, or laminated fabric, these suppliers offer high-quality products at competitive prices.

🚀 Need bulk non-woven fabric? Contact your preferred supplier today!

0 notes

Text

Best Practices for Working with PP Multifilament Yarn

Polypropylene (PP) multifilament yarn is widely recognized for its durability, versatility, and lightweight characteristics. These properties make it a popular choice in various applications, from textiles to industrial materials. As industries increasingly adopt PP filament yarn for their production processes, understanding best practices for working with this material becomes crucial. This article outlines essential practices to ensure optimal performance when utilizing PP multifilament yarn, with a focus on quality, handling, and application techniques.

Understanding PP Filament Yarn

PP filament yarn is made from long, continuous strands of polypropylene, resulting in a yarn that is both strong and flexible. Its high tensile strength makes it ideal for applications where durability is critical, such as in ropes, nets, and upholstery. The manufacturing process of PP multifilament yarn involves melting polypropylene granules, extruding them through spinnerets, and then cooling and stretching the filaments to enhance their properties. Familiarity with the characteristics of PP filament yarn is the first step in effectively utilizing it in any project.

Selecting the Right Supplier

When sourcing PP multifilament yarn, selecting a reputable manufacturer is crucial. Quality can vary significantly among different suppliers, impacting the final product's performance and durability. Look for a PP multifilament yarn manufacturer that adheres to international quality standards and has a proven track record in the industry. Reading reviews and seeking recommendations can also help in making informed decisions. A reliable supplier not only ensures high-quality yarn but also provides essential documentation and support for proper usage.

Storage and Handling

Proper storage and handling of PP multifilament yarn are essential to maintain its integrity and performance. Store the yarn in a cool, dry place away from direct sunlight to prevent degradation. Prolonged exposure to UV rays can weaken the fibers, leading to reduced strength and lifespan. Additionally, avoid storing the yarn near chemicals or solvents that might compromise its quality. Handling the yarn with care during transportation and processing is equally important. Preventing kinks, knots, or excessive tension during handling can significantly enhance its usability.

Preparing for Production

Before beginning any project with PP multifilament yarn, proper preparation is key. Ensure that all machinery and tools are clean and well-maintained. Dirt, debris, or rust can cause damage to the yarn during the manufacturing process. It’s also important to check the tension settings on your machinery. Adjusting the tension according to the specifications of the yarn will help in achieving consistent quality.

Utilizing the Right Techniques

When working with Multifilament yarns in India, adopting the correct techniques during weaving, knitting, or sewing is vital for achieving the desired results. For weaving applications, consider using specialized looms designed for multifilament yarns to ensure even tension and prevent breakage. In knitting, use needles that can accommodate the finer strands of the yarn, as using inappropriate sizes can lead to snags or uneven stitches. When sewing with PP multifilament yarn, select a needle that is suitable for heavy-duty fabrics, ensuring that it can pierce through the yarn without causing damage.

Testing and Quality Control

Implementing testing protocols during production can significantly enhance the quality of products made with PP multifilament yarn. Conduct tensile strength tests to assess the yarn's durability and ensure it meets specific requirements. Regular quality checks can help identify any inconsistencies in the yarn, such as variations in thickness or color, that might affect the final product's performance. Documenting these tests and maintaining a record can provide valuable insights into the yarn's quality over time, allowing manufacturers to make necessary adjustments.

Compatibility with Other Materials

When incorporating PP multifilament yarn into a project, consider its compatibility with other materials. For instance, when blending it with other fibers or materials, understand how the characteristics of PP yarn interact with those substances. Testing various blends can help determine the optimal combination for specific applications, such as achieving desired aesthetics, strength, or flexibility. Properly selecting compatible materials can enhance the overall quality and performance of the finished product.

Maintenance of Final Products

Products made from PP multifilament yarn require proper maintenance to ensure longevity. Educating end-users about the care requirements for items like ropes, nets, or upholstery can help in preserving their performance. Recommend washing with mild detergents and avoiding harsh chemicals that might degrade the fibers. Additionally, advise users to store items properly when not in use, particularly avoiding prolonged exposure to sunlight or extreme temperatures. Providing maintenance guidelines can significantly enhance customer satisfaction and extend the life of the products.

Environmental Considerations

As industries move towards sustainable practices, understanding the environmental impact of using PP multifilament yarn is becoming increasingly important. While polypropylene is recyclable, not all products made from this material are designed with recycling in mind. Encourage manufacturers to adopt eco-friendly practices, such as using recycled materials in their processes or developing strategies for responsible disposal. Educating consumers about the recyclability of PP products can also foster a culture of sustainability within the industry.

Innovation and Continuous Improvement

The textile and manufacturing industries are constantly evolving, and so are the technologies and methods used to work with PP multifilament yarn. Staying updated on the latest advancements in yarn production, processing technologies, and application techniques is essential for manufacturers aiming to maintain a competitive edge. Attending industry conferences, participating in workshops, and engaging with peers can provide valuable insights into emerging trends and best practices. Continuous improvement in processes and products not only enhances quality but also contributes to overall efficiency and customer satisfaction.

Conclusion

Working with PP multifilament yarn offers numerous advantages, but achieving the best results requires a commitment to best practices. By understanding the characteristics of PP filament yarn, selecting the right suppliers, maintaining proper storage and handling, and adopting effective production techniques, manufacturers can enhance the quality of their products significantly. Testing, compatibility with other materials, and attention to maintenance further contribute to successful outcomes. As the industry evolves, embracing innovation and sustainability will ensure that the use of PP multifilament yarn remains effective and responsible. By following these guidelines, businesses can maximize the potential of PP Multifilament yarn manufacturer and around the globe, leading to improved performance and customer satisfaction. Frequently Asked Questions (FAQs)

How should I store PP multifilament yarn? Store the yarn in a cool, dry place away from direct sunlight. Avoid dragging it across rough surfaces to prevent fraying, and arrange multiple spools neatly to avoid tangling. What should I do if my PP multifilament yarn is fraying or breaking? Ensure your equipment is set up correctly for the specific yarn you are using. Check for rough edges on machines that may be causing fraying, and perform regular maintenance to prevent these issues.

How can I ensure the quality of PP multifilament yarn? Conduct thorough testing of the yarn for consistency in thickness, strength, and color before starting any project. Work with a reputable PP multifilament yarn manufacturer to ensure stringent quality control during production.

0 notes

Text

Associates NonWovens manufactures and circulates products and merchandises to diverse sectors including medicine, garment, packaging, and the agricultural industry. A moderating conglomerate, the company caters to various target groups and has earned global recognition. Associates NonWovens is a premier establishment, involved in the formulation, manufacturing and distribution of a variety of non woven products. Our product lines include products like PP Spunbond Non Woven (Sealing Bags, Fabric Roll, Metallic Laminated Non Woven Bags & Metallic Laminated Non Woven Fabric Rolls), Needle Punch Non-Woven Fabric, Grass Mats and Tearaway Cotton Embroidery Paper, Aluminium Foil Containers, Aluminum House-Hold Foil, Non-Woven Insole Board, Stroble Insole Board. We deliver custom made products, amplifying the product range offered.

#PP Spunbond Non-Woven Fabric#Laminated Non Woven Fabric#Grass Mat#Tearaway Embroidery Paper#Printed Nonwoven Fabric#TP Sheet#Fashion Felt

0 notes

Text

Enhancing Fabrication: BS Masterbatch's Innovation in PP Non-Woven Masterbatch Solutions

Understanding PP Non-Woven: PP non-woven fabrics are engineered materials made from thermoplastic polymers, primarily polypropylene. These fabrics are versatile and find applications across a wide range of industries, including hygiene products, medical supplies, filtration media, automotive interiors, and more. PP non-woven fabrics offer numerous advantages, including high strength-to-weight ratio, breathability, moisture resistance, and ease of fabrication. By leveraging masterbatch solutions, manufacturers can enhance the properties and aesthetics of PP non-woven fabrics to meet specific application requirements and market demands.

Tailored Masterbatch Solutions: BS Masterbatch offers a comprehensive range of masterbatch solutions specifically formulated for PP non-woven applications. Whether customers require color masterbatches for branding and visual appeal, additive masterbatches for functionality and performance enhancements, or specialty compounds for niche applications, BS Masterbatch provides tailored solutions that meet their precise requirements and objectives. By collaborating closely with customers, BS Masterbatch develops customized formulations that address specific processing parameters, end-use conditions, and market trends, ensuring optimal performance and value.

Color Vibrancy and Consistency: Color plays a critical role in PP non-woven applications, influencing product aesthetics, brand recognition, and consumer appeal. BS Masterbatch's color masterbatches for PP non-woven fabrics are engineered to deliver vibrant hues, excellent color consistency, and superior dispersion properties. Whether customers require standard colors, custom shades, or special effects, BS Masterbatch's color masterbatches offer unmatched performance and reliability, ensuring that PP non-woven fabrics stand out in the marketplace with brilliance and clarity.

Functionality and Performance Enhancements: In addition to color, BS Masterbatch's additive masterbatches for PP non-woven fabrics offer a wide range of functionality and performance enhancements. These additives can improve properties such as UV stability, antimicrobial resistance, flame retardancy, antistatic properties, and more, depending on the specific requirements of the application. By incorporating these additives into PP non-woven fabrics, manufacturers can tailor their products to meet the diverse needs of end-users in various industries, from healthcare and hygiene to automotive and industrial applications.

Process Optimization and Efficiency: BS Masterbatch's PP non-woven masterbatch solutions are designed to enhance processability, efficiency, and productivity in fabric manufacturing operations. Whether customers use spunbond, meltblown, or needle-punched processes, BS Masterbatch's masterbatches are formulated to ensure uniform dispersion, minimal agglomeration, and easy incorporation into the polymer matrix. This enables manufacturers to achieve consistent results, reduce downtime, and optimize production costs, ultimately improving their competitive advantage in the market.

Quality Assurance and Compliance: BS Masterbatch places a strong emphasis on quality assurance and compliance with regulatory standards in its PP non-woven masterbatch manufacturing process. The company adheres to stringent quality control measures at every stage of production, from raw material sourcing to final product testing, to ensure that its masterbatches meet the highest quality standards and customer specifications. Moreover, BS Masterbatch's masterbatches comply with relevant industry regulations and certifications, providing customers with peace of mind and confidence in the performance and safety of their products.

Sustainability and Environmental Responsibility: As a responsible corporate citizen, BS Masterbatch is committed to sustainability and environmental responsibility in its PP non-woven masterbatch manufacturing operations. The company actively seeks to minimize its environmental footprint by adopting eco-friendly practices, reducing waste generation, and promoting the use of recycled materials. Moreover, BS Masterbatch offers eco-friendly masterbatch formulations that comply with regulatory standards and support customers' sustainability goals, helping to create a more sustainable future for the non-woven fabric industry.

In conclusion, BS Masterbatch's innovation in PP non-woven masterbatch solutions is driven by a commitment to excellence, customization, and sustainability. By offering tailored masterbatch solutions that enhance color vibrancy, functionality, and process efficiency, BS Masterbatch empowers manufacturers to create PP non-woven fabrics that meet the highest quality standards and market demands. As the demand for high-performance non-woven fabrics continues to grow, BS Masterbatch remains at the forefront of innovation, driving progress and excellence in the industry. With its unwavering dedication to quality, customization, and sustainability, BS Masterbatch continues to redefine the standards of excellence in PP non-woven masterbatch manufacturing, ensuring a bright and vibrant future for the industry.

0 notes

Text

Geomembrane uses a plastic film that plays the role of anti-seepage material in these cases. On the other hand, geotextile materials use nonwoven fabrics. Since they are geosynthetic materials, geotextiles are used in applications such as drainage and separating gravel & soil. They are also used for dewatering polluted liquids and protecting geomembranes. Water can pass through geotextile material rather easily since it is made using geosynthetic materials. This means that it is made up of synthetic fibers by using techniques such as needle punching and weaving. The good thing is that these days you get great products in both these segments.

Difference in terms of water permeability

Geomembrane happens to be impermeable to water but geotextile materials are not so.

Difference in terms of application

Geotextiles are made using nonwoven fabrics and, as such, these materials are used for strengthening foundations. Geomembrane is made using the likes of high-density polyethylene and it is used commonly to prevent seepage.

Difference in terms of characteristics

Geotextile is exceptional in terms of drainage isolation, strengthening properties, anti-seepage, and filtration. On top of that it has features such as the following:

· low weight

· heat resistance

· high tensile strength

· anti-freezing properties

· permeability

The main reason for this is the materials that are used to make it. Yet another great quality of geotextiles is their ability to resist corrosion. On the other hand, geomembranes are made using plastic films which are well known for their anti-seepage qualities. They are also blessed with qualities such as the following:

· a small specific gravity

· resistance to corrosion

· robust elongation

· low-heat resistance

· malleability

· average frost resistance

You can use both these materials together or either one of them for strength in your intended application. Geomembrane is used normally in engineering constructions where you need seepage-proof materials that also have other qualities.

The most prominent among those are isolation, good drainage material, firm foundations, and anti-cracking. Yet another major difference between these two materials is that geotextile is highly preferred in case of applications with anti-filtering purposes. On the contrary, geomembrane is used mainly for seepage-proofing. As their name would indicate, geotextiles are made using nonwoven fabrics and are used mainly for consolidating subsoil. Geomembranes are made mainly of high-density polyethylene and are used primarily for seepage-proofing. When you combine both you get composite geomembrane that can be divided into one cloth & one membrane or two cloths & one membrane.

There are different kinds of geomembranes that you get for lining purposes. It also helps that you get them in such various qualities and designs for various requirements. The most prominent among them are FPP (permaliner flexible polypropylene) and FPE (permaflex flexible polyethylene). When it comes to geotextiles the two varieties are woven and nonwoven. Nonwoven geotextiles are used mostly in drainage applications because they are capable of filtering without getting clogged and woven geotextiles are used mostly in unpaved roads. Nonwoven PP (polypropylene) geotextiles are made mostly using needle-punched PP staple fibers.

NOTE: Supreme Geotech Private Limited specializes in offering flood control and water resource protection solutions that are both very prominent and cost-effective.

0 notes

Text

What is SMS non-woven fabric?

What is SMS non-woven fabric?

Did you know that there is a growing demand for SMS Non-woven Fabric during the coronavirus pandemic? Does SMS fabric provide the best protection and strength?Get more news about sms nonwoven fabric seller,you can vist our website!

SMS fabric is used in various applications, including industrial and medical purposes as well as textile and consumer goods. SMS materials are extensively used in the healthcare setting, they are commonly made with coveralls, isolation gowns, surgical face masks, etc. SMS Fabric Spunbond-Meltblown – Spunbond is a primary nonwoven tri-laminate fabric. It is made up of a layer of melt-blown polypropylene and is sandwiched between two layers of spun-bond polypropylene. Each of the individual fabric layers contributes to the SMS consequence. When these two fabrics are combined, it provides comfort, water resistance, and breathability. The manufacturing process of SMS Nonwoven Fabric There are many ways to bond SMS fabric, but the most common method is thermo-bonding. One side of the roller has a smoother surface, and the other side has tiny pins. Together creates embossed finishes on the opposite side of the fabric. These pins penetrate the fabric only 20% and aid in bonding the layers.

SMS fabric is a medical SMS fabric made of polypropylene. It is an exceptional trilineage development that provides high rigidity and durability that is similarly delicate, durable, and simple. In addition, this nonwoven SMS fabric material has some novel highlights, such as medical repeatability (alcoholism, hostility to blood, against oil), anti-static, anti-buildup and anti-bacterial, extra soft, hydrophilic, etc. SMS texture is a clinical SMS surface made of polypropylene. It is an exceptional quarterly improvement that gives high unbending nature and solidness that is sensitive, strong, and easy to work. Additionally, this nonwoven SMS surface material has somebody of-a-sort features like clinical repeatability (antagonistic to alcohol, against blood, against oil) grade, unfriendly to static, threatening to development and antagonistic to bacterial, extra fragile, hydrophilic, etc.

This clinical SMS texture is for the most part used in clinical and neatness things, for instance, separation outfits, patient outfits, wound thought, lab clothing, strategy outfits, cautious window hangings, covers and face cloak, kid diapers, and leg sleeves of adulthood diapers etc. Things made by this cycle extensively used in tidiness markets, for instance, newborn child diapers, sterile napkins, and adult diapers. Various uses of this dress are clinical center things like covers, covers, wraps, outfits, covers, beds, nonessential attire and general additional items, for instance, teabags, vacuum channel packs, shoe covers, hair nets, facemasks, vehicle covers, coat covers, shopping sacks. , Residue cover, disguise net, cultivating net, etc.

SMS Nonwoven (Spunbond + Meltblown + Spunbond Nonwovens) is a blended nonwoven surface, which is a spondbond and meltblading composite thing with high strength, extraordinary channel execution, no paste, non-unsafe, and so forth As of now, it predominantly makes clinical and prosperity work affirmation things like cautious clothing, cautious covers, guarded clothing, hand wash, totes, and so on The material development is fiber. PP’s finished name is polypropylene, Chinese name is polypropylene. non woven is a shortening for nonwoven, nonwovens, or nonwovens. Nonwoven surfaces are molded by going strands through the flying course or accurately and subsequently through a spoon, needle, or hot-moving, finally wrapping up. ppnw meaning PP fiber is made of non-weight. Due to the possibility of the PP itself, the surface shows strong execution around the end, yet the hydrophilic execution is poor. Spunbond + Meltblown + Spunbond Nonwovens, which is comprised of a three-network organization of Spunbond non-woven textures + dissolve blown non-woven textures + Spunbond non-three-layer hot-rolls. Normal weight an area: 30–500 gsm; Unique width: 1500 mm and 2400 mm; This compound is related to non-woven surfaces, is a spend bond and relax blown composite thing, non-hurtful and unscented, uncommonly profitable tiny creatures. Through exceptional treatment of the contraptions, it can achieve against static, threatening to a heavy drinker, against plasma, water-repellent, and water-delivering properties.

Shaky SMS Items: Because of its waterproof breather, especially proper for the prosperity market, similar to clean napkins, sterile pads, kid diapers, grown-up incontinence diaper side spillage edge and support, etc. Medium-thickness: SMS things are sensible for use in the clinical field. Cautious outfits, cautious cover, cautious cover materials, cleaned clothes, wound wraps, fix balms, etc … furthermore used to make overalls, guarded dress, fitting for the business. etc SMS things with their incredible separation execution, especially SMS things that have gone through three-path and against static treatments, are more fitting as first rate clinical prosperity materials and have been extensively used in the world.

Thick SMS They are for the most part used as high-capability channel materials for various gases and liquids. They are moreover splendid high-capability oil-holding materials for use in diminishing mechanical wastewater, cleaning marine oil, and current wipes. Clinical non-woven SMS, using 100% polypropylene as unrefined material, non-toxic, non-fiber shedding, the high amazing speed of tiny creatures restriction; the material surface is value and full, can effectively improve thing quality.SMS can override unadulterated cotton surfaces, sensitive, delicate, and skin-obliging. The spund bond layer contains interminable fiber with extraordinary breaking force and stretching.

0 notes

Photo

PP Woven Geotextiles Manufacturer are made from Polypropylene or high tenacity polyester yarns. These woven geotextile fabrics individual extruded yarns are then twisted together. These twisted yarns are then woven together to provide relative dimensional stability to each other and form a geotextile.

For more details contact us on 99255 01713 or Visit us @ https://geosyntheticindia.com/

#Geogrid Manufacturers in India#Needle Punched Non Woven Geotextile#PP Woven Geotextiles Manufacturer#Non Woven Fabric Geotextile#Non Woven Geo Fabric Sheet#Non Woven Geotextile Manufacturers#Non Woven Polypropylene Geotextile Fabric#Non-Woven Geotextile Fabric

0 notes

Text

Air Filter LW-1209A

Filton LW-1209AAir Filter for 3 (E36) 325 td

Black PP panel CarAir Filter for BMW. The OE NO is 13711247405. The filter material is added with a dipping process than the ordinary hot-rolled needle-punched non-woven fabric, which can effectively improve the filtration efficiency of the product and protect the engine more effectively. By making full use of the high efficiency interception of chemical fiber, Filton Filter is low resistance, high efficiency and long service life.

https://www.filtonfilter.com/air-filter/lw-1209a.html

2 notes

·

View notes

Text

Non Woven Fabric Suppliers

Foshan Rayson Non-woven Co., Ltd. is a Sino-US joint venture, established in 2007, located in the town of Foshan Shishan High-tech Zone, less than 30 minutes from the Guangzhou Baiyun International Airport, adjacent to Volkswagen, Honda, CMO and other enterprises, with a complex covering an area of roughly 80,000 square meters and employing over 400 people. The company specializes in the production of spunbond non-woven fabrics and non-woven fabric products, with more than 90 percent of its products sold in more than 30 countries. Foshan Rayson Non-woven Co., Ltd. is a seasoned manufacturer in the non-woven fabric industry with years of experience. It is committed to non-woven fabric research, development, and production and has 10 advanced non-woven fabric production lines, capable of producing PP non-woven fabrics, SS non woven fabric, SMS, meltblown, needle punch and spunlace non woven fabric, with the producing weight range from 10gsm to 150gsm within 4.2m width, with an annual production amount weighing over 36,000 tons. The company is capable of producing non-woven fabrics of many different colors and sizes, suitable for many different uses. In addition, Foshan Rayson Non-woven Co., Ltd. is a quick responder to market demand. Noticing a demand in the European market, the company developed a non-woven fabric tablecloth that quickly became popular within that market. Aided by the use of its automatic cutting and folding machines, the company is capable of producing non-woven fabrics that best suit a customer's sizing needs. Recently, the company's new release of internationally SGS certified non-woven fabrics became widely used in the agricultural market. Through the production of environmentally safe fabrics in a variety of colors and sizes, Foshan Rayson Non-woven Co., Ltd. has gained the trust of its customers. Faced with fierce market competition, Foshan Rayson Non-woven Co., Ltd. has managed to thrive its commitment of maintaining quality control and industry credibility. The company are devoted to "dependable, innovative, enthusiastic, shared", committed to provide effective and efficient customer service.

Non Woven Fabric Suppliers

1 note

·

View note

Text

Coated bottom and non-woven fabric bottom

What is the difference between coated bottom and non-woven fabric bottom in the wall covering industry What is the difference between the coated bottom and the non-woven fabric bottom in the wall covering industry: The coated bottom coating bottom wall covering has excellent mold and moisture resistance, keeping it clean for a long time, and extending the service life of the wall covering. Construction: When the general construction master adjusts the glue, because the ratio of the original glutinous rice glue to the water may not reach the best or not evenly mixed, and the coating has a certain function of blocking water, when applying the coated wall covering, the general water It doesn't matter if there are more copies. Non-woven bottom non-woven bottom wall cloth is composed of directional or random fibers on the basis of fabric.

It is a new generation of environmentally friendly materials. It has the characteristics of moisture-proof, breathable, non-toxic, non-irritating, recyclable, etc., and has a relatively good feel thick. Construction: Nowadays, many wall coverings are made of non-woven fabric. The construction master must pay attention to it when sticking, and must use a soft brush to stick the cloth. If you use a hard scraper on the wall, excessive force will produce a little on the edge when sticking the cloth.

Scratch marks similar to creases are smoothed. Although the surface cloth is flattened, the non-woven base cloth on the back still has a little wrinkle, which makes customers think it is a quality problem. When pasting, please paste it evenly in one direction. If small bubbles are generated after pasting, please use a small needle tube to inject a certain amount of glue, and then scrape the wall cloth. The non-woven fabric is prone to creases, and the high-precision smooth surface tends to look uneven on the side.

What are the types of non-woven fabrics required for masks[ Due to the impact of emergencies, the demand for masks for increased equipment has increased. Medical surgical masks and N95 masks generally adopt a multilayer structure, referred to as SMS structure: the inner and outer sides are spunbonded layers (S); the middle is the meltblown layer ( M), generally divided into single layer or multilayer. Flat masks are generally PP spunbond + meltblown + PP spunbond, and three-dimensional cup masks are generally PET polyester needle punched cotton + meltblown + needle punched cotton or PP spunbond.

It can be seen that the non-woven fabrics required for masks are mainly spunbonded and meltblown, among which spunbonded non-woven fabrics use a relatively thick fiber diameter of about 20 microns. The process of meltblown non-woven fabric is to feed polymer-melt extrusion-fiber formation-fiber cooling-net formation-reinforcement into cloth. The diameter of meltblown fibers can reach 1-5 microns, and they are generally made of polypropylene with high-melt fat fibers. These ultrafine fibers with unique capillary structure increase the number and surface area of fibers per unit area, thereby making meltblown fabrics With good filtering, shielding, thermal insulation and oil absorption, meltblown fabric can be called the 'heart' of medical surgical masks and N95 masks.

However, the domestic output of meltblown non-woven fabrics is relatively low. Spunlace nonwovens are useful for masks, but they are relatively rare. Nowadays, some mask companies have chosen to use spunlaced fabrics for the inner layer, because they can absorb moisture and wick away sweat without producing moisture, and are soft and comfortable. And on February 10th, a subsidiary of Huamao Co., Ltd. stated that the pure cotton spunlace non-woven fabric produced can be used as the inner layer (skin layer) of N95 masks. China Textile Institute's product WeisaierTM (English name NWCELLTM) has been applied to medical masks and other fields.

1 note

·

View note

Text

BA1b Research Narrative week 3

Fairy Tales, what is it?

Encyclopedia Britannica describes a fairy tale as:

‘a wonder tale involving marvelous elements and occurrences, though not necessarily about fairies.’

According to Vladimir Propp ‘A fairy tale may be termed any development proceeding from villainy or a lack through intermediary functions to marriage or to other functions employed as a denouement’ (1968, p. 92).

Fairy Tale doesn’t have to be your classic Disney film, but fairy tales do end ‘happily’.

‘Happily,’ means that justice is served.

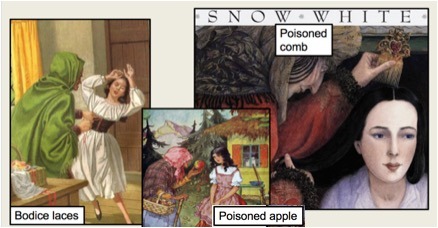

In the Grimms’ Snow White, the stepmother is forced to dance to her death in red-hot iron slippers fresh from the fireÉ This is a ‘happy’ ending.

Fairy tales come to a definite conclusion, an ‘orderly resolution’ (Warner, 1994).

The Origins

Märchen

Popular folktales, oral in origin. These pre-date written records, so it’s difficult to be sure about their exact origins. Many are hundreds, possibly thousands, of years old.

Kunstmärchen

Literary or artistic fairy tales.

Mostly produced in the 19th century, such as The Happy Prince (1888) by Oscar Wilde and The Little Mermaid (1837) by Hans Christian Andersen.

The oldest Fairy tales weren’t intended for children, but evidence suggests that they had serious meanings and contained important ritualistic elements. The clear polarity between good and evil acted as a warning of what might happen if you strayed from the righteous path. We can draw links with myth (and perhaps also religion) although myths are arguably more impossible? Because we can never be that heroic or that perfect in our actual lives.

By contrast, fairy tales, in spite of their ‘wonderful’ – or magical – aspects, are about ‘everyman’ and ‘everywoman’. Characters are rarely named (they could be us). Initiative, endurance, bravery, and patience can help everyone overcome giants, beasts and witches.

Blood and gore!

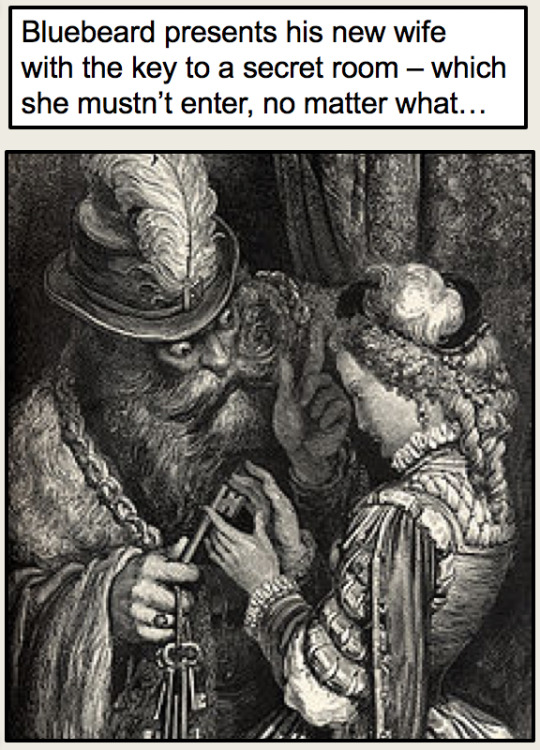

First written down by Charles Perrault (1697) Bluebeard tells the cheerful tale of a woman who marries a serial killer! The indelibly bloody key to his forbidden chamber is the only magic element in the story.

Bluebeard presents his new wife with the key to a secret room which she mustn’t enter, no matter what. Inside the room are all his dead wives (as depicted in Georges Méliès’ 1901 film version)

(In the mediaeval versions of Cinderella her step-sisters slice off their toes to fit the slipper)

The step-sisters (who are physically beautiful but inwardly ugly) are punished by having their eyes pecked out by pigeons.

This dark inversion of the birds who ‘help’ Cinderella offers another warning – suggesting that the natural world can only ever be appeased, not tamed. And the glass slipper was originally made of squirrel fur.

Pan’s Labyrinth (2006) is a great example of a modern Fairy tale done in the same aesthetic as the old medieval fairy tales.

Function 12, ‘The hero is tested, interrogated, attacked, etc., which prepares the way for his receiving either a magical agent or helper.’ (Propp, 1968, p. 39).

Sex!

In ‘The Grandmother’s Tale’ there’s no red hood (or cap). The wolf is a ‘bzou’ (werewolf) and the unnamed girl must choose between 2 paths: the path of pins (virtue) or the path of needles – needles being a symbol of ‘penetration’.

(Unlike Lucy Sprague Mitchell and others) Disney approved of fantasy

He wanted it to come ‘fully alive for those who dream’ (Stone, 1981).

‘As we do it, as we tell the story, we should believe it ourselves. It’s a “once upon a time” story and we shouldn’t be afraid of a thing like that’ (Walt Disney in notes for Cinderella, 15th January 1948, from the Disney archive).

Happy ever after?

The fairy tale scholar Jack Zipes (2011) accuses the ‘Disney versions’ of being so overwhelming that our idea of happiness is now ‘filtered through a Disney lens’. According to Zipes, these films ‘reinforce stereotypes and help maintain the patriarchal order’.

But the Grimms, writing in 1812, weren’t exactly radical gender revolutionaries.

In fact, scholars have noted that the fairy tale format begins with the disintegration of a family unitÉ and ends with the creation of another (through marriage).

Peace, stability, patriarchal order is maintained. This is the very nature of the fairy tale.

Nostalgia: the Disney version

But ironically, as noted by Zipes (1995), Disney used ‘the most up-to-date technological means to maintain the ‘old world’ order.

Animation allowed the believable creation of a fantasy world – and the recreation of a specifically ‘19th century’ patriarchal order. As Dan North (2009) says, in a (good quality!) blog about Lotte Reiniger’s fairy tale films, ‘animation allows the construction of a completely fabricated fantasy space’.

Propp’s ‘functions’ 1 and 31

Function 1

One of the members of a family absents himself from home.

Function 31

The hero is married and ascends the throne.

Before Propp fairy tale were categorised differently e.g. in the Aarne-Thompson Classification System) according to ‘type’ or ‘motif’:

• Animal stories

• Fantastical stories

• Stories of everyday life

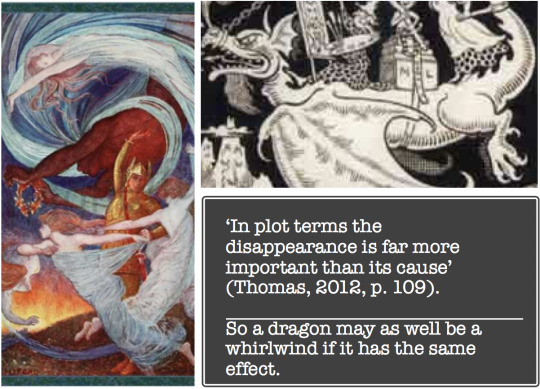

• Stories including the appearance of a dragon

•

But many tales belonged in more than one category. The system did nothing to illuminate the underlying structure of the fairy tale. Propp was the first to make a sequential structural analysis of the fairy tale: what happens, in what order.

The Law of Contrast – other people should be antithetical to the hero; therefore, if the hero is generous, other characters should be ‘stingy’ to contradict him.

The Law of Repetition – actions in folk tales are typically repeated 3 times

The Law of Twins: two people can appear together in the same role, and should be similar in nature

The Law of Contrast – other people should be antithetical to the hero; therefore, if the hero is generous, other characters should be ‘stingy’ to contradict him. The same way Cinderella is contrasting to her evil sisters in every way, physically and mentally.

Then along came Propp…

In his 1928 work Morphology of the Folktale the Russian formalist Vladimir Propp analysed 100 Russian fairy tales and found striking similarities between them. Propp was analysing chronological story rather than plot. But please note that the traditional fairy tale – unlike many other forms of narrative, ‘which play with chronology’ (Puckett, 2016, p. 184) – is plotted in chronological order.

Propp stated 4 fundamental principles (1968, pp. 21–23)

1. Functions of characters serve as stable, constant elements in a tale, independent of how and by whom they are fulfilled. They constitute the fundamental components of a tale.

2. The number of functions known to the fairy tale is limited. As we have seen, Propp says there are only 31 (at least, in the Russian tales he analysed).

3. The sequence of functions is always identical.

4. All fairy tales are of one type in regard to their structure.

He found that all 100 of the tales he analysed were built on a pattern drawn from 31 functions, occurring in a set order. In other words, only 31 things can happen in a fairy tale. But, the word ‘morphology’ means the study of forms, and in doing this work Propp was analysing form as separate from content.

Function 14: the hero acquires the use of a magical agent.

‘It doesn’t matter (on the level of plot) whether someone is given a magic horse or buys some magic beans or steals a magic sword. The key thing is that they [i.e. the hero] have received a magical object’ (Thomas, 2012, p. 107).

Propp identified 7 key characters who each have their own ‘sphere of action’

• The Villain

• The Donor

• The Helper

• The Princess (or ‘sought-for person’) and her Father (who function as a single ‘agent’)

• The Dispatcher

• The Hero

• The False Hero

Characters are not fixed, and a single character may inhabit more than one ‘sphere of action’. If a villain inadvertently gives something important to the hero, then he or she is also at that moment acting as a donor.

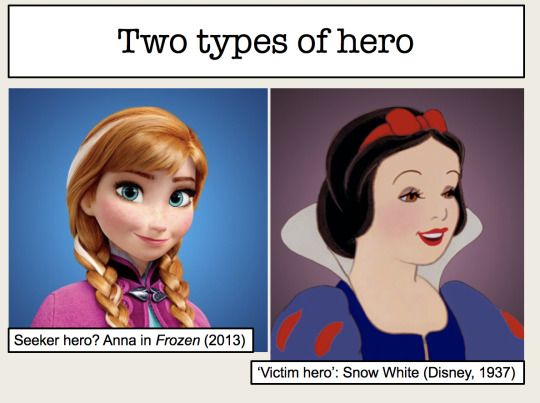

The hero: there are two types in a fairy tale

Directly suffers from the action of the villain in the complication (victim-hero)

Agrees to liquidate the misfortune or lack of another person (seeker hero)

The villain

• The villain appears twice. ‘First, he makes a sudden appearance from outside (flies to the scene, sneaks up on someone)’.

• The ‘second appearance’ is as a person ‘who has been sought out’.

The princess

• She is ‘sought after’ often a ‘reward’ that the hero (eventually) receives.

• Often bound up with her ‘father’

• appears twice, the second time ‘she is introduced as a personage who has been sought out’.

The donor

• ‘The donor is encountered accidentally’.

• The donor provides the hero with a magical object or helper (may do so unwillingly).

• Not necessarily benevolent, e.g. Rumpelstiltskin gives a magical gift to a miller’s daughter (spins straw into gold) but demands her firstborn child in return.

The magical helper is introduced as a gift

Disney’s Fairy Godmother (1950) could be seen as a donor (who presents Cinderella with ‘magical helpers’, i.e. footmen for her carriage) or as the ‘helper’ herself.

In general, the donor tests the hero somehow.

The false hero

Assumes the role of hero but is unable to complete the hero’s task, e.g. Lord Farquaad in Shrek (2001)

The dispatcher

Sends the hero away for some reason – therefore, often plays a pivotal role in inciting the action (similar to Vogler’s ‘herald’ archetype).

Function 8

‘This function is exceptionally important, since by means of it the actual movement of the tale is created’ (Propp, 1968, p. 31).

The first 7 functions ‘prepare the way for this function, create its possibility of occurrence, or simply facilitate its happening.’ (The first 7 functions set up the action.)

5 notes

·

View notes

Text

Top 10 Non-Woven Materials: Uses & Benefits

Non-woven materials are revolutionizing industries with their durability, cost-effectiveness, and eco-friendly nature. Here’s a quick look at the top 10 non-woven materials, their uses, and the benefits they offer:

1. Polypropylene (PP) Non-Woven Fabric

Uses: Shopping bags, surgical masks, and packaging.

Benefits: Lightweight, durable, and recyclable.

2. Polyester (PET) Non-Woven Fabric

Uses: Automotive interiors, filtration systems, and furniture.

Benefits: High strength, water resistance, and long-lasting.

3. Spunlace Non-Woven Fabric

Uses: Wet wipes, hygiene products, and cleaning cloths.

Benefits: Soft, highly absorbent, and strong.

4. Meltblown Non-Woven Fabric

Uses: Medical masks, air filters, and oil absorbents.

Benefits: Superior filtration and fine fiber structure.

5. Geotextile Non-Woven Fabric

Uses: Road construction, drainage, and soil stabilization.

Benefits: Robust, UV-resistant, and enhances soil strength.

6. Viscose Non-Woven Fabric

Uses: Diapers, wound dressings, and personal care products.

Benefits: Skin-friendly, biodegradable, and highly absorbent.

7. Biodegradable Non-Woven Fabric

Uses: Grocery bags, compostable packaging, and agricultural covers.

Benefits: Environmentally sustainable and decomposable.

8. Needle-Punched Non-Woven Fabric

Uses: Carpets, blankets, and soundproofing.

Benefits: Flexible, durable, and versatile.

9. Spunbond Non-Woven Fabric

Uses: Disposable gowns, agricultural sheets, and carry bags.

Benefits: Lightweight, breathable, and economical.

10. Laminated Non-Woven Fabric

Uses: Waterproof bags, protective clothing, and promotional products.

Benefits: Moisture-resistant and highly durable.

Conclusion

Non-woven materials offer tailored solutions for industries ranging from healthcare to agriculture. With a focus on sustainability and innovation, they are driving a greener and more efficient future.

https://favouritehub.com/top-10-non-woven-materials-uses-benefits/

0 notes

Text

How do you manufacture non woven fabrics ?

Tulip Fabrics Private Limited is one of the leading non woven fabrics manufacturers in India and also non woven rolls manufacturer in India. Non woven fabrics manufacturing consists of a series of manufacturing steps. They include forming a fibrous web, entangling or bonding the fibres in the web to impart mechanical strength to the structures. Special properties are also imparted to the fabrics according to customer specifications. They are not made by weaving or knitting and they are not required to be converted to yarn. They are single use disposable or a very durable fabric. The web bonding processes include needle punching, stitch bonding, thermal bonding, chemical bonding and hydro entanglement.

Tulip fabrics private limited is one of the best PP Spunbond non woven fabrics manufacturers in India. Spunbonding is an one step manufacturing process from the polymer stage to the finished non woven products. The major steps include web formation, web bonding and winding into rolls.

We at Tulip Fabrics Private Limited is also one of the leading manufacturers of PP Spunbond fabrics. Polypropylene fabric is a thermoplastic polymer which is manufactured to non woven fabric. These fabrics have main applications in non woven bags, interlining, masks, filters etc. During the manufacture of the non woven fabrics from the polypropylene granules, the residues are again converted to polypropylene granules. Spunbond and meltblown are the most common methods to produce non-woven fabrics. Extruder machine starts melting when PP granules arrive. This machine has 8 heating zones. In spunbonding process, fabrics are built directly from thermoplastic polymer such as polypropylene, polyester or polyethylene. The molten polymer is extruded through a spinneret, cooled slightly and laid on a moving conveyor belt to form a web. The fibre bonds as this web cools down.

0 notes

Text

PP Needle Punched Fabrics

This layered web moves next through one or more needlelooms (moving boards with hundreds of barbed needles) to entangle the fibers and consolidate the web. The frequency and direction of punching, degree of needle penetration and the architecture of the needles themselves can all be varied to control the physical characteristics of the resultant fabric. The resultant product is a dense, strong fabric with good resilience, suitable for an array of end applications.

0 notes

Text

INDUSTRIAL SEWING MACHINE

Double Needle, Four Thread Chain stitch Sewing Machine. (2800 RPM)

APPLICATION

For Seaming Hemming of light to heavy weight fabric such as PP/HPDE Woven cloth. Most suitable for making builder Bags.

About ARMSTRONG

Armstrong is a leading manufacturer and exporter of industrial machinery and spare parts in the HDPE/PP Woven Sack Industry. The company was established in 1982 as Stitchman with the sole purpose to deliver high-quality industrial sewing machines and spare parts to several national and international players. Due to its strict quality control processes and high customer satisfaction ratio, Armstrong grew by leaps and bounds leaving a lasting impression on its regional and national customers. A precipitous rise in its clientele led the promoters to give serious thought to expanding their product range. As a result, Armstrong plummeted from being a trader of industrial sewing machines and spare parts to a manufacturer and exporter of different types of industrial machineries and spare parts required in the HDPE/PP Woven Sack Industry. The company tied up with several international giants, like Juki (Japan), Newlong Industrial Co. Ltd. (NLI) (Japan), Orsan OPS (Turkey), and many more to leave no stone unturned in exemplifying innovation and goodwill.

The expansion not only made Armstrong an authority in the HDPE/PP Woven Sack Industry, but also a leader in the national and international markets. Today, Armstrong is not only an ISO 9001:2015 certified company but also functions in more than 66 countries providing effective industrial solutions to several manufacturers and traders of industries related to the HDPE/PP Woven Sack Industry.

About ARMSTRONG

Armstrong is a leading manufacturer and exporter of industrial machinery and spare parts in the HDPE/PP Woven Sack Industry. The company was established in 1982 as Stitchman with the sole purpose to deliver high-quality industrial sewing machines and spare parts to several national and international players. Due to its strict quality control processes and high customer satisfaction ratio, Armstrong grew by leaps and bounds leaving a lasting impression on its regional and national customers. A precipitous rise in its clientele led the promoters to give serious thought to expanding their product range. As a result, Armstrong plummeted from being a trader of industrial sewing machines and spare parts to a manufacturer and exporter of different types of industrial machineries and spare parts required in the HDPE/PP Woven Sack Industry. The company tied up with several international giants, like Juki (Japan), Newlong Industrial Co. Ltd. (NLI) (Japan), Orsan OPS (Turkey), and many more to leave no stone unturned in exemplifying innovation and goodwill.

The expansion made Armstrong an authority in the HDPE/PP Woven Sack Industry and a leader in the national and international markets. Today, Armstrong is not only an ISO 9001:2015 certified company but also functions in more than 66 countries providing effective industrial solutions to several manufacturers and traders of industries related to the HDPE/PP Woven Sack Industry.

#industrialsewingmachine#sewingmachine#sewing#industrialsewing#juki#jukisewingmachine#sewingmachines#armstrong

0 notes

Text

Geotextile For Soil Stabilization

Geotextiles are created from chemically resistant synthetic fibres so that biodegradation can be prevented. These fabrics are either matted or knitted together by needle punching or heat-sealing. Although all geotextiles happen to be permeable their hydraulic and mechanical properties tend to vary quite a lot. Geotextiles are used for soil stabilization in civil construction projects. The most prominent areas of such applications are roads, drainage structures, and landfills, to name a few.

The functions of geotextiles

Following are the main functions of geotextiles:

· separation

· filtration

· drainage

· reinforcement

· protection

Geotextiles are often used to separate several layers of soil with varied particle sizes as this helps each such layer to retain its function and integrity. They also act as filters by retaining soil particles as they allow water to flow through the soil. They are also capable of acting as drains by discharging and gathering gases or liquids that the structure does not need functionally.

A comparison of woven and non-woven geotextiles

Woven geotextiles are created by weaving polyester or polypropylene fibres. On the other hand, non-woven geotextiles are more like felts but they are also made from the same fibres. Woven geotextile fabrics that are used for soil stabilization primarily play the role of reinforcement and separation. Non-woven geotextile fabrics are used mostly for filtration and drainage.

Common areas of application for geotextile soil stabilization fabrics

These fabrics are used mostly for embankments, steepened slopes, and retaining walls. By using geogrids or/and high-strength geotextile you can construct embankments on soft soil foundations. You can also use geotextiles along with geogrids for the purpose of reinforcing steepened slopes. The same combination can also be used for creating retaining walls or reinforced soil walls.

Conclusion

These days, you get a lot of companies that are offering factory-seamed geotextile soil stabilization fabrics. These are created according to customized lengths and widths. These companies also offer you a wide array of seaming capabilities such as nonwoven, monofilament wovens, and slit-film wovens to high-strength and high-performance PET (polyester) and PP (polypropylene) geotextiles. You can also be sure that you would get re-rolling and off-line slitting along with quick delivery to your job site from these companies.

0 notes