#PLC industrial automation solution

Text

Applications of PLC

The list of Applications of PLC :-

✅Glass Industry

✅Chemical industry

✅Automobile industry

✅Oil and Gas Power Plant

✅Wind Turbine System

✅Robotic Automation System

👉 Contact us on :- ✉️ [email protected]

#allen bradley#rockwell automation#plc#automation#viralpost#microsoft#technology#development#viral#bestdeals#tumblr trends#Applications#solution#industrial automation

1 note

·

View note

Text

"The Crucial Role of Industrial Control Integrators: Driving Efficiency and Innovation in Modern Industry"

The Essential Role of an Industrial Control Integrator in Modern Industry

In today’s fast-paced industrial environment, the expertise of an Industrial Control Integrator has become indispensable. These professionals or companies specialize in designing, implementing, and maintaining complex control systems that are critical for optimizing industrial processes. This blog delves into the pivotal role of an Industrial Control Integrator, explaining their key responsibilities and the impact they have on industrial efficiency.

What is an Industrial Control Integrator?

An Industrial Control Integrator is a specialized expert or firm responsible for creating and managing control systems that automate and regulate industrial machinery and processes. These control systems encompass both hardware and software components, which work together to enhance performance, increase reliability, and streamline operations.

Core Responsibilities of an Industrial Control Integrator

Control System Design and Engineering:

Needs Analysis: The integrator begins with a comprehensive assessment of the client’s specific requirements. This involves understanding their industrial processes and defining the desired outcomes.

Custom System Design: Based on the assessment, the integrator designs a bespoke control system, selecting the appropriate sensors, controllers, and communication protocols to meet the client’s needs.

Integration and Installation:

Hardware Setup: The integrator manages the installation of essential components such as Programmable Logic Controllers (PLCs), Human-Machine Interfaces (HMIs), and other field instruments.

Software Configuration: They also configure the software that governs the control system, ensuring seamless communication between hardware and other operational systems.

Testing and Commissioning:

System Testing: Before full deployment, the integrator conducts rigorous testing to identify and rectify any issues, simulating real-world conditions to verify system performance.

Commissioning: Once testing is complete, the integrator supervises the final commissioning process, making any necessary adjustments to ensure optimal functionality.

Training and Ongoing Support:

Staff Training: Integrators provide training for the client’s personnel, equipping them with the knowledge to operate and maintain the new system effectively.

Continued Support: They offer ongoing maintenance and support services to resolve any issues and ensure the system continues to operate smoothly.

Why Industrial Control Integrators are Vital

Boosting Efficiency:

Industrial Control Integrators streamline processes by automating operations, which reduces manual input and enhances precision. This leads to improved productivity and reduced operational costs.

Enhancing Safety:

Integrators implement advanced control systems that monitor conditions in real time, increasing workplace safety by triggering alarms or shutdowns when necessary.

Ensuring Reliability:

By designing systems with redundancy and fail-safes, integrators help minimize downtime, which is crucial for meeting production targets and maintaining product quality.

Facilitating Scalability:

As businesses expand, their control systems must adapt. Integrators create flexible solutions that can be easily scaled or upgraded to meet growing demands.

Incorporating Emerging Technologies:

With the rise of Industry 4.0, integrating new technologies such as the Internet of Things (IoT), advanced analytics, and Artificial Intelligence (AI) is becoming increasingly important. Control integrators are key to incorporating these innovations into existing systems.

The Future of Industrial Control Integration

The field of industrial control integration is continuously evolving, driven by technological advancements and shifting industry needs. Future trends include:

AI and Machine Learning Integration: Enhancing predictive maintenance and process optimization.

IoT Integration: Enabling more detailed data collection and real-time analytics.

Enhanced Cybersecurity: Addressing the increasing need for robust security measures to protect industrial control systems from cyber threats.

Conclusion

Industrial Control Integrators are essential in ensuring the efficiency, reliability, and safety of modern industrial processes. Their expertise in designing, implementing, and maintaining control systems is crucial for optimizing operations and keeping pace with technological advancements. For businesses looking to upgrade or implement control systems, partnering with a skilled Industrial Control Integrator can be the key to achieving greater efficiency and performance.

#Industrial Control Integrator#Industrial Automation#Control Systems Engineering#Programmable Logic Controllers (PLCs)#Human-Machine Interfaces (HMIs)#Industrial Process Optimization#Automation Solutions#System Integration#Industrial Efficiency#Operational Reliability#Advanced Control Systems#Industry 4.0#Internet of Things (IoT)#Artificial Intelligence (AI) in Industry#Predictive Maintenance#Industrial Cybersecurity#Control System Design#Industrial Technology Trends#Engineering and Integration Services#Manufacturing Automation

0 notes

Text

Manufacturing Execution System Software in pune | India

The MES is not only responsible for providing technical advice but also for carrying out the assigned responsibilities. Planning, constructing, and maintaining all works, buildings, airfields, dock installations, and other structures is the responsibility of the Military Engineering Services.

#MES Manufacturing Execution System Pune#System Software India#Solutions for OEMs and Machine Builders Pune#Conveyors India#PLC Automation Pune#PLC and SCADA Service Provider India#Automators Industrial Projects#Let’s Get in Touch#Company

0 notes

Text

BLIIoT | BACnet gateway BA115 Support Multi-Protocol Conversion for Building Management Systems

Introduction

With the development of communication technology and control technology, in order to achieve efficient and intelligent management of buildings, centralised monitoring and management has become an inevitable trend in the development of intelligent management of buildings. In this context, high-performance building HVAC data transmission solutions - protocol conversion gateway came into being, widely used in building automation and HVAC system applications.

BLIIoT always insists on the core of the user's needs, and constantly expands its applications in a variety of industrial fields. Recently, we have developed a new series of BLIIoT Building Automation HVAC gateways, This series of products not only have excellent stability and anti-interference capabilities, but also have deep industry applications, aiming to bring users a new building automation data collection and conversion experience.

Product Description

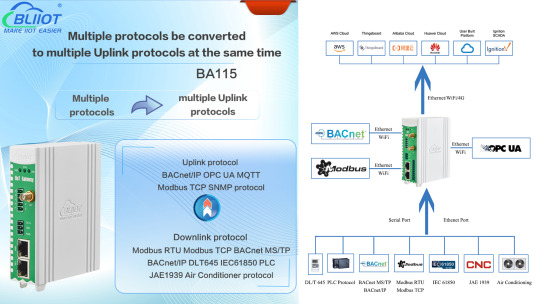

The multi-protocol to BACnet gateway BA115 is a protocol conversion gateway designed for converting various devices, power meters, and air-conditioning hosts into BACnet protocols for docking with BA systems.

The multi-protocol to BACnet gateway BA115 has powerful hardware interfaces, including 2/6 RS485/RS232 serial ports, 2 network ports and 1 4G/WiFi wireless transmission interface, providing users with flexible communication and connection solutions.

Multi-protocol to BACnet gateway BA115 uplinksupports BACnet/IP, OPC UA, MQTT, Modbus RTU, Modbus TCP, and SNMP protocols.

In the downlink, BA115 supports multiple protocols, such as Modbus RTU, Modbus TCP, BACnet MS/TP, BACnet/IP, DL/T645, IEC104, IEC61850, PLC, air conditioning protocol and JAE1939, enabling it to communicate and communicate with various types of equipment. data collection.

By using BLIIoT patented guide rail buckle technology, the installation process is simplified and the practicality of the gateway is ensured.

Product features

Supported protocols:

Downlink protocol: Modbus RTU, Modbus TCP, BACnet MS/TP, BACnet/IP, DL/T645, IEC104, IEC61850, PLC protocol, Air Conditioning protocol and JAE1939, etc.,

Uplink protocols: BACnet/IP, OPC UA, MQTT, Modbus RTU, Modbus TCP, and SNMP protocols.

Hardware interface:

6*RS485/RS232 serial ports: The serial ports are independent of each other. Each serial port parameter can be set to collect different protocols. The serial port can also set the master-slave relationship independently. It can be configured as either a master station or a slave station.

2*network ports: used for data collection and forwarding. The LAN port has a routing function and provides a channel for other devices to connect to the external network.

4G or WiFi wireless transmission interface: Provides diverse communication options to adapt to different industrial environment need.

Data security:

Support data TSL/SSL, X.509 certificate, SNMP V1/V2, key encryption and other security gateway functions.

Remote Configuration Support:

Support remote configuration, providing users with convenient management and monitoring methods, no longer need to visit engineers, saving maintenance costs.

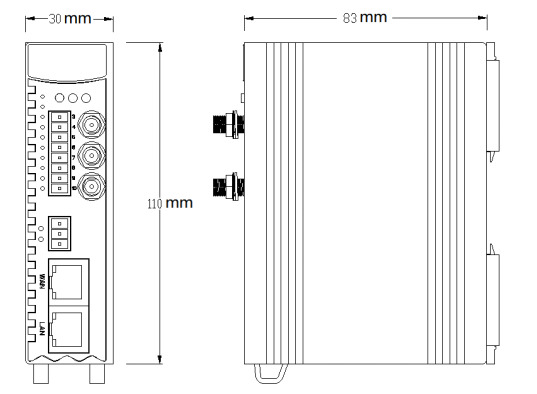

Product Size: L x W x H: 30 x 83 x 110mm

Safety and Stability:

Industrial-grade design: Durable shell material meets industrial environment requirements.

Stability: Efficient communication protocol conversion ensures stable operation of the system.

Environmental adaptation:

Operating temperature range: -40~80℃, adapting to various industrial environments. Protection grade: IP30, ensuring the reliability of the equipment in harsh environments.

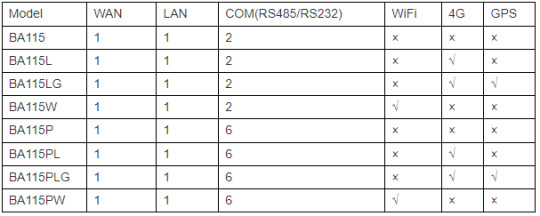

Model List

Application scenarios

Multi-protocol to BACnet gateway is widely used in building automation systems, energy management systems, air conditioning systems, smart factories, and BA systems protocol conversion.

More information about Multi-protocol to BACnet gateway BA115 : https://www.bliiot.com/industrial-iot-gateway-p00425p1.html

#IoT#IoT Solution#Industrial Automation#Smart Energy#BMS#BAS#HVAC#Modbus#BACnet#OPC UA#MQTT#IEC 104#DLT645#PLC#BLIIoT

0 notes

Text

Where IoT Can Improve Beer Production Processes

In the beer production process there are manufacturing malt, crushing raw materials, saccharification, fermentation, storage and maturation, filtration, filling and packaging and other processes. Need to use the wind separator, sieving machine, saccharification pot, fermentation equipment, filtration machine, filling machine, packaging machine and other food machinery and equipment. The automation and intelligence of these food machinery and equipment together promote the automated production of beer.

How to use the Internet of Things (IoT) to realize the digitalization, intelligence and visualization of the production and management process in beer factories?

Solution

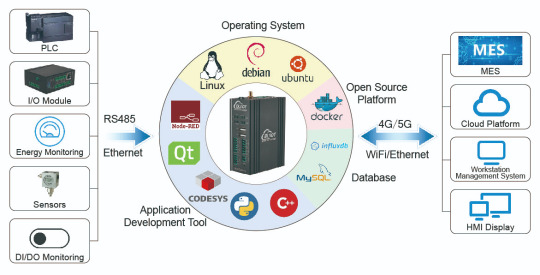

Use BLIIoT EdgeCOM to monitor each production process on the production line; and connect PLC to the EdgeCOM, so that you can not only check the data on HMI, at the same time, the data can be uploaded to the OPC UA client(MES, DCS, etc.).

PLC receives and processes sensor data, controls equipment hydraulic, pneumatic, electrical parameters, etc., while BLIIoT EdgeCOM responsible for controlling the entire production process, to achieve the purpose of information interoperability.

What EdgeCOM implements in the system?

Control commands are sent to the PLC by analyzing the data collected by the PLC.

Write a program through Node-RED or QT to get the data to be displayed from the device, and finally display the data in charts, lists, or other forms on the corresponding interface.

Transfers data to enterprise management systems such as MES.

Advantage of EdgeCOM

Support a variety of communication protocols, reducing communication costs.

EdgeCOM collect the operation status, sensing data, recipe data and alarm information of the equipment, and judge whether it meets the production requirements, according to the analysis results, the EdgeCOM sends control instructions to PLC through OPC UA, then PLC drives the mechanical arm and conveyor belt and other equipment to execute the corresponding actions.

Real-time recording of production line data (e.g., sensor readings, control commands, and product classification), which can be uploaded to My SQL databases, enterprise-level MES, DCS, SCADA, etc., or cloud-based platforms for further analysis.

Support LINUX, Ubuntu, Debian, and other OS, and support Node-Red, QT, Python, C++ and other application programs. Users can program it by themselves according to their needs.

Supports remote configuration and remote upgrade. View More

0 notes

Text

#BD Engineering#BD Engineering Solution#industrial automation#industrial engineering#industrial equipment#plc scada training#plc#hmi#vfd

0 notes

Text

All About Allen Bradley PLCsSeries| Roc Automation

Almost all control engineers are well familiar with the name Allen-Bradley. With the corporation’s long history of innovation well earlier the age of modern pc systems, it is understandable that numerous early progress in digital automation happened here. It is founded in 1903, prior the release of the first Programmable Logic Controller, Allen-Bradley had already gathered extensive experience in the world of electronics that is becoming a worldwide leader in evolving new components & technologies. Allen Bradley PLCs are familiar all over the world.

Allen-Bradley is accredited with inventing the term PLC when it launched one of the first-ever PC (programmable controllers) in 1970, the 1774 PLC.

In the latest major hardware modification of the chassis-based platform, Allen-Bradley released the innovative ControlLogix line of automation controllers. In advanced years, the CompactLogix series and the MicroLogix series were arrived, trying to cover other market segments for definite project scopes.

Know about latest PLC Hardware Platforms like ControlLogix PLCs, CompactLogix PLCs etc.

CompactLogix Allen Bradley: This PLC was first released in 2008 to answer market requests for cost-efficient controllers. There are two variations of the CompactLogix line. One of them includes modular, yet chassis-free controllers, that comprise the L30ER to L35X models. The other variation involves all-in-on controller solutions like L23, L2XER, & L1XER models with rooted digital and analog Input/Output connections.

All CompactLogix PLCs arise with a slot for an SD card & an implanted USB port. The newest models in the CompactLogix platform were freshly rebranded as CompactLogix 5380 & its antecedent, CompactLogix 5370.User memory can series from 0.6 MB up to 10 MB. In addition, the 5380 PLC arrives with two Ethernet ports with up to 1 Gbps of speed.

Second one is MicroLogix PLCs: The unique compact & cost-effective line from Allen Bradley is MicroLogix which was launched in 1994.

These minor controllers are derived with a built-in processor, power supply, & Input/Output. Built for minor applications, there were models with both implanted and expansion I/O support. Various models from the 1000 to 1500 are now obsolete, but still broadly in use.

These ControlLogix PLCs are the first publication part of the Logix platform.

The newest model in this series is ControlLogix 5580, or L8x, which comes with twenty times faster speed than its antecedent, the L7 series. The ControlLogix5580 derives with memory from 3MB up to 20MB. They are well-suited with all communication procedures from Allen-Bradley: ControlNet, Ethernet module, DeviceNet, & DH+. Ethernet/IP speeds can range up to 1 Gbps, which is usually suitable for modern automation requirements of high volumes of data.

Allen-Bradley has been an essential of the industrial manufacturing community for over a century, & the control system software and hardware formed along with Rockwell Automation is certain to persist a main player in almost every industry, for almost any project size and scope.

For further information, pay a visit to ROC Automation

2 notes

·

View notes

Text

digital temperature controllers in India

In the ever-evolving landscape of industrial automation, precision and efficiency are paramount. As industries strive to optimize processes and reduce operational costs, electronic timers have emerged as essential components in automation systems. In India, the demand for electronic timers for industrial automation is on the rise, driven by the need for reliable and programmable solutions in manufacturing, packaging, and various other sectors.

What Are Electronic Timers?

Electronic timers are devices that control the timing of operations in various industrial applications. Unlike traditional mechanical timers, these electronic versions offer enhanced accuracy, programmability, and flexibility. They can be configured to trigger actions based on specific time intervals, making them ideal for tasks such as machinery operation, process control, and automation sequencing.

Why Electronic Timers Are Essential for Industrial Automation

Precision TimingOne of the primary advantages of electronic timers is their ability to provide precise timing control. In industrial automation, even minor delays can lead to inefficiencies or product defects. Electronic timers ensure that processes occur at the exact moment needed, enhancing overall operational efficiency.

ProgrammabilityMany electronic timers offer advanced features, including programmable settings that allow users to customize their operation. This flexibility enables industries to tailor the timers to specific applications, whether it’s for controlling the duration of a machine cycle, managing conveyor belts, or coordinating automated tasks.

Improved ReliabilityElectronic timers are designed for durability and reliability in harsh industrial environments. They are less prone to wear and tear compared to mechanical timers, which can lead to malfunction over time. This reliability translates to reduced downtime and maintenance costs, making electronic timers a sound investment for industrial automation.

Integration with Automation SystemsElectronic timers can easily integrate with other automation components, such as PLCs (Programmable Logic Controllers) and SCADA (Supervisory Control and Data Acquisition) systems. This seamless integration allows for greater control and monitoring of industrial processes, providing operators with real-time data and insights.

The Growing Demand for Electronic Timers in India

As India’s manufacturing sector continues to expand, the need for efficient automation solutions is becoming increasingly evident. The government’s initiatives, such as "Make in India," aim to boost domestic manufacturing and attract foreign investment. This growth has led to a heightened demand for reliable components like electronic timers that enhance production efficiency and reduce costs.

Diverse ApplicationsElectronic timers are versatile tools used across various industries, including automotive, food and beverage, pharmaceuticals, and textiles. Their ability to control processes like packaging, assembly lines, and quality assurance makes them invaluable in modern industrial settings.

Cost-EffectivenessWith the rising cost of labor and the need for competitive pricing, manufacturers are looking for ways to automate processes to save on operational costs. Electronic timers contribute to cost-effectiveness by optimizing workflows and reducing human error, thus leading to higher productivity.

Innovation and TechnologyThe technological advancements in electronic timers, including features like remote monitoring and control, have made them more appealing to Indian industries. As businesses adopt Industry 4.0 practices, the demand for smart, connected devices like electronic timers is expected to increase.

How to Choose the Right Electronic Timer for Your Needs

When selecting electronic timers for industrial automation, consider the following factors:

Application RequirementsIdentify the specific needs of your automation processes. Determine whether you need a simple timer for basic tasks or a more advanced model with programmable features and integration capabilities.

Specifications and FeaturesLook for timers with the necessary specifications, such as voltage ratings, time ranges, and output types. Features like delay settings, multi-function capabilities, and user-friendly interfaces can enhance usability.

Brand ReputationChoose timers from reputable manufacturers known for quality and reliability. Research reviews and seek recommendations to ensure you invest in a product that meets industry standards.

Support and WarrantyConsider the level of customer support offered by the manufacturer. A good warranty can provide peace of mind and protection against potential defects or issues.

Conclusion

The demand for electronic timers for industrial automation in India is steadily increasing as industries seek to enhance efficiency and reduce costs. With their precision, programmability, and reliability, electronic timers play a vital role in modern automation systems. As Indian manufacturing continues to grow and innovate, investing in advanced automation solutions like electronic timers will be key to staying competitive in the global market.

By understanding the benefits and features of electronic timers, businesses can make informed decisions that optimize their operations and drive growth. Embrace the future of industrial automation with electronic timers and take your processes to the next level!

#Buy Industrial Digital Counters Online#electronic timers for industrial automation in India#digital temperature controllers in India#contactor suppliers in India#overload relay price list in India

0 notes

Text

Meticulous Research® has released a report titled "Industrial Automation Software Market by Product (SCADA, DCS, MES, HMI, PLC, IT and Software Environment Integration Solutions, Production Process Test Systems), Deployment Type, End User, and Geography - Forecast to 2029." The global industrial automation software market is projected to grow at a CAGR of 7.4%, reaching $59.5 billion by 2029. This growth is driven by increasing demand for reliable manufacturing, the need for mass production with lower operational costs, and the rise of Industry 4.0 technologies. Additionally, emerging automation-driven industries in developing regions present significant opportunities for market players. The report segments the market by product, deployment type, end user, and geography, while also evaluating competitors and analyzing regional dynamics.

#Industrial Automation Software Market#Factory Automation Software#Industrial Automation Software#Industrial Process Control#Industrial Automation

0 notes

Text

Applications of the Rockwell Automation 2711R PanelView 800 HMI

Manufacturing Industry

Oil and Gas Industry

Food and Beverage Industry

Water and Wastewater Treatment

Automotive Industry

🌐Website :- https://asteamtechno.com

👉Contact us :- +91 95372 40404

📧Email :- [email protected]

#trending#tumblr trends#automation#viralpost#bestdeals#allen bradley#viral#trendingnow#rockwell automation#plc#automotive#application#industrial automation#technology#tech#software#solution

0 notes

Text

SCADA Integrators

The Essential Guide to SCADA Integrators: Enhancing Efficiency and Control

In today’s fast-paced industrial landscape, the role of SCADA (Supervisory Control and Data Acquisition) systems is more crucial than ever. These systems allow businesses to monitor, control, and optimize their operations in real time. However, the effectiveness of a SCADA system often hinges on the expertise of SCADA integrators. In this blog, we’ll delve into what SCADA integrators do, why they are important, and how they can help businesses unlock the full potential of their SCADA systems.

What Are SCADA Integrators?

SCADA integrators are specialists who design, implement, and manage SCADA systems tailored to a company’s specific needs. They play a critical role in ensuring that all components of a SCADA system work harmoniously together. This includes integrating hardware, software, and network elements to create a cohesive system that provides real-time monitoring and control.

Why SCADA Integrators Are Vital

Customization and Optimization: SCADA integrators bring a wealth of expertise in tailoring systems to fit unique operational requirements. They ensure that the SCADA system is not just a generic solution but a customized tool that enhances the specific processes of a business. This includes configuring dashboards, setting up alarms, and optimizing data collection methods.

Seamless Integration: Integrators are adept at bridging various components of a SCADA system. This means connecting sensors, PLCs (Programmable Logic Controllers), and other field devices with the central SCADA software. Their work ensures that data flows seamlessly from the field to the control room, facilitating accurate and timely decision-making.

Enhanced Security: Security is a major concern for SCADA systems, as they are often linked to critical infrastructure. SCADA integrators implement robust security measures to protect against cyber threats and ensure that sensitive data remains secure. This involves setting up firewalls, encryption protocols, and regular security audits.

Scalability: As businesses grow, their SCADA systems need to evolve. SCADA integrators help in scaling the system by adding new components, expanding data storage, and integrating with other enterprise systems. This scalability ensures that the SCADA system continues to meet the changing needs of the business.

Troubleshooting and Support: Even the most well-designed SCADA systems can encounter issues. SCADA integrators provide ongoing support and troubleshooting services to resolve any problems quickly. Their expertise minimizes downtime and ensures that operations continue smoothly.

Choosing the Right SCADA Integrator

When selecting a SCADA integrator, consider the following factors:

Experience and Expertise: Look for integrators with a proven track record and experience in your industry. Their familiarity with specific applications and standards can significantly impact the success of your SCADA system.

Customization Capabilities: Ensure that the integrator can tailor the system to your specific needs rather than offering a one-size-fits-all solution. Customization can lead to better efficiency and effectiveness.

Support Services: Assess the level of ongoing support and maintenance offered. A reliable SCADA integrator should provide comprehensive support to address any issues that arise post-implementation.

Security Measures: Verify that the integrator has a strong focus on security, implementing best practices to safeguard your system against potential threats.

Conclusion

SCADA integrators are indispensable partners in harnessing the full power of SCADA systems. Their expertise in customization, integration, security, scalability, and support ensures that businesses can achieve optimal performance and reliability from their SCADA solutions. By choosing the right SCADA integrator, companies can not only enhance their operational efficiency but also stay ahead in an increasingly competitive market.

If you’re considering upgrading or implementing a SCADA system, investing in a skilled SCADA integrator can make all the difference. With their help, you can unlock new levels of control, insight, and efficiency in your operations.

#SCADA Integrators#SCADA Systems#Industrial Automation#Control Systems#Data Acquisition#SCADA Integration#Industrial Control#System Optimization#SCADA Security#Automation Solutions#Industrial Efficiency#Custom SCADA Solutions#SCADA Support#PLC Integration#Real-Time Monitoring

0 notes

Text

Conveyor Systems for OEM Machine Builder Partners in pune | India

Our capacity to provide process advancements to our OEM partners and apply process improvements to their customers go hand in hand. Every project we work on demonstrates our dedication to fulfilling new criteria and hygienic design. This not only helps the initiatives of our OEM partners, but it also fosters trust, which strengthens our relationship.

#Solutions for OEMs and Machine Builders Pune#Conveyors India#PLC Automation Pune#PLC and SCADA Service Provider India#Automators Industrial Projects#Let’s Get in Touch#Company Automators Industrial Project#Smart Factory Solutions#Energy

0 notes

Text

SINAMICS V20 - Simplify Automation with Flexible Drive Solution

The SINAMICS V20 is an affordable entry-level AC drive from Siemens that has been designed for easy use and high resistance to wear and tear. SINAMICS V20 is the best compromise in functionality, performance, and ease of use for basic tasks of motion control, whether it is an industrial application or a simple commercial premises. Naksh Technology is glad to announce that we supply and engage ourselves in the distribution of the SINAMICS V20 to give our clients tangible drive solutions suitable for numerous industrial applications.

Key Features of SINAMICS V20:

Ease of Commissioning and Operation: The SINAMICS V20 is remarkably easy to set up, as its name suggests. The control panel is user-friendly and easy to navigate, allowing for simple parameterization and commissioning. Within a matter of minutes, you can have the drive system working, thanks to the decreased downtime and leaving rapid deployment within reach for numerous applications. The pre-set configurations and the plug-in functionality simplify the integration process.

Energy Efficiency: The SINAMICS V20 is built on the principles of energy efficiency with a view to reducing operational costs. The device is fitted with ECO mode which alters the power consumption for the distinct operational loads thus optimizing the power consumed. Additional features such as the automatic motor flux reduction helps to save costs by decreasing losses in low torque situations thus enhancing long-term efficiency.

Rugged and Reliable Design: The V20 has been specifically designed to operate in extreme environmental conditions. Its sturdy structure is able to prevent penetration by dust, heat, and moisture owing to a conformal coating that shields the internal parts. Additionally, it can withstand operating temperatures between -10°C to 60°C, enabling the drive to work under extreme conditions associated with the industry. The device has a built-in resistance to overload, under-voltage, and short circuit to ensure safe operation.

Compact and Flexible: Due to the compactness of the SINAMICS V20, it can be used on applications where space is a constraint. The ability to mount several units side by side enables convenient installation in compact spaces without compromising power performance. Its extensive input voltage range and multi-rating capabilities allow it to meet the various requirements of worldwide industries.

Integrated Communication: For sectors aiming to optimize their operations, the SINAMICS V20 comes with in-built communication ports that enable easy interfacing with automation systems and PLCs. Further, the drive can be simply networked to higher control systems for real-time watching and managing your drive system.

Advanced Control and Performance: The SINAMICS V20 provides dependable and steady motor control for numerous applications. It supports V/f control and FCC (flux current control) for enhanced performance with different classes of motors, allowing for controlled and smooth speed up and slow down even with heavy loads. The drive also has the capability of speed and torque regulation making it ideal for use in instances that need reliable and accurate results within a given time frame.

Applications of SINAMICS V20:

The SINAMICS V20 drive can be applied in a variety of sectors and application fields; for instance:

Pumps and Fans: Providing adjustment within tight tolerances is offered for the control of electric motors in HVAC systems, water pumps, and ventilation equipment where energy efficiency is of utmost importance.

Compressors: It optimizes the control of air and gas compressors which reduces wear and improves performance.

Conveyors: The V20 offers smooth control features making it very useful for systems such as conveyors and material handling systems in manufacturing and logistics.

Mixers and Agitators: Perfect for managing industrial engines, allowing speed regulation efficiently for the operation of viscous products.

Ready to Boost Your Operations with SINAMICS V20?

When it comes to raising the level of control, energy efficiency, and reliability of automation systems, the solution to go for is the SINAMICS V20. Contact Naksh Technology today to find out how the SINAMICS V20 will be advantageous for your business. Allow us to assist you in the selection process and guarantee that this leading Siemens programming product performs optimally in your systems.

0 notes

Text

#BD Engineering Solution#BDengineering#Industrial engineering#industrial equipment#industrial automation#PLC#HMI#VFD#Siemens#Mitsubishi#Delta#Omron#Panasonic

0 notes

Text

The Art of Salt Packaging: Bottles, Pouches, and Beyond with Nichrome

Since salt is a staple in every kitchen, its packaging needs to be anything but ordinary. With the evolution of packaging, today’s options have become more versatile and advanced than ever before. At Nichrome, we understand this evolution, therefore, our innovative salt packaging solutions are designed to meet the diverse needs of the industry.

Let’s take a closer look at the various packaging formats and the cutting-edge machines we offer to bring these solutions to life.

The Timeless Jar: Convenience Meets Precision

Jars offer convenience and control, making it simple to pour the right amount every time. At Nichrome, our edible salt filling machines are designed to make jar packaging efficient and precise. With automated systems and advanced controls, we ensure that every jar is filled accurately, minimizing waste and maintaining consistent quality.

Pouches: The Portable Powerhouse

Pouches are lightweight, easy to handle, and take up less space, making them perfect for today’s busy lifestyles. Nichrome’s salt packing machines excel in this area, offering seamless filling, sealing, and packaging of salt pouches. Our machines are engineered to maintain the integrity of the product while extending its shelf life, ensuring that consumers get the best experience possible. Whether it’s a small sachet for individual use or a larger pouch for family-sized needs, our machines deliver with precision and reliability.

Why Nichrome?

In the world of salt packaging, one size doesn’t fit all. Therefore with Nichrome, you don’t have to settle for less. Explore our range of solutions and discover how we can help you take your packaging to the next level.

Vertical Form Fill Seal Machines

At Nichrome, we understand the importance of staying ahead in the dynamic world of packaging. Our Vertical Form Fill Seal (VFFS) machines are a testament to our commitment to innovation. These machines form pouches from flat film rolls, fill them with salt, and seal them with precision. The VFFS machines are engineered for high-speed operation and reliable sealing, making them ideal for high-volume production. With the ability to handle various products, these machines offer flexibility and efficiency, ensuring that your packaging needs are met with excellence.

Saltpack

The Saltpack VFFS machine by Nichrome is specifically designed for the salt industry. With its open construction and robust design, the Saltpack is built to withstand the demands of rigorous salt packaging. Its low running cost and dust-tight electrical panel ensure reliable operation under constant use. Additionally, the Saltpack offers optional fillers for packing other free-flow and viscous products, making it a versatile choice for various packaging needs.

VFFS Multilane Series

For those who require simultaneous packaging of multiple products, the VFFS Multilane Series is a game-changer. This advanced machine features multiple lanes, allowing for efficient and high-speed packaging of various products. The Multilane Series is designed to handle a wide range of industries, providing exceptional performance and productivity. Its ability to pack multiple products within the same machine saves valuable time and resources, making it an invaluable asset for any packaging operation.

Multilane Stickpack with Volumetric Multiple Cavity Filler

When it comes to free-flow products like salt, the Multilane Stickpack with Volumetric Multiple Cavity Filler stands out. This high-end machine ensures maximum productivity and efficiency, thanks to its advanced design and large product hopper. With its CE certification and PLC controller, the Multilane Stickpack simplifies operations and delivers superior results.

Conclusion

At Nichrome, we are dedicated to providing innovative packaging solutions that meet the highest standards of quality and reliability. Our expertise extends beyond salt packaging to include a wide range of food, liquid, spice, snack, and more. We are committed to empowering businesses with the tools they need to achieve efficiency and excellence.

From jars to pouches, and from VFFS machines to advanced Multilane systems, Nichrome is your partner in packaging innovation. Explore our solutions and discover how we can help you take your packaging to the next level.

0 notes

Text

Global Hvac Thermostats Market Research and Future Opportunities Overview 2024 - 2031

The global HVAC (Heating, Ventilation, and Air Conditioning) thermostats market is experiencing a transformative phase driven by technological advancements, increased awareness of energy efficiency, and a growing emphasis on smart home solutions. This article provides an in-depth analysis of the market, including its drivers, challenges, key players, and future trends.

Introduction to HVAC Thermostats

The global HVAC thermostats market is on a robust growth trajectory, driven by the demand for energy-efficient solutions and technological advancements in smart home integration. Despite challenges related to costs and competition, the market's potential for innovation and sustainability presents significant opportunities.

HVAC thermostats are devices that regulate the temperature and humidity levels in residential and commercial buildings. They play a crucial role in maintaining comfort and energy efficiency by controlling heating and cooling systems. With the advent of smart technology, modern thermostats offer features such as remote access, learning capabilities, and integration with home automation systems.

Market Overview

Market Size and Growth Rate

As of 2023, the global HVAC thermostats market is valued at approximately USD 3.5 billion and is expected to grow at a CAGR of 7.8% from 2024 to 2030. This growth is primarily fueled by the rising demand for energy-efficient solutions and the growing adoption of smart home technologies.

Key Drivers of Market Growth

Rising Energy Costs: Increasing energy prices have compelled consumers and businesses to seek energy-efficient solutions, making advanced HVAC thermostats more appealing.

Technological Advancements: The integration of IoT (Internet of Things) technologies in thermostats is enhancing user experience and functionality, driving adoption.

Government Initiatives: Various governments worldwide are promoting energy-efficient systems through incentives and regulations, boosting the HVAC thermostat market.

Challenges Facing the Market

While the market is poised for growth, it also faces several challenges:

High Initial Costs: The upfront investment in advanced thermostats can deter some consumers, especially in cost-sensitive markets.

Market Competition: The increasing number of players and rapid technological changes can create a competitive environment, putting pressure on pricing.

Market Segmentation

The HVAC thermostats market can be segmented based on various factors:

By Type

Mechanical Thermostats: Traditional thermostats that operate on mechanical components.

Digital Thermostats: Electronic devices that offer more precise temperature control.

Smart Thermostats: Advanced devices that can be controlled remotely and learn user preferences.

By Application

Residential: Primarily used in homes for temperature regulation.

Commercial: Utilized in offices, retail spaces, and other commercial establishments.

Industrial: Employed in manufacturing facilities and warehouses for climate control.

By Region

North America: The largest market due to high adoption rates of smart technology.

Europe: Driven by stringent energy efficiency regulations and a growing emphasis on sustainable building practices.

Asia-Pacific: Rapid urbanization and industrial growth are leading to increased demand for HVAC solutions.

Key Players in the Market

The HVAC thermostats market is home to several leading players, including:

Honeywell International Inc.

Nest Labs (Google LLC)

Emerson Electric Co.

Johnson Controls International plc

Ecobee Inc.

These companies are focusing on innovation, strategic partnerships, and expanding their product portfolios to maintain competitive advantages.

Future Trends

Smart Home Integration

The trend toward smart homes is expected to accelerate the adoption of HVAC thermostats. Features like voice control, mobile app integration, and learning algorithms will become standard offerings.

Energy Management Systems

As energy efficiency becomes a priority, HVAC thermostats will increasingly be integrated into larger energy management systems, allowing users to monitor and optimize energy usage more effectively.

Sustainability Focus

The push for sustainability will drive the development of eco-friendly HVAC thermostats that minimize energy consumption and reduce carbon footprints.

Conclusion

The global HVAC thermostats market is on a robust growth trajectory, driven by the demand for energy-efficient solutions and technological advancements in smart home integration. Despite challenges related to costs and competition, the market's potential for innovation and sustainability presents significant opportunities. As consumers and businesses prioritize comfort and energy efficiency, HVAC thermostats will play a vital role in shaping the future of climate control systems. Staying attuned to market trends and technological advancements will be crucial for stakeholders aiming to thrive in this dynamic environment.

0 notes