#DLT645

Explore tagged Tumblr posts

Text

BLIIoT | BACnet gateway BA115 Support Multi-Protocol Conversion for Building Management Systems

Introduction

With the development of communication technology and control technology, in order to achieve efficient and intelligent management of buildings, centralised monitoring and management has become an inevitable trend in the development of intelligent management of buildings. In this context, high-performance building HVAC data transmission solutions - protocol conversion gateway came into being, widely used in building automation and HVAC system applications.

BLIIoT always insists on the core of the user's needs, and constantly expands its applications in a variety of industrial fields. Recently, we have developed a new series of BLIIoT Building Automation HVAC gateways, This series of products not only have excellent stability and anti-interference capabilities, but also have deep industry applications, aiming to bring users a new building automation data collection and conversion experience.

Product Description

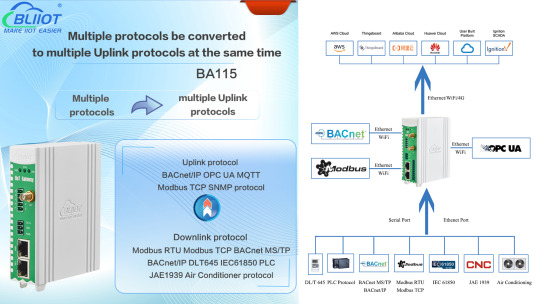

The multi-protocol to BACnet gateway BA115 is a protocol conversion gateway designed for converting various devices, power meters, and air-conditioning hosts into BACnet protocols for docking with BA systems.

The multi-protocol to BACnet gateway BA115 has powerful hardware interfaces, including 2/6 RS485/RS232 serial ports, 2 network ports and 1 4G/WiFi wireless transmission interface, providing users with flexible communication and connection solutions.

Multi-protocol to BACnet gateway BA115 uplinksupports BACnet/IP, OPC UA, MQTT, Modbus RTU, Modbus TCP, and SNMP protocols.

In the downlink, BA115 supports multiple protocols, such as Modbus RTU, Modbus TCP, BACnet MS/TP, BACnet/IP, DL/T645, IEC104, IEC61850, PLC, air conditioning protocol and JAE1939, enabling it to communicate and communicate with various types of equipment. data collection.

By using BLIIoT patented guide rail buckle technology, the installation process is simplified and the practicality of the gateway is ensured.

Product features

Supported protocols:

Downlink protocol: Modbus RTU, Modbus TCP, BACnet MS/TP, BACnet/IP, DL/T645, IEC104, IEC61850, PLC protocol, Air Conditioning protocol and JAE1939, etc.,

Uplink protocols: BACnet/IP, OPC UA, MQTT, Modbus RTU, Modbus TCP, and SNMP protocols.

Hardware interface:

6*RS485/RS232 serial ports: The serial ports are independent of each other. Each serial port parameter can be set to collect different protocols. The serial port can also set the master-slave relationship independently. It can be configured as either a master station or a slave station.

2*network ports: used for data collection and forwarding. The LAN port has a routing function and provides a channel for other devices to connect to the external network.

4G or WiFi wireless transmission interface: Provides diverse communication options to adapt to different industrial environment need.

Data security:

Support data TSL/SSL, X.509 certificate, SNMP V1/V2, key encryption and other security gateway functions.

Remote Configuration Support:

Support remote configuration, providing users with convenient management and monitoring methods, no longer need to visit engineers, saving maintenance costs.

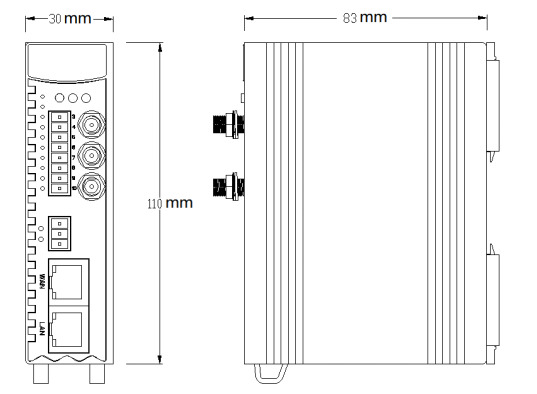

Product Size: L x W x H: 30 x 83 x 110mm

Safety and Stability:

Industrial-grade design: Durable shell material meets industrial environment requirements.

Stability: Efficient communication protocol conversion ensures stable operation of the system.

Environmental adaptation:

Operating temperature range: -40~80℃, adapting to various industrial environments. Protection grade: IP30, ensuring the reliability of the equipment in harsh environments.

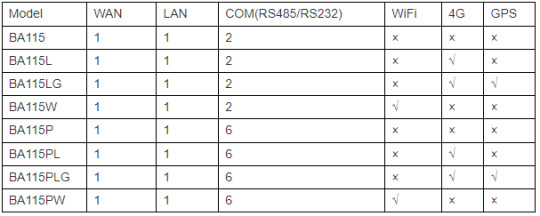

Model List

Application scenarios

Multi-protocol to BACnet gateway is widely used in building automation systems, energy management systems, air conditioning systems, smart factories, and BA systems protocol conversion.

More information about Multi-protocol to BACnet gateway BA115 : https://www.bliiot.com/industrial-iot-gateway-p00425p1.html

#IoT#IoT Solution#Industrial Automation#Smart Energy#BMS#BAS#HVAC#Modbus#BACnet#OPC UA#MQTT#IEC 104#DLT645#PLC#BLIIoT

0 notes

Text

How Arm Embedded Controller BL302 Help Power Industry Developing?

Introduction

In the power industry, real-time collection, processing and analysis of power facility data is critical to improving system stability and reliability.

4G industrial computer can perfectly solve this problem. Quad-core 64-bit processor with 1.8GHz processing capability makes the industrial computer have powerful computing and processing capabilities. Moreover, the industrial computer is also equipped with rich interfaces and compatibility, such as 4 RS485/RS232, 2 network ports, 2 DI ports, 2 PWM ports, 2 USB ports and 1 HDMI port. In addition, the industrial computer also supports the independent development of non-standard protocols, such as DLT645, IEC101, IEC104 and so on.

The compatibility of industrial computer is one of its important features. It is compatible with multiple development environments and programming languages such as Node-Red, QT and Python, providing users with more convenient and flexible development options. This means that users can choose the most suitable development methods and tools according to their needs and preferences. At the same time, the industrial computer also supports guide rail installation, which can be easily installed in power facilities, does not take up too much space, and is more compact and efficient.

Security

IPC also attaches great importance to security. It supports national secret encryption, which can protect the data security in the system. For the power industry, the security and confidentiality of data is very important, because any data leakage or tampering may lead to serious consequences. The encryption function of the industrial computer can effectively protect the security of data and avoid potential risks and threats.

Features

1. Data acquisition and monitoring

It can connect various sensors and measuring equipment to collect data of power equipment in real time, such as current, voltage, power, etc. Through data collection and monitoring, the status of power equipment can be known in time, which is convenient for fault diagnosis and prediction.

2. Remote control and signaling

The remote control and remote signaling functions of electric equipment can be realized through network connection. Users can operate power equipment through the monitoring center or mobile terminal, such as switch control, restart equipment, etc. At the same time, the industrial computer can also receive remote signaling information from power equipment and monitor equipment status in real time.

3. Energy consumption management

It can monitor and manage the energy consumption of electric equipment. By monitoring energy consumption data of electrical equipment in real time, energy usage can be analyzed and optimized to improve energy efficiency and save costs.

4. Remote diagnosis and maintenance

Fault diagnosis and maintenance of electrical equipment can be carried out through remote connection. Maintenance personnel can remotely access the industrial computer to obtain equipment status information, identify problems and perform corresponding maintenance.

5. Data analysis and prediction

With strong computing power, real-time analysis and prediction of power equipment data can be performed. Through the analysis of historical data and real-time data, it is possible to discover equipment operation trends and abnormal behaviors, and take corresponding measures in advance to avoid equipment failures and power outages.

6. Safety monitoring and protection

It can be used for safety monitoring and protection of electrical equipment. By connecting safety sensors and surveillance cameras, the industrial computer can monitor the safety status around the equipment in real time, and trigger corresponding alarms or protective measures to ensure the safety of the equipment.

Summarize

4G industrial computer plays an important role in the power industry. It provides strong support for the stability and reliability of the power system by collecting, processing and analyzing power facility data in real time. Quad-core 64-bit processor, rich interfaces and compatibility, and security encryption function make the industrial computer one of the indispensable equipment in the electric power industry. In the future, with the continuous development and innovation of technology, it is believed that industrial computer will play a greater role in the electric power field and make greater contributions to the development of the electric power industry.

More information of Industrial Computer view: https://www.bliiot.com/edge-computing-gateway-p00359p1.html

0 notes

Text

one of the stupid sounds-like-a-cyberpunk-story-technobabble-line-but-is-actually-just-true things I've learned at $dayjob is that in the 70's chinese engineers developed their own entire system for doing SCADA called DLT645 that is wholly incompatible with the rest of the world and which almost no-one outside china knows how to use because it can only be found on old chinese factory machines.

There are a handful of western engineers who know how it works and most of them only know it because they got contracted to design a chip or interface for chinese hardware.

It's not hard per se but it is extremely obscure and rare so almost no one even knows it exists. If you go looking for information on DLT645 in English you will find copies of the same three documents over and over again and one (1) C# library for interfacing with it.

58 notes

·

View notes

Text

BL103UA Energy monitoring BACnet to MQTT 2RJ45 Industrial IoT gateway

BACnet gateway BL103 is a cost-effective industrial IoT Gateway, for building automation and HVAC control systems, which is used to convert BACnet MS/TP to BACnet/IP, Modbus to BACnet/IP, BACnet to MQTT, BACnet to OPC UA protocol.

BACnet gateway BL103 adopts embedded ARM MCU, based on Linux OS, equipped with 1WAN/LAN, 1LAN, 1 RS485, 4G module optional.

BACnet gateway BL103 has powerful protocol conversion function, which can realize simultaneous acquisition of multiple protocols, including: BACnet MS/TP, BACnet/IP, Modbus RTU, Modbus TCP, DLT645. Upstream supports BACnet/IP, Modbus TCP, MQTT, OPC UA It has built-in cloud drivers such as Huawei Cloud, Alibaba Cloud, KPIIOT, Amazon Cloud, Thingsboard Cloud, and Sparkplug B, which can be directly connected to various mainstream cloud platforms.

BACnet gateway BL103 supports OPENVPN network security protection protocol, is compatible with TLS SSL X.509 root certificate and other data encryption technologies to ensure data security.

Moreover, BACnet Gateway BL103 adopts the unique data integrity technology of breakpoint data supplementary transmission.

BACnet gateway BL103 integrates the user-friendly configuration interface, as well as functions such as remote configuration and remote firmware upgrade;

The BACnet gateway BL103 adopts a fastened structure, redundant power supply design, and can be installed on a standard DIN35 rail.

0 notes

Text

Multi-function Energy Meter

https://www.acrelenergy.com/products/multi-function-energy-meter/

Multi function energy meter refers to the watt-hour meter which has more than two functions, such as time-sharing and measurement demand, in addition to measuring active power (reactive power), and can display, store and output data, and has powerful data acquisition and processing functions. Digital multifunction meter is suitable for all common power parameters, real-time power measurement, energy measurement and power quality analysis in power grid. The user-friendly operation method of Acrel multifunction meter manufacturer provide digital multifunction meter that more convenient to use, if you want to know more about multifunction meter price and other info, please contact us.

Multi-function Energy Meter Types

AMC Single Phase Current Meter

AMC series measure current and have RS-485port,Modbus protocol and alarm function.

AMC Single Phase Voltage Meter

AMC series measure voltage and support RS-485port Modbus protocol and Analog output.

AMC Three Phase Ampere Meter

AMC 3 phase digital ampere meter display is clear and beautiful, and can replace the traditional analog pointer meter. It is a kind of high performance automation instrument which is suitable for ind...

AMC Three Phase Energy Meter

This series of meters have RS-485port, Modbus-RTU protocol. Analog output, alarm output, switching input/output can be selected.

APM800 Series

three phase smart power quality energy analyzer meter APM800 high accuracy class 0.5S with RS485 Modbus.

PZ Series

PZ series can measure current , voltage, power, power factor and Kwh parameters with RS485 Modbus, 2DI/DO and alarm functions.

Multifunction Meter Working Principle

When the energy meter is working, the voltage is divided by the resistance, and the current is sampled on the sampling resistor by the current transformer, and then sent to the dedicated power chip for processing, and converted into a digital signal to the CPU for calculation. Due to the use of a dedicated power processing chip, the voltage and current sampling resolution is greatly improved, and there is enough time to measure the power more accurately so that the measurement accuracy of the electric energy meter has been significantly improved. Smart energy meter application is more and more wide.

The CPU in the figure is used for time-sharing billing and processing various input and output data, reads the data of the dedicated energy chip through the serial interface and completes the time-sharing active energy metering and maximum demand metering functions according to the preset time period. According to the needs, display various data, communicate through infrared or RS485 interface, and complete the monitoring of operating parameters, record and store various data.

Multi-function Energy Meter Features

l The multiple rates can be set in 4 time zones, 10 periods, and four rates (peak and flat valley)

l The sub-harmonic measurement can reach 2-63 times.

l With voltage crest factor, telephone crest factor, current K factor, and waveform recording functions

l Configurable Ethernet (Modbus-TCP protocol) function

l Support Modbus-RTU and DLT645 protocol at the same time

l Expandable optional module

0 notes

Text

开源一个阿里边缘计算网关WebSocket协议dlt645智能电表驱动程序

项目地址 在这里。本项目是阿里云物联网边缘计算网关驱动,用于中国电力标准DLT645智能电表. 目前驱动仅支持Aliyun 物联网平台,符合阿里云边缘网关WebSocket协议。 可以通过串口连接并采集多个Dlt电表数据(同一串口下,暂不支持多串口)并转换为阿里云边缘网关WebSocket协议。使用前应先连接好Dlt电表与串口。(本地 调试工具开发中)。

阿里云物联网平台操作指南

边缘计算网关详细的WebSocket协议见阿里云官网SDK linkedge-thing-access-websocket_client_sdk 。

目前仅支持 “onlineDevice”,”reportProperty” 和 “getProperty” 方法,更多方法待开发。

使用前需要在阿里云物联网平台新建产品和设备.新建产品参考模型见项目文件 model.json.

需要安装阿里云边缘计算网关程序, 并

View On WordPress

0 notes

Text

BLIIoT Industrial 4G Ethernet Edge Gateway BL110 Collects Siemens S7-1500 PLC to the Server for Monitoring

BLIIoT Industrial 4G Ethernet Edge Gateway BL110 used to convert Modbus, Modbus TCP, DLT645, PLC, BACnet MS/TP, BACnet/IP and other industrial protocols to MQTT, OPC UA, BACnet/IP, Modbus TCP and other protocols. Support BLRMS (also known as BLIIOT RMS) and can facilitate remote upgrades of software versions as well as device management.

#iot#iiot#iotsolutions#smartfactory#industrialautomation#iotgateway#plcgateway#plc#modbus#mqtt#bacnet#dlt645#iec#opcua#scada#ignition#thingsboard#awscloud#huaweicloud#alibabacloud#siemens#omron#mitsubishi#schneider#abb#delta#remotemonitoring#remotemanagement#BLIIoT#BLIIoT Applications

0 notes

Text

Why Industrial IoT Gateway is the Key to Digital Transformation

With the continuous development of IoT technology, digital transformation is becoming more and more popular. However, due to the diverse protocols used by the equipment, the equipment cannot communicate with each other.

BLIIoT Industrial gateways is a good choice for digital transformation.

1, Compatible with various communication protocols

Modbus RTU, Modbus TCP, Siemens PLC, Mitsubishi PLC, OMRON PLC, Delta PLC, BACnet MS/TP, BACnet/IP, DLT645, OPC UA, MQTT

2, Data acquisition and processing

3, Real-time monitoring

Check our website to learn more about IoT gateway.

0 notes

Text

BLIIoT Industrial IoT Edge Gateway BL110 for Photovoltaic System Monitoring

BLIIoT Industrial IoT Edge Gateway BL110 is connected through RS485, and uses the modbus protocol to collect the data of inverters, environmental detection equipment, and electric energy meters. Then upload to the server using MQTT.

#iot#iotsolutions#iiot#modbus#mqtt#opcua#edgecomputing#remotemonitoring#photovoltaic#inverters#meter#awscloud#ignition#scada#thingsboard#huaweicloud#alibabacloud#smartcities#smartenergy#BLIIoT#BLIIoT Applications

0 notes

Text

BL103E Security monitoring 2RJ45 BACnet Industrial IoT gateway

BACnet gateway BL103 is a cost-effective industrial IoT Gateway, for building automation and HVAC control systems, which is used to convert BACnet MS/TP to BACnet/IP, Modbus to BACnet/IP, BACnet to MQTT, BACnet to OPC UA protocol.

BACnet gateway BL103 adopts embedded ARM MCU, based on Linux OS, equipped with 1WAN/LAN, 1LAN, 1 RS485, 4G module optional.

BACnet gateway BL103 has powerful protocol conversion function, which can realize simultaneous acquisition of multiple protocols, including: BACnet MS/TP, BACnet/IP, Modbus RTU, Modbus TCP, DLT645. Upstream supports BACnet/IP, Modbus TCP, MQTT, OPC UA It has built-in cloud drivers such as Huawei Cloud, Alibaba Cloud, KPIIOT, Amazon Cloud, Thingsboard Cloud, and Sparkplug B, which can be directly connected to various mainstream cloud platforms.

BACnet gateway BL103 supports OPENVPN network security protection protocol, is compatible with TLS SSL X.509 root certificate and other data encryption technologies to ensure data security.

Moreover, BACnet Gateway BL103 adopts the unique data integrity technology of breakpoint data supplementary transmission.

BACnet gateway BL103 integrates the user-friendly configuration interface, as well as functions such as remote configuration and remote firmware upgrade;

The BACnet gateway BL103 adopts a fastened structure, redundant power supply design, and can be installed on a standard DIN35 rail.

0 notes

Text

BL103 Building automation 2RJ45 BACnet Industrial IoT gateway

BACnet gateway BL103 is a cost-effective industrial IoT Gateway, for building automation and HVAC control systems, which is used to convert BACnet MS/TP to BACnet/IP, Modbus to BACnet/IP, BACnet to MQTT, BACnet to OPC UA protocol.

BACnet gateway BL103 adopts embedded ARM MCU, based on Linux OS, equipped with 1WAN/LAN, 1LAN, 1 RS485, 4G module optional.

BACnet gateway BL103 has powerful protocol conversion function, which can realize simultaneous acquisition of multiple protocols, including: BACnet MS/TP, BACnet/IP, Modbus RTU, Modbus TCP, DLT645. Upstream supports BACnet/IP, Modbus TCP, MQTT, OPC UA It has built-in cloud drivers such as Huawei Cloud, Alibaba Cloud, KPIIOT, Amazon Cloud, Thingsboard Cloud, and Sparkplug B, which can be directly connected to various mainstream cloud platforms.

BACnet gateway BL103 supports OPENVPN network security protection protocol, is compatible with TLS SSL X.509 root certificate and other data encryption technologies to ensure data security.

Moreover, BACnet Gateway BL103 adopts the unique data integrity technology of breakpoint data supplementary transmission.

BACnet gateway BL103 integrates the user-friendly configuration interface, as well as functions such as remote configuration and remote firmware upgrade;

The BACnet gateway BL103 adopts a fastened structure, redundant power supply design, and can be installed on a standard DIN35 rail.

0 notes

Text

Connect industrial field devices to OPC UA servers through OPC UA gateways

At present, most PLCs on the market are connected to OPC UA Server through OPC UA software running on industrial PCs, which requires both industrial PCs as hardware and the purchase of OPC UA licenses, which is expensive. Now we will introduce an embedded OPC UA gateway BL110 from BLIIOT. Users can directly connect various brands of PLCs to OPC UA servers through this embedded gateway hardware. We refer to this embedded hardware as an OPC UA Gateway. Users no longer need licenses for industrial computers or OPC UA software, which greatly reduces the cost and application difficulty. Beilai technology adopts OPC UA protocol to connect to MES system for industrial Internet of Things field data collection. There are two solutions: 1. Use BL200UA to directly transfer IO to OPC UA (this was introduced in the previous article); 2. Use BL110 industrial intelligence Gateway, transfer industrial communication protocols such as (Modbus, DLT645, PLC, frequency converter, IO module) to OPC UA, and connect to OPC UA server

1. What is OPC UA? OPC Unified Architecture is a new technology created by OPC Foundation, which is more secure, reliable, neutral (independent of suppliers), and transmits raw data and preprocessed information for manufacturing sites to production planning or enterprise resource planning (ERP) systems. Using OPC UA technology, all required information can reach every authorized application and every authorized person anytime and anywhere. OPC UA is independent of the manufacturer, applications can use it to communicate, developers can use different programming languages to develop it, and different operating systems can support it. OPC UA makes up for the shortcomings of the existing OPC, adding important features such as platform independence, scalability, high availability, and Internet services. As an important communication protocol (IEC 62541) in Industry 4.0, OPC UA is also the most promising connection standard in the industrial field.

2. What is MES? The white paper of MESA (Manufacturing Execution System Association) defines MES (Manufacturing Execution Systems): "The manufacturing execution system transmits information to optimize the production process from order to finished product. MES is not just a single information system of a factory, but a system integrated horizontally, vertically, and between systems, the so-called management system, for various enterprise information systems that have been paid attention to in recent years, such as SCP, ERP, CRM, and data warehouses. For example, as long as the object of the factory is included, MES is inseparable. To sum up, MES can be summarized as one purpose - how to execute manufacturing, two core databases - real-time database and relational database, two communication interfaces - interface with control layer and interface with business planning layer, four key functions - Production management, process management, process management and quality management, etc.

3. What is the relationship between OPC UA and MES? As a functional module of MES, the data acquisition system is responsible for providing basic monitoring data for MES and is an important part of MES. OPC technology, as the underlying data acquisition technology often used in MES, is widely used in MES data acquisition systems. OPC UA technology is a new technology proposed by the OPC Foundation, the purpose is to eliminate its limitations on the basis of satisfying the functions of classic OPC technology.

4. Why MES manufacturers choose OPC UA 1. The OPC UA network protocol will not be blocked by the technology of the buying country! 2. Data encryption, high security, can pass through the firewall. 3. OPC UA is a unified framework and will not be limited by platforms such as windows and lunix. OPC UA can be deployed on PCs, mobile phones or embedded devices. In addition, OPC UA can also run naked without an operating system. 4. There is no limitation of programming language C#, C++, python, java can be used as OPC UA programming language. 5. OPC UA has been ecologicalized, and there are various products, no matter what level, from small sensors to large server data centers, the products are very rich. The concept of Industrial Internet of Things and Industry 4.0 is very hot now, and OPC UA is playing a key role in it. As long as it is an enterprise with a manufacturing and processing plant, the use of OPC UA must be an inevitable trend.

How to realize the conversion of IO signals, sensor signals, PLC and other field device data to OPC UA in the process of industrial intelligent digital transformation?

There are two mainstream methods: 1. Convert on-site data to OPC UA through software such as kepware; 2. Install PLCs that support OPC UA such as (Siemens S7-1200, Mitsubishi FX-5U, etc.). The method has the problem of cost! Beilai Technology BL110UA OPC UA Gateway, as a cost-effective industrial intelligent gateway, supports converting field devices to OPC UA protocol! The problem that originally required thousands or even tens of thousands of dollars to solve can be solved with a few hundred yuan! At present, Beilai Technology BL110UA can collect hundreds of industrial field communication protocols including Modbus, DLT645, and PLC protocols to meet the needs of most customers! As a member unit of OPC UA Foundation, Beilai Technology actively participates in the promotion of OPC UA, and is committed to the research and development and production of OPC UA related products!

0 notes

Text

APM800 Series

https://www.acrelenergy.com/products/apm800-series/

APM series power meters of ACREL are ac digital multifunction meters that are designed according to IEC standards and synchronized with international advanced technology. APM series three phase energy meters have full power measurement, energy statistics, analysis of power quality and network communications and other functions, and 3 phase digital energy meters are mainly used for comprehensive monitoring of the quality of power supply network.

This series of 3 phase energy meter use a modular design, with a rich function of the external DI / DO module, AI / AO module, event recording (SOE) module with T-Flash (TF) card, network communication module, temperature and humidity measurement module, can achieve full power measurement of electrical circuit and monitoring of switch status, dual RS485 with Ethernet interface can realize data copying of RS485 master station, eliminating the need for data switching exchange. PROFIBUS-DP interface can realize high-speed data transmission and networking function. Acrel can provide multifunction meter with rs485 in good price.

Technical parameter of APM800 Series

Connection

3 phase 3 wire, 3 phase 4 wire

Frequency

45-65Hz

Rated Voltage

AC 100V, 110V, 400V, 690V

Rated Voltage

AC 1A, 5A

Accuracy

Class 0.2s(APM801, APM830) Class 0.5s(APM800, APM810)

Installation

Panel mounted

Basic function

four-quadrant electric energy

real-time and maximum demand

Standard card capacity: 4G, MicroSD(TF) card up to 32G capacity

2DI+2DO

RS485/Modbus

Additional function

/F: muti tariff

/MD82: 8DI+2DO

/MLOG: SD card

/MD84: 8AI+4AO

/MCE: Ethernet

/MCP: Profibus-DP

MTN: 4 channels 2m NTC temperature measurement

MTP: 2 channels PT100 temperature measurement

MTH/: 1 way temperature and humidity control

/MCM: the second RS485

Communication

RS485 port/Modbus-RTU protocol and DLT645 protocol

RJ45 port (Ethernet)/Modbus-TCP http DHCP protocol

Auxiliary power supply

AC/DC 85~265V or AC/DC 115~415V

0 notes