#PCB designer

Explore tagged Tumblr posts

Text

Die fünf Hauptfunktionen von Lötstopp-Lochverschlüssen

1️⃣ Verhindern des Fließens von Lötzinn durch die Durchkontaktierungen und Vermeidung von Kurzschlüssen während des PCB-Wellenlötens, insbesondere wenn die Durchkontaktierungen auf BGA-Pads platziert sind. Es ist notwendig, die Löcher vor der Vergoldung zu verschließen, um das BGA-Löten zu erleichtern.

2️⃣ Vermeiden von Flussmittelrückständen innerhalb der Durchkontaktierungen.

3️⃣ Nach der Oberflächenmontage und Bauteilplatzierung muss die Leiterplatte auf einer Testmaschine einem Vakuumsaugtest unterzogen werden, um einen Unterdruck für die Fertigstellung zu erzeugen.

4️⃣ Verhindern des Fließens von Lötpaste in die Löcher und Vermeidung von Lötfehlern, die die Lötung während der Montage beeinträchtigen könnten.

5️⃣ Verhindern des Herausspringens von Lötkugeln während des Wellenlötens, was zu Kurzschlüssen führen könnte.

2 notes

·

View notes

Text

Key Benefits of Professional Electronic Circuit Designs in Product Development

Electric circuit boards are a common component of almost all modern electronics, and electronic circuit designs is necessary for each and every one of these devices to function. It takes years of experience to design a high-quality electric circuit board, and experts in the field can put the best design schematics into practice to ensure that the product or appliance works as intended. When it comes to design the professionals follow a structured approach like consultation, product design, quality check, followed by client feedback.

For the greatest product development in Australia, a qualified PCB designer or electronics design engineer tests, prototypes, and makes design changes before delivering the finished product to the customer. In order to guarantee high-quality work, it's critical to choose a PCB design services provider with a staff of experienced electronics specialists. Because they are aware of the costs associated with PCB prototyping, professionals complete the process as cheaply as feasible. Poor PCB board design in the context of RF designs can have a number of detrimental repercussions that result in loss or product failure.

An Overview of the Services Provided by Companies That Design Circuit Boards

The Internet of Things, or IoT, has revolutionised the electronics industry by utilising high-speed embedded microcontrollers and wireless networks to link numerous gadgets. Many items, such as lightbulbs and temperature sensors, may be remotely controlled via the Internet of Things without requiring human involvement.

Animal Deterrent Systems: With the use of modern animal deterrent devices, crops may be protected against birds and other animals without endangering them. Using a wireless audio system to produce moving noises, this technique confuses and dissuades birds from flying into fields.

Calibration Repairs: Top designers are capable of doing the crucial and important task of calibrating various RCD testers. Electronics design companies also offer cable repair and calibration services.

Product Development: Professionals can design new electrical items based on specifications provided by clients. Professionals may help with ideation, IP protection, and product design.

The top experts in the field of electronics have years of expertise building circuit boards and utilising various microcontroller technologies. Hiring the most recognised electrical design professionals is the ideal plan of action for anyone intending to manufacture a product or keen to integrate electronics into real items.

Source: https://extrondesignservice.blogspot.com/2024/10/key-benefits-of-professional-electronic.html

1 note

·

View note

Text

MJS Designs, Inc.

From design to production since 1976. Turn to MJS Designs for high-quality and accuracy in complex printed circuit board engineering design, CAD layout, prototyping, box / system build, cable assembly, procurement, volume assembly, test development, testing and fulfillment.

Address: 4130 E Wood St, Suite 100, Phoenix, AZ 85040, USA Phone: 602-437-5068 Website: https://mjsdesigns.com

0 notes

Text

IM FREEEEEE

#(FROM PROJECTS)#personal#the engineering chronicles#WILL HOPEFULLY NEVER NEED TO SLEEP THREE NIGHTS ON THE FLOOR OF THE ENGINEERING BUILDING AGAIN!!!#one class the final project was to build a karaoke machine which my partner and i had planned on making look like actual speakers and#microphone but we couldn’t find the stuff in time and her mom made a joke abt singing into hairbrushes and we decided to take that and#run lol we used a pink sparkly makeup box to store our circuit and cut out holes for the speakers and decorated it with makeup and put the#hairbrush mics inside and it was very fun actually and our class voted us as one of the groups to go to project day which was pretty cool!!#project day did get canceled bc of. asnow day which was unfortunate especially considering we stayed up until 4am the night before#preparing our documents for it and trying to perfect the karaoke machine when we could have been putting that time toward project number#2 😐 but whatever we still get our extra credit and i can say i qualified for it so im happy enough#then project 2 was for another class but we’re lab partners in both (+ another guy for this project) and it was digital monster pet so we#made a dragon i was mostly on design so i hand CADed the whole thing which was living hell if i never want to lay eyes on solidworks#again but also he came out very cute after MUCH hasle putting him together with all the wires and components bc our wires from the kit are#so bad they’re constantly getting disconnected from each other which we didn’t know would happen bc the labs we usually do we don’t have to#connect them together like that since you’re not routing them thru bodies etc and they’ve worked great until now but anywya.#i did the lcd faces and the light sensor and a couple other things + a lot of the code was copy and paste from past labs and fitting it to#suit the project but for the most part it was a shit ton of hardware on my end while she and the other guy managed the rest of the code#which i really wish i could have been more involved with but oh well. as it is though he’s my baby i birthed him <3 we’re planning on#meeting up over weekends next semester to change some stuff and add other extra features that we missed we got a decent grade 85% but we#all agreed we don’t want to leave him like this we want to add the extra features we had come up with and also i think we should switch out#our motors for servos bc the motors we were required to use#instead suck they’re not strong at all compared to what a servo can do for you. also we want to make it so you can not only pet him which w#already have with light sensors but also wash him with a Hall effect sensor and magnet so like we’d stick the sensor inside and the magnet#inside a little cad brush or sponge is what im envisioning and i have an expression in mind for what we’d do then. also paint him and#redesign the platform he stands on bc it’s rlly cramped and also make a pcb bc we only have him with the microcontroller and breadboards rn#and i might mess with his face piece a bit too im not sure. oh and speakers!!! those were technically a requirement but we didn’t get them#done on time but i want to make him play music sooooo bad so definitely that. anyway want to be more involved in the software when we do#all this. pretty excited actually :]

7 notes

·

View notes

Text

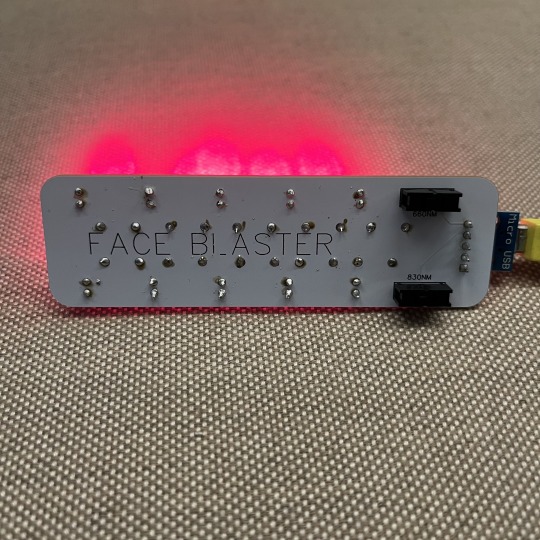

just another wild hardware hacking prototype for fun. now i know why nobody uses white PCBs, the solder burns are super obvious and painful to look at.

30 notes

·

View notes

Text

And so it begins... In the middle of midterm season...

6 notes

·

View notes

Text

The Benefits of Ordering Printed Circuit Boards Online: A Guide to Choosing the Right PCB Manufacturer

In today's rapidly advancing technological landscape, printed circuit boards (PCBs) play a crucial role in various electronic devices, from smartphones to industrial machinery. As demand for these essential components grows, businesses and hobbyists alike seek efficient and cost-effective solutions for obtaining high-quality PCBs. One of the most convenient methods is to order printed circuit boards online. In this article, we will explore the advantages of ordering PCBs online and provide insights into selecting a reputable PCB manufacturer.

Why Order Printed Circuit Boards Online?

Ordering printed circuit boards online offers several benefits, making it an attractive option for many businesses and individuals:

Convenience: The ability to order PCBs from the comfort of your home or office eliminates the need for in-person visits to manufacturers or suppliers. This convenience saves time and effort, allowing you to focus on your projects or business operations.

Wide Range of Options: Online PCB manufacturers offer a variety of options in terms of materials, layer counts, finishes, and more. This flexibility allows you to customize your PCBs according to your specific requirements and budget.

Cost-Effectiveness: Many online PCB manufacturers provide competitive pricing, especially for bulk orders. Additionally, you can easily compare prices and services from different providers, ensuring you get the best value for your money.

Quick Turnaround Times: Online ordering often comes with expedited production and shipping options, allowing you to receive your PCBs faster. This is particularly beneficial for projects with tight deadlines or when you need quick prototypes.

Access to Advanced Technologies: Many online PCB manufacturers offer advanced technologies such as high-frequency PCBs, flexible PCBs, and more. This access to cutting-edge technology ensures your designs are compatible with the latest industry standards.

Choosing the Right PCB Manufacturer

Selecting the right PCB manufacturer is crucial to ensuring the quality and reliability of your printed circuit boards. Here are some key factors to consider when choosing a PCB manufacturer:

Experience and Reputation: Look for a manufacturer with a solid track record and positive reviews from previous customers. Experienced manufacturers are more likely to produce high-quality PCBs and provide reliable service.

Quality Assurance: Ensure the manufacturer follows strict quality control measures, such as ISO certification and regular testing. High-quality PCBs are essential for the proper functioning and longevity of your electronic devices.

Customer Support: Good customer support is vital, especially if you encounter issues during the ordering process or with the final product. Choose a manufacturer that offers responsive and helpful customer service.

Manufacturing Capabilities: Check the manufacturer’s capabilities, including the types of PCBs they can produce, their layer count capacity, and the materials they use. Make sure they can meet your specific design requirements.

Lead Times and Shipping: Consider the manufacturer’s production lead times and shipping options. Quick turnaround times are crucial for meeting project deadlines, so choose a manufacturer that can deliver within your required timeframe.

Pricing and Payment Terms: While cost is an important factor, it should not be the sole consideration. Ensure the manufacturer offers transparent pricing and flexible payment terms that suit your budget.

Conclusion

Ordering printed circuit boards online is a convenient and cost-effective way to obtain high-quality PCBs for your projects. By choosing a reputable PCB manufacturer, you can ensure the reliability and performance of your electronic devices. Whether you are a business looking to streamline your supply chain or a hobbyist working on a personal project, ordering PCBs online provides a seamless and efficient solution.

For those ready to place a printed circuit board order online, consider the factors outlined above to select the right PCB manufacturer for your needs. With the right partner, you can bring your electronic designs to life with precision and quality.

#printed circuit board#pcb manufacturer#pcb supplier#printed circuit board order online#pcb design & manufacturing services#pcb circuit manufacturer in ahmedabad#electronic circuit design company

2 notes

·

View notes

Note

Do you also host a chapter of the fumo club

I don’t actually own any fumos at all. They’re kind of overpriced for what they are, and they don’t have PCB Yukari so they’re automatically invalid and stained with sin. Any Touhou merchandise line that creates an IN/IaMP Yukari first rather than the one where she’s chilling out is indelibly cursed. Your main image of Yukari is the one where she’s working? Where she’s having to do troublesome things? Where she’s not getting her healthy six hours of lying around yawning and stretching time? You’re cruel to her.

#this is a little tongue-in-cheek but she barely ever wears her IaMP design in ZUNart#and her PCB design is quite distinctive too if you actually understand how to cut fabric

18 notes

·

View notes

Text

Stane Jagodič – "Contemporary Golgotha" (1999)

#art#photography#design#white#fashion#black#painting#illustration#portrait#light#jesus#christ#christmas#intel#motherboard#cyber#geek#nerd#circuit#pcb#chip#electronics#components

10 notes

·

View notes

Text

#pcb#pcba#pcbassembly#pcb manufacturer#pcb board#pcb factory#pcb fabrication#aluminum pcb#pcb design#pcb prototype

2 notes

·

View notes

Text

PCB schematic/design/fabrication/assembly

MPN TECH Pte Ltd provides One-Stop PCBA Solutions in Singapore, which support from R&D prototype to mass production. We have built long-term collaborations with many local startups, SIMES, MNCS, etc. We also have lots of overseas PCBA projects in Europe and the US. If any questions feel free to let me know.

Our Solutions:

PCB Design;

PCB Fabrication;

Components souring;

PCB Assembly;(SG Local machine Assembly)

3 notes

·

View notes

Text

LED PCB Assembly

What is the LED Circuit Board assembly?

Generally, LED PCB assembly is considered to be a circuit board that has the LED components soldered to it. The LED is soldered to the printed circuit board and features a chip that creates the light as electrically connected. A thermal heat sink and a ceramic base are used to bond the chip. Not all the PCB products can be used in Led industry, as an LED PCB is easy to create a high volume of heat, but making it hard to cool with traditional methods. For this reason, metal core PCB is widely used in LED application because of their enhanced ability to dissipate heat, especially aluminum pcb is often used to fabricate PCB for LED lights.

We’ve had great LED PCB assembly experiences with top LED chips to brand such as Cree, Luxeon, Osram, Nichia, Lumileds, MLS, EVERLIGHT, Samsung, LG, Seoul., etc. PCB LED lights can be incorporated into numerous lighting applications due to their combination of excellent energy efficiency, low cost and maximum design flexibility.

Application of LED PCB Assembly

Hitechpcba serves customers in different industries, providing highly reliable and innovative LED PCBs for various applications:

• Horticulture light LED PCB Assembly

• LED controller PCB Assembly

• Computer LED display and indicators

• LED lights PCB Assembly for medical use

• Automotive LED PCBs Assembly include PCBs for brake lights and headlights

• Street lighting LED PCB Assembly

• Flashlights and camping accessories

• Traffic light PCB Assembly

• Commercial lighting LED PCB Assembly

LED PCB Assembly specification

Number of layers for LED PCB

These layers are made up of aluminum and magnesium, but now have Copper base material and Ceramic base materials for LED PCB industry, we can meet it.

Aluminum LED PCBs stand out among other PCBs because it has a good insulation characteristic and has a better machinery performance, the cheap cost is one important factor too.

Types of layers for LED PCB Assembly

Normally, the base layer is made using aluminum alloy metal.

This aluminum alloy substrate used in making the base makes it ideal for through-hole technology which transfers and dissipates heat.

A thermal insulation layer is made using some ceramic polymer which has good viscoelasticity characteristics.

It is highly heat resistant and protects the PCB against heat and mechanical stress.

The circuit layer, which is covered by a copper foil which can range from one to ten ounces.

LED Board type- single or in panel

Some boards are shapeless. For this reason, LED PCB panels are used. This reduces time, labor production and testing time.

Some LED PCB Assembly is done on a single board while others are done on panel boards.

LED PCB Assembly Process

Roughly, the PCBA process can be divided into theses phases: soldering paste printing > SMT (surface mounted technology) > reflow soldering > AOI (automated optical inspection)> THT (through-hole technology) > wave soldering > touch-up and cleaning > IC-programming > FCT (functional tests) > aging testing.

Below we show you the process.

Step1. Summarizing Project Information

Before contacting your supplier, make sure you have all the project information. Suppliers will need info following for quoting LED PCB assembly:

Gerber

BOM

LED PCB specification

Quotation quantity

Once you have gathered these information, you can contact us and request for a quote.

Of course, you can also provide the schematic, LED PCB Assembly pictures and even samples to us. The more details they have, the more accurate the supplier’s quotation will be.

Step2. Discussion and details about custom LED PCB Assembly

Different projects will have different requirements. Remember the special requirements mentioned in step 1? That’s going to be the focus of this session. Equipment and engineering capacity will not be identical between suppliers. Make sure your supplier has the equipment to produce and assemble major components and the corresponding testing capabilities.

For example, some vendors don’t have X-ray testing equipment, which means they can’t check the mount quality of BGA chips. Outsourcing this step will increase risk and cost. That’s what you don’t want.

Also, pay attention to time taken by the supplier to quote. Motherboards often contain hundreds or even thousands of components, and they are supplied by different manufacturers. To ensure the quality of the components, the supplier sourcing team will make multi-inquiries from these manufacturers or authorized suppliers to match customer’s requirement, which usually takes 2-3 business days, and even longer for some scarce chips. Therefore, if your project is complex and the supplier quotes you within few hours, double check with them.

Step3. Sample and feedback

After confirming the PI, the supplier will usually provide pre-production samples for your approval. At the same time, the supplier will also confirm with you the logistics plan of the bulk goods. Make sure they understand your shipping requirements, including details on packaging, customs clearance, taxes, etc.

For us to have a successful LED PCB Assembly process, its functions must be defined. Compliance requirement is defined to reduce the effect when components are selected.

The Bill of Materials is then generated from the information installed on the LED PCB.

All this information is used to assemble components which are identified from MOB to the LED PCB.

After that, the routing of traces is determined to each component, based on the size, shape of the circuit board and location of connectors.

Hitech Circuits is trusted by thousands of electronic engineers on their LED PCB assembly projects, from consumer, led bulb to precisely medical LED light, we can help you from the beginning of design stage; From commercial flood LED to industrial high power LED, from automotive LED to military LED, Venture is the perfect place for your LED PCB assembly requirement.

Hitech Circuits has been participated in hundreds and thousands of LED lighting projects, by providing LED PCB and also LED PCB assembly service.

Our LED PCB assembly had covered both ends of the Lighting Class LED size spectrum, assembling some of the largest (2 meter long boards) and some of the smallest LED Lighting applications which used in Medical Endoscopes.

LED PCB Assembly is very crucial in the current industrial development. Many electrical devises are being innovated and the old once being improved.

LED PCBs are useful due to the fact that they are made using materials that can transfer and dissipate heat. This characteristic increases device durability.

The world is changing with new technology, especially PCB technology that plays an essential role in the application of LED circuits. And the LED industry is taking advantage of this technology and growing faster.

As a full feature PCB solutions provider with more than a decade of experience, we're capable to provide LED PCB fabrication, components procurement and LED PCB assembly all under one roof. We can work with you to develop metal core PCB, aluminum circuit boards customized to your specific applications. We feature competitively priced PCBs made with standard FR-4 material that includes a thermal aluminum clad layer that will efficiently dissipate heat, keep all LED PCB components cool and significantly enhance the performance of your products.

LED pcb board, LED pcb assembly

LED with its advantages of high brightness, high efficiency, low heat, long life, is considered the most development potential in the 21st century lighting. In the market and policy driven by the rapid development of the domestic LED industry blowout has formed a relatively complete industrial chain, including the production of epitaxial wafers, chip preparation, packaging, integration, LED application. In 2010, China's LED industry scale, up from $ 827 billion in 2019 to 220 billion yuan, an annual growth rate of over 70%, higher than the 50% level of growth of the global LED lighting industry output value. Among them, the middle and lower reaches of the most complete industrial chain, accounting for 90% of the overall percentage of the GDP.Chinahas become the world's leading LED manufacturing base and important application market.

To further promote the technological innovation of the LED industry, construction and wide application of independent industry chain, China Electronic Appliance Corporation and industry associations to organize the theme of "Focus on the core energy LED Exhibition will be held November 9-11, 2010 in Shanghai International Expo Center and the 78th China Electronics Fair over the same period will be held will create from raw materials, epitaxial wafers, chip, LED bracket, LED accessories, LED packaging and supporting materials, the LED backlight upstream firm to the upstream and downstream enterprises of the display, lighting, landscaping, decorative lighting, traffic lights, automotive lighting, special lighting, to the equipment, instrumentation, software, finance, consulting and other service enterprises and technological exchanges and market trading platform, help the domestic industry sustained and healthy development, and promote the steady expansion of the LED application market.

In the LED industry chain upstream of the epitaxial wafers and LED chips accounted for 70% of the profits of the whole industry, and technology-intensive, capital-intensive, where the core technology of the LED. Well-known epitaxial wafer and chip production enterprises will be exhibited a number of energy-efficient, low heat, cost-effective LED products, many of whom have excellent products of international advanced level.

LED electronic pcb assembly manufacturing 100% Original LED Chip with one-stop in-house pcba services

3 notes

·

View notes

Text

PCB Manufacturing in Toronto: Expertise, Services, and Local Industry Insights

Discover PCB manufacturing in Toronto, a hub of innovation and quality in electronic manufacturing services. Learn about the specialized capabilities, technological advancements, and diverse offerings of PCB manufacturers Toronto. Explore how local expertise and cutting-edge facilities contribute to producing high-quality printed circuit boards for various industries and applications worldwide. For more details visit our website www.crimpcircuits.com

#pcb manufacturing toronto#printed circuit board design#metal clad pcb#printed circuits#rigid flex pcb#full turnkey pcb services#turnkey pcb services#pcb parts#eagle software#pcb designing#flexible pcb#pcb assembly#printed circuit board manufacturers#pcb manufacturers in canada#circuit board manufacturers in canada#pcb quote#pcb prototype services in canada

2 notes

·

View notes

Text

MJS Designs, Inc.

From design to production since 1976. Turn to MJS Designs for high-quality and accuracy in complex printed circuit board engineering design, CAD layout, prototyping, box / system build, cable assembly, procurement, volume assembly, test development, testing and fulfillment.

Address: 4130 E Wood St, Suite 100, Phoenix, AZ 85040, USA Phone: 602-437-5068 Website: https://mjsdesigns.com

0 notes

Text

What is a Printed Circuit Board?

Printed Circuit Boards are boards that connect various points together through lines and pads. They allow signals and power to connect between two separate physical devices. While the term “printed circuit board” is typically used, other terms to describe these include “printed wiring board” and “printed wiring card.”

#marketing#investing#finance#branding#pcb circuit#pcb#pc build#pcb assembly#flexible circuit board#pcb board fabrication#pcb circuit design#pcb circuit in Gujarat#pcb design company#Printed Circuit Boards

3 notes

·

View notes

Text

coming up with little PCBs to practice my surface mount soldering skills, this one is going to be a 2cm x 2cm target marker for warhammer. two tiny red LEDs and a switch on the front, and a coin cell battery on the back.

23 notes

·

View notes