#Order Lathe Machine

Explore tagged Tumblr posts

Text

How To Get A Fabulous Lathe Machine On A Tight Budget

Looking for a lathe machine that doesn't break the bank? Discover expert tips on how to get a fabulous lathe machine on a tight budget, brought to you by Ambica Enterprises. Learn how to shop smart and get the best deals!

Introduction

If you're reading this, you're probably looking for a way to get your hands on a high-quality lathe machine without draining your savings. Let’s face it—lathe machines are a vital part of any workshop, whether you're working in wood, metal, or even plastic. However, they can come with a hefty price tag that might make you second-guess your decision.

But don't worry! You can get a fabulous lathe machine on a tight budget. Yes, you heard that right. With a little bit of knowledge, strategic shopping, and an eye for value, it's totally possible to land the lathe of your dreams without compromising on quality or performance. And, if you’re wondering where to begin your search, Ambica Enterprises has got your back.

In this article, we’ll show you how to navigate the world of lathe machines, especially if you’re working within a limited budget. So, buckle up, and let’s dive into the world of budget-friendly lathe shopping!

Know More -

1. Understanding Your Needs: What’s the Best Lathe Machine for You?

Before you start scouring the internet for deals, it’s important to understand what type of lathe machine you actually need. There are different types of lathes for different purposes, so knowing your requirements will save you time, money, and a lot of headaches.

What Kind of Materials Are You Working With?

Lathes are used to shape and cut materials like wood, metal, and plastic. If you're primarily working with wood, you’ll need a wood lathe, while a metal lathe machine would be more appropriate for metalworking. Here’s a quick breakdown:

Wood Lathes: Used for turning wood into cylindrical shapes, perfect for creating furniture, bowls, or spindles.

Metal Lathes: Designed to cut and shape metals, essential for machining, tooling, or creating precision parts.

Multi-purpose Lathes: Great for beginners who need versatility, offering a range of capabilities from metalworking to woodturning.

What’s Your Experience Level?

If you’re just starting out, consider opting for a smaller, more affordable lathe that still offers the features you need. You don’t want to spend a fortune on a machine that’s overkill for your skills. That said, make sure it’s still durable enough to handle the kind of projects you want to create.

Beginner: Go for a compact, user-friendly lathe with simple controls and safety features.

Intermediate/Advanced: Look for a lathe with more power, versatility, and advanced capabilities.

Knowing these details will help you make a more informed decision about which lathe is the best fit for your needs.

2. How to Spot a Great Deal: Tips for Finding the Best Price

Now that you know what kind of lathe you need, it’s time to hunt for a deal. The good news is, you don’t have to compromise on quality just because you’re working with a limited budget. Here’s how to make sure you get the best price on a fabulous lathe machine.

Shop Around—Don’t Settle for the First Option

Don’t rush into a purchase! Take the time to compare prices across multiple retailers, both online and offline. Look for special sales, discounts, and promotions. Some stores may offer seasonal deals or clearance sales, so if you’re not in a hurry, you might be able to score a fantastic deal.

Read Also -

Consider Refurbished or Used Lathes

Buying a brand-new lathe machine can be expensive, but you don’t always need the latest model. Refurbished or used lathes are often just as good as new ones and can save you a substantial amount of money. Here’s what you need to consider when buying a second-hand lathe:

Condition: Make sure the lathe is in good working condition. Test it out if possible and check for any visible signs of wear and tear.

Warranty: Ask if the lathe comes with a warranty, especially if it’s refurbished.

Reputation of the Seller: Stick to trusted brands or sellers who offer transparent and reliable service.

Negotiate!

It’s always worth trying to negotiate the price. Many sellers, especially in smaller stores or online marketplaces, may be willing to offer a discount, especially if you’re buying multiple items or if you’ve found a similar product for a lower price elsewhere.

3. Features to Look for When Buying a Budget-Friendly Lathe Machine

It’s tempting to simply go for the cheapest option, but make sure you’re not sacrificing essential features in the process. You can still find a lathe that fits your budget and meets your requirements. Here are some important features to keep an eye out for:

Motor Power and Speed Control

The motor power determines how well the lathe will perform. Look for one that offers enough torque for your materials. Speed control is another crucial feature, especially if you plan to work with different materials or varying sizes.

Wood Lathes: Opt for at least a 1 HP motor for general woodworking projects.

Metal Lathes: Go for at least a 2 HP motor for smoother cuts in metal.

Swing Over Bed and Distance Between Centers

The swing over bed refers to the largest diameter piece the lathe can handle, while the distance between centers is the maximum length of the material you can turn. If you're working with larger projects, these measurements are critical.

Build Quality and Durability

Even if you’re on a budget, you don’t want to buy a lathe that will fall apart after a few uses. Ensure the lathe is made of high-quality materials like cast iron, which offers stability and longevity.

4. Should You Buy Online or In-Store? Pros and Cons

When it comes to buying a lathe machine, one question that often comes up is whether to purchase online or in-store. Each option has its benefits, so it’s all about finding the right balance between convenience and customer service.

Also Read This -

Buying Online

Pros:

Access to a wider variety of options and brands

Better comparison of prices

Convenience of shopping from home

Cons:

Limited ability to test the lathe before purchase

Shipping costs and delivery time

No immediate customer support

Buying In-Store

Pros:

Immediate purchase and no shipping delays

Ability to test the lathe before you buy it

Direct interaction with knowledgeable sales staff

Cons:

Limited selection of models

Potentially higher prices

Ultimately, it depends on your priorities. If you value convenience and a broader selection, online shopping might be the way to go. If you prefer to test before you invest, head to a physical store like Ambica Enterprises, where you can get firsthand experience and advice.

5. FAQs About Buying a Lathe on a Budget

Q: How do I know if a lathe is worth the money?

A: Check for reviews, ensure it has the essential features you need, and compare prices with other models to see if you're getting a good deal.

Q: Can I find a decent lathe for under $1,000?

A: Yes, absolutely! Look for smaller, entry-level models or consider refurbished options. Brands like Ambica Enterprises offer great value for the money.

Q: How much should I expect to pay for a high-quality lathe?

A: It depends on the size and features, but expect to pay anywhere from $500 to $2,000 for a reliable lathe, even on a tight budget.

6. Conclusion: Get the Best Lathe Without Breaking the Bank

Getting a fabulous lathe machine in India on a tight budget is entirely possible if you approach your purchase with some strategy and patience. By understanding your needs, shopping smart, and keeping an eye out for key features, you can find the perfect lathe without overspending.

And remember, if you’re in the market for a reliable and affordable lathe, look no further than Ambica Enterprises. With a reputation for providing high-quality machines at competitive prices, you’re bound to find something that fits your needs and budget. Happy turning!

#Lathe Machine#Lathe Machine Manufacturer#Lathe#Lathe Machine Price in India#Lathe Machine Price#Lathe Machine Supplier#Lathe Machine for Sale#Lathe Machine India#Lathe Machine in India#Lathe Machine Jodhpur#Lathe Machine Rajasthan#Lathe Machine Online#Buy Lathe Machine#Order Lathe Machine#Online Lathe Machine#Best Lathe Machine#Purchase Lathe Machine#Ambica Enterprises

1 note

·

View note

Text

How To Improve Lathe Machine at Work In 60 Minutes

When it comes to optimizing the performance of a lathe machine, time is of the essence. Whether you're operating in a high-precision machining environment or handling more basic manufacturing tasks, ensuring that your lathe machine operates at peak efficiency is vital for maintaining productivity and quality.

In this guide, we’ll cover key strategies and techniques to improve lathe machine performance in just 60 minutes, providing you with actionable tips that can make a real difference in your daily operations.

1. Perform a Thorough Machine Inspection

Before diving into adjustments or upgrades, it’s crucial to conduct a comprehensive inspection of the lathe machine. This step ensures that the machine is in a stable, functioning state, and can help pinpoint areas that need immediate attention. Here are the critical aspects to examine:

Check for Wear and Tear

Inspect the spindle, bed, and tool holders for signs of wear. Any loose parts or damaged components can cause instability during operation, leading to inaccurate cuts and potential machine damage. Ensure that all components are securely fastened and there’s no excessive movement in parts that should be stationary.

Know More Here -

Inspect Lubrication

Proper lubrication is key to reducing friction and wear on moving parts. Check the oil levels in the lubrication system and replenish if necessary. Clean any clogged oil passages to ensure smooth operation, preventing overheating or damage to critical components.

Clean the Machine

Dirt and debris can build up over time, affecting the machine's accuracy. Wipe down the lathe machine thoroughly, removing any chips, coolant residue, or contaminants from the bed and tooling areas. A clean workspace is essential for better precision and longevity of the machine.

2. Align and Calibrate the Machine

Misalignment of components can cause errors in machining operations, leading to faulty output and excessive wear. Here’s how to ensure proper alignment and calibration:

Check and Align the Tailstock and Tool Post

Use a dial indicator to check the alignment between the tailstock and the spindle. Misalignment can cause deflection during cutting, leading to poor surface finishes or inaccurate cuts. Adjust the tailstock and tool post to ensure they are perpendicular to the spindle axis.

Calibrate the Feed Mechanism

The feed mechanism plays a crucial role in maintaining accuracy during the cutting process. Recalibrate the feed rates according to the material you’re working with and the type of cut you need. Ensure that the drive motor is working smoothly, and adjust the gears or feed rods if necessary.

Test the Machine

Run a test cut on a scrap piece of material after alignment to confirm that the lathe is cutting accurately. Use measuring tools like a micrometer or vernier calipers to check the dimensions of the test piece.

3. Optimize Cutting Tools and Toolholders

The performance of your cutting tools is directly linked to the overall effectiveness of your lathe machine. Suboptimal tools can drastically affect the quality of your work and increase the time required for finishing.

Inspect Cutting Tools for Sharpness

A dull cutting tool increases cutting forces, generates more heat, and causes excessive wear on both the tool and the workpiece. Inspect each cutting tool carefully and replace any tools that are showing signs of dullness or chipping. Use a tool sharpening machine to bring tools back to their optimal sharpness.

Ensure Proper Toolholder Setup

Improper toolholder setup can lead to tool vibration, reducing both accuracy and surface finish. Double-check that the toolholders are securely fastened and correctly aligned with the workpiece. If using indexable tools, ensure they are seated properly in the holder.

4. Adjust the Speed and Feed Settings

Speed and feed settings are critical for achieving the desired finish and ensuring efficiency during machining. Incorrect settings can result in poor surface quality, tool wear, and wasted material. Here’s how to optimize these parameters:

Set the Correct Spindle Speed

The spindle speed determines the rate at which the tool engages the material. Too high a speed can result in overheating, while too low can lead to poor cutting efficiency. Refer to the material’s cutting parameters and adjust the spindle speed accordingly. For example, soft materials like aluminum require higher speeds, while harder materials like steel require lower speeds.

Adjust Feed Rates

Feed rates control how quickly the cutting tool moves along the workpiece. For finer finishes, lower feed rates are preferred, while roughing operations benefit from higher feed rates. Adjust the feed settings based on the material type and tool geometry for optimal results.

Check Out This Blog -

5. Maintain the Coolant System

The coolant system serves a dual purpose in lathe machine operations: it reduces friction and helps remove heat from the cutting area, improving the tool life and ensuring that the material doesn’t overheat.

Check Coolant Levels

Ensure that the coolant tank is filled to the correct level. Low coolant levels can cause the tool and workpiece to overheat, leading to poor machining results.

Clean the Coolant Filter

Over time, filters can become clogged with debris, reducing the coolant’s effectiveness. Clean or replace the coolant filter to ensure a steady flow of coolant during the machining process.

Use the Right Coolant for the Job

Different materials may require different types of coolants. For example, water-based coolants are typically used for softer materials, while synthetic oils might be more suitable for tougher metals. Always check the coolant’s condition and replace it if necessary.

6. Minimize Vibration for Better Accuracy

Vibration during machining can compromise the precision of your workpiece and cause rapid wear to both the machine and the cutting tools. To minimize vibrations, consider these adjustments:

Balance the Workpiece

Ensure the workpiece is securely clamped in the chuck or collet. Any imbalance in the workpiece can lead to unwanted vibrations. Check for any irregularities and correct them before starting the cut. Know More - Lathe Machine in India

Use Damping Techniques

If your lathe machine has a vibration-damping system, ensure it is properly installed and functioning. Additionally, you can use specialized tool holders designed to absorb vibrations or opt for vibration-damping materials to enhance stability.

7. Regular Maintenance and Scheduling

To maintain long-term performance, regular maintenance is crucial. Set a schedule for ongoing checks and minor adjustments to keep the machine in optimal working condition. Make use of preventive maintenance practices to reduce the likelihood of machine downtime and breakdowns.

Check This Post -

Lubricate Regularly

Establish a routine lubrication schedule, depending on the manufacturer’s guidelines and machine usage. Proper lubrication reduces wear and prevents parts from seizing or overheating.

Monitor and Replace Worn Components

Over time, components such as bearings, belts, and gears will wear down. Regularly inspect these parts and replace them before they cause significant damage. Keeping a stock of spare parts can help prevent delays in production.

Document Machine Settings and Performance

Keep a log of all machine settings, adjustments, and any performance issues. This documentation can help identify patterns of wear or mechanical failures, allowing you to address them proactively before they become critical problems.

Conclusion

Improving your lathe machine’s performance in just 60 minutes is entirely possible with a systematic approach and a focus on key areas like alignment, calibration, tool optimization, and maintenance. By following the strategies outlined in this article, you can ensure that your machine operates at peak efficiency, delivering high-quality results with minimal downtime.

Regular attention to the health of your lathe machine in India is essential for maintaining its longevity and maximizing productivity in the workplace.

#Lathe Machine#Lathe Machines#Lathe#Lathe Machine Supplier#Lathe Machine Price in India#Lathe Machine Price#Lathe Machine Manufacturer#Lathe Machine for Sale#Buy Lathe Machine#Purchase Lathe Machine#Order Lathe Machine#Lathe Machine Exporter#Best Lathe Machine#Top Lathe Machine#Lathe Machine Jodhpur#Lathe Machine Rajasthan

0 notes

Text

Best Of 2023 from @big-low-t

What were some of my favorite songs from 2023 releases? Here ya go... in no particular order: (links to the songs in the titles)

††† (Crosses) - "Light As A Feather"

Poison Ruin - "Harvest"

Slowdive - "Kisses"

Fugative - "Blast Furnace"

HOME FRONT - "Faded State"

Ningen Isu - "Farewell To The World"

Djunah - "Seven Winds of Sekhmet"

Soft Play - "Punks Dead"

Traindodge - "Unfinished Secrets"

GEL - "Honed Blade"

Killing Joke - "Full Spectrum Dominance"

SOFT VEIN - "PERFECT TEETH"

Emma Anderson - "The Presence"

Motorama - "And Yes"

Human Tetris - "Fade"

Lathe Of Heaven - "Ekpyrosis"

Drab Majesty - "The Skin And The Glove"

Bakar - "Alive"

Fiddlehead - "Sullenboy"

Cemented Minds - "Flowers For Handcuffs"

King Krule - "Seaforth"

Unwed Sailor - "Mais Oui"

Spotlights - "The Alchemist"

GUMM - "Slogan Machine"

Metallica - "Shadows Follow"

18 notes

·

View notes

Text

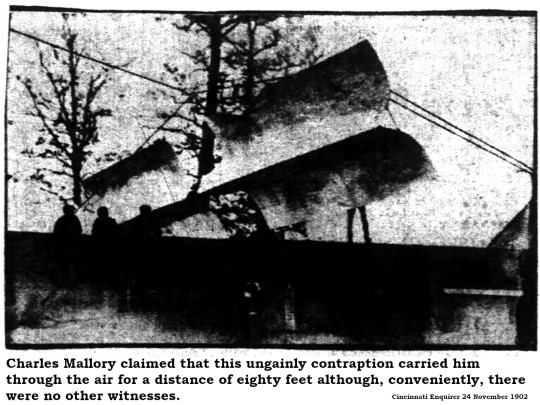

While The Wright Brothers Toiled, Cincinnati’s Flying Machine Fanatics Tanked

Ohio license plates proclaim the Buckeye State as the “Birthplace of Aviation.” Had fate turned out differently, that sobriquet could have applied to Cincinnati. Over the years, several Cincinnati tinkerers tried unsuccessfully to loft a heavier-than-air craft.

As far back as 1834, a Cincinnati resident named Albert Masson constructed a vehicle he described as an “aerial steam boat.” According to a writer signed only as “J.L.” (possibly John Laughlin, secretary of the Ohio Mechanics Institute), in the Liberty Hall and Cincinnati Gazette newspaper [3 July 1834]:

“The boat is about ten feet long; the ribs being covered in silk, in order to render it very light. – The engine, of two horse power, is placed in the middle, and turns four vertical shafts projecting over the bow and stern, into each of which are fixed 4 spiral silken wings, which are made to revolve with a sufficient velocity to cause the vessel to rise.”

According to “J.L.”, the entire apparatus weighed about 60 pounds and Mr. Masson intended to fly the contraption on July 4 – the very next day. At the time of publication, the aerial steam boat was on display “on Race street, nearly opposite the old Lath Factory, below Third street.”

Mr. Masson did not go airborne on Independence Day and, in August, his flying machine was on earthbound display at the Commercial Exchange. The Daily Cincinnati Republican reported, “There is nothing of the balloon principle connected to the apparatus.” and that it was “a beautiful and ingenious piece of mechanism.”

As beautiful and ingenious as it was, the aerial steam boat appears not to have ever achieved flight and all references to it cease after 1834. Tom D. Crouch, curator of aeronautics at the National Air and Space Museum and a former chief of education for the Ohio Historical Society, has researched Masson’s invention extensively, publishing his findings in the Journal of the American Aviation Historical Society [Spring 1974]. According to Mr. Crouch:

“If we are to believe the articles published in the Cincinnati papers, and there seems no reason to doubt them, then Albert Masson was the first person in history to produce a heavier-than-air craft, powered by a prime mover, that was actually intended to fly.”

Although Mr. Masson vanished into the mists of history, between 1840 and 1902, Cincinnati newspapers printed at least 404 articles with the phrase "flying machine." Some of these reports featured home-grown Cincinnati aeronauts.

Cincinnatians awoke on 27 Oct 1889 to learn that a local man, one Ferdinand W. Randall of Main Street, had built a flying machine. In fact, this inventor had quite a surprise for the scientific community. As related by the Cincinnati Enquirer:

"He not only has a flying machine, but claims to have discovered perpetual motion."

The newspaper goes on to relate that Mr. Randall's inventions have "something lacking." That "something" was, of course, money.

Mr. Randall, approximately 35 years in age at the time, was a photographer. His workshop was on Main Street. His flying machine was described as a "peculiar-looking sail-boat" suspended by a wire from the ceiling. It was basically a boat hull, with a screw propeller and rudder at the rear, four wheels and an "intricate mass of fans and wire cables." Two black wings, wider and longer than the boat, were suspended above. According to the Enquirer,

"The beauty about Mr. Randall's machine is that it can move on land, in the water, or in the air."

Randall told the Enquirer he had read every book available on aeronautics and is "undoubtedly well posted on the subject." Well posted or not, Mr. Randall joined the roster of inventors whose aircraft never left the ground.

Curiously, just 18 months later, the Cincinnati newspapers found yet another potential flying machine. This one was created by a mechanic named John Randall, of 322 Vine Street, who had built a flying machine remarkably similar to the airship unveiled by Ferdinand Randall - a boat 18 feet long with a mass of wires attached.

Similar flying machines and identical names? Not a coincidence. The Randalls were brothers who had operated Randall Brothers Outdoor Photographers for several years. The younger brother struck out on his own and got work as a mechanic and electrician.

Ferdinand apparently gave the flying machine to his brother because the machine described in 1891 is almost identical to the 1889 machine with one exception. John replaced the two black wings atop Ferdinand’s machine with a large canvas balloon. In other words, it was no longer a heavier-than-air machine, but only a mechanically propelled lighter-than-air craft. Not the same thing at all.

Had another local man succeeded, Kennedy Heights or Norwood might be known as the birthplace of manned flight. Alas, Charles M. Mallory did not succeed. In fact, he failed again and again and again. Sometimes spectacularly.

In August 1902, the 40-year-old Mallory, a pattern maker with the Bullock Electric Manufacturing Company, announced that he would launch a new flying machine into the air from a vacant lot in Kennedy Heights. With a large crowd observing, he rolled out a contraption described by the Cincinnati Enquirer:

"It was as if two monster Mexican hats had been inverted and joined together by a framework that had wings on either side. At one end was a rudder."

With a squad of volunteers tugging away, Mallory's monstrosity "scudded along the scaffolding for a few feet and then toppled over on one side."

Mallory tried again in November 1902 at the grounds of the old Norwood Inn. This time, instead of human volunteers, Colonel James E. Fennessy, a local theatrical impresario, volunteered to tow the contraption aloft with his automobile. Col. Fennessy got bored waiting for Mallory to prepare his flying machine and drove home. Fennessy sent a chauffeur out to Norwood with another automobile, but he, too, lost patience.

When Mallory was finally ready, no automobiles could be found, despite messengers and phone calls. While waiting in vain for another runabout, Mallory agreed to pose for photographs in his machine, hoisted to the top of a derrick. The wind caught the contraption and dashed it to the ground from a height of 25 feet. Although Mallory was unhurt, his flying machine was in tatters.

Mallory attempted another flight in August 1903 off Lookout Mountain in Tennessee but, again, the wind dashed his contraction to flinders. Interestingly, Mallory told the Cincinnati Post at that time that he had achieved an 80-foot flight in Norwood, a feat suspiciously unseen by any other witness.

Four months later, the Wright boys grabbed the prize.

3 notes

·

View notes

Text

youtube

If you want the ultimate in lightweight strength, stiffness, and durability, then the Forgeline forged monoblock is going to get you there. Starting from a 140 lb. raw forging of 6061-T6 aluminum, our USA-made one piece forged monoblock wheels undergo a complex machining operation, including both lathe and milling processes, to carve a complete custom made-to-order wheel from a solid block of forged aluminum. They are then hand-finished and powder coated in-house in your choice of color. Available in 17 to 22-inch diameters in a range of widths and offsets to fit most applications. Learn more at: https://forgeline.com/series/one-piece-monoblock-series-wheels

🇺🇸🇺🇸🇺🇸

#forgeline#forgelinewheels#forgedwheels#customwheels#forgedmonoblock#notjustanotherprettywheel#doyourhomework#madeinUSA#Youtube

2 notes

·

View notes

Text

The Tea Girl's Gambit, Chapter Five

My legs were hurrying me to class but my head was a-swirl with confusion, shame and, unmistakably...envy. Not just shame at the envy, which was familiar in the way a toothache is familiar, but also shame at having been actually, actually seen committing the envy. I was reeling with the peculiar sense of having been recognized. My depths measured and plumbed and somehow known. It was terrifying. My heart was smashing frantically around like a bird trapped behind glass.

I turned down a rarely used servant’s passage, leaned against the wall and slumped down to sitting. I heaved a deep breath. I was over-reacting. There was no way that girl could actually know anything about me, right? I was fairly sure there hadn’t been any spellcraft involved. She had just looked at me.

I shook my head, bemused. Why had she looked at me? Nobody else did. People’s attention slipped off me like oil slipped off of water and I liked it that way. It was safe.

My heart was slowing down. There was no way she could have known what I was thinking when I saw her. I had never spoken my secret to another soul other than Kisma, never written it down. I knew the consequences of my yearning, even as a quiet child among the older, rougher kids of Stuhkrad.

The adults of the town hadn’t liked to talk about the small, moss-covered statues scattered in the forests and ravines around the milltown, but the older kids couldn’t gossip enough about their mingled, hybrid bodies. The town children called them kuffa. Most of them had been smashed and buried by the Imperial settlers when they’d driven out the native forest people a generation ago.

But once, exploring in the woods beyond the clear-cuts with my brother Carame and his friends, we’d found a narrow cave and slipped inside. I would have faltered, but Carame was fearless and his courage was like a drug to me. One of the boys had swiped a chemical light-stick from the Foundry. He broke it with a hiss and a sizzle of reagents mixing and the darkness flooded with brassy, white light.

I remembered the rich, earthy reds and browns and yellows of the little shrine. I remembered the little pots of unguents, the glittering quartz, the figurines and the swell of their breasts and their cocks. I remembered the older boys shouting with glee as they smashed everything and urinated on it. I remembered Carame pausing in the frenzy to turn and look at where I stood frozen against the wall, his face deep in shadow, unreadable.

I took a sharp breath and staggered to my feet, pushing down the razor-edged feeling in my throat. I was late to alchemy class.

I slipped into Advanced Principles while professor Yvell was still lecturing, my face numb and dry. I tried to concentrate but everything seemed very distant and hard to understand.

Memories continued to flood my head. The rattle of stones against brickwork around me as I ran from a gang of bullies, my whole back stinging, lungs burning. Every day, running after school. Hiding in the Foundry, a sprawling complex of workshops and labs that also contained the town’s singular, tiny, non-private library. The Foundry was Gresha’s domain, and I liked Gresha. She was a tall, stooped, squint-eyed and white-haired and gruffly kind. She gave off the smell of burnt leather and quenched iron.

Gresha was busy, because the Foundry fed the mill and the loggers with a constant supply of carefully machined new gears and cleats and plates and wheels to replace broken parts as well as chemical lights and waxes and lubricants and a hundred other things. All the same, Gresha let me read by the wood stove while she mixed powders or grumbled around in the next room, the whine of the lathe cutting on and off.

She had other staff doing piecework and delivering finished orders. Fenn had a big, calm face and limitless patience and I liked to watch his clever hands as he worked. He was mute, but he pointed carefully at each tool he used and re-positioned the light so I could see what he was doing with them. I watched him fix the boiler so many times that soon I began doing it in his stead, so he could finish his orders sooner and maybe have more time to bake a tasty treat for everyone.

Heather was a brisk, no-nonsense, ruddy-cheeked woman, Gresha’s lifelong ‘companion’, who had a sharp tongue for Gresha but a soft spot for me. She liked to rouse me from my reading nest of burlap bags by the stove to sweep or to chop onions, but always made sure I had a full belly.

The accredited town alchemist lived very handsomely in a whitestone house at the top of the hill and charged customers dearly. Gresha wasn’t officially an alchemist, had certainly never trained at a university, but she had a keen, methodical mind and she was brilliant at seeing what a thing might be able to do.

She casually nudged me towards certain books and when I came to her for more, she hmph-ed and her eyebrows, which were always growing back from being burnt off, climbed in the way they did when she tried something and it worked to her satisfaction. She asked me questions about the books—did the long-winded descriptions of how to render materials down to their basic underlying principles bore me? What about the chapter on crystalline liquids had I liked best? I found that I liked to impress her with my responses and quickly learned to see past the ways she tried to hide it.

Soon, she started dictating her notes while she was elbows deep in a project and had me scribe for her. She would look over my shoulder and poke at the page with a blunt finger and show me how, no, this is the abbreviation for sulfuric acid and that’s not how to copy a cipher correctly, try this, see? She began to check less and less often for mistakes, and I ate up the tiny signs of her satisfaction with glowing pride.

Carame had begun working in the mill and came home more and more hollow-eyed every night, ate, then slept and left again in the pre-dawn darkness. Without him to protect me, the everyday torture of school intensified and I got thrashed in the street and pelted with stones even more often. To give my bullies the slip, I began to spend more and more time at the Foundry and made fewer trips at odder hours to the shouting, crowded graybrick tenement that my older brothers and sisters and mother occupied.

My sister Kisma had started working nights at a bakery. I still risked visits to see her before her shift started and we slipped away to the roof among the flapping lines of laundry to smoke her halfpenny tobacco and giggle and watch sunset bands of pink and orange melt into the dark blue dusk. She told me about sneaking leftover dough out of work with her friends one night and stuffing it in the mouths of the vainglorious statues that lined the town square, so that all the pigeons came and ate it all and covered their strong chins and proud barrel chests with runny white streaks, so it looked, she laugh-snorted, “like they’d all been eating bird ass!”

I told her about when Gresha had set me to mixing up some bio-phosphate to dope an set of passive light emitters for the hanging walkways at the mill, I’d had some left over, and mixed the extra into the bowl of slop that Heather left at the Foundry door each night for the town’s stray cats. For a night, all the street cats of Stuhkrad had run around glowing neon blue and meowing their exasperation. Heather had such a fright she’d scolded me about it for a week.

“What! Eli! That was you?” Kisma sounded simultaneously amused and reproachful. “You’re lucky nobody started a witch-hunt. And how did you know the cats would be alright?!” She shook her head. “Maybe leave the pranks to your big sister, kid.”

My feet were hanging over the edge of the building. I kicked them, pouting. Truthfully, I wasn’t usually so daring and had only done the deed so I could impress my older sister, for once.

“I knew the cats would be alright! I did the factoring myself,” I mumbled sulkily. I knew Kisma didn’t really understand the stuff I was learning at the Foundry. But it still stung a bit, that she assumed I hadn’t known.

She raised her eyebrows at me. “You’re really smart, Eli. But you can also be really, really, really dumb, you know that?” She sighed. “Oh, I just worry about you sometimes.”

Truthfully, I was somewhat worried, too. All of my brothers were heading to the mill, or to be bargemen and cart drivers, and when I tried to imagine following them, of living that life, there was only a yawning, all-devouring blankness. I thought Gresha was training me to take her place, and at least that didn’t seem so bad. When she sat me down and told me in her gravelly voice that she was going to aim me at the Imperial merit exams, I spluttered and gaped, but in my belly a tiny circle of light opened. I could leave. I could get out.

I fed and grew that tiny light with long winter nights of obsessive reading and ciphering and memorizing tables and properties and principles until I closed my eyes to sleep and saw numbers dancing on my closed eyelids. I bent all my waking hours towards alchemy, which needed no inherited talent or gift of sorcery. I cut school and rarely went home and spent nearly all my time at the Foundry, working in the shop or studying. Lots of kids my age had already dropped out of the town school to work at the mill or on the steep slopes of the logging clear-cuts. It began to get safer for me to walk the narrow, cobbled streets without risking a beating.

Some nights, rubbing my booksore eyes, I thought guiltily of my sister Kisma sitting alone on the roof, again. But there was so, so much to do. I had seen her last week, hadn’t I? Or was that last fortnight?

And last spring, after four years of study, when the guarded wagons came to Stukrad with the merit tests locked inside, I watched them roll through the cobbled streets and up the hill biting the inside of my cheek so hard that my mouth filled with warm, metal-salty blood.

Two days later, I floated out of the testing hall, my shoulders tense and taut as lashed mill cables, my lip half-chewed through, my stomach a wreck, my eyes bloodshot, my hair a snarled bird’s nest, knowing I had demolished the test. I slept for two days on Gresha’s spare cot in one of the backrooms, waking only to piss and to drink the cold broth she’d left by my head. And cry. I hadn’t been able to cry since I was ten, but some blockage had crumbled, some rusty switch had finally slid into place inside me, and I bit Gresha’s pillow and shuddered with waves and waves of sobs that seemed to rise ceaselessly from someplace deep inside me.

Results from the exams took months to come back. In the meantime, I occupied my hands working for Gresha in the Foundry. I visited Kisma, who was getting married, and brought her a small blue dropper bottle of contraceptive—which I was ridiculously proud of, not least of all because any control by women over the reproductive power of the Democracy was frowned on by Imperial social hygienists. By teaching me how to make it, Gresha had clearly staked her trust in me. I found Carame, who was getting roaring drunk at the tavern with his mates, and brought him similar bottle but with a hangover cure in it instead. I didn’t visit Carame again.

When the results came, Heather insisted all four of us cluster around the scarred table in the kitchen before she even brought out the envelope. I tore it open, scanned it, then gasped and stumbled backwards and tripped over a chair. Heather grabbed the letter, squinted, whooped, and yanked me up and sank my head into her bosom. Gresha grunted, brought out a bottle of peach brandy and conferred upon me (when I had extracted myself from Heather) a sagacious nod. Fenn hefted a steaming, gold-crusted pie as large as wagon wheel out of the oven. I looked around at the three of them and tried to fix their faces in my memory. This is what I wanted to remember, when I thought of home. This good, glowing evening, surrounded by people who cared about me.

~ ~ ~

In the back of the lecture hall, I swallowed my emotions. My throat ached. I missed Heather, and Gresha and Fenn. Starting out at the University had been very lonely. I felt so out of place here. But hadn’t I felt so out of place in Stuhkrad, too? I woke up so many mornings full of relief that I wasn’t back there anymore, and that couldn’t be faked, right? Ididn’t think that I would ever willingly return, even though that probably made me a horrible person. I felt guilty about it, because it was ungrateful and disloyal to Gresha and Heather, Kisma and Fenn, and even Carame, wasn’t it? But when I thought of going back there, even to work with Gresha in the Foundry, I felt such a crushing suffocation. But why?

I had unpleasant memories, but so did everyone. Why did the thought of a life there, with the few and only people in the world who cared about me, fill me with a heavy and endless dread? Why did that life feel like it would be a living death?

My attention was yanked back to the lecture hall as Master Yvell finished a long, droning speech and the assembled students burst into enthusiastic applause. What was going on? Nobody applauded Yvell. Then I saw the sweep of his arm as he looked offstage and realized that he had been introducing someone.

She walked onto the lecture stage and I could only stare.

2 notes

·

View notes

Text

CNC Precision Automatic Lathe machining

CNC Precision Automatic Lathe machining (also know as Swiss-type Automatic Lathe machining ) .

This machine suits for customized high precise small item component parts mass production ,and would take much advantage than other machining methods.

But compare with screws ,if you make mass production order ,another machining methods -- Cold Heading Machining might be a better choice .

To get the best solution for small sample order and mass production order ,Tik Precision company offer different CNC machining choices and also provide professional suggestion on your machining solutions if your project needed. 🤗

Contact our engineer team for project inquiry now 👉 Irina Dai

✉ Email :[email protected] 📱 Phone /Whatsapp /Wechat :+86 135 4486 6467 🔗LinkedIn :https://lnkd.in/gdidYz7C 🔍Web :www.tikprecision.com

-------- #machining#CNCmachining#CNC #precisionmachining#machiningsolutions#cncmanufacturing#5axis#cncmilling#5axismachiningcenters #5axismachining#cncporn#engineering#CNCshop#cncmachinist#5axiscnc#cncmill#lathework#cnclathe #5thaxis#endmill#carparts#caraccessories#wheelhub#Engineering#PrecisionEngineering#Components#5eksen#5axiscnc#customparts#mechanical#optics#optical#sensor

2 notes

·

View notes

Text

ITI Fitter Tools Suppliers and Manufacturers

As we are leading ITI Fitter Tools Suppliers, we offer a comprehensive range of tools designed for professionals in various industries. Our tools are engineered with precision to ensure long-lasting performance and meet industry standards.

Reliable ITI Fitter Tools Suppliers for Every Industry

We are committed to being trusted ITI Fitter Tools Suppliers, delivering premium tools to industries such as manufacturing, automotive, construction, and more. Our tools are known for their durability, accuracy, and reliability, which makes them a preferred choice for professionals across sectors.

Top ITI Fitter Tools Manufacturer Using Cutting-Edge Technology

As a prominent ITI Fitter Tools Manufacturer, we leverage advanced manufacturing techniques to produce high-quality tools that meet stringent quality standards. Our products undergo rigorous testing to ensure they perform well even in the most demanding industrial environments. From basic hand tools to specialized fitter tools, we manufacture everything needed for accurate fitting work.

Wide Range of ITI Fitter Tools Available

Our wide range of fitter tools includes:

Hammers: Precision-designed hammers for heavy-duty fitting tasks.

Files and Rasps: High-quality files for smooth finishes and shaping.

Measuring Instruments: Vernier calipers, micrometers, and gauges for precise measurements.

Chisels and Punches: Robust chisels and punches for cutting and shaping metal.

Screwdrivers and Wrenches: Essential tools for assembling and disassembling components.

Each tool is carefully crafted using top-grade materials to ensure performance, safety, and durability.

Why Choose Us as Your ITI Fitter Tools Supplier?

There are several reasons to partner with us for your fitter tool needs:

Quality Assurance: We ensure that every tool meets the highest standards of quality and performance.

Competitive Pricing: Our pricing structure is designed to offer great value without compromising on quality.

Custom Solutions: As an experienced ITI Fitter Tools Manufacturer, we offer customized tools for specific industrial requirements.

Reliable Customer Service: We provide support to ensure our clients get the right tools for their needs, with fast delivery times and excellent after-sales service.

How to Contact Us for Your ITI Fitter Tools Needs

If you’re in search of dependable ITI Fitter Tools Suppliers or looking to collaborate with a reputable ITI Fitter Tools Manufacturer, reach out to us today. We ensure the best solutions tailored to your specific project needs. Whether you require standard tools or custom-made equipment, our team is ready to assist with expert advice and top-quality products.

We offers the complete trade tools & machines of fitter trade as per ncvt syllabus. We ensures the quality of our tools as per professional standards in size, length, weight, grip and height as well. TAPARIA, Pie, Kohinoor, ambika, NEW MEN, EVERREADY, EASTMEN, DEWALT, BOSCH are also available LATHE Machine (ALL GEARED) for iti use are available as per syllabus demands C.N.C Milling Trainer at reasonable price are available for iti use .

0 notes

Text

Machined Washers: Types, Materials, Benefits and Supplier India

The CNC Machining Process Behind Precision Washers

Ever wondered how a CNC Machined Washer is made? The process begins with a solid metal bar—like stainless steel, aluminum, or brass—which is loaded into a CNC lathe or milling machine. Guided by a digital blueprint, the machine cuts the washer to exact dimensions, ensuring smooth edges and precise thickness. Compared to stamping or laser-cutting, this method offers far better control over tolerances and finish.

One of the biggest perks of CNC machining is repeatability. Whether you’re producing one Custom Machined Washer or a thousand, each one will be identical. This is crucial in industries where component uniformity is critical—like aerospace, automotive, and precision instruments. Plus, CNC machines allow for rapid prototyping and quick adjustments, which makes them ideal for both low-volume custom orders and high-volume production runs of CNC Machined Washers.

0 notes

Text

How To Handle Lathe Machine Challenge With Ease Using These Tips

Lathe machines are fundamental tools in many industries, offering precision and versatility. However, operating a lathe machine can present various challenges, from maintaining cutting efficiency to ensuring machine longevity. At Ambica Enterprises, we understand that mastering lathe machine operations requires attention to detail and the right approach.

This guide will provide you with valuable tips to overcome common lathe machine challenges and optimize performance.

Understanding the Basics of Lathe Machines

Lathe machines are primarily used for shaping and machining metal, wood, or other materials by removing excess material through a rotating workpiece. This process, known as turning, enables the creation of complex shapes and fine finishes. While lathe machines are indispensable in manufacturing, they come with their own set of challenges. By understanding their mechanics and functions, operators can tackle these hurdles with greater confidence and precision.

1. Correct Tool Selection for Efficient Cutting

Choosing the right cutting tool for the material being machined is critical to achieving high-quality results. Lathe machine tools vary in design and material, and selecting an incorrect tool can lead to premature wear, poor surface finish, and wasted time.

Material Compatibility: Ensure that the cutting tool material is compatible with the workpiece material. For example, carbide tools are ideal for harder metals, while high-speed steel tools are suited for softer materials like aluminum.

Tool Geometry: Pay attention to the rake angle, relief angle, and cutting edge geometry, as these factors directly impact the cutting efficiency and tool life.

Coating Selection: Tools with coatings like TiN (Titanium Nitride) or TiAlN (Titanium Aluminum Nitride) can improve performance by reducing friction and heat, extending tool life.

By understanding these elements, you can optimize cutting performance and avoid excessive tool wear.

Also Check -

2. Proper Machine Setup for Smooth Operations

One of the most common causes of lathe machine issues is improper setup. Ensuring that the machine is set up correctly from the outset can save time and prevent machining errors. Here are a few setup tips to follow:

Workpiece Alignment: Always ensure that the workpiece is securely clamped and aligned. Misalignment can lead to vibration, inaccurate cuts, and damage to both the workpiece and the cutting tool.

Spindle Speed and Feed Rate: Adjust the spindle speed and feed rate according to the material and tool specifications. An inappropriate speed/feed combination can cause tool chatter, poor surface finish, or excessive wear.

Cutting Depth: Start with shallow cuts and gradually increase depth to prevent overloading the machine and tool. Excessive cutting depth can result in overheating and reduced tool life.

By carefully considering these aspects, you'll set the stage for smooth, precise machining operations.

3. Overcoming Lathe Machine Vibration Issues

Vibration is one of the leading causes of poor machining quality. It can lead to surface imperfections, inaccurate dimensions, and premature tool wear. There are several ways to reduce or eliminate lathe machine vibration:

Proper Tool Holding: Ensure that tools are securely held in the tool post, as loose tooling can amplify vibration during cutting.

Machine Stiffness: Use a lathe machine with adequate rigidity and damping systems. Machines with poor structural integrity are more susceptible to vibrations.

Balanced Workpieces: If the workpiece is not properly balanced, it can lead to uneven cutting forces. Use a balancing fixture if necessary to stabilize the workpiece during rotation.

By addressing these points, you can minimize vibration and enhance machining precision.

4. Optimizing Coolant Use for Longevity and Performance

Coolant plays a vital role in reducing heat and friction during the machining process. Insufficient or improper coolant application can lead to overheating, tool wear, and poor surface finishes. To optimize coolant use:

Choose the Right Coolant: Select a coolant suited to the material and cutting operation. For example, water-soluble coolants are effective for light machining, while oil-based coolants are more suitable for heavy cutting.

Flow Rate and Pressure: Maintain an adequate coolant flow rate and pressure to ensure proper cooling and chip removal. Insufficient coolant flow can lead to thermal buildup and tool damage.

Maintain Cleanliness: Regularly clean the coolant system to prevent clogging and contamination. Contaminated coolant can affect its cooling performance and lead to rust and corrosion on the machine.

A well-maintained coolant system ensures longer tool life and improved machining performance.

5. Preventing Lathe Machine Overheating

Lathe machines are subject to high levels of heat generation, particularly during heavy cutting operations. Overheating can cause severe damage to both the machine and the workpiece. To prevent overheating:

Monitor Cutting Parameters: Keep track of the spindle speed, feed rate, and depth of cut to avoid excessive heat buildup. If the machine becomes too hot, reduce the cutting parameters or allow the machine to cool down periodically.

Regular Maintenance: Ensure that the lathe machine's cooling system is in optimal condition. This includes checking for coolant leaks, clogged filters, and worn pumps.

Material Considerations: Some materials, such as titanium or stainless steel, generate more heat during machining. In such cases, adjust cutting parameters and increase coolant flow to mitigate overheating risks.

By closely monitoring heat levels, you can protect your lathe machine from overheating and ensure consistent, high-quality results.

Read This Blog -

6. Troubleshooting Lathe Machine Inaccuracy

Achieving precise dimensions is one of the primary goals in lathe machining. If the machine begins to show signs of inaccuracy, it’s important to troubleshoot the underlying cause promptly. Here are some steps to follow:

Check for Tool Wear: Worn tools can lead to dimensional inaccuracies. Replace tools regularly to ensure consistent performance.

Inspect for Machine Wear: Lathe machines experience wear over time, which can lead to inaccuracies. Check the lead screw, tailstock, and other critical components for wear and adjust or replace parts as needed.

Recheck Machine Alignment: Ensure that the machine is aligned correctly, as misalignment can cause off-center cuts and dimensional discrepancies.

By systematically addressing the sources of inaccuracy, you can restore precision to your machining operations.

7. Extending Lathe Machine Life with Regular Maintenance

A well-maintained lathe machine in India not only performs better but also lasts longer. Regular maintenance is essential for preventing mechanical failures and ensuring consistent performance. Here's a maintenance checklist:

Lubrication: Regularly lubricate critical parts such as the spindle, carriage, and slideways to reduce friction and prevent wear.

Cleanliness: Keep the machine free from debris, dust, and chips. A clean machine runs more efficiently and reduces the risk of malfunctions.

Calibrate Regularly: Perform routine calibration to ensure that the machine's movements and tool positions remain accurate. This helps prevent issues with precision and extends machine life.

Investing in routine maintenance will save time, reduce repair costs, and keep your lathe machine running smoothly for years.

Also Check -

8. Handling Lathe Machine Tooling Challenges

Tooling is a crucial aspect of lathe machine operation. Poor tooling can lead to high operating costs, reduced accuracy, and frequent tool replacements. To tackle tooling challenges:

Tool Wear Monitoring: Monitor the wear on cutting tools and replace them as necessary to maintain consistent cutting performance.

Tool Life Management: Use tool management systems to track tool life and schedule replacements before they fail.

Tooling Compatibility: Always ensure that the tooling is compatible with the machine and the material being worked on. Using the wrong tools can compromise both machine performance and machining quality.

By managing tooling efficiently, you can avoid excessive costs and ensure that your lathe machine operates at peak efficiency.

Conclusion: Mastering Lathe Machine Operations with Confidence

Handling lathe machine challenges with ease requires a combination of technical knowledge, careful planning, and attention to detail. By following the tips and best practices outlined above, you can improve machining efficiency, extend tool life, and enhance the overall quality of your work.

At Ambica Enterprises, we are committed to providing the support and expertise needed to help you navigate these challenges and achieve optimal results with your lathe machine.

#Lathe Machine#Lathe Machines#Lathe Machine Price#Lathe Machine India#Lathe Machine in India#Lathe Machine Manufacturer#Lathe Machine Supplier#Lathe Machine Exporter#Lathe Machine for Sale#Lathe#Lathe Machine Online#Order Lathe Machine#Buy Lathe Machine#Top Lathe Machine#Best Lathe Machine#Lathe Machine Price in India#Lathe Machine Jodhpur#Lathe Machine Rajasthan#Lathe Machine Tips

1 note

·

View note

Text

How To Become Better With Lathe Machine In 10 Minutes

Want to master the lathe machine in just 10 minutes? Discover effective tips and techniques with Ambica Enterprises that will boost your skills fast!

Introduction

Lathe machines are crucial in the world of machining, used for turning, shaping, and polishing a variety of materials like metal, wood, and plastic. If you're looking to become better at using a lathe machine but feel like time is always against you, you've come to the right place! In just 10 minutes, you can start making noticeable improvements in your lathe skills. Sounds too good to be true? Trust me—it's possible when you focus on the right techniques, strategies, and tips.

In this guide, we're going to show you how to become better with lathe machine operations quickly, with practical steps that are easy to implement. Whether you're a novice or someone with a little experience under your belt, there’s always room for improvement. So, let’s dive right in and discover how you can get better with your lathe machine in no time—brought to you by Ambica Enterprises.

Also Check Below: -

1. Understand the Basics of the Lathe Machine

Before diving into advanced techniques, you must understand the fundamentals. The lathe machine works by rotating a workpiece against a tool, which is typically a cutting tool, to shape the material. Here are the key components you need to familiarize yourself with:

Key Lathe Components:

Headstock: Holds the motor and drive mechanism.

Tailstock: Supports the other end of the workpiece.

Carriage: Holds and moves the cutting tool.

Bed: The base where all parts are mounted.

Chuck: Grips the material you’re working with.

Knowing these components and their functions will make your work easier and give you confidence when you operate the machine. A quick glance at the manual for your specific lathe machine model can also go a long way in helping you get to know its controls.

2. Set Up Your Lathe Machine for Success

Setting up your lathe machine properly is crucial for efficient and safe operation. Here’s how you can set yourself up for success in just a few minutes:

Step-by-Step Lathe Setup:

Check the Chuck: Ensure the chuck is properly tightened and positioned on the spindle.

Select the Right Tool: Choose the appropriate cutting tool for your material. Make sure it's securely fixed in the tool holder.

Adjust the Speed: Set the spindle speed to match the material you're working with. Metal requires slower speeds than wood or plastic.

Set the Feed Rate: Adjust the feed rate depending on how quickly you want the tool to move along the workpiece.

Check the Tailstock: Make sure it's aligned and locked in place if you’re using it.

The right setup can significantly impact the quality of your work. A few minutes of preparation now will save you time and frustration later.

3. Improve Your Precision: Mastering the Fine Details

The key to becoming better with a lathe machine lies in your precision and control. Mastering the fine details of lathe operation is what separates beginners from experts.

Read This Article -

Key Tips for Precision:

Use Dial Indicators: To measure the exact position of your cutting tool and ensure the workpiece is perfectly centered.

Move the Carriage Slowly: Don't rush the cutting process. The slower you go, the more control you’ll have over the tool.

Check the Tool Angle: Keep the cutting tool at the right angle to avoid excessive wear and tear. The angle varies depending on the material and the type of cut you need.

Keep the Tool Sharp: Dull tools result in rough cuts. Sharpen your tool regularly for smoother results.

The more precise you are, the smoother and cleaner your cuts will be, resulting in a professional finish.

4. Safety First: Don’t Cut Corners

Let’s get real: safety should never be an afterthought. It's easy to get caught up in the excitement of working on your lathe machine, but neglecting safety can lead to accidents. Here are a few basic safety tips to follow:

Wear Safety Gear: Always wear safety goggles and gloves to protect your eyes and hands from debris.

Secure the Workpiece: Ensure the material is properly secured in the chuck to avoid it flying off during operation.

Keep the Area Clean: A clean workspace is a safe workspace. Remove any clutter or tools that could get in your way.

Know Your Emergency Stops: Familiarize yourself with the emergency stop buttons on your lathe machine.

By practicing these safety habits, you’ll create an environment that allows you to work more confidently and efficiently.

5. Get Comfortable with Different Lathe Operations

According to Ambica Enterprises, lathe machine in India's aren’t just for simple turning—they’re incredibly versatile and can perform a variety of operations. The more operations you’re comfortable with, the more versatile you become as a machinist.

Common Lathe Operations:

Turning: The most basic lathe operation, used to reduce the diameter of a workpiece.

Facing: Cutting a flat surface at the end of a workpiece.

Taper Turning: Gradually reducing the diameter of a workpiece along its length.

Thread Cutting: Creating threads on a workpiece, typically for bolts or screws.

Drilling: Using the lathe to drill holes in your material.

Start by learning one operation at a time. As you get better, try combining operations to create more complex parts!

6. Experiment with Different Materials

Working with a variety of materials will broaden your skill set. Each material requires different techniques, speeds, and cutting tools. Here’s a quick rundown of how different materials can affect your lathe work:

Metal: Slow speeds, high cutting force. Use coolant to prevent overheating.

Wood: High speeds, low cutting force. The grain of the wood may cause tear-outs, so adjust accordingly.

Plastic: Moderate speeds and pressure. Be mindful of material heating up during the process.

Try working with different materials to discover how they behave under the lathe. Each new material will teach you something new about your machine and cutting techniques.

7. Common Mistakes to Avoid

We’ve all been there—making mistakes while operating a lathe. But don't sweat it; knowing what to avoid can help you steer clear of some common pitfalls. Here are a few mistakes to watch out for:

Incorrect Speed Settings: Too fast or too slow can cause issues. Always match the speed to the material and operation.

Improper Tool Setup: If the tool isn’t set correctly, you’ll end up with uneven cuts.

Forgetting to Lubricate: Lubricating your workpiece and cutting tool is vital for smooth operation and longer tool life.

Rushing the Process: The rush to finish can result in mistakes. Patience is key to high-quality work!

By avoiding these mistakes, you’ll be on your way to smoother, more precise lathe work.

Read Awesome Article Here -

FAQs

Q1: How can I learn more advanced lathe techniques? A1: The best way to learn advanced techniques is through practice and research. Consider attending a workshop or enrolling in a machining class to take your skills to the next level.

Q2: Can I use a lathe machine for both wood and metal? A2: Yes! You can use a lathe machine for both wood and metal. Just make sure to adjust the speed and use the appropriate cutting tools for each material.

Q3: How often should I sharpen my lathe tool? A3: It depends on the material and how often you’re using the tool, but you should sharpen it regularly to maintain a clean, precise cut. Dull tools can lead to poor-quality work and wasted time.

Q4: How do I prevent vibrations when using the lathe? A4: Ensure the lathe is properly mounted on a solid, level surface. Use the correct cutting speed, and make sure the workpiece is securely held in place.

Conclusion

Becoming better with a lathe machine doesn’t have to take years of experience. With the right setup, techniques, and a bit of practice, you can significantly improve your skills in just 10 minutes! From understanding the basics and safety to experimenting with different materials, each small improvement adds up.

Remember, it's not about rushing the process, but about refining your techniques over time. If you follow the tips provided by Ambica Enterprises, you’ll soon find yourself creating workpieces that are both precise and professional.

So, are you ready to make those 10 minutes count?

#Lathe Machine#Lathe Machine in India#Lathe Machine India#Lathe Machine Supplier#Lathe Machine Manufacturer#Lathe Machine Price#Lathe Machine Price in India#Lathe Machines#Lathe#Lathe Machine for Sale#Buy Lathe Machine#Purchase Lathe Machine#Order Lathe Machine#Best Lathe Machine#Top Lathe Machine

1 note

·

View note

Text

Transform Production with Elite CNC Lathe Machines for Sale

In precision-driven industries, CNC lathe machines for sale are the linchpin of efficiency, accuracy, and scalability. For automotive suppliers, aerospace manufacturers, and engineering firms, upgrading to advanced CNC lathe technology isn’t just an investment—it’s a strategic leap toward dominating competitive markets. The High-Speed Drilling And Tapping Center Series Lathe Machine T600-21T redefines industrial machining, blending cutting-edge automation with robust engineering to tackle the most demanding production challenges.

Why CNC Lathe Machines Are Critical for Industrial Excellence CNC lathe machines eliminate human error, reduce waste, and slash cycle times through automated precision. Outdated equipment risks costly delays, rework, and inconsistent quality. For TOB clients, the T600-21T delivers:

High-Speed Machining: Spindle speeds up to 4,000 RPM handle steel, titanium, and composites with surgical precision.

Multi-Tool Versatility: Turret systems enable seamless transitions between drilling, tapping, and threading operations.

Vibration-Dampening Bed: The reinforced structure ensures stability during high-torque tasks, maintaining ±0.003mm tolerances.

Automated Feed Control: Optimizes tool paths to reduce material waste by 30% and accelerate production.

Unmatched Engineering for High-Stakes Applications

Precision Components: Hardened steel cross slide and carriage guarantee durability in 24/7 operations.

Tailstock Flexibility: Supports long workpieces for complex geometries in shafts, pins, and hydraulic fittings.

Smart Speed Adaptation: Adjustable spindle settings cater to materials from aluminum to hardened alloys.

Industry 4.0 Integration: Real-time monitoring and predictive maintenance compatibility for smarter workflows.

Applications Driving ROI Across Sectors

Aerospace: Crafting turbine blades, landing gear, and engine components.

Automotive: Machining transmission systems, brake rotors, and custom fasteners.

Medical Devices: Producing implants, surgical tools, and diagnostic equipment.

Energy Sector: Fabricating valves, pump connectors, and pipeline parts.

Tailored Solutions for Your Production Line Beyond standard models, we offer customization for spindle configurations, control interfaces, or specialized tooling. Whether you need high-volume throughput or prototype agility, the T600-21T adapts to your workflow, ensuring seamless integration into existing systems.

Why Partner with Us?

Decades of Expertise: Proven track record in CNC lathe innovation and industrial solutions.

End-to-End Support: Installation, training, and maintenance services to maximize uptime.

Custom-Built Flexibility: Modify machines to meet regional standards, niche applications, or unique specs.

Upgrade to Unrivaled Precision Today Don’t let inefficiencies hold back your growth. The T600-21T CNC Lathe Machine combines speed, durability, and intelligence to future-proof your operations. Contact us to schedule a demo, request a quote, or discuss bulk-order incentives—and position your business as a leader in precision manufacturing.

Elevate Efficiency with CNC Lathe Machines for Sale—Connect Now!

0 notes

Text

Machine Tools in Manufacturing: Growth Drivers and Challenges

The global machine tools market size is expected to reach USD 137.43 billion by 2030, registering to grow at a CAGR of 7.0% from 2025 to 2030 according to a new report by Grand View Research, Inc. The increased need for higher efficiency and precision in complex machining tools, as well as lower operating costs in industries, such as aerospace, automotive, and defense, have led to an increased usage of machine tools.

The machining time is more expensive than the setup fees, material expenses, and fees for custom finishing a job or workpiece. Owing to all these advantages, manufacturers are gradually shifting toward the automation of machines to reduce time by rolling out connectivity networks and deploying the latest software. Such technological developments are anticipated to boost the sales of machine tools in the forecast period.

Machine Tools Market Report Highlights

Machine tools are used across various industries and industry verticals, including automobile, aerospace, and others, to manufacture various components with precision and speed while ensuring adequate flexibility.

Metal cutting machines are widely utilized in many end-use sectors such as automotive, mechanical engineering, metal working, and aerospace, to produce completed products with the necessary geometry by cutting various types of ferrous and non-ferrous metals.

The use of CNCs as milling machines, lathes, abrasive jet cutters, laser cutters, press brakes, punch presses, and other industrial instruments has been expanding quickly with the development of computers.

The electrical and electronics industry is one of the world’s largest industries. It includes a broad range of goods, from bulky consumer electronics to tiny electrical parts.

For More Details or Sample Copy please visit link @: Machine Tools Market Report

The machine tools products are increasingly getting complex in line with the shifting customer preferences toward higher-quality products. Hence, manufacturers are also gearing up to develop complex products and are accordingly automating their CNC machining processes to enhance product quality while reducing operating costs. For instance, in July 2020, SKODA AUTO Germany GmbH launched automated supplying and ordering of parts for CNC processing lines at its plant in Vrchlabi, Czech Republic as part of the efforts to increase the productivity of the plant.

Machine tool manufacturers are trying aggressively to develop energy-efficient tools to cater to the manufacturers’ needs to reduce operating costs while eliminating errors in manufacturing, leveraging IoT technology and predictive analytics capabilities. For instance, automotive companies are increasingly opting for CNC machining in line with the growing demand for spare parts with higher precision.

Industry 4.0 is particularly encouraging digital transformation across the entire automotive industry, spanning automotive OEMs, dealers, and suppliers, among other industry stakeholders, which bodes well for the growing demand for CNC machine tools. The motorsport industry is particularly using CNC machine tools to reduce manufacturing time and to ensure that components are manufactured flawlessly. As such, various racing car manufacturers are striking partnerships with CNC machine tool providers to manufacture precision components.

List of Key Players of Machine Tools Market

Amada Machine Tools Co., Ltd.

CHIRON GROUP SE

DMG MORI. CO., LTD.

DN Solutions

Georg Fischer Ltd.

HYUNDAI WIA CORP

JTEKT Corporation

Komatsu Ltd

We have segmented the global machine tools market on the basis of type, technology, end use, and region

#MachineTools#MachineToolsMarket#ManufacturingIndustry#MarketResearch#Automation#Industry40#CNCmachines#PrecisionMachining#Metalworking#IndustrialAutomation#SmartManufacturing#IoT#AIinManufacturing#AdvancedManufacturing

0 notes

Text

High-Quality CNC Turning Services for Precision Machining

In today’s competitive manufacturing industry, CNC Turning Services play a crucial role in delivering high-precision components for various applications. At XC Machining, we specialize in providing custom CNC turning solutions to meet the demands of industries such as automotive, aerospace, medical, and electronics.

What Are CNC Turning Services?

CNC turning is a subtractive machining process where a rotating workpiece is shaped using cutting tools. This advanced method ensures accuracy, consistency, and efficiency in producing complex parts with tight tolerances. Whether you need prototypes or large-scale production, our CNC turning solutions guarantee superior results.

Why Choose XC Machining for CNC Turning?

At XC Machining, we utilize state-of-the-art CNC lathes and cutting-edge technology to manufacture high-quality turned components. Our services offer:

Precision Engineering – Achieving exact specifications with minimal errors.

Fast Production – Efficient turnaround times for all order sizes.

Material Versatility – Working with metals like aluminum, stainless steel, brass, and plastics.

Cost-Effective Solutions – Competitive pricing without compromising quality.

Industries We Serve

Our CNC turning services cater to diverse industries requiring high-performance machined parts. From medical implants to aerospace fittings, we deliver reliable solutions tailored to your needs.

0 notes

Text

詠翊科技有限公司

YONG YI CNCTETCH.Co.,LTD.

詠翊科技創立於2005年4月,團隊已擁有CNC銑床加工約二十年之專業加工經驗,其生產領域涵蓋電子、光學及半導體自動化設備…等產業。

目前廠內設備共有CNC銑床機台10台、傳統銑床7台、傳統車床及平面研磨機台共近20台精密設備。 此外亦陸續積極擴大規模及採購新的生產設備以有效擴張產能及服務範圍。 本公司可依據客戶之需求協助開發設計加工,各零件接單生產流程皆採嚴謹加工生產技術及品管檢驗作業,搭配各項表面處理,如:陽極、電鍍、代工代料代表處,全都處理到好。

詠翊科技本著「感恩的心、勤儉向上、追求創新、技術增長,並懷著���力不懈的敬業態度」,贏得各設備大廠及日本客戶一致的好評與信任。日後亦會秉持我們一貫的優良作風,「品質第一、快速交貨」,繼續為客戶服務。

Yongyi Technology was founded in April 2005. The team has about 20 years of professional processing experience in CNC milling machine processing. Its production fields cover electronics, optics and semiconductor automation equipment… and other industries.

Currently, the factory has 10 CNC milling machines, 7 traditional milling machines, and nearly 20 traditional lathes and surface grinding machines, a total of nearly 20 precision equipment. In addition, it has also been actively expanding its scale and purchasing new production equipment to effectively expand its production capacity and service scope. Our company can assist in the development, design and processing according to the needs of customers. The production process of each part order adopts rigorous processing and production technology and quality control inspection operations, with various surface treatments, such as anodizing, electroplating, and OEM representative offices. Handled well.

Yongyi Technology has won unanimous praise and trust from major equipment manufacturers and Japanese customers with its “gratitude, thrift, pursuit of innovation, technological growth, and unremitting dedication”. In the future, we will uphold our consistent good style of “quality first, fast delivery” and continue to serve customers.

#cncprocessing#cncprecision processing#semiconductor components#automation equipment#precision components#robot arm#stainless steel processing#engineering plastic#ceramic processing#cnc加工#cnc精密加工#半導體零組件#自動化設備#精密零組件#機器手臂#不鏽鋼加工#工程塑膠#陶瓷加工

0 notes

Text

Precision Engineering Machines Market: Growth Insights and Opportunities

The global precision engineering machines market size is expected to reach USD 22.05 billion by 2030, expanding at a CAGR of 6.8% from 2023 to 2030, according to a new study by Grand View Research Inc. Precision engineering tools have gained popularity because of their exact accuracy as production methods become more productive and efficient. The scope of precision engineering is expanding as a result of the increasing technological capability. Precision engineering equipment makes automated procedures possible, which reduces the amount of time needed for component machining. The machines may work continuously without any manual aid or oversight once the machinist enters the codes into the computer. Industrial automated devices, such as robots, have proven to be beneficial for both discrete and continuous manufacturing in several ways. Among these benefits are raised productivity and improved production methods.

The COVID-19 outbreak caused damage to the market by stifling innovation, cutting into profitability, reducing cash flow, and throwing the economy out of balance. Numerous events had to be postponed in 2020 because of the COVID-19 epidemic, which hindered vendors from showcasing their cutting-edge products or advances. On the other hand, less skilled workers may struggle to handle precise engineering equipment, which could result in machine damage and risk the manufacturing unit's financial investments. As a result, finding qualified operators is a significant barrier to the company's expansion. The lack of qualified manufacturing workers, such as precision machines and tool and die makers, is having an impact on sectors including steel and aerospace.

Modern times have seen a rapid introduction of a wide variety of novel and innovative technology. Among this diverse and cutting-edge range, programmed automation is one of the most popular and frequently utilized technologies. The concept of machine automation has entirely transformed as a result of programmed automation's ability to execute instructions entered by a human into the systems. With the use of programmed automation found in precision engineering machines, a manufacturer is able to make several identical copies of the same product without the need for human labor.

Precision Engineering Machines Market Report Highlights

The growth is linked to the increase in demand for autonomous vehicles, new transportation technologies, improvements in robotics, design, and manufacturing techniques, as well as the introduction of EVs in some countries

The expansion of oil and gas industries and the use of modern machinery for precise manufacturing such as lathes and spinning machines are anticipated to drive the market growth

The growing trend of incorporating advanced technology into products to boost machinery efficiency at drilling sites with greater depths and pressure requirements is projected to benefit the European and MEA markets

Precision Engineering Machines Market Segmentation

Grand View Research has segmented the global precision engineering machines market based on end-use and region:

Precision Engineering Machines End-use Outlook (Revenue, USD Million, 2018 - 2030)

Automotive

Non-Automotive

Aerospace & Defense

Engineering & Capital Goods

Power & Energy

Others

Precision Engineering Machines Regional Outlook (Revenue, USD Million, 2018 - 2030)

North America

US

Canada

Europe

UK

Germany

France

Italy

Spain

Asia Pacific

China

India

Japan

Australia

South Korea

Latin America

Brazil

Mexico

Argentina

Middle East & Africa (MEA)

A.E.

Saudi Arabia

South Africa

Order a free sample PDF of the Precision Engineering Machines Market Intelligence Study, published by Grand View Research.

0 notes