#Optical Ceramics Industry

Explore tagged Tumblr posts

Text

Exploring the dynamic world of laser welding - Technology Org

New Post has been published on https://thedigitalinsider.com/exploring-the-dynamic-world-of-laser-welding-technology-org/

Exploring the dynamic world of laser welding - Technology Org

In the realm of manufacturing and engineering, advancements in technology continually redefine the boundaries of what is possible. Among these innovations, laser micro welding stands out as a remarkable technique that has revolutionized the way delicate components are joined together.

Laser welding. Illustrative photo. Image credit: Chokniti Khongchum via pexels.com, free license

How laser micro welding works

At its core, laser micro welding is a welding possess that utilizes a focused laser beam to join small components with extreme accuracy. Unlike traditional welding methods that often involve heat-intensive processes, such as arc welding or gas welding, laser micro welding operates on a different principle, harnessing the power of coherent light to melt and fuse materials together.

The different possible applications

One of the key advantages of laser micro welding is its ability to achieve high-quality welds in materials with varying compositions and thicknesses. Whether it’s dissimilar metals, thermoplastics, or even fragile materials like glass or ceramics, laser micro melding offers a level of precision that is unmatched by other, conventional, welding techniques.

The benefits of laser micro welding

One of the most important features of laser micro welding is its minimal heat-affected zone (HAZ). Unlike other welding methods that can cause deformation, warping, or material damage due to excessive heat, laser micro welding minimizes thermal impact on the surrounding area.

Efficiency and cost-effectiveness

Laser micro welding also offers practical benefits. It offers unmatched repeatability and consistency, ensuring that each weld meets the highest standard or quality and reliability. This is critical in industries where precision is non-negotiable, such as medical device manufacturing or aerospace engineering, where the smallest defect could have significant consequences.

The future of laser micro welding

Technology is constantly developing, and so do the potential applications of laser micro welding. From microelectronics and microfluidics to jewelry and dental prosthetics, this technique knows no boundaries. Laser micro welding is on its way to becoming the forefront of innovation.

#aerospace#applications#arc#ceramics#efficiency#engineering#Features#Future#gas#glass#Heat#how#impact#Industries#Innovation#innovations#it#laser#Light#Manufacturing#material#materials#medical#Metals#microelectronics#Microfluidics#One#Optics & photonics news#Other#Other posts

0 notes

Text

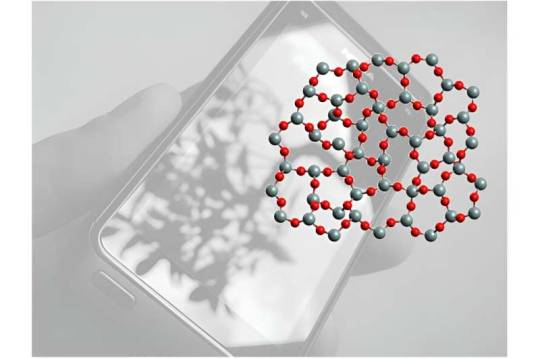

Stability of rings of atoms in glass materials can help predict performance of glass products

Glass is being used in a wider range of high-performance applications, including those for consumers and industry, military and aerospace electronics, coatings and optics. Because of the extreme precision demanded for use in products such as mobile phones and jet aircraft, glass substrates must not change their shape during the manufacturing process. Corning Incorporated, a manufacturer of innovative glass, ceramics and related materials, invests a tremendous amount of resources into studying the stability of different types of glass. Recently, Corning researchers found that understanding the stability of the rings of atoms in glass materials can help them predict the performance of glass products. This capability is important because the most widely used glass is silicate glass, which consists of different sizes of atomic rings connected in three dimensions. Conducting neutron scattering experiments at the Department of Energy's Oak Ridge National Laboratory, ORNL and Corning scientists discovered that as the number of smaller, less-stable atomic rings in a glass increases, the instability, or liquid fragility, of the glass also increases.

Read more.

20 notes

·

View notes

Text

Global top 13 companies accounted for 66% of Total Frozen Spring Roll market(qyresearch, 2021)

The table below details the Discrete Manufacturing ERP revenue and market share of major players, from 2016 to 2021. The data for 2021 is an estimate, based on the historical figures and the data we interviewed this year.

Major players in the market are identified through secondary research and their market revenues are determined through primary and secondary research. Secondary research includes the research of the annual financial reports of the top companies; while primary research includes extensive interviews of key opinion leaders and industry experts such as experienced front-line staffs, directors, CEOs and marketing executives. The percentage splits, market shares, growth rates and breakdowns of the product markets are determined through secondary sources and verified through the primary sources.

According to the new market research report “Global Discrete Manufacturing ERP Market Report 2023-2029”, published by QYResearch, the global Discrete Manufacturing ERP market size is projected to reach USD 9.78 billion by 2029, at a CAGR of 10.6% during the forecast period.

Figure. Global Frozen Spring Roll Market Size (US$ Mn), 2018-2029

Figure. Global Frozen Spring Roll Top 13 Players Ranking and Market Share(Based on data of 2021, Continually updated)

The global key manufacturers of Discrete Manufacturing ERP include Visibility, Global Shop Solutions, SYSPRO, ECi Software Solutions, abas Software AG, IFS AB, QAD Inc, Infor, abas Software AG, ECi Software Solutions, etc. In 2021, the global top five players had a share approximately 66.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

2 notes

·

View notes

Text

LED PCB Assembly

What is the LED Circuit Board assembly?

Generally, LED PCB assembly is considered to be a circuit board that has the LED components soldered to it. The LED is soldered to the printed circuit board and features a chip that creates the light as electrically connected. A thermal heat sink and a ceramic base are used to bond the chip. Not all the PCB products can be used in Led industry, as an LED PCB is easy to create a high volume of heat, but making it hard to cool with traditional methods. For this reason, metal core PCB is widely used in LED application because of their enhanced ability to dissipate heat, especially aluminum pcb is often used to fabricate PCB for LED lights.

We’ve had great LED PCB assembly experiences with top LED chips to brand such as Cree, Luxeon, Osram, Nichia, Lumileds, MLS, EVERLIGHT, Samsung, LG, Seoul., etc. PCB LED lights can be incorporated into numerous lighting applications due to their combination of excellent energy efficiency, low cost and maximum design flexibility.

Application of LED PCB Assembly

Hitechpcba serves customers in different industries, providing highly reliable and innovative LED PCBs for various applications:

• Horticulture light LED PCB Assembly

• LED controller PCB Assembly

• Computer LED display and indicators

• LED lights PCB Assembly for medical use

• Automotive LED PCBs Assembly include PCBs for brake lights and headlights

• Street lighting LED PCB Assembly

• Flashlights and camping accessories

• Traffic light PCB Assembly

• Commercial lighting LED PCB Assembly

LED PCB Assembly specification

Number of layers for LED PCB

These layers are made up of aluminum and magnesium, but now have Copper base material and Ceramic base materials for LED PCB industry, we can meet it.

Aluminum LED PCBs stand out among other PCBs because it has a good insulation characteristic and has a better machinery performance, the cheap cost is one important factor too.

Types of layers for LED PCB Assembly

Normally, the base layer is made using aluminum alloy metal.

This aluminum alloy substrate used in making the base makes it ideal for through-hole technology which transfers and dissipates heat.

A thermal insulation layer is made using some ceramic polymer which has good viscoelasticity characteristics.

It is highly heat resistant and protects the PCB against heat and mechanical stress.

The circuit layer, which is covered by a copper foil which can range from one to ten ounces.

LED Board type- single or in panel

Some boards are shapeless. For this reason, LED PCB panels are used. This reduces time, labor production and testing time.

Some LED PCB Assembly is done on a single board while others are done on panel boards.

LED PCB Assembly Process

Roughly, the PCBA process can be divided into theses phases: soldering paste printing > SMT (surface mounted technology) > reflow soldering > AOI (automated optical inspection)> THT (through-hole technology) > wave soldering > touch-up and cleaning > IC-programming > FCT (functional tests) > aging testing.

Below we show you the process.

Step1. Summarizing Project Information

Before contacting your supplier, make sure you have all the project information. Suppliers will need info following for quoting LED PCB assembly:

Gerber

BOM

LED PCB specification

Quotation quantity

Once you have gathered these information, you can contact us and request for a quote.

Of course, you can also provide the schematic, LED PCB Assembly pictures and even samples to us. The more details they have, the more accurate the supplier’s quotation will be.

Step2. Discussion and details about custom LED PCB Assembly

Different projects will have different requirements. Remember the special requirements mentioned in step 1? That’s going to be the focus of this session. Equipment and engineering capacity will not be identical between suppliers. Make sure your supplier has the equipment to produce and assemble major components and the corresponding testing capabilities.

For example, some vendors don’t have X-ray testing equipment, which means they can’t check the mount quality of BGA chips. Outsourcing this step will increase risk and cost. That’s what you don’t want.

Also, pay attention to time taken by the supplier to quote. Motherboards often contain hundreds or even thousands of components, and they are supplied by different manufacturers. To ensure the quality of the components, the supplier sourcing team will make multi-inquiries from these manufacturers or authorized suppliers to match customer’s requirement, which usually takes 2-3 business days, and even longer for some scarce chips. Therefore, if your project is complex and the supplier quotes you within few hours, double check with them.

Step3. Sample and feedback

After confirming the PI, the supplier will usually provide pre-production samples for your approval. At the same time, the supplier will also confirm with you the logistics plan of the bulk goods. Make sure they understand your shipping requirements, including details on packaging, customs clearance, taxes, etc.

For us to have a successful LED PCB Assembly process, its functions must be defined. Compliance requirement is defined to reduce the effect when components are selected.

The Bill of Materials is then generated from the information installed on the LED PCB.

All this information is used to assemble components which are identified from MOB to the LED PCB.

After that, the routing of traces is determined to each component, based on the size, shape of the circuit board and location of connectors.

Hitech Circuits is trusted by thousands of electronic engineers on their LED PCB assembly projects, from consumer, led bulb to precisely medical LED light, we can help you from the beginning of design stage; From commercial flood LED to industrial high power LED, from automotive LED to military LED, Venture is the perfect place for your LED PCB assembly requirement.

Hitech Circuits has been participated in hundreds and thousands of LED lighting projects, by providing LED PCB and also LED PCB assembly service.

Our LED PCB assembly had covered both ends of the Lighting Class LED size spectrum, assembling some of the largest (2 meter long boards) and some of the smallest LED Lighting applications which used in Medical Endoscopes.

LED PCB Assembly is very crucial in the current industrial development. Many electrical devises are being innovated and the old once being improved.

LED PCBs are useful due to the fact that they are made using materials that can transfer and dissipate heat. This characteristic increases device durability.

The world is changing with new technology, especially PCB technology that plays an essential role in the application of LED circuits. And the LED industry is taking advantage of this technology and growing faster.

As a full feature PCB solutions provider with more than a decade of experience, we're capable to provide LED PCB fabrication, components procurement and LED PCB assembly all under one roof. We can work with you to develop metal core PCB, aluminum circuit boards customized to your specific applications. We feature competitively priced PCBs made with standard FR-4 material that includes a thermal aluminum clad layer that will efficiently dissipate heat, keep all LED PCB components cool and significantly enhance the performance of your products.

LED pcb board, LED pcb assembly

LED with its advantages of high brightness, high efficiency, low heat, long life, is considered the most development potential in the 21st century lighting. In the market and policy driven by the rapid development of the domestic LED industry blowout has formed a relatively complete industrial chain, including the production of epitaxial wafers, chip preparation, packaging, integration, LED application. In 2010, China's LED industry scale, up from $ 827 billion in 2019 to 220 billion yuan, an annual growth rate of over 70%, higher than the 50% level of growth of the global LED lighting industry output value. Among them, the middle and lower reaches of the most complete industrial chain, accounting for 90% of the overall percentage of the GDP.Chinahas become the world's leading LED manufacturing base and important application market.

To further promote the technological innovation of the LED industry, construction and wide application of independent industry chain, China Electronic Appliance Corporation and industry associations to organize the theme of "Focus on the core energy LED Exhibition will be held November 9-11, 2010 in Shanghai International Expo Center and the 78th China Electronics Fair over the same period will be held will create from raw materials, epitaxial wafers, chip, LED bracket, LED accessories, LED packaging and supporting materials, the LED backlight upstream firm to the upstream and downstream enterprises of the display, lighting, landscaping, decorative lighting, traffic lights, automotive lighting, special lighting, to the equipment, instrumentation, software, finance, consulting and other service enterprises and technological exchanges and market trading platform, help the domestic industry sustained and healthy development, and promote the steady expansion of the LED application market.

In the LED industry chain upstream of the epitaxial wafers and LED chips accounted for 70% of the profits of the whole industry, and technology-intensive, capital-intensive, where the core technology of the LED. Well-known epitaxial wafer and chip production enterprises will be exhibited a number of energy-efficient, low heat, cost-effective LED products, many of whom have excellent products of international advanced level.

LED electronic pcb assembly manufacturing 100% Original LED Chip with one-stop in-house pcba services

3 notes

·

View notes

Text

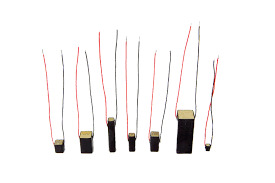

Powerhouse of Precision: Exploring the Key Features of Piezo Stacks

Piezo stacks are innovative devices that utilize the piezoelectric effect to achieve precise and controlled movements. These stacks consist of multiple layers of piezoelectric ceramic materials stacked together, enabling them to generate high forces and displacements with nanoscale precision. In this infographic, we explore the key features, working principle, and applications of piezo stacks.

For More Information Please visit, pzt stacks

Key Features of Piezo Stacks:

Nanoscale Precision: Piezo stacks offer exceptional precision, allowing for nanometer-level movements and control. This precision is crucial in applications such as microscopy, semiconductor manufacturing, and optical alignment.

High Force Output: Despite their compact size, piezo stacks can generate significant amounts of force. The stacked design allows for the amplification of force, enabling precise control even in applications that require high force requirements.

Rapid Response: Piezo stacks can respond to electrical signals in microseconds, enabling fast and dynamic adjustments. Their rapid response is vital in applications that require quick positioning or movement changes.

Direct Drive and Non-Magnetic Operation: Piezo stacks operate without the need for mechanical gears or magnetic components. This direct drive mechanism eliminates backlash and allows for precise control, even in non-magnetic environments.

Working Principle of Piezo Stacks:

Piezoelectric Effect: Piezo stacks utilize the piezoelectric effect, which refers to the ability of certain materials to generate an electric charge when subjected to mechanical stress. This effect allows the stack to convert electrical signals into precise mechanical movements.

Layered Structure: Piezo stacks consist of multiple thin layers of piezoelectric ceramics. Each layer is carefully engineered to maximize the piezoelectric effect.

Voltage Application: When a voltage is applied to the stack, an electric field is created within the piezoelectric layers. This field causes the layers to expand or contract, resulting in precise mechanical displacements.

Applications of Piezo Stacks:

Precision Positioning: Piezo stacks are extensively used in positioning systems for microscopy, atomic force microscopy (AFM), lithography, and optical alignment. Their precise control allows for accurate positioning and scanning.

Micro-dispensing and Jetting: Piezo stacks find application in micro-dispensing and jetting systems, enabling precise control of fluid flow. They are utilized in industries such as inkjet printing, pharmaceuticals, and biotechnology.

Active Damping and Vibration Control: Piezo stacks are employed in active damping and vibration control systems to minimize unwanted vibrations. They find use in precision manufacturing equipment, semiconductor fabrication, and optical instruments.

Adaptive Optics: In astronomy and laser applications, piezo stacks are used in adaptive optics systems to compensate for atmospheric distortions. They allow for real-time adjustments of deformable mirrors, improving image quality and resolution.

Conclusion:

Piezo stacks provide an effective solution for achieving precision and control in various industries. Their nanoscale precision, high force output, rapid response, and direct drive operation make them invaluable in applications requiring accurate positioning, micro-dispensing, vibration control, and adaptive optics. With ongoing advancements in technology, piezo stacks are poised to continue empowering innovation and driving progress in precision engineering and control systems.

2 notes

·

View notes

Text

Sirens Market Research by Key players, Type and Application, Future Growth Forecast 2022 to 2032

In 2022, the global sirens market is expected to be worth US$ 170.1 million. The siren market is expected to reach US$ 244.0 million by 2032, growing at a 3.7% CAGR.

The use of sirens is expected to increase, whether for announcements or on emergency vehicles such as ambulances, police cars, and fire trucks. A siren is a loud warning system that alerts people to potentially dangerous situations as they happen.

Rapidly increasing threats and accidents have resulted in more casualties and missed business opportunities in developing economies. Demand for sirens is expected to rise during the forecast period as more people use security solutions.

As a result of rising threats and accidents in developing economies, the number of victims and lost business opportunities has rapidly increased. Adopting security solutions, such as sirens, is an effective way to deal with these challenges. Long-range sirens are used in mining and industrial applications, whereas motorised sirens are used in home security. Hand-operated sirens are used when there is no power or when a backup is required.

Some additional features of sirens include a solar panel upgrade system to keep the batteries charged and a number of digital communication methods, including Ethernet, satellite, IP, fiber optic and others. Sirens have conformal coatings on their electronics, which help protect them against harsh environments. Some of the systems are made in such a way that they can be expanded or scaled depending on future capabilities.

Omni-directional sirens can be used in areas of high noise levels and those with large population densities as they provide a greater area of coverage. Sirens have external controls with triggers, which can be customized according to needs. The lightening types of sirens include bulb revolving, LED flashing and xenon lamp strobe. The loud speakers in sirens are adopted from latest piezoelectric ceramic technology.

Get a Sample Copy of this Report @ https://www.futuremarketinsights.com/reports/sample/rep-gb-4274

Other sirens are hydraulic or air driven and mostly find applications in plants and factories. Lithium batteries have replaced alkaline batteries in sirens now, since lithium batteries need not be replaced for several years. Modern sirens use latest technologies and find applications in civil defense, emergency vehicles, security systems and others. Typically, sirens are made of stainless steel, aluminum or UV stabilized polycarbonate to avoid corrosion and are equipped with protection cages. An LED flashing siren has a light source with a semi-permanent lifespan and it is used in places where bulb replacement is a problem.

Region-wise Outlook

In the global sirens market, the dominant share is held by the U.S., India, China, Japan, Australia, Germany, Singapore and the UAE. This can be attributed to the demand for security solutions in developed as well as developing economies.

The regional analysis includes:

North America (U.S., Canada)

Latin America (Mexico. Brazil)

Western Europe (Germany, Italy, France, U.K, Spain)

Eastern Europe (Poland, Russia)

Asia-Pacific (China, India, ASEAN, Australia & New Zealand)

Japan

The Middle East and Africa (GCC Countries, S. Africa, Northern Africa)

The report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain. The report provides in-depth analysis of parent market trends, macro-economic indicators and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various market factors on market segments and geographies.

Market Participants

Some of the key market participants identified in the global siren market are Acoustic Technology Inc., Sentry Siren Inc., MA Safety Signal Co. Ltd, Whelen Engineering Co. Inc., Federal Signal Corporation, B & M Siren Manufacturing Co., Projects Unlimited Inc., Phoenix Contact, Mallory Sonalert Products and Qlight USA Inc.

Rising population and rapid urbanization have led to an increase in demand for security solutions. The need for implementation of security has paved way for the use of electronic equipment on a large scale globally, which in turn has created opportunities for the global sirens market. As these products are durable with a high voltage capacity and easy to install, they find high selling propositions. Characteristics and properties of electronic and pneumatic equipment play a vital role in security solutions, thereby driving the global sirens market with a rise in diverse end-user applications, such as industrial warning systems, community warning systems, campus alert systems and military mass warning systems.

Report Highlights:

Detailed overview of parent market

Changing market dynamics in the industry

In-depth Polishing / Lapping Film market segmentation

Historical, current and projected market size in terms of volume and value

Recent industry trends and developments

Competitive landscape

Strategies of key players and products offered

Potential and niche segments, geographical regions exhibiting promising growth

A neutral perspective on market performance

Must-have information for market players to sustain and enhance their market footprint.

Browse Detailed Summary of Research Report with TOC @ https://www.futuremarketinsights.com/reports/sirens-market

Key Segments

Product Type:

Electronic

Electro-mechanical

Rotating

Single/dual toned

Omnidirectional

By Application:

Civil defense

Industrial signaling

Emergency vehicles

Home/vehicle safety

Security/warning systems

Military use

Others

By Installation Type:

Wall mounting

Self-standing

Water proof connector

By Regions:

North America

Europe

Asia Pacific

Latin America

MEA

2 notes

·

View notes

Text

Regional Analysis of the Advanced Ceramics Market: Opportunities and Challenges

The global advanced ceramics market was valued at approximately USD 107.00 billion in 2023 and is projected to experience a compound annual growth rate (CAGR) of 4.2% from 2024 to 2030. This growth is largely driven by the increasing demand for advanced ceramics across a variety of industries, alongside the expanding medical and telecom sectors. Advanced ceramics—often referred to as technical ceramics—are characterized by their enhanced properties, such as improved magnetic, optical, thermal, and electrical conductivity. These materials offer a range of benefits, including higher efficiency in end products, which helps reduce production and energy costs for manufacturers. Asia Pacific remains the dominant regional market for advanced ceramics, leading the world in consumption.

In the U.S., the growing demand for lightweight materials in diverse industries has been a key factor behind the rising consumption of advanced ceramics. This trend is particularly notable in the electrical and electronics sectors, where there is an increasing need for uninterrupted connectivity. The expansion of electric vehicle (EV) and defense industries in the country has also contributed significantly to the market's growth, further boosting the demand for advanced ceramics.

Gather more insights about the market drivers, restrains and growth of the Advanced Ceramics Market

Regional Insights

North America:

In 2023, North America accounted for more than 28.0% of the global advanced ceramics market revenue. The region’s market growth is being propelled by the flourishing electronics, medical, and electric vehicle (EV) sectors. A key factor driving market expansion in North America is the growing demand for high-performance semiconductors, which are essential for ultra-high frequency signal transmission and ensuring reliable connectivity in modern communication networks. This demand for advanced materials in the semiconductor industry is expected to further drive growth in the region.

US:

The U.S. advanced ceramics market is projected to grow at a CAGR of 4.0% during the forecast period. The rapid growth of the electronics, medical, and EV industries is expected to continue stimulating demand for advanced ceramics. Additionally, the rising need for high-quality semiconductors that enable better connectivity is expected to play a crucial role in the market’s expansion.

Europe:

The advanced ceramics market in Europe is poised for significant growth. A major factor driving this growth is the region's increasing focus on environmental sustainability and stringent regulations, which are pushing industries to adopt advanced ceramic materials known for their durability and eco-friendly attributes. Moreover, ongoing research and development (R&D) activities aimed at improving the properties of advanced ceramics, along with advancements in manufacturing processes, are expected to contribute to market growth in Europe.

Germany:

Germany plays a leading role in the European advanced ceramics market, thanks to its strong manufacturing base and cutting-edge technological capabilities. The automotive industry in Germany is a major consumer of advanced ceramics, using these materials in applications such as exhaust systems, engine components, and brake systems. Furthermore, Germany’s emphasis on renewable energy and sustainability is helping to drive the adoption of advanced ceramics in industries related to energy production and environmental technologies.

Asia Pacific:

The Asia Pacific region was the largest consumer of advanced ceramics in 2023, holding a market share of over 40.0%. The growth of the advanced ceramics market in this region is supported by the expansion of key industries such as electric vehicles (EV), medical devices, and electronics. For example, in November 2023, Hyundai Motor began construction of a KRW 2 trillion (USD 1.52 billion) EV plant in South Korea, which is expected to further boost demand for advanced ceramics. Rapid industrialization, urbanization, and infrastructure development across the region are also contributing to the growing demand for advanced ceramics, due to their superior properties such as high-temperature resistance, hardness, and corrosion resistance.

China:

China remains one of the largest markets for advanced ceramics in the Asia Pacific region, driven by its robust manufacturing capabilities, technological advancements, and favorable government policies that encourage innovation and industrial development.

India:

India’s advanced ceramics market is projected to grow steadily in the coming years, fueled by the rapid development of end-use industries such as healthcare, aerospace & defense, and electrical & electronics. Government initiatives like 'Make in India,' combined with increased investment in R&D, are expected to further propel the market’s growth.

Central & South America:

In Central and South America, the advanced ceramics market is witnessing steady growth, driven by factors such as rapid industrialization, infrastructural development, and the increasing adoption of advanced technologies across various sectors. Industries such as electronics, automotive, healthcare, and energy are particularly benefiting from the superior properties of advanced ceramics, including their high strength, thermal stability, and chemical resistance.

Brazil:

Brazil’s advanced ceramics market is set to experience significant growth, fueled by the country’s diverse industrial base, which includes sectors like manufacturing, aerospace, and oil & gas. Additionally, Brazil’s ongoing infrastructure projects and increasing investments in R&D are expected to further support market growth.

Middle East & Africa:

The advanced ceramics market in the Middle East and Africa is anticipated to see substantial growth over the forecast period. The Middle East, in particular, is a major hub for oil & gas exploration, and the demand for advanced ceramics in this sector is rising due to the materials' high-temperature resistance and wear properties, making them ideal for equipment and machinery used in harsh environments. Additionally, the healthcare sector in the region is expanding rapidly, driving the demand for advanced ceramics in medical devices and implants.

Saudi Arabia:

Saudi Arabia is expected to experience steady growth in the advanced ceramics market, largely due to its significant investments in infrastructure projects and its ambitious Vision 2030 plan, which aims to diversify the economy. The country's thriving petrochemical industry, along with a growing focus on renewable energy projects, provides ample opportunities for the adoption of advanced ceramics in a variety of applications.

Browse through Grand View Research's Category Advanced Interior Materials Industry Research Reports.

The global diamond market sizewas estimated at USD 41.49 billion in 2024, growing at a CAGR of 3.3% from 2025 to 2030.

The global blasting automation services market size was valued at USD 699.6 million in 2024 and is projected to grow at a CAGR of 14.5% from 2025 to 2030.

Key Companies & Market Share Insights

Some of the key players in the global advanced ceramics market include Kyocera Corp. and CoorsTek, both of which are renowned for their strong market presence and diverse product offerings in the ceramics industry.

Kyocera Corp.:

Kyocera Corporation, headquartered in Japan, is a multinational leader in electronics and ceramics manufacturing. The company’s advanced ceramics division offers a broad portfolio of products designed for various high-performance applications. These include cutting tools, industrial components, and electronic devices. Kyocera’s advanced ceramics are highly regarded for their exceptional quality, durability, and performance, making them a preferred choice across multiple industries. Notable sectors benefiting from Kyocera’s advanced ceramics include automotive, aerospace, and medical industries, where the materials' strength, wear resistance, and thermal stability are crucial. The company’s continued focus on innovation and material science has helped maintain its competitive edge in the market.

CoorsTek:

CoorsTek, a privately held company based in the United States, is another significant player in the advanced ceramics sector. Specializing in the production of technical ceramics, CoorsTek manufactures a wide range of advanced ceramic products that serve industries such as semiconductor manufacturing, medical devices, aerospace, and industrial equipment. The company's ceramics are particularly sought after for their reliability and precision in demanding applications. CoorsTek's diverse product offerings are essential for critical components that require high performance, such as semiconductor components, medical implants, and advanced mechanical parts. With a strong focus on technological innovation, CoorsTek continues to enhance its ceramic manufacturing capabilities to meet the evolving needs of its global customer base.

Both Kyocera and CoorsTek are leaders in advancing the capabilities of ceramic materials, driving innovations that meet the increasing demand for high-performance, sustainable, and cost-effective solutions in industries worldwide. Their continued investments in R&D and global manufacturing capacity further solidify their positions as key players in the rapidly expanding advanced ceramics market.

Key Advanced Ceramics Companies:

The following are the leading companies in the advanced ceramics market. These companies collectively hold the largest market share and dictate industry trends.

3M

AGC Ceramics Co., Ltd.

CeramTec GmbH

CoorsTek Inc.

Elan Technology

KYOCERA Corporation

Morgan Advanced Materials

Murata Manufacturing Co., Ltd.

Nishimura Advanced Ceramics Co., Ltd.

Ortech Advanced Ceramics

Saint-Gobain

Order a free sample PDF of the Market Intelligence Study, published by Grand View Research.

0 notes

Text

The Growing Demand for Quartz Powder and Its Industrial Uses

Quartz powder, a finely ground form of the naturally occurring mineral quartz, is widely used in a variety of industries due to its unique properties. It is a hard, chemically inert material with high resistance to heat and electrical conductivity, making it essential in manufacturing products that require durability, precision, and reliability. Quartz powder manufacturers play a pivotal role in supplying this versatile material to industries such as ceramics, glassmaking, paints, and electronics, among others.

What is Quartz Powder?

Quartz powder is produced by grinding quartz stones, which are primarily composed of silicon dioxide (SiO2), into fine particles. This powder can vary in size, ranging from a few microns to larger granules, depending on the end-use requirements. The mineral quartz is abundant in nature and comes in various forms, including rock crystal, amethyst, citrine, and rose quartz. These forms are processed to create powder, which is then refined to meet specific quality standards required by different industries.

The primary appeal of quartz powder lies in its physical properties. It is extremely hard and abrasion-resistant, making it a crucial material in the production of items that require sturdiness, such as tiles, countertops, and adhesives. Its natural transparency, combined with its high chemical stability, also makes it ideal for use in glass manufacturing, where it serves as a primary raw material for creating high-quality glass products.

Applications of Quartz Powder

Glass Industry: Quartz powder is one of the most important raw materials in glass production. It is used to make both flat and container glass, including bottles, windows, and decorative glass. The high purity of quartz powder ensures the production of clear, durable glass with excellent optical properties.

Ceramics: Quartz powder is an essential component in the ceramic industry, where it is used in the production of porcelain, tiles, and sanitary ware. Its high melting point and low thermal expansion make it an ideal additive for improving the strength and durability of ceramics.

Paints and Coatings: In the paint industry, quartz powder is used as a filler material to improve the texture and finish of coatings. It also enhances the durability and performance of paints, making them more resistant to wear and tear.

Electronics: Quartz powder plays a key role in the electronics industry, particularly in the production of semiconductors. It is used as a raw material for manufacturing components such as capacitors, transistors, and resistors. Its electrical insulation properties make it a preferred material for these applications.

Construction: In construction, quartz powder is used as a component of ready-mix concrete, providing the material with added strength and stability. It is also employed in the production of high-performance adhesives, sealants, and flooring.

Refractories: Quartz powder is used in the manufacture of refractory materials, which are resistant to high temperatures and are crucial in industries such as metallurgy and the production of steel. Its high melting point makes it indispensable in this sector.

Quality Standards for Quartz Powder

For quartz powder to be effective in its various applications, it must meet stringent quality standards. The purity of the quartz, which is typically measured as a percentage of SiO2, plays a significant role in determining the material’s performance. Manufacturers must ensure that the quartz powder is free from impurities such as iron, aluminum, and other trace elements that could compromise the final product’s quality.

Another important factor is particle size. Different industries have varying requirements when it comes to the fineness of quartz powder. For example, the glass industry typically requires ultra-fine quartz powder manufacturers, while the construction industry may be more concerned with coarser grades for specific applications.

Leading Quartz Powder Manufacturers

Quartz powder manufacturing requires specialized expertise and state-of-the-art technology to produce high-quality products that meet industry standards. Companies involved in the production of quartz powder must possess a strong commitment to quality control and innovation, ensuring their products contribute to the success of their customers.

One such company, Sudarshan Group, is recognized as a leading supplier of quartz powder in India. With years of experience in the industry, Sudarshan Group has established itself as a trusted name for its consistent quality, reliable supply, and dedication to customer satisfaction. The company’s commitment to delivering high-quality quartz powder has made it a preferred choice among a wide range of industries.

Conclusion

The demand for quartz powder continues to grow as industries strive for materials that offer superior performance and durability. From glass manufacturing to electronics, quartz powder is a versatile and essential material that contributes to the creation of countless everyday products. As more industries rely on quartz powder for various applications, the role of quartz powder manufacturers becomes even more crucial. Their ability to deliver high-quality, precision-grade products ensures that industries can maintain the quality and performance of their products. Companies like Sudarshan Group exemplify the high standards and expertise required to succeed in this competitive sector, making them key players in the quartz powder manufacturing industry.

0 notes

Text

Understanding Diamond Suspensions - An Overview

Diamond suspensions have emerged as a crucial tool in various industrial and scientific applications, providing a highly efficient means of polishing, grinding, and cutting materials. These suspensions consist of finely dispersed diamond particles suspended in a liquid medium, allowing for precise control over surface finishing and material removal processes. In this article, we will explore the composition, applications, benefits, and considerations associated with diamond suspensions.

Composition of Diamond Suspensions

At the core of diamond suspensions is the diamond particle, renowned for its exceptional hardness and wear resistance. These particles can vary in size, typically ranging from a few microns to several hundred microns, depending on the intended application. The diamond particles are mixed with a suitable liquid medium, which can be water-based or oil-based, along with various additives to enhance the suspension's stability and performance. The choice of liquid medium often depends on the specific requirements of the application, such as the type of material being worked on or the desired surface finish.

Applications of Diamond Suspensions

Diamond suspensions are used across multiple industries, including manufacturing, automotive, aerospace, and electronics. In the manufacturing sector, they are instrumental in precision grinding and polishing applications. The ability to achieve ultra-fine finishes makes diamond suspensions particularly valuable in the production of optical components, semiconductor wafers, and precision machinery parts. Additionally, diamond suspensions are utilized in dental applications for the polishing of dental prosthetics and instruments, ensuring a high level of accuracy and smoothness.

In the automotive and aerospace industries, these suspensions facilitate the machining of hard materials such as ceramics and superalloys. The exceptional hardness of diamond allows for efficient material removal while maintaining dimensional accuracy. Furthermore, in the electronics sector, diamond suspensions are employed in the production of integrated circuits and other microelectronic components, where surface integrity is paramount.

Benefits of Using Diamond Suspensions

The use of diamond suspensions offers numerous advantages over traditional grinding and polishing methods. Firstly, their hardness allows for superior material removal rates, resulting in faster processing times. This efficiency is particularly beneficial in high-volume production environments where time is of the essence. Secondly, diamond suspensions provide a consistent and controllable polishing action, reducing the risk of damage to delicate surfaces. This precision is crucial in applications where even minor imperfections can compromise the performance of the final product.

Moreover, diamond suspensions produce finer surface finishes compared to other abrasive materials, making them ideal for applications requiring a high level of surface quality. The use of diamond also minimizes the generation of heat during machining processes, which helps to preserve the integrity of heat-sensitive materials.

Considerations When Using Diamond Suspensions

While diamond suspensions offer significant advantages, several considerations must be taken into account when utilizing them. The cost of diamond particles can be relatively high compared to other abrasives, which may impact overall production costs. Additionally, the selection of the appropriate particle size and concentration is critical, as these factors directly influence the effectiveness of the suspension for specific applications.

Another important consideration is the proper maintenance and handling of diamond suspensions. Users must ensure that the suspensions are adequately mixed to prevent settling of the diamond particles, which can lead to uneven polishing or grinding. Moreover, proper cleaning and storage practices are essential to extend the life of the suspensions and maintain their performance.

Diamond suspensions represent a cutting-edge solution in the realm of precision machining and surface finishing. Their unique composition, characterized by the inclusion of hard diamond particles in a liquid medium, facilitates high efficiency and superior results in various industrial applications. As industries continue to demand higher precision and better surface finishes, the relevance of diamond suspensions will undoubtedly grow, paving the way for innovations that leverage their exceptional properties. Understanding their benefits and considerations will help manufacturers and technicians harness the full potential of diamond suspensions in their processes.

0 notes

Text

Processing & applications of refractory metal bar

The most common definition of refractory metals includes five elements: niobium, molybdenum, tantalum, tungsten, and rhenium. They share some properties, including a melting point above 2000 °C and high hardness at room temperature. Their machineabilities are quite different, we will introduce the processed & applications for these metal in solid bar form here.

Most common processing for refractory mental is sintering, that is press powder or mixed powder into certain shape, sintered in vacuum sintering furnace. This forms simply sintered metal blanks. Different temperature & sintering time is used for different material and dimensions. Simply sintered metal bars are basically used as additive in stainless steel and other no-ferrous alloys, to improve the properties. It only requires purity and limits gas elements for this usage.

Other applications which requires the material to be more dense, uniform grain, better machinability, resistance on temperature & wear. Forging, & repeat forging can make the material suitable for these applications. Metal bars can be forged from ingots, or smaller bars are cut from plates. Below we listed the applications for forged metal bars.

Niobium bar application: Electronic industry, chemistry, electronic industry, steel, ceramics, electronics, nuclear energy industries, and superconductor technology; melted cast ingots and alloying agents. Widely used in manufacturing various kinds of alloy steel, high temperature alloy, optical glass, cutting tool, electronics and superconducting materials and other industries.

Molybdenum bar application: Produce crucible for all the traditionally utilized procedures in the field of sapphire development, utilized as upgraded dissolving and cementing vessels, a wide range of glass liquefy, high power densities and the progression of power through power diodes and transistors create heat. molybdenum and its compounds are the ideal substrate for power hardware. At the point when utilized as a base plate, molybdenum dependably disseminates heat. Also, used as in other high temperature furnaces.

Based on different physical properties, Mechanical properties, Chemical properties, Machinability, Recrystallization behavior. Molybdenum alloys with various scopes of properties which are unequivocally built to meet the necessities of every individual application.

Tantalum bar application: Most important properties of tantalum are corrosion resistance & high melting point, it can be used any surroundings required these properties if not consider cost factor. Tantalum is a bit expensive compare to other refractory metals, this makes it is considered for extreme environments.

Tungsten bar application: to make emission cathodes, high temperature forming bars, support wires, printer pins, various electrodes, stainless steel additives, heating elements of quartz furnace, etc. They are also engaged in guns, rockets, satellites, airplanes and ships.

Rhenium bar is commonly used in the production of high temperature materials, super alloy additives and high temperature fields such as aerospace

Niobium & tantalum materials have much better ductility than molybdenum & tungsten, while tungsten has the poorest ductility & machineability amount all refractory metals. Our main non-ferrous metals are refractory metals, which are extraordinarily resistant to heat and wear. They are mostly used in the materials science, metallurgy and engineering, etc.

https://www.etimaterials.org/molybdenum/molybdenum-bar/ https://www.etimaterials.org/tantalum/ https://www.etimaterials.org/tungsten/tungsten-bar-2/

0 notes

Text

The Efficiency and Precision of Fiber Laser Machines

Fiber laser machines are transforming industries that require precise cutting, engraving, and marking capabilities. These high-performance machines use advanced fiber laser technology to generate a concentrated beam of light that delivers unparalleled accuracy and speed. As manufacturing demands grow, fiber laser machines are increasingly recognized as the ideal tool for applications that require fine detail, minimal waste, and high efficiency.

How Fiber Laser Machines Work

Fiber lasers produce an intense beam of light by amplifying light within fiber optics. The laser beam, created by an active fiber, is channeled through flexible fiber cables rather than mirrors or other optical systems. This technology is unique to fiber lasers and provides greater reliability, as the optical system requires minimal maintenance and eliminates the need for constant realignment. The focused energy of the laser allows for high-precision cuts, marking, and engraving on various materials, including metals, plastics, and some ceramics.

A significant feature of fiber laser machines is their efficiency in energy usage. Traditional lasers typically require more power to produce the same intensity, but fiber lasers operate with improved energy-to-light conversion rates, which reduces energy consumption and makes them environmentally friendly. Additionally, fiber lasers have longer lifespans due to their durable design, leading to lower maintenance costs and improved cost-efficiency over time.

Benefits of Fiber Laser Machines

Fiber laser machines are celebrated for their precision, making them an essential tool in industries where intricate designs and accuracy are paramount. They are frequently used in electronics, jewelry, medical device manufacturing, and automotive industries to cut, mark, or engrave metals and other materials. The quality of the cut provided by fiber lasers is exceptionally smooth, requiring minimal post-processing.

Another notable benefit of fiber laser machines is speed. Unlike traditional cutting methods, fiber lasers can cut through materials quickly and with great detail. This speed, combined with the precision of the cuts, allows manufacturers to boost productivity and meet higher production demands without compromising quality.

Fiber laser machines are also versatile in material compatibility. While they are especially effective on metals like stainless steel, aluminum, brass, and copper, fiber lasers can also handle non-metal materials like plastics and ceramics, depending on the machine's specifications. This adaptability makes them a valuable asset for businesses that work with diverse materials.

Applications of Fiber Laser Machines

The versatility and accuracy of fiber laser machines make them indispensable in various industries. In the electronics industry, they are used for marking and engraving components, ensuring clear, durable markings on tiny parts. The jewelry industry benefits from their ability to engrave intricate designs on metals without damaging delicate materials. Automotive and aerospace companies use fiber laser machines to cut components and mark parts with tracking information, which helps improve quality control.

Medical device manufacturers also use fiber lasers for engraving serial numbers and other markings, crucial for traceability in regulatory compliance. Additionally, small businesses and artists have found fiber lasers useful for custom engraving on items like gifts, awards, and decorative items.

Choosing the Right Fiber Laser Machine

Selecting the right fiber laser machine depends on several factors, including the type of material being processed, the desired level of precision, and production volume. Higher-wattage machines are suitable for thick metals, while lower-wattage models are ideal for detailed engraving. For a wide range of fiber laser machine options, visit iehk.com and explore various models that could fit your specific needs.

In summary, fiber laser machines represent an efficient, versatile solution for businesses looking to achieve high-quality cuts, engravings, and markings. With a range of applications across industries, they are a powerful tool for anyone looking to enhance production quality and efficiency.

1 note

·

View note

Text

Automotive Electronic Components & Thermal Management Solutions - Techni3

For more than two decades, Laird, a DuPont business, has capitalized on its materials science expertise to help Tier 1 automotive suppliers resolve complex electronics design challenges where the structure of the module causes EMI suppression and heat channeling issues. We are designers helping designers avoid wasted effort – and costs – and speeding the time-to-market for key automotive components.

Review our portfolio of automotive component protection solutions. Then contact us today.

Superior Protection From a Global Innovator in Material Science

EV Powertrain Electronics

Our team of engineers applies extensive industry knowledge about sub-assembly design to help safeguard automotive powertrain electronics from heat and EMI issues while resolving complex structural issues.

Examples include PFC chokes and transformers, which by their nature are not perfectly efficient and generate heat. Each must be housed individually – and thermally potted.

We get behind the wheel to help with thermal management solutions issues facing electric vehicles and offer two key differentiators. First, we are vertically integrated down to the magnetic ceramic powder. Second, as a significant thermal compounds supplier we are again vertically integrated down to the resins and fillers.

These differentiators help give us the green light to assume responsibility for automotive powertrain electronics performance and quality assurance across a much larger swath of the supply chain than our competitors.

LED Component Systems

Our team of engineers applies extensive industry knowledge about sub-assembly design to help suppress EMI crosstalk from LED automotive component systems. And to improve thermal management for electric vehicles, for example.

Modern lighting systems are comprised of a power supply, a digital control board, and a light source – all ideally physically separated from each other. The pressure to reduce size frequently results in placing the analog, digital, and optical functions close together and not electrically isolated. This can create electrical crosstalk and can expose the optics to processing chemicals needed for the analog and digital circuits.

Laird has a complete line of non-silicone and low outgassing silicone-based pads, greases and dispensable products. Most importantly, we have the experience to advise you about deploying a variety of strategies. Our multi-functional solutions help cool components and suppress EMI simultaneously – using a single space-saving product.

EV Powertrain ElectronicsADAS / Autonomous Driving Systems

Our team of engineers applies extensive industry knowledge about sub-assembly design to help safeguard ADAS electronic components from EMI and excessive heat while resolving complex structural issues.

Progressive ADAS sensor designs consume more power and emit more heat. To remain competitive, manufacturers must ensure optimum sensor efficiency or face the risk of throttled power, in turn sacrificing sensitivity, range and performance.

electromagnetic interference solutions is a barrier to function and compliance. Increasing transistor switching speeds cause various device fundamentals and harmonics to interact with each other, and the outside world, in unanticipated ways.

EV/PHEV Battery Packs

Our team of engineers applies extensive industry knowledge about sub-assembly design to help safeguard EV/PHEV battery packs from the consequences of excessive heat.

With increased charging speeds, battery packs emit ever increasing amounts of heat. Are packs actively or passively cooled? Must the thermal material act as a dielectric barrier? Is the pack silicone- or non-silicone mandated? Are the thermal materials themselves relied upon for mechanical support or for high compliance?

Ultimately, the appropriate choice of thermal interface materials satisfies the design constraints while simultaneously satisfying the economics. It comes after extensive evaluation of the total cost of ownership and true cost of implementation in a serial production setting. Huge material volumes are required. The importance of fast placement of preferred materials cannot be overstated.

Infotainment/Cluster Systems

Our team of engineers applies extensive industry knowledge of mechanical, thermal and electronic design to help safeguard infotainment/cluster systems from heat and EMI issues while resolving complex structural issues.

Infotainment electronics are employing greater functionality and higher speeds, causing more pronounced EMI and thermal challenges. A passive cooling strategy is imperative to eliminate the fan without relinquishing any gains in the power budget.

Following 20+ years of experience in infotainment electronics, Laird has a first-hand perspective on strategies that have succeeded and failed. We consult with our customers comprehensively on ridding systems of unwanted EMI and growing thermal loads, and on helping design teams succeed as they go-to-market.

0 notes

Text

Magnesium oxide ceramics

Magnesium oxide is widely used as an industrial refractory material because its melting point is almost the highest among common oxides, about 2800℃, which is higher than common refractory materials such as zirconium oxide (about 2700℃) and aluminum oxide (about 2050℃). In addition to its high melting point, magnesium oxide also has other advantages, such as good chemical stability, and is not easy to react with metals when used for alloy casting; magnesium oxide is prone to hydration reaction, especially in the presence of acid, it will dissolve quickly; magnesium oxide has a stable structure and good high-temperature thermal insulation performance... With various advantages, magnesium oxide has been developed into refractory materials such as crucibles for melting metals, ceramic cores for metal casting, thermocouple sleeves, and electric heating tubes, while other properties and uses have been ignored.

In recent years, due to the increasing requirements of modern industrial technology for materials, some other excellent properties of magnesium oxide ceramics have gradually attracted people's attention, especially microwave dielectric properties and optical properties.

1. Microwave dielectric properties. Magnesium oxide ceramics are very excellent low-dielectric microwave dielectric materials with extremely low dielectric loss. Their dielectric constant is about 9, and tanδ<1.6×10-6, which is comparable to or even better than the microwave dielectric properties of the most commonly used alumina ceramics. More importantly, the sintering temperature of alumina ceramics is relatively high, usually above 1500°C. Although liquid phase sintering greatly reduces the sintering temperature, the microwave dielectric properties will also deteriorate. In contrast, magnesium oxide microwave dielectric ceramics can be obtained at very low temperatures. For example, someone added 4% LiF to MgO and sintered it at 950°C to obtain magnesium oxide microwave dielectric ceramics with good microwave dielectric properties. Its dielectric constant is 9.6, and the Q×f value can reach 282230GHz. By extending the insulation time, its Q×f value can even be greatly increased to 751500GHz. Considering that the density of magnesium oxide is also lower than that of alumina, and its thermal conductivity is good (the thermal conductivity of pure magnesium oxide is about 55W/m·K), it can be expected that it should have good application prospects as a substrate material.

2. Optical properties. As an inorganic non-metal with a face-centered cubic structure, magnesium oxide crystals are transparent, and their linear transmittance under visible light exceeds 80%. Therefore, through appropriate sintering processes, magnesium oxide ceramics can obtain higher transparency. For example, someone used SPS technology to obtain transparent 0.02at%Yb-doped magnesium oxide ceramics at 1100℃/60min, and its linear transparency under visible light exceeded 70%. Another special feature of magnesium oxide transparent ceramics is that the wavelength range of transmission is very wide, and the transmittance is higher at infrared wavelengths. For example, someone prepared 1%LiF-doped magnesium oxide ceramics, and its light transmittance exceeded 80% in the wavelength range of 2000-6000nm, and the highest was about 86%, which is not much lower than the current magnesium aluminum spinel with too high infrared transmittance. Another feature of transparent magnesium oxide is that it is relatively easy to prepare. We know that under pressureless conditions, transparent aluminum oxide often needs to be sintered at a high temperature of about 1800℃ in a hydrogen furnace to obtain it. In comparison, it is much easier to prepare transparent magnesium oxide. For example, someone used nano-magnesium oxide powder as raw material, sintered it at 1400℃ in an ordinary muffle furnace for 2 hours, and obtained translucent magnesium oxide with a density of 98.1%. Therefore, we can reasonably infer that transparent magnesium oxide ceramics have the potential to become high-performance infrared window materials.

0 notes

Text

Vacuum Coating Equipment Market Trends and Opportunities: Global Outlook (2023-2032)

The global demand for Vacuum Coating Equipment was valued at USD 25154.8million in 2022 and is expected to reach USD 40702.1 Million in 2030, growing at a CAGR of 6.20% between 2023 and 2030

Vacuum coating equipment is a specialized technology used to apply thin films or coatings to various surfaces under vacuum conditions. This equipment is widely employed across industries such as electronics, automotive, aerospace, optics, and packaging, where it is used to enhance surface properties like durability, corrosion resistance, electrical conductivity, and optical reflectivity. Vacuum coating processes, including physical vapor deposition (PVD) and chemical vapor deposition (CVD), allow for the precise deposition of metals, ceramics, and other materials onto substrates. The vacuum environment ensures high-quality coatings with uniform thickness and minimizes contamination, making it ideal for producing high-performance components like semiconductor chips, solar panels, and decorative coatings on consumer products. As industries increasingly focus on energy efficiency, sustainability, and advanced manufacturing techniques, the demand for vacuum coating equipment continues to grow, driven by its versatility and ability to produce superior coatings for a wide range of applications

The vacuum coating equipment market has been experiencing steady growth, driven by technological advancements, increasing demand across various industries, and the need for high-performance, durable coatings. Key findings from recent market studies highlight several important trends and factors influencing the growth and future direction of this market:

1. Strong Demand from Electronics and Semiconductor Industry

The electronics and semiconductor industries are among the largest consumers of vacuum coating equipment. As the demand for advanced electronics, smartphones, displays, and semiconductor devices grows, there is a corresponding increase in the need for vacuum coatings to enhance the performance, durability, and functionality of electronic components. Thin films produced using vacuum coating processes like physical vapor deposition (PVD) are critical for semiconductor manufacturing, contributing to significant growth in this segment.

2. Growth in Solar Energy and Renewable Technologies

The rise in renewable energy, particularly the growth of solar energy, is driving demand for vacuum coating equipment used in the production of solar panels. Thin-film solar cells require precise vacuum deposition to achieve the desired efficiency and energy absorption. As governments and industries push for cleaner energy sources, the solar power sector continues to expand, presenting a key growth opportunity for the vacuum coating equipment market.

3. Automotive Industry Shift Toward Lightweight and Durable Materials

The automotive industry is increasingly adopting vacuum coating technologies to improve the performance and aesthetic appeal of components. The use of vacuum coatings on automotive parts such as headlights, mirrors, and decorative trims enhances durability and resistance to wear, corrosion, and heat. Moreover, the shift toward electric vehicles (EVs) and lightweight materials is boosting the demand for coatings that reduce friction and improve efficiency, further driving the use of vacuum coating equipment in the automotive sector.

4. Technological Advancements in Coating Processes

Ongoing advancements in vacuum coating technologies, including the development of new materials, improved deposition techniques, and automation, are contributing to market growth. Innovations in thin-film deposition techniques, such as magnetron sputtering, ion beam deposition, and advanced PVD and CVD methods, are enabling the production of highly precise coatings with enhanced properties. These advancements are attracting industries that require cutting-edge solutions, such as aerospace, medical devices, and optics.

5. Increasing Use in Medical Devices and Healthcare Applications

Vacuum coatings are increasingly used in the medical devices and healthcare sectors to improve the performance and longevity of instruments and implants. Biocompatible coatings produced via vacuum deposition enhance the wear resistance and corrosion resistance of medical implants, surgical tools, and diagnostic equipment. With the rising demand for advanced medical technologies and minimally invasive devices, the vacuum coating equipment market is gaining momentum in this sector.

6. Rising Focus on Energy Efficiency and Sustainable Manufacturing

As industries seek to reduce their environmental impact and improve energy efficiency, vacuum coating equipment manufacturers are focusing on developing energy-efficient systems. Modern vacuum coating equipment offers high throughput, low energy consumption, and minimal material waste, aligning with global sustainability goals. The push for greener manufacturing processes is encouraging the adoption of vacuum coating technologies across industries such as packaging, where sustainable and recyclable coatings are becoming more popular.

7. Asia-Pacific Dominates the Market

The Asia-Pacific region, particularly countries like China, Japan, South Korea, and Taiwan, is the largest and fastest-growing market for vacuum coating equipment. This growth is driven by the region’s dominance in electronics manufacturing, semiconductor production, and the rapid expansion of the automotive and solar energy industries. Additionally, government support for industrial modernization and advanced manufacturing technologies is boosting the adoption of vacuum coating equipment in the region.

8. Automated and Digitalized Equipment

The trend toward automation and digitalization is impacting the vacuum coating equipment market, with manufacturers integrating IoT (Internet of Things), artificial intelligence (AI), and advanced control systems into their machines. Automated vacuum coating systems allow for real-time monitoring, remote operation, and enhanced process control, improving overall efficiency and reducing operational costs. This shift toward smarter, automated equipment is attracting industries that require high-precision, reliable coating processes.

9. Challenges of High Initial Investment

One of the key challenges facing the vacuum coating equipment market is the high initial cost of purchasing and maintaining advanced systems. While vacuum coating offers long-term cost savings and performance benefits, the upfront investment can be a barrier for small and medium-sized enterprises (SMEs). However, the return on investment (ROI) in terms of improved product quality and extended product lifespan is encouraging more companies to adopt these technologies despite the initial cost hurdles.

10. Competitive Landscape and Strategic Collaborations

The vacuum coating equipment market is highly competitive, with several key players investing in research and development to innovate and expand their product offerings. Major companies such as Applied Materials, Inc., Bühler Group, ULVAC Technologies, Oerlikon Balzers, and Singulus Technologies are at the forefront of technological advancements in the market. Strategic partnerships and collaborations between manufacturers, research institutions, and end-user industries are driving innovation and helping companies meet the evolving demands of various sectors

Access Complete Report - https://www.credenceresearch.com/report/vacuum-coating-equipment-market

Key Players

Applied Materials

Lam Research

Leading Coating

IHI

BOBST

Buhler Leybold Optics

Mustang Vacuum Systems

Denton Vacuum, LLC

Oerlikon Balzers

Von Ardenne

S Incon

DE TECH

Optorun

Kyky Technology

Foxin Pvd

ULVAC

Kolzer

The vacuum coating equipment market is shaped by several trending factors that are driving its growth and influencing its future direction. These trends reflect technological advancements, evolving industry needs, and broader market dynamics across various sectors such as electronics, automotive, healthcare, and renewable energy. Here are the key trending factors in the vacuum coating equipment market:

1. Increasing Demand for Miniaturization in Electronics

The electronics industry’s push towards miniaturization, especially in semiconductors, microchips, and wearable devices, is driving the demand for advanced vacuum coating technologies. As electronic components become smaller and more complex, precise thin-film coatings are required to ensure functionality, durability, and performance. Vacuum coating equipment, particularly for processes like physical vapor deposition (PVD) and chemical vapor deposition (CVD), plays a critical role in meeting these requirements. The growing production of smartphones, sensors, microelectromechanical systems (MEMS), and other high-tech devices is fueling this trend.

2. Expansion of Renewable Energy Sector

The renewable energy sector, particularly solar energy, is a major growth driver for vacuum coating equipment. Thin-film solar cells, which require high-quality vacuum coatings for improved efficiency and longevity, are becoming increasingly popular as the world moves towards sustainable energy solutions. Solar panel manufacturers rely on vacuum coating equipment to deposit thin layers of materials such as cadmium telluride (CdTe) or amorphous silicon to enhance energy absorption. The rising global focus on clean energy and government initiatives promoting solar power adoption are creating a strong demand for vacuum coating technology in this sector.

3. Growth in the Automotive Industry

The automotive industry is increasingly adopting vacuum coating technologies to improve the aesthetics, durability, and functionality of vehicle components. Vacuum coatings are used in headlights, mirrors, trim parts, and engine components to enhance their resistance to wear, heat, and corrosion. With the rise of electric vehicles (EVs) and the focus on lightweight materials, the need for specialized coatings to reduce friction and improve energy efficiency is growing. Additionally, vacuum coating is used in decorative applications to give vehicle parts a premium metallic finish without compromising environmental regulations, making it a growing trend in automotive design and production.

4. Advancements in Medical Devices and Healthcare Applications

The medical devices sector is another key area where vacuum coating equipment is seeing increased demand. Biocompatible coatings produced through vacuum deposition are essential for medical implants, surgical instruments, and diagnostic tools, improving their wear resistance, corrosion protection, and overall performance. The increasing development of minimally invasive devices, along with the rising demand for advanced healthcare technologies, is driving the adoption of vacuum coating technologies in this field. This trend is particularly relevant as the global healthcare sector continues to expand and innovate.

5. Rising Demand for Energy-Efficient Coating Systems

As industries worldwide focus on reducing energy consumption and improving operational efficiency, the demand for energy-efficient vacuum coating systems is rising. Manufacturers are developing vacuum coating equipment with advanced energy management systems that minimize power usage while maximizing throughput. The trend towards greener manufacturing practices is also pushing for vacuum coating technologies that offer low emissions, minimal material waste, and sustainable energy sources. Energy-efficient equipment is particularly in demand in industries like automotive, electronics, and packaging, where sustainability is becoming a critical focus.

6. Increased Use of Smart and Automated Vacuum Coating Equipment

The integration of smart technologies, such as IoT (Internet of Things), AI (Artificial Intelligence), and real-time monitoring systems, into vacuum coating equipment is gaining traction. Automated vacuum coating systems allow for improved process control, monitoring of critical parameters like temperature and pressure, and predictive maintenance to prevent equipment failures. These smart systems reduce downtime, optimize coating quality, and increase overall operational efficiency. Automation and digitalization are becoming key trends, particularly in industries like semiconductor manufacturing, where precision and efficiency are paramount.

7. Growing Adoption of Multi-Functional Coatings