#Nuts Manufacturing and Processing

Explore tagged Tumblr posts

Text

#cashew machine#cashew processing machine#cashew machinery#cashew processing process#parivartan cashew machinery#cashew nut processing machine#fully automatic cashew processing plant#Cashew processing machinery manufacturer

0 notes

Text

How to Start a Nut Bolt Manufacturing Business

Want to start your own Nut Bolt Manufacturing Business and unlock massive earning potential? 🛠️✨ Follow us now for expert tips and step-by-step guides! 🚀 #NutBoltBusiness #SmallScaleManufacturing #StartupOpportunities

Nuts and bolts are two different tools made of iron or steel, they are often used together to give the final shape to structures or to fasten them. Nuts and bolts are the most important items used in industries to make structures. They are available in many shapes, colours, and sizes. India is one of the fastest-growing manufacturing industries in the world, and manufacturing and infrastructure…

#bolt nut manufacturing business#business ideas#business ideas 2025#how to start a bolt and nut manufacturing business#manufacturing business from home#manufacturing business ideas#new business ideas#nut and bolt business#nut and bolt manufacturing business#nut bolt#nut bolt business#nut bolt machine#nut bolt making business#nut bolt making machine#nut bolt manufacturing#nut bolt manufacturing business ideas#nut bolt manufacturing process#small business ideas

0 notes

Text

Best Nuts Honey Manufacturer & Supplier in India - Molten Gold

In the heart of India, where tradition meets innovation, Molten Gold stands as a beacon of excellence in the realm of nuts honey manufacturing. Known for its unparalleled quality and commitment to purity, Molten Gold has carved a niche for itself as the best nuts honey manufacturer and supplier in India. This blog explores the journey, quality, and unique offerings of Molten Gold, highlighting why it is the preferred choice for honey enthusiasts and health-conscious consumers alike.

A Legacy of Purity and Quality

Molten Gold's journey began with a simple yet profound vision: to provide the finest quality honey infused with the goodness of premium nuts. With a deep-rooted commitment to purity, Molten Gold sources its honey from the most pristine and unpolluted regions of India. The brand's dedication to quality is evident in every jar of nuts honey it produces. Each batch undergoes rigorous testing to ensure it meets the highest standards of purity and taste.

Unique Offerings

What sets Molten Gold apart from its competitors is its innovative approach to honey production. The brand specializes in creating unique blends of honey infused with a variety of nuts. From almonds and cashews to walnuts and pistachios, Molten Gold offers a delightful range of nuts honey that caters to diverse tastes and preferences. Each blend is crafted with precision, ensuring that the nuts and honey complement each other perfectly, creating a harmonious symphony of flavors.

Health Benefits of Nuts Honey

Nuts honey is not just a treat for the taste buds; it is also a powerhouse of health benefits. The combination of honey and nuts provides a rich source of essential nutrients, antioxidants, and healthy fats. Regular consumption of nuts honey can boost immunity, improve digestion, enhance heart health, and provide sustained energy. Molten Gold’s nuts honey, made from the finest ingredients, ensures that consumers receive maximum health benefits in every spoonful.

Sustainable and Ethical Practices

Molten Gold is not just about producing high-quality nuts honey; it is also committed to sustainable and ethical practices. The brand works closely with local beekeepers and nut farmers, ensuring fair trade and sustainable sourcing. By supporting local communities and adopting eco-friendly practices, Molten Gold contributes to the preservation of biodiversity and the promotion of sustainable agriculture.

Customer-Centric Approach

At the core of Molten Gold's success is its unwavering focus on customer satisfaction. The brand goes above and beyond to ensure that its customers have a delightful experience with every purchase. From easy online ordering to prompt delivery and exceptional customer service, Molten Gold leaves no stone unturned in meeting and exceeding customer expectations.

Awards and Recognition

Molten Gold's commitment to excellence has not gone unnoticed. The brand has received numerous awards and accolades for its superior quality nuts honey and ethical practices. These recognitions serve as a testament to Molten Gold's dedication to maintaining the highest standards in the industry.

Conclusion

In the crowded marketplace of honey manufacturers, Molten Gold shines brightly as the best nuts honey manufacturer and supplier in India. With its unwavering commitment to quality, innovative offerings, health benefits, sustainable practices, and customer-centric approach, Molten Gold has earned the trust and loyalty of consumers across the country. Whether you are a health enthusiast or a connoisseur of fine honey, Molten Gold's nuts honey promises a delightful and nutritious experience that is second to none. Experience the golden touch of Molten Gold and elevate your honey consumption to a whole new level of excellence.

#Best nuts honey manufacturer in India#Top supplier of nuts honey in India#Premium nuts honey products India#Organic nuts honey manufacturer India#Leading exporter of nuts honey from India#High-quality nuts honey supplier India#Nuts honey with almonds and cashews India#Buy nuts honey online in India#Natural nuts honey brand India#Pure nuts honey manufacturer India#Best price for nuts honey India#Where to buy nuts honey in India#Best nuts honey for health benefits India#Wholesale nuts honey supplier India#Trusted nuts honey manufacturer India#Best nuts honey for immunity India#Nuts honey with walnuts and pistachios India#Nuts honey production process in India#Top-rated nuts honey brand India#Ethical nuts honey supplier India

0 notes

Text

10000 Ton Per Year

Fully Automatic plant, with centralized controls, parallel continuous processing with lowest ever cost of conversion.

A well integradted cashew processing plant, includes different sections and makes an Industrial level investment. With more and more automation in place, now the labour requirement is at its miminum.

Our specialisation is an online processing plant, which further reduces manpower requirements, visit us for more information on an industrial scale plant.

#cashew#cashew machine#cashew processing machine#cashew nut machine#automatic cashew shelling machine#10000 ton turnkey project#cashew machine manufacturing

0 notes

Text

Cashew Processing Machinery, Cashew Nut Processing Machine, Cashew Processing Machines Unit Manufacturer and Supplier - Gayathri Industries

#Cashew Processing Machinery#Cashew Nut Processing Machine#Cashew Processing Machines Unit Manufacturer and Supplier - Gayathri Industries

0 notes

Text

Unique jewelry made from the foraged shells of black walnuts. Black walnuts, well known for the hardness of their shells and their use for production of dark dye or ink, are also a symbol of protection, mindfulness, growth, and wisdom.

Each piece of one-of-a-kind! It should be noted that no pair of earrings will match exactly, instead I have paired them by approximate similarity in shape and size.

Each shell is carefully cleaned and sealed. Care is still recommended when wearing them, especially pieces that use jump rings instead of eye hooks, because the drilled holes could be structurally fragile depending on location and thickness.

Not recommended if you have a known allergy to walnuts or other nuts that can cause skin irritation. They're cleaned and sealed but I would rather you not take the chance!

As with all new earrings, I highly recommend you disinfect the hooks before wearing. The manufacturing and shipping process are not done in a perfectly sterile environment.

Come visit my shop today!

24 notes

·

View notes

Note

I hate it when people say Blackrock doesn't have decent food or have no culture at all. ''They're all to busy doing work for Blackrock to have a culture'' BITCH THERES A THING CALLED WORK CULTURE TOO. As long as there's people/demons there's going to be a basis for how they would interact with each other ''oh it's too cold to grow food there'' ??? THERES STILL A DECENT FOOD SOURCE IN COLD PLACES?? REINDEER. BIRDS. FISHES. FUCK MAYBE EVEN PENGUINS, SEALS AND WHALES SINCE THEY PROBABLY ARENT ENDANGERED IN THEIR WORLD AND IS A PROBABLE FOOD SOURCE. ASSUMING THEY DONT WASTE ANY PART THEY GET ENOUGH NUTRIENTS. They don't need to grow food to have some food. They could just hunt yk yk. Still, as much as fun to think Blackrock's region is all ice snow and rock I do want to think it's more like ''our climate cold af and our winters long and horrible but we do get summer long enough tbh'' bet their wheat and other grains is genetically engineered to be more resistant to the cold, I just searched it up and it turns out Rye is most resistant to the cold so I guess Blackrock has Rye as one their most common grain. Secondly I believe their food are PACKED with nutrients. Made to only take a small bite or two and giving you an energy boost to get trough the day, some come with a LOT of flavour some too bland, but the richer you are the more flavor choices you got. I wanna believe Blackrock makes insane bread. Bread with cheese. Bread with nuts . Bread with berries and nuts. Bread so sweet it should be dessert. Bet they bank on sandwiches too. Bet they could make grilled cheese that can kill you. I'm not forgetting demons don't need to eat but they can still want. And I'd like to think of reasons why. As funny as it is, it also feels so lazy to just say "yeah their food bland af haha" about Blackrock man

A lot of these are actually good points (and I love world building backed up by real world phenomena and whatnot!!).

I could see how “the government would want to waste resources on making actually good food for their population so it’s all over processed tasteless bars” could be an excuse but… they literally don’t need to eat. Eating in that sense would just be more of a want. Why waste resources manufacturing products that people literally don’t want,,

Honestly, seeing how their faction is portrayed (in both fan and canon material), I would say that their (work) culture would be something to the effect of the work culture of modern South Korea/Japan (with the whole thing about cram schools, insanely brutal work culture, and ALL HAIL SAMSUNG) with European influences here and there because I hc that.

But yeah that”s my two cents sorry if that went a little bit more hc-y

#phighting hot takes#phighting!#phighting roblox#roblox phighting#phighting#hot take#💬mod yapgraft💬#blackrock phighting#GLORY TO SAMSUNG

27 notes

·

View notes

Text

History Fun Fact #7

Despite popular belief, George Washington Carver did not invent Peanut Butter. Peanuts, which are native to the New World tropics, were mashed and ground roasted peanuts into paste by Ancient Incas and the Aztecs hundreds of years ago. Evidence of modern peanut butter that we've come to know today, comes from US patent #306727 issued to Marcellus Gilmore Edson of Montreal, Quebec in 1884, for a process of milling roasted peanuts between heated surfaces until the peanuts reached "a fluid or semi-fluid state." As the product cooled, it set into what Edson described as "a consistency like that of butter, lard, or ointment." In 1890, George A. Bayle Jr., owner of a food business in St. Louis, manufactured peanut butter and sold it out of barrels. J.H. Kellogg, yes the cereal dude, when he's not obsessed with circumcising babies. Secured US patent #580787 in 1897 for his "Process of Preparing Nutmeal," which produced a "pasty adhesive substance" that Kellogg called "nut-butter." And the claim that Carver discovered hundreds of new and important uses for the peanut, Fathered the peanut industry, and Revolutionized southern US agriculture. False. Research done by Barry Mackintosh, who served as bureau historian for the National Park Service (which manages the G.W. Carver National Monument), states the following:

"Most of Carver's peanut and sweet potato creations were either unoriginal, impractical, or of uncertain effectiveness. No product born in his laboratory was widely adopted. The boom years for Southern peanut production came prior to, and not as a result of, Carver's promotion of the crop. Carver's work to improve regional farming practices was not of pioneering scientific importance and had little demonstrable impact."

39 notes

·

View notes

Text

#cashew machine#cashew processing machine#cashew machinery#cashew processing process#parivartan cashew machinery#cashew nut processing machine#cashew nut processing plant manufacturer#Cashew processing machinery manufacturer

0 notes

Note

What kind of work can be done on a commodore 64 or those other old computers? The tech back then was extremely limited but I keep seeing portable IBMs and such for office guys.

I asked a handful of friends for good examples, and while this isn't an exhaustive list, it should give you a taste.

I'll lean into the Commodore 64 as a baseline for what era to hone in one, let's take a look at 1982 +/-5 years.

A C64 can do home finances, spreadsheets, word processing, some math programming, and all sorts of other other basic productivity work. Games were the big thing you bought a C64 for, but we're not talking about games here -- we're talking about work. I bought one that someone used to write and maintain a local user group newsletter on both a C64C and C128D for years, printing labels and letters with their own home equipment, mailing floppies full of software around, that sorta thing.

IBM PCs eventually became capable of handling computer aided design (CAD) work, along with a bunch of other standard productivity software. The famous AutoCAD was mostly used on this platform, but it began life on S-100 based systems from the 1970s.

Spreadsheets were a really big deal for some platforms. Visicalc was the killer app that the Apple II can credit its initial success with. Many other platforms had clones of Visicalc (and eventually ports) because it was groundbreaking to do that sort of list-based mathematical work so quickly, and so error-free. I can't forget to mention Lotus 1-2-3 on the IBM PC compatibles, a staple of offices for a long time before Microsoft Office dominance.

CP/M machines like Kaypro luggables were an inexpensive way of making a "portable" productivity box, handling some of the lighter tasks mentioned above (as they had no graphics functionality).

The TRS-80 Model 100 was able to do alot of computing (mostly word processing) on nothing but a few AA batteries. They were a staple of field correspondence for newspaper journalists because they had an integrated modem. They're little slabs of computer, but they're awesomely portable, and great for writing on the go. Everyone you hear going nuts over cyberdecks gets that because of the Model 100.

Centurion minicomputers were mostly doing finances and general ledger work for oil companies out of Texas, but were used for all sorts of other comparable work. They were multi-user systems, running several terminals and atleast one printer on one central database. These were not high-performance machines, but entire offices were built around them.

Tandy, Panasonic, Sharp, and other brands of pocket computers were used for things like portable math, credit, loan, etc. calculation for car dealerships. Aircraft calculations, replacing slide rules were one other application available on cassette. These went beyond what a standard pocket calculator could do without a whole lot of extra work.

Even something like the IBM 5340 with an incredibly limited amount of RAM but it could handle tracking a general ledger, accounts receivable, inventory management, storing service orders for your company. Small bank branches uses them because they had peripherals that could handle automatic reading of the magnetic ink used on checks. Boring stuff, but important stuff.

I haven't even mentioned Digital Equipment Corporation, Data General, or a dozen other manufacturers.

I'm curious which portable IBM you were referring to initially.

All of these examples are limited by today's standards, but these were considered standard or even top of the line machines at the time. If you write software to take advantage of the hardware you have, however limited, you can do a surprising amount of work on a computer of that era.

44 notes

·

View notes

Text

finally!! finished the guitar pedal my dad got the kit for like a year and a half ago

i redesigned it from scratch because the construction of the original clone was annoying and i think it’s dumb that guitar pedals sometimes use reverse-polarity power and you’re just supposed to guess, so this one takes either polarity through the same jack.

photographic evidence of how this distortion pedal works! based on the Proco RAT of 70s fame, essentially we just clip the signal peaks to introduce other frequencies, which make up the distortion we hear. the FFT on my scope didn’t show much, but either i didn’t tune it right or the instrumentation is just limited here, because we can see pretty clearly the flattened peaks on the processed signal (2, 3) compared to the input (1).

i learned some things about design for manufacturing (DFM) from this project, not just from the original clone board but also from shortcomings of my own design (it turns out that’s a LOT of wires to manage in that small space). if i did it over, i’d put the pins on a 0.1” pitch grid across the board, probably use larger components, and take more care in choosing the shape of the PCB to fit the enclosure around all the hardware. I might even have split it up into a few tiny boards! just for kicks. i also probably would have soldered wires onto the kick switch at an angle, so that they’re not stressed or bent on their way to their final configurations.

the light pipe in particular was a challenge because it turned out the cap on the pipe was small enough that it would slide all the way through the hole meant for a THT LED. I could have fixed this with a washer if I had one, but I eventually hot glued a nut to the cap and let it be.

big thanks to my friends and partners including @thinkpadt530 who helped me with this! i learned a lot from them all, and definitely would not have finished without them. <3

7 notes

·

View notes

Text

Is oat milk actually healthy at all?

https://www.telegraph.co.uk/health-fitness/diet/nutrition/is-oat-milk-healthy/

Where once in a café you would simply need to choose between a flat white, cappuccino or latte, these days, it’s all about the milk. Oat, almond, pea, soya, or good old cow’s, the options are seemingly endless.

And amongst the various plant-based alternatives, the nation has a clear favourite. Oat milk has left behind its competitors and is the UK’s most popular non-dairy milk, with around a third of Britons drinking it, according to a 2021 report.

The smooth and creamy plant-based alternative has gained a loyal fanbase amongst young people, with the oat milk latte being a favourite, however its appeal extends far beyond.

Those who are lactose intolerant, have nut allergies or are simply trying to reduce their dairy intake find the taste and texture of oat milk (undoubtedly the best plant-based alternative to froth for a coffee) impossible to resist.

But, as we become increasingly aware of the dangers posed by ultra-processed foods (UPFs), and with many of us prioritising protein-rich and nutritional diets, is oat milk really as healthy as we think?

What exactly is oat milk?

In its simplest form, oat milk is made from oats and water. The two ingredients are blended together and the solids are strained out. Really, you could easily make a batch at home.

However, many packaged variations contain added ingredients such as sweeteners and thickeners to improve the milk’s texture, shelf life, and nutritional value. They are also processed and fortified in different ways – all of these components determine how healthy the final product is.

“Some manufacturers will make it from an oat-based syrup,” explains Jenna Hope, a registered nutritionist and author of How To Stay Healthy. “They’ll essentially mill, refine, and process the oats then combine that base with water. Emulsifiers, thickeners, oils, and fortified nutrients are often then added as well.”

Unsweetened oat milk contains around 45 calories, 1.4 grams of fat, 0.4 grams of protein, and 6.5g of carbohydrates per 100ml.

2 notes

·

View notes

Text

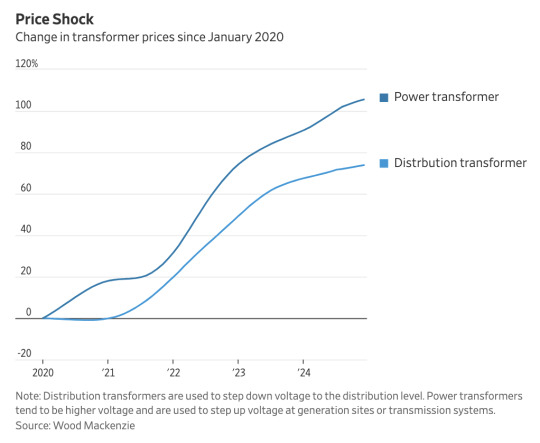

How Tariffs Could Shock America’s Power System. (Wall Street Journal)

Excerpt from this Wall Street Journal story:

America’s power grid is due for some big investments. Tariffs could now make that much costlier.

As surging power demand from places such as data centers is set to strain the system, transformers, the nuts and bolts of the power system, look particularly vulnerable. These are devices that step up or down voltages as electricity moves from power plants to homes and factories. New ones are also required every time a new source of electricity—whether wind, solar or natural gas—connects to the grid. The lack of these components can therefore hold up more power from being brought online.

The power industry has already been experiencing a shortage of transformers, for which demand is expected to jump even more in the coming years. Suppliers have been reluctant to invest large sums of capital to expand production capacity because such investments have long break-even timelines, according to a report from Wood Mackenzie.

The National Renewable Energy Laboratory estimates that about 55% of in-service distribution transformer units are older than 33 years and approaching their end of life. Distribution transformer capacity might need to increase 160% to 260% by 2050 compared with 2021 levels to meet demand, according to the NREL.

So far, the Trump administration has imposed 25% tariffs on steel and aluminum, as well as a 10% across-the-board tariff on China. But more could come: The one-month pause on Trump’s proposed 25% tariffs on Canada and Mexico is set to expire in early March. Meanwhile, Trump has ordered federal agencies to explore reciprocal tariffs on trading partners around the world. He has also floated tariffs on copper.

Transformers could become a chokepoint. Only about 20% of transformer demand can be met by the domestic supply chain, according to Wood Mackenzie, which also estimated that transformer prices have already risen 70% to 100% since January 2020 because of inflation for raw materials such as electrical steel and copper. Steel is also an essential component of transformers, and notably, Cleveland-Cliffs is the only domestic producer of grain-oriented electrical steel for them. Assuming that Trump moves ahead with 25% tariffs on Canada and Mexico, and imposes tariffs on copper as well, Wood Mackenzie estimates that transformer prices could increase by an additional 8% to 9%.

Mexico, Canada and China are important sources of electrical equipment to the U.S. In 2024, China accounted for over 32% of U.S. low-voltage transformer equipment imports and Mexico accounted for 36% of high-voltage transformer imports, according to Wood Mackenzie. Canada accounted for about 16% of U.S. imports of high-voltage switchgear and 100% of imported utility poles. Utilities typically go through a lengthy process to test the reliability of transformers they are purchasing and tend to require custom specifications, so it isn’t an easy process to switch to a new supplier, notes Chris Seiple, Wood Mackenzie vice chairman.

Worth watching is whether tariffs become a tailwind for U.S. manufacturers. GE Vernova said at a conference Wednesday that it is too early to determine what the tariffs’ financial implications are for the company. It does seem less exposed for now: Chief Executive Scott Strazik said Canada, Mexico and China account for less than 5% of its imports into the U.S. The company has transformer factories in the U.S. and Europe. It also announced in January that it would invest nearly $600 million in U.S. factories and facilities over the next two years, including for gas turbines, transformers and switchgears.

3 notes

·

View notes

Text

xxxi. second chances

☾⋆。𖦹 °✩⋆。° ✮

CHAPTER THIRTY-ONE ─ second chances.

❛ cause in this city's barren cold, i still remember the fist fall of snow ❜

Narrator's Perspective

There's nothing like a good meal after a long day of work. Eunyoung and Yumi realized the credibility of this statement as they sat at the dining table in their apartment, munching away to glory, not uttering a word until every crumb of food from their plates had disappeared.

"I don't think we need to wash the dishes now," Yumi piped.

"It's not like we have the energy to do that anyways," Eunyoung replied, leaning back in her chair, sighing.

"Don't you sit on your CEO chair and order people around all day?" Yumi teased.

"Are you kidding?" she exclaimed, slightly offended. Her fatigue seemed to have hindered her ability to detect playful sarcasm, "I've been answering a million calls for the past two days, and all the reporters are dying to know all the details of Sunjae..." she trailed off- the words were too painful to utter, "Anyways, it's as if the whole office is working on the same case. Have you ever seen my eyes this puffy. I'm single-handedly improving the income of all tissue paper manufactures."

"God, forget I ever asked," Yumi muttered, putting her hands up.

"Tell me, how's stuff at our office?" Eunyoung changed the topic swiftly, "Any turbulence?"

"I wouldn't say turbulence," answered Yumi thoughtfully, "But this case I'm on right now is straight out of an Agatha Christie novel. This woman's husband got hit by a bus and he died. It seems so simple, but the woman is insisting that he was murdered. I can't tell you more because of attorney-client confidentiality, but it's completely nuts. Like, they should have given this case to- I don't know, Hercule Poirot or Sherlock Holmes, not me. I swear the woman's on crack or something because I've never met someone so ecstatic in my life. Taesung and I barely sat through the interview-"

"Wait wait what did you just say?" Eunyoung asked, suddenly sitting up straight, trying to make sure she didn't mishear Yumi.

"Huh?" Yumi went quiet suddenly, realizing that this was the first time she mentioned Taesung being on the case with her, "Oh, that's right. Kim Taesung is a cop now. Violent crimes division. Who would've imagined? Not me." She let out an unnatural giggle which definitely didn't sound like something that would come out of a sober person's mouth.

"Girl, you're blabbering slow down," Eunyoung said, leaning on the table between them, looking straight into Yumi's eyes that were staring intently at the floor, "You're saying that Kim Taesung- high school delinquent became a cop? And he's working with you? What is this? A badly written rom-com?"

"You think I'm making it up?" Yumi ejaculated defensively.

"I- goodness," Eunyoung sighed, her eyes blinking rapidly as her brain tried to digest all this new information, "After fifteen years. And it hasn't even been fifteen years since..."

Her thoughts trailed away. Her eyes landed on the CD player she moved to the living room in the hope that her heart would ache a little less. But there it was, staring down at her. There were a million different thoughts racing through her mind. How much pain must Yumi be in? Things had happened so fast for her, and she had no time to process the shock fully.

A bone-chilling wind entered through the kitchen window, goosebumps erupting on both of their arms. The world seemed to hold it's breath for a moment and the stillness was almost uncomfortable. Then, it started. It had started snowing, and the snow would soon wrap the whole city in a white, icy blanket; And it was just like the night of the Eclipse concert, starting slowly, then transitioning into a full-fledged storm. It wasn't unlike the news of Sunjae's death, that creeped up on her slowly, hardly believable at first and then becoming increasingly every second that passed.

Eunyoung's hand reached for Yumi's, holding it tightly, "Are you okay?" the question was barely a whisper, because she knew that neither of them were.

"No."

The clock struck twelve, and the display on the CD player flashed, then showed the numbers 2:00. Then the walls around them melted away as they were flung through space and time once again.

💿

"Excuse me, you two girls!" the teacher's voice hollered through the classroom, "Sleeping in class, both of you sisters! Aren't you the slightest bit ashamed?"

Eunyoung and Yumi jerked awake, looking at each other as if to ask, "Is he talking about us?" Eunyoung's eyes took a quick glance at the calendar in the corner of the room. June 2008. She had to stop the sigh of relief from escaping her mouth. Sunjae was alive, and she had another chance to set things right.

"Stand up when I'm talking to you!" the teacher's voice boomed as they both stood up abruptly, "Go stand at the back of the class! Sleeping while I'm explaining such important concepts... kids these days," he muttered in annoyance as Yumi and Eunyoung moved to the back of the class as a couple of kids snickered at them; But they couldn't care less. They had more pressing matters on their mind.

I have to set things right. Yumi thought to herself with determination. Heck, she was ready to accept that she liked the stupid boy. She had to save him; Save him from the misery he would face in the future. She wanted to preserve that spark in his eyes, and she was willing to go to any lengths to do it. Ten days had already passed in this timeline. The clock was ticking, and she understood that she had to work fast.

"Why do we always end up in school when we switch timelines?" Eunyoung hissed in frustration as the bell went off.

☾⋆。𖦹 °✩⋆。° ✮

nana's notes: here we go! round two.

delphi's notes: they're motivated again guys.

next chapter: saturday (out now!) list of chapters here!

#( +🎧 ) nayoung ?!#— nayoung's writing#TOWARDS YOU — lovely runner.#lovely runner#lovely runner fanfiction#lovely runner x oc#ryu sunjae#sunjae#ryu sunjae x oc#kim taesung#taesung x oc#song geonhee#byeon wooseok#kim minji#newjeans#newjeans minji#minji icons#newjeans icons#wonyoung#jang wonyoung#ive wonyoung#ive wonyoung icons#headers edited by me :)

6 notes

·

View notes

Note

Random Lucas question — because his psychometry also works through his lips and not just his hands, do you think wearing lip balm (or lipstick) would bother him (e.g. plagued by visions of its manufacturing process)?

Likewise, do you think his gloves are special (made specifically to turn off his psychometry) or would any gloves work (maybe long-term use nullifies whatever he senses)?

Ohhhhhh my gosh you have no IDEA how much time I spend thinking about this stuff. XD

For my own sanity, I keep it intentionally vague, because it's vague to start with. I mean, he canonically can't remember anything even though he presumably woke up wearing the same clothes. How does THAT work!? O_o

BUT! I have figured out a few rules:

While he's able to sense things with his whole body, the ability basically follows the same pattern as touch sensitivity, so strongest in the hands, mouth (I've decided to just not worry about what eating is like until I get a specific fic idea lol), etc.

Like any other sensory noise a person perceives, he can choose to tune things out or pay active attention to varying degrees. (But it's also subject to the "don't think about a pink elephant" phenomenon, so he likes having a buffer.)

I think his gloves might be special somehow, but I don't know and he doesn't know either. :P Even if so, I think it's a case of any barrier being better than nothing in a pinch.

Thanks for this ask! It's reassuring that someone else is out there overthinking this stuff, so I'm not just driving myself nuts alone. :P

(Also, some of the thoughts it inspired re: food and clothing are for sure making their way into future fics. >_>;)

5 notes

·

View notes

Text

National Peanut Butter Day

Spread this creamy, nutty treat far and wide, experiment with mouthwatering recipes or tuck into a classic peanut butter and jelly sandwich.

Who doesn’t love peanut butter? Whether as an ingredient in a candy bar or some cookies, or simply eaten by the spoonful, pretty much everyone loves it in some way or another. And, of course, it provides the most important ingredient to one of America’s favorite quick and easy meals: the Peanut Butter and Jelly Sandwich.

So now it’s time to celebrate National Peanut Butter Day!

History of National Peanut Butter Day

Peanut butter is a culinary treat that actually most people think is a fairly modern invention, as food histories go. However, that may not be exactly the case.

I’m going to take this God-given gift of being funny, and I’m going to spread it out like peanut butter on everything I do.

Peanut butter, as it is known today, has only been around for a little over a hundred years. But, actually, there is some evidence that ancient Aztec and Inca peoples may have been grinding peanuts into a sort of paste several hundred years ago (or maybe even a few thousand years ago!).

As far as the modern world is concerned, peanut butter arrived via the United States at some time in the late 1800s. Some theories claim that, like many foods, peanut butter probably started in someone’s kitchen in their home. One popular theory suggests that a woman named Rose Davis started making peanut butter in New York at some point in the 1840s. She got the idea from her son, who had learned about something similar that was being made in Cuba at the time.

Many people credit George Washington Carver with the invention of producing peanut butter but, while he was an amazing inventor credited with more than 300 uses for peanuts and is considered the father of the peanut industry, Carver did not actually invent peanut butter.

The creation of modern peanut butter, along with its production processes, can be traced back to at least three more people. In fact, it was Canadian Marcellus Edson who patented “peanut paste” first, back in 1884, but this was created from roasted peanuts. In 1895, Dr. John Harvey Kellogg, of the famed Kellogg’s cereal company, filed to patent a process using raw peanuts to create peanut butter, which was then referred to as “nut meal”. Then, in 1903, a peanut butter-making machine was patented by Dr. Ambrose Straub of St. Louis, Missouri.

As far as National Peanut Butter Day is concerned, it seems that this auspicious occasion was created many years ago, to allow peanut butter lovers to celebrate the creation of this wonderful food. And celebration is the whole purpose of the day!

National Peanut Butter Day Timeline

14th Century A.D. Peanut butter is invented

The Incan peoples of Peru are believed to have been the first to mash up peanuts into paste and use it for food. It was more coarse than modern peanut butter (and was likely unsweetened) but was the predecessor to today’s smoother, sweeter version.

1840 Rose Davis creates modern peanut butter

A resident of New York, Rose Davis was rumored to have gotten the idea for peanut butter from her son, who had traveled to Cuba. So she started making it in her own kitchen.

1884 First peanut butter patent is granted in the United States

Marcellus Gilmore Edson was a Canadian chemist who first applied for (and was granted) a patent for a peanut paste which he called “peanut candy”. Although he held the patent, no evidence shows that he never actually made the product available commercially.

1890 Bayle’s Peanut Butter claims status as “original”

St. Louis food manufacturer, Bayle’s, is rumored to have collaborated with a doctor who was looking for ways for patients to ingest protein when they could not chew meat. This led to the production of ground peanut paste, which was originally sold from barrels for 6 cents per pound.

1928 Peter Pan becomes the first branded peanut butter

Receiving a license for his creative churning process from inventor Joseph L. Rosenfeld, Peter Pan makes its name on the market. This is followed only a few years later by Rosenfeld’s own brand, Skippy.

How to Celebrate National Peanut Butter Day

Celebrating this day can be something super simple or extra involved. No matter how it is enjoyed, Peanut Butter is the star of the show on this day! Try out some of these ideas for getting involved:

Enjoy Eating Some Peanut Butter

Peanut butter can be eaten and used in many different recipes, whether sweet or savory, baked or fried. Plus, a lot of people see nothing wrong in sitting down and indulging in a jar of the creamy or crunchy delight with a spoon. What more would a person need? Today is the day that can be best appreciated in whatever way each person’s taste buds enjoy the most.

There are some individuals who commit to eating nothing but peanut butter-themed foods on National Peanut Butter Day. There are even schools that will serve peanut butter sandwiches to their students on this festive day. What better sandwich is there in the world?

Try Some New Peanut Butter Recipes

Families and friends can celebrate National Peanut Butter Day by getting together and creating delicious recipes containing peanut butter, from cookies and cakes to sauces. These can of course be consumed at home, or some prefer to make a day of it and go on a picnic-style outing. No matter what way it is eaten, getting creative in the kitchen with peanut butter can be a whole load of fun!

Try out some of these ideas for creating peanut butter dishes:

Crispy Tofu Stir Fry with Cauliflower Rice. Super delicious and vegan (which is great for the health and the environment), this Asian inspired dish tosses cubes of tofu into a peanut butter marinade sauce after being baked and also pan fried.

African Peanut Soup. Filled with chicken, nutritious sweet potatoes and other vegetables, this peanut soup is super healthy and also delicious!

Peanut Butter Frozen Yogurt. Easier than it sounds, this recipe simply requires combining premade yogurt, peanut butter, vanilla extract and maple syrup. Place in bite-sized dollups on a parchment lined cookie sheet and freeze (or make them into popsicles). A perfectly delightful summer snack for kids and adults!

Peanut Butter and Jelly Ice Cream. Speaking of frozen treats, why not make one out of the tasty ingredients of this classic American sandwich? The combination of sweet with salty is fabulous–especially when using crunchy peanut butter!

Share Some Peanut Butter Treats

After checking to be sure there aren’t any allergies, a great way to celebrate National Peanut Butter Day is by making (or buying) and sharing a variety of treats that include peanut butter.

Take a plate of peanut butter cookies to share with coworkers at the office, create a peanut butter pie to give to the neighbors, or take a close friend out to a restaurant for a peanut butter shake! National Peanut Butter Day is certainly tasty in any way that it is celebrated, but most people will find that it is best enjoyed when shared with others!

Learn Some Facts for National Peanut Butter Day

In celebration of National Peanut Butter Day, it’s time to brush up on some interesting facts and tidbits that can be shared with friends, while also sharing a peanut butter sandwich.

Peanut Butter was officially introduced to the world at the 1904 World’s Fair in St. Louis, Missouri, USA where a businessman named George Bayle started selling it. But it still took some time to gain popularity.

The first recorded recipe for a Peanut Butter and Jelly Sandwich was in 1901. It was written by Julia Davis Chandler and published in the Boston Cooking School Magazine.

In the United States, in order for a product to be labeled as “peanut butter” it must contain at least 90% peanuts. This rule keeps the manufacturers from substituting other ingredients into the mix.

The US has elected two different peanut farmers to represent them as the President of the United States of America. These include Thomas Jefferson of Virginia (who was president between 1801 and 1809) and Jimmy Carter of Georgia (who was president between 1977 and 1981). However, since peanut butter didn’t yet exist when Jefferson was president, the peanuts grown on his farms were probably not used to make this delicious treat.

Source

#Peanut Butter Milkshake#Chocolate Peanut Butter Cup a la Mode#Peanutbutter Cream Pie#food#USA#dessert#original photography#travel#vacation#whipped cream#ice cream#Peanut Butter Cookie Butter Batter#Reese's Peanut Butter Chocolate Cake Cheesecake#Adam's Peanut Butter Cup Fudge Ripple Cheesecake#Canada#Chocolate Peanut Butter Shudder#National Peanut Butter Day#NationalPeanutButterDay#Peanut Butter Cup Perfection#homemade Heaven and Hell Cake#24 January

1 note

·

View note