#Non electric soda Machine Manufacturers

Explore tagged Tumblr posts

Text

Blue Star Soda Fountain Machine Company Provides Soda Water Bottle Machine in Delhi. These machines are designed by their own senior professionals by using food-grade components and modern techniques. We provide Non electric soda Machine at the best Prices. It’s the best Non electric soda Machine Manufacturers, suppliers & exporters in India.

#Non electric soda Machine Manufacturers#Mobile soda machine manufacture#Soda Fountain Machine Manufacturers

0 notes

Text

Best Washing Machine Repair Tips: Troubleshoot It Yourself.

Discover how to do common washing machine repair at home. Learn expert DIY fixes for problems like non-starting, poor drainage, and excessive noise. Save time and money with our comprehensive guide to washing machine maintenance and repair. Has your reliable washing machine started to develop a malfunction or tow? Don't panic! Most of the washer issues are easily solvable and you should not always call a professional for repair services. To that end, this ultimate guide for washing machine repair takes you through selected professionals’ advice on how to get back on track in doing your laundry effectively. So, if you own a car that refuses to start, produces some funny noises, or perhaps leakages; our detailed directory got you fronted. Well, as it has been said, let’s get started diving into the hows of how you can become your appliance repair guru.

Safety First: Your DIY Repair Toolkit

Before we jump into washing machine repair, let's talk safety. It's crucial to protect yourself and your appliance during any DIY fix. Always start by unplugging your washer and turning off the water supply. This simple step prevents electrical shocks and potential water damage. Next, gather your essential tools for washing machine repair. You'll need: - Screwdrivers (both flathead and Phillips) - Pliers (needle-nose and adjustable) - Flashlight or headlamp - Multimeter for electrical testing - Level for balance issues - Your washer's user manual Additionally, it's wise to have some cleaning supplies on hand: - Microfiber cloths - All-purpose cleaner - White vinegar - Baking soda Remember, if at any point you feel overwhelmed or unsure, it's okay to call a professional. Your safety should always come first. Now that we're prepared, let's move on to diagnosing the problem of your washing machine repair.

Laundry Appliance Issues: What's Wrong with Your Washer?

Just knowing that there is a problem is already halfway to solving a problem especially when it comes to appliances. Begin by observation: use your head and the information obtained through your senses. Coughing, sneezing, whistling, hissing, roaring, etc are some of the sounds that should alert one to check for the existence of leaks. These sensory cues can help to give you an indication in the right direction most of the time. Most washing machines that exist in the market today come with an error code flashing system that alerts the user when something is wrong. Such codes are very beneficial as they are used to locate certain problems. These codes can be read by referring to the user manual of your vehicle. Can't find your manual? Don't worry. A majority of manufacturers have online databases that one can use to look for error codes using the model number. Here are some common symptoms and what they might indicate: - No power: Electrical issues or faulty control board - Won't fill with water: Water supply problems or inlet valve issues - Won't drain: Clogged drain hose or faulty pump - Excessive noise: Unbalanced load or worn parts - Leaking: Damaged seals, hoses, or pump By carefully observing your machine's behavior, you'll be better equipped to tackle the problem head-on. Common Issues and DIY Fixes Now that we've covered diagnostics, let's dive into specific problems and their solutions. Remember, always start with the simplest fix and work your way up to more complex solutions. Washing Machine Repair: Washer Won't Start A silent washer can be frustrating. Here's what to check: - Power supply: Ensure it's plugged in and the outlet is working. Test the outlet with another appliance to be sure. - Circuit breaker: Check if it's tripped. If so, reset it and see if that solves the issue. - Door latch or lid switch: These safety features prevent the washer from starting if the door isn't properly closed. Clean the latch and ensure it's engaging correctly. - Start switch or timer: If these components are faulty, they may need replacement. Use your multimeter to test for continuity. - Control board: While less common, a faulty control board can prevent your washer from starting. This typically requires a professional diagnosis. Washing Machine Repair: No Water? No Problem! When your washer won't fill, follow these steps: - Check water supply: Ensure both hot and cold water valves are fully open. - Inspect inlet screens: These small filters can become clogged with debris. Disconnect the hoses and clean the screens gently with a brush. - Examine inlet valves: If water still won't flow, the inlet valves might be faulty. Test them with a multimeter and replace them if necessary. - Pressure switch: This component senses when the tub is full. A faulty switch may prevent the washer from filling. - Water level control: If this mechanism is broken, it won't signal the machine to fill with water. Washing Machine Repair: Drainage Dilemmas A washer full of water is no fun. Here's how to tackle drainage issues: - Locate the drain hose: Check for kinks or clogs. Straighten any bends and clear visible blockages. - Clean the pump filter: This often-overlooked component traps small items that can impede drainage. Clean it regularly to prevent issues. - Inspect the drain pump: If it's not working, water won't be expelled from the machine. Listen for a humming sound when the washer should be draining. - Check for coin traps: Some models have a separate trap for small items. Clean it out if your model has one. - Examine the drive belt: A loose or broken belt can prevent the pump from operating correctly. Washing Machine Repair: Spin Cycle Woes If your clothes aren't spinning dry, try these fixes: - Redistribute the load: Unbalanced loads often cause spin issues. Spread clothes evenly and try again. - Check the drive belt: A loose or worn belt can slip, preventing proper spinning. Inspect and replace if necessary. - Examine the motor coupler: This plastic and rubber component can wear out over time. If broken, the washer won't agitate or spin. - Lid switch or door lock: A faulty switch can trick the washer into thinking the lid is open, preventing spinning. - Clutch assembly: In older top-load washers, a worn clutch can cause spinning problems. Washing Machine Repair: Shaking, Rattling, and Rolling Excessive vibration can be more than just annoying. Here's how to smooth things out: - Level the machine: Use a bubble level to check, and adjust the feet accordingly. An unbalanced washer can cause significant vibration. - Inspect shock absorbers: These components reduce vibration during the spin cycle. If they're worn, your washer may shake excessively. - Check suspension springs: These support the tub and dampen movement. Worn springs can cause the tub to bounce around. - Examine the tub bearing: A worn bearing can cause the tub to wobble, creating noise and vibration. - Balance the load: Sometimes, the solution is as simple as redistributing clothes more evenly in the tub. Washing Machine Repair: Leaks and Drips: Water on the floor? Here's how to keep things dry: - Identify the source: Determine if the leak is coming from the front, back, or underneath the washer. - Check door seals and gaskets: Inspect for wear or damage. Clean thoroughly and replace if necessary. - Inspect hose connections: Ensure all hoses are tight and undamaged. Look for cracks or loose clamps. - Examine the pump: A leaky pump can cause water to pool under the machine. Check for cracks or loose fittings. - Look at the tub seal: If water is leaking from under the tub, the seal may need replacement. - Overflow issues: If your washer is overflowing, check the water level switch and pressure sensor hose for problems. - Preventive Care: Keep Your Washer Happy Washing Machine Repair: Tips and Tricks An ounce of prevention is worth a pound of cure, especially when it comes to appliances. Here are some washing machine preventive maintenance tips to keep your washing machine in top shape: - Regular cleaning: Run an empty hot water cycle with vinegar monthly to prevent odors and buildup. - Use the right detergent: High-efficiency (HE) washers require special low-sudsing detergent. Using the wrong type can cause issues. - Don't overload: Stick to the manufacturer's recommended capacity to prevent strain on the motor and suspension. - Leave the door open: After each use, keep the door or lid open to allow the drum to dry, preventing mold and mildew. - Check hoses regularly: Inspect for bulges, cracks, or leaks. Replace hoses every 3-5 years as preventive maintenance. - Clean the lint filter: If your washer has one, clean it regularly to ensure proper water flow. - Avoid washing very small loads: This can throw the washer off balance and cause unnecessary wear. - When to Call the Pros Washing Machine Repair:: When to call Technicians? While many washer issues can be DIY-ed, some problems require professional attention. Consider calling a technician if you fail to solve Washing Machine Problems: - You encounter electrical issues beyond your expertise - The motor shows signs of failure (burning smell, won't run) - There's extensive water damage or flooding - You've tried multiple DIY fixes without success - Your washer is still under warranty (DIY repairs might void it) When choosing a washing machine preventive maintenance, look for: - Licensed and insured technicians - Good online reviews and ratings - Upfront pricing and estimates - Warranty on parts and labor Remember, sometimes washing machine replacement parts is more cost-effective than repair, especially for older machines. Consider the washing machine's lifespan and the cost of repairs when making this decision to washing machine repair.

Eco-friendly Washing Tips

While fixing your Laundry appliance maintenance, why not adopt some eco-friendly habits? These practices not only help the environment but can also extend your machine's life and reduce utility bills: - Use cold water: Most clothes clean well in cold water, saving energy on heating. - Choose full loads: This maximizes efficiency and reduces wear on your machine. - Use energy-efficient cycles: Many modern washers have eco-friendly settings that use less water and energy. - Try natural cleaners: Vinegar and baking soda can be effective, eco-friendly alternatives to harsh chemicals. - Opt for concentrated detergents: These require less packaging and often work better in modern machines. - Air dry when possible: This saves energy and is gentler on your clothes. - Smart Washer Troubleshooting Own a smart washing machine? These high-tech appliances can bring their own set of challenges: - Connectivity issues: If your washer won't connect to WiFi, try resetting your router and the washer's WiFi module. - App problems: Ensure your app is up to date and try uninstalling and reinstalling if issues persist. - Software updates: Keep your washer's firmware updated to ensure optimal performance and security. - Error codes: Smart washers often have more detailed error codes. Consult your manual or the manufacturer's website for specific troubleshooting steps. - Sensor malfunctions: Many smart features rely on sensors. If these malfunctions, it can affect various cycles. A professional diagnosis might be needed.

Conclusion: Fixing Laundry Appliance Issues

With washing machine repair tips, it is now easier and safer to handle the hanging Laundry appliance issues that you have. Always go for the basic and simple approach to address the problem from the root cause. Most washing machine problems have simple solutions that could help in avoiding wastage of time and/or money. But, always remember safety and never do anything beyond your abilities, particularly when it is useful to ask for help from a professional. This means that if swirls and proper use are taken it goes a long way in avoiding washer troubles. It is about time to take care of many fine details and good habits, so that the Laundry appliance maintenance lasts longer, and common nuisances are fixed going forward to make laundry less of a burden.

FAQs

How often should I clean my washing machine?Washing machine repair practices play an important role in the longevity of washing machines with cleaning being one of them. Do a cleaning once a month, or if there is a bad smell or residue that is observed in the container. It should also be noted that it is necessary to always leave the door open after its use so that it can dry. Even though this may sound a little harsh, this routine helps your dryer washer to remain fresh and fully functioning by extending its performance and cleanliness.What causes a washing machine to leak from the bottom? Washing Machine Repair: Washing machine leaks from the bottom often stem from a few key issues. A damaged pump can allow water to escape during the drain cycle. Worn tub seals, which keep water inside the drum, may deteriorate over time and cause leakage. Loose or cracked hose connections, either internal or where hoses attach to the washer and dryer machine, can also lead to water pooling underneath. Additionally, a faulty water inlet valve or a crack in the tub itself might be culprits. Regular inspection of these components and prompt attention to any signs of wear can prevent minor leaks from becoming major problems.Can I use vinegar to clean my washer?White vinegar is another excellent natural cleaner for washing machines. It also is acidic to dissolve soap scum, mineral deposits, mildew, and the like. For your washers, you can produce two cups of white vinegar directly into the washer drum and start a hot wash. In case you are using a top-loading washing machine, you should interrupt the cycle for one hour allowing the vinegar solution to work on the garments. Why does my washing machine smell bad?Odors often result from mold or mildew growth due to trapped moisture. Regular cleaning and leaving the door open after use can prevent this. Be updated on washing machine repair tips.How do I know if my washer's motor is failing?If you hear strange sounds coming from your washing machine combo, smell a burning odor, or notice that it’s not spinning or agitating correctly, it might be a sign that something is wrong.Is it worth repairing an old washing machine? If it is going to cost Washing Machine Repair more than fifty percent to repair your broken washing machine then it can be cheaper to replace it with a new one. This is because one can easily spend a lot on getting the parts, the labor required to install them as well as the possible additional costs for future damages. In some instances, it becomes cheaper to purchase a new washing machine since one will not be held responsible for the costs that will be incurred in the future by the machine.How can I make my washing machine more energy-efficient?When it comes to doing laundry, one must only use cold water, wash clothes when the basin is full; use cycles that save energy. If your previous machine is old and decrepit, then change it with a new powerful but energy-conserving one, preferably one that is ENERGY STAR certified. These models are designed to be more energy and water-efficient which means you will be using less and saving money by cutting power bills as well as the environment. By following these simple washing machine repair tips as well as maintaining your washing machine according to these suggestions, you will be able to help the machine last as long as possible. A much-maintained washing machine does a better job and at the same time, it is cheaper compared to the frequently bought one. Happy laundering! Read the full article

0 notes

Text

youtube

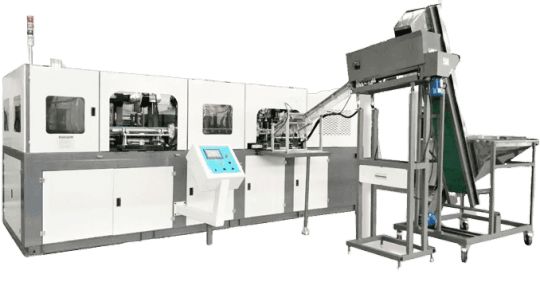

PET BOTTLE BLOW MOLDER

We would be happy to help and advise if you have any questions or inquiries.

PET BOTTLE BLOW MOLDING MACHINE

CAPACITY

Up to 15,000 bottles per hour

CAVITIES

Up to 8 cavities

PERFORMANCE

Satisfaction Guaranteed

2 Years Quality Warranty

On Time Delivery Guaranteed

OVERVIEW

Steplead’s BMA series blow molding machines produce the highest quality PET containers for a wide range of applications, sizes, and production demands. Our blow molders exceed previous blowing capacity, cost, and bottle quality benchmarks. Steplead’s industrial blow molding equipment reliably manufactures PET bottles and containers with precision engineering. Advanced temperature controls and adjustable blowing pressure deliver consistent, high-quality results. Trust Steplead for customizable stretch blow molding systems optimized for your PET bottle production needs. Contact our experts today to learn more about our high-performance blow molders for various industries.

youtube

ADVANTAGES

UP TO 50%

Steplead certified parts with additional warranty

UP TO 25%

Less maintenance

UP TO 20%

Less energy using lower engine speed and larger hydraulic pump.

Save Cost

The great advantage of stretch blow moulding machine is to stretch the container in both the axel and hoop directions, which name biaxial stretching and it will greatly improve the container’s top load, clarity, drop impact tolerance, barrier abilities and tensile strength. As a result, the raw material cost can be save for about 10-15% by reducing the weight of container.

Wide Application

The stretch blow molding process making PET bottles is popular in beverage industry production for juice, water, soda, and many other products. Since 1970’s, this blow moulding technique is applied widely to package chemical detergent and soda bottles.

High Efficiency

This blow moulder can achieve you any extra ambition of blowing production. No matter considering production output, reliability or efficiency, for non-carbonated water, csd (carbonated soft drink), and hotfill products, with maximum 6 cavities to produce up to 6,000 containers per hour.

PRODUCT SPECIFICATIONS

Download

2,000 ~15,000 Bottles500ml / Per Hour

Max Container Volume: 2L

Max Cavities: 8

Clamping Force: 320KN

Power: 120Kw

Dimension: 3,600 x 2,000 x 2,210MM

PREMIUM

LAYOUT COLLECTION

The best way to experience our wide collection of production layouts for your project.

Layout for 10,000BPH

Factory layout of 10,000bph soda drink filling line for 500ml - 2L PET bottles

Click to Download

Layout for 2,000-3,000BPH

Factory layout of 2,000-3,000bph cola drink filling line for 500ml - 2L PET bottles

Click to Download

Layout for 10,000BPH

Factory layout of 10,000bph soda drink filling line for 500ml - 2L PET bottles

Click to Download

Layout for 2,000-3,000BPH

Factory layout of 2,000-3,000bph cola drink filling line for 500ml - 2L PET bottles

Click to Download

Layout for 10,000BPH

Factory layout of 10,000bph soda drink filling line for 500ml - 2L PET bottles

Click to Download

Layout for 2,000-3,000BPH

Factory layout of 2,000-3,000bph cola drink filling line for 500ml - 2L PET bottles

Click to Download

Previous slide

Next slide

RELATED EQUIPMENT

HOW TO ENSURE THE SAFE AND EFFICIENT PRODUCTION OF BOTTLE BLOW MOLDING MACHINE.

Here is a list of all the types of technical questions concerning bottle blowing molding machine that you can find.

What Safety Precautions Would Be Needed For Blow Molding Machine Operation

Safety Precautions for blow molding machine operation

These precautions are for the sake of preventing operators and other staff from being hurt or preventing machine from being damaged when trouble occurs. Because devices of this machine use pneumatic and electrical control, which features big power and quick working speed, therefore any errors of operation may lead to dangerous consequences. The machine is equipped with some safety devices to protect the operators. Before operation, please check whether these safety devices work properly.

1. Safety Precautions: 1) Operator must wear safety helmet, slip-proof shoes and working clothesduring installation, inspection and maintenance. 2) Make sure to install the machine in a dry, bright and clean location. The ground around the machine should be solid and its surface should be slip-proof. 3) Never put tools and other articles onto the machine or any other moving parts. 4) Don’t climb onto the machine when it is running and don’t touch the moving parts. Before inspection and maintenance, the power and gas source must be switched off and ensure that air pressure of gas circuit is environmentalatmosphere.Note: Once the pressure of operation gas circuit is environmental atmosphere, mold base components will automatically descend. 5) When operate parts of heating devices, turn off the power first and operate after it completely cools down. 6) Please pay special attention to the safety warning board installed on dangerous parts of the machine.

2. The Safety Guard and Safety Door on the Machine 1) A limit switch is installed on the safety door to pick up the bottles. When the safety door opens, this limit switch will be activated to stop the machine from operation. Therefore, it’s important to check whether this limit switch can work normally before operating the machine. 2) It’s forbidden to dismantle the safety door on the machine and the safety cover on automatic chainsunless necessary maintenance and inspection are needed. And after maintenance and inspection, the safety door and the safety cover on automatic chains must be reinstalled as its original way. 3) Emergency Stop Button There are two buttons for emergency stop on the machine. One is on the operation panel and the other is on the back of the machine. They are used for emergencies. If each of the emergency stop buttons being pressed, both the power and gas source are switched off simultaneou sly and the machine stops all operation immediately. 4) Overpressure Protection The machine uses compressed air. The safety valve is respectively installed on high and low-pressure air collector. If the pressure in air intake is too high, the safety valve will be automatically opened to ensure of the safety. Air pressure for operation: Air intake 0.8Mpa Air pressure for blowing: Air intake 3.5MPa 5) Grounding The machine has contact for grounding. Before using the machine, connect the earth wire, which should be chosen according the local standard.

What Are Precautions Else Needed For Operation Of Blow Molding Machine

Precautions Related with Operation of Blow Molding Machine

Before operating the machine, read and understand the operation regulation in the operation manual or have relative training for operation.

(1) Emergency Stop

① There are two emergency stop buttons on this machine. The gas supplies stops and piston of air cylinder at the mold base and press preform falls down when each one of the buttons is pressed. The piston returns when turning and releasing the emergency button clockwise.

② There is a safety lever installed at the right side of bottle picker connected with the switch to prevent the bottle or preform from going to the next circle. If bottles or preform press on the safety lever, the machine will stop immediately until they are

removed. Note: Don’t operate the machine until you are sure of the security.

(2) Adjustment of Position and Speed

The position and speed valve of magnetic switch and approach switch on gas cylinder of movement devices has been properly adjusted before the machine leaves the factory. Don’t try to make the machine run quicker by changing their position or adjust the speed valve. Otherwise, it may cause damage of the machine or lead to malfunction.

(3) Inspections Related with Automatic Operation

① Confirm the safety for the operator. Check with eyes carefully the surrounding of the machine to make sure that it is safe in this area.

② Make sure that all safety devices can function normally.

③ Ensure all limit switches are in position and properly tightened.

④ Check whether the air pressure for operation and blowing is normal.

⑤ Check the adjustment of various speed

⑥ Check the temperature and circulation of cooling water.

(4) Safety during Bottle Blowing

① Never open the guarding gate or climb into it during bottle blowing.

② Never touch movement parts during bottle blowing.

③ Keep close attention to the working status of the machine. If abnormal situation or noise occurs, stop the machine immediately. Look for reasons and get rid of the troubles. If alarm occurs, the machine will stop automatically. The machine can be operated again only after the troubles are eliminated.

What is The Safety of Maintenance and Repairation of Blow Molding Machine

The Safety of Maintenance and Repairation of Blow Molding Machine

(1) Before repairing the machine, switch off the power and hang a warning plate of “Repairing, Switch on Prohibited” at the power switches. Before repairing, use electroscope to check that the power has already being switched off.

(2) It should bear regulated pressure to replace pneumatic units such as gas pipe, valve and connectors. It should get the approval from professional engineers to replace these units. Before replacing, make sure that the air pressure of gas circuit has been reduced to environmental atmosphere.

(3) The capacity should be in accordance with corresponding regulation when replacing fuses or other electric units. It should get approval from professional engineers or technicians for the replacement.

(4) Never touch any electrical devices with wet hands.

(5) When repairing the mold on the machine, insert a cushion (A rectangle wood block of 15×20 cm, which length should be the same with the length when the mold opens to its maximum extent) into the opened mold clamp device.

(6) Lubricate the machine after it stops.

(7) Use proper tools to maintain and repair the machine. Exert proper moment when tightening the bolts and nuts.

(8) Carefully check the repaired area after maintenance and repair to prevent any tools from being left in the machine.

What Precautions You May Need for The Gas Circuit System of Blow Molding Machine

Precautions of Gas Circuit System of Blow Molding Machine

Note: The density of high-pressure air is very high and any leakage of it shall lead to serious consequences.

(1) It’s strictly forbidden to change the position of safety valve on the air collector. (2) Impact of compressed air collector is strictly prohibited. (3) Open the gas outlet valve slightly to discharge the gas slowly when relieving the pressure. (4) Switch off the gas source and open the outlet valve as well as ensure that the reading on pressure meter is zero before removing parts on gas circuit. (5) Discharge the gas thoroughly if the machine has stops operation for a long time. (6) When replacing any pneumatic units, check under low pressure to reconfirm its safety and gradually increase the air pressure.

(7) Check the safety of gas circuit regularly. Check Every Day ① Check pressure meter of air collector to make sure that every pressure value is normal. ② Check and monitor the gas circuit system (air collector, pipes, valves and air cylinder) to make sure that there is no gas leakage. ③ Ensure that hoses are not bent or damaged and every part of gas circuit system is solidly tightened.

Check Every Week ① Dry the accumulated water in high and low pressure air collector and filters. ② Check whether the magnetic coil and bolt is loose. ③ Check and clean the air muffle.

Check Every Six Month Check the accuracy of every pressure meter on air collector and gas circuit.

#pet bottle blowing machine#bottle blowing machine#blowing machine#blow moulding#blow moulding machines#pet bottle blower#pet bottle blower australia#pet bottle blowing machine uk#pet bottle blowing machine australia#pet bottle blow molding machine#Youtube

0 notes

Text

Global Top 32 Companies Accounted for 41% of total Caustic Soda and Urea market (QYResearch, 2021)

Sodium hydroxide is also known as caustic soda, caustic, and lye. Anhydrous (100%, solid) caustic soda has a chemical formula of NaOH and a molecular weight of 40.00.

Urea, also known as carbamide, is an organic compound with chemical formula CO(NH2)2. This amide has two –NH2 groups joined by a carbonyl (C=O) functional group. Urea serves an important role in the metabolism of nitrogen-containing compounds by animals and is the main nitrogen-containing substance in the urine of mammals. It is a colorless, odorless solid, highly soluble in water, and practically non-toxic. Urea is widely used in fertilizers as a source of nitrogen and is an important raw material for the chemical industry.

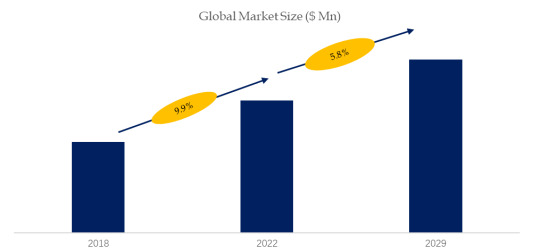

According to the new market research report “Global Caustic Soda and Urea Market Report 2023-2029”, published by QYResearch, the global Caustic Soda and Urea market size is projected to reach USD 156.31 billion by 2029, at a CAGR of 5.8% during the forecast period.

Figure. Global Caustic Soda and Urea Market Size (US$ Million), 2018-2029

Above data is based on report from QYResearch: Global Caustic Soda and Urea Market Report 2023-2029 (published in 2023). If you need the latest data, plaese contact QYResearch..

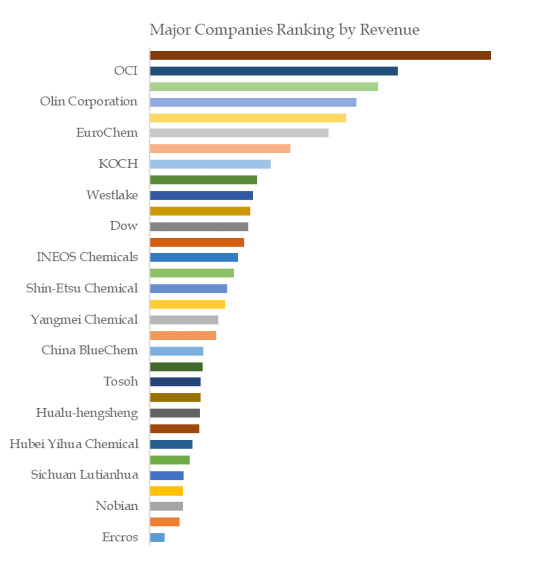

Figure. Global Caustic Soda and Urea Top 32 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

Above data is based on report from QYResearch: Global Caustic Soda and Urea Market Report 2023-2029 (published in 2023). If you need the latest data, plaese contact QYResearch.

The global key manufacturers of Caustic Soda and Urea include Yara, OCI, CF Industries, Olin Corporation, QAFCO, EuroChem, Nutrien, KOCH, OxyChem, Westlake, etc. In 2021, the global top five players had a share approximately 17.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Getting a Beverage Machine Is a Boon Really

People who frequently throw parties, own a restaurant, or just simply enjoy beverages a lot, and then it is high time that you invest in beverage machines.

A beverage machine can carry a gallon of your favorite drinks and help you in making better use of your time instead of making a new drink. For any type of use, there are various types of machines available.

If you are serving frozen treats like slush, smoothies, and shakes then refrigerated beverage machines are an ideal one. Even in serving cold sodas, you can use these, since for different flavors majority of the models have multiple valves. Normally these kinds of machines have to be plugged in. Compared to other kinds of machines they also cost more and will typically be made of stainless steel, so once you are sure you will be serving lots of cold beverages constantly then get.

Insulated beverage machines and plastic injection machineries are made of durable polycarbonate or polyurethane, hence it will insulate your drinks so that they stay at a constant temperature the entire time. They are made of sturdy, dent-resistant material; as a result, you can bring them anywhere and not worry about banging them up too much. Compared to refrigerated beverage machines they are cheaper and it comes in different styles and colors.

Non-insulated beverage machines do not require electricity so they are the cheapest kind. It is easier to carry around and less difficult to maintain but it does not maintain the temperature of the drink. During camps, picnics, sporting events, and other outdoor activities these kinds of machines are perfect to bring. These are available in different forms and styles like insulated machines.

They can also add more flair to the party or the room apart from the ease of use and the conservation of time brought on by the use of beverage machines from a beverage machines manufacturer.

Another major advantage of using beverage machines is that they allow you to use disposable cups. Cleaning the machine is the only thing that you have to worry about. Cleaning the machine is easy, although if you are going to be serving different types of drinks now and then, then you have to do it constantly.

2 notes

·

View notes

Text

Material Relationships

Do you design around a material or do you choose materials for your design? Both approaches equally apply it just depends on your perspective.

If you’re a blacksmith, a seamstress, a carpenter or a glass blower, you design around your material of choice. These professionals or craftsman have become expert on the properties of their particular material and on the treatments and techniques that can be used to get the desired outcomes for the design.

The relationship that exists between materials, design and humans is as old as mankind itself. In-fact the evolution of humanity is inextricably linked to development of materials and material processes.

Material History 1

Throughout our existence, human development has been intrinsically linked to materials and how they can be used. So much so, that phases of human development are named after the predominant material of the time.

Stone Age

Bronze Age

Iron Age

The stone age started 2.5 million years ago when man learnt that cracking rocks together made fire and sharp edges for tools. Like to today, materials were used to create tools for making other things, constructing buildings for shelter, producing weapons for hunting and to protect against or attack an enemy. Tools and weapons from the Stone Age were not just made of stone, other natural materials such as antler, bone, plant fibres, leather, and wood were also employed. Materials that are all still substantially used today. Amazingly, monuments from the times, such as Stonehenge, have stood the test of time.

Stone Age Jewelry Fazael, Upper Palaeolithic The Israel Museum, Jerusalem

Stonehenge – www.english-heritage.org.uk

The Bronze Age started around 3300BC. At the time, bronze (an ally of tin and copper) was the hardest know metal and was produced by what is arguably the first recognised industrial process – mining, smelting and casting. A key benefit was its ability to be cast into different shapes to service different purposes.

Bronze Age Weapons and tools - Monaghan County Museum

Bronze flesh hook – The British Museum

The Iron age started around 1200BC. Scarcity of tin forced the search for alternative metals, primarily in the context of having stronger weapons. Throughout the ages weapon development has driven advancements in materials and material processing. Language, religion and culture also developed and had a major impact on the use of materials. Precious metals and jewels being used in religious artefacts or to reflect a person’s social status.

Iron Age Cremation Bucket - The British Museum

Interestingly technological advancement has speeded up as each age has passed. Driven by scientific advancements and capitalism, the use of iron underpinned the industrial age as steel (the necessary material for the steam engines) drove the industrial revolution but that wasn’t until the 19th century.

In the 1300s glass came in to its own but as with steel it wasn’t until production techniques had been developed to enable the material to be mass produced did the use of glass and steel really take off. Mass production of glass comprises two methods the first of which is the float glass process, in which molten glass floats on a bed on molten metal, typically tin or lead. The second is mould blowing where molten glass is blown into a preformed mould that can be reused multiple times.

Plastic is a collective name for a wide range of materials and in its earliest form appeared at the beginning of the 20th century. As a material, plastics offered an affordable way to mass produce a range of products that touches nearly all aspects of modern life, from cups to synthetic heart valves.

With the newest materials, we are entering the realms of what was science fiction. Nanotechnology is defined as the study and use of structures between 1 nanometer and 100 nanometers in size; it would take eight hundred 100 nanometer particles side by side to match the width of a human hair. Nanomaterials like Graphene can be processed at much lower temperatures which means they are much cheaper to manufacture and offer more flexibility in processing and applications. There will be medical benefits in drug delivery, gene therapy, and tissue engineering. Artificial photosynthesis is now possible. Battery size and charge length is set to significantly improve, which has far reaching implications for our modern lives that are so dependent on powered devices.

Types of Material 2

Materials can be classified into six main groups: metals, polymers, ceramics, glass, composites and other natural materials:

Metals Some well-known base metal examples are aluminium, copper, iron, nickel, zinc, silver and gold. Alloys are made up of a combination of base metals and other materials to produce materials with different characteristics.

Steel – A combination of iron and carbonStainless steel – A combination of Steel and chromium

Bronze - A combination of copper and tin.

Brass - A mixture of copper and zinc.

Polymers There are three groups of polymers (plastics):-

Thermoplastics which may be reformed with heat. e.g. PVC, HIPS, nylon, polycarbonate, PET, acrylic.

Thermosetting plastics which once moulded or formed cannot be reformed by heat. e.g. Melamine(MF) and epoxy resin

Elastomers - rubbers long chain elastic molecules. e.g. neoprene, natural rubber. Used for car tyres and elastic bands.

Ceramics Ceramics are made by heating together materials such as silica, chalk and clays.

Glass Glass is made from sand, soda ash and limestone that when melted at very high temperature forms a new material that when cooled is a solid- and transparent, it has numerous applications in our daily lives.

Composite Are mixtures of materials which give improved properties. One of the materials is the matrix or binding chemical and the other is the reinforcer. A good example is GRP - glass reinforced polyester(plastic) resin. where the glass fibres increase the strength of the polyester resin. Carbon fibre reinforced epoxy resin is stronger and lighter than steel.

Other Natural A natural material is any product or physical matter that comes from plants, animals, or the ground, such as minerals and metals. Common Other Natural Materials are

Fabrics – Common examples of natural fabrics are cotton, wool and silk.

Wood – Soft and hard woods including Oak, pine, bamboo and cork.

Leather – Animal skin mostly produced from cattle.

Stone – Granite, sand and precious gems are examples.

Material Properties 3

As a non-craftsman, we often make material choices based on a rudimental understanding of a material properties. Often finding out at the end of the process, to our costs, it was the wrong choice. A designer needs more than a rudimentary understanding of a material’s properties. It is critical to whether the design is going to function as intended and be fit for purpose.

Materials have their own science and material science has evolved standardised test methods for defining and measuring the properties of materials. There are several more property measurements than the one listed below, however these are very specialised, like chemical and atomic properties which aren’t necessary to know when choosing standard materials:

Acoustic - absorption, Speed, reflection, transfer

Electrical - conductivity, resistivity, magnetic, capacitance

Manufacturing - castability, machinability

Mechanical - tensile, durably, wear, pressure, creep, elasticity, flexibility, hardness, malleability, plasticity, weight, stiffness,

Optical - absorbance, colour, luminosity, reflectivity, photosensitivity

Thermal – boiling point, flammability, melting point, conductivity, expansion.

Material Selection 4

Material selection is fundamental from an engineering design perspective and becomes more a personal preference in art. There are seven main factors that will affect a material's performance and its suitability:

Function For certain applications, “What will your design be used for?” will dictate the kind of material to use, otherwise the following needs consideration:

Properties

Performance-driven design vs. cost-driven design

Life span

Aesthetic needs

Expectations from client or end user

Application Some applications, if products fail to meet certain standards, there are serious consequences for both the company and the end user. Consider:

Standards or legal requirements

Ease of use

Special needs

Possible effects of material on end user

Failure & consequences

Additional manufacturing services needed to ensure legitimacy of product

Environment For a successful long-lasting product, the material needs to be tough enough for its environment, especially outdoor or multiple use.

Types of corrosion in environment

Level of corrosion

Possible chemical interactions that affect properties/structure

Coatings or protective finishes required

Interacting components or systems Is the design a fully functional end product or is it a component, things to consider are:

Surrounding materials

Possible interaction with differing materials

How to ensure your component doesn't fail first

Maintenance Certain products will sometimes need to be maintained or designed to be replaced. Consideration needs to be given to ow the material choice can affect maintenance and repair options:

Ease, frequency, and cost of maintenance/repair

Access to maintenance resources

If its a component hold up if it's made of X material?

Supply chain & manufacturing Cost and speed to produce can be improved by choosing common materials, or where and how the material is sourced:

Where it will be ordered from and/or manufactured.

Are you starting with raw materials that will need to pre-treatment, which may involve extra time, effort, and resources.

Specialty materials may require specialty manufacturing or suppliers

Fabrications Certain materials are better for certain fabrications, you'll need and match the best material for those operations.

Ductility

Thickness

Malleability

Strength

Edging & placement

Scrap from cutting fabrications or defects

Humanity’s changing relationship with materials

Scientists and engineers are producing new types of materials (eg Graphene), evolving new ways to advance the properties of materials and new fabrication techniques, like 3D printing. In many instances, material choice is driven by social attitudes, fashion, health concerns and more recently environmental impact. Over time, some materials have gone out of favour and others banned. One such material that is out of favour is plastic; this was and arguably still is one of most used materials worldwide.

Grenfell Tower - Splash News (https://www.thesun.co.uk/news/3806536/cladding-grenfell-tower-flammable-cheap/)

What was once seen as a panacea material, it is now seen to be one of the most prolific pollutants and has caused significant environmental issues. Plastics damage to the environment especially the seas, oceans and the wildlife that lies within them. Plastic itself is not the problem, it’s been society’s disposal mindset, use it once and throw it away, even though it is reusable. Society is now changing its attitudes and with it the movement toward sustainability and renewables. Almost overnight plastic products have been replaced with paper and metal-based alternatives, these include straws and cups. This is a clear example of how society and consumers attitudes can and do affect the choice and use of materials.

Ivory is another material that has been banned due to changes in society’s attitude. Other materials like asbestos, which was found to be a serious health hazard is now banned. The choice of cladding material in the Grenfell Tower disaster is a deadly example of questionable material choice.

Mixed Material Designs

I’m interested in materials and finding ways to use and combine them in new and innovative ways. I like to go beyond creative design concepts and solve the problem of what materials and fabrication processes are required in order to produce a functioning piece. I like to know what a material’s properties are and learn the fundamental fabrication skills for that material and to experiment with how materials can be combined in a design. On occasions I will start a design with specific material combinations or fabrication processes in mind.

I myself favour wood and steel, I’m fascinated by their property contrasts and how this can be so impactful in designing things that have a function and a value beyond just being an object. More recently I’ve experimented with bio-resins and want to include this moder material in to my final project.

Bibliography

1 Material History

https://en.wikipedia.org/wiki/History_of_materials_science

https://www.nanowerk.com/nanotechnology/introduction/introduction_to_nanotechnology_1.php

2 Material Types

https://www.the-warren.org/ALevelRevision/engineering/Materialclasses.html

https://simplicable.com/new/materials

https://en.wikipedia.org/wiki/Natural_material

3 Material Properties

https://www.the-warren.org/ALevelRevision/engineering/materials1.htm

https://en.wikipedia.org/wiki/List_of_materials_properties

4 Material Selection

https://blog.mchoneind.com/blog/choosing-a-material-for-your-engineering-design

1 note

·

View note

Text

Types of wear-resistant ceramic pipe and its application in industrial production

Including abrasion resistant ceramic pipe elbow, straight pipe , structural tee, head size, radius sections , adjustable pipe , mainly used for the air force , pumping slurry pipeline and other materials . Because the transmission medium with high hardness, flow speed , flow characteristics, can effectively reduce the transmission medium to the wall to produce long-lasting impact, abrasion , corrosion fatigue causes the pipe was gradually worn out speed. 1 , the definition of wear-resistant ceramic pipe Depending on the working conditions of wear on the wear-resistant ceramic pipe lining materials have different choices. Resistant ceramic lined pipe ( lining of aluminum oxide , silicon carbide , zirconia, silicon nitride , sialon , aluminum nitride, boron nitride , etc. ) ; resistant alloy tube ; hexsteel wearable pipe fittings ; rubber resistant steel grinding tube ; wear-resistant plastic tube ; wear-resistant cast stone pipe ; wearable self-propagating composite pipe ; rare earth alloy wear-resistant pipe. 2 , the main application of wear-resistant ceramic pipe In addition to used in coal-fired power plants wear elbow ash , slag pipe , powder , powder tube back , desulfurization pipes , but also widely used in the following industries: Mining : Coal industry CWS , washing mud , mine backfill , mine coal powder ; Metal mines : concentrate and tailings transport wear elbow ; Metallurgy : Steel mill blast of pulverized coal injection , slag and other transmission pipelines ; CAO, zinc Bei sands pipeline , transporting steel alloys, refining , etc. Preferably wear elbow ; Cement : raw slurry wet rotary kiln production line conveyor , coal transportation, upgrading cutting machine , pneumatic conveying finished unloading cement , concrete wear elbow . Chemical : pulverized coal pipeline , transporting raw materials such as silica fume wear elbow . The main application sectors 3 , wear-resistant ceramic pipe In addition to used in coal-fired power plants wear elbow ash , slag pipe , powder , powder tube back , desulfurization pipes , but also widely used in the following industries: Mining : Coal industry CWS , washing mud , mine backfill , mine coal powder ; Metal mines : concentrate and tailings transport wear elbow ; Metallurgy : Steel mill blast of pulverized coal injection , slag and other transmission pipelines ; CAO, zinc Bei sands pipeline , transporting steel alloys, refining , etc. Preferably wear elbow ; Cement : raw slurry wet rotary kiln production line conveyor , coal transportation, upgrading cutting machine , pneumatic conveying finished unloading cement , concrete wear elbow . Chemical : pulverized coal pipeline , transporting raw materials such as silica fume wear elbow . 4, the detailed use of wear-resistant ceramic pipe Transport has been around electricity, metallurgy, coal , petroleum, chemicals, building materials , machinery and other industries, and high-speed developing. When the wear-resistant ceramic grinding large pipeline materials (such as ash , coal , ore concentrates , tailings, cement, etc. ) , there is an abrasion resistant ceramic pipe faster , especially wear elbow faster. When the pipeline in the wear-resistant ceramic having a strong corrosive gas , liquid or solid , there is a problem of corrosion and wear-resistant ceramic pipe is quickly destroyed . When the pipeline resistant ceramic materials with higher temperatures , there is a heat-resistant steel prices are very expensive problem. After resistant ceramic pipe market, these problems are solved. Wear resistant ceramic pipe is widely used in mine backfill serious , transporting ore concentrate and tailings , coal-fired power plant feed powder , slag , ash and other wear-resistant ceramic pipes are also very suitable . Resistant ceramic pipes are transported strong corrosive acid, alkali , salt and abrasive both solid , wear-resistant ceramic pipe ideal liquid delivery . In the high-temperature corrosion resistant ceramic pipe , high temperature or high-temperature ablation wear occasions using very safe and reliable. 5 , wear-resistant ceramic pipe production technology Resistant ceramic pipes are using self- propagating high temperature synthesis - centrifugation manufacture. After that is placed inside the centrifuge tube seamless steel mold , joined in the steel and aluminum oxide powder mixture , the mixture called thermite in chemistry , centrifuge tube mold rotation reaches a certain speed , through a Mars ignite thermite , thermite now own , the combustion wave spread rapidly , following violent chemical reaction occurs when the spread.

Chapter One – What are Alumina Ceramics?

Alumina Ceramic Liner is an industrial ceramic that has high hardness, is long wearing, and can only be formed by diamond grinding. It is manufactured from bauxite and can be shaped using injection molding, die pressing, isostatic pressing, slip casting, and extrusion.

Products made from alumina, some of which are shown in the image below, are wear, chemical, erosion, corrosion, and high temperature resistant and bioinert, making them perfect for medical implants.

Alumina ceramics are a technical ceramic due to their properties and price to performance ratio. The classification of alumina ceramics is based on their alumina content, which can vary from 70% to 99.9%. The higher the purity of alumina, the stronger is its wear and corrosion resistance.

Chapter Two – Properties of Alumina Ceramics

Alumina ceramics are made from a white granular material that is similar to table salt or a very fine silky dense powder. The three general types of alumina are hydrated, calcined, and tabular. Each type has a variety of grades.

The types of alumina vary according to the amount of soda (Na2O), iron (Fe2O3) and silica (SiO2) they contain as well as their chemical purity and the properties of the powder used in the production process.

Calcined:

To produce calcined alumina, aluminum oxide is heated to 1050° C or 1900° F. The super heating removes all chemicals and water creating a very pure, 99.99% pure, with a 9 on the Mohs hardness scale, which is just below a diamond’s Mohs rating of 10.

Hydrated:

Alumina hydrate, or alumina hydroxide, is used as a glaze because of its ability to stay in suspension in glaze slurries and adhesive qualities.

Tabular:

Tabular alumina is produced by heating aluminum oxide to 1650° C or 3000° F. It has a high heat capacity, excellent thermal temperature, strength, and volume stability. It is formed from sintering balls of calcined alumina, which are crushed to form a powder. Tabular alumina has high refractory properties, mechanical strength, wear resistance, chemical purity, dielectric properties, and corrosion resistance in acids and alkaline.

Properties of AluminaHigh Temperature Ability

Alumina is used in oxidizing and reducing atmospheres up to 1650°C or 2900°F as well as vacuum environments of 2000°C or 3600°F. At 1000° C, it keeps 50% of the tensile strength it has at room temperature. While metals are weakened by high temperatures, alumina ceramics retain their strength when they return to normal temperatures and are unchanged.

Abrasion Resistant

Abrasion wears down a material by rubbing it away by friction. The resistance to abrasion means a material will maintain its original structure even after mechanical wear. Alumina ceramics are high in abrasion resistance due its hardness.

Chemical Resistance

Alumina is resistant to acids and alkalis at high temperatures because it is inert, not chemically reactive, which makes it resistant to the effects of chemicals such as solvents and salt solutions.

Density

The density of a material is its mass divided by its volume, which is read as grams per cubic centimeter (g/cm3) where grams is mass and cubic centimeters is volume. As the volume increases, the density of the material increases. Alumina ceramics are made from fine particles that do not allow for voids in the material. The fewer voids means the material has high volume and density. The density of alumina ceramics varies according to the temperature. At 25° C, its density is 3.965 g/m3 at standard atmospheric pressure.

Mechanical

The mechanical properties of a material is determined by its strength, which is the amount of stress and strain it can endure. Alumina has superior strength and hardness that improves with the purity of the different grades.

Thermal

Alumina has high resistivity and reduces thermal shock. The increased purity of alumina increases its resistivity.

Dielectric

Alumina ceramics make a perfect insulation material because of its dielectric equality, the inability of an electric current to pass through them.

Hardness

Hardness tells the ability of a material to be able to endure mechanical wear and abrasion. Alumina ceramics are harder than steel and tungsten carbide tools. They are harder than sapphire and are excellent for mill linings and bearings. According to Rockwell hardness, alumina ceramics are at HRA80-90, second only to diamonds and above stainless steel.

ZTA ceramic liner is zirconia toughenedalumina ceramic liner ,belonging to inorganic non-metallic materials, is a good wear-resistant materials. Zirconia toughening alumina ceramic is added pure 99 Zr02 zirconia, the particles form ZrO2 toughened alumina ceramic. Alumina toughness can be significantly improved when zirconia is added as appropriate. It can be said that the toughening of alumina ceramics is the toughening method most used at present, and about 20% zirconia (ZrO2) is added to toughen the alumina.

ZTA toughening effect mainly comes from the following mechanism:

(1) to make the aluminum oxide grain refinement.

(2) Zirconia phase change toughening.

(3). Micro-crack toughening.

(4). Crack steering and bifurcation. Zirconia toughened alumina mechanical properties: ZTA

(zirconia toughened alumina) ceramic density > 4.1, Rockwell hardness > 90, Vickers hardness >

1300, fracture toughness 6.0, flexural strength 480MPa, compressive strength 3600MPa, ZTA toughening alumina ceramic liner is added on the basis of alumina zirconia ceramic ingredients, abrasion resistance and toughness between the alumina ceramic and zirconia ceramics, zirconia ceramics because the higher prices, the user once The larger the amount investment, the largest number of manufacturers are mostly European and American companies and BHP Billion and other groups.

What is Concrete Pump Pipe?

Concrete pump pipeline is used with concrete pumps to ensure that the concrete is delivered correctly and safely to where it needs to be. It's an essential part of truck-mounted concrete pumps, trailer pumps, or placing booms. The concrete pump pipe is the most wearing component on a concrete pump as it has the biggest contact and the most friction with the concrete. The durability of pipes is one of the major factors to the pumping efficiency.

0 notes

Text

#Non electric soda Machine Manufacturers#Mobile soda machine#Mobile soda machine manufacture#Soda machine price#Soda Fountain Machine Manufacturers

1 note

·

View note

Text

What to do with your unwanted home appliances?

Your washing machine and refrigerator have spent a good ten years serving your needs. There are other appliances too that’s been around, slowly stepping into old age. You could do with a set of new machines around the house. But, how do you know it’s time to buy new appliances and what do you do with the old ones?

Signs that show your metal appliances are young no more

An old washing machine displays these old age signs:

It makes loud noises when its drum is in motion during the spin or wash session.

It uses too little water indicating a leakage .

It uses too much water, indicating that water isn’t draining.

The machine uses up multiple cycles for washing rather than one.

An old refrigerator displays these old age signs:

When water leaks from underneath due to a leak in the water connection.

Water is leaking inside the fridge due to a plugged drain pipe.

The refrigerator is not cooling anymore due to dust accumulation or a blocked air vent.

What a Scrapyard can offer you for your old home metal appliances?

Scrap metal recycling is a widely accepted operation implemented to repurpose metals. At our scrapyard, we have a ton of metals sold by countless owners. We get a lot of steel and aluminium metals sold to us. We want to help you collect more of such metals to make a fortune from scrap.

In today’s blog, we’re going to look at the appliances you can check in aluminium and steel. Their scrap metal prices differ from each other, and they are found in different applications.

We’ve provided a comprehensive list to help you understand what to look for in metal appliances at home. Keep collecting them until you can sell them in bulk.

What you should look for in steel

At Metal Force Recycling, we offer a steel scrap price for up $1.00 – $1.70. We have various steel items that reach our scrapyard. Let’s help you make a list of the things that you can sell to us.

Refrigerators

Freezers

Washing machines

Clothes dryers

Dishwashers

Bicycles

Weight benches

Auto parts like engines, exhausts, wheel rims

There are several other steel parts that you will find. However, much of those are found in commercial and manufacturing companies rather than homes.

What you should look for in Aluminium

At Metal Force Recycling, we offer an aluminium scrap price for up $0.80 – $1.30. The production of fresh aluminium requires more power and extracting tools for natural mining of ores. When junk aluminium is recycled, it uses up 5% of the energy used during ore extraction methods. So, opt for recycled aluminium to reduce energy consumption.

Electrical systems

Pots

Pans

Car bonnets

Truck engines

Gearboxes

Old furniture

Tyres

Soda cans

Power cables

Cookware

We are a licensed wrecking company that buys metals of all kinds, ferrous and non-ferrous. Call our experts to get a hold of what types of metals you should look for around you. If you already have a bunch of scrap waiting to be sold, connect with us for a free quote.

0 notes

Text

INTRODUCTION OF AUTOMATIC MINERAL WATER FILLING MACHINE

FEATURES :

Integrated rinser - filler - capper , rotary , fully automatic

FULLY NECK HOLDING design

NO CHANGE PARTS , NO BOTTLE - NO RINSE / NO FILL / NO CAP

Filling size capability from 200 to 2000 ml

Infeed air conveyor for feeding empty bottles

Automatic cap elevator cum orientator for feeding closures

SS304 , non magnetic , torque adjustable capping heads

Online inspection lamp box for filled bottles

Rinse water and product water delivery pumps included , along with internal piping

SS304 cladded machine platform and rotor housings

All contact parts are made from SS304

Fully automatic operation on monoblock , untouched by the human hand

UV lamp sterilisation on cap chute

Online cap washing option available

SS304 cabinet , electrical control panel with all safety features

Online shrink tunnel option available

Liquid Filling Technologies for Water Bottles

Xinmao Drink Machinery offers large collection of liquid filling machines with various filling technologies. These filling technologies are applicable to fill for liquid various viscosities. Since water has a very low viscosity, you should choose the right machinery for your water bottle filling line. The following filling machines are recommended for water bottles:

Mechanical gravity filter

For low viscosity liquid such as water, juice and wine, gravity filling machines are one of the best options for your production line.

Flow meter filter

Flow meter filling machines are best for liquids like water, juice, CSD and wine. This filter can be used for juice filling machine or wine filling machine.

Vacuum filter

Vacuum filling machines are an option for low and medium viscosity liquids such as water, juice, wine and condimen.

Weighing filter

Weight filling machines are suitable for large container filling applications. These filters are one of options for water or juice bottle filling line.

Benefits of Automatic Liquid Filling Machinery for Water Bottles

Xinmao Drink Machinery offers a wide range of machinery solutions capable of filling for low-viscosity liquids such as water with the bottle shape like PET circular or square. The following are the benefits of installation of a liquid filling machine in your assembly line.

Higher Productivity

Higher Productivity is an important goall of beverage companies. The machine has adjustable speed limits to increase and decrease the speed as and when required. The production can be regulated as per demand forces in the market, leading to higher productivity.

Cost-effective and time-saving

Purchasing water filling machines is a high investment, but it is the best strategy to reduce labor and time costs. The companies can focus on more fruitful sources of the business without time waste.

"Xinmao Drink Machinery" Well Known a Manufacturer Of Mineral Water Bottling Machine, Packaged Drinking water bottling machine, pure water bottling machine, natural water bottling plant, Carbonated Drink Bottling Machine, Synthetic Juice Bottling Machine, natural Juice Hot Filling Bottling Machine, Filling Capping Machine, Soft Drink glass bottling Machine, Flavored Milk bottling Machine, Flavored Water Bottling Machine, PET bottling Machine, Glass bottling machine, PET Can Rinser Filler Seamer Machine, Soda bottling Machine, Oil Bottling Machine etc. We customized machine as per customer requirement according customer products.

As a professionable manufacturer and supplier, Xinmao Drink Machinery specializes in the packaging industry and offer a wide selection of automatic water filling machines at reasonable price. Our products have several features like a PLC system, touchscreen interface and several containers of different shapes and sizes. You’ll find 3-in-1 washing filling capping machine as well as bottle labeling machine for your complete water bottle packaging line here.

0 notes

Text

Conveying Equipment

https://www.nielmachinery.com/products/powder-conveying-equipment-system/

Conveying Equipment

The conveyor is a machine that frictionally drives the material in a continuous manner. It can be used to form a material conveying process on a certain conveying line from the initial feeding point to the final discharging point. It can carry out the transportation of broken materials as well as the transportation of individual items. In addition to pure material handling, it can also be combined with the requirements of the process in the production process of various industrial enterprises to form a rhythmic flow line. Therefore, the conveying equipment is widely used in various modern industrial enterprises.

Conveying Equipment List

Vacuum Conveyor

NZKS vacuum conveyor unit is using a whirlpool air pump extracting air. The inlet of absorption material tap and the whole system is made to be in a vacuum state. The powder grains of material is absorbed into the material tap with ambient air and formed to be the air flowing with material passing the absorption material tube, they arrive at the hopper.

Vacuum Conveyor

Auger Conveyor

Auger conveyor is also called material hoist. The vibrating screw feeder can lift a variety of powder materials. The material box and the auger are made of stainless steel. The vibration amplitude of each switch motor and vibration motor can be adjusted.

Auger Conveyor

Bucket Elevator

The bucket elevator is suitable for lifting from a low place to a high place. After the material is supplied to the hopper through the vibrating table, the machine automatically runs continuously upwards.

Bucket Elevator

Belt Conveyor

Belt Conveyor is widely used in home appliances, electronics, electrical appliances, machinery, tobacco, injection molding, post and telecommunications, printing, food and other industries, assembly, testing, debugging, packaging and transportation of objects.

Belt Conveyor

Roller Conveyor

Roller conveyor is suitable for the transportation of all kinds of boxes, bags, pallets, etc., bulk materials, small items or irregular items that need to be placed on the pallet or in the tote. It can transport a single piece of material with a large weight, or withstand a large impact load.

Roller Conveyor

Application Industry of Conveying Equipment

Fine chemicals: pigments, dyes, coatings, carbon black, titanium dioxide, iron oxide, ceramic powder, heavy calcium, light calcium, bentonite, molecular sieves, kaolin, silica gel, activated carbon, etc.

Pesticide ore: urea, ammonium chloride, ammonium bicarbonate, soda powder, solid pesticides, tungsten powder, pesticide additives, copper concentrate powder, coal powder, phosphate rock powder, alumina powder, etc.

Building materials: cement, clay, yellow sand, quartz sand, clay powder, silica, limestone powder, dolomite powder, sawdust powder, glass fiber, silica, talcum powder, etc.

Food industry: flour, starch, cereals, milk powder, food additives, etc.

Classification of Conveying Equipment

The powder conveying equipment refers to the material handling machinery that continuously transports materials on a certain line, also known as the assembly line. The conveying line can be transported horizontally, obliquely and vertically, or it can form a space conveying line, which is generally fixed. The conveyor has a large conveying capacity and a long transportation distance, and can also complete several process operations simultaneously in the conveying process, so the application is very extensive.

Belt conveyor

The belt conveyor consists of a driving device, a tensioning device, a conveyor belt, a middle frame and a roller to form a conveyor belt.

As traction and load-bearing member, the bulk material or the finished product is continuously conveyed.

Auger conveyor

Auger conveyor is commonly known as an auger, suitable for horizontal conveying of granular or powdery materials, inclined to convey, vertical transport and other forms. The transport distance varies according to the deformity, generally from 2 meters to 70 meters.

Bucket elevator

The bucket elevator utilizes a series of hoppers that are uniformly fixed to the endless traction member, vertical. A continuous conveying machine that lifts materials. The bucket elevator has the advantages of large conveying capacity, high lifting height, stable and reliable operation, and long service life.

Roller conveyor

Roller conveyors can transport parts with a flat bottom at a horizontal or small angle of inclination products, such as plates, rods, tubes, profiles, trays, box containers and various workpieces. For non-flat bottom items and flexible items, delivery can be achieved by means of a tray. It has the characteristics of simple structure, reliable operation, convenient maintenance, economy, energy-saving, etc. The most outstanding thing is that he can be well connected and matched with the production process, and has functional diversity.

Vacuum conveyor

Vacuum feeder is a dust-free and closed pipeline conveying equipment that transports particles and powder materials by means of vacuum suction. The pressure difference between vacuum and environmental space is used to form gas flow in the pipeline and drive powder. The material movement to complete powder delivery.

Development Trend of Conveying Equipment

In the future, the conveyor will develop towards large-scale development, expanding the scope of use, automatic sorting of materials, reducing energy consumption, and reducing pollution.

Continue to develop into a large-scale.

Expand the scope of use of the conveyor. Develop conveyors that can operate in environments with high temperatures, low temperatures, corrosive, radioactive, and flammable materials, as well as materials that can transport hot, explosive, agglomerated, and viscous materials.

Make the structure of the conveyor meet the requirements of the single handling of the automatic control of the material handling system.

Reducing energy consumption to save energy has become an important aspect of scientific research in the field of transportation technology.

Reduce the dust, noise and exhaust gas generated by various conveyors during operation.

About Neil Machinery

The conveying equipment is one of the main parts of Neil mechanical products. Neil Machinery provides a roller conveyor, belt conveyor, ribbon conveyor, screw feeder, vacuum feeder, chain conveyor, sterilization conveyor, etc. Equipment, and can be designed and manufactured according to the needs of customers. These conveying equipment can form a complete powder production line with other products of Neil Machinery. You can leave a message or consult us according to specific needs.

0 notes

Text

Advantages and Disadvantages of Prefabricated Construction Products

Zhonglian Group has won a favorable reputation through 13 years of growth and development. Serving 60 countries and regions in the world, including Southeast Asia, Africa, South America, French island countries, Pacific island countries. At present, major product lines such as Steel products, Prefabricated Steel structure, Building Materials, and Chemicals have been formed, which will continue to develop in deeper professions and brand building.

For Prefabricated Steel Structure, is composed of steel material structure. The Structure is mainly made of profile steel & steel plate, steel column, and steel truss girder artifacts, such as weld is required between each component or parts, bolt connection. The weight is lighter, and the construction is simple with installation at a short time, widely used in large factories, stadiums, high-rise, and other fields.

It can be produced as a steel structure warehouse, steel structure house, steel structure school, hospital, steel structure packing, mall, hotel, temporary house, temporary working area, showroom, dormitory building, etc.

For Building materials: We take design and quality as the core, we're driven by material and process research and development, we are the international lead medium and high-end one-stop project solution provider which provides the integration of original design, engineering construction, materials selection, and purchase, whole-house customization, soft furnishing and after-sales service for customers.

For Chemical Products: Zhonglian mainly produces more than 50 fine chemical products in the categories of polyurethane joint mixture series, industry chemicals series, soap & detergent chemicals, food additive chemicals as well as agriculture chemicals. We cooperate with the biggest manufacturer as a partner in China and Korea. We have professional services, carefully product inspection, and correct customs declaration documents; we are wanting to trade with our customers with safety at reasonable prices.

Our Head office is located in Guangzhou City with 500 square meters of offices and 200 square meters of showrooms. We also have branch offices and warehouses in Foshan and Yiwu. We are a 13 years audited golden supplier of Alibaba. We often attend the famous exhibition domestic and overseas every year, such as the Canton fair, Worldbex in the Philippines, AfricaExpo in Tanzania, Bathmat in France, etc. We have established and continuously improved the management system. The Zhonglian Team is always full of passion to carry our mission: We Serve, We Build, Happy life.

As the prefab homes are built at the factory, so the permits are completed at the state level. Most of the time these home builders have more than one project of building homes in the plant since the inspectors are always on the construction site. They allow continuous inspections as well as seamless transitions from one aspect of the build to a new one. Thus, the homes are inspected in the plant, local permitting for establishment and utilities are being handled easily. By making this process simpler, permitting is completed without stoppage and a house gets constructed that much faster.

Aluminum Venetian blinds are characterized by tenacity, damp-proof, rust-proof, non-aging, non-fading, sturdily, and durability.

It is widely used blinds, which can be installed in kitchen, balcony, bathroom, office, etc. You will get a simple and elegant view by installing it.

·Adopt high-quality aluminum alloy blades, stiffness made strong, flexibility is high.

·Color is rich, well-made.

·Flexibility is good, changeful form can heat insulation sunshade, free to adjust indoor light, block ultraviolet light

·Crossbar, beams, leash, ladder rope unified color matching, and the beauty is generous.

·Fluctuation beam unified the lacquer that bakes, not to drop paint, rusty.

·Width of the aluminum slat: 16mm, 25mm, 35mm, 50mm

·Thickness of the aluminum slat: 0.16mm, 0.18mm, 0.21mm

·Size available: Width8’’-100’’, Height:6”-138”

·Color options: as a color swatch

·Light control: Diffused light, complete privacy

·Operation system control: Standard cord

·Tilt Control: Wand control or cord control

·Soil and dust resistant: Good

·Window Shape “Horizontal

·Safety feature: Yes

·UV protection: 75%-90%

Specification

1: Salt width: 16mm, 25mm, 35mm, 50mm

2: Slat thickness: 0.16mm, 0.18mm, 0.21mm

3: Slat color type: Solid color, Pearl shining, whole, wood grain

Window Blinds

Aluminum Venetian blinds are characterized by tenacity, damp-proof, rust-proof, non-aging, non-fading, sturdily, and durability.

PVC Blind

Roman shades clear outdoor monsoon PVC blind with 316 stainless steel corrosion protection

Steel Products Steel Structure

Steel Products Main products: Steel Structure, Steel Coil& Sheet, Steel Beam & Bar Profile, Steel Tube& Pipe, Steel Wire & Nails, Steel Roofing & Wall Sheets, Sandwich Panel, Scaffolding & Props, Wire Mesh.

Building Materials