#Nitrile

Explore tagged Tumblr posts

Text

𝗩𝗔𝗟𝗣𝗥𝗢 𝗘𝗫𝗧𝗥𝗘𝗠𝗘 𝗜𝗜

Features: Liner: Knitted Jersey, Liner Color: White Nitrile Coating, Texture: Smooth Coating Color: Blue, Length: 26 cm Features: The gloves have a heavy weight nitrile full coated. The inner is a 100% jersey with a cotton wristing,canvas safety cuff. The gloves are excellent for all round general handling situations. Applications: Cargo Handling, Handling Boxes, Recycling Industrial Manufacturing, Mechanical, Warehousing

Visit: https://sams-solutions.com/.../nitrile-gloves-valpro...

To place your order online : https://www.ppe-online.com/.../nitrile-gloves-valpro...

0 notes

Text

COMPREHENSIVE PROTECTION: THE VERSATILITY OF NITRILE GLOVES

by ads Converclick on June 10, 2024

Nitrile gloves have become an essential part of personal protective equipment (PPE) due to their versatility and reliability across various industries.

0 notes

Text

#personalprotectiveequipment#covid#ppe#facemask#eyewear#staysafe#coronavirus#nitrile#recreation#safety#fun#safetyfirst#gloves#mask#fashionaccessory#vehicle#helmet#socialdistancing#medicalsupplies#visioncare#electricblue#leisure#t#sunglasses#masks#nitrilegloves#conquercovid#pandemic#glasses#medical

0 notes

Text

From out of the shadows.

I wanna meet some folks like me…

#cross dressing art#crossdressgirls#cross dressing#crossdress#androgyny#black and white#gloves#nitrile

0 notes

Text

Exploring NBR Material for O-Rings: A Comprehensive Guide

O-rings are versatile sealing components used in various industries, from automotive to aerospace, pharmaceuticals to food processing. They play a critical role in preventing leakage, maintaining pressure, and ensuring the integrity of various systems. When it comes to choosing the right material for o-rings, NBR (Nitrile Butadiene Rubber) stands out as a popular and reliable choice.

Understanding NBR Material

Composition: NBR is a synthetic rubber compound composed of acrylonitrile and butadiene. The ratio of these two components can be adjusted to achieve specific properties, making NBR a versatile material.

Key Properties:

Excellent resistance to oil and fuel.

Good abrasion resistance.

Wide temperature range (-40°C to 120°C, depending on the formulation).

Superior tensile strength and tear resistance.

Resistance to ozone and weathering.

Low cost compared to some other elastomers.

Suitable for both dynamic and static sealing applications.

Applications of NBR O-Rings

Automotive Industry: NBR o-rings are commonly used in engines, transmissions, and hydraulic systems due to their outstanding resistance to oil and fuel. They help maintain the integrity of automotive components, ensuring reliable performance.

Industrial Machinery: In various industrial applications, such as pumps, compressors, and valves, NBR o-rings provide effective sealing solutions for both static and dynamic operations. Their resilience to wear and tear makes them a preferred choice.

Food and Beverage Industry: NBR o-rings are often used in food and beverage processing equipment where they come into contact with oils and fats. Their resistance to these substances helps maintain hygiene and prevent contamination.

HVAC Systems: Heating, ventilation, and air conditioning systems rely on NBR o-rings to seal refrigerants and maintain efficient operations.

Hydraulic Systems: NBR o-rings are preferred for hydraulic systems due to their compatibility with hydraulic fluids and excellent sealing properties.

Advantages of NBR O-Rings

Cost-Effective: NBR o-rings are economical compared to some other elastomers, making them a cost-effective choice for many applications.

Oil and Fuel Resistance: Their exceptional resistance to oil and fuel ensures the longevity of seals in environments where exposure to these substances is common.

Versatility: NBR material can be formulated to meet specific requirements, making it versatile for various applications.

Temperature Range: NBR o-rings can perform well in a wide temperature range, allowing them to be used in both high and low-temperature applications.

Durability: NBR o-rings are known for their durability and long service life, reducing maintenance and replacement costs.

Considerations for Selecting NBR O-Rings

Compatibility: Ensure that NBR is compatible with the fluid or media the o-ring will come into contact with. NBR may not be suitable for all chemicals or solvents.

Temperature Range: Be aware of the operating temperature range of your application and choose an NBR formulation that can withstand it.

Compression Set: Evaluate the O-ring's ability to maintain its shape and sealing properties over time, especially in applications with continuous compression.

Hardness: NBR o-rings are available in different hardness levels (measured in durometer). Select the appropriate hardness for your specific application.

Advantages of using silicone grease with PTFE (Polytetrafluoroethylene) during the installation of NBR O-rings include improved lubrication, which reduces friction during assembly, and enhanced sealing effectiveness, as the PTFE helps to create a smoother, more uniform surface, reducing the risk of O-ring damage or deformation during installation. This combination of silicone grease and PTFE further ensures the longevity and reliability of the sealing system.

NBR O-rings are a reliable and cost-effective choice for many sealing applications. Their excellent resistance to oil and fuel, versatility, and durability make them a preferred option in many industries. When selecting NBR O-rings, consider factors such as compatibility, temperature range, compression set, and hardness to ensure optimal performance. By understanding the properties and applications of NBR material, you can make informed decisions for your sealing needs.

0 notes

Text

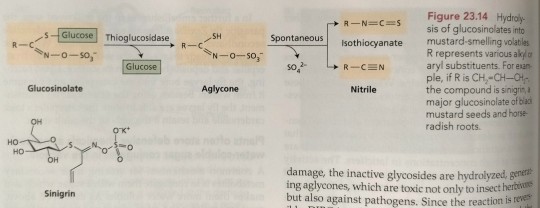

When the tissue is damaged, the released myrosinase and glucosinolates mix, resulting in the irreversible production of an unstable aglycone, which then rearranges into a variety of biologically active compounds, mostly nitriles and isothiocyanates (Figure 23.14).

"Plant Physiology and Development" int'l 6e - Taiz, L., Zeiger, E., Møller, I.M., Murphy, A.

#book quotes#plant physiology and development#nonfiction#textbook#hydrolysis#mustard#volatiles#myrosinase#glucosinolate#unstable#aglycone#nitrile#isothiocyanate#sinigrin#black mustard#horseradish

0 notes

Photo

12 Pairs Blue Oil Resistant Durable And Anti- Slip Gloves Nitrile Rubber

0 notes

Text

Nitrile Glove

Nitrile gloves perform excellent features as a type of disposable gloves, very soft, and strong enough to do anything disposable gloves can do. They offer the best splash protection against chemicals among the disposable gloves, they also have excellent barrier properties against biohazards, water-soluble substances, weak acids and bases, aliphatic solvents as well as oils and fats. They do not contain latex proteins which reduces the allergic reaction risk.

For the medical industry, nitrile gloves get the highest rate regarding safety and durability. They are reliable for the most hazardous tasks in a hospital. Nowadays, nitrile gloves are also massively used in other industries, such as food processing, homework, agriculture, animal husbandry, chemical laboratories, automotive and precise instrument manufacturing.

What are the Nitrile Gloves Made of?

Nitrile gloves are made of nitrile rubber, a reprocessed form of latex, from butadiene (H2C=CH-CH=CH2) and acrylonitrile (H2C=CH-CN), mainly produced by low-temperature emulsion polymerization.

The features of nitrile gloves depend on the composition of butadiene and acrylonitrile. The butadiene component gives the copolymer elasticity and resistance to low temperatures, acrylonitrile is responsible for the good chemical resistance. Increasing the content of one of these components will reduce the propriety of the other. Thus, the manufacturer need to equilibre the ingrediants to produce the market required products.

0 notes

Text

Gorilla Flex Cool II Nitrile foam finish palm coated cut resistant glove

Features:

Unique NBR micro foam finish provides excellent dry,

wet and oil grip performance.

360 degree breathable coating keeps hand cool &

comfortable. Ergonomically design for superior fit, feel & comfort.

Special blend of engineered covered yarn for high cut performance & protection.

Excellent abrasion resistance allows long term use and better durability.

Product is in compliance with reach directives, Oeko Tex certified & azo free dyestuff. Coating: Black nitrile rubber coating. 30% coating content.

Liner: 15GG machine knitted. Grey, Black & Red. Nylon & spandex. 70% liner content. Length: 220-280mm.

Size: Medium, Large, XLarge.

Application:

General maintenance, agriculture, automotive, construction, mechanical assemble, precision machinery, engineering workshops & logistic.

Visit : https://sams-solutions.com/products/gorilla-flex-cool-ii

#empiral#gorilla#nitrile#gloves#handprotection#safety#safetyfirst#safetyequipment#follower#highlightseveryone

0 notes

Text

THE BEST NITRILE GLOVES OF 2024: A COMPREHENSIVE GUIDE

0 notes

Text

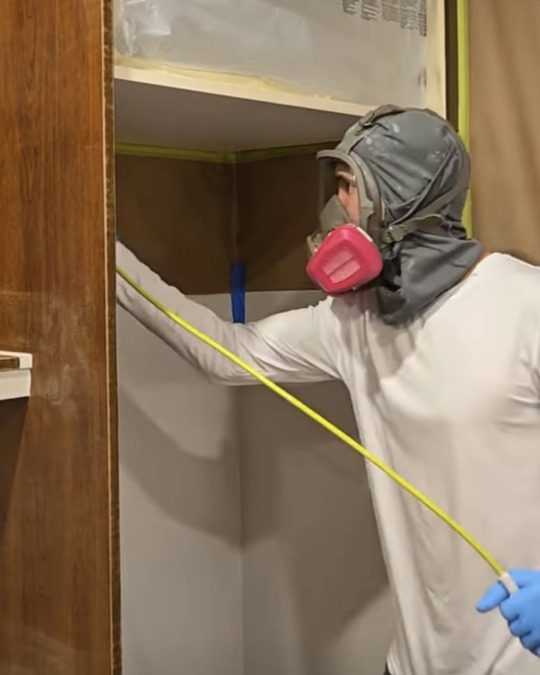

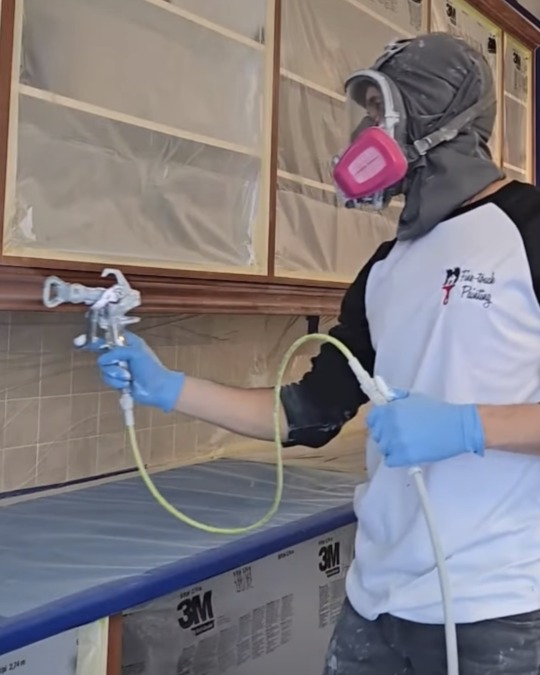

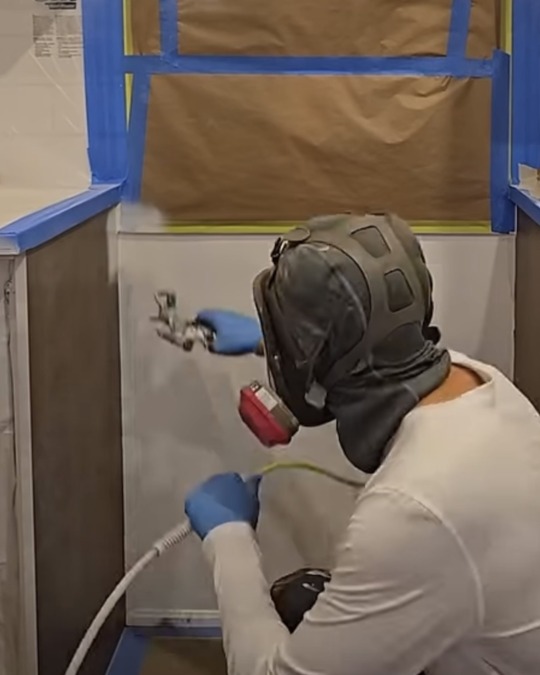

Young painter who wears a full face respirator over a spray sock, and blue nitrile gloves. I love seeing the masks head harness strapped over his head.

#respirator#full face respirator#gas mask#protection#safety gear#protective wear#work wear#workwear#nitrile gloves#masked men#guysingear

21 notes

·

View notes

Text

From "Bondage Bed Stocks" ft Bondagefan70

51 notes

·

View notes

Text

cleaning out my bedside drawers and realising that when i whittle it down to just the essentials it kind of looks like its all sex stuff but like. weird sex stuff.

18 notes

·

View notes

Text

it turns out catheter ablations require you to remove all jewelry beforehand due to burn risk. i had four/five (depending on how you count) that were still healing... all of them closed up by the time i was out. at home now and while the nostril is a loss i've salvaged both secondary lobes and the industrial please fucking CLAP that shit hurted so bad

#txt#yes i sterilized i used probably a dozen alcohol wipes + set the one i dropped on fire for half a minute to be extra sure + nitrile gloves#i was tearing up involuntarily when i got to the industrial#jesus FUCKING christ

26 notes

·

View notes

Text

Empiral Gorilla Chem I | 15mil (0.38mm) Flock Lined | Chemical Resistant Nitrile Glove |

Visit : https://sams-solutions.com/product/gorilla-chem-i

Now place your order Online : https://www.ppe-online.com/products/gorilla-chem-i

0 notes

Text

look no ones saying it HAS to be erotic dentist roleplay but like- i really wanna put my hands in your mouth and i just so happen to enjoy nitrile gloves and if youre comfortable with it id like to get in there with some small mirrors and instruments. so.

#fr i dont really have like a dentist thing but i love teeth and nitrile gloves and have a slight medfet streak so#might as well be a dentist kink. i guess.

21 notes

·

View notes