#NdT

Explore tagged Tumblr posts

Text

Suddenly I feel like watching AAA.

This woman has a story.

17 notes

·

View notes

Text

Ultrasonic inspection involves the propagation of high-frequency sound waves through a material to identify internal flaws & irregularities. Read More!

9 notes

·

View notes

Text

How BioScan LTD Performs Heat Exchanger Inspection for Industrial Tanks

Industrial tanks rely heavily on heat exchangers to maintain efficient operation. Regular heat exchanger inspection is crucial for preventing costly downtime and ensuring product quality. Bioscan LTD, a leading provider of tank inspection services, offers a reliable and effective method for heat exchanger integrity testing.

Understanding Heat Exchanger Integrity Testing

Heat exchanger integrity testing, also known as heat exchanger inspection or heat exchanger testing, evaluates the overall health of the exchanger. This process identifies potential problems like leaks, cracks, corrosion, and other defects that can compromise heat transfer efficiency and lead to product contamination. Bioscan LTD utilizes an advanced method for heat exchanger testing methods known as hydrogen tracer gas testing.

Bioscan LTD's Hydrogen Tracer Gas Method

This non-destructive testing (NDT) technique leverages the unique properties of hydrogen gas. Due to its small size, hydrogen can penetrate even the most minuscule cracks and imperfections within the heat exchanger. Bioscan LTD's procedure for heat exchanger testing involves:

Pressurization: The service side (heating/cooling) of the exchanger is pressurized with a hydrogen tracer gas.

Air Circulation: A constant airflow is established on the product side using a closed-loop system with a membrane pump.

Hydrogen Detection: Bioscan LTD's high-sensitivity sensors meticulously monitor the product side for any hydrogen gas concentration.

Data Analysis: Measured values are recorded and analyzed to pinpoint leaks or defects.

Benefits of Bioscan LTD's Heat Exchanger Inspection Services

Bioscan LTD's heat exchanger inspection offers several advantages:

Accurate Leak Detection: The hydrogen tracer gas method excels at detecting even the smallest leaks, ensuring a comprehensive inspection.

Non-Destructive Testing: This method avoids damaging the heat exchanger, minimizing downtime and repair costs.

Detailed Reporting: Bioscan LTD provides a comprehensive report outlining the inspection findings, including defect locations and severity.

Improved Efficiency: Regular heat exchanger testing with Bioscan LTD helps maintain optimal heat transfer efficiency, saving energy costs.

Enhanced Safety: Early detection of leaks and defects prevents potential safety hazards associated with exchanger failures.

Why Choose Bioscan LTD for Heat Exchanger Inspections?

As a trusted tank inspection company, Bioscan LTD offers unparalleled expertise in heat exchanger integrity testing. Their hydrogen tracer gas method provides a reliable, non-invasive solution for heat exchanger testing. By partnering with Bioscan LTD for regular heat exchanger inspection, you can ensure the smooth operation of your industrial tanks, optimize product quality, and minimize the risk of costly downtime.

For superior heat exchanger testing methods and comprehensive tank inspection services, contact Bioscan LTD today.

#HeatExchangerTesting#HeatExchangerInspection#IntegrityInspections#TankInspectionServices#NDT#IndustrialMaintenance#TubeHeatExchangers#VesselCrackTest#SafetyFirst#IndustrialSafety#BioScanLTD#HeatExchangerIntegrity#TestingMethods#IndustrialTanks#EquipmentReliability

1 note

·

View note

Text

Multi - Frequency Eddy Current Testing Machine - Magkrafndt

Eddy Current Testing Machines use advanced technology to identify and sort materials based on conductivity, hardness, and other essential physical properties accurately.

#magkraftndt#frequencyeddycurrentmachine#mpimachine#magnafluxmachine#ndt#demagnetizermachine#eddycurrenttestingmachine#magneticparticletestingmachine#mpimachinemanufacturer

0 notes

Text

When it comes to inspecting materials or components without causing any damage, Non-Destructive Testing (NDT) plays a crucial role. Whether you’re in construction, manufacturing, aerospace, or automotive industries, choosing the right Non Destructive Testing lab ensures your product is safe, reliable, and compliant with quality standards.

0 notes

Text

What do you wish you knew when you started in NDT?

I began my journey in NDT back in 2009, thanks to a supervisor who gave me a shot. I’ll be honest—when I started, I had no idea what I was doing.

Over time, I picked up tips, tricks, and best practices from experienced technicians, online forums, industry magazines, and, yes—plenty of trial and error. Some of the things I learned seemed so obvious in hindsight that I couldn’t help but wonder: Why wasn’t this covered in my initial training?

Since then, I’ve completed numerous Level I, II, and III courses across multiple NDT methods, and I’ve also taught several Level I and II classes using various training materials passed down by multiple Level IIIs. Each instructor brought their own insights, yet even with all that combined experience, I still haven’t seen the kind of practical knowledge I desperately needed when I was just starting out.

We, as NDT professionals, have gained so much through hands-on experience—but too often, that knowledge isn’t making its way to the next generation of techs.

Red Menace NDT aims to change that. We’re developing new classroom training programs for Magnetic Particle, Liquid Penetrant, and Ultrasonic Testing, designed to bridge that gap.

I invite all technicians—Level I, II, or III—to share the one thing they really wish they’d known when they began their careers. Let’s make sure the next wave of NDT professionals gets the knowledge we had to work so hard to find.

#ndt things#ndt#ndtinspection#nondestructivetesting#qualitycontrol#ndttesting#ultrasound#Liquidpenetrant#Magneticparticle#NDTClassroom

0 notes

Text

Magnetic Particle Testing (MT): Enhancing Surface Crack Detection in Industrial Components

Magnetic Particle Testing (MT) is a widely used non-destructive testing (NDT) method designed to identify surface and slightly subsurface discontinuities in ferromagnetic materials. This inspection technique plays a crucial role in industries such as aerospace, automotive, oil & gas, and manufacturing by ensuring the structural integrity of components without causing damage. By using finely milled iron particles and magnetic fields, MT testing effectively detects cracks, seams, laps, and other flaws that are invisible to the naked eye. Compared to other NDT methods, magnetic particle inspection is cost-effective, fast, and highly reliable. Engineers and quality control professionals rely on magnetic testing to maintain safety standards and extend equipment life.

#MagneticParticleTesting#MagneticTesting#NonDestructiveTesting#NDT#MTTesting#SurfaceInspection#IndustrialInspection#QualityControl#WeldTesting#MaterialTesting

0 notes

Text

If you're looking for accurate and reliable wire rope NDT testing equipment, Best NDT Inspection offers the ideal solution. Designed for professionals in industries like mining, oil & gas, cranes, elevators, and cableways, their advanced non-destructive testing systems ensure the structural integrity and safety of wire ropes without causing any damage or downtime.

Best NDT Inspection's equipment is known for its ease of use, robust performance in harsh environments, and high detection sensitivity. Whether you're inspecting a hoist rope in a crane or a suspension cable in a cable car, their devices deliver detailed reports, real-time alerts, and intelligent data analysis for preventive maintenance.

Why Choose Best NDT Inspection for Wire Rope Testing?

High-Accuracy Magnetic Flux Leakage (MFL) Technology: Detects internal and external flaws like broken wires, corrosion, wear, and core defects.

Real-Time Monitoring: Get instant insights and detailed logs for better decision-making on-site.

Portable and Easy to Operate: Lightweight design allows on-the-go inspections without disrupting operations.

Data Storage & Reporting: USB & wireless data transfer options, along with comprehensive reporting tools.

Customizable Models: Tailored for various rope diameters and industrial applications.

Cost-Effective Maintenance: Helps reduce unexpected downtime and extend the life of wire ropes.

Global Support & Training: Backed by expert support and onsite or remote training sessions.

Ideal For:

Mining operations

Offshore drilling rigs

Construction cranes

Aerial tramways and cable cars

Elevator systems in high-rise buildings

With increasing regulatory demands and safety standards, having trusted wire rope NDT testing equipment is no longer optional—it’s a necessity. Best NDT Inspection understands the critical nature of these inspections and delivers solutions that are not only compliant but also user-friendly and budget-conscious.

Ready to Inspect with Confidence?

Explore the full range of wire rope NDT solutions and request a free consultation. Don’t leave safety to chance—equip your team with the right tools to detect hidden dangers before they turn into costly failures.

Contact Us:

Phone: 65-84797783

Visit: https://www.bestndtinspection.com/

#nondestructivetesting#ndt#ndtservices#ndtinspection#bestndtinspection#industrialsafety#singapore#qualityassurance#qualitycontrol#safetyfirst

0 notes

Text

Il progetto europeo MIMOSA sviluppa giunzioni 3D tra metalli AM e carbon-fiber per velivoli più leggeri e riciclabili. Protagonisti TÜV Italia e Bytest, eccellenze nei test e nella certificazione. Scopri i risultati su Alessandria today.

#additive manufacturing#aeronautica sostenibile#aerostrutture#Alessandria today#atomizzazione#Bytest#certificazione aeronautica#certificazione processi#compositi carbonio#distretto aerospaziale Piemonte#eco-design#Economia circolare#Fenice#fibre di carbonio#Giorgio De Pasquale#giunzioni ibride#Google News#green aviation#Horizon Europe#innovazione materiali#italianewsmedia.com#laboratorio Volpiano#Lava#Leonardo#life-cycle assessment#lightweight structures#NDT#Pier Carlo#POLITECNICO DI TORINO#progetto MIMOSA

0 notes

Text

Beyond Basics: Exploring the Future of Advanced NDT Services

Advanced NDT services are transforming industrial inspection with smarter, faster, and more accurate techniques. From phased array ultrasonic testing to cutting-edge NDT inspection, these non-destructive testing services ensure asset reliability without compromising safety. As industries demand higher precision, NDT technologies evolve to deliver deeper insights and data-driven decisions. Embrace the future with advanced NDT services designed for complex challenges and critical operations.

0 notes

Text

The Role of Computed Radiography in Non-Destructive Testing (NDT)

Computed Radiography plays a crucial role in NDT (Non-Destructive Testing) by offering faster, more accurate imaging without damaging the tested materials. Unlike traditional methods, it digitizes radiography tests, improving inspection quality and data storage. In industries where both destructive testing and non destructive testing are used, computed radiography ensures safer, more efficient evaluations. As NDT continues evolving, digital solutions like computed radiography are setting new standards in quality control and safety assurance.

#ComputedRadiography#NDT#NonDestructiveTesting#DestructiveTestingAndNonDestructiveTesting#RadiographyTest

0 notes

Text

Ultrasonic tests play a pivotal role in ensuring the structural integrity of materials without causing harm. Here are a few ultrasonic terminologies. Read More!

#non-destructive testing#ndt techniques#ndt technique#ndt methods#ndt#ndt testing#ultrasonic inspection#ultrasonic testing

6 notes

·

View notes

Text

"Ensuring Integrity: The Importance of Non-Destructive Testing (NDT) in Modern Industries"

Non-Destructive Testing (NDT) allows industries to assess the integrity of materials and structures without causing damage. Using methods like ultrasonic, radiographic, and magnetic testing, NDT ensures safety, quality, and compliance across sectors like manufacturing, aerospace, and construction.

#NonDestructiveTesting#NDT#MaterialIntegrity#TechForSafety#QualityAssurance#IndustrialTesting#InspectionTech#EngineeringSafety#ManufacturingExcellence#StructuralIntegrity

0 notes

Text

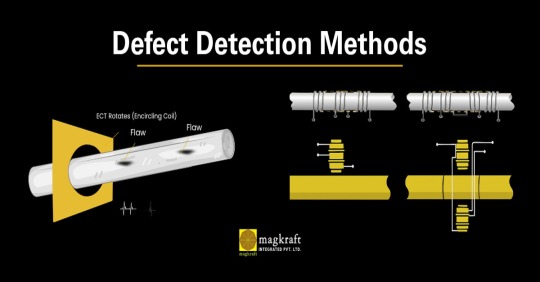

Defect Detection Method by Eddy Current Testing Machine - Magkraftndt

The Eddy current testing machine generates surface and near-surface defects in metal parts. It detects cracks, changes in hardness, and other flaws in a non-destructive way without influencing the material using electromagnetic fields.

#magkraftndt#mpimachine#magnafluxmachine#ndt#demagnetizermachine#eddycurrenttestingmachine#magneticparticletestingmachine#mpimachinemanufacturer

0 notes

Text

Red Menace NDT at the NCMS Sustainment Accelerator – July 22–24!

Red Menace NDT is excited to participate in the NCMS Sustainment Accelerator, taking place July 22th–24th at the Riverfront Convention Center of Craven County in New Bern, North Carolina.

We’ll be on site assisting in the demonstration of new, cutting-edge technologies and equipment in the field of Non-Destructive Testing (NDT).

This is a fantastic opportunity to see innovative tools in action and learn about the future of inspection technologies.

Come by to meet our team, chat with us, and our colleagues about the breakthroughs happening in the world of NDT. Whether you're an industry expert or simply curious about emerging technologies, we’d love to connect.

Hope to see you there!

1 note

·

View note

Text

Magnetic Particle Testing (MT): Enhancing Surface Crack Detection in Industrial Components

Magnetic Particle Testing (MT) is a widely used non-destructive testing (NDT) method designed to identify surface and slightly subsurface discontinuities in ferromagnetic materials. This inspection technique plays a crucial role in industries such as aerospace, automotive, oil & gas, and manufacturing by ensuring the structural integrity of components without causing damage. By using finely milled iron particles and magnetic fields, MT testing effectively detects cracks, seams, laps, and other flaws that are invisible to the naked eye. Compared to other NDT methods, magnetic particle inspection is cost-effective, fast, and highly reliable. Engineers and quality control professionals rely on magnetic testing to maintain safety standards and extend equipment life.

#MagneticParticleTesting#MagneticTesting#NonDestructiveTesting#NDT#MTTesting#SurfaceInspection#IndustrialInspection#QualityControl#WeldTesting#MaterialTesting

0 notes