#Multi Axis simultaneous Control system

Explore tagged Tumblr posts

Text

Choosing Between Flexbox and Grid for Your Basic Layout Structure

Introduction

Beyond the aesthetics of web design, the choice of layout structure forms the backbone of a project's responsiveness and adaptability. At the heart of this decision lie two powerful CSS tools: Flexbox and Grid. These elements are more than mere design choices; they dictate how a webpage responds to different screen sizes and user interactions, impacting usability and visual appeal.

Understanding the Basics

Flexbox: Flexbox is a one-dimensional layout model best suited for organizing items within a container, offering flexibility in managing space distribution, alignment, and order. Its strength lies in its ability to handle complex layouts while maintaining simplicity in code structure. Grid: Grid is a two-dimensional layout system that creates a grid-based design, allowing precise placement and alignment of elements in rows and columns. Its advantages include fine control over both the rows and columns, making it ideal for overall page structure and layout alignment. Both Flexbox and Grid can be effectively utilized for basic layouts by structuring a header, main content area, and footer with distinct approaches tailored to their strengths.

Comparative Analysis

Flexbox Pros: - Efficient for arranging elements in a single direction, vertically or horizontally. - Great for small-scale layouts like navigation menus or individual components within a page. - Simplified syntax and intuitive approach make it easier to learn and use. Cons: - Complex layouts might require nested flex containers, leading to potential complications. - Challenges in controlling the alignment of both rows and columns simultaneously. Suitable Scenarios: Ideal for smaller, simpler layouts or for organizing elements in one direction, such as in menus or single-axis content layouts. Grid Pros: - Perfect for managing both rows and columns simultaneously, enabling more precise layouts. - Best for complex and multi-dimensional layouts, especially entire page structures. - Offers fine control over placement, making it suitable for responsive designs. Cons: - Complexity in understanding and implementing for beginners due to its comprehensive grid structure. - Not as effective for single-axis layouts compared to Flexbox. Suitable Scenarios: Best suited for larger-scale layouts or designs that demand strict control over both rows and columns, like entire webpage structures or responsive grid systems.

Usage Scenarios

Flexbox Scenarios Where Flexbox Shines: - Small-Scale Components: Flexbox excels in organizing smaller elements within a webpage, like menus, buttons, or individual sections. - Single-Direction Layouts: It's perfect for arranging elements in a single direction, simplifying the structure for one-dimensional layouts. - Mobile-First Designs: Ideal for mobile-responsive designs where content needs to adapt to smaller screens with straightforward layout adjustments. Grid Scenarios Distinct Advantages of Grid: - Full-Page Layouts: Grid is optimal for structuring entire pages, managing complex alignments in multiple directions (rows and columns). - Multi-Dimensional Layouts: Perfect for designs that require precision in both row and column placement, ensuring a cohesive and responsive layout. - Responsive Grid Systems: Offers extensive control for building responsive grid systems that adapt seamlessly across various screen sizes.

Responsiveness and Adaptability

Flexbox and Responsiveness Catering to Responsive Design: Flexbox simplifies responsiveness by allowing elements to adjust based on available space and container size. It facilitates flexible resizing of components within a single direction, aiding in responsive designs. Adaptability in Viewport Sizes: Flexbox is particularly suitable for smaller devices where elements need to flexibly adjust in a single axis, making it easier to adapt content to varying viewport sizes. Grid and Responsiveness Catering to Responsive Design: Grid systems provide a more comprehensive approach to responsiveness by allowing precise control over both rows and columns, enabling intricate adjustments for various screen sizes. Adaptability in Viewport Sizes: Grid excels in handling complex layouts across different viewport sizes, ensuring elements maintain their specified placement and alignment in both axes, enhancing adaptability in various screen sizes.

Best Practices and Recommendations

Choosing Between Flexbox and Grid When to Choose Flexbox: Opt for Flexbox when dealing with simpler, single-direction layouts or smaller components within a webpage. It's ideal for basic layouts requiring flexibility in one axis. When to Choose Grid: Prefer Grid for more complex, multi-dimensional layouts or when structuring entire pages. Choose it when precise control over both rows and columns is necessary. Combining Flexbox and Grid Effective Combination: Consider using Flexbox within specific sections or components within a grid-based layout. For instance, employing Flexbox to organize elements within grid-defined areas can harness the strengths of both techniques. Hybrid Approach: Experiment with combining both Flexbox and Grid to achieve optimal results. For instance, using Flexbox for header and footer elements while implementing Grid for the main content area can leverage the strengths of each method within a single layout.

Real-world Application

Flexbox in Real Projects Project Example: Portfolio Website In a portfolio website, Flexbox was utilized to arrange sections within the main content area. Each project section was organized in a single direction, allowing for easy adaptation to various screen sizes. This choice enhanced responsiveness, especially for mobile devices, providing a seamless browsing experience. Grid in Real Projects Project Example: E-commerce Platform An e-commerce platform used Grid to structure its product listings and category sections. The complex layout demanded precise alignment in both rows and columns, ensuring scalability across different viewport sizes. This choice significantly improved the scalability and responsiveness of the platform, offering a consistent and visually appealing layout.

Conclusion

Flexbox and Grid stand as powerful tools in the realm of web design, each offering distinct advantages based on the nature of the layout and design requirements. Distinguishing Factors: Flexbox excels in simpler, single-direction layouts and smaller components, offering flexibility and ease of use. On the other hand, Grid shines in complex, multi-dimensional layouts, providing precise control over both rows and columns. Significance of Choosing the Right Layout: The choice of layout structure forms the foundation of a project's scalability and responsiveness. A well-thought-out decision between Flexbox and Grid, or a strategic combination of both, is pivotal in ensuring a website's adaptability across various devices and screen sizes. Read the full article

2 notes

·

View notes

Text

Top 5 Benefits of CNC Press Brake Bending in Sheet Metal Fabrication

Introduction

In the world of metal fabrication, precision and efficiency are key factors in producing high-quality products. CNC Press Brake Bending is a game-changing technology that has revolutionized sheet metal fabrication. This advanced bending process utilizes computer-controlled machinery to achieve unparalleled accuracy, consistency, and speed. Whether you're working with aluminium, stainless steel, or mild steel, CNC Press Brake Bending ensures the perfect bend every time.

1. High Precision and Accuracy

One of the standout advantages of CNC Press Brake Bending is its ability to deliver exceptional precision. Traditional bending methods often rely on manual adjustments, which can lead to inconsistencies and errors. However, CNC (Computer Numerical Control) technology eliminates human errors by automating the bending process.

Tight Tolerances: CNC press brakes can achieve tolerances as tight as ±0.1mm, ensuring that every bend meets exact specifications.

Consistent Bends: Whether it's the first piece or the thousandth, CNC technology ensures uniformity in every product.

Multi-Axis Control: Advanced CNC press brakes feature multi-axis programming, allowing for complex bends with high accuracy.

By leveraging CNC Press Brake Bending, manufacturers can produce components with unparalleled precision, reducing rework and material waste.

2. Enhanced Efficiency and Speed

Speed is a critical factor in any manufacturing process, and CNC Press Brake Bending significantly improves production efficiency. Unlike manual bending machines, CNC press brakes can complete complex bending tasks in a fraction of the time.

Automated Programming: Once the design is input into the CNC system, the machine executes bends automatically, minimizing setup time.

Rapid Tool Changes: Modern CNC press brakes come with automatic tool-changing capabilities, reducing downtime between projects.

Simultaneous Operations: CNC technology allows multiple bends to be performed in a single setup, increasing overall production speed.

With faster cycle times and optimized workflows, CNC Press Brake Bending enables manufacturers to meet high-volume production demands without compromising on quality.

3. Versatility in Design and Material Handling

Another significant advantage of CNC Press Brake Bending is its versatility in handling different materials and complex designs. Whether the requirement is for simple bends or intricate multi-step formations, CNC press brakes can accommodate various shapes, sizes, and thicknesses.

Wide Range of Materials: CNC press brakes can bend a variety of metals, including stainless steel, aluminium, copper, and titanium.

Complex Geometries: CNC-controlled back gauges and customizable tooling allow for intricate bends and detailed designs.

Variable Thicknesses: The same machine can work with thin sheets or thick plates without requiring significant adjustments.

This flexibility makes CNC Press Brake Bending the ideal choice for industries such as aerospace, automotive, construction, and electronics, where precision and customization are crucial.

4. Cost-Effectiveness and Waste Reduction

Cost efficiency is a critical aspect of any manufacturing process. CNC Press Brake Bending helps businesses save money by reducing waste, minimizing errors, and improving overall productivity.

Reduced Material Waste: CNC-controlled bending ensures precise calculations, minimizing material wastage due to errors.

Lower Labor Costs: Automation reduces the need for manual intervention, lowering labour expenses.

Energy Efficiency: Modern CNC press brakes are designed to optimize energy consumption, reducing operational costs.

Minimal Rework: Accurate bending means fewer defects, leading to less rework and material scrapping.

By investing in CNC Press Brake Bending, businesses can streamline their manufacturing processes, reduce costs, and increase profitability.

5. Improved Safety and Operator Comfort

Safety is a top priority in any metal fabrication facility. Traditional press brakes require skilled operators to manually adjust and align metal sheets, which can lead to workplace injuries. CNC Press Brake Bending enhances safety by automating most of the bending process.

Reduced Manual Handling: CNC systems control the bending force and positioning, minimizing the need for manual adjustments.

Safety Sensors and Guards: Modern CNC press brakes are equipped with laser safety systems and light curtains to prevent accidents.

Ergonomic Work Environment: CNC automation reduces physical strain on operators, creating a safer and more comfortable workspace.

By implementing CNC Press Brake Bending, manufacturers can ensure a safer working environment while maintaining high production efficiency.

Conclusion

In today's competitive manufacturing industry, CNC Press Brake Bending plays a vital role in achieving high-quality, precision sheet metal fabrication. With benefits such as unmatched accuracy, increased efficiency, versatile design capabilities, cost-effectiveness, and improved safety, CNC press brakes have become an indispensable tool for modern metal fabrication companies. Whether for small-scale custom projects or large-scale industrial production, CNC press brake bending ensures consistency, reliability, and superior results.

Contact Us Today!

At Yash Lasertek, we specialize in CNC Press Brake Bending services, delivering precision, efficiency, and cost-effective solutions for all your metal fabrication needs. Our advanced CNC press brakes are designed to handle complex projects with utmost accuracy.

Visit Us to learn more about how our CNC press brake bending services can benefit your next project.

Call us today to discuss your requirements and get a customized solution tailored to your needs!

#CNCPressBrakeBending#SheetMetalFabrication#MetalBending#PrecisionEngineering#ManufacturingTechnology#MetalFabrication#CNCBending#PressBrakeTechnology

0 notes

Text

Precision CNC Machining Services Revolutionizing Manufacturing with Accuracy

Precision CNC machining services are transforming the manufacturing industry with their unmatched accuracy, efficiency, and versatility. Utilizing computer numerical control (CNC) technology, these services deliver exceptional precision in producing complex components for various industries, including aerospace, automotive, and medical. By automating intricate machining processes, CNC systems minimize human error, ensuring consistent quality and tighter tolerances. They enable rapid prototyping, custom part production, and scalability, meeting the demands of modern manufacturing. Additionally, advanced materials compatibility and high-speed operations reduce lead times and costs. Precision CNC machining is driving innovation, redefining manufacturing standards, and enabling businesses to achieve superior performance and reliability.

Unparalleled Accuracy The Hallmark of Precision CNC Machining Services

Precision CNC machining services deliver unmatched accuracy in manufacturing, reducing human error and ensuring component consistency. Advanced technology enables precise control over dimensions, tolerances, and finishes. This precision not only meets stringent industry requirements but also enhances overall product quality. CNC machines employ computer-guided tools to fabricate complex geometries, maintaining tight tolerances that manual methods cannot achieve. As a result, manufacturers can produce parts with exceptional repeatability, regardless of scale or complexity. This accuracy is critical in sectors like aerospace, automotive, and medical, where even the smallest discrepancies can lead to significant issues.

Accelerating Production Speeds Without Sacrificing Quality Precision CNC Machining Services

CNC machining significantly boosts production speed while maintaining consistent quality. By automating intricate processes, it eliminates delays caused by manual intervention, enabling faster turnaround times. Programmable tools allow manufacturers to produce multiple parts simultaneously or sequentially with minimal setup changes. This efficiency reduces lead times, ensuring timely delivery for high-demand markets. Furthermore, the automation eliminates bottlenecks, streamlining operations and maximizing productivity. By leveraging precision CNC machining services,businesses can scale production without compromising on precision or consistency, meeting market demands with greater agility and reliability.

Complex Designs Made Simple Precision CNC Machining Services Advanced Capabilities

Precision CNC machining services excel in producing intricate and complex designs. Modern CNC machines are equipped to handle multi-axis operations, enabling the creation of parts with intricate contours, undercuts, and detailed features. These capabilities allow manufacturers to innovate, pushing the boundaries of design possibilities. Prototypes and production runs benefit from the ability to translate digital models into physical components seamlessly. Whether producing intricate molds, medical implants, or aerospace components, CNC machining ensures precision in every detail. The ability to execute complex designs efficiently revolutionizes industries that rely on advanced engineering solutions.

Material Versatility Precision CNC Machining Services Adapts to All Needs

One of the standout features of precision CNC machining services is its versatility with materials. From metals like aluminum, titanium, and stainless steel to plastics, composites, and even exotic materials, CNC machines can handle diverse substrates with ease. This adaptability ensures that manufacturers across industries can utilize CNC technology to meet their unique requirements. Material versatility also simplifies prototyping, allowing businesses to test and refine designs before full-scale production. Whether for lightweight aerospace parts or durable automotive components, CNC machining guarantees precision across all material types, ensuring durability and performance in the final product.

Cost Effective Manufacturing Through Automation Precision CNC Machining Services

CNC machining services offer a cost-effective solution by automating manufacturing processes. By reducing labor-intensive tasks, companies save on operational costs while maintaining high-quality output. The minimal waste generated during production further contributes to cost savings, as precision CNC machining services optimize material usage. Additionally, the reduced need for rework or adjustments ensures more efficient resource utilization. This affordability allows small and medium-sized enterprises to access high-precision manufacturing capabilities previously reserved for larger corporations, democratizing innovation and fostering competition across industries.

Enhancing Sustainability with Precision CNC Machining Services Technology

Precision CNC machining contributes to sustainability by minimizing waste and optimizing energy consumption. Traditional manufacturing often results in significant material loss, whereas precision CNC machining services programs operations to maximize material efficiency. Advanced machines also consume less energy compared to conventional methods, aligning with modern sustainability goals. Recyclable materials can be processed with minimal environmental impact, and precise operations reduce the likelihood of defective parts that would otherwise require disposal. Manufacturers embracing CNC machining can align with eco-conscious practices, reducing their carbon footprint while maintaining operational excellence.

Revolutionizing Industries with Customization and Scalability Precision CNC Machining Services

Precision CNC machining services empower industries with unparalleled customization and scalability. Manufacturers can produce bespoke parts tailored to specific applications, meeting client demands with precision. This level of customization ensures compatibility and functionality in diverse industries, from medical implants to aerospace innovations. Scalability is equally transformative; CNC machines can seamlessly transition from prototyping to full-scale production, accommodating both small-batch and large-volume requirements. By combining customization with scalability, CNC machining equips businesses to adapt to market dynamics, fostering innovation while maintaining a competitive edge in a rapidly evolving industrial landscape.

Conclusion

Precision CNC machining services are at the forefront of modern manufacturing, redefining accuracy, efficiency, and innovation. By leveraging advanced computer-controlled technology, these services empower businesses to produce intricate, high-quality components with minimal errors and maximum consistency. Their versatility supports a wide range of industries, ensuring scalability and cost-effectiveness while maintaining superior performance. As manufacturing demands evolve, precision CNC machining continues to play a pivotal role in meeting challenges, driving innovation, and enhancing competitiveness. Whether for rapid prototyping or mass production, CNC machining ensures manufacturers can achieve precise results, setting new benchmarks for quality and efficiency in the industry.

0 notes

Text

MX-Lab DED (Direct Energy Deposition) and Alloy Research Machine | INSSTEK

The INSSTEK MX-Lab is a DED (Direct Energy Deposition) and material research machine designed specifically for advanced material development and research applications. It integrates Insstek's DED technology with a versatile platform that enables scientists and engineers to experiment with various metal powders, alloys, and composite materials.

The MX-Lab is ideal for research institutes, universities, and industries involved in material science and metallurgy. It allows researchers to explore new materials, develop specialized alloys, and improve material properties through innovative DED processes. With precise control over deposition parameters, including laser power, powder feed rate, and scanning speed, users can fine-tune the material properties for specific applications.

This machine supports a wide range of metal powder materials, enabling users to experiment with different combinations and create unique material compositions. The MX-Lab is also used for multi-material deposition, gradient structures, and complex geometries, making it a powerful tool for material research, prototyping, and small-scale production.

The Insstek MX-Lab DED and alloy research machine is specifically designed for powder metallurgy research and material development. Its key features include:

Simple System for Easy Entry into DED: The MX-Lab provides an intuitive and accessible system, allowing for easier adoption of Direct Energy Deposition (DED) technology, particularly for researchers and new users in material science.

Focus on Powder Metallurgy Research: The machine is optimized for advanced powder metallurgy, enabling precise experimentation and development of new alloys and material properties.

3-Axis System & DMT Technology: Equipped with a 3-axis motion system and Insstek’s patented DMT (Direct Metal Tooling) technology, it provides precise and stable metal deposition, ensuring high-quality builds and complex geometries.

Accurate & Stable CVM Powder Feeding System: The built-in CVM (Controlled Variable Method) Powder Feeding System delivers consistent and accurate powder feed, which enhances the stability and precision of material deposition.

Hexa-Feeding System for Multi-Materials: The machine features a Hexa-Feeding System, allowing the use of multiple materials simultaneously. This enables multi-material research, including the creation of functionally graded materials (FGMs) and complex alloy compositions.

LFM-1 Technology (Built-in): LFM-1 (Laser Focusing Mechanism) technology is incorporated into the system, enhancing laser focusing capabilities for improved accuracy during material deposition. This ensures precision in microstructures and better control over material properties.

If you are looking for DED (Direct Energy Deposition) technology, you can find it at INSSTEK.

Click here to contact INSSTEKView more: MX-Lab DED (Direct Energy Deposition) and Alloy Research Machine

0 notes

Text

Metro-B14 — Slicing Stone Slabs From Blocks

Introduction

In the competitive world of stone cutting, efficiency, precision, and innovation are paramount. Shri Bhagwati Machines Pvt. Ltd., located in Ajmer, India, has established itself as a leader in this field with its state-of-the-art METRO-B14 Multi Cutter Machine. This machine is not just a tool; it represents a significant leap in technology and design that promises to enhance productivity and reduce operational costs for stone manufacturers. In this document, we will delve into the features, benefits, and unique technologies that make the METRO-B14 a must-have for any serious stone cutting operation.

Key Features

· World’s First Successful DUAL RPM SPINDLE Designed for Twin Output Over Single Shaft to Deliver the highest production.

· Unique and fabricated beam, designed without any wheel-carriages to lower the motion friction.

· X axis is working on very Especially Designed “U Shape” Main Box made of thick Cast Iron Material provides excellent compression strength and high vibration damping capacity.

· Machine Bridge Motion by virtue of LINEAR MOTION BEARING SYSTEM gives Highest Positioning Accuracy & Smooth Motion.

· Positioning Accuracy can be controlled up to 0.05 mm.

· No Cutter Marks on Slabs.

· Equivalent water flow on each blades by unique water spray system.

· Stainless steel cutter guard with spray technology.

· Equipped with servo motors for fast to & fro travelling and accurate movement.

· Powerful for hard density granite material.

METRO-B14 Multi Cutter Machine

· Shri Bhagwati Machine Pvt. Ltd. is the visionary behind the DRSH (DUAL RPM SINGLE HOUSING) technology. With a focus on innovation and excellence, we have redefined the cutting machine landscape. Metro B-14 is 6th generation masterpieces of Multi-Blade Granite Block Cutters are nothing short of technological marvels. Designed and crafted by Shri Bhagwati Machine Pvt. Ltd., they bring a new dimension to stone cutting.

· Their magical capabilities enable them to deliver top-tier production levels while keeping power costs minimal and cycle times shorter than ever before. The secret behind these remarkable products lies in their revolutionary DRSH (DUAL RPM SINGLE HOUSING) technology.

· DRSH, or Dual RPM Single Housing, is a groundbreaking concept that defies conventional wisdom. This technology allows the machine to achieve unprecedented levels of production and tool longevity while consuming significantly less power. These machines aren’t just about cutting-edge technology; they’re also incredibly user-friendly. The programmed interface is designed with the user in mind, ensuring ease of operation. The use of “RITTAL” enclosure and switch gears from SIEMENS/SCHNEIDER guarantees the latest safety features, making them robust enough to withstand electrical fluctuations.

Technical Specifications

Axis Motion

Speed & Power

Features

Cables

Industry Impact

The METRO-B14 has already made a significant impact in the stone cutting industry. Numerous clients have reported increased productivity and efficiency after integrating this machine into their operations. Here are some testimonials from satisfied customers:

· Client A: “Since we started using the METRO-B14, our production has doubled. The precision and speed are unmatched!

· Client B: “The energy savings alone have made this machine a worthwhile investment. We highly recommend it to anyone in the stone cutting business.”

Unmatched Cutting Speed

The METRO-B14 is engineered for speed without sacrificing quality. Its ability to cut multiple blocks simultaneously reduces cycle times, enabling businesses to meet tight deadlines and increase throughput.

Durability and Reliability

Constructed with high-quality materials, the METRO-B14 is built to withstand the rigors of daily use in demanding environments. Key aspects of its durability include:

· Reinforced Structure: The machine’s robust design ensures stability during operation, reducing the risk of misalignment.

· Quality Bearings: The use of LM bearings minimizes friction, leading to longer service life and reduced maintenance costs.

Feedback from Operators

Operators have praised the METRO-B14 for its ease of use and reliability. Many have highlighted the machine’s user-friendly interface, stating that they were able to operate it effectively with minimal training.

Conclusion

The METRO-B14 Multi Cutter Machine from Shri Bhagwati Machines Pvt. Ltd. is a testament to innovation in the stone cutting industry. With its advanced technologies, user-friendly design, and robust performance, it is the ideal solution for businesses looking to enhance their cutting operations. By investing in the METRO-B14, companies can achieve higher productivity, lower operational costs, and superior quality in their stone products.

Click Here for detailed product video

0 notes

Text

Discover the Future of Machining with Cutting Edge Equipment

Machining has come a long way from its humble beginnings. Today, industries demand high precision, efficiency, and versatility. Enter the world of advanced machining solutions like Vertical Turning Lathes (VTLs), 5 axis turnmills, and special purpose machines. These state of the art tools are redefining the boundaries of what’s possible in manufacturing.

The Power of Vertical Turning Lathes

Vertical Turning Lathes (VTLs) are game-changers for industries requiring the machining of large, heavy, and complex parts. Unlike traditional lathes, VTLs hold the workpiece vertically, offering significant advantages in stability and accuracy.

Stability and Precision

The vertical orientation means the workpiece’s weight is supported by the machine base, reducing deflection and vibration. This stability ensures that even the heaviest and most cumbersome parts are machined with unparalleled precision. Whether you’re dealing with large castings or forgings, a VTL can handle the task with ease.

Efficiency in Machining

VTLs are not just about stability; they also bring efficiency to the table. With the ability to perform multiple operations without repositioning the workpiece, these machines reduce setup times and increase throughput. This means more parts machined in less time, directly impacting your bottom line.

The Versatility of 5 Axis Turnmill machines

While VTLs are great for specific tasks, sometimes you need a machine that can do it all. Enter the 5 axis turnmill, a versatile powerhouse capable of milling and turning in a single setup.

Complex Geometries Made Simple

5 axis turnmill machines shine when it comes to machining complex geometries. The additional axes allow for simultaneous multi axis machining, which means intricate parts can be produced without the need for multiple setups. Imagine crafting intricate aerospace components or elaborate automotive parts in a fraction of the time traditionally required.

Reduced Lead Times

One of the standout benefits of a 5 axis turnmil machine is the reduction in lead times. By combining turning and milling processes, manufacturers can streamline their production lines, reduce handling, and improve overall efficiency. This machine’s ability to work on multiple faces of a part simultaneously can significantly cut down production cycles.

Special Purpose Machines for Unique Needs

Not all machining tasks can be handled by standard equipment. That’s where special purpose machines come into play. Designed for specific applications, these machines offer bespoke solutions that cater to unique manufacturing requirements.

Tailored Solutions

Special Purpose machines are engineered to address specific production challenges. Whether it’s a custom built machine for a unique part or an automated solution for high volume production, these machines are tailored to meet the exact needs of your operation. This bespoke approach ensures optimal performance and efficiency.

Increased Productivity

By focusing on a particular task, special purpose machines can operate at peak efficiency, leading to increased productivity. These machines often incorporate automation and advanced control systems, further enhancing their capability to deliver consistent, high quality results.

Conclusion

As manufacturing continues to evolve, the demand for high precision, efficient, and versatile machining solutions grows. Vertical Turning Lathes, 5 axis turnmills, and special purpose machines are at the forefront of this evolution, offering innovative solutions to meet the diverse needs of modern industries.

At WIDMA, we understand the importance of staying ahead of the curve. That’s why we are committed to providing advanced machining solutions that help our clients achieve their production goals with precision and efficiency. Embrace the future of machining with WIDMA and take your manufacturing capabilities to the next level.

#special purpose milling machine#vertical turret lathe#5 axi turn mill#5 axis vertical turning machine#widma

0 notes

Text

Beyond Limits: Innovations in CNC Drilling Services

In today's fast-paced industrial landscape, precision and efficiency are paramount. This is where CNC (Computer Numerical Control) drilling services shine, offering unparalleled accuracy and speed in various drilling applications. From aerospace to automotive industries, CNC drilling has revolutionized manufacturing processes, pushing the boundaries of what's possible.

CNC drilling services utilize advanced machinery controlled by computer programs to execute precise drilling operations. This technology enables complex patterns, depths, and angles to be achieved with incredible consistency and reliability. By automating the drilling process, CNC systems minimize human error and maximize productivity, making them indispensable in modern manufacturing facilities.

One of the key innovations in CNC drilling services is the integration of advanced software and hardware solutions. Modern CNC machines are equipped with sophisticated software that translates design specifications into precise drilling instructions. This software allows for seamless communication between design engineers and machine operators, ensuring that the final product meets exact specifications.

Another notable innovation is the development of multi-axis CNC drilling machines. Unlike traditional drilling machines limited to linear movements, multi-axis CNC machines can move along multiple axes simultaneously, enabling complex drilling operations in three-dimensional space. This capability opens up new possibilities for intricate and challenging drilling tasks across various industries.

Furthermore, advancements in tooling technology have significantly enhanced the performance and efficiency of CNC drilling services. High-speed steel (HSS) and carbide drill bits are commonly used in CNC drilling applications due to their durability and precision. Additionally, specialized coatings and geometries optimize tool life and chip evacuation, further improving drilling accuracy and efficiency.

The benefits of CNC drilling services extend beyond precision and efficiency. These services also offer versatility, allowing for the drilling of a wide range of materials, including metals, plastics, and composites. Whether it's creating intricate patterns on aerospace components or drilling precise holes in automotive parts, CNC drilling services can handle diverse manufacturing requirements with ease.

Moreover, CNC drilling services contribute to cost savings and waste reduction in manufacturing processes. By minimizing errors and optimizing material usage, manufacturers can achieve higher yields and lower production costs. Additionally, the ability to produce complex components in a single operation reduces the need for secondary machining operations, further streamlining the manufacturing workflow.

In conclusion, CNC drilling services represent a cutting-edge solution for precision drilling applications across various industries. With continuous innovations in technology and tooling, these services continue to push the boundaries of what's achievable, enabling manufacturers to create high-quality products with unmatched accuracy and efficiency.

1 note

·

View note

Text

Unlocking Precision: Understanding CNC Machine Configuration

CNC (Computer Numerical Control) machines have revolutionized manufacturing by automating and streamlining the production of intricate parts with unparalleled precision and efficiency. At the heart of every CNC machine lies its configuration – a carefully orchestrated combination of components and parameters that determine its capabilities and performance. In this blog, we'll delve into the essential elements of CNC machine configuration, shedding light on the key components that drive its functionality and versatility.

Machine Type: CNC machines come in various types, each designed for specific machining operations and applications. Common types include:

CNC Milling Machines: Used for cutting and shaping solid materials, such as metal, wood, and plastics, using rotating cutting tools.

CNC Lathes: Ideal for machining cylindrical parts by rotating the workpiece against stationary cutting tools.

CNC Routers: Employed for cutting and carving materials like wood, foam, and composites using computer-controlled routing heads.

CNC Plasma Cutters: Utilized for cutting metal sheets and plates using a high-velocity jet of ionized gas (plasma). Selecting the appropriate machine type depends on factors such as the desired machining operations, material types, part complexity, and production volume.

Axis Configuration: The axis configuration of a CNC machine refers to the number and orientation of its motion control axes. Common configurations include:

3-Axis Machines: Capable of moving along three linear axes (X, Y, Z) to perform 2D and 3D machining operations.

4-Axis Machines: Incorporate an additional rotary axis (typically A or B) for rotating the workpiece, enabling more complex machining operations and angular cuts.

5-Axis Machines: Feature two additional rotary axes (typically A and B or A and C), allowing for simultaneous movement and rotation in multiple directions, expanding the range of machining possibilities and enhancing precision.

Multi-Axis Machines: Combine three or more linear and rotary axes to achieve intricate machining capabilities, such as simultaneous milling, turning, and grinding. The axis configuration determines the machine's flexibility, precision, and suitability for specific machining tasks.

Control System: The control system is the brain of the CNC machine, responsible for interpreting the part design data (usually in the form of G-code) and translating it into precise movements and commands for the machine's motors and actuators. Key components of the control system include:

CNC Controller: The central unit that processes the G-code instructions and coordinates the motion of the machine axes.

Motor Drives: Power the machine's motors and provide precise control over their speed and position.

Feedback Systems: Include encoders and sensors that provide feedback on the position, velocity, and acceleration of the machine axes, ensuring accurate motion control.

Human-Machine Interface (HMI): Allows operators to interact with the CNC machine, input machining parameters, monitor the machining process, and troubleshoot any issues. Modern CNC machines may utilize proprietary control systems or industry-standard platforms such as Fanuc, Siemens, or Mitsubishi, each offering unique features and capabilities.

Tooling and Workholding: Tooling and workholding play a critical role in CNC machining, enabling the secure fixation of workpieces and the precise execution of machining operations. Key components include:

Cutting Tools: End mills, drills, inserts, and other cutting tools tailored to specific materials and machining operations.

Tool Changers: Automatic or manual systems for changing cutting tools during machining processes, reducing downtime and increasing productivity.

Workholding Devices: Vises, clamps, fixtures, and chucks that securely hold the workpiece in place during machining, ensuring stability and accuracy. Proper selection and setup of tooling and workholding solutions are essential for achieving optimal machining results and minimizing setup time.

CNC machine configuration encompasses a myriad of components and parameters that determine the machine's capabilities, performance, and versatility. By understanding the machine type, axis configuration, control system, and tooling/workholding options, manufacturers can select and configure CNC machines to meet their specific machining requirements and production goals. Whether producing precision parts for aerospace, automotive, or medical applications, CNC machines stand ready to unlock the potential of modern manufacturing with their unparalleled precision and efficiency.

0 notes

Text

How many ways CNC machine tool systems can be classified?

CNC (Computer Numerical Control) machining is a manufacturing process that utilizes pre-programmed computer software to control the movement and operation of machine tools. These machine tools can include lathes, mills, routers, grinders, and other types of equipment used for precision cutting, drilling, shaping, and finishing of different materials.

Since its inception in the 1950s, CNC machining has revolutionized the manufacturing industry and has become an integral part of various industries such as aerospace, automotive, medical, and more. With continuous advancements in technology and software capabilities, CNC machining continues to evolve, offering a wide range of options for manufacturers to choose from.

One way to classify CNC machine tool systems is based on their motion control technology. This includes three main categories: 2-axis, 3-axis, and multi-axis systems. Let's take a closer look at each of these categories and their subcategories:

2-Axis Systems

2-axis systems are the most basic type of CNC machine tool system, with only two axes (X and Y) controlled by the computer software. These systems are typically used for simple operations such as drilling, facing, and boring. They are commonly found in manual milling machines that have been retrofitted with CNC controls.

3-Axis Systems

3-axis systems have three axes (X, Y, and Z) controlled by the computer software, allowing for more complex operations such as contouring, pocketing, and slotting. These systems are commonly used in modern CNC milling and turning machines.

Multi-Axis Systems

Multi-axis systems have additional axes, usually referred to as A, B, and C, controlled by the computer software. This adds more flexibility and complexity to the machining process, allowing for operations such as 3D surface machining and simultaneous five-axis milling. Multi-axis systems are commonly used in high-precision industries such as aerospace and medical manufacturing.

CNC machining has become an integral part of various industries in Canada, such as aerospace, automotive, medical, and more. With continuous advancements in technology and software capabilities, CNC machining continues to evolve, offering a wide range of options for manufacturers to choose from.

One major advantage of using CNC machining is its ability to produce complex and precise parts with high accuracy and repeatability. This is especially beneficial in industries where quality and precision are crucial, such as aerospace and medical manufacturing.

CNC castings in Canada also play a significant role in the manufacturing process. Casting is a cost-effective method for producing large quantities of identical parts with complex shapes and designs. With the use of CNC machining, these castings can be further refined and finished to meet specific requirements, resulting in high-quality end products.

Moreover, CNC machining offers a faster and more efficient production process compared to traditional methods. With the use of computer software and automated processes, CNC machines can produce parts with minimal human intervention, reducing the risk of errors and increasing productivity.

In Canada, there are various companies that specialize in providing CNC machining services. These companies not only offer machining services but also provide expertise in design, engineering, and prototyping. This allows for a seamless production process from concept to final product.

Another benefit of CNC machining in Canada is its ability to work with a wide range of materials such as metals, plastics, and composites. With the use of different cutting tools and techniques, CNC machines can effectively handle different materials, making it a versatile option for manufacturers.

In addition to its advantages, CNC machining in Canada also contributes to the country's economy. With the growing demand for precision and high-quality products, the need for CNC machining services continues to rise, creating job opportunities and contributing to economic growth.

Furthermore, with advancements in technology, CNC machining in Canada continues to evolve and improve. New techniques and software are constantly being developed, allowing for even more complex and precise parts to be manufactured. This not only benefits the manufacturers but also the end consumers who can enjoy high-quality products at competitive prices.

In conclusion, CNC machining in Canada is a crucial aspect of modern manufacturing. Its ability to produce high-quality, complex parts with efficiency and precision makes it an essential process for various industries. As technology continues to advance, we can only expect CNC machining in Canada to become even more advanced and integral in the manufacturing process. So whether it's for cnc castings or general machining needs, Canada has a wide range of reputable companies that offer top-notch CNC machining services. So if you're looking for quality and reliable manufacturing solutions, look no further than CNC machining in Canada. With its numerous benefits and constantly evolving technology, it's clear that CNC machining is here to stay and will continue to play a vital role in the growth of Canada's economy. So don't hesitate to utilize this advanced manufacturing process for your business needs, and experience the advantages it has to offer first-hand. Choose CNC machining in Canada and take your production to the next level. Happy machining! So, whether you're in need of CNC castings in Canada or general machining services in Canada, be sure to consider utilizing CNC machining for high-quality and efficient results. From its early origins to its current advancements, CNC machining has proven to be a valuable asset for many industries and will continue to do so in the future. So why not take advantage of this technology and see how it can benefit your business today? Give CNC machining in Canada a try and witness its power for yourself.

0 notes

Text

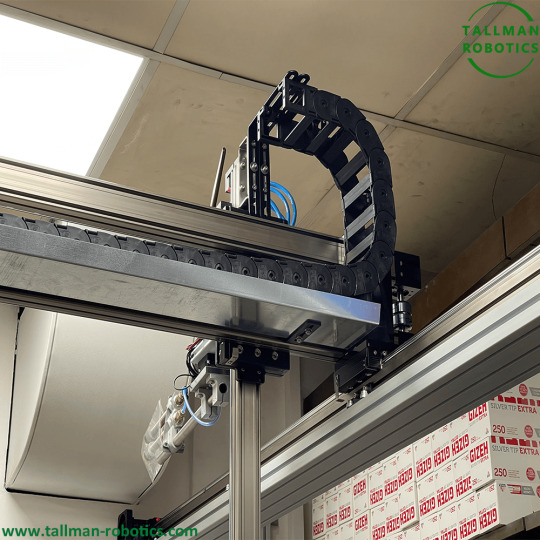

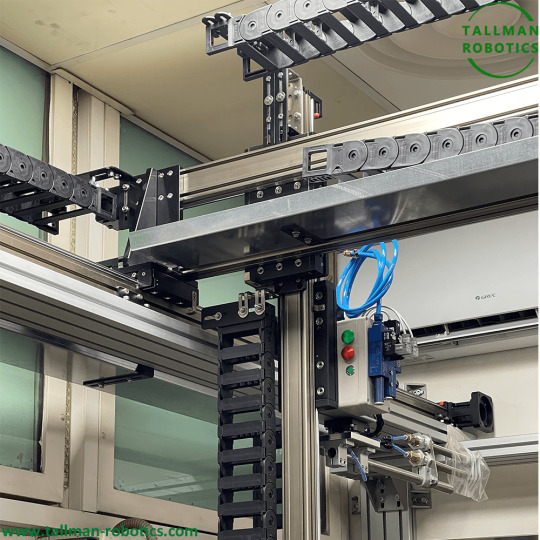

Multi Axis Linear Systems Are Working in Italy Client's Stores

Multi-axis linear systems, also known as multi-axis linear stages or multi-axis positioning systems, are mechanical systems designed to provide precise and controlled movement in multiple linear directions. These systems are commonly used in various applications where precise positioning and motion control are required, such as industrial automation, manufacturing, semiconductor manufacturing, microscopy, and research.

A multi-axis linear module typically consists of multiple linear stages or actuators that are combined and coordinated to enable movement in two or more linear axes. These axes can be orthogonal (perpendicular) to each other or arranged in any other desired configuration. The number of axes can vary depending on the specific application requirements. Each linear stage in a multi-axis system is equipped with a motor or actuator that generates the necessary force to move the stage along its linear path. The stages are usually guided by precision linear bearings or linear guides to ensure smooth and accurate motion. The stages may also incorporate position feedback sensors, such as encoders, to provide feedback on the position and enable closed-loop control. To achieve coordinated motion in multiple axes, a multi-axis linear modules relies on a control system. The control system coordinates the movement of each stage, ensuring synchronized motion and accurate positioning. It receives input commands or trajectories and translates them into appropriate control signals for each axis. The control system may include a motion controller, servo drives, and software algorithms for trajectory planning and motion synchronization. Multi-axis linear systems offer several advantages, including: 1. Precise positioning: These systems provide high-precision positioning capability, allowing for accurate alignment and motion control. 2. Flexibility: Multi-axis systems can be customized and configured to meet specific application requirements, such as the number of axes, travel range, load capacity, and motion profiles. 3. Compact design: The integration of multiple axes into a single system results in a compact and space-saving design, making them suitable for applications with limited space. 4. Increased throughput: By enabling simultaneous motion in multiple axes, multi-axis systems can improve overall productivity and throughput in automated processes. 5. Versatility: These systems can be used in various applications, including pick-and-place operations, assembly, inspection, testing, and scanning. It's important to note that the specific characteristics and capabilities of multi-axis linear modules can vary depending on the manufacturer, design, and intended application. Therefore, it's recommended to consult with system suppliers or experts to determine the most suitable system for a particular use case. You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data. Read the full article

#Cartesianmulti-axissystems#linearsystems#MiniatureMulti-AxisSystems#Multi-Axis(XY)LinearActuator#multi-axislinearstages#Multi-AxisPositioningSystems#Multi-AxisSystems#Multi-axissystemswithlinearmotors

0 notes

Text

"Accelerating System Performance with AXI4 Stream DMA, AXI Stream DMA, and eSPI IP Digital Blocks"

Digital blocks play a crucial role in modern electronic systems, providing essential functionality for communication, data transfer, and control. Among these blocks, the AXI4 Stream DMA, AXI Stream DMA, and eSPI IP are three critical components that enable efficient data transfer and communication between different modules in a system. In this blog, we will explore these digital blocks and their features, applications, and benefits.

AXI4 Stream DMA: The AXI4 Stream Direct Memory Access (DMA) is a digital block that facilitates high-speed data transfer between different modules in a system. It is a flexible and scalable interface that allows the transfer of large amounts of data between a source and a destination without involving the CPU. The AXI4 Stream DMA block is designed to be integrated into an AXI4-based system and supports a wide range of data transfer modes and burst sizes.

One of the main advantages of using the AXI4 Stream DMA block is its ability to offload data transfer tasks from the CPU, thereby reducing the workload on the processor and improving system performance. This makes it ideal for applications that require high-speed data transfer, such as video processing, audio processing, and network data transfer.

AXI Stream DMA: Similar to the AXI4 Stream DMA, the AXI Stream DMA is a digital block that provides a high-bandwidth, low-latency interface for data transfer in an AXI-based system. The AXI Stream DMA block is optimized for streaming data transfer and is ideal for applications that require real-time data transfer, such as audio and video processing, image processing, and machine learning.

One of the key features of the AXI Stream DMA block is its support for multiple channels, which enables simultaneous data transfer between different modules in a system. This feature makes it ideal for applications that require parallel data transfer, such as multi-camera video processing and multi-channel audio processing.

eSPI IP: The Enhanced Serial Peripheral Interface (eSPI) is a digital block that provides a high-speed, low-latency interface for communication between different modules in a system. The eSPI IP block is designed to replace the legacy Low Pin Count (LPC) interface and improve system performance by providing faster data transfer rates, higher bandwidth, and improved scalability.

One of the key features of the eSPI IP block is its support for multiple devices, which enables communication between different modules in a system, such as the CPU, chipset, and peripherals. This feature makes it ideal for applications that require efficient communication between multiple devices, such as server systems, high-performance computing systems, and embedded systems.

In conclusion, the AXI4 Stream DMA, AXI Stream DMA, and eSPI IP are three critical digital blocks that enable efficient data transfer and communication between different modules in a system. These blocks are designed to improve system performance, reduce CPU workload, and enable real-time data transfer and communication. As digital systems continue to evolve, these blocks will play an increasingly important role in enabling faster, more efficient, and more scalable systems.

0 notes

Text

INNOVATING FOR EXCELLENCE :MESSUNG GROUP

Since their pioneering start in 1981, Messung Group has been committed to building industrial excellence in India. Messung has indigenously developed new products, and joined hands with strategic industry majors for different technologies to improve productivity and transform spaces for Indian industry, homes and businesses.

Messung’s expertise is offered under three broad businesses, each serving different industries:

· Automation & Controls

· Electrical Engineering

· Workplace Technology

AUTOMATION & CONTROLS

Our portfolio of Automation Solutions serves not just Industry, but Building, Home, Office & Hotel Automation applications too.

Industrial Automation & Control

Messung presents advanced automation systems capable of controlling, in a distributed and redundant way, complex industrial processes, machines and high-performance production lines.

Messung’s portfolio of essential components, intelligent devices and integrated systems facilitate well-informed decision-making and efficient controls. They offer reliable, real-time solutions with flexibility and scalability for expansions and easy integration in the future.

Messung Industrial Automation solutions cover a gamut of applications in Process Automation, Servo & Motion Control Automation, and General Purpose Automation.

Products include:

NX-ERA PLC developed indigenously by Messung (as per IEC 61131 programming standard)

XM-PRO Remote I/Os innovated by Messung including Modbus RTU and CanOpen.

Variable Frequency Drives (VFDs) from Fuji Electric, Japan

Servo & Motion Control products from Fuji Electric, Japan (IEC 61131-3)

Multi Axis simultaneous Control system from Sigmatek, Austria

Messung Messung’s turnkey solutions are Industry 4.0-compatible, smart Cloud-based solutions to provide “Any time Anywhere” supervisory and control features.

Home, Office & Hotel Automation & Controls

Messung provides KNX-based automation solutions to transform interiors into luxurious spaces, enhancing user comfort and enabling users (home owners) to perform complex tasks with ease.

Messung's unique and customisable touch switches and solutions for lighting control, climate control, curtain control, security, energy management, etc. reduce energy consumption and achieve a sophisticated high-performance property.

Messung offers comprehensive automation solutions for hotels, providing enhanced guest experience and ease of maintenance.

Messung offers the most globally renowned solution for A/V control, creating the perfect balance and synchronicity between the audio and video control elements present in any home, office or hotel, with other control solutions like lighting, climate, shutters, security, etc.

Products include:

· Customisable Touch Switches, complete range of Actuators, Sensors, and Smart Phone Interface from Zennio, Spain

· Complete scheduling, conferencing, and monitoring solutions for offices and, A/V, Multi-room audio and Synchronized smart control solutions for homes from Crestron, USA

Building & Infrastructure Automation & Controls

Messung’s IOT-enabled BMS solution based on the Niagara Framework provides control and supervision of HVAC, Security, CCTV, Intrusion Alarm and Fire systems, including diesel genset, water pumping systems, and other third party systems, which are now mandatory in all modern buildings. The open solutions provide a sustainable foundation that supports and evolves with your building system's lifecycle, helping you achieve over 30% savings in energy and operational costs while maximising occupant comfort and productivity.

Messung partners with Distech, Canada for their unique building management products and solutions. Products include:

· Software

· BMS controllers

· Bacnet/IP controllers

· Bacnet MS/TP controllers

· Lonworks controllers

· Field Devices

· HMI Displays

ELECTRICAL ENGINEERING

Messung provides reliable, intelligent and world-class solutions for the Power Monitoring and Distribution sector besides customised Energy Management systems that provide complete visibility of electrical usage in industry, infrastructure and data centres.

Distribution & Control

Messung has tied up with Wöhner, Germany for revolutionary Busbar and offers the complete range of low voltage power distribution control system as per IEC 61439. Messung provides smart power distribution control panels with Wohner’s busbars and their own automation products like PLC, HMI and Scada.

Products from Wohner include:

· CrossBoard

· 30Compact, 60Classic & 185Power Busbar systems

· Electronic components

· Panel accessories

Energy Management

Messung offers the complete, customised energy management solution as per IEEE 519 including Network visualisation software as per ISO 50001 to help enterprises optimise power usage, improve power protection and increase productivity by reducing downtime, safety risks and electricity bills.

Messung partners through the complete lifecycle with an end-to-end PLM solution that covers the full gamut of ‘analytics-measure-analyse-solve-supervise-alert’ for efficient energy management including detailed mitigation.

With their expertise in electrical engineering, and incorporating best-in-class products from Janitza and Fuji Electric Consul Neowatt, Messung enhances productivity and the reliability of your critical electrical assets.

Products include:

· Class A Power Quality Analysers from Janitza (IEC 61000-4-30 / EN 50160 / 61000-2-4)

· DIN Rail Power Quality Analysers and meters from Janitza

· Network visualisation software and IT solutions from Janitza

· Single Phase Online UPS from Fuji Electric Consul Neowatt

· Three Phase Online UPS from Fuji Electric Consul Neowatt

· Active Harmonic Filter from Fuji Electric Consul Neowatt

· Industrial-grade Servo Stabilisers from Fuji Electric Consul Neowatt

WORKPLACE TECHNOLOGY

Messung’s experience of the health hazards, safety risks and challenges of the industrial workplace has inspired them to find and deliver meaningful solutions. Under their ‘Navonmesh Make in India’ initiative, Messung designs and manufactures the ‘AFM-Plus Series’ of world-class solutions for ESD, General and Cleanroom Workplaces.

Messung has also partnered with Uchida, Japan, for their cleanroom chairs and stools.

ESD Workplace Systems

Messung indigenous ‘AFM-Plus Series’ offers world-class ESD-safe furniture at competitive prices. These products provide unmatched ergonomics and flexibility, and leverage the latest volumetric ESD technology for reliable ESD protection for years.

Products include:

· ESD chairs & stools (standard and high versions)

· Aluminum ESD worktables

· ESD trolleys, storage racks and drawer cabinets

General Workplace Systems

For general workplaces, Messung designs and manufactures a world-class range of workplace furniture that is modular, flexible and cost-effective. The chairs & stools offer unmatched ergonomics while the other furniture promotes convenience and productivity in the work environment.

Products include:

Non-ESD chairs and stools (standard and high versions)

Alluminium and MS Worktables for work shops and general assembly and repair

Trolleys, storage racks and drawer cabinets in Alluminium Mild Steel

Aluminum work benches with granite or Stainless steel table tops (for chemical labs)

Cleanroom Workplace Systems

Cleanrooms are utilised as a part of specialised industrial production or scientific research for products such as electronics, pharmaceutical products and medical equipment. They are designed to maintain extremely low levels of airborne particulates and contaminants – as per various international standards i.e. Federal Std. 209, British Standard 5295, ISO-14644-1.

For such controlled environments, we offer a range of world-class furniture that fulfil global cleanroom criteria, and provide unmatched ergonomics and convenience in cleanroom applications.

Products include:

Cleanroom chairs from Uchida, Japan - ISO 5 / class 100

SS Cleanroom worktables - as per ISO-14644-1 guidelines

Conclusion

Messung is a dynamic diversified group, working with passion and diligence to deliver the most advanced and cost-effective solution for Indian industry. Across the industry spectrum, Messung partners with OEMs and end users to deliver the most efficient solutions: best-in-class products that build world-class industrial automation solutions, building automation solutions, and home, office & hotel automation solutions; custom-built workplace technology systems for ESD, general and cleanroom applications; cutting-edge power distribution & control and energy management solutions.

Integrating strategy and technical consulting expertise with deep domain knowledge and real-world experience, Messung helps industries, institutions and OEMs to improve efficiency and optimise their processes and workplaces. To find out how Messung innovation can benefit your operations, contact today.

#Automation Solutions#Industrial Automation solutions#Process Automation#Servo & Motion Control Automation#General Purpose Automation#Variable Frequency Drives (VFDs)#Servo & Motion Control products#Multi Axis simultaneous Control system#KNX-based automation#energy management#BMS solution based on the Niagara Framework#Energy Management systems#low voltage power distribution control system#smart power distribution control panels#PLC#HMI Busbar systems#energy management solution#Class A Power Quality Analysers#Single Phase Online UPS#Three Phase Online UPS#Active Harmonic Filter#Industrial-grade Servo Stabilisers#cleanroom chairs and stools#ESD-safe furniture#volumetric ESD#ESD chairs#ESD worktables#ESD trolleys#workplace furniture#building automation solutions

0 notes

Text

Free ip camera software mac

#Free ip camera software mac for mac

#Free ip camera software mac install

#Free ip camera software mac upgrade

#Free ip camera software mac software

For Wi-Fi remote viewing, enter the same HTTP address into the web browser from another computer or iOS device on the same Wi-Fi network.

#Free ip camera software mac install

Drag TENVIS Camera Search Tool into Applications to install the search tool in MAC.

#Free ip camera software mac for mac

Run H264 Search Tool.dmg for Mac in CD 2.

#Free ip camera software mac software

Take a note on the HTTP access address shown by IP Cam. This section will focus on connecting your IP camera, software installation and basic network.

Multi-Color Mode: Black and White, High Contrast and Night Vision.

View from iPhone, iPod Touch, iPad using the Safari browser.

View from Safari browser to get both audio and video.

View from web browsers on any operating systems (without audio).

IP Cam also supports audio capture, so you can remotely listen to the audio captured by mac's microphone while viewing live camera. Sighthound Video works with most IP cameras and webcams and is perfect for home or business use. Sighthound Video enables you to quickly set up an intelligent video surveillance system using your Mac. You can even view IP Cam using Safari browser from another mobile device such as iPhone, iPad or iPod Touch. The smartest video surveillance software for the Mac. Run IP Cam on your mac, and via Wi-Fi network, you can view live images captured by your mac's built in FaceTime camera (or any mac compatible USB/Firewire camera) on web browser from any computer.

Advanced HTML5 Web client allows you to connect to your recorder remotely without installing any software/plugins.IP Cam turns your mac into a IP surveillance camera.

You can connect to the Recorder from another Mac, from a PC, or from iPhone/iPad.

Advanced iPhone/iPad app lets you control the recorder, receive motion events, and more.

You can see all motion events in the time line.

Visually shows when video was recorded.

However, the basic working remains to be free of cost in all of them.

#Free ip camera software mac upgrade

These are the free IP cam software which also come with some upgrade options too. With the increasing risk of security, options are also increasing and hence I have shortlisted 15 of such options under this list.

Records video on internal hard drive, or any attached or network hard drives. 15 Best Free IP Camera Software for Home Security 2022.

Records video always or on schedule or only when motion is detected. XMEye for Windows/Mac PC software download, VMS compliant with Hikvision, Dahua, XiongMai, ONVIF network cameras, DVRs, NVRs.

Auto-detection for many camera models, so you do not even need to know the address of your camera to add it.

Visually create camera groups and different layouts to quickly switch between your home/office cam groups, etc.

Watch multiple cameras on the same screen.

Record video on your Mac from unlimited number of IP cameras simultaneously.

Monitor IP cameras from many manufacturers (Axis, Foscam, Panasonic and many more).

freeload trial to see why users say "extremely easy to use" and "no other Mac program in camera management comes close". Use companion iPhone app or a Web Browser to monitor your place from anywhere. Review recorded video and incidents effortlessly using one-click replay. Monitor one IP Camera or dozens installed at different sites, seamlessly. It lets you keep an eye on your home and business. IP Camera Recorder is a video surveillance solution for Mac, PC and iPhone.

0 notes

Text

Revolutionizing Precision Manufacturing

In this modern maze of manufacturing, precision is crucial. Whether in the aerospace, automotive, or medical device sphere, never before has precision by parts and components reached such a premium level. Indeed, the technology leading the dynamic of this market demand for highly accurate constituents involves three key approaches: vertical turning lathes, 5-axis turnmills, and special-purpose machines. Today's integration of advanced technologies in precision manufacturing marks a significant milestone, positioning the industry at the forefront of innovation.

Expanding Technologies

a. Vertical Turning Lathes

Vertical turning lathes (VTLs) are machines used to conduct precise machining on large, heavy, and complex parts. Unlike conventional lathes, where the workpiece is horizontally located, the positioning of the workpiece is vertical in a VTL. Due to this arrangement, the floor space occupied by this type of machine is reduced, and the cutting forces, along with the heat generated from the cutting process, automatically force the chip away from the machine. This orientation is especially advantageous for components having larger diameters, making them more precise and productive.

b. 5-Axis Turnmills

Turnmills were developed by combining the functions of turning and milling in a single machine to simultaneously take care of all five axes of motion. 5-Axis Turnmills excel with high precision by single clampings, which is necessary for complex shapes and size variability while performing turning and milling functions. The multi-axis capability allows manufacturers to produce complicated cuts or parts more affordably and faster.

c. Special-Purpose Machines

Special purpose machines are those custom-designed to carry out particular tasks in manufacturing that standard machines cannot handle. They can fully define themselves due to their inability to perform certain tasks as assigned by them, thus bringing out their positive quality. Custom-fit to unique production needs, special-purpose machines offer unparalleled efficiency and precision for specified applications.

Integration in Manufacturing

The logical integration of vertical turning lathes, 5-axis turn mills, and special-purpose machines in a manufacturing setup is a significant leap toward automation and efficiency. Manufacturers find it more convenient to have smooth processing from raw material to finished products with better control and accuracy. The versatility can well be attributed to the role of software and automation in allowing the machines to communicate and coordinate among themselves perfectly, thereby optimizing production cycles and reducing human error.

The Impact of Integration on Industries

Aerospace is one such sector whose high prerequisites of precision and reliability have resulted in immense benefits from effectively integrating these technologies. Today, it becomes possible to fabricate aircraft engine and airframe components to much higher accuracies and in less time. This factor, in turn, contributes to greatly enhanced flight safety and fuel efficiency.

Similarly, the automotive industry has utilized these technologies to produce complex parts like engines and transmission systems with much more precision and efficiency. The intricate medical devices section is a clear innovation of how these integrated technologies bring out a uniquely new level of precision and customization.

WIDMA's Role in Precision Manufacturing

WIDMA, a pioneer in providing comprehensive machining solutions, is crucial in revolutionizing precision manufacturing. With its expertise in developing cutting-edge vertical turning lathes, 5-axis turn mills, and special-purpose machines, WIDMA offers manufacturers unparalleled precision, efficiency, and flexibility. Its innovative solutions are designed to meet the diverse needs of various industries, enabling them to produce parts with exceptional accuracy and reduced turnaround times. By integrating WIDMA's advanced technologies, manufacturers can significantly enhance their production capabilities, achieving higher levels of quality and productivity.

Conclusion

Incorporating vertical turning lathes, 5-axis turn mills, and special purpose machines are poised to revolutionize manufacturing, enhancing precision, reducing lead times, boosting efficiency, and offering solutions previously unattainable. By adopting these technologies, manufacturers significantly enhance their capabilities and establish themselves as leaders in industry innovation. As these technologies continue to advance and become more integrated, they will further transform the manufacturing landscape, setting new standards for quality and efficiency.

0 notes

Text

State of the Art Automation Technology: A Revolution for Industries

Automation is the name of the game in Industrial processes for the future. With a 6.3% CAGR, the manufacturing and process control industry is set to grow to approximately $117.7 billion globally by 2025. It presents a unique opportunity for existing players to upscale on technology key to efficiency. If you’re a manufacturer, getting state-of-the-art control systems boosts capacity.

Mitsubishi Electric India brings some of the most revolutionary factory automation equipment for new-age plants. Maximise your revenue per square foot and get ahead of your competition. Look at the different industrial automation systems you can take advantage of!

The World of Automation

Transitioning from the age of information to the age of collaboration is not easy. If you’ve been a seasoned manufacturing and design house in India, then reputation is something that is at the pinnacle of your business. However, to maintain the quality in your operations, innovation is a constant requirement.

Partnering with Mitsubishi Electric India allows you to bring innovation to the forefront of your operations. With cutting edge industrial automation and factory automation systems, Mitsubishi Electric can help you break the new ground quickly. Generate economies of scale in your operations while reducing your overruns with simple, functional, and easy-to-maintain automation technology.

Technology that Drives Operations

From a range of next gen groundbreakers, Mitsubishi’s CNCs stand out and apart from similar systems in the market. Taking up a fraction of the space of Gen-3 systems, this new control manifest allows you to obtain an unparalleled level of productivity in your manufacturing process. Installing the new Gen-4 CNCs allows you to take on projects that require attention to detail and precision operations. Due to extensive innovation, not only are these CNCs easy to control, but they also enhance the capacity of each operator and reduce their stress simultaneously.

Computerized Numerical Controllers

Mitsubishi India offers top-of-the-line computerized numerical controllers to provide shameless integration and automation in your industrial systems. If you’re looking to expand your business and gain global reach.

Mitsubishi Electric’s CNCs realise the idea of human-machine interaction with integrated touchscreen panels that are easy to use and navigate. Using a dedicated CPU to process G-code at light speed, these CNCs can help you enhance your fine segment processing capacity resulting in shorter cycle times!

Coupled with this, ultra-high-speed industrial automation systems from Mitsubishi India offer high accuracy in-process and can deliver consistent results. With such reliable manufacturing, your products are always quality-oriented.

The new M800W and M800S/M80 series are notable winners of the Good Design Award in FY 2015 and deliver unparalleled integration even today. The two-split multi-window panel creates a user-friendly interface for quick and adequate control over process lynchpins. A slim and flat design helps you in reducing housing space and maximising your revenue with multi-compatible operability and selectable mounts.

While the CNCs from Mitsubishi India already gained the high-grade 5-axis machining function in Gen 3, the SSS control opens up a world of new possibilities in Gen 4. The significantly enhanced lathe and auto-lathe features in gen 4 give your processes access to a diversified multi-part-system simultaneous machining. Additionally, enhanced milling features enable the time-bound creation of complex projects requiring complicated shape cuts using deformed work-pieces.

Thus, overall the new series of CNC industrial automation technology from Mitsubishi India, adds an extensive new scope to how you imagine engineering and manufacturing. However, that’s not all.

Technology that’s Interactive

Our world is slowly transitioning from having pockets of information to global collaboration. At such a time, a primary business requirement is having machines that ease your in-process interaction to realise ideas quicker. Mitsubishi Electric pays special attention to these details in its industrial automation CNCs and brings the power of IoT to your fingertips.

You can manipulate and navigate complex designs through a 3D conceptualization process. It enables higher rates of consistency in quality and reliable design outcomes. With little effort, your employees can seamlessly enhance quality-oriented output.

The integration with IoT allows you to install the NC Visualiser application on your server PC to regulate and monitor the status of your machines' status. Along with machine status checks, your operators get a bird’s eye view of alarm triggers along with machine status checks. It helps establish KPIs and derivative data that are beneficial for mitigating risks and improving production capacity.

Mitsubishi Electric’s state-of-the-art next-gen CNC systems are easy to maintain as well. When it comes to maintaining current systems, the downtime affects productivity severely. However, with the new range of CNCs, maintenance is a breeze due to alarm history storage. Recording the times of alarm occurrence enables early troubleshooting. Pre-empting downtime and acquisition of modal coordinates at the time of alarm occurrence can help you implement and plan an agile factory setup like none other.

Automation is the Game Changer You Need

Thus, for a world that’s moving as fast as ours, obtaining Mitsubishi Electric India’s smart technology for industrial automation can skyrocket your growth. Reduce your revenue, increase operator morale, take on more complex projects, and set your brand apart like none other. Contact Mitsubishi PLC and get yourself FA solutions that change the game for your brand. Visit the link, to find out more about Mitsubishi’s state-of-the-art industrial technology and how you can use them to leverage KPIs and obtain tangible results immediately.

FAQs

1. What kind of products can I get from Mitsubishi Electric India?

For businesses, Mitsubishi offers a gamut of factory automation systems. These include CNCs and other controllers, Drive Products, Visualisation software and hardware, Industrial Robots, Low-Voltage Power Distribution Equipment, Power Monitoring Gear, and Medium-Voltage Power Distribution Mechanisms.

2. Where can I find the catalogue?

You can log onto Mitsubishi Electric India, and check out the catalogue of all the products Mitsubishi has to offer.