#Mounted type boom sprayers

Explore tagged Tumblr posts

Text

Revolutionizing Agriculture with Mounted Type Boom Sprayers

Agriculture is an essential sector for the growth and development of any economy. With the ever-increasing population, there is a need to increase the yield of crops to meet the food demand. The conventional methods of crop spraying, such as hand spraying or tractor-mounted sprayers, are becoming obsolete due to their limitations. These methods are not efficient, and they can lead to over-spraying, which can damage the crops and the environment. This is where mounted type boom sprayers come in handy. Mounted type boom sprayers are an innovative technology that is revolutionizing agriculture.

What are Mounted Type Boom Sprayers?

Mounted type boom sprayers are a type of agricultural sprayer that is mounted on a vehicle, such as a truck or a tractor. They consist of a tank that stores the spraying material and a boom that sprays the material on the crops. The boom is a long arm that can extend up to several meters, and it has multiple spray nozzles that can spray the material evenly on the crops. Mounted type boom sprayers are designed to be efficient, and they can cover a large area in a short time, making them ideal for large-scale farming operations.

Advantages of Mounted Type Boom Sprayers

Mounted type boom sprayers offer several advantages over traditional crop spraying methods. Here are some of the advantages:

1) Efficient

Mounted type boom sprayers are efficient and can cover a large area in a short time. This makes them ideal for large-scale farming operations. With a mounted type boom sprayer, farmers can spray their crops quickly and efficiently, saving time and labor costs.

2) Precision Spraying

Mounted type boom sprayers are designed to spray the material evenly on the crops, ensuring that every part of the crop is covered. This precision spraying ensures that the crops receive the right amount of material, reducing wastage and saving costs.

3) Cost-Effective

Mounted type boom sprayers are cost-effective in the long run. Although they may be expensive to purchase, they can save farmers money in the long run. This is because they are efficient, and they can spray the crops quickly and evenly, reducing the amount of material required. This, in turn, saves farmers money on the cost of the material and labor.

4) Environmentally Friendly

Mounted type boom sprayers are environmentally friendly. They are designed to spray the material evenly on the crops, reducing the amount of material required. This, in turn, reduces the amount of material that is released into the environment, reducing pollution and protecting the environment.

5) Versatile

Mounted type boom sprayers are versatile and can be used for a wide range of applications. They can be used for spraying pesticides, herbicides, and fertilizers, making them ideal for a range of crop spraying applications.

Applications of Mounted Type Boom Sprayers

Mounted type boom sprayers are versatile and can be used for a wide range of crop spraying applications. Here are some of the applications of mounted type boom sprayers:

1) Pesticide Spraying

Mounted type boom sprayers are ideal for pesticide spraying. They can spray the pesticide evenly on the crops, ensuring that every part of the crop is covered. This precision spraying reduces the amount of pesticide required, reducing costs and protecting the environment.

2) Herbicide Spraying

Mounted type boom sprayers are also ideal for herbicide spraying. They can spray the herbicide evenly on the weeds, ensuring that every part of the weed is covered. This precision spraying reduces the amount of herbicide required, reducing costs and protecting the environment.

3) Fertilizer Spraying

Mounted type boom sprayers are ideal for fertilizer spraying. They can spray the fertilizer evenly on the crops, ensuring that every part of the crop receives the right amount of fertilizer. This precision spraying ensures that the crops receive the right amount of nutrients, promoting healthy growth and increasing yields.

4) Crop Dusting

Mounted type boom sprayers can also be used for crop dusting. Crop dusting involves the application of a fine powder, such as fungicide or insecticide, onto the crops. Mounted type boom sprayers can spray the powder evenly on the crops, ensuring that every part of the crop is covered.

5) Soil Stabilization

Mounted type boom sprayers can also be used for soil stabilization. They can spray a mixture of soil and stabilizing material, such as lime or cement, onto the soil. This mixture stabilizes the soil, preventing erosion and promoting healthy plant growth.

How to Use Mounted Type Boom Sprayers

Using mounted type boom sprayers requires proper training and knowledge. Here are some steps to follow when using mounted type boom sprayers:

- Fill the Tank

Fill the tank with the material to be sprayed, such as pesticide or fertilizer.

- Adjust the Boom Height

Adjust the boom height to ensure that the nozzles are at the right height for the crops to be sprayed.

- Calibrate the Sprayer

Calibrate the sprayer to ensure that it is spraying the material evenly on the crops.

- Check the Wind Direction

Check the wind direction to ensure that the material is not sprayed onto neighboring crops or into nearby water sources.

- Spray the Crops

Spray the crops, ensuring that every part of the crop is covered.

- Clean the Sprayer

Clean the sprayer after use to prevent the buildup of residue and to ensure that it is ready for the next use.

Conclusion

Mounted type boom sprayers are an innovative technology that is revolutionizing agriculture. They offer several advantages over traditional crop spraying methods, including efficiency, precision spraying, cost-effectiveness, environmental friendliness, and versatility. Mounted type boom sprayers can be used for a wide range of crop spraying applications, including pesticide spraying, herbicide spraying, fertilizer spraying, crop dusting, and soil stabilization. Using mounted type boom sprayers requires proper training and knowledge, but once mastered, they can save farmers time and money while promoting healthy plant growth and increasing yields.

1 note

·

View note

Text

Orchard – 200 Tractor Mounted

Introducing SHAKTIMAN Rakshak Orchad – 200 Tractor-Mounted Type Boom Sprayer, designed to deliver exceptional spraying performance for a wide range of crops like cereal, pluses and vegetable.

This advanced sprayer combines precision engineering with robust construction, making it an indispensable tool for modern farmers seeking to maximize crop health and productivity.

1 note

·

View note

Text

Top 5 Tractor Mounted Boom Sprayers Revolutionizing Farming

Tractor mounted boom sprayers are essential pieces of equipment in modern farming, transforming how farmers approach crop protection and irrigation. These sprayers help farmers apply pesticides, herbicides, and fertilizers more efficiently and uniformly across large areas of farmland. With advancements in technology, these sprayers are becoming more powerful and easier to use, revolutionizing agricultural practices.

In this article, we'll explore the top five tractor mounted boom sprayers that are making a significant impact on farming. We will also discuss their benefits, features, and how they are improving productivity in the agricultural sector.

What is a Tractor Mounted Boom Sprayer?

A tractor mounted boom sprayer is a device that attaches to a tractor to spray chemicals or water over large fields. These sprayers consist of a boom—a long horizontal arm that holds spray nozzles at various intervals. The nozzles distribute the spray evenly across the land, ensuring that crops receive the right amount of treatment.

Tractor mounted boom sprayers are used for various tasks, including applying pesticides, herbicides, fertilizers, and water. They are commonly used in large-scale farming operations where traditional methods of spraying, such as handheld sprayers, are not feasible.

Why Choose Tractor Mounted Boom Sprayers?

Efficiency and Coverage

One of the main advantages of using a tractor mounted boom sprayer is the increased efficiency and coverage it offers. These sprayers can cover large areas quickly, allowing farmers to treat entire fields in a fraction of the time it would take using manual methods.

Uniform Application

Tractor mounted boom sprayers ensure that chemicals or fertilizers are applied evenly across the crops. The even distribution minimizes waste and ensures that each plant receives the correct dosage, leading to healthier crops and better yields.

Cost-Effective

While the initial cost of purchasing a tractor mounted boom sprayer may be high, the long-term benefits make it a cost-effective investment. These sprayers can help farmers save on labor costs, reduce chemical usage, and improve overall farm productivity.

Reduced Labor Intensity

With a tractor mounted boom sprayer, farmers no longer need to rely on manual labor for spraying, which can be time-consuming and physically demanding. This reduction in labor intensity allows farmers to focus on other important tasks and optimize their workflow.

Top 5 Tractor Mounted Boom Sprayers for Modern Farming

1. Tractor Sprayer Pump

Tractor sprayer pumps are an integral part of the tractor mounted boom sprayer system. They provide the necessary pressure to deliver the spray solution efficiently. A high-quality tractor sprayer pump ensures consistent pressure, which is essential for even distribution. The pump's reliability and durability are key factors in maintaining the sprayer's performance over time.

Tractor sprayer pumps are designed to handle large volumes of spray fluid, making them suitable for both small and large-scale farming operations. These pumps can be powered by the tractor’s engine or have their own power source, depending on the model.

By choosing the right tractor sprayer pump, farmers can improve their spraying efficiency and achieve optimal results in crop protection and fertilization.

Tractor Sprayer Pump

2. Tractor Operated Sprayer

The tractor operated sprayer is another essential tool for farmers looking to cover large areas quickly and effectively. These sprayers are powered by the tractor’s engine, ensuring that the sprayer runs at optimal speeds and delivers a consistent flow of chemicals or water.

Tractor operated sprayers are known for their versatility and ability to be adjusted according to the specific needs of the crops. These sprayers can be equipped with various types of nozzles to accommodate different spraying tasks, whether it’s applying pesticides, herbicides, or fertilizers.

Farmers can benefit from the tractor operated sprayer by reducing their workload and improving the uniformity of their spray applications. These sprayers are especially useful in larger fields where traditional manual spraying methods are inefficient.

Tractor Operated Sprayer

3. Tractor Mounted Boom Sprayer

The tractor mounted boom sprayer is the backbone of many modern farming operations. This type of sprayer is designed to cover large areas with minimal effort. The boom can be extended or retracted depending on the field size, and the spray nozzles are strategically placed to ensure uniform coverage.

One of the standout features of tractor mounted boom sprayers is their ability to adjust the spray width, making them suitable for different crop types and field conditions. This flexibility helps farmers optimize their spraying operations, saving both time and money.

Whether you’re spraying for pest control, weed management, or fertilization, the tractor mounted boom sprayer provides an efficient solution to meet the needs of modern agriculture.

Tractor Mounted Boom Sprayer

4. Mini Tractor Sprayer

For farmers with smaller plots of land, a mini tractor sprayer is an ideal option. These sprayers are designed to be more compact and lightweight, making them easier to maneuver in tight spaces. Despite their smaller size, mini tractor sprayers still deliver powerful performance and can be equipped with a variety of nozzles for different spraying tasks.

Mini tractor sprayers are perfect for small to medium-sized farms where large tractor mounted boom sprayers may be too cumbersome. They offer excellent maneuverability without sacrificing spray coverage or efficiency.

Mini Tractor Sprayer

5. Tractor Trailed Sprayer

The tractor trailed sprayer is a great option for farmers looking for flexibility and adaptability. This type of sprayer is attached to the back of a tractor and can be towed across fields. Trailed sprayers are designed to handle large volumes of spray fluid, allowing for greater coverage and more efficient spraying.

Tractor trailed sprayers are often preferred for their ability to be easily detached from the tractor when not in use. This makes them ideal for farmers who need to switch between tasks quickly. Additionally, trailed sprayers can be equipped with a variety of booms and nozzles, making them versatile for different types of crops.

Tractor Trailed Sprayer

Features to Look for in a Tractor Mounted Boom Sprayer

When choosing a tractor mounted boom sprayer, there are several important features to consider. These features will help ensure that the sprayer meets your specific needs and provides the best possible performance.

Adjustable Boom Length

An adjustable boom length allows farmers to customize the width of the spray coverage, making it easier to adapt to different field sizes. This feature is particularly useful for farmers working in areas with varying crop types or irregularly shaped fields.

Nozzle Variety

The nozzle is a critical component of any sprayer. Different nozzles allow for different spray patterns, making it easier to target specific areas of the field. Whether you need a fine mist for pesticides or a heavier spray for fertilization, the right nozzle can make a big difference in the effectiveness of the application.

Durability and Build Quality

A tractor mounted boom sprayer is a significant investment, so it’s important to choose a model that is built to last. Look for sprayers made from high-quality materials that can withstand the harsh conditions of farming. Corrosion-resistant components and strong frames ensure that the sprayer will continue to perform well over time.

Ease of Use

Simplicity is key when choosing farm equipment. A sprayer that is easy to operate will reduce the learning curve and allow you to get the job done quickly. Features such as simple controls, easy-to-fill tanks, and adjustable settings will enhance your spraying efficiency.

Tank Capacity

The tank capacity of the sprayer determines how much liquid can be carried at once. Larger tanks mean fewer trips to refill, which is especially important for large farms. However, it’s also important to find a balance between tank size and the weight of the sprayer, as a larger tank may be more difficult to handle in smaller fields.

Conclusion

Tractor mounted boom sprayers have truly revolutionized farming, making it easier for farmers to protect and nourish their crops. The five sprayers discussed in this article are among the best in the industry, each offering unique features that cater to different farming needs.

From the powerful tractor sprayer pump to the versatile tractor trailed sprayer, these tools are designed to improve efficiency, reduce labor, and increase crop yields. Whether you're running a small farm or a large-scale operation, there is a sprayer to meet your needs.

Investing in a tractor mounted boom sprayer can significantly enhance your farming operations, giving you more time to focus on other aspects of your farm. So, choose wisely, and watch your productivity grow.

0 notes

Link

0 notes

Text

Optimizing Crop Care: A Comprehensive Guide to Modern Agriculture Sprayers

Introduction:

In the ever-evolving landscape of agriculture, the adoption of modern technologies is paramount for enhancing crop care and optimizing yields. One integral component of this technological revolution is the use of advanced agriculture sprayers. These devices play a pivotal role in efficiently applying pesticides, fertilizers, and other treatments to crops, ensuring their health and productivity. In this comprehensive guide, we delve into the world of modern agriculture sprayers, exploring their types, features, and the benefits they bring to contemporary farming practices.

Types of Modern Agriculture Sprayers:

Tractor-Mounted Sprayers:

These sprayers are affixed to tractors and leverage the tractor's power source. With adjustable booms and precise controls, they offer flexibility in application, making them suitable for various crop types and field sizes.

Air Blast Sprayers:

Incorporating air blast technology, these sprayers generate a powerful air stream to disperse spray materials uniformly. They are particularly effective in orchards and vineyards, reaching every part of the canopy for comprehensive coverage.

Tractor-Operated Sprayers:

Designed to be operated from a tractor, these sprayers are versatile and maneuverable. They provide an efficient means of applying treatments across large agricultural areas while minimizing manual labor.

Grape and Orchard Sprayers:

Tailored for the specific needs of fruit orchards, grapevines, and other tree crops, these sprayers often feature adjustable booms, air deflectors, and precision controls to protect delicate fruit clusters and ensure even coverage.

Key Features of Modern Agriculture Sprayers:

Precision Control Systems:

Modern sprayers are equipped with precision control systems that allow farmers to regulate spray patterns, adjust nozzle settings, and target specific areas. This precision helps minimize wastage and ensures effective treatment.

GPS Integration:

Some sprayers feature GPS technology, enabling precise mapping of fields and optimized spray patterns. This integration contributes to accuracy in application, reducing overlap and improving overall efficiency.

Adjustable Boom Structures:

The inclusion of adjustable boom structures provides adaptability to varying crop heights and row spacings. Farmers can customize the spray width and height, ensuring comprehensive coverage in diverse agricultural settings.

Efficient Liquid Transfer:

Modern sprayers are designed for efficient liquid transfer from the tank to the nozzles. This ensures a consistent and controlled flow of spray materials, contributing to uniform coverage and optimal resource utilization.

Reduced Drift Technology:

To minimize the environmental impact, many modern sprayers are equipped with technology to reduce chemical drift. This ensures that the spray is directed precisely onto the target crops, preventing contamination of neighboring areas.

Benefits of Using Modern Agriculture Sprayers:

Increased Efficiency:

Modern sprayers streamline the application process, covering larger areas in less time compared to traditional methods. This increased efficiency translates to higher productivity and reduced labor requirements.

Enhanced Crop Health:

The precise application enabled by modern sprayers contributes to enhanced crop health. Farmers can target specific areas, addressing pest and disease concerns effectively and promoting overall crop vitality.

Resource Optimization:

With adjustable settings and GPS integration, modern sprayers optimize the use of resources such as water, pesticides, and fertilizers. This not only reduces costs for farmers but also aligns with sustainable agricultural practices.

Versatility Across Crops:

Whether in row crops, orchards, or vineyards, modern sprayers offer versatility. Farmers can adapt the equipment to the unique needs of different crops and field layouts, maximizing its utility throughout the farming operation.

Ease of Operation:

User-friendly controls and automated features make modern sprayers easy to operate. Farmers can focus on strategic decision-making, knowing that the equipment efficiently handles the intricacies of spray application.

Conclusion:

In the realm of modern agriculture, optimizing crop care is a multifaceted endeavor, and agriculture sprayers stand at the forefront of this mission. From precision control systems to GPS integration and reduced drift technology, these devices exemplify innovation in farming practices. As farmers continue to embrace these advancements, the landscape of crop care evolves, promising increased yields, resource efficiency, and sustainable agriculture for the future.

0 notes

Link

There are typically three types of screens installed into a ULV sprayer system: a coarse screen, a medium screen, and a fine screen. All of these are mounted at various positions, such as a suction hose, between the pump and the boom or tube, respectively, and in the nozzle.

1 note

·

View note

Photo

Boom Sprayer Machine | Farm Implements-Fieldking

The boom sprayer is ideal for uniform and effective crop spraying. In order to make the best choice in boom sprayers, "Fieldking" is the leader in the market. For multipurpose plant protection, FIELDKING mounted type 300, 550, 600, and 1100 ltr. boom sprayers connected to the three-point linkage of the tractor and receiving drive from (P.T.O) are employed. All types of field crops can be sprayed with these sprayers.

#boom sprayer#sprayer machine#agriculture#agricultural implements#farming#farmers#farm implements#farm equipment

0 notes

Link

Year;2009

Manufacturer: HAGIE

Model: STS10

Serial Number: U1611001087

Condition: Used

Hours: 2372

Capacities:

Capacity: 1,000 gal

Category Specific:

Boom Width: 90 ft

Tank: Stainless Steel

Foam: Yes

Auto Boom Leveling: Yes

Auto Boom Shut Off: Yes

Boom Return to Height: Yes

Boom Material: Steel

Boom Breakaway: Yes

Fill Location: Front

Nozzle Spacing: 15 in

Nozzle Body Type: Five

Fence Row Nozzle: Yes

Fenders: Yes

Wheel Shields; Yes

Premium Lighting; Yes

Chassis;

Auto Guidance Ready: Yes

Hydraulic Tread Adjust: Yes

Tire Type: Row Crop

Front Tire % Remaining: 50

Rear Tire % Remaining: 30

Interior:

Air: Yes

Heat: Yes

GPS Ready: Yes

Instructional Seat: Yes

Powertrain:

Drive: 4 WD

Traction Control: Yes

All-Wheel Steer: Yes

Engine:

Engine Manufacturer: CUMMINS

Engine Turbo: Yes

6.7 Cummins 90 ft boom, 15 in centers, 60/80/90 ft Five-way nozzle bodies with nozzles, stainless line Norac UC5 boom height sensor Richway foam marker Five section shut offs with extra end nozzles and fence row nozzles Rear wheel nozzles 1000 gallon stainless tank 3 in. front fill All wheel steering (turn on and off with the push of a button) Ag Leader harness and mounts, no monitor or receiver 320/90R50 tires, fronts are about 50%, rears are about 30% Sprayer has some rust spots, especially on inside of front wheels (see pics) Overall a nice, clean, straight, low hour unit with nothing rewelded.

FOR MORE INFORMATION CALL

913 647 9576

0 notes

Text

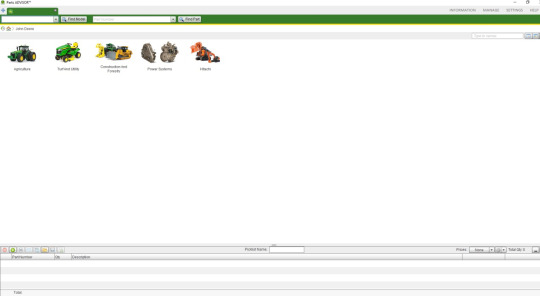

John Deere Parts ADVISOR AG + CF + CCE + HITACHI for John Deere Service Advisor EDL V3 or V2 Free Download

What is John Deere Parts Advisor? John Deere Parts ADVISOR makes doing that as comfortable and productive as possible. However, its flexibility enables you to quickly find the parts you need in a way that matches your preferred workflow.

John Deere Parts Advisor Functions: 1.Maintenance 2.Spare Parts 3.Technical specifications 4.Tables 5.Diagrams and many other data

John Deere Parts Advisor Free Download: John Deere Parts Advisor 2020 https://mega.nz/file/DkgniSwL#rJVAqWODRnxQp8m_KJtTQ4vTAYFCUp7mmY0CPazK3oc

John Deere Parts ADVISOR v1.7.1 [06.2017] AG + CF + CCE + HITACHI https://mega.nz/file/KW5l1SJR#7YFZMu3z6509CgrV9sNOLCKaF1a5USPluXzo0CcsMR4

John Deere Service Advisor EDL (Electronic Data Link) heavy duty diagnostic adapter for construction equipment, agriculture, engines John Deere.

John Deere Diagnostic kit includes software John Deere Service Advisor Agriculture or Construction and Forestry version.

John Deere Service Advisor Agriculture workshop service manual, repair manual, electrical wiring diagram, hydraulic diagram, diagnostic, assembly and disassembly engine, transmission.

John Deere AG Management Solutions, Attachments, Backhoes, Combines and Headers, Cotton Harvestings, Excavators, ForkLifts, Hay and Forages, MAte Hand Cut and Shredderses, Plantings and Seedings, Skid Steers, Sprayers, Sugar Cane Harvesters, Tillages, Tractors, Worksite Pro Attachments.

John Deere Service Advisor CF (Construction and Forestry), workshop service manual, repair manual, diagnostic, electrical wiring diagram, hydraulic diagram John Deere.

John Deere Service Advisor CCE (Commercial and Consumer Equipment)dealer technical assistance, diagnostics, connection readings, calibrations, interactive tests, specification, tools, assemble and disassemble presented all models John Deere Construction Equipment and some models Hitachi, Euclid, Bell and Timberjack.

John Deere Parts Advisor Support Models: AGRICULTURE * 2-Way Integral Disk Plows * Aerator * Air Conditioning System * AMS * AMT * Applicator * Attachment, 60-in Mower Deck (2520 Tractor And X495, X595 X-Series Lawn Tractors) * Attachment, Combine * Attachment, Mid-Mount Rotary Mower, Mower Decks, And 3-Bag MCS (2210 And 4×10 Series Cuts) * Attachment, Mower Deck (4000 Series Cuts) * Attachments * Axle * Backhoe * Backhoe, Loader * Bagger * Bale Accumulator * Bale Conveyor * Bale Ejector * Bale Processor * Bale Unroller * Baler * Baler Engines * Baler, Hand-Tie * Baler, Large Square * Baler, Round * Bar, Tool * Bedder * Bicycle * Binder, Corn * Binder, Grain * Blade * Blower, Ensilage And Forage * Blower, Power * Boom * Bottom * Box Blade * Broom, Rotary * Bucket * Bulldozer * Cab * Carrier, Implement * Carrier, Killefer * Carrier, Rear * Carrier, Tool * Carrier, Tool, Drawn * Carrier, Tool, Integral * Carrier, Toolbar * Cart, Commodity * Cart, Coulter * Cart, Dump * Cart, Grain * Cart, Seed * Charger, Battery * Chassis, Vehicle * Chipper, Shredder * Chopper * Chopper, Hay * Chopper, Rotary * Clod-Buster * Combine * Combine, Attachment * Combine, Belt Pickups & Pickup Platforms * Combine, Cab, Operator * Combine, Corn Head * Combine, Engine (Power Unit) * Combine, Platform (Cutting) * Combine, Platform (Flex Cutterbar/Rigid) * Combine, PTO * Combine, Row-Crop Head * Combine, Sprayer * Combine, Transport Frame (For Combine Header) * Combine, Windrow Spreader * Compactor * Component, Remanufactured * Compressor, Air * Conditioner, Field * Conditioner, Hay * Corn Head * Corrugator * Cotton Plow * Crane * Cuber, Hay * Cuber, Stationary * Culta-Carrier * Cultivator * Cultivator, Beet-Bean-Vegetable * Cultivator, Field * Cultivator, Listed Corn * Cultivator, Listed Crop * Cultivator, Planting Attachment * Cultivator, Row-Crop * Cummins Engine * Cutter, Corn * Cutter, Rotary * Cutter, Stalk * Cutting Platform * Deck * Defoliator, Beet * Digger, Posthole * Digger, Potato * Disc Mower * Disk * Disk Plow, Border * Ditcher * Drawbar, Cart * Drawbar, Harrow * Drill * Drill, Air * Drill, Grain * Drill, Grain (Attachment) * Drill, Grass Seed * Drill, Grassland * Drill, Rangeland * Drill, Soybean And Grain * Drill, Tru-Vee * Driver, Post * Driver, Crop * Driver, Grain * Duster * Ejector * Elevator * Engine * Engine, Combine * Engine, Cummins * Engine, Marine (Series 300 Diesel) * Engine, Marine (Series 400 Diesel) * Engine, Miscellaneous * Engine, Natural Gas * Engine, OEM (Series 200 Diesel) * Engine, OEM (Series 300 Diesel) * Engine, OEM (Series 400 Diesel) * Engine, OEM (Series 500 Diesel) * Engine, OEM (Series 700 Diesel) * Engine, OEM For Irrigation * Engine, OEM For Multi-Purpose And Stationary * Engine, Powertech * Engine, Powertech Plus * Excavator * Feeder, Bunk * Fertilizer Attachmnet * Fertilizer, Distributor * Finisher, Mulch * Finisher, Seedbed * Flail Shredder * Fluffer, Swath * Food Plot Seeder * Forklift * Front Loader * Frontier * Gang Bolt Dimensions * Generator * Genset * Grapple * Green System * Greenstar * Grill, Barbecue * Grill, Gas * Grinder, Knife * Grinder, Mixer * Grooming Mower * Grub Breaker * Hagie * Harrow, Disk * Harrow, Disk (Bush And Bog) * Harrow, Finishing * Harrow, Offset (Plowing) * Harrow, Roller * Harrow, Spike Tooth * Harrow, Spring Tooth (Drawn) * Harvester * Harvester Head * Harvester, Bean * Harvester, Beet * Harvester, Beet (Attachment) * Harvester, Cotton * Harvester, Ensilage And Forage * Harvester, Ensilage And Forage (Attachment) * Harvester, Ensilage And Forage (Engines) * Harvester, Ensilage And Forage (Pull-Type) * Harvester, Ensilage And Forage (Self-Propelled) * Harvester, Forage * Harvester, Potato * Hay Merger * Header Transport * Hi-Crop Implements * Hi-Cycle * Hitch * Hitch, 3-Point * Hitch, Grain Drill * Hitch, Minimum Tillage * Hitch, Multiple Planter * Hitch, Tandem (For Mowers And Hay Conditioners) * Hitch, Tandem (Moldboard Plow, Disk Tillers) * Hoe, Bed * Hoe, Power * Hoe, Rotary * Hoist, Bolster * Husker, Corn * Hydraulic Marker * Implement, Tillage * Incorporator, Herbicide * Integral Disk Harrow * Ivs * Jack, Lift * Kernel Processor * Land Leveler * Land Plane * Landshaper * Lifter, Beet * Lifter-Loader, Beet * Lister, Drawn * Lister, Integral * Lister, Middlebreaker (Integral) * Lister, Planting Attachment * Loader * Loader, Bale * Loader, Farm * Loader, Four-Wheel Drive * Loader, Skid-Steer * Loader, Skid-Steer, Attachment * Loader, Tractor-Mounted * Loader, Two-Wheel Drive * Material Collection System * Mill, Double-Geared * Mill, Hammer * Mill, Roller * Miscellaneous Products * Mixer, Feed * Monitor, Seed * Motor, Cam-Lobe * Mover, Stack * Mower * Mower Bar, Forage Harvester * Mower, Attachment * Mower, Conditioner * Mower, Dain * Mower, Flail * Mower, High Lift * Mower, Hydraulic Gang * Mower, Power * Mower, Reel-Mounted * Mower, Rotary * Mower, Sickle * Mower, Tractor-Mounted * Mulch Finisher * Mulch Master * Overseeder * Packer, Crowfoot * Packer, Rooller * Picker, Corn * Picker, Cotton * Pickup, Forage Harvester * Planter * Planter, Attachment * Planter, Cotton And Corn * Planter, Lister * Planter, Narrow * Planter, Potato * Planter, Unit * Platform * Platform (Cutting) * Plow * Plow, Cable * Plow, Chisel * Plow, Disk * Plow, Disk (Drawn) * Plow, Disk (Integral) * Plow, Disk (Semi-Integral) * Plow, Moldboard * Plow, Moldboard (Drawn) * Plow, Moldboard (In Furrow) * Plow, Moldboard (In-Furrow) * Plow, Moldboard (Integral) * Plow, Moldboard (On-Land) * Plow, Moldboard (Semi-Integral) * Plow, Moldboard (Two-Way Drawn) * Plow, Moldboard (Two-Way Integral) * Plow, Reversible Moldboard * Plow, Snow * Plows * Power Unit * Powr-Till * Product Identification Number Guide * Progrator * PTO * Pulverizer * Pump * Pump Drive * Pump, Chemical Transfer * Pump, Portable Centrifugal * Pump, Radial Piston * Pump, Tire * Rake * Rake, Bean * Rake, Hay * Rake, Sweep * Rate Drive * Reed Cart * Reed Loader * Ripper * Ripper, Disk * Ripper, Mulch * Ripper, Row Crop * Ripper, Toolbar * Rotary Tiller * Row Crop Cultivator * Row-Crop, Forage Harvester * Saw, Chain * Scarifier * Scoop * Scraper * Scraper, Farm * Scraper, Utility Box * Seeder, Air * Seeder, Central Metering * Seeder, Combine * Seeder, Endgate * Seeder, Landscape * Seeder, Air System * Shaver, Corn * Sheller, Corn * Sheller, Cylinder * Sheller, Hand * Sheller, Power (Spring) * Shredder, Feeder * Shredder, Flail * Sickle Bar * Silage Defacer * Single Unit Planter * Snapper, Corn * Snow Blower * Snow Blower (Tractor-Mounted) * Special Tools * Sprayer * Sprayer, 3-Point Hitch * Sprayer, Attachment * Sprayer, Highway * Sprayer, Hooded * Sprayer, Integral * Sprayer, Orchard And Grove * Sprayer, Paint * Sprayer, Pull-Type * Sprayer, Self-Propelled * Sprayer, Skid-Mounted * Spreader * Spreader, Fertilizer * Spreader, Fertilizer And Grain * Spreader, Fertilizer And Seed * Spreader, Manure * Spreader, Spin * Stacker * Stacker, Hay * Stripper, Bascket Attachment * Stripper, Cotton * Stripper, Trailer Air Attachments * Subsoiler * Support Wheel * Sweeper, Lawn * Tedder * Telescopic Handler * Thinner, Synchronous * Threshing Cylinder * Tiller, Disk * Tiller, Disk (Attachment) * Tiller, Mulch * Tiller, PTO * Tiller, Seeding * Tiller, Tractor-Mounted * Tool Bar * Tool, Cabinet * Tool, Seeding * Topper, Beet * Topsaver, Beet * Track * Tractor * Tractor Attachments * Tractor, Compact Utility * Tractor, Compact Utility, Attachment * Trailer * Trailer Cart * Transmission * Transporter, All Material (AMT) * Treader, Mulch * Unloader, Silo * Utility Trailer * Utility Vehicle * Utility Vehicle, Attachment * V-Ripper * V-Ripper (Integral) * Vacuum, Blower * Variable Speed * Wagon * Wagon, Auger * Wagon, Boxes * Wagon, Chuck * Wagon, Ensilage And Grain * Wagon, Forage * Wagon, Hi-Dump * Wagon, Stack * Washer, High-Pressure * Weather Enclosure And Sunshade * Weeder, Rod * Welder * Wheel, Lift Assist * Wheel, Reel Lift Assist (Toolbar) * Windrower * Windrower, Cab Operator * Windrower, Engine * Windrower, Platform * Wood Chipper (PTO) TURF AND UTILITY * 2-Cycle * 32cm * 36cm * 4 Cycle * 4-Cycle * 40cm * 43cm * 47cm * 52 * 52cm * 54cm * Aerator * Air Conditioning System * Alternator * AMT * Applicator * Attachment, 2-Bag Bagger, Tiller, Snow Thrower, Blade, Power Flow (Scotts Lawn Tractors) * Attachment, 2-Bag Bagger, Tiller, Snow Thrower, Blade, Power Flow, Cart, (Sabre Lawn Tractors) * Attachment, 2-Stage Snowblower, Front Blade, And Rotary Broom (1400 And 1500 Front Mowers) * Attachment, 36-In Lawn Roller * Attachment, 40-In Aerator Spreader, 40-In Plug Aerator, 40-In Thatcherator, 48-In Plug Aerator) * Attachment, 60-In Mower Deck (2520 Tractor And X495, X595, X-Series Lawn Tractors) * Attachment, Mid-Mount Rotary Mower, Mower Decks, And 3-Bag MCS (2210 And 4×10 Series Cuts) * Attachment, Mower Deck (120, 140, 300, 312, 314, 316, 317, 318, 322, 330, 332, 425, 445, 455 Lawn Tractors) * Attachment, Mower Deck (1400 And 1500 Series Front Mowers) * Attachment, Mower Deck (4000 Series Cuts) * Attachment, Mower Deck And Power Flow Blower Assembly (325, 335, 345, 355D Lawn Tractors) * Attachment, Mower Decks (F620, F680, F687 ZTrak Front Mowers) * Attachment, Mower Decks And 2 & 3 Bag PowerFlow Material Collection System Power Flow Blower Assembly (LX And GT Series Lawn Tractors) * Attachment, Mower Decks, Front Blade, Power Flow Blower Assembly (GX255) * Attachment, Mower Decks, Front Blade, Power Flow Blower Assembly (LX280) * Attachment, Mower Decks, Front Blade, Power Flow Blower Assembly (LX289) * Attachment, Power Flow Blower Assembly (LT, LX, STX, GT, And 400 Series Lawn Tractors) * Attachment, Snow Blower, Snow Thrower, Snow Blade, MCS (Scotts Lawn Tractors) * Attachment, Snowblower, Snow Blade, And MCS (Sabre Lawn Tractors) * Attachment, Tractor Trunk * Attachment, V-Flex 7-Iron Mower Deck (1400 And 1500 Series Front Mowers) * Attachments * Backhoe * Backhoe, Loader * Bagger * Bale Unroller * Baler * Battery * Bicycle * Blade * Blade, Snow * Blower, Golf Turf * Blower, Power * Bottom * Box Blade * Broom, Rotary * Brushcutter * Bucket * Bulldozer * Bunker * Cab * Cart, Dump * Cart, Utility * Charger, Battery * Chipper, Shredder * Chopper, Rotary * Clipper * Compactor * Component, Remanufactured * Compressor, Air * Consumer Product Accessories * Cotton Plow * Cultivator, Field * Cutter, Rotary * Deck * Digger, Posthole * Disc Mower * Disk * Ditcher * Drill, Grain * Driver, Post * Edger * Engine * Engine, OEM (Series 200 Diesel) * Engine, Powertech * Engine, Repower * Europro * Excavator * Eztrak * Fertilizer, Distributor * Field Vehicle * Finisher, Mulch * Food Plot Seeder * Forklift * Front Attachments * Front Loader * Frontier * Generator * Generator, Portable * Genset * Grapple * Green System * Grrensmower * Grill, Barbecue * Grill, Gas * Grooming Mower * Harrow, Disk * Harvester * Hay Merger * Header Transport * Heater, Space * Hitch, 3-Point * Implement, Tillage * Injection System * Land Leveler * Land Plane * Lawn Tractors * Loader * Loader Attachment * Loader, Bale * Loader, Farm * Loader, Four-Wheel drive * Loader, Skid-Steer * Loader, Skid-Steer, Attachment * Loader, Tractor-Mounted * Log Splitter * Material Collection System * Miscellaneous Products * Mower * Mower Deck * Mower, Attachment * Mower, Boom * Mower, Electric * Mower, Fairway * Mower, Flail * Mower, Front * Mower, Gang * Mower, Green * Mower, Hydraulic Gang * Mower, Professional Turf * Mower, Reel-Mounted * Mower, Riding * Mower, Rotary * Mower, Sickle * Mower, Tractor-Mounted * Mower, Turf System * Mower, Walk-Behind * Mower, Walk-Behind (Commercial) * Mower, Wide Area * Mulch Finisher * Mulcing * Overseeder * Packer, Roller * Planter * Planter, Unit * Plow * Plow, Disk * Plow, Moldboard (Integral) * Power Unit * Product Identification Number Guide * Profi * Progator * Pulverizer * Pump * Pump, Portable Centifugal * Quik-Trak * Rake * Rake, Bunker And Field * Rake, Hay * Riding Mowers * Rotary Tiller * Sabo * Sabre * Saw, Chain * Saw, Multi-Purpose * Scarifier * Scotts * Scraper * Scraper, Utility Box * Seeder, Landscape * Shredder * Shredder, Leaf * Sickle Bar * Silage Defacer * Snow Blower * Snow Blower (Tractor-Mounted) * Snow Blower (Walk-Behind) * Snow Thrower * Snowmobile * Spin Steer * Sprayer * Sprayer, Paint * Spreader * Spreader, Fertilizer * Spreader, Manure * Sweeper, Lawn * Tedder * Telescopic Handler * Thatcher * Tiller, Disk (Attachment) * Tiller, PTO * Tiller, Tractor-Mounted * Tiller, Walk-Behind * Tool Bar * Tool, Cabinet * Tractor * Tractor Attachments * Tractor, Compact Utility * Tractor, Compact Utility, Attachment * Tractor, Lawn * Tractor, Lawn And Garden * Trailer * Trailer Cart * Trailer, Snowmobile * Trailer, Utility * Transporter, All Material (AMT) * Trimmer * Trimmer, Cutter * Trimmer, Edger * Trimmer, Edger (Electric) * Trimmer, Edger (Gas) * Trimmer, Edger (Hedge) * Trimmer, Cutter * Utility Triler * Utility Vehicle * Utility Vehicle, Attachment * Vacuum, Blower * Wagon * Walk-Behind Mower * Washer, High-Pressure * Weather Enclosure And Sunshade * Welder * Wood Chipper (PTO) * Ztrak CONSTRUCTION AND FORESTRY * AMT * Arches, Log * Attachments * Axle * Backhoe * Backhoe, Loader * Bar, Tool * Bicycle * Blade * Blower, Power * Boom * Box Blade * Broom, Rotary * Brushcutter * Bucket * Bulldozer * Bundler * Cab * Charger, Battery * Compactor * Component, Remanufactures * Components * Compressor, Air * Crane * Crawler * Crawler Loader * Deeretrax * Delimber * Dozer, Crawler * Engine * Engine, Marine (Series 300 Diesel) * Engine, Marine (Series 400 Diesel) * Engine, Natural Gas * Engine, OEM (Series 200 Diesel) * Engine, OEM (Series 300 Diesel) * Engine, OEM (Series 400 Diesel) * Engine, OEM (Series 500 Diesel) * Engine, OEM (Series 700 Diesel) * Engine, OEM For Multi-Purpose And Stationary * Engine, Powertech * Engine, Powertech Plus * Excavator * Excavator – EX-5 * Excavator Logger * Feller Buncher * Feller Buncher, Track * Felling Head * Forestry Swing Machine * Forklift * Forwarder * Frontier * Genset * Grader, Motor * Grapple * Grill, Barbecue * Grill, Gas * Harvester * Harvester Head * Heater, Space * Land Leveler * Land Plane * Loader * Loader, Crawler * Loader, Four-Wheel Drive * Loader, Front * Loader, Knuckleboom * Loader, Log * Loader, Rear * Loader, Skid-Steer * Loader, Skid-Steer, Attachment * Loader, Two-Wheel Drive * Logger * Logger Components * Master Trax * Miscellaneous Products * Mower * Packer, Roller * Plow, Cable * Plow, Moldboard (Integral) * Power Unit * Product Identification Number Guide * Progrator * Pump Drive * Pump, Portable Centrifugal * Rake * Rake, Brush (Integral) * Rake, Landscape * Ripper * Ripper, Hydraulic * Saw, Chian * Scarifier * Scarifier, Scraper * Scraper * Scraper, Elevating * Scraper, Utility Box * Seeder, Landscape * Shear Head * Sideboom * Skidder, Log * Slash Bundler * Slasher * Tractor * Tractor, Compact Utility, Attachment * Trailer * Transmission * Transporter, All Material (AMT) * Tree Harvester * Truck, Articulated Dump * Undercarriage * Utility Vehicle * Utility Vehicle, Attachment * Vacuum, Blower * Variable Speed * Weather Enclosure And Sunshade * Welder * Winch POWER SYSTEMS * Axle * Engine * Engine, Marine (Series 300 Diesel) * Engine, Marine (Series 400 Diesel) * Engine, Natural Gas * Engine, OEM (Series 200 Diesel) * Engine, OEM (Series 300 Diesel) * Engine, OEM (Series 400 Diesel) * Engine, OEM (Series 500 Diesel) * Engine, OEM (Series 700 Diesel) * Engine, Powertech * Engine, Powertech Plus * Genset * Power Unit * Pump Drive * Transmission HITACHI * Excavator – EX * Excavator – EX-7 * Excavator – EX-7B * Excavator – EX-2 * Excavator – EX-3 * Excavator – EX-5 * Excavator – EX-6 * Excavator – UH * Excavator – Zaxis * Forester – EX-5 * Forester – Zaxis * Truck

#John Deere Service Advisor EDL#John Deere Service Advisor#John Deere Diagnostic Kit#John Deere Diagnostics Kit

0 notes

Text

The Incredible Influence of a Tractor Sprayer

A tractor sprayer is a type of agricultural machinery used to spray liquid fertilisers, pesticides, and herbicides on crops. A large tank holding the chemical solution, a pump to pressurise the solution, and a spray boom with nozzles mounted on a tractor's back make up the system. In order to change the width and coverage of the spray pattern, a tractor sprayer's boom can be divided into sections that can each be individually controlled. This prevents chemical waste and damage to neighbouring plants while enabling the operator to apply chemicals to the target area precisely and accurately.

The most crucial crop production practices are those related to plant protection, using the sprayer to apply the most pesticide products possible. In agriculture, one of the most frequent and important tasks is the application of fungicides, herbicides, and insecticides. The conflict between economic expansion and environmental protection in agricultural production has been caused by traditional agricultural spraying methods. In recent decades, spraying techniques have continuously improved. Not only is a sprayer necessary for pesticide application, but other factors like the type and size of the plant canopy, the area of a plant leaf, the crop's height, and the number of plants being applied are also crucial for better outcomes.

Advantages of tractor sprayers

1) Efficiency gain: Tractor sprayers can quickly and effectively cover large areas, which saves time and labour during spraying operations.

2) Application accuracy: Tractor sprayers come with a spray boom that can be adjusted to precisely and accurately deliver chemicals to defined areas, minimising waste and maximising effectiveness.

3) Versatility: Tractor sprayers can be used for a wide range of tasks, such as the application of fertiliser, pesticides, and even water for irrigation.

4) Cost-effectiveness: Due to their efficiency and accuracy, tractor sprayers are frequently more cost-effective than alternative chemical application techniques like aerial spraying or manual application.

5) Reduced environmental impact: Careful application reduces chemical waste and the effects of chemicals on the environment, including the quality of the soil and water.

6) Mobility: Because tractor sprayers are portable, farmers can quickly and effectively apply chemicals to various parts of their crops as needed.

How does the tractor spray operate?

1) Fill the tank: The liquid chemical solution that will be sprayed on the crops is put into the tractor sprayer tank.

2) Solution pressurisation: The tank's solution is pressurised using a pump. Under this pressure, the solution must be forced through the spray nozzles in order to produce a fine spray mist.

3) Adjust the spray boom: To achieve the desired spray pattern, the spray boom is adjusted to the desired height and width, and any necessary nozzle adjustments are made.

4) Start spraying: As the tractor operator moves the sprayer over the field, the spray nozzles are turned on to start applying the chemical solution to the crops.

5) Continue spraying: Spraying continues as the tractor and sprayer are driven across the field until the entire area has been sprayed.

6) Rinse the system: To ensure that no chemical residue is left in the system after spraying is finished, the sprayer system should be thoroughly rinsed.

How is a tractor-sprayer maintained?

1) Clean the sprayer after each use: Each time you use the sprayer, clean it. After every use, rinse the sprayer tank and nozzles with clean water to avoid chemical buildup and clogging. Additionally, use water to clean the hoses and pump.

2) Regularly inspect the sprayer: Examine the sprayer on a regular basis for any indications of damage, such as leaks, cracks, or worn-out components. Any damaged parts must be replaced right away.

3) Check and replace filters: To prevent clogs and guarantee proper flow, regularly inspect and clean the sprayer's filters. When necessary, swap out the filters.

4) Lubricate moving parts: To ensure smooth operation and prevent rust and corrosion, lubricate moving parts like the pump, valves, and spray booms.

5) Store the sprayer properly: In order to protect it from the elements and avoid rust and corrosion, store the sprayer in a tidy, dry, and covered area.

6) Follow the manufacturer's instructions: Adhere to the manufacturer's maintenance guidelines, which include suggested maintenance intervals and techniques.

7) Have a professional service the sprayer: To make sure the sprayer is operating properly and to identify any potential issues before they become significant issues, have it serviced by a professional at least once per year.

Conclusion

Finally, a tractor sprayer is a crucial piece of equipment for farmers and other agricultural workers. It is a very effective and adaptable piece of machinery that enables precise and accurate chemical application to crops, improving crop yields, lowering costs, and having little negative environmental impact. A tractor sprayer needs routine maintenance to function properly and last a long time. Farmers can make sure that their tractor sprayer is in good working order and available for use when needed by adhering to the manufacturer's instructions and carrying out routine inspections and maintenance. An investment in a tractor sprayer is worthwhile for any agricultural operation due to its many advantages and benefits.

Dolls Export Pvt. Ltd. has received numerous accolades for being a trusted name in the production of agricultural products like Argo Chemicals, bio-fertilizers, and sprayers. We provide a wide selection of agricultural sprayers. Particularly, tractor sprayers, tractor mounted sprayers, boom sprayers, turbo atomizer sprayers, air misters, tractor-trailer sprayers, roller-mounted sprayers, air blast sprayers, mounted high pressure sprayers, orchid sprayers, vineyard sprayers, and field sprayers. European Standards are met by the high quality of our sprayers. You may feel free to contact us in case of any query.

0 notes

Video

Mil Mi-2R 'SP-SAR' by Alan Wilson Via Flickr: c/n 512617092. Built 1972. This is a civilian crop-sprayer variant. On outside display at the Muzeum Lotnictwa Polskiego. Krakow, Poland. 23-8-2013. The following info is taken from the museum website:- "The Mi-2 helicopter was designed in the Soviet Union at the Mikhail Mil bureau. Built on licence in Poland since 1965 at the WSK Świdnik. The agricultural variant was first flown in 1968. 5,450 Mi-2 were manufactured in total, including 350 in the agricultural variant. They were used in Poland by the PZL Świdnik Helicopter Service Works, later by the Świdnik “Heliseco” Service Works. The Mi-2 is an all-metal multipurpose helicopter with nosewheel-type landing gear and three bladed, metal main rotor. The cockpit houses crew of two (pilot and operator), and eight occupants or 700 kg payload can be carried. The powerplant consists of two 405 HP (298 kW) GTD-350 turboshaft engines, manufactured by the PZL WSK Rzeszów. The “crop duster” version is equipped with two 600 litres GRP hoppers (mounted on fuselage sides) and a boom assembly for atomizers. Both pumps and atomizers are electrically powered. In the chemical fertilizer-spreading configuration the hoppers are fitted either with pneumatic tubes (using airflow forced by electric fans) or with electrically-powered centrifugal spreaders. The helicopter on display was handed over on 10.06.2008 to the PAM as a gift from “Heliseco”. It was manufactured in 1972 and has flown 2823 hrs. in Poland, Egypt, Iraq and Nigeria.."

0 notes

Text

Maximize Farm Efficiency with Tractor Mounted Sprayers

In today’s agriculture, the need for efficient and time-saving tools is essential. A tractor mounted sprayer plays a crucial role in improving farm productivity by offering precision spraying for crops. It ensures the even distribution of fertilizers, pesticides, and water across large fields, making it a must-have for modern farmers.

Benefits of a Tractor Mounted Sprayer

A sprayer for tractor offers multiple advantages over traditional manual spraying methods. These include:

Wide Coverage: Tractor-mounted sprayers can cover vast areas in minimal time, improving efficiency.

Precision Application: They deliver an accurate spray pattern, minimizing chemical wastage and protecting crops.

Time and Labor Savings: With a tractor operated sprayer, the need for manual labor is reduced significantly, saving both time and effort.

Why Choose a Sprayer for Tractor?

Modern sprayers for tractors come equipped with advanced features that ensure effective spraying. These machines offer:

Adjustable Nozzles: Farmers can control the spray intensity and pattern to suit their specific field needs.

High Capacity: Tractor-mounted sprayers have larger tanks, making them ideal for extensive fields.

Durable Build: Built for long-term use, they can withstand rough farm conditions.

Types of Tractor Sprayers

Farmers can choose a sprayer based on their requirements:

Boom Sprayers: These are perfect for large farms where uniform spraying is essential.

Air Blast Sprayers: These are ideal for orchards and dense crop fields.

Mounted Power Sprayers: Compact and powerful, these machines are suitable for small to medium-sized fields.

How to Use Tractor Operated Sprayers Effectively

Calibrate Regularly: Adjust the nozzles and pressure for precise spraying.

Maintain Equipment: Regular cleaning and maintenance ensure durability and smooth performance.

Safety Precautions: Use protective gear and follow safety guidelines while spraying chemicals.

Conclusion

A tractor mounted sprayer is a valuable addition to any farm, saving time and reducing costs. By investing in a reliable sprayer for tractor, farmers can achieve efficient and effective crop care, ensuring healthier yields and increased productivity.

0 notes

Text

The Art of Grape Spraying: Techniques and Equipment for Vineyard Health

Introduction

Grapes are among the world's most prized crops, valued for their use in winemaking, fresh consumption, and a variety of culinary delights. To ensure the health and vitality of grapevines, vineyard owners and viticulturists employ a range of techniques and specialized equipment, including grape sprayers. These tools play a crucial role in safeguarding grapevines from pests, diseases, and nutritional deficiencies. In this article, we will explore the art of grape spraying, including the techniques and equipment used to promote the well-being of vineyards and the quality of grape harvests.

The Importance of Grape Spraying

Grapevine health is essential for vineyard sustainability and the production of high-quality grapes. Grape spraying, or foliar application, involves the targeted application of treatments, including pesticides, fungicides, herbicides, and fertilizers, directly to the grapevine foliage. This proactive approach to grapevine care serves several vital purposes:

Pest and Disease Control: Grapevines are susceptible to a range of pests and diseases, including aphids, powdery mildew, and downy mildew. Spraying treatments can prevent or mitigate these threats, preserving vine health.

Nutrient Management: Nutritional deficiencies can hinder grapevine growth and fruit development. Foliar fertilization through spraying provides essential nutrients directly to the grapevine, promoting vigorous growth and fruit quality.

Precision Application: Grape spraying allows for precision and efficiency in treatment application. By targeting the foliage and minimizing drift, it reduces the risk of unintended harm to the environment and neighboring crops.

Enhanced Productivity: Healthy grapevines produce better yields of high-quality grapes, which are essential for the production of fine wines and other grape-based products.

Techniques of Grape Spraying

Effective grape spraying involves the application of treatments in a controlled and precise manner. Several techniques are commonly employed in vineyard management:

Timing: The timing of spray applications is critical and varies throughout the growing season. Early-season sprays target pests like aphids, while mid-season sprays combat diseases like powdery mildew. Late-season sprays focus on maintaining grapevine health and ripening the fruit.

Directional Spraying: Grape sprayers are designed to apply treatments directly to the grapevine foliage, minimizing waste and drift. The direction of the spray and the angle of the nozzles are adjusted to ensure comprehensive coverage.

Adjuvants: Adjuvants, such as surfactants or spreader-stickers, are often added to spray solutions to improve adherence to the grapevine leaves, enhance coverage, and increase treatment effectiveness.

Spray Volume: The volume of spray applied per acre is carefully calculated to ensure optimal coverage without excessive runoff. This calculation considers factors such as vine density and foliage density.

Equipment for Grape Spraying

Grape spraying equipment is designed to meet the specific needs of vineyard care. Common types of equipment used in grape spraying include:

Backpack Sprayers: These handheld sprayers are suitable for small vineyards or spot treatments. They provide flexibility and precision in targeting specific areas.

Tractor-Mounted Sprayers: Tractor-mounted sprayers are ideal for larger vineyards. They are equipped with adjustable booms and nozzles that allow for uniform coverage and efficient treatment application.

Air Blast Sprayers: Air blast sprayers use high-velocity air to propel spray droplets onto grapevines. They are effective for thorough coverage in dense vine canopies.

Electrostatic Sprayers: These advanced sprayers charge spray droplets electrostatically, improving adhesion to grapevine foliage and reducing drift.

Conclusion

The art of grape spraying is a fundamental aspect of vineyard management, ensuring the health, productivity, and quality of grapevines. Through the precise application of treatments and the use of specialized equipment, viticulturists can protect their vineyards from pests and diseases, optimize nutrient uptake, and ultimately produce grapes of exceptional quality. As the vineyard industry continues to evolve, the techniques and equipment employed in grape spraying will play an ever-important role in the cultivation of this cherished fruit.

0 notes

Text

Concrete Pumps

All You Must Know About Concrete Pumps

If you are planning to buy the best quality concrete pumps, then we are your best companions as we deal with the best quality pumps to help you in your work.

What Is A Concrete Pump?

A concrete pump is a hydraulic mechanism that is used to move liquid concrete. There are two types of concrete pumps.

The first type of concrete pump is mounted on a truck, or there are more extended units on semi-trailers. It is known as a concrete boom pump since a remote-controlled robotic articulating arm (called a boom) is used to precisely position concrete. On most of the larger building sites, boom pumps are used because they are capable of pumping at extremely high volumes and because of the labor-saving aspect of the positioning boom. They reflect an alternative to concrete line pumps.

The second primary type of concrete pump is placed on a trailer and is generally referred to as a line pump or concrete pump built on a vehicle. This pump involves manually connecting steel or flexible concrete mounting hoses to the system outlet. Such hoses are interconnected and lead to wherever the concrete has to be mounted. The length of the hoses varies depending on the diameter of the hose, usually between 10', 12.5', 25' and 50'. Line pumps generally pump concrete at lower volumes than boom pumps and are used for smaller volume concrete placing applications such as swimming pools, roads, and single-family home concrete slabs and most ground slabs.

Why You Must Lookout For Our Concrete Pumps?

The Standard Series sprayer comes with these "Only On A Concrete pumps" features: Advantage Drive System–Runs quiet and has a lifetime guarantee Smart Control 3.0 Pressure Control–Delivers stable spray ventilator with no pressure changes at all spray pressures Stability Pump with Max Flo+ –Submerged foot valve comfortably handles the thickest Ceramic and Stainless Steel Ball Sets and Concrete Pumps.

The TexSpray Mark X 240 Volt is our most efficient Airless / Texture electrical device. At almost double the Mark V output, it is the sprayer of choice for seriously skilled contractors who take advantage of the 240-volt power available at a construction site or with a generator. A real powerhouse, it can quickly spray skim coat and drywall mud in an orange peel, splatter or knockdown finish in a Level 5 finish. It can also add the full collection of primers and paints.

LED display - It is a simple and easy-to-read LED display displays to pressure read job/lifetime/gallon indicator as well as self-diagnosis.

WatchDog Pump Protection System–Saves the pump from damage when paint or texture material runs out or when the pump fails.

ProConnect 2 Pump Removal System–Replace the pump using no tools in seconds to get back to work on-board toolbox easily–End frustration and save time by never again looking for instructions, filters, and equipment Ready to spray–Save set-up time, thanks to the 100 f toolbox.

Pdequipment Is The Best In The Industry

PdQuipment is the largest provider of private data within the industry for Concrete Pumps. We have proprietary sets of pricing and inventory, sales, and traffic information combined with public trends, economic and permit data covering 900 localities and 96 percent of U.S. markets, including over 40,000 current and potential subdivisions. PdQuipment serves six primary sectors of the industry — builders and developers, building manufacturers of materials, financial institutions, school districts, infrastructure, and commercial retail — with critical data and insights. PdQuipment tracks more than 3.2 million plots of lot and land and collects data on more than 100 million households and more than 360 markets for remodeling operation.

0 notes

Photo

What Is a Boom Sprayer in Farm Machinery? A boom sprayer is an agricultural machine that sprays insecticides, herbicides, and fertilizer to protect crops. So, while looking for a boom sprayer "Fieldking" is the market leader. Fieldking mounted type 300, 550, 600, and 1100 ltr. boom sprayers linked to the tractor's three-point linkage and driven by P.T.O. are used for multifunctional plant protection. This machine can spray many types of field crops.

#boom sprayer#agricultural machinery#farming#farm implement#agricultural equipment#sprayer#fieldking boom sprayer

0 notes

Text

John Deere PartsManager Pro v6.5.5 Agricultural

This parts catalog is presented for Tractors, Combines, Cotton Harvesting, Sprayers, Engines, Hay & Forage, Utility Vehicles and other agricultural equipment from Heavy Duty Truck Scanner John Deere. This parts catalog includes original numbers of spare parts John Deere. The catalog is presented in the PartsManager Pro shell.

This parts catalog comes on Installation DATA and Database DVD. The Installation does not require you to enter any keys or license files.

You can print parts diagrams, parts lists, user notes, picklists, and quotes.

Note:

Windows XP, 7, 8, 8.1, 10 Supported. No expire. Free remote assistance with installation by request.

You can order this John Deere Service Advisor software with AirMail, Express Courier Delivery or download from our server.

John Deere AG:

Hint: Click show all

2-WAY INTEGRAL DISK PLOWS AERATOR AIR CONDITIONING SYSTEM AMS AMT APPLICATOR ATTACHMENT, 60” MOWER DECK ATTACHMENT, COMBINE ATTACHMENT, MID-MOUNT ROTARY MOWER, MOWER DECKS, AND 3-BAG MCS ATTACHMENT, MOWER DECK (4000 SERIES CUTS) ATTACHMENTS AXLE BACKHOE BACKHOE LOADER BAGGER BALE ACCUMULATOR BALE CONVEYOR BALE EJECTOR BALE PROCESSOR BALE UNROLLER BALER BALER ENGINES BALER, HAND-TIE BALER, LARGE SQUARE BALER, ROUND BAR, TOOL BEDDER BICYCLE BINDER, CORN BINDER, GRAIN BLADE BLOWER, ENSILAGE AND FORAGE BLOWER, POWER BOOM BOTTOM BOX BLADE BROOM, ROTARY BUCKET BULLDOZER CAB CARRIER, IMPLEMENT CARRIER, KILLEFER CARRIER, REAR CARRIER, TOOL CARRIER, TOOL, DRAWN CARRIER, TOOL, INTERGAL CARRIER, TOOLBAR CART, COMMODITY CART, COULTER CART, DUMP CART, GRAIN CART, SEED CHARGER, BATTERY CHASSIS, VEHICLE CHIPPER, SHREDDER CHOPPER CHOPPER, HAY CHOPPER, ROTARY CLOD-BUSTER COMBINE COMBINE, ATTACHMENT COMBINE, BELT PICKUPS & PICKUP PLATFORMS COMBINE, CAB, OPERATOR COMBINE, CORN HEAD COMBINE, ENGINE (POWER UNIT) COMBINE, PLATFORM (CUTTING) COMBINE, PLATFORM (FLEX CUTTERBAR/RIGID) COMBINE, PTO COMBINE, ROW-CROP HEAD COMBINE, SPRAYER COMBINE, TRANSPORT FRAME (FOR COMBINE HEADER) COMBINE, WINDROW SPREADER COMPACTOR COMPONENT, REMANUFACTURED COMPRESSOR, AIR CONDITIONER, FIELD CONDITIONER, HAY CORN HEAD CORRUGATOR COTTON PLOW CRANE CUBER, HAY CUBER, STATIONARY CULTA-CARRIER CULTIVATOR CULTIVATOR, BEET-BEAN-VEGETABLE CULTIVATOR, FIELD CULTIVATOR, LISTED CORN CULTIVATOR, LISTED CROP CULTIVATOR, PLANTING ATTACHMENT CULTIVATOR, ROW-CROP CUMMINS ENGINE CUTTER, CORN CUTTER, ROTARY CUTTER, STALK CUTTING PLATFORM DECK DEFOLIATOR, BEET DIGGER, POSTHOLE DIGGER, POTATO DISC MOWER DISK DISK PLOW, BORDER DITCHER DRAWBAR, CART DRAWBAR, HARROW DRILL DRILL, AIR DRILL, GRAIN DRILL, GRAIN (ATTACHMENT) DRILL, GRASS SEED DRILL, GRASSLAND DRILL, RANGELAND DRILL, SOYBEAN AND GRAIN DRILL, TRU-VEE DRIVER, POST DRYER, CROP DRYER, GRAIN DUSTER EJECTOR ELEVATOR ENGINE ENGINE, COMBINE ENGINE, CUMMINS ENGINE, MARINE (SERIES 300 DIESEL) ENGINE, MARINE (SERIES 400 DIESEL) ENGINE, MISCELLANEOUS ENGINE, NATURAL GAS ENGINE, OEM (SERIES 200 DIESEL) ENGINE, OEM (SERIES 300 DIESEL) ENGINE, OEM (SERIES 400 DIESEL) ENGINE, OEM (SERIES 500 DIESEL) ENGINE, OEM (SERIES 700 DIESEL) ENGINE, OEM FOR IRRIGATION ENGINE, OEM FOR MULTI-PURPOSE AND STATIONARY ENGINE, POWERTECH ENGINE, POWERTECH PLUS EXCAVATOR FEEDER, BUNK FERTILIZER ATTACHMENT FERTILIZER, DISTRIBUTOR FINISHER, MULCH FINISHER, SEEDBED FLAIL SHREDDER FLUFFER FOOD PLOT SEEDER FORKLIFT FRONT LOADER FRONTIER GANG BOLT DIMENSIONS GENERATOR GENSET GRAPPLE GREEN SYSTEM GREENSTAR GRILL, BARBECUE GRILL, GAS GRINDER, KNIFE GRINDER, MIXER GROOMING MOWER GRUB BREAKER GUIDE HARROW, DISK HARROW, DISK (BUSH AND BOG) HARROW, FINISHING HARROW, OFFSET (PLOWING) HARROW, ROLLER HARROW, SPIKE TOOTH HARROW, SPRING TOOTH (DRAWN) HARVESTER HARVESTER, HEAD HARVESTER, BEAN HARVESTER, BEET HARVESTER, BEET (ATTACHMENT) HARVESTER, COTTON HARVESTER, ENSILAGE AND FORAGE HARVESTER, ENSILAGE AND FORAGE (ATTACHMENT) HARVESTER, ENSILAGE AND FORAGE (ENGINES) HARVESTER, ENSILAGE AND FORAGE (PULL-TYPE) HARVESTER, ENSILAGE AND FORAGE (SELF-PROPELLED) HARVESTER, FORAGE HARVESTER, POTATO HAY MERGER HEADER TRANSPORT HEATER, SPACE HI-CROP IMPLEMENTS HI-CYCLE HITCH HITCH, 3-POINT HITCH, GRAIN DRILL HITCH, MINIMUM TILLAGE HITCH, MULTIPLE PLANTER HITCH, TANDEM (FOR MOWERS AND HAY CONDITIONERS) HITCH, TANDEM (MOLDBOARD PLOW, DISK TILLERS) HOE, BED HOE, POWER HOE, ROTARY HOIST, BOLSTER HUSKER, CORN HYDRAULIC MARKER IMPLEMENT, TILLAGE INCORPORATOR, HERBICIDE INTEGRAL DISK HARROW IVS JACK, LIFT KERNEL PROCESSOR LAND LEVELER LAND PLANE LANDSHAPER LIFTER, BEET LIFTER-LOADER, BEET LISTER, BOTTOM LISTER, DRAWN LISTER, INTEGRAL LISTER, MIDDLEBREAKER (INTEGRAL) LISTER, PLANTING ATTACHMENT LOADER LOADER ATTACHMENT LOADER, BALE LOADER, FARM LOADER, FOUR-WHEEL DRIVE LOADER, SKID-STEER LOADER, SKID-STEER, ATTACHMENT LOADER, TRACTOR-MOUNTED LOADER, TWO-WHEEL DRIVE MATERIAL COLLECTION SYSTEM MILL, DOUBLE-GEARED MILL, HAMMER MILL, ROLLER MISCELLANEOUS PRODUCTS MIXER, FEED MONITOR, SEED MOTOR, CAM-LOBE MOVER, STACK MOWER MOWER BAR, FORAGE HARVESTER MOWER, ATTACHMENT MOWER, CONDITIONER MOWER, DAIN MOWER, FAIL MOWER, HIGH LIFT MOWER, HYDRAULIC GANG MOWER, POWER MOWER, REEL-MOUNTED MOWER, ROTARY MOWER, SICKLE MOWER, TRACTOR-MOUNTED MULCH FINISHER MULCH MASTER OVERSEEDER PACKER, CROWFOOT PACKER, ROLLER PANBREAKER PICKER, CORN PICKER, COTTON PICKUP, FORAGE HARVESTER PLANTER PLANTER, ATTACHMENT PLANTER, COTTON AND CORN PLANTER, LISTER PLANTER, NARROW PLANTER, POTATO PLANTER, UNIT PLATFORM PLATFORM (CUTTING) PLOW PLOW, CABLE PLOW, CHISEL PLOW, DISK PLOW, DISK (DRAWN) PLOW, DISK (INTEGRAL) PLOW, DISK (SEMI-INTEGRAL) PLOW, MOLDBOARD PLOW, MOLDBOARD (DRAWN) PLOW, MOLDBOARD (IN FURROW) PLOW, MOLDBOARD (INTEGRAL) PLOW, MOLDBOARD (ON-LAND) PLOW, MOLDBOARD (SEMI-INTEGRAL) PLOW, MOLDBOARD (TWO-WAY DRAWN) PLOW, MOLDBOARD (TWO-WAY INTEGRAL) PLOW, REVERSIBLE MOLDBOARD PLOW, SNOW PLOWS POWER UNIT POWR-TILL PRODUCT IDENTIFICATION NUMBER GUIDE PROGATOR PTO PULVERIZER PUMP PUMP DRIVE PUMP, CHEMICAL TRANSFER PUMP, PORTABLE CENTRIFUGAL PUMP, RADIAL PISTON PUMP, TIRE RAKE RAKE, BEAN RAKE, HAY RAKE, SWEEP RAKE DRIVE REED CART REED LOADER RIPPER RIPPER, DISK RIPPER, MULCH RIPPER, ROW CROP RIPPER, TOOLBAR ROTARY TILLER ROW CROP CULTIVATOR ROW-CROP, FORAGE HARVESTER SAW, CHAIN SCARIFIER SCOOP SCRAPER SCRAPER, FARM SCRAPER, UTILITY BOX SEEDER, AIR SEEDER, CENTRAL METERING SEEDER, COMBINE SEEDER, ENDGATE SEEDER, LANDSCAPE SEEDING, AIR SYSTEM SHAVER, CORN SHELLER, CORN SHELLER, CYLINDER SHELLER SHELLER, HAND SHELLER, POWER (SPRING) SHREDDER, FEEDER SHREDDER, FLAIL SICKLE BAR SILAGE DEFACER SINGLE UNIT PLANTER SNAPPER, CORN SNOW BLOWER SNOW BLOWER (TRACTOR-MOUNTED) SPECIAL TOOLS SPRAYER SPRAYER, 3-POINT HITCH SPRAYER, ATTACHMENT SPRAYER, HIGHWAY SPRAYER, HOODED SPRAYER, INTEGRAL SPRAYER, ORCHARD AND GROVE SPRAYER, PAINT SPRAYER, PULL-TYPE SPRAYER, SELF-PROPELLED SPRAYER, SKID-MOUNTED SPREADER SPREADER, FERTILIZER SPREADER, FERTILIZER AND GRAIN SPREADER, FERTILIZER AND SEED SPREADER, MANURE SPREADER, SPIN STACKER STACKER, HAY STRIPPER, BASKET ATTACHMENT STRIPPER, COTTON STRIPPER, TRAILER AIR ATTACHMENTS SUBSOILER SUPPORT WHEEL SWEEPER, LAWN TEDDER TELESCOPIC HANDLER THINNER, SYNCHRONOUS THRESHING CYLINDER TILLER, DISK TILLER, DISK (ATTACHMENT) TILLER, MULCH TILLER, PTO TILLER, SEEDING TILLER, TRACTOR-MOUNTED TOOL BAR TOOL, CABINET TOOL, SEEDING TOPPER, BEET TOPSAVER, BEET TRACK TRACTOR TRACTOR ATTACHMENTS TRACTOR, COMPACT UTILITY TRACTOR, COMPACT UTILITY, ATTACHMENT TRAILER TRAILER CART TRANSMISSION TRANSPORTER, ALL MATERIAL (AMT) TREADER, MULCH UNLOADER, SILO UTILITY TRAILER UTILITY VEHICLE UTILITY VEHICLE, ATTACHMENT V-RIPPER V-RIPPER (INTEGRAL) VACUUM, BLOWER VARIABLE SPEED WAGON WAGON, AUGER WAGON, BOXES WAGON, CHUCK WAGON, ENSILAGE AND GRAIN WAGON, FORAGE WAGON, HI-DUMP WAGON, STACK WASHER, HIGH-PRESSURE WEATHER ENCLOSURE AND SUNSHADE WEEDER, ROD WELDER WHEEL, LIFT ASSIST WHEEL, RELL LIFT ASSIST (TOOLBAR) WINDROWER WINDROWER, CAB OPERATOR WINDROWER, ENGINE WINDROWER, PLATFORM WOOD CHIPPER (PTO) i-SERIES

Screenshots for John Deere PartsManager Pro v6.5.5 Agricultural:

0 notes