#Molded Foam Component Market Industry

Text

Molded Foam Component Market 2024: Emerging Trends, Major Driving Factors, Business Growth Opportunities

Molded Foam Component Market provides in-depth analysis of the market state of Molded Foam Component manufacturers, including best facts and figures, overview, definition, SWOT analysis, expert opinions, and the most current global developments. The research also calculates market size, price, revenue, cost structure, gross margin, sales, and market share, as well as forecasts and growth rates. The report assists in determining the revenue earned by the selling of this report and technology across different application areas.

Geographically, this report is segmented into several key regions, with sales, revenue, market share and growth Rate of Molded Foam Component in these regions till the forecast period

North America

Middle East and Africa

Asia-Pacific

South America

Europe

Key Attentions of Molded Foam Component Market Report:

The report offers a comprehensive and broad perspective on the global Molded Foam Component Market.

The market statistics represented in different Molded Foam Component segments offers complete industry picture.

Market growth drivers, challenges affecting the development of Molded Foam Component are analyzed in detail.

The report will help in the analysis of major competitive market scenario, market dynamics of Molded Foam Component.

Major stakeholders, key companies Molded Foam Component, investment feasibility and new market entrants study is offered.

Development scope of Molded Foam Component in each market segment is covered in this report. The macro and micro-economic factors affecting the Molded Foam Component Market

Advancement is elaborated in this report. The upstream and downstream components of Molded Foam Component and a comprehensive value chain are explained.

Browse More Details On This Report at @https://www.globalgrowthinsights.com/market-reports/molded-foam-component-market-101483

Global Growth Insights

Web: https://www.globalgrowthinsights.com

Our Other Reports:

Molded Foam Component Market

Narrowband IoT (NB-IoT) Chipset Market Growth

Global Hydrogen Production Equipment by Electrolysis of Water Market Growth

Global UVC LED Market Size

Global Truffle Oil Market Share

Flow Switches Market Forecast

Hand Dryers Market Size

Smart Meter Market Growth Rate

Earmuffs Market Analysis

Blockchain in Telecom Market Share

Ultrasonic Level Sensors Market Growth

Roof Insulation Market

Global Student Information System Market Size

Global Lithium-Sulfur Battery Market Growth

Thermoplastic Polyurethane (TPU) Market Forecast

Global Distributed Natural Gas-Fueled Generation Market Share

AI (Artificial Intelligence) Image Recognition Market Growth Rate

Circular Push Pull Connectors Market Size

Fleece Knitting Yarn Market Share

Apheresis Machines Market Analysis

Underwater ROV Market

Metal Seals Market Growth

Global Automotive Remote Diagnostics Market Growth

Global Portable Engine Driven Pumps Market Size

Global Strapping Market Share

Isolator Gloves Market Forecast

Ion Exchange Resins Market Size

Sterilization Equipment and Disinfectants Market Growth Rate

Commercial Aircraft Battery Management System (BMS) Market Analysis

Burn Treatment Anti-Infectives Products Market Share

Cloud Infrastructure Services Market Growth

Security Screening Market

Global Breast Imaging Equipment Market Size

Global Food Grade Phosphates Market Growth

Agarose Market Forecast

Global Industrial Door Sensing Devices Market Share

Intelligent Hearing Protection Device Market Growth Rate

Air Quality Apps Market Size

Commercial Clothes Dryer Market Share

Digital Impression Standalone Scanners Market Analysis

#Molded Foam Component Market Size#Molded Foam Component Market Share#Molded Foam Component Market Trends#Molded Foam Component Market Industry#Molded Foam Component Market Growth

0 notes

Text

Injection Molding for Medical Device Parts: Pursuing Excellence to Ensure Health and Safety

Medical plastic components are vital to the healthcare industry. They are widely used in the production of medical devices, instruments, and tools essential for diagnosing, treating, and monitoring patients. These parts are generally made using injection molding technology, which ensures high standards of quality and safety through strict adherence to industry standards.

I. Injection Molding: The Tool for Shaping Medical Parts

Injection molding is a process where molten plastic is injected into molds to create parts that then cool and solidify into the desired shape. This technique is crucial in manufacturing medical components due to its precision and versatility.

II. Common Injection Molding Techniques: Meeting Diverse Needs

There are several types of injection molding processes that cater to various medical part requirements:

Standard Injection Molding: The basic method where molten plastic is injected into a mold to form the part.

Insert Molding: Metal or other materials are placed into the mold before injecting plastic, which integrates these inserts into the final part, enhancing its functionality.

Overmolding: This technique combines two different materials or colors into one part, improving its appearance and functionality.

Microcellular Foam Injection Molding: Gas is injected into the plastic to create a foam structure, which reduces the part’s weight and enhances its performance.

Nano Injection Molding: Uses nanotechnology to fuse plastic and metal into a single, sturdy part.

Blow Molding: Ideal for producing hollow medical containers and tubing.

Extrusion Molding: Used to create continuous plastic profiles, such as medical catheters.

III. Applications of Injection Molding in Medical Parts: Protecting Health

Injection molding technology is essential for producing various medical components:

Medical Device Casings and Components: Includes housings, panels, buttons, and connectors that ensure the proper functioning and ease of use of medical devices.

Syringe and Infusion Set Parts: Such as plungers, barrels, and connectors, which are crucial for precise drug delivery and patient safety.

Respiratory Devices: Includes respirators and oxygen masks, which require high standards of sealing and hygiene.

Medical Containers: Plastic containers, bottles, and packaging for drugs and reagents, ensuring safe storage and transport.

Dental Equipment: Includes items like impression trays and braces, designed to meet specific dental treatment needs.

Surgical Tools: Includes handles and grips for surgical instruments, requiring ergonomic design and biocompatible materials.

IV. Choosing a Medical Parts Injection Molding Factory: Quality Comes First

Selecting the right factory for medical parts injection molding is crucial. Consider the following factors:

Certification: Choose a factory with ISO 13485 certification, which ensures compliance with quality management standards for medical devices.

Experience and Technology: The factory should have extensive experience in medical injection molding and advanced technology to meet custom needs.

Project Support and Communication: The factory should provide expert project support and maintain clear communication to ensure smooth project execution.

V. The Importance of Quality in Medical Injection Molding: The Cornerstone of Health

The quality of medical injection-molded parts is critical for patient safety and the overall health of the healthcare industry. High-quality parts help reduce risks, improve treatment outcomes, and build patient trust, adding significant value for medical device manufacturers.

AbleMed brings extensive experience in medical injection molding, strictly adhering to ISO 13485 standards. Our skilled engineering team provides expert advice and project support, helping clients bring their medical products to market quickly and cost-effectively with high-quality solutions.

Frequently Asked Questions

What materials are used in medical injection molding? Medical injection molding typically uses medical-grade plastics such as polypropylene (PP), polyethylene (PE), polycarbonate (PC), and polyether ether ketone (PEEK), as well as high-performance polymers like ETFE and PPSU, to meet various application needs.

What standards and regulations apply to medical injection molding? Medical injection molding must comply with international and regional standards and regulations, including ISO 13485:2016 (Medical Device Quality Management Systems) and FDA regulations, to ensure product safety and effectiveness.

0 notes

Text

Custom Sportswear Uniforms Exporter in Pakistan

Overview of Pakistan's Sports Gloves Industry

The sports goods manufacturing industry in Pakistan has witnessed remarkable growth in recent years, particularly in the sports gloves sector. This expansion has been driven by increasing domestic demand as well as a thriving export market. Sialkot, known as the hub of sports goods manufacturing, along with other industrial areas, has seen a significant rise in production facilities dedicated to creating high-quality, customized sports gloves.

These manufacturers are producing a wide range of specialized sports gloves designed for various sports such as cricket, hockey, and football. The gloves are meticulously crafted using premium materials, including top-grade treated leather, robust mesh fabric, shock-absorbing foam, abrasion-resistant reinforcements, and molded plastic components. This combination ensures maximum protection and flexibility for athletes, enhancing their performance in different sports.

Bern JC Sportswear Company

One of the leading companies in the sports apparel manufacturing sector is Bern JC, based in Sialkot. With over 15 years of experience, Bern JC has established itself as a trusted provider of high-quality sports attire, serving regional teams, sports associations, and tour operators. Their extensive product range includes cricket kits, football jerseys, gloves, and thermal tracksuits.

Expertise in Custom Sportswear

Bern JC is renowned for its expertise in creating customized sportswear tailored to the specific needs of institutional clients. The company boasts an in-house design team of over 50 professionals who specialize in developing bespoke sports accessories and outfits, including tailored gloves, jerseys with digital prints and logos, as well as matching tracksuits and shoes. Utilizing advanced 3D design software, Bern JC allows clients to visualize and refine their concepts before proceeding to final production.

This capability enables regional sports organizations and institutions to receive fully customized kits for tournaments, delivered within 20-30 days, at competitive prices, all without the need for imports.

Product Range and Materials

Bern JC offers a diverse selection of gloves for various sports, including cricket, hockey, and football. Their product catalog features innovative designs made from high-quality leather, mesh fabric, foam padding, and polycarbonate plastic moldings, ensuring durability, comfort, and performance.

Order Quantities and Export Capabilities

Bern JC caters to both small and large customers, facilitating bulk orders on a monthly basis. Despite the customized nature of their products, the price per unit remains affordable, making it accessible to a wide range of clients.

Custom Sports Gloves Services

One of Bern JC’s core strengths is its ability to manufacture custom sports gloves. The company’s experienced designers work closely with clients to develop specialized glove designs that meet the specific requirements of teams or individual players. By incorporating desired protective features, logos, colors, and sizes, Bern JC delivers high-performance gloves that are fully customized to match team uniforms.

With state-of-the-art infrastructure and skilled craftsmen, Bern JC can produce bulk quantities of sportswear every month, ensuring timely delivery and maintaining high standards of quality.

Affordable Pricing and Bulk Order Options

Bern JC stands out for offering competitive pricing and low minimum order quantities on their gloves, even for custom orders. This makes them an ideal supplier for domestic sports teams, regional sports associations, and local companies organizing sports events. Their large production capacity further allows them to accommodate bulk orders efficiently.

Global Export Credentials

Bern JC has earned a reputation as a quality-driven and reliable sportswear manufacturer, serving not only domestic clients but also international buyers. The company holds the necessary international compliance certificates, enabling them to export substantial quantities of products each month. Their competitive pricing, thanks to local manufacturing, coupled with excellent customer service, has made them a preferred supplier of custom sportswear on a global scale.

Get in Touch

To learn more about Bern JC Custom Sportswear Manufacturers, please visit our website:

https://www.bernjc.com/sportwear

Contact Information

WhatsApp: +923044442200

Email: [email protected]

#custom sportswear manufacturer in pakistan#apparel manufacturer#sportswear manufacturer#custom sportswear manufacturer

0 notes

Text

Digital Commerce Platform Market Developments, Trends & Opportunities till 2032

Digital Commerce Platform Market provides in-depth analysis of the market state of Digital Commerce Platform manufacturers, including best facts and figures, overview, definition, SWOT analysis, expert opinions, and the most current global developments. The research also calculates market size, price, revenue, cost structure, gross margin, sales, and market share, as well as forecasts and growth rates. The report assists in determining the revenue earned by the selling of this report and technology across different application areas.

Geographically, this report is segmented into several key regions, with sales, revenue, market share and growth Rate of Digital Commerce Platform in these regions till the forecast period

North America

Middle East and Africa

Asia-Pacific

South America

Europe

Key Attentions of Digital Commerce Platform Market Report:

The report offers a comprehensive and broad perspective on the global Digital Commerce Platform Market.

The market statistics represented in different Digital Commerce Platform segments offers complete industry picture.

Market growth drivers, challenges affecting the development of Digital Commerce Platform are analyzed in detail.

The report will help in the analysis of major competitive market scenario, market dynamics of Digital Commerce Platform.

Major stakeholders, key companies Digital Commerce Platform, investment feasibility and new market entrants study is offered.

Development scope of Digital Commerce Platform in each market segment is covered in this report. The macro and micro-economic factors affecting the Digital Commerce Platform Market

Advancement is elaborated in this report. The upstream and downstream components of Digital Commerce Platform and a comprehensive value chain are explained.

Browse More Details On This Report at @https://www.globalgrowthinsights.com/market-reports/digital-commerce-platform-market-100549

Global Growth Insights

Web: https://www.globalgrowthinsights.com

Our Other Reports:

Laboratory Analytical Instrumentation MarketMarket Size

Global Energy Harvesting System MarketMarket Share

Global Parenteral Packaging MarketMarket Growth

Stem Cells MarketMarket

Clinical Reference Laboratory Services MarketMarket Share

Concrete Waterproofing Admixture MarketMarket Growth Rate

Female Stress Urinary Incontinence Treatment Devices MarketMarket Forecast

Global Ghee MarketMarket Size

Succulent Plant MarketMarket Growth

Vanadium Redox Battery (VRB) MarketMarket Analysis

SASE (Secure Access Service Edge) MarketMarket Size

Global Automotive Inertial Measurement Unit (IMU) Sensors MarketMarket Share

Global Battery Management System MarketMarket Growth

Collaborative Robots MarketMarket

Urometer MarketMarket Share

Automotive Rubber Molded Components MarketMarket Growth Rate

Throat Lozenges MarketMarket Forecast

Global UVC LED MarketMarket Size

Vascular Surgery Minimally Invasive Surgical Instruments MarketMarket Growth

Medicinal Mushroom Extract MarketMarket Analysis

Nickel-plated Steel Sheet in Batteries MarketMarket Size

Global Augmented and Virtual Reality MarketMarket Share

Global C. difficile Infection Therapeutic Drug MarketMarket Growth

Orthopedic Biomaterials MarketMarket

Electric Vehicle Battery Swapping System MarketMarket Share

Capsule Endoscopy System MarketMarket Growth Rate

Fabric Softeners and Conditioners MarketMarket Forecast

Global Civilian Less Lethal and Self Defense Weapons MarketMarket Size

Pharmaceutical Contract Manufacturing and Contract MarketMarket Growth

Automotive Steering Systems MarketMarket Analysis

Cloud Crew Management System MarketMarket Size

Global Silicon Carbide Wafer MarketMarket Share

Global Solution Polymerized Styrene-Butadiene Rubber (SSBR) MarketMarket Growth

Aircraft Interface Device MarketMarket

Beauty Jelly MarketMarket Share

Clone Imager MarketMarket Growth Rate

Graphite Polystyrene Foam Board Market Market Forecast

Global Pneumatic On-off Guns MarketMarket Size

Methyl Chloroform MarketMarket Growth

0 notes

Text

Foam Conversion

Foam Conversion:- Transforming Ideas into Functional Reality

In the realm of manufacturing and design, foam conversion plays a pivotal role in transforming raw materials into a wide array of practical and innovative products. From custom packaging solutions to intricate components for industries ranging from automotive to healthcare, foam conversion processes enable the creation of versatile and efficient applications. Let's explore the fascinating world of foam conversion and its impact across various sectors.

Understanding Foam Conversion

Foam conversion refers to the process of shaping and customizing foam materials into desired forms, sizes, and functionalities. This transformation involves intricate techniques such as cutting, shaping, laminating, and molding, tailored to meet specific requirements dictated by industry standards, design specifications, and customer needs.

Applications Across Industries

Foam conversion finds extensive applications across diverse industries, including:

1. Packaging: Custom foam inserts for packaging delicate items such as electronics, medical devices, and automotive components ensure secure transit and protection from damage.

2. Automotive: From seat cushions and headrests to noise and vibration dampening materials, foam conversion enhances comfort and safety in vehicles while improving acoustics and thermal insulation.

3. Medical: Foam materials are crucial in medical applications, ranging from surgical positioning aids and patient positioning systems to wound care products and orthopedic supports, providing comfort and support for patients and healthcare professionals alike.

4. Construction: Insulation boards, seals, and gaskets made from foam materials contribute to energy efficiency and structural integrity in buildings, enhancing thermal and acoustic insulation properties.

5. Sports and Leisure: Foam conversion is essential in creating padding for sports equipment, mattresses, pillows, and recreational products, offering comfort and safety in various leisure activities.

Customization and Versatility

One of the key strengths of foam conversion lies in its ability to be customized according to specific requirements. Manufacturers can tailor foam materials in terms of density, thickness, shape, and surface characteristics to optimize performance and functionality. Advanced cutting technologies such as water jet cutting, die-cutting, and CNC routing ensure precision and consistency in production, meeting stringent quality standards and design specifications.

Sustainability and Innovation

Innovation in foam conversion extends beyond functionality to sustainability. Manufacturers are increasingly focusing on eco-friendly materials and processes, reducing waste through efficient material utilization and recycling initiatives. By incorporating recycled and biodegradable foam materials, the industry is advancing towards more sustainable solutions while maintaining high standards of performance and durability.

Future Prospects

As technology continues to evolve, the future of foam conversion holds promising opportunities for enhanced efficiency, precision, and sustainability. Advancements in material science, digital manufacturing technologies, and automation are poised to further streamline production processes and expand the scope of applications across global markets.

Conclusion

Foam conversion exemplifies the convergence of creativity, precision engineering, and practical application. From protecting valuable goods during transit to enhancing comfort and safety in everyday products, foam conversion plays a pivotal role in shaping modern manufacturing landscapes. As industries evolve and consumer demands grow, the versatility and innovation inherent in foam conversion will continue to drive progress, offering solutions that meet the challenges of today and the opportunities of tomorrow.

0 notes

Text

Inserts and Dividers Market to Set Phenomenal Growth from 2024 to 2030:

According to HTF Market Intelligence, theGlobal Inserts and Dividers market to witness a CAGR of 5.1% during forecast period of 2024-2030. Asia Pacific Inserts and Dividers Market Breakdown by Application (Packaging, Storage, Transportation, Others) by Type (Paperboard, Corrugated Board, Foam Inserts, Molded Pulp Dividers, Plastic Inserts, Partition Inserts, Others) by Industry Verticals (Food & Beverages, Personal Care, Electronic Goods, Automotive, Industrial Goods, Pharmaceuticals, Others) and by Geography (China, Japan, India, South Korea, Australia, Southeast Asia, Rest of Asia-Pacific). The Inserts and Dividers market size is estimated to increase by USD Billion at a CAGR of 5.1% from 2024 to 2030.. Currently, market value is pegged at USD 4.1 Billion.

Get Detailed TOC and Overview of Report @

Inserts and dividers are components used to separate, protect, or organize items within a container or packaging. They are commonly employed in various industries to ensure the safe transportation and storage of products.

Some of the key players profiled in the study are Cascades (Canada), DS Smith (United Kingdom), GWP Group (United Kingdom), Innerpak (United States), Innerpak Inc. (United States), International Paper Company (United States), Kraft Group, LLC. (United States), M & M Box Partitions Co (United States), Micor Packaging Pty Ltd (United States), Mondi Group (United Kingdom), Mount Vernon Packaging, Inc. (United States), Multicell Packaging Inc. (United States), Myton Industries Inc. (United States), NEFAB Group (Sweden), Packaging Corporation of America (United States), Smurfit Kappa Group plc (Ireland), Storopack Hans Reichenecker GmbH (United States).

Book Latest Edition of Global Inserts and Dividers Market Study @ https://www.htfmarketintelligence.com/buy-now?format=1&report=6942

About Us:

HTF Market Intelligence is a leading market research company providing end-to-end syndicated and custom market reports, consulting services, and insightful information across the globe. HTF MI integrates History, Trends, and Forecasts to identify the highest value opportunities, cope with the most critical business challenges and transform the businesses. Analysts at HTF MI focuses on comprehending the unique needs of each client to deliver insights that are most suited to his particular requirements.

Contact Us:

Craig Francis (PR & Marketing Manager)

HTF Market Intelligence Consulting Private Limited

Phone: +15075562445

[email protected]

0 notes

Text

The Aluminum Slug Market: Trends, Drivers, and Future Prospects

The aluminum slug market plays a pivotal role in the broader aluminum industry, supplying critical components for a diverse array of end-use applications. These small, cylindrical pieces of aluminum are essential in the manufacturing of various products, ranging from aerosol cans to automotive components. This article delves into the current trends, key drivers, challenges, and future prospects of the aluminum slug market.

Sample Report: https://www.econmarketresearch.com/request-sample/EMR0075/

Market Overview

Aluminum slugs are intermediate products in the aluminum processing chain, produced primarily through the extrusion process. They are further processed into end products by means of impact extrusion, a technique that involves forcing the slug into a mold at high pressure to create hollow shapes. This method is particularly valued for its ability to produce lightweight, durable, and corrosion-resistant items.

Key Applications

The aluminum slug market caters to several significant sectors:

Packaging Industry: One of the largest consumers of aluminum slugs is the packaging industry, especially for producing aerosol cans and beverage containers. The demand for convenient, lightweight, and recyclable packaging solutions has driven the growth in this sector.

Automotive Industry: Aluminum slugs are used to manufacture various automotive components such as shock absorber tubes, airbag inflators, and engine parts. The automotive industry's shift towards lightweight materials to enhance fuel efficiency and reduce emissions has bolstered the demand for aluminum slugs.

Pharmaceutical and Cosmetic Industries: The demand for aluminum tubes in the pharmaceutical and cosmetic industries has been robust, as these sectors require packaging that ensures product safety, hygiene, and extended shelf life.

Electrical and Electronics Industry: Aluminum’s excellent conductivity and lightweight properties make slugs valuable for producing electrical components and housings for electronic devices.

Gate Full Information: https://www.econmarketresearch.com/industry-report/aluminum-slug-market/

Other Reports:

SOC Containers Market Growth

HVAC Chillers Market Size

Aluminum Slug Market

Digital Brain Health Market Analysis

Cognitive Robotics Market Trends

Industrial IoT Display Market Share

Edible Offal Market Application

Potato and Yam Derivatives Market

Surgical Booms Market Overview

Marine Application Market Opportunities

Wind Power Parks Market Revenue

Fuel Cells In Aerospace And Defense Market

Floor Adhesive Market Sales

Pet Fitness Care Market Technology

Axial Flux Motor Market Drivers

Audio and Video Equipment Market Types

Self Stabilizing Spoon Market Challenges

Solar Backsheet Films Market Outlook

Marine Sensors Market Analysis

Dry Shipping Container Market Segmentation

Blood Stream Infection Testing Market Size

Ethyl Vanillin Market Growth

Prebiotic Fiber Market Future

Solar Watch Market Trends

Industrial and Commercial Floor Scrubbers Market Analysis

Electro-Mechanical Brake Market Share

Fiber-Reinforced Plastics Recycling Market Segmentation

Closed Cell Foam Market Drivers

Perfume Ingredient Chemicals Market Technology

Bucket Wheel Excavator Market Revenue

Female Fragrance Market Sales

Yard Crane Market Outlook

0 notes

Text

Exploring Polystyrene: Manufacturing and Market Trends (2023-2034)

Polystyrene stands as a versatile plastic polymer deeply embedded in various aspects of our daily lives. Its utility extends from packaging and food containers to insulation materials, showcasing a wide range of benefits. Despite its adaptability, polystyrene raises environmental concerns due to its non-biodegradable nature. In this comprehensive examination of polystyrene, we will delve into its unique characteristics, manufacturing processes, diverse applications, and the environmental challenges it presents. We'll explore its lightweight composition, durability, and moldable properties that make it a preferred material for many industries. Furthermore, we'll examine its significant role in sectors such as packaging, food service, and construction. With the global polystyrene market valued at around 11.2 million tons in 2023, it is projected to grow at a Compound Annual Growth Rate (CAGR) of 3.39% until 2034.

Introduction

Polystyrene is a synthetic resin characterized by its robust, rigid, and translucent properties. It is derived from styrene, a liquid hydrocarbon, which acts as the monomer in the polymerization process. Polystyrene's unique attributes, such as its lightweight nature and insulation properties, drive its utilization across various industries. The benefits of polystyrene plastic injection molding encompass its minimal shrinkage, versatility in being utilized in blended and foam states, and its moldability. Polystyrene, like all thermoplastics and can be easily molded, exhibiting minimal shrinkage throughout the injection molding process.

Various forms of polystyrene exist, each tailored for specific applications:

1. Solid Plastic: This category includes General Purpose Polystyrene (GPPS) and High Impact Polystyrene (HIPS), designed for different levels of impact resistance. High-impact grades of polystyrene typically contain 6–12% elastomers, while medium-impact grades have about 2–5%. High impact polystyrene (HIPS) resins are valued for their ease of processing, good dimensional stability, impact strength, and rigidity. These qualities make HIPS suitable for a variety of applications where toughness and durability are required, such as packaging, appliances, and consumer goods.

2. Foam: Expanded Polystyrene (EPS) and Extruded Polystyrene (XPS) are foam variants suitable for insulation, packaging, and construction purposes.

3. Films: Oriented Polystyrene (OPS) finds applications in packaging films, offering clarity and stiffness. Oriented Polystyrene (OPS) is processed through orientation techniques to enhance its strength and clarity. Commonly used in clear containers, trays, and lids for food packaging, OPS offers excellent transparency, making it ideal for showcasing food items like salads, desserts, and deli products. OPS stands as a versatile material in the food packaging industry, meeting the demands for both aesthetic appeal and functional performance.

Manufacturing Process

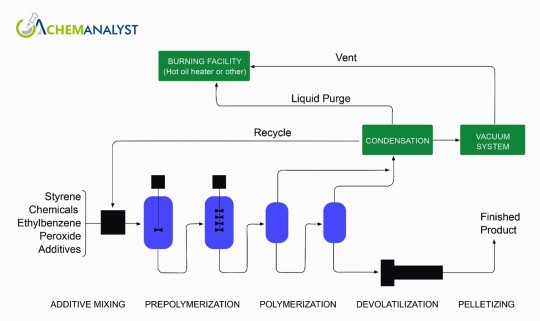

Polystyrene is produced through batch processes that ensure high conversion efficiency, minimizing emissions of unreacted styrene. In the batch bulk polymerization process, styrene monomer, and optionally comonomer, are dissolved in a feed dissolver. The continuous mass peroxide-initiated polymerization of styrene is a multi-stage process designed for efficiency and control. Beginning with the monomer and chemicals into a mixing section, the mass reaction occurs in the presence of a solvent. This mixture then progresses to the polymerization section, typically comprising two continuously stirred tank reactors (CSTRs), where heat generated during the reaction is dissipated by evaporating volatile components. Following the reaction, the polymer solution undergoes devolatilization in two consecutive stages under vacuum conditions, eliminating monomers and low-boiling compounds. The resulting polymer is then transferred to the pelletizing unit, supplied with heat via a thermal oil system.

Polymerization Stage

CSTR reactors facilitate precise control over molecular weight, Alternative configurations, like CSTR combined with plug flow reactors (PFR), offer flexibility to meet diverse process needs.

Devolatilization Stage

The devolatilization section ensures efficient removal of monomers and organic substances, minimizing polymer degradation without additional agents through high rates of heat and mass transfer. This stage consists of a two-step process with low residence periods and high heat and mass transfer rates. Even at very low operating temperatures, the effective removal of monomers and organic compounds is ensured by this special combination.

Expanded polystyrene (EPS), synthesized through suspension polymerization and impregnation with a blowing agent like pentane, and exhibits rigidity, lightweight nature, and low thermal conductivity. Expanded Polystyrene (EPS) foam is derived from expandable polystyrene beads, a rigid cellular plastic containing an expansion agent, typically sourced from oil. The EPS manufacturing process intricately links back to the initial chemical transformation from oil to expandable polystyrene. Now, we delve into the subsequent stages leading to the formation of EPS foam parts. In the first stage of pre-expansion, the raw beads undergo heating in specialized pre-expanders using steam. This process reduces the material density significantly, transforming hard beads into cellular plastic beads with small, closed cells containing air. Following pre-expansion, the beads undergo intermediate maturing and stabilization. As the recently expanded particles cool, they form a vacuum inside, which is compensated for by air diffusion. This enhances mechanical elasticity and expansion capacity, achieved during the material's intermediate maturing in aerated silos or mesh bags, where simultaneous drying occurs. In the final stage of expansion and molding, the stabilized pre-expanded beads are transferred to molds, where they are exposed to steam again to bind together. This results in the formation of large blocks through block molding or products in their final finished shape through shape molding, catering to various applications like boards, panels, and cylinders.

Market Dynamics

The global Polystyrene market is propelled by its distinctive attributes, including its water-resistant nature, making it a preferred choice in the packaging industry. Additionally, its ability to blend seamlessly with other polymers further enhances its versatility and widens its range of applications. Polystyrene's utilization in the manufacturing of automotive components and electronic goods is poised to drive market growth in the coming years, owing to its properties such as insulation and high strength.

Applications of Polystyrene:

1. Construction

Polystyrene is extensively utilized in the construction industry for various purposes. It is a key component in the production of lightweight concrete blocks, which are prized for their ease of handling and installation on construction sites.

2. Appliances

Polystyrene, both in solid and foam forms, is a prevalent material choice for a wide array of appliances, including refrigerators, air conditioners, ovens, microwaves, vacuum cleaners, and blenders.

3. Automotive

Polystyrene serves as a fundamental material in the manufacturing of numerous automotive components.

4. Electronics

Polystyrene is essential for crafting housing and components in televisions, computers, and IT equipment. Its lightweight and moldable nature allow for intricate designs that balance functionality and aesthetics.

5. Food Packaging

Polystyrene foodservice packaging is renowned for its superior insulation properties, which effectively maintain food freshness for extended periods. Compared to alternative packaging materials, polystyrene offers better insulation for hot & cold foods.

Market Outlook:

The global Polystyrene market is anticipated to reach approximately 17.8 million tonnes by 2034. Its affordability, combined with its excellent insulation capabilities, makes polystyrene a preferred choice in various industries, meeting both practical and economic needs effectively. Asia Pacific region is the leading consumer of Polystyrene and with rapid urbanization & construction paired with increasing dispensable income anticipated to remain so in the coming years.

Polystyrene Key Market players

Significant companies in the Global Polystyrene market are Total Petrochemicals, INEOS Styrolution, PS Japan, Jiangsu Laidun Baofu Plastifying, Zhenjiang Chi Mei Chemical, Shanghai Secco Petrochemical, Formosa Plastics, Versalis, Trinseo, Supreme Petrochem Limited, LG Chem, DIC Corporation, and Jiangsu Lyan Qingfeng Newmaterial.

Challenges and Opportunities

While the polystyrene market offers numerous opportunities, it also faces several challenges that impact its growth.

· Environmental Concerns: One of the significant challenges facing the polystyrene market is its environmental impact. Polystyrene is non-biodegradable and can persist in the environment for hundreds of years, contributing to pollution and posing risks to wildlife.

· Shift Towards Alternatives: Growing awareness of environmental and health issues associated with polystyrene has led to a shift towards alternative materials in various industries. Biodegradable and compostable alternatives, as well as recyclable plastics, are gaining popularity as consumers and businesses seek more sustainable options, posing a competitive challenge for the polystyrene market.

Conclusion:

The polystyrene market is diverse and driven by its versatile properties and cost-effectiveness. It finds applications in packaging, construction, automotive, electronics, and more. Polystyrene's advantages include its lightweight nature, thermal insulation properties, and moldability. In packaging, it is known for its resistance to moisture and impact, making it suitable for food packaging and protective materials. High Impact Polystyrene has remarkable dimensional stability alongside easy thermoforming capabilities. Its high impact resistance renders it ideal for various applications such as refrigerator liners, toilet seats, and disposable items, offering both functionality and aesthetic appeal, especially when painted. Additionally, its suitability for food packaging, exemplified by yogurt cups, underscores its versatility. Polystyrene foams leverage their excellent thermal insulation properties for diverse applications in construction and packaging.

0 notes

Text

Fashion and sustainability meet in the Adidas Yeezy Foam Runner

Adidas' Yeezy Foam Runner has become an industry-leading sneaker, captivating fashion enthusiasts with its futuristic design and sustainable materials. In this article, we delve into the world of Adidas Yeezy Foam Runner, exploring its unique features, eco-friendly construction, and the cultural impact it has made since its debut.

Adidas Yeezy Foam Runner introduction

The fake foam runners represents a departure from traditional sneaker design, featuring a sculpted silhouette crafted entirely from a proprietary foam material. A collaboration between Kanye West and Adidas, the Foam Runner is a model of innovation and sustainability that redefines footwear design boundaries.

A distinctive cutout design and minimalist construction separate the Foam Runner from conventional sneakers at first glance. A lightweight, eco-friendly shoe that leaves a smaller environmental footprint, the Foam Runner is made from EVA foam and algae, which is unlike traditional sneakers, which are made from synthetic materials such as rubber and leather.

Algae as an eco-friendly building material

As a key component of its construction, the Adidas Yeezy Foam Runner utilizes algae, one of the most innovative aspects of the shoe. In order to create a foam material that serves as the foundation of the Foam Runner, algae, a renewable resource abundant in nature, is harvested and processed.

Adidas and Kanye West have demonstrated a commitment to sustainability and environmental stewardship by using algae in their production process. An eco-friendly alternative to traditional manufacturing methods that rely on fossil fuels and synthetic materials, algae cultivation requires minimal resources and produces little waste.

By capturing carbon dioxide and purifying water during the cultivation process, algae not only reduce the shoe's carbon footprint, but also contribute to cleaner air and waterways. Therefore, the Foam Runner represents a paradigm shift in footwear design, highlighting the possibility of sustainable materials revolutionizing the footwear industry as a whole.

A Foam Runner's Appeal: Fashion and Function

Adidas Yeezy Foam Runner offers more than just eco-friendly construction; it is a unique blend of fashion and functionality that resonates with consumers everywhere. Whether worn casually or incorporated into more avant-garde fashion ensembles, the shoe's futuristic design and futuristic aesthetic makes it a statement piece in any wardrobe.

With its ergonomic fit and breathable construction, the Foam Runner prioritizes comfort and performance without sacrificing style. With its custom fit and enhanced support, the foam material molds to the wearer's foot. Moreover, the shoe's lightweight design and durable construction allow it to be worn for a variety of activities, from running errands to working out.

Foam runners' cultural impact

Fashion critics and sneaker enthusiasts have consistently praised the Adidas Yeezy Foam Runner since its debut, cementing its status as a cultural icon. A conversation about sustainability and innovation has sparked around its distinctive design and eco-friendly construction, inspiring other brands to explore alternative methods of production.

The Foam Runner is also highly sought after due to its limited availability and high demand, with secondary market resale prices often exceeding retail value. In addition to its popularity among celebrities and influencers, it appears on red carpets, magazine covers, and social media feeds worldwide, solidifying its status as an essential fashion accessory.

The Foam Runner: Practical Considerations

For consumers considering investing in the Adidas Yeezy Foam Runner, practical considerations play a crucial role in the decision-making process. Although the shoe's innovative design and sustainable materials make it an attractive choice for fashion-forward individuals, the price point may deter budget-conscious shoppers. Get more info about fake shoes.

Despite its environmental responsibility and superior performance, many consumers consider the Foam Runner to be a worthwhile investment for both style and sustainability, recognizing the long-term value of a shoe that prioritizes sustainability. It is possible for consumers to contribute to positive change within the fashion industry by aligning their purchasing decisions with their values by supporting brands like Adidas and Kanye West that champion innovation and ethical production practices.

Finally, the Adidas Yeezy Foam Runner embodies the Yeezy brand's spirit of innovation and creativity with its groundbreaking fusion of fashion and sustainability. The Foam Runner offers a glimpse into the future of footwear, where style and sustainability go hand in hand thanks to its eco-friendly construction and futuristic design. Fashion can be both innovative and responsible as consumers increasingly prioritize ethical consumption and environmental stewardship, inspiring positive change within the industry and beyond with the Foam Runner.

0 notes

Text

Impact of Technological Advancements on the Polyvinyl Chloride Market

Polyvinyl Chloride (PVC): An Essential Plastic in Today's World

Production and Uses of PVC

PVC is one of the most widely produced plastics globally. Each year, over 30 million tonnes of PVC is produced worldwide. The annual production of PVC in the United States alone is over 6 million tonnes. The primary raw materials used in PVC production are chlorine and ethylene. These raw materials undergo a polymerization reaction in the presence of a catalyst to produce PVC resin. This resin can then be compounded with additives and processed into a variety of finished products.

Some of the major uses of PVC include pipes, fittings, profiles, sheets, films, foams, cables, bottles, auto parts, medical devices, flooring, wallpapers, and synthetic leather. Due to its low cost, durability, versatility, and corrosion resistance, PVC has become an essential material for plumbing, pipe fitting, siding, flooring, upholstery, banners, and wires & cables. It is estimated that over 70% of PVC produced globally is used in pipes, profiles & fittings, window profiles, flooring, wires & cables, films, sheets, and bottles.

Economic Impact of the PVC Industry

The global PVC industry generates over $100 billion in annual revenue. In the United States alone, the total economic impact of the PVC industry is estimated to be over $60 billion. The North American PVC industry directly employs around 60,000 people and indirectly creates over 500,000 jobs across various industries including construction, automotive, chemicals, electronics, healthcare and more. It is becoming increasingly important for growth in the global economy. The overall economic impact and jobs supported by the PVC industry are projected to grow significantly in the coming years due to increasing demand from emerging markets.

Sustainability and End-of-Life Management of PVC

Despite its economic benefits and wide range of applications, PVC has faced criticism over environmental concerns. One of the main issues is the production of dioxins in the rare incidents of uncontrolled burning or accidental fires involving PVC. However, the vinylation process has become cleaner over time and dioxin emissions have reduced significantly. PVC products themselves do not contain any toxic material upon use and disposal if handled properly.

Moreover, major initiatives are underway globally to improve the sustainability of PVC throughout its lifecycle. Lightweighting of profiles and reducing thickness without compromising performance is helping optimize material usage. Closed-loop recycling allows PVC products to be recovered and reused repeatedly.

The PVC industry, associations and value chain partners have come together to establish effective collection and recycling programs worldwide. The European Union has set a PVC recycling target of 800,000 tonnes by 2025. In the US, around 1 billion pounds of PVC was collected for recycling in 2019. With growing eco-consciousness globally, sustainability is becoming an important strategic priority for the long-term growth of the PVC industry. Comprehensive efforts are required across the value chain to advance towards a truly circular economy model.

Evolving Trends and Growth Potential

Development of novel processing techniques is enhancing the scope of applications for PVC. Advances in blow molding and extrusion have made it possible to manufacture complex hollow products with thin-walled design. New methods like structural foaming allow production of strong yet lightweight materials for furniture, automotive parts, and construction components. Emerging 3D printing technologies are extending PVC's reach into areas like prototyping, architecture, and customized medical devices.

Market prospects appear bright, especially in developing countries with infrastructure growth and increasing standards of living. Global PVC demand is forecast to increase 3-4% annually over the medium term. Growing emphasis on environmental protection and sustainability also generates lucrative opportunities. With its versatile characteristics and circular business models, PVC is poised to remain a pivotal plastic material for many years to come, significantly contributing to economic development worldwide. Successful evolution and overcoming challenges will determine how much of the future potential can be realized.

0 notes

Text

Light weight cement bricks in Hyderabad

Composition and Manufacturing Process of Lightweight Bricks

Materials Used

Lightweight bricks are typically made from materials such as fly ash, sand, cement, and foaming agents. These ingredients are carefully mixed to achieve the desired density and strength.

Production Method

The manufacturing process involves mixing the raw materials with water and a foaming agent to create a foam-like consistency. This mixture is then poured into molds and allowed to cure, resulting in lightweight yet durable bricks.

Advantages of Lightweight Bricks

Thermal Insulation

One of the key benefits of lightweight bricks is their superior thermal insulation properties. These bricks help regulate indoor temperatures, reducing the need for excessive heating or cooling.

Reduced Structural Load

Due to their lightweight nature, these bricks exert less pressure on the building's foundation and structural components. This not only minimizes construction costs but also enhances overall structural integrity.

Environmental Benefits

Lightweight bricks are often crafted from recycled materials, making them an eco-friendly choice for sustainable construction projects. Additionally, their lightweight design requires less energy for transportation and installation, further reducing carbon emissions.

Comparison with Traditional Bricks

When compared to traditional clay bricks, lightweight bricks offer several distinct advantages, including improved insulation, reduced weight, and enhanced durability. Additionally, their modular design allows for faster and more cost-effective construction.

Applications of Lightweight Bricks

Residential Buildings

Lightweight bricks are ideal for residential construction projects, offering homeowners a cost-effective and energy-efficient solution for their housing needs. From exterior walls to interior partitions, these bricks can be used in various applications to enhance comfort and durability.

Commercial Construction

In commercial construction, lightweight bricks are widely used for their versatility and performance. Whether it's office buildings, shopping malls, or industrial facilities, these bricks provide architects and builders with a lightweight yet sturdy building material that meets the highest standards of quality and safety.

Cost Analysis of Lightweight Bricks

Price Comparison

While lightweight bricks may initially seem more expensive than traditional clay bricks, their long-term benefits often outweigh the initial investment. With lower energy costs and reduced maintenance expenses, these bricks offer significant savings over their lifespan.

Long-term Savings

Moreover, the lightweight design of these bricks translates to lower transportation costs and easier handling during construction, further reducing overall project expenses. Additionally, their superior insulation properties can lead to substantial savings on heating and cooling bills over time.

Availability of Lightweight Bricks in Hyderabad

In Hyderabad, lightweight bricks are readily available from various manufacturers and suppliers. Hyderabad Builders and contractors can choose from a wide range of options to suit their specific project requirements, ensuring optimal performance and cost-effectiveness.

Factors Affecting the Price of Lightweight Cement Bricks

Raw Material Costs

The cost of raw materials, such as cement, sand, and fly ash, can significantly impact the price of lightweight cement bricks. Fluctuations in material prices due to market demand and supply can influence the overall cost of production.

Transportation

Transportation costs also play a crucial role in determining the final price of lightweight bricks. Factors such as distance, fuel prices, and logistics can affect the overall affordability of these bricks, especially in regions with limited access to raw materials.

Market Demand

Market demand for lightweight bricks can influence pricing dynamics, with higher demand often leading to increased prices. However, competition among manufacturers and suppliers can help stabilize prices and ensure affordability for consumers.

Popular Lightweight Cement Brick Manufacturers in Hyderabad

Hyderabad boasts a vibrant construction industry, with numerous manufacturers specializing in lightweight cement bricks. Some of the most popular brands include XYZ Bricks, ABC Construction Materials, and DEF EcoBricks, known for their quality products and reliable services.

Customer Testimonials and Reviews

Many homeowners and builders in Hyderabad have praised the performance and durability of lightweight cement bricks. Positive testimonials and reviews highlight the energy-saving benefits, ease of installation, and long-term cost savings associated with these innovative building materials.

Tips for Choosing the Right Lightweight Cement Bricks

When selecting lightweight cement bricks for a construction project, it's essential to consider factors such as thermal conductivity, compressive strength, and environmental impact. Consulting with experienced architects and engineers can help ensure the optimal choice for your specific needs.

Sustainable Practices in Lightweight Brick Usage

As sustainability becomes increasingly important in the construction industry, incorporating lightweight bricks into building projects can help reduce environmental impact and promote resource efficiency. From energy-efficient designs to recycled materials, there are numerous ways to embrace sustainable practices in lightweight construction.

Future Trends in Lightweight Construction Materials

Looking ahead, the demand for lightweight construction materials is expected to continue growing, driven by factors such as urbanization, population growth, and environmental concerns. Advancements in technology and manufacturing processes will likely lead to even more innovative solutions for sustainable and cost-effective building materials.

Conclusion

In conclusion, lightweight bricks offer a compelling alternative to traditional construction materials, providing numerous benefits in terms of thermal insulation, structural integrity, and environmental sustainability. With their versatility and performance, these bricks are poised to play a significant role in shaping the future of construction in Hyderabad and beyond.

FAQs

0 notes

Text

Polyurethane Foaming Machines: The Key to Efficient and High-Quality Foam Production

Polyurethane foaming machines play a pivotal role in the realm of foam production, serving as the unsung heroes behind the creation of various foam products that surround us in our daily lives. These machines are the driving force behind the efficient and high-quality production of foam materials, contributing to a wide range of industries such as furniture manufacturing, automotive, insulation, and more.

At the heart of the polyurethane foaming process lies the intricate machinery that transforms liquid polyurethane into the versatile foam we encounter in countless applications. The significance of these foaming machines extends beyond mere production— they embody the synergy of precision engineering and advanced technology.

One of the primary advantages of polyurethane foaming machines is their ability to cater to diverse foam requirements. The versatility of these machines allows manufacturers to produce foams with varying densities, rigidity, and other specific properties tailored to the intended application. Whether it's the soft cushioning in your couch, the insulation in your home, or the padding in your car seats, polyurethane foaming machines are the architects of comfort and functionality.

Efficiency is a cornerstone of foam production, and polyurethane foaming machines excel in optimizing this crucial aspect. These machines are designed to ensure a seamless and continuous production process, minimizing downtime and maximizing output. The ability to precisely control the foam's characteristics, such as density and cell structure, enhances the overall efficiency of the production line, resulting in consistent and high-quality foam products.

The intricate process begins with the mixing of polyol and isocyanate, the two main components of polyurethane foam. The polyurethane foaming machine facilitates the precise blending of these components, creating a homogeneous mixture. This mixture is then dispensed into molds or onto surfaces, where it undergoes a chemical reaction and expands to form the desired foam product. The precision and control exerted by the foaming machine during this process are paramount in determining the final quality of the foam.

In addition to efficiency, the polyurethane foaming process also emphasizes sustainability. The industry has witnessed a growing awareness of environmental concerns, and manufacturers are increasingly adopting eco-friendly practices. Polyurethane foaming machines contribute to this trend by allowing for the use of recycled and environmentally friendly materials in the foam production process. This aligns with the global shift towards sustainable manufacturing practices and reinforces the role of polyurethane foaming machines as key players in responsible production.

Moreover, the advancements in technology have led to the development of automated and computer-controlled polyurethane foaming machines. These sophisticated machines not only enhance precision and efficiency but also offer real-time monitoring and adjustment capabilities. The integration of smart technologies into foam production not only streamlines the manufacturing process but also enables manufacturers to adapt quickly to changing demands and market trends.

In conclusion, polyurethane foaming machines are the backbone of efficient and high-quality foam production. Their versatility, efficiency, and adaptability make them indispensable in various industries. As the demand for foam products continues to rise, the role of these machines in shaping our everyday comfort and convenience cannot be overstated. From the furniture we relax on to the insulation that keeps our homes cozy, polyurethane foaming machines silently contribute to a world filled with comfort and innovation.

#Polyurethane Foaming Machine#Continuous Foaming Machine#PU Foaming Machine#Polyurethane Machine#best foam machine#foam maker machine#foam machine

0 notes

Text

Ceramic Packages Market 2024: Emerging Trends, Major Driving Factors, Business Growth Opportunities

Ceramic Packages Market provides in-depth analysis of the market state of Ceramic Packages manufacturers, including best facts and figures, overview, definition, SWOT analysis, expert opinions, and the most current global developments. The research also calculates market size, price, revenue, cost structure, gross margin, sales, and market share, as well as forecasts and growth rates. The report assists in determining the revenue earned by the selling of this report and technology across different application areas.

Geographically, this report is segmented into several key regions, with sales, revenue, market share and growth Rate of Ceramic Packages in these regions till the forecast period

North America

Middle East and Africa

Asia-Pacific

South America

Europe

Key Attentions of Ceramic Packages Market Report:

The report offers a comprehensive and broad perspective on the global Ceramic Packages Market.

The market statistics represented in different Ceramic Packages segments offers complete industry picture.

Market growth drivers, challenges affecting the development of Ceramic Packages are analyzed in detail.

The report will help in the analysis of major competitive market scenario, market dynamics of Ceramic Packages.

Major stakeholders, key companies Ceramic Packages, investment feasibility and new market entrants study is offered.

Development scope of Ceramic Packages in each market segment is covered in this report. The macro and micro-economic factors affecting the Ceramic Packages Market

Advancement is elaborated in this report. The upstream and downstream components of Ceramic Packages and a comprehensive value chain are explained.

Browse More Details On This Report at @https://www.globalgrowthinsights.com/market-reports/ceramic-packages-market-100566

Global Growth Insights

Web: https://www.globalgrowthinsights.com

Our Other Reports:

Global Magnetic Nanoparticles MarketMarket Share

Global Portable Power Station MarketMarket Growth

Phased Array Antenna MarketMarket

Car Electronics & Communication Accessories MarketMarket Share

Water Filter Jugs MarketMarket Growth Rate

Outdoor Playground Equipment MarketMarket Forecast

Global Sepsis Treatment MarketMarket Size

Battery Electric Car MarketMarket Growth

Gantry or Cartesian Robots MarketMarket Analysis

Digital Pathology MarketMarket Size

Global Microbiome Sequencing Services MarketMarket Share

Global Medical Marijuana MarketMarket Growth

High Speed Steel (HSS) Metal Cutting Tools MarketMarket

Mobile Telemedicine MarketMarket Share

Invisible Orthodontics MarketMarket Growth Rate

Wireless Charging Ic MarketMarket Forecast

Global Thermostat MarketMarket Size

UAV Drones MarketMarket Growth

Cell Phone Charging Station MarketMarket Analysis

Terahertz Spectroscopy MarketMarket Size

Global Small Household Appliances MarketMarket Share

Global Network Slicing MarketMarket Growth

Dicyandiamide (CAS 461-58-5) MarketMarket

Electric Heater MarketMarket Share

Somatosensory Game MarketMarket Growth Rate

Consumer Electronics and Home Appliances MarketMarket Forecast

Global Portable Engine Driven Pumps MarketMarket Size

2 shot Injection Molding MarketMarket Growth

Water and Wastewater Treatment Equipment MarketMarket Analysis

Wool Felt MarketMarket Size

Global Music Production Software MarketMarket Share

Global Rice Milling MarketMarket Growth

Advanced Analytics MarketMarket

Pharmacovigilance and Drug Safety Software MarketMarket Share

Noise Suppression Sheet MarketMarket Growth Rate

Arm Microprocessor MarketMarket Forecast

Global Faced Fire Resisting Panels MarketMarket Size

Memory Foam Side Sleeper Market Market Growth

All-Iron Redox Flow Battery MarketMarket Analysis

5-Sulfoisophthalic Acid Monosodium Salt MarketMarket Size

0 notes

Text

Gidea PAC

Gidea PAC is a consulting firm that primarily focuses on the cosmetics market from the perspective of its major field of expertise. We are a consulting organization that provides services in the fields of design and packaging, and we also provide these services ourselves.

A prior customer brought to our attention the fact that we are the most reputable cosmetic packaging maker that also provides boutique services cosmetic jars wholesalesThis information was brought to our attention by the customer. We were provided with this information to employ to our advantage around a while ago.

When it comes to the question of who exactly we are, where do we stand?

Ningbo Gidea Packaging Co.,Ltd. is a well-known company that was founded in 2003 with the objective of focusing in the design and production of high-quality plastic containers for premium cosmetics, beauty, and skincare goods. The firm's goal is to become the industry leader in this particular field. Packaging these products is the primary focus of the company's attention at the moment. One of the most important goals of this organization is to ensure that the containers they manufacture are of the highest possible quality. The corporation is currently concentrating the majority of its emphasis on the packaging of these products as the primary focus of the attention that it is giving to the subject. The airless bottles, lotion bottles, and cream jars that it offers are some of the things that are considered to be among the most significant products that it offers. It also offers a variety of other products. Additionally, there are other items available, such as bottles that do not have any air inside of them.

Providing customisation services such as design, mold opening, sample manufacture, sample shipment, and printing in order to meet the specific requirements that you have outlined is one of the things that brings us a great deal of satisfaction here at Gidea. This is one of the things that brings us a great deal of satisfaction. This is one of the things that gives us a great lot of satisfaction, and we are grateful for it. Twenty highly talented people who are experts in their respective industries and have a high degree of experience in those fields make up our team. Each of these professionals has a high level of expertise in their industry. It is the responsibility of these personnel to oversee a number of departments, such as the department of sales, the department of purchasing, the department of records, quality control, marketing, and finance. Our team is comprised of green hands and elites who are absolutely bursting with vitality, and they work together as if they were a large family. Our crew is an extraordinary collection of both wholesale lotion bottles Every single one of them is incredibly vivacious and enthusiastic about the work that they do.

containers for cosmetics that can be modified to accommodate all of your specific requirements and preferences in terms of both their design and their functionality

There are many different types of containers that are included in our selection of items. Some of these containers include jars, airless bottles, lotion bottles, dropper glass bottles, roll-on bottles, tubes, and atomizers. In addition, we provide a complete assortment of components, which includes products such as trigger sprayers, foam pumps, sprayer pumps, and dispensing closures, amongst other options. Another one of the services that we offer is the service of providing our customers with a wide selection of components from which to choose. As a result of your shopping with us, you will have the option to choose from a diverse selection of beauty and cosmetic boxes, which will, in addition, contribute to the overall improvement of the quality of your shopping experience.

All of the brands that you own will be included in the bundle that our team will put together for you with all of the brands.

Since Gidea initially began providing its services to clients from all around the world, it has been more than fourteen years since the company first entered the market. North America, East Europe, the Middle East, and Australia were only some of the countries from which these clients originated. Other countries included those from the Middle East, East Europe, and Australia. These consumers hail from a wide range of nations and regions that are dispersed across the globe in a variety of different regions. We have been able to cultivate a strong relationship with a sizeable number of our customers over the course of our company's existence, and we are delighted to have our products available in a wide range of countries that are situated in different parts of the world. At the production base that we have built in Shangyu, Zhejiang, we have invested close to 200 million yuan in the creation of cutting-edge manufacturing facilities and cutting-edge technology. These facilities and technologies are used to produce cutting-edge products. All together, the production site in Shangyu encompasses a total area of sixty thousand square meters. Zhejiang is the location of the production base, which is another factor that should be taken into consideration. The establishment of a production base in Shangyu, which is a component of this development, is another thing that we have done. Due to the fact that we are capable of independently completing all of the procedures, we are able to make things that are of a high quality. The reason for this is because we are able to carry out the action in question.

1 note

·

View note

Text

The Future of Construction: Fischer Rapid Installation Foam PU 1/750 B3 Sets a New Benchmark

Insulation foam is simple to install in both newly constructed homes and older ones. Foam insulation is a reasonably quick and simple alternative for home insulation that works well for both thermal and acoustic insulation. Your house’s heating costs will probably drop significantly once your foam insulation is installed. You will consume less heat energy to maintain the same high levels of thermal comfort in your house since the foam insulation layer helps to keep more heat in. Fischer Rapid Installation Foam PU 1/750 B3 has significantly improved upon or outperformed competing foam insulation materials, setting a new standard for the building sector. It is important to find a hardware tools supplier that can meet these requirements with perfect quality and most affordable prices.

The New Benchmark

Because of its ability to insulate against heat and sound, foam insulation is frequently employed in construction. Fischer Rapid Installation Foam PU 1/750 B3 might become more well-liked by contractors, architects, and builders if it provides quicker installation, increased effectiveness, greater insulation performance, or other noteworthy attributes.

For filling, insulating, and isolating window connection joints as well as the connection joints of door frames, finishing elements, wall connections, wall penetrations, and cavities, Fischer Rapid Installation Foam Premium PU 500/750 is the best choice. A tremendous amount of joint sound insulation is present. The water pressure resistance test report attests to its usefulness as fountain foam. The fischer fix adapter, allowing the continued use of opened cans, is attached to the brown fischer adapter foam PU 500/750 dispenser. The solid valve provides the greatest degree of protection against obstructions and gas leaks. For end users, protective gloves are provided.

Benefits of Fischer Rapid Installation Foam PU 1/750 B3

You might be amazed at how affordable a choice natural insulating foam is for house insulation given all of its benefits. From high-quality thermal and acoustic insulation for your home's walls, roof, and any other necessary locations, insulating foam is 99% air, making it very light, weighing about 8 kilograms per cubic metre. The foam is simple to adapt to all house surfaces and constructions. Additionally, it is non-toxic, non-polluting, and fire-resistant; simple to implement as a DIY insulation project in the home. It has exceptional levels of water and airtightness and is environmentally sound, despite the appearance of being industrial.

Joints between panels, fasteners, and welds at the point of material contact are absent. Additionally, this foam can be used to fill odd surfaces. Foam usage gets rid of substructures, intricate joints, and thermal bridges. Foam's surface can be molded however you choose. Rounded edges and jointless insulation are simple to make overlap on two planes (for instance, while insulating the basement ceiling from below). It is possible to spray additional shielding on foam. Occasionally they are necessary, such as when foam is exposed to UV rays or there is a chance of a large amount of water present.

Conclusion

Compared to comparable insulation products on the market, the value of heat transport is lower in Fischer Rapid Installation Foam PU 1/750 B3. Additionally, mounting bolts with a high heat conductivity coefficient do not pierce spray insulation with resistance to chemicals, solvents, and biological factors. Most chemical substances are resistant to foam. Its qualities are superior to those of other commercially available insulating materials in this regard. However, when choosing coatings, make sure to carefully consider their compatibility. It is best to utilize the equipment and supplies the manufacturer suggests. For other components that are laid out in panels, the rapidity of foam spraying is an indicator that is impossible to achieve, often involving the installation of further constructions, fastening fasteners, or the collaboration of several persons. Additionally, It is categorized as a substance authorized for marketing and all-purpose construction application. Thus, in conclusion, one can easily say that Fischer Rapid Installation Foam PU 1/750 B3 doesn’t set a new benchmark in the construction industry but is the benchmark in itself.

0 notes

Text

Automotive Expanded Polypropylene (EPP) Foam Market Analysis Demand, Statistics, Top Manufacturers, Revenue by Reports and Insights 2030

The latest market report published by Credence Research, Inc. “Global Automotive Expanded Polypropylene (EPP) Foam Market: Growth, Future Prospects, and Competitive Analysis, 2016 – 2028. The global automotive expanded polypropylene (EPP) foam market has witnessed steady growth in recent years and is expected to continue growing at a CAGR of 6.80% between 2023 and 2030. The market was valued at USD 0.45 billion in 2022 and is expected to reach USD 0.71 billion in 2030.

The global automotive expanded polypropylene (EPP) foam market is driven by several factors, including the low cost, high mechanical qualities, and adaptability of EPP foam, making it a commonly utilized material in the automobile sector. The foam is known for its energy absorption, impact resistance, thermal insulation, chemical resistance, and recyclability. Its applications range from packaging and consumer goods to building and construction, making it a versatile material in various industries.

One of the key drivers of the market is the increasing demand for passenger safety and the need for noise, vibration, and harshness (NVH) reduction in automobiles. Expanded polypropylene foam is widely used in automotive components such as bumpers, door panels, and seats due to its lightweight design and enhanced functionality. The foam's ability to absorb energy and improve passenger safety is contributing to its growing adoption in the automotive industry.

Browse 170 pages report Global Automotive Expanded Polypropylene (EPP) Foam Market By Product Type (Synthetic Polypropylene , Bio-Based Polypropylene, Other Product Types)By Product Form (Fabricated EPP, Molded EPP) -Growth, Future Prospects & Competitive Analysis, 2016 – 2030)- https://www.credenceresearch.com/report/automotive-expanded-polypropylene-epp-foam-market

The Asia Pacific region leads the global market, accounting for over one-third of the market share in 2022. This growth can be attributed to the rapid industrialization, accessibility to raw resources, and availability of labor in countries like China, India, and Japan. North America and Europe collectively account for just under 50% of the market share in 2022, with Europe holding over 22% share in the same year.

The automotive industry has witnessed a surge in the demand for lightweight materials that offer exceptional strength and durability. This is where Automotive Expanded Polypropylene (EPP) Foam comes into play as one of the key market drivers. EPP foam, known for its remarkable energy absorption capabilities and excellent cushioning properties, has found extensive usage in various automotive applications such as bumpers, seating systems, instrument panels, door trims, and headrests. The growing emphasis on passenger safety combined with stringent regulations regarding vehicle crashworthiness have fueled the adoption of EPP foam in automobiles.

Why to Buy This Report-

The report provides a qualitative as well as quantitative analysis of the global Automotive Expanded Polypropylene (EPP) Foam Market by segments, current trends, drivers, restraints, opportunities, challenges, and market dynamics with the historical period from 2016-2020, the base year- 2021, and the projection period 2022-2028.

The report includes information on the competitive landscape, such as how the market's top competitors operate at the global, regional, and country levels.

Major nations in each region with their import/export statistics

The global Automotive Expanded Polypropylene (EPP) Foam Market report also includes the analysis of the market at a global, regional, and country-level along with key market trends, major players analysis, market growth strategies, and key application areas.

Browse Full Report: https://www.credenceresearch.com/report/automotive-expanded-polypropylene-epp-foam-market

Visit: https://www.credenceresearch.com/

Related Report: https://www.credenceresearch.com/report/u-bolt-clamps-market

Related Report: https://www.credenceresearch.com/report/automotive-testing-and-inspection-market

Browse Our Blog: https://www.linkedin.com/pulse/automotive-expanded-polypropylene-epp-foam-market-rising-singh

Browse Our Blog: https://tealfeed.com/automotive-expanded-polypropylene-epp-foam-market-doun3

About Us -

Credence Research is a viable intelligence and market research platform that provides quantitative B2B research to more than 10,000 clients worldwide and is built on the Give principle. The company is a market research and consulting firm serving governments, non-legislative associations, non-profit organizations, and various organizations worldwide. We help our clients improve their execution in a lasting way and understand their most imperative objectives. For nearly a century, we’ve built a company well-prepared for this task.

Contact Us:Office No 3 Second Floor, Abhilasha Bhawan, Pinto Park, Gwalior [M.P] 474005 India

0 notes