#Moisture Silica Gel Suppliers

Explore tagged Tumblr posts

Text

Silica Gel Breather Manufacturers

At Ravistat, we are proud to be one of the premier silica gel breather manufacturers in the industry. Our world-class products provide superior air filtration and a safe environment for workers who must handle hazardous materials on a regular basis. We use only top quality components, such as high grade stainless steel casing and rust resistant borosilicate glass interior tubes for maximum strength durability. All our systems have been designed with an innovative modular construction method which allows easy installation even in difficult locations or where space is limited because all parts can be replaced quickly without much effort from your team’s skilled engineers. Plus as part of our commitment to customer service excellence.

we offer technical support services so that you get help when needed most! Investing in highly efficient breathing solutions will save time thereby improving productivity at your workplace while ensuring occupational safety guidelines are met every step of the way with us by your side! Make sure you choose Ravistat--the leading provider among Silica Gel Breathe Manufacturers now!

#manufacturers#silica gel#breather silica gel#Breather Silica Gel Transformer#Moisture Silica Gel#Moisture Silica Gel Manufacturers#Moisture Silica Gel Suppliers#Moisture Silica Gel Exporters#Manufacturers#Suppliers#Exporters in India

0 notes

Text

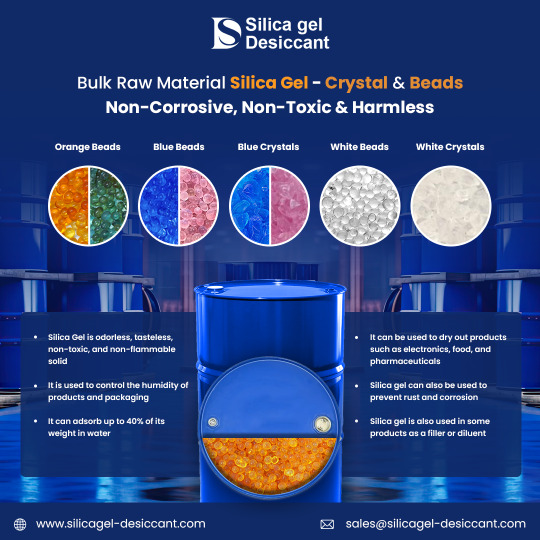

Explore the multifaceted wonders of silica gel desiccant! From preserving the vibrant hues of dried flowers to ensuring transformers breathe easy, from keeping humidity at bay with dehumidifiers to safeguarding the potential of seeds through drying, this powerhouse adsorbent is indispensable across a spectrum of applications. Embrace the marvels of silica gel desiccant with us! its versatility and reliability in nurturing everything from delicate blooms to essential machinery! Feel free to reach out to us for further information! Call: +91 9879203377 W: https://www.silicagel-desiccant.com

#desiccant beads#silicagel supplier#indicating silica#moisture absorbers#manufacturer#humiditycontrol#non-indicating silicagel#blue silica gel#transformer breather#silicadesiccant

0 notes

Text

Finding the Right Molecular Sieve Supplier in Dubai: A Guide for Industries

Dubai, a global hub for commerce and industry, is home to a growing demand for advanced materials that support various industrial applications. Among these materials, molecular sieves are crucial for processes that require precise separation, adsorption, and purification. Whether you’re involved in the petrochemical, pharmaceutical, or environmental sectors, finding a reliable molecular sieve supplier in Dubai can significantly impact your operations.

Understanding Molecular Sieves

Molecular sieves are crystalline substances with uniform pore sizes, designed to separate molecules based on size and shape. These sieves are often made from materials like zeolite, activated carbon, or silica gel, and are widely used for gas purification, drying, and separating hydrocarbons.

The unique structure of molecular sieves allows them to adsorb specific molecules while excluding others. This selective adsorption makes them invaluable in industries that demand high purity levels, such as natural gas processing, air separation, and the manufacturing of pharmaceuticals.

The Importance of Choosing the Right Supplier

Choosing the right supplier for molecular sieves in Dubai is crucial for several reasons:

Quality Assurance: High-quality molecular sieves are essential for achieving the desired results in adsorption and separation processes. A reputable supplier will provide products that meet stringent quality standards, ensuring consistency and reliability in your operations.

Technical Support: Working with a knowledgeable supplier who understands the specific needs of your industry can provide valuable insights and technical support. This can be especially important when selecting the right type and grade of molecular sieve for your application.

Supply Chain Reliability: In industries where downtime can be costly, having a reliable supplier with a robust supply chain is essential. A supplier based in Dubai with a strong logistical network can ensure timely delivery of materials, minimizing disruptions to your operations.

Customization Options: Different industries have varying requirements for molecular sieves. A good supplier should offer a range of products and be willing to customize solutions to meet your specific needs, whether you require specific pore sizes, shapes, or adsorption capacities.

Key Industries Relying on Molecular Sieves in Dubai

Petrochemical Industry: Dubai’s booming petrochemical industry relies heavily on molecular sieves for processes like natural gas purification, dehydration of hydrocarbons, and the separation of nitrogen from oxygen. Molecular sieves play a critical role in ensuring that end products meet stringent purity standards.

Pharmaceutical Manufacturing: The pharmaceutical industry in Dubai uses molecular sieves in the production of active pharmaceutical ingredients (APIs) and the drying of solvents. The ability to achieve high levels of purity is essential in this sector, where even trace amounts of moisture or contaminants can affect product quality.

Environmental Applications: Molecular sieves are also used in environmental protection, particularly in the treatment of wastewater and the removal of volatile organic compounds (VOCs) from air emissions. In Dubai, where environmental regulations are becoming increasingly stringent, the demand for effective molecular sieve solutions is on the rise.

Food and Beverage Industry: The food and beverage sector in Dubai uses molecular sieves for applications like the drying of food products and the purification of gases used in packaging. Ensuring that these materials meet food-grade standards is critical to maintaining product safety and quality.

What to Look for in a Molecular Sieve Supplier in Dubai

When searching for a molecular sieve supplier in Dubai, consider the following factors:

Reputation and Experience: Look for a supplier with a proven track record in the industry. Experience matters, as it indicates that the supplier has a deep understanding of the market and the technical aspects of molecular sieves.

Product Range: A good supplier should offer a comprehensive range of molecular sieves, including different pore sizes, shapes, and materials. This variety ensures that you can find the right product for your specific needs.

Certifications and Compliance: Ensure that the supplier’s products meet international quality standards and are compliant with relevant regulations. Certifications such as ISO can be a good indicator of quality and reliability.

Customer Support: Excellent customer service is essential, especially if you need assistance with product selection, troubleshooting, or after-sales support. Choose a supplier who is responsive and willing to go the extra mile to meet your needs.

Competitive Pricing: While quality should never be compromised, it’s important to find a supplier who offers competitive pricing. This balance between cost and quality is crucial for maintaining profitability in your operations.

Top Molecular Sieve Suppliers in Dubai

Dubai is home to several reputable suppliers of molecular sieves, each offering a range of products and services tailored to different industries. Some of the top suppliers include:

Supplier A: Known for their extensive product range and commitment to quality, Supplier A offers molecular sieves for a variety of applications, including gas purification and petrochemical processing. They also provide technical support and custom solutions.

Supplier B: With a focus on environmental applications, Supplier B offers molecular sieves designed for air and water purification. Their products are certified to meet international standards, and they have a strong presence in the UAE market.

Supplier C: Specializing in the pharmaceutical and food industries, Supplier C provides molecular sieves that meet stringent purity and safety standards. They offer a range of sizes and materials, with an emphasis on customer support and innovation.

Conclusion

In the fast-paced and competitive industrial landscape of Dubai, finding the right molecular sieve supplier is essential for maintaining the efficiency and quality of your operations. Whether you’re in petrochemicals, pharmaceuticals, or environmental protection, partnering with a reputable supplier can make all the difference in achieving your business goals.

By focusing on quality, reliability, and customer support, you can ensure that your molecular sieve needs are met with precision and expertise. As Dubai continues to grow as a global industrial hub, the role of molecular sieves—and the suppliers who provide them—will remain vital to the city’s ongoing success.

0 notes

Text

Aluminium Coil Manufacturers

Printed Circuit Board Entry

Marudhar’s Printed Circuit Board (PCB) entry sheets are manufactured with state-of-the-art equipment which matches international standards. Tight thickness tolerance, flatness, dimensional accuracy, grease-free surface and hardness optimal for burr-free drilling required in the manufacture of PCB are ensured. Marudhar Industries is one of the leading Aluminium Coil Manufacturer, supplier, and exporters in india. We Provoide High Quality Aluminium Coil at best price.

Continuous upgrades and process improvement enable us to keep pace with the demands of its ever-growing clientele.

Aluminum PCB (Printed Circuit Board) Entry Sheets

Specifications:

Marudhar’s Printed Circuit Board (PCB) entry sheets are manufactured with state-of-the-art equipment which matches international standards. Tight thickness tolerance, flatness, dimensional accuracy and grease-free surface and hardness optimal for burr-free drilling required in the manufacture of PCB are ensured.

Continuous upgrades and process improvement enable us to keep pace with the demands of its ever-growing clientele. Application Standards:

ASTM-B-209M, Aluminium association — aluminium standards and data, Marudhar manufacturing limits (as applicable).

Packing:

The PCB entry sheets are wrapped with HDPE, hardboard on top and bottom of the stack, hoop iron along the length of the sheets and is placed on wooden skids with runners and finally put in wooden boxes. Silica gel packets for moisture protection are used.

Applications:

Electronic circuit boards

Foil Stock

Marudhar’s foil stock is produced from high-quality rolling ingots and concast coils. Manufactured with sophisticated equipment, the foil stock is free of surface and subsurface defects. Matching international quality standards, it can be rolled to thin gauges of aluminium foil for a number of applications.

Foil Stock

Specifications:

Marudhar’s foil stock is produced from high-quality rolling ingots and concast coils. Manufactured with sophisticated equipment, the foil stock is free of surface and subsurface defects. Matching international quality standards, it can be rolled to thin gauges of aluminium foil for a number of applications.

Stringent quality checks ensure a world-class range of sheets, extrusions and foil products from Marudhar. Continuous upgrades and process improvement enable it to keep pace with the demands of its ever-growing markets. Flatness:

Less than 20 I units (typical)

Wedge:

Within 0.7% (typical)

Coil Build-up Quality:

Weave — 2 mm (max), total shift 5 mm (max)

Surface Quality:

Suitable for foil rolling

Application Standards:

ASTM — B -209M, Aluminium association — aluminium standards and data, Marudhar manufacturing limits (as applicable).

Packing:

Foil stock is wrapped in HDPE fabric and hardboard, strapped with hoop iron and placed in an eye-to-sky or eye-to-wall position. Moisture protection is provided with silica gel packets.

Applications:

Pharma / Confectioneries / Cigarette Foils

Foils

Tetra packs Closure Stock (PP Caps)

Marudhar’s closure stock is rolled to very fine tolerances to yield more closure per ton of stock and to allow uninterrupted operation of high-speed, multiple-cavity presses. Its strength, high formability, low earring and printable surfaces make it ideal for pilfer-proof caps and vial seals.

PP Cap Sheets (Closure Stock)

Specifications:

Marudhar’s closure stock is rolled to very fine tolerances to yield more closure per ton of stock and to allow uninterrupted operation of high-speed, multiple-cavity presses. Its strength, high formability, low earring and printable surfaces make it ideal for pilfer-proof caps and vial seals.

Packing:

Sheet: Sheets are placed in wooden boxes on wooden skids with runners along the length of the sheet. They are wrapped in HDPE with hardboard on top and bottom of the stack. Hoop iron strapping runs along the length of the sheets. Silica gel packets are put in the boxes for moisture protection.

Alternatively, they are wrapped in a poly-laminated gunny or polythene, strapped with a hoop iron strap and clip and placed on a wooden pallet. Edge guards are used and the sheets are wrapped with protective thermocol sheets.

Coil: Coil is placed on wooden pallets in either eye-to-sky or eye-to-wall condition, wrapped in HDPE fabric and hardboard, and strapped with hoop iron. Silica gel packets are used for moisture protection.

Applications:

Pilfer-Proof Caps

Vial Seals

Cream Containers & Caps

Fin Stock (HVAC)

By meeting the stringent specifications of globally competitive companies, Marudhar’s flat fin stock has proved its worth in air conditioners, car radiators and heat exchangers. With the help of high-quality ingots, state-of-the-art gauge ,shape control and precision slitting. We manufacture fin stock that has tight gauge tolerances and excellent slit edges. A tight build-up combined with internal sound metallurgical properties produce good drawability required for all types of finning.

Fin Stock [HVAC Foils]

Specifications:

By meeting stringent specifications of globally competitive companies, Marudhar’s flat fin stock has proved its worth in air conditioners, car radiators and heat exchangers. With the help of high-quality ingots, state-of-the-art gauge and shape control and precision slitting, we manufacture fin stock that has tight gauge tolerances and excellent slit edges. A tight build-up combined with internal sound metallurgical properties produce good draw ability required for all types of finning;

Packing:

Marudhar’s flat fin stock is packed on wooden skids in either eye-to-sky or eye-to-wall condition, wrapped in HDPE fabric and hardboard and strapped with hoop iron. Moisture protection is ensured with silica gel packets and as the final step, the entire packed product is placed in a wooden cage.

Applications:

Air Conditioners

Car Radiators

Automobile Heat Exchangers

Tread Plated

Marudhar’s pattern sheets are ideal for decorative applications and interior panelling for trucks, cabins, etc. Available in five designs — diamond, five-bar, two-bar, propeller, and north star — the sheets can be bent easily or curved to take the shape of the structure in which they are fixed. Pattern sheets are light, rust-free, hygienic and easy to clean, and because they are made from aluminium, they are resistant to corrosion and denting.

The sheets are manufactured with state-of-the-art equipment employing sophisticated process technology. With stringent quality control measures in place, the company sets the standard in aluminium panelling.

Pattern Sheets/Coils (Chequered/Tread Plates)

Specifications:

Marudhar’s pattern sheets are ideal for decorative applications and interior panelling for trucks, cabins, etc.

Available in five designs — diamond, five-bar, two-bar, propeller, north star — the sheets can be bent easily or curved to take the shape of the structure in which they are fixed. Pattern sheets are light, rust-free, hygienic and easy-to-clean and because they are made from aluminium, they are resistant to corrosion and denting.

The sheets are manufactured with state-of-the-art equipment employing sophisticated process technology. With stringent quality control measures in place, the company sets the standard in aluminium panelling.

Packing:

Marudhar’s pattern sheets are packed with a poly-laminated gunny, hardboard, strapped with hoop iron and clip, and placed on a pallet.

Applications:

Decorative applications like interior panelling for trucks, cabins, etc.

Cast Coil

Marudhar’s cold rolled coils/sheets are precision-finished to match international standards. They have good shape, high tolerance, versatility and blemish-free surfaces. They are used in commercial and general engineering applications such as bus bodies, cladding and fan blades. The company meets the demands of its ever-growing clientele with continuous upgrades and process improvement.

Aluminium Alloy Cast Coil

Specifications:

Our cast coils are used to produce superior-quality Insulation Cladding, Flooring Sheets, Roof Sheets, Nets, Balls Chain, Circles, Chequered Sheets, Cold Rollind, Utensils Making and many more products.Aluminium and its alloy cast coils are of a smooth surface, have no burr and are of high quality in terms of flatness and surface roughness.

According to the analysis, the chemical composition, homogenizing, shearing, intrinsic properties organization, hardness and other mechanical properties of materials will affect the application. In common the cast coils come with the tempers range as O. The thickness is 6–8mm and the width is 762–1250mm.

Product Name Aluminium Alloys Cast Coil Grades 1070, 1060, 1050, 1100, 1200, 1235, 3003, 3004, 3105, 8011, 8079, GEQ Temper O Specification Thickness: 6–8mm Width: 762–1250mm Quantity tolerance ±10% ID 200, 305, 405 and 505mm Surface treatment Mill finish Application Insulation Cladding, Flooring Sheets, Roof Sheets, Nets, Balls Chain, Circles, Chequered Sheets, Cold Rolling, Utensils Making and many more products Packaging Wooden Pallet Remark Aluminium Alloys Cast Coils can be customized

Application:

Insulation Cladding, Flooring Sheets, Roof Sheets, Nets, Balls Chain, Circles, Chequered Sheets, Cold Rolling, Utensils Making and many more products.

Slit quality:

Free from nicks, cuts and burrs.

Coil build-up:

Uniform and tight enough to be handled horizontally.

Applicable standards:

ASTM — SB -209M, Aluminium association — aluminium standards and data, Marudhar manufacturing limits (as applicable).

Packing:

Aluminium Alloys Cast Coils are placed on wooden skids in an eye-to-wall position. It is wrapped in HDPE fabric and hardboard and strapped with hoop iron. Moisture protection is ensured with silica gel packets and the entire packed product is placed in a wooden box. Cable Armouring Strips

Marudhar meets global standards in the manufacture of its cable wrap stock, which is widely used in various cable brands.

With the help of high-quality ingots and state-of-the-art control systems, Marudhar manufactures cable wrap stock with tighter gauge tolerances and meets excellent elongation and length requirements.

Cable Armouring Strips Stock (Cable Armoring Coils)

Specifications:

Our aluminium cable armouring strip stock is used as a conductor to wound on the core of the underground cables. Aluminium strip for cable armouring is required with high electrical conductivity According to the analysis, the chemical composition, cold rolling, shearing, heat treatment processes, internal properties organization, electrical conductivity, hardness and mechanical properties of materials will affect the application of cable core armouring winding.

In common, the aluminum strips alloys used in dry type transformers are 1050, 1060, 1070 and 1100 the temper is O which means soft, the thickness is 0.170–2.3mm and the width is 150–1250mm.

Product Name Aluminium Strip for cable core armouring Grades 1050,1060,1070, 1100 Temper O, H18 Specification Thickness: 0.150–2.3mm Width: 150–1250mm Quantity tolerance ±10% ID 152.4, 200, 305, 405 and 505mm Surface treatment Mill finish Application Cable Core Armouring Packaging Wooden Pallet Remark Aluminium Strip can be customized.

Chemical Composition:

1050 Aluminium Strip Chemical composition (%) Element Al Si Fe Mg Zn Mn Ti Cu V Standard Value ≥99.5 0.0431 0.203 0.0013 0.0093 0.0104 0.0200 0.0022 0.0039 1060 Aluminium Strip Chemical composition (%) Element Al Si Fe Mg Zn Mn Ti Cu V Standard Value ≥99.6 0.0431 0.203 0.0013 0.0093 0.0104 0.0200 0.0022 0.0039 1070 Aluminium Strip Chemical composition (%) Element Al Si Fe Mg Zn Mn Ti Cu V Standard Value ≥99.7 0.0431 0.203 0.0013 0.0093 0.0104 0.0200 0.0022 0.0039 1100 Aluminium Strip Chemical composition (%) Element Al Si Fe Mg Zn Mn Ti Cu V Standard Value ≥99.0 0.0431 0.203 0.0013 0.0093 0.0104 0.0200 0.0022 0.0039

Application:

Underground cables and Telecom Cables core winding and armouring, distribution/power grid cables winding, electric cable sheathing/shielding parts.

Slit quality:

Free from nicks, cuts and burrs. Lateral flatness on all slitted edges as per standards.

Coil build-up:

Uniform and tight enough to be handled horizontally.

Applicable standards:

ASTM — SB -209M, Aluminium association — aluminium standards and data, Marudhar manufacturing limits (as applicable).

Packing:

Cable Armouring Strips Stock is placed on wooden skids in an eye-to-wall position. It is wrapped in HDPE fabric and hardboard and strapped with hoop iron. Moisture protection is ensured with silica gel packets and the entire packed product is placed in a wooden box.

GEQ Coils/Sheets

Marudhar leads in the production of exceptional GEQ coils/sheets. Our expertise ensures industry-leading standards, delivering coils/sheets known for their top-tier quality and performance. With a dedication to precision and innovation, we tailor products to your exact requirements, guaranteeing reliability and excellence across various applications.

GEQ Strips Stock

Specifications:

Our general engineering quality stock is used to produce superior-quality INSULATION CLADDING, FLOORING SHEETS, NETS, BALLS CHAIN, CIRCLES. Aluminium GEQ Stock is of a smooth surface, has no burr and is of high quality.

According to the analysis, the chemical composition, cold rolling, shearing, heat treatment processes, intrinsic properties organization, hardness and other mechanical properties of materials will affect the application.

In common the GEQ alloy comes with the tempers range as O, H12, H14, H16, H18, H22, H24 and H26. The thickness is 0.150–4mm and the width is 50–1250mm.

Product Name Aluminium GEQ Strips (IN COILS AND SHEETS FORM) Grades GEQ Temper O, H12, H14, H16, H18, H22, H24, H26 Specification Thickness: 0.150–4mm Width: 50–1250mm Quantity tolerance ±10% ID 76, 152.4, 200, 305, 405 and 505mm Surface treatment Mill finish Application Insulation Cladding, Flooring Sheets, Nets, Ball Chains, Circles Packaging Wooden Pallet Remark Aluminium Strip can be customized with cut to width and cut to length for sheets form requirements with tight tolerane of ±1mm

Application:

Insulation Cladding, Flooring Sheets, Nets, Ball Chains, Circles.

Slit Quality:

Free from nicks, cuts and burrs.

Coil build-up:

Uniform and tight enough to be handled horizontally.

Applicable standards:

ASTM — SB -209M, Aluminium association — aluminium standards and data, Marudhar manufacturing limits (as applicable).

Packing:

Cable GEQ Strips Stock is placed on wooden skids in an eye-to-wall position. It is wrapped in HDPE fabric and hardboard and strapped with hoop iron. Moisture protection is ensured with silica gel packets and the entire packed product is placed in a wooden box.

Transformer Strips

Marudhar consistently adheres to global benchmarks in the production of its transformer strip, a crucial component widely integrated into diverse transformer brands. Leveraging premium-grade ingots and cutting-edge control mechanisms, Marudhar ensures the fabrication of transformer strip featuring enhanced gauge tolerances, while surpassing exacting elongation and length prerequisites.

Transformer Strips Stock

Specifications:

Our aluminium transformer strip stock is used as a conductor in dry-type transformers to wound on the core instead of copper winding. Aluminium strip for transformer wingding is required with high electrical conductivity (AA1100: >59% IACS, AA1050: >59.5% IACS, AA1060: >61.3% IACS, AA1070: >62.6% IACS), soft, smooth surface, no burr and high quality.

According to the analysis, the chemical composition, cold rolling, shearing, heat treatment processes, internal properties organization, electrical conductivity, hardness and mechanical properties of materials will affect the application on transformer winding.

In common, the aluminum strips alloys used in dry type transformers are 1050, 1060 and 1070 the temper is O which means soft, the thickness is 0.130–4.0mm and the width is 10–1250mm.

Product Name Aluminium Strip for Transformer Winding Grades 1050,1060,1070, 1100 Temper O Specification Thickness: 0.130–4mm Width: 10–1250mm Quantity tolerance ±10% ID 152.4, 200, 305, 405 and 505mm Surface treatment Mill finish Application Transformer Winding Packaging Wooden Pallet Remark Aluminium Strip can be customized.

Chemical Composition:

1050 Aluminium Strip Chemical composition (%) Element Al Si Fe Mg Zn Mn Ti Cu V Standard Value ≥99.5 0.0431 0.203 0.0013 0.0093 0.0104 0.0200 0.0022 0.0039 1060 Aluminium Strip Chemical composition (%) Element Al Si Fe Mg Zn Mn Ti Cu V Standard Value ≥99.6 0.0431 0.203 0.0013 0.0093 0.0104 0.0200 0.0022 0.0039 1070 Aluminium Strip Chemical composition (%) Element Al Si Fe Mg Zn Mn Ti Cu V Standard Value ≥99.7 0.0431 0.203 0.0013 0.0093 0.0104 0.0200 0.0022 0.0039 1100 Aluminium Strip Chemical composition (%) Element Al Si Fe Mg Zn Mn Ti Cu V Standard Value ≥99.0 0.0431 0.203 0.0013 0.0093 0.0104 0.0200 0.0022 0.0039

Application:

Power Transformer winding and metal cladding, distribution/power transformer winding, electric cable sheathing/shielding parts.

Slit quality:

Free from nicks, cuts and burrs. Lateral fillets on all slitted edges as per standards.

Coil build-up:

Uniform and tight enough to be handled horizontally.

Applicable standards:

ASTM — SB -209M, Aluminium association — aluminium standards and data, Marudhar manufacturing limits (as applicable).

Packing:

Cable Transformer Strips Stock is placed on wooden skids in an eye-to-sky position. It is wrapped in HDPE fabric and hardboard and strapped with hoop iron. Moisture protection is ensured with silica gel packets and the entire packed product is placed in a wooden box.

Eyelet Stock

Marudhar upholds international standards in the fabrication of its eyelet stock, a fundamental material extensively utilised in a variety of applications. Through the utilisation of primary ingots and advanced control systems, Marudhar delivers eyelet stock with meticulous gauge tolerances, alongside meeting stringent elongation and length criteria, establishing a product of unparalleled quality and reliability.

Eyelet Strips Stock

Specifications:

Our aluminium eyelet strip stock is used to produce superior-quality eyelets. It comprises two parts — EYELETS RIVET TORUS STOCK and EYELETS RIVET FLAT STOCK. Aluminium eyelets rivet torus stock is soft, of a smooth surface, has no burr and is of high quality. According to the analysis, the chemical composition, cold rolling, shearing, heat treatment processes, intrinsic properties organization, hardness and other mechanical properties of materials will affect the application.

In common, for making the aluminium eyelets rivet torus stock the alloys used are 1050 and 1100 with the temper O which means soft, the thickness is 0.120–0.200mm and the width is 12–1250mm. While the eyelets rivet flat stock comes with GEQ alloy having tempers range as O, H12, H14, H22 and H24. The thickness is 0.120–0.350mm and the width is 18–1250mm.

Product Name Aluminium Strips for Eyelets Grades 1050, 1100, 8011, GEQ Temper O, H12, H14, H22, H24 Specification Thickness: 0.150–0.350mm Width: UPTO 1250mm Quantity tolerance ±10% ID 76, 152.4, 200, 305, 405 and 505mm Surface treatment Mill finish Application Eyelets Rivet Torus and Eyelets Rivet Flat parts Packaging Wooden Pallet Remark Aluminium Strip can be customized.

Chemical Composition:

1050 Aluminium Strip Chemical composition (%) Element Al Si Fe Mg Zn Mn Ti Cu V Standard Value ≥99.5 0.0431 0.203 0.0013 0.0093 0.0104 0.0200 0.0022 0.0039 1100 Aluminium Strip Chemical composition (%) Element Al Si Fe Mg Zn Mn Ti Cu V Standard Value ≥99.0 0.0431 0.203 0.0013 0.0093 0.0104 0.0200 0.0022 0.0039

Application:

Eyelets assembly comprising eyelets rivet torus and eyelets rivet flat parts.

Slit quality:

Free from nicks, cuts and burrs.

Coil build-up:

Uniform and tight enough to be handled horizontally.

Applicable standards:

ASTM — SB -209M, Aluminium association — aluminium standards and data, Marudhar manufacturing limits (as applicable). Marudhar Industries is one of the leading Aluminium Coil Manufacturer in India

Packing:

Eyelets Strips Stock is placed on wooden skids in an eye-to-sky position. It is wrapped in HDPE fabric and hardboard and strapped with hoop iron. Moisture protection is ensured with silica gel packets and the entire packed product is placed in a wooden box.

0 notes

Text

How Fly Ash Ensures High Quality Building Materials?

Fly ash manufacturers in India have been constantly offering high-quality solutions to enhance the construction projects. Fly ash that is released during the coal combustion as a by product can be used in concrete to give it more stability. This new addition has led to an incredibly great journey for the construction companies.

Most manufacturers realize it is important to choose high quality fly ash solutions to ensure best outcomes. The best quality can help create sustainable and durable projects.

1. The first aspect that you get with a high-quality fly ash is strength. You will notice that the quality is measured by the chemical composition, fineness and reactivity. We will look at each of these factors individually to understand better.

a. The chemical composition of fly ash is the first thing to consider, according to the fly ash supplier in India. The composition can influence the pozzolanic activity, which means the fly ash can react well with calcium hydroxide in water.this can help form highly cementitious compounds. The fly ash component wth silica, aluminum and other reactive components can lead to strong compositions owing to the pozzolanic activity.

b. When you have finer fly ash particles, you would notice that it covers a larger surface area. This is an integral part as it can ensure smooth and extensive pozzolanic activities. When you are looking for high-quality fly ash, make sure to seek an understanding of the fineness requirements specified. It can contribute towards greater strength.

c. The reactivity of the fly ash is also an important factor to determine its strength. It will help you understand if the fly ash can participate in the chemical reactions. This will eventually help in creating concrete microstructures and long-term performance.

2. The second crucial parameter to consider when opting for fly ash is the durability of the components. You must check if it can easily manage the external parameters like moisture and chemical exposure easily. here is how the quality of fly ash can influence the durability.

a. Fly ash manufacturers in India believe that the component can reduce permeability of the concrete. This occurs while filling the voids and capillaries in the matrix. You will minimize the intake of harmful substances such as chlorides and water in this way. This would ensure that the fly ash is optimally distributed and enhances the overall density. This also makes the fly ash resistant to chemical reactions.

b. You will also notice that high quality fly ash may reduce the reactive agents in aggregates and alkalis, which occurs via cement hydration. This would lead to formation of expansive gel and cracking/deterioration of concrete. You can use this to create a stable environment that can preserve the integrity of the structures.

c. Owing to exposure to sulphates in the soil and groundwater, which can cause expansion and cracking of concrete. With high quality fly ash, you can reduce the levels of unburned carbon and sulphur compounds. This would recude the permeability and improve the quality.

3. Lastly, the most focused parameter is the sustainability of the fly ash. According to fly ash supplier in India, the quality of fly ash can reduce the carbon footprint.

0 notes

Text

Heatless Air Dryer Suppliers in India

A growing focus on energy efficiency Heatless Air Dryer Suppliers in India, industries are increasingly turning towards Heatless Air Dryers. These dryers offer a sustainable alternative to traditional refrigerant dryers, eliminating the use of harmful coolants and significantly reducing energy consumption.

If you're looking for an eco-friendly way to remove moisture from compressed air, understanding the landscape of Heatless Air Dryer Suppliers in India is crucial. This blog post dives deeper into this topic, with a specific focus on Inertech Projects Pvt Ltd, a leading supplier in the Indian market.

Why Choose Heatless Air Dryer Suppliers in India?

There are several compelling reasons to consider Heatless Air Dryer Suppliers in India:

Energy Efficiency: Heatless dryers utilize desiccant technology to absorb moisture, requiring significantly less energy compared to refrigerant dryers. This translates to cost savings on your electricity bills and a reduced environmental footprint.

Environmentally Friendly: Heatless dryers eliminate the use of harmful refrigerants, minimizing environmental impact. This is particularly important for industries with strict environmental regulations.

Reliable Performance: Reputable Indian suppliers offer heatless dryers known for their durability and reliability. These dryers can operate effectively in harsh Indian conditions, ensuring consistent performance.

Cost-Effectiveness: While the initial investment for a heatless dryer might be slightly higher, the long-term operational cost savings due to lower energy consumption make them a cost-effective choice.

Types of Heatless Air Dryers Offered by Indian Suppliers

Indian suppliers offer a variety of Heatless Air Dryer Manufacturers, Suppliers, Dealers, Wholesalers, Distributors, Exporters, and Traders in Ahmedabad, Gujarat, India. options to cater to diverse industrial needs. Here's a breakdown of the two main types:

Desiccant Air Dryers: These dryers employ desiccant materials like silica gel or activated alumina to attract and retain moisture from compressed air. The desiccant is regenerated periodically using either a purge air system or a heatless regeneration process.

Features Offered by Inertech Projects Pvt Ltd:

Highly efficient in removing moisture to very low dew points.

Suitable for applications requiring extremely dry air.

Available in various sizes and configurations to meet specific flow rate demands.

Membrane Dryers: These dryers utilize semi-permeable membranes that allow compressed air to pass through while separating water vapor.

Features offering top-rated Inertech Projects

Simple and compact design.

Lower maintenance requirements compared to desiccant dryers.

Ideal for continuous operation and smaller compressed air systems.

Key Considerations When Choosing Heatless Air Dryer Suppliers in India

Selecting the right Heatless Air Dryer Supplier in India requires careful consideration of several factors:

Experience and Reputation: Opt for established suppliers known for their expertise in Heatless Air Dryer technology and a proven track record of delivering quality products.

Product Range: Ensure the supplier offers a variety of heatless dryer options to match your specific flow rate, pressure, and dew point requirements.

After-Sales Service: Reliable after-sales service is crucial for maintaining optimal dryer performance. Choose a supplier with a robust service network and qualified technicians for support.

Cost: While cost is a factor, prioritize quality and long-term value over the cheapest option.

Specifications to Consider When Choosing a Heatless Air Dryer

Flow Rate Capacity: Select a dryer with a flow rate capacity that exceeds your compressed air system's maximum output to ensure efficient moisture removal.

Pressure Rating: Choose a dryer that can handle the pressure range of your compressed air system.

Dew Point: The dew point is the temperature at which moisture condenses in compressed air. Select a dryer that achieves the desired dew point for your application.

Power Consumption: Compare the power consumption of different heatless dryer models to optimize energy savings.

Regeneration Cycle: Understand the regeneration cycle of desiccant dryers (purge air or heatless) and its impact on compressed air loss.

Finding the Right Heatless Air Dryer Supplier in India

Several resources can help you find reputable Heatless Air Dryer Manufacturers in India:

Inertech Projects Pvt Ltd is the top provides detailed specifications for each of their Heatless Air Dryer models. Here are some key factors to consider:

Industry Directories: Online directories list manufacturers and suppliers of industrial equipment, including Heatless Air Dryers.

Industry Associations: Associations related to compressed air systems or specific industries might have supplier recommendations.

Online Reviews and Recommendations: Read online reviews and recommendations from other businesses that have purchased Heatless Air Dryers from Indian suppliers.

By considering these factors and conducting thorough research, you can identify the most suitable Heatless Air Dryer supplier in India to meet your specific needs and contribute to a more sustainable future.

1 note

·

View note

Text

Pharmaceutical Desiccants is a worldwide supplier of Pillow Pak desiccant from 'Desiccare Inc.'. The moisture absorbing packets are filled with silica gel, molecular sieve, clay and activated carbon desiccants, which are solutions to several damages.

0 notes

Text

Silica Gel Drying Oven, Silica Gel Drying Oven Suppliers, Manufacturers in India

Silica Gel Drying Oven: Capacity Available 25 kg, 50 Kg, 100 Kg & 200 Kg. Helps to Remove Moisture from Silica Gel Which Contains Moisture from Air. Customised Trays & Trolley Available.

Silica Gel Drying Oven, Silica Gel Drying Oven Manufacturers, Silica Gel Drying Oven Suppliers, Silica Gel Drying Oven in India, Silica Gel Drying Oven Exporters, Silica Gel Drying Oven Delhi, Silica Gel Drying Oven Haryana.

0 notes

Text

Silica gel Commercial Grade - Desiccachemical

Silica gel, a porous, transparent substance with a high surface area, effectively adsorbs moisture, protecting products from damage. Available in white (non-indicating) and blue (indicating) types, silica gel absorbs 25-40% moisture by weight, reaching saturation upon reaching its maximum capacity. Desiccachemical, a leading supplier of high-quality silica gel desiccant, offers a wide range of products to meet your specific needs. Contact us today to learn more.

0 notes

Text

Whitespice Chemical: A Trusted Name in Silica Gel Manufacturing

Whitespice Chemical has established itself as a trusted name in the field of silica manufacturing in Kolkata. With a commitment to quality and innovation, the brand has become synonymous with excellence, catering to a broad spectrum of industries ranging from pharmaceuticals to electronics.

Unrivaled Product Quality:One of the key reasons behind Whitespice Chemical's prominence is its unwavering dedication to producing silica gel of unparalleled quality. The company adheres to stringent quality control measures throughout the manufacturing process, ensuring that each batch meets international standards. This commitment to excellence has earned Whitespice Chemical a reputation as a reliable supplier for businesses seeking top-tier silica gel products.

Diverse Product Range:Whitespice Chemical offers a diverse range of silica gel products tailored to meet the specific requirements of different industries. Whether it's for moisture control in pharmaceuticals or as a desiccant in electronics, the brand provides customized solutions. This versatility has positioned Whitespice Chemical as the go-to choice for businesses seeking comprehensive silica gel solutions.

Cutting-edge Manufacturing Facilities:The brand's state-of-the-art manufacturing facilities in Kolkata are equipped with cutting-edge technology, enabling efficient and precise production of silica gel. Whitespice Chemical's commitment to staying at the forefront of industry advancements ensures that its products consistently meet and exceed customer expectations.

Stringent Quality Assurance Practices:Quality assurance is at the heart of Whitespice Chemical's operations. Rigorous testing procedures are implemented at every stage of the manufacturing process, from raw material inspection to the final product. This meticulous approach guarantees that customers receive silica gel products that not only meet industry standards but also surpass them.

Customer-Centric Approach:Whitespice Chemical's success can be attributed not only to its high-quality products but also to its customer-centric approach. The brand values long-term partnerships and strives to understand the unique needs of each client. This personalized attention sets Whitespice Chemical apart, making it a preferred choice for businesses seeking a reliable and responsive silica gel supplier in Kolkata.

Global Reach and Local Presence : While Whitespice Chemical has a global reach, serving clients across borders, its local presence in Kolkata remains a strong asset. This proximity allows for quick response times, efficient communication, and seamless collaboration with clients. The brand's commitment to both global standards and local support further solidifies its position as a leader among silica gel manufacturers in Kolkata.

Conclusion: In the realm of silica gel manufacturing, Whitespice Chemical stands tall as the epitome of excellence. With a commitment to quality, a diverse product range, and a customer-centric approach, the brand has rightfully earned its reputation as one of the best silica gel manufacturers in Kolkata. For businesses seeking top-tier silica gel products, Whitespice Chemical emerges as the undisputed choice, offering a perfect blend of quality, innovation, and reliability.

0 notes

Text

Surprising Ways to Reuse Silica Gel

Have you ever unboxed a new pair of shoes or electronics and found a tiny packet labelled 'do not eat' and wondered what on earth it's for? This small, seemingly useless packet of silica gel has many surprising uses you may not have thought of. But first, what are silica gels, and why is it in our packages?

Silica gel is a granular, porous form of silicon dioxide that is commonly used as a desiccant to absorb moisture. It has high adsorption capacity and can hold up to 40% of its weight in water vapour. This makes the gel ideal for protecting goods during transport and storage, as excess moisture can cause damage or spoilage. Silica gel, a versatile desiccant, is also commonly used in pharmaceuticals to protect against moisture damage.

So, one way to reuse silica gel is to extend the shelf life of medications. Silica gel can be placed in the boxes where you keep medications to absorb moisture and prevent degradation. This is especially important for moisture-sensitive medications, such as those that are hygroscopic or deliquescent. Silica gel can also be used to protect pharmaceuticals from microbial growth

Here are some other ways:

Drying a wet smartphone

If you've accidentally dropped your smartphone in water, the gel can come to the rescue. Simply put your damp device in a bag with a few packets and leave it overnight; the gel will absorb the moisture and potentially save your phone from water damage.

Storing shoes

This one may seem obvious, but it's still worth mentioning. Silica gels are great for storing shoes, especially if you live in a humid climate or have sweaty feet. The gel will help absorb any moisture and prevent your shoes from developing that dreaded musty smell.

Gym bags

Did you forget to take your sweaty gym clothes out of your bag? No problem, just throw in some silica gel packets, and they will help absorb the moisture and prevent any funky doors from developing.

Protecting important documents

Important documents like birth certificates or passports can easily get damaged by moisture. To protect them, store them with silica gel packets in a sealed plastic bag.

Preserving jewellery

Another surprising use for these gel packets is preserving jewellery. Place a few packets in your jewellery box to help absorb moisture and prevent your precious pieces from tarnishing.

About the author:

PharmPak is a trusted supplier of high-quality disposable gloves, sticky labels, personal protective equipment (PPE), and other hygiene products. They offer a wide selection of products to meet the needs of customers in both residential and commercial settings, including hospitals, laboratories, and other industries. Their products are designed with top-quality materials to ensure durability, comfort, and optimal protection against hazards, whether it's spills, splatters, or other dangers. They take pride in our commitment to providing exceptional customer service and high quality products and strive to make the ordering process as easy and efficient as possible.

0 notes

Text

MOISTURE SILICA GEL

A semi-transparent hard granule known as "silica gel" is a moisture absorber made from amorphous silica. They are excellent moisture absorbents with a wide range of absorption capacities depending on the surrounding environment. Moisture Silica Gel absorbs moisture signalling the saturation degree by changing color.

A silica gel breather design is simple and easy to install. The arrangement is placed inside the transformer conservator and includes a pot or tube filled with fresh silica gel. This is placed above the oil level, to remove maximum moisture from the air. By protecting the insulating oil, silica gel assures insulation to the entire transformer parts.

Breather silica gel transformers is used in breather transformers to manage moisture levels and keep it from entering the machinery. They are mostly beneficial in preserving transformer oil from moisture damage. They are created with the application's needs in mind, according to industry standards.

#MOISTURES SILICA GEL MANUFACTURERS#MOISTURES SILICA GEL SUPPLIERS#MOISTURE SILICA GEL#MOISTURES SILICA GEL EXPORTERS

0 notes

Text

#desiccant beads#indicating silica#orange silica gel#moisture absorbers#blue silica gel#manufacturer#silicagel supplier

0 notes

Text

What The Role of Desiccants in the Automotive Industry Experts Want You to Know

The part of Desiccants in the Automotive Assiduity preface In the fast- paced and dynamic world of the automotive assiduity, perfection and trustability are consummate. Manufacturers and suppliers strive to insure that every element performs at its stylish, and this includes keeping humidity and moisture at bay. In this regard, desiccants play a pivotal part in maintaining the integrity of automotive products. In this comprehensive composition, we will claw into the significance of desiccants in the automotive assiduity and their colorful operations, showcasing their significance in enhancing product quality and life.

1. What is Desiccants ?

Desiccants are hygroscopic substances able of absorbing and retaining humidity from the girding terrain. They work by creating a dry terrain within a sealed space, effectively precluding the build up of condensation and moistness. In the automotive assiduity, desiccants are primarily used to cover sensitive factors and accoutrements from humidity damage during manufacturing, shipping, and storehouse.

2. Why Desiccants used in Automotive industries?

During the manufacturing process of automotive factors, exposure to humidity can lead to erosion, declination, and indeed complete failure of corridor. To help similar issues, desiccants are integrated into the product line. From the manufacturing of electronic control units( ECUs) to airbag modules and optic detectors, desiccants are strategically placed to insure optimal performance and tractability.

3. Desiccants used in Automotive Storage & Shipping

The trip of automotive corridor from the manufacturer to the assembly line involves colorful stages of transportation and warehousing. These stages can subdue the factors to varying temperature and moisture conditions. Desiccants are incorporated into packaging accoutrements to guard the products from humidity- related damages during conveyance and storehouse. By barring humidity, desiccants help maintain the original quality of the factors until they're ready for installation.

4 Several types of Desiccants for in the Automotive Industry

Several types of desiccants find operations in the automotive sector. Each type possesses distinct characteristics suited for specific conditions. Some generally used desiccants include

Silica Gel Silica gel is one of the most extensively used desiccants in the automotive assiduity. Its high face area and excellent humidityabsorbing capacity make it an ideal choice for guarding sensitive electronic factors.

Molecular Sieve Molecular sieve desiccants are preferred for operations where exceptionally low moisture situations are needed. They're generally used in air exertion systems and energy tanks to maintain dry conditions.

Clay Desiccants Clay desiccants are provident and effective for humidity immersion. They're generally used for guarding larger automotive factors during shipping and storehouse.

Calcium Chloride Desiccants These desiccants have a high humidity immersion rate and are ideal for diving extreme moisture conditions during conveyance.

5. Impact on Automotive Performance

The use of desiccants in the automotive assiduity has a direct impact on product performance and overall quality. Then is how desiccants contribute to enhancing automotive performance Enhanced Electrical Performance humidity can compromise the electrical integrity of colorful automotive factors, leading to malfunctions or failure. Desiccants insure that sensitive electronics, similar as ECUs, detectors, and infotainment systems, remain dry and function optimally. Increased Life By guarding automotive corridor from humidity- related damage, desiccants contribute to the extended lifetime of factors. This leads to advanced client satisfaction and reduces the need for frequent reserves. Improved Safety In critical safety factors like airbag modules, any humidity intrusion could lead to malfunction during deployment. Desiccants guarantee that these safety features remain in perfect condition, furnishing dependable protection to passengers.

6. Environmental Impact piecemeal from their performance benefits,

Desiccants also play a part in reducing the environmental impact of the automotive assiduity. By conserving the quality of factors, desiccants help help unseasonable failures, reducing the overall waste generated. also, desiccants themselves can frequently be disposed of in aneco-friendly manner. 7. unborn Trends As the automotive assiduity continues to evolve, so will the use of desiccants. inventions in desiccant technology will lead to more effective and sustainable results for humidity control. Manufacturers will concentrate on integrating smarter humidity operation systems to meet the adding demands of the assiduity.

Conclusion

Desiccants are obscure icons in the automotive assiduity, quietly icing that critical factors perform at their stylish. From guarding electronic systems to conserving safety features, their impact on product quality and life can not be exaggerated. As the automotive assiduity embraces advancements in humidity control, desiccants will remain necessary for achieving peak performance and client satisfaction.

#humiditycontrol#moistureabsorbers#shipping#desiccantsilicagel#packagingsolutions#automotive#cargo transport#cargo shipping#self care#desiccant#Automotive industries#electronic systems#Clay Desiccants#automotive products

0 notes

Text

How to Maintain and Clean Your Desiccator Cabinet for Optimal Performance

Desiccator cabinets are essential equipment in laboratories and other settings where moisture-sensitive materials need to be stored. To ensure the longevity and effectiveness of your desiccator cabinet, proper maintenance and cleaning are crucial. Global Lab Supply understands the importance of maintaining desiccator cabinets for optimal performance. In this article, we will provide a guide on how to maintain and clean your desiccator cabinet, along with tips and best practices to keep it in excellent working condition.

Regular Inspection:

Regular inspection is the first step in maintaining your desiccator cabinet. Check for any signs of damage, such as cracks or loose fittings, and ensure that the seals are intact and functioning properly. Addressing any issues promptly can prevent moisture ingress and maintain the effectiveness of the cabinet.

Desiccant Replacement:

The desiccant, typically silica gel or other moisture-absorbing materials, plays a critical role in maintaining a dry environment within the desiccator cabinet. Regularly inspect and replace the desiccant as needed to ensure its effectiveness. Follow the manufacturer's guidelines for proper desiccant replacement frequency and procedure.

Cleaning the Interior:

Cleaning the interior of the desiccator cabinet is essential to remove any debris or contaminants that may affect its performance. Follow these steps for cleaning:

a. Remove all contents from the desiccator cabinet.

b. Wipe the interior surfaces with a lint-free cloth or sponge dampened with a mild cleaning solution. Avoid abrasive cleaners that may damage the cabinet.

c. Rinse the cloth or sponge with clean water and wipe down the surfaces again to remove any cleaning residue.

d. Allow the cabinet to air dry completely before replacing the desiccant and contents.

Sealing and Lubrication:

The seals of the desiccator cabinet should be regularly inspected and maintained. Clean the seals with a mild soap solution and water, then dry them thoroughly. Lubricate the seals with a silicone-based lubricant to ensure smooth operation and a proper seal. Be cautious not to over-lubricate, as excessive lubricant can attract dust or interfere with the sealing effectiveness.

Exterior Maintenance:

Maintaining the exterior of the desiccator cabinet is also important. Wipe the exterior surfaces with a damp cloth and mild cleaning solution to remove any dirt or stains. Avoid using harsh chemicals or abrasive materials that may damage the cabinet's finish. Dry the exterior surfaces thoroughly to prevent water damage.

FAQs (Frequently Asked Questions):

Q1. How often should I clean my desiccator cabinet?

The frequency of cleaning your desiccator cabinet depends on factors such as usage, environmental conditions, and the type of materials stored. However, as a general guideline, it is recommended to clean the interior of the cabinet every 3 to 6 months or whenever you notice debris or contaminants that may compromise its performance.

Q2. Can I use alcohol or solvents to clean my desiccator cabinet?

It is not recommended to use alcohol or solvents to clean your desiccator cabinet, as they may damage the seals, plastic components, or the overall structure. Stick to mild cleaning solutions and water for routine cleaning.

Q3. How do I know if the seals of my desiccator cabinet need replacement?

Inspect the seals regularly for any signs of wear, cracking, or loss of elasticity. If you notice any significant damage or if the seals no longer provide a tight seal, it is recommended to replace them. Contact the manufacturer or a reputable supplier for replacement seals specific to your desiccator cabinet model.

Q4. Can I use a vacuum cleaner to remove debris from my desiccator cabinet?

Avoid using a vacuum cleaner to remove debris from your desiccator cabinet, as it may create static electricity or damage the delicate components. Instead, use a lint-free cloth or sponge to wipe away debris manually.

Q5. Are there any specific safety precautions to follow during desiccator cabinet maintenance?

When cleaning or maintaining your desiccator cabinet, ensure that it is disconnected from any power sources if applicable. Wear appropriate personal protective equipment, such as gloves and safety glasses, to protect yourself from cleaning solutions or potential contaminants.

Conclusion:

Maintaining and cleaning your desiccator cabinet is essential for optimal performance and longevity. By following the guidelines provided by Global Lab Supply, you can ensure that your desiccator cabinet remains in excellent condition, providing a dry and moisture-controlled environment for your sensitive materials. Regular inspections, desiccant replacement, proper cleaning techniques, seal maintenance, and exterior care are key steps in maintaining the functionality and efficiency of your desiccator cabinet. Remember to always follow the manufacturer's instructions and consult with a reputable supplier for specific maintenance recommendations or replacement parts.

Original Sources: https://globallabsupply.blogspot.com/2023/06/how-to-maintain-and-clean-your.html

0 notes

Text

Swambe Chemical’s Versatile Silica Gel Breather Transformer

We are the leading supplier of silica gel breather transformer, for the last 40 years. Our silica gel breathers are manufactured with unique properties and we have our own recipe. The high-quality crystals of silica gel for transformer breathers have been in demand due to their higher moisture adsorption capacity. Visit our website for more details or call us on 9879203377.

Mail ID: [email protected]

0 notes