#Methacrylate Monomers Market

Explore tagged Tumblr posts

Text

Acrylate Monomers Market Share, Trends and Forecast Report by 2025-2033

The Reports and Insights, a leading market research company, has recently releases report titled “Acrylate Monomers Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033.” The study provides a detailed analysis of the industry, including the global Acrylate Monomers Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Acrylate Monomers Market?

The global acrylate monomers market was valued at US$ 10,562.7 Million in 2024 and is expected to register a CAGR of 5.3% over the forecast period and reach US$ 16,812.4 Million in 2033.

What are Acrylate Monomers?

Acrylate monomers are a class of reactive chemicals derived from acrylic acid or methacrylic acid, characterized by a vinyl group that enables polymerization. They serve as key building blocks in the production of various polymers and resins, widely used in adhesives, coatings, sealants, and biomedical applications. These monomers offer properties such as high durability, UV resistance, and flexibility, making them essential in industries like automotive, electronics, and healthcare.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/2642

What are the growth prospects and trends in the Acrylate Monomers industry?

The acrylate monomers market growth is driven by various factors and trends. The acrylate monomers market is experiencing significant growth, driven by increasing demand in adhesives, coatings, sealants, and polymer manufacturing across industries such as automotive, construction, and healthcare. Factors like rising urbanization, infrastructure development, and advancements in UV-curable coatings are fueling market expansion. Additionally, the shift towards sustainable and bio-based acrylates is gaining traction due to environmental concerns and stringent regulations. Asia-Pacific dominates the market, led by rapid industrialization in China and India, while North America and Europe witness steady demand driven by innovations in high-performance materials. However, volatility in raw material prices and regulatory challenges may impact growth. Hence, all these factors contribute to acrylate monomers market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Product Type

Acrylic Acid-Based Monomers

Glacial Acrylic Acid

Technical Acrylic Acid

Acrylate Esters

Methyl Acrylate (MA)

Ethyl Acrylate (EA)

Butyl Acrylate (BA)

2-Ethylhexyl Acrylate (2-EHA)

Specialty Acrylate Monomers

Hydroxyethyl Acrylate (HEA)

Hydroxypropyl Acrylate (HPA)

Glycidyl Acrylate

Carboxylic-Modified Acrylate

Phosphoric-Modified Acrylates

Bio-Based Acrylates

By Production Process

Petrochemical-Based Process

Propylene Oxidation

Acetylene Carbonylation

Bio-Based Production

Fermentation Process

Biomass-Derived Acrylic Acid

By Function

Crosslinking Agents

Surface Modification Additives

Thickening Agents

Weather-Resistant Polymers

Low Volatile Organic Compound (VOC) Formulations

Others

By Application

Paints, Coatings & Inks

Architectural Paints

Industrial Coatings

Automotive Coatings

Marine Coatings

Printing Inks

Wood Coatings

Adhesives & Sealants

Pressure-Sensitive Adhesives (PSA)

Construction Adhesives

Packaging Adhesives

Automotive Sealants

Plastics & Polymers

Polyacrylates

Copolymers & Homopolymers

Superabsorbent Polymers (SAP)

Water Treatment Chemicals

Flocculants & Coagulants

Dispersants

Corrosion Inhibitors

Others

Detergents & Cleaning Products

Liquid Laundry Detergents

Dishwashing Liquids

Surface Cleaners

Construction & Infrastructure

Concrete Admixtures

Waterproofing Agents

Structural Sealants

Others

Electronics & Optical Applications

Textiles & Fibers

Healthcare & Personal Care Products

North America

United States

Canada

Europe

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

Benelux

Nordic

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America

Brazil

Mexico

Argentina

Middle East & Africa

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

BASF SE

Dow

Arkema

Evonik Industries AG

Mitsubishi Chemical Corporation

Synthomer plc

LG Chem Ltd.

Nippon Shokubai Co., Ltd.

Sumitomo Chemical Co., Ltd.

View Full Report: https://www.reportsandinsights.com/report/Acrylate Monomers-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

0 notes

Text

#Basic Methacrylate Copolymer Market Size#Basic Methacrylate Copolymer Market Overview#Basic Methacrylate Copolymer Market Analysis

0 notes

Text

Poly Methyl Methacrylate (PMMA) Prices: Trends and Market Dynamics

Poly Methyl Methacrylate (PMMA), also known as acrylic or plexiglass, is a widely used thermoplastic polymer. Its versatility, excellent optical clarity, and resistance to impact and weathering make it a popular choice across various industries, including automotive, construction, electronics, and healthcare. However, like many other polymers, PMMA prices are influenced by a complex interplay of factors ranging from raw material costs to global market dynamics.

Key Factors Affecting PMMA Prices

Raw Material Costs: PMMA is primarily derived from methyl methacrylate (MMA) monomer. Fluctuations in the prices of MMA significantly impact PMMA prices. MMA prices, in turn, are influenced by the costs of petrochemical feedstocks like propylene and acetone. Any disruption in the supply chain or volatility in crude oil prices directly affects the cost of production.

Supply and Demand Dynamics: PMMA demand is driven by its diverse applications, particularly in high-growth sectors like automotive and electronics. For instance, PMMA is extensively used in LED screens, which have seen rising demand due to advancements in display technology. Conversely, oversupply in the market can lead to price reductions as manufacturers compete for buyers.

Energy Costs: The production of PMMA is energy-intensive. Rising energy costs, whether due to geopolitical tensions or seasonal demand fluctuations, can lead to increased production costs, which are often passed on to end-users.

Economic Conditions: Macroeconomic factors such as inflation, currency exchange rates, and global economic growth significantly influence PMMA prices. During periods of economic slowdown, reduced industrial activity can lead to lower demand, putting downward pressure on prices.

Regulatory and Environmental Policies: Stringent environmental regulations around the use of petrochemical derivatives and the push for sustainable alternatives can influence PMMA production costs and market dynamics. Additionally, initiatives to recycle PMMA are gaining traction, potentially altering the supply landscape.

Get Real time Prices for Poly Methyl Methacrylate (PMMA): https://www.chemanalyst.com/Pricing-data/polymethyl-methacrylate-50

Regional Trends in PMMA Pricing

Asia-Pacific: The Asia-Pacific region dominates the PMMA market, both in terms of production and consumption. China, in particular, is a significant player due to its vast manufacturing base. PMMA prices in this region are highly competitive but sensitive to shifts in demand from the electronics and automotive sectors.

North America and Europe: In developed markets like North America and Europe, PMMA prices are influenced by advanced applications, such as aerospace and medical devices. Additionally, stricter environmental regulations often lead to higher production costs.

Middle East and Africa: The Middle East benefits from proximity to petrochemical feedstocks, often resulting in more stable prices. However, limited domestic consumption means that exports play a critical role in price determination.

Recent Trends and Forecast

In 2023, PMMA prices experienced significant fluctuations due to disruptions in the global supply chain and energy market volatility. As of late 2024, prices are stabilizing, supported by improving economic conditions and steady demand recovery post-pandemic. Analysts forecast moderate growth in PMMA prices over the next five years, driven by sustained demand from key industries and ongoing innovations in PMMA recycling technologies.

Conclusion

Understanding PMMA price trends requires a thorough analysis of multiple factors, including raw material costs, market demand, and regional dynamics. As industries continue to innovate and adopt sustainable practices, the PMMA market will likely evolve, presenting new opportunities and challenges for stakeholders. Keeping an eye on these developments will be crucial for businesses aiming to navigate this complex market effectively.

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Poly Methyl Methacrylate#Poly Methyl Methacrylate Price#Poly Methyl Methacrylate Prices#Poly Methyl Methacrylate Pricing#Poly Methyl Methacrylate News#india#united kingdom#united states#germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

0 notes

Text

Polymer Emulsion: A Guide to Understanding its Properties and Applications

Polymer Emulsion: A Guide to Understanding its Properties and Applications Latex emulsions are synthesized using an emulsion polymerization process. In this process, monomers such as acrylates, methacrylates, and vinyl esters are dispersed in water along with surfactants that help stabilize the growing polymer particles. Free radical initiators are then used to trigger the polymerization reaction, forming polymer particles directly within the water phase. The small particle size and charge imparted by the surfactants allows the polymer particles to remain suspended in water, creating a stable dispersion. Latex emulsions exhibit properties intermediate between water-based latexes/dispersions and 100% solid polymers. Their viscosity and film properties can be tailored depending on the glass transition temperature (Tg) and molecular weight of the polymer. Get More Insights On Polymer Emulsion Market https://patilojaswani.livepositively.com/polymer-emulsion-a-guide-to-understanding-its-properties-and-applications/new=1

0 notes

Text

0 notes

Text

Methyl Methacrylate Market Trends: Insights and Analysis

Overview Methyl methacrylate (MMA) is an organic compound with the formula C5H8O2. It is a colorless, volatile liquid that is slightly soluble in water but very soluble in most organic solvents. MMA's main uses are in the production of poly(methyl methacrylate) (PMMA), which is better known by trade names like Plexiglas or Acrylic glass, and as a chemical intermediate in the production of other substances and industrial chemicals. Production and synthesis Commercially, MMA is produced via the hydrolysis of methacrylic anhydride which itself is produced from acetone cyanohydrin or via the acid-catalyzed esterification of methacrylic acid with methanol. In laboratory settings, it can also be prepared by the condensation of acetone with malonic acid followed by decarboxylation. Globally, over 3 million tons of MMA are produced annually. It is one of the 150 most commonly produced chemicals and a valuable petrochemical product. The key manufacturers are located in Asia, North America and Western Europe. Uses and applications of PMMA Polymerization of MMA yields poly(methyl methacrylate) or PMMA, which is a transparent thermoplastic often used as a lightweight or shatter-resistant alternative to glass in applications such as aircraft canopies or windows and aquariums. It is easily worked, molded or thermoformed due to its low melting point. Some common uses of PMMA include: - Signage and displays: Thin PMMA sheets are often used as an alternative to acrylic glass in illuminated signage due to its light weight and shatter resistance. It is also used as the glazing material on bus/taxi stop shelters. - Construction: PMMA finds use in architectural applications like skylight domes, greenhouse glazing and translucent wall panels. It can also be used to produce bathtubs or sanitary fittings needing high durability and an aesthetically pleasing finish. - Medical and dental: Clear and impact-resistant PMMA sheets are commonly used as the material for orthodontic appliances and in medical devices like inhalers or eyeglass frames. It is also employed as an insulator in bone cements used for joint replacements. - Electronics: Various consumer electronic devices, especially mobile phones and PDAs, employ PMMA for touchscreens and display lenses owing to its durability and optical clarity. Conclusion In summary, methyl methacrylate is an essential building block in modern materials production. As the monomer for PMMA plastic sheet and specialist polymers, it delivers technical advantages of strength, clarity and formability paired with economical processability. Its versatility as an intermediate also means that by controlled reaction with many different molecules, it enables the cost-effective synthesis of various industrial chemicals in demand. With growing applications across markets, MMA's global output and relevance will likely remain substantial for the foreseeable future. Care must continue to be taken regarding the associated human health and environmental impacts through prudent handling and process design.

0 notes

Text

Innovation in Clarity: Exploring the Applications of Poly Methyl Methacrylate (PMMA) (2023-2034)

Ever heard of Polymethyl methacrylate (PMMA)? PMMA is a transparent and rigid thermoplastic, crafted from the monomer methyl methacrylate, holding impressive resistance to UV light and weathering. With its crystal-clear clarity, PMMA finds its way into a myriad of applications, from sleek car windows and durable smartphone screens. Read more about the versatility and manufacturing of PMMA in this blog! The global Poly Methyl Methacrylate (PMMA) market is likely to flourish at a CAGR of 4.05% by the year 2034.

Introduction

A scientific term, Poly (methyl methacrylate), refers to the clear and lightweight plastic commonly called acrylic or plexiglass. In its natural state, it's easily broken, but it can be colored, textured, and shaped in many ways. Crystal-clear plastic, known as Polymethyl methacrylate (PMMA) or acrylic, stands out for its toughness. Unlike glass, it won't shatter, making it a popular choice as a substitute. PMMA boasts several advantages over other clear plastics like polycarbonate (PC) and polystyrene (PS). These include superior resistance to sun damage and weather, exceptional light transmission, and the ability to be colored in any shade imaginable.

Scientific Properties: PMMA is scratch resistant and remains unaffected by aqueous solutions. However, exposure to certain chemicals like aromatic or chlorinated hydrocarbons, esters, or ketones can compromise its surface.

Sound and Break-Resistance: PMMA acts as a sound-resistant material, reducing the transmission of external sound waves. This quality makes it ideal for constructing spaces that require internal sound insulation, such as audio studios, libraries, quiet rooms, and vehicles.

Environmental Sustainability: PMMA exhibits excellent outdoor durability, resisting corrosion, ultraviolet light, and various environmental factors. Furthermore, it is both recyclable and BPA-free, making it one of the safer plastics in terms of environmental impact. These characteristics contribute to PMMA's sustainability profile, aligning with eco-conscious practices and initiatives.

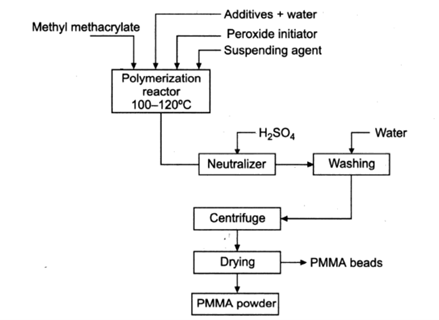

Manufacturing Process

PMMA, derived from methacrylic acid (CH2=C[CH3]CO2H), is a significant member of the acrylic resin family. Its production primarily involves propylene, obtained from the lighter fractions of crude oil, and benzene, reacting to form cumene or isopropylbenzene. The resulting cumene undergoes oxidation to cumene hydroperoxide, then acid treatment to yield acetone. Subsequently, acetone undergoes a three-step process to produce methyl methacrylate (CH2=C[CH3]CO2CH3), a flammable liquid. Methyl methacrylate is polymerized, either in bulk liquid form or as fine droplets suspended in water, using free-radical initiators to form solid PMMA. This polymerization process links the molecules together, resulting in the formation of PMMA with a repeating unit structure.

The polymerization reactor receives a feed mixture consisting of a monomer, water acting as the reaction medium, suspending agents, and a monomer-soluble initiator. To adjust the density of the aqueous medium, decrease the monomer's water solubility, and increase interfacial tension, an inorganic salt is added. Polymerization occurs at around 100°C. After polymerization, the resulting slurry is neutralized with sulfuric acid before undergoing filtration or centrifugation. The material is then dried. This method ensures the controlled production of the desired polymer, achieved through the precise interaction of monomers, reaction medium, initiators, and additives within the polymerization reactor.

Applications of Poly Methyl Methacrylate (PMMA)

Construction

PMMA is very useful in building. It is commonly used for shatterproof skylights. It may also be found in many shower and bath systems, and many people prefer acrylic over ceramic tiles. As previously said, acrylic may be found in many sound-proof rooms, audio studios, and automobiles.

Automotive

PMMA sheets are utilized in automobile windows, motorbike windshields, interior and exterior panels, fenders, and other vehicle components. Colored acrylic sheets are also utilized in automotive indication light covers and interior light covers, among other applications. It is also utilized for ship windows (salt resistance) and aviation applications.

Electronics

Because of its superior optical clarity, high light transmission, and scratch resistance, PMMA is widely utilized in LCD/LED television screens, computers, smartphone displays, and electrical equipment. PMMA is also utilized as a cover material in solar panels due to its strong UV resistance and light transmission properties, which allow for high energy conversion efficiencies.

Furniture

PMMA provides exceptional features like transparency, hardness, and attractiveness to make chairs, tables, kitchen cabinets, bowls, and table mats in any shape, color, or finish.

Market Outlook:

The PMMA market is embracing sustainability. As environmental concerns grow, manufacturers are seeking eco-friendly solutions for PMMA, either through bio-based materials, improved recycling, or circular economy approaches. This aligns with the global push for sustainability and positions PMMA to meet evolving consumer and regulatory demands. Additionally, PMMA's clear optics, biocompatibility, and easy sterilization make it ideal for healthcare applications like lenses, instruments, and dental materials. As healthcare technology advances, PMMA's properties are well-suited for these demanding medical uses, creating exciting opportunities for market growth and diversification.

Poly Methyl Methacrylate (PMMA) Major Players

Significant companies in the Global Poly Methyl Methacrylate (PMMA) market are Mitsubishi Rayon Co., Ltd., Evonik, Chi Mei Corporation, Sumitomo Chemical, LX MMA, Wanhua Chemical, Suzhou Double Elephant Optical Materials, and Kuraray Co., Ltd., Lotte MCC, and Others.

Poly Methyl Methacrylate (PMMA) market restraints

The Poly Methyl Methacrylate (PMMA) market faces several restraints as well. These are as follows:

Fluctuating Raw Material Prices: Poly Methyl Methacrylate (PMMA) production relies on raw materials like bisphenol A and phosgene, the prices of which are subject to market volatility. Fluctuations in raw material costs can affect the overall production costs and profit margins for Poly Methyl Methacrylate (PMMA) manufacturers.

Difficulty in Recycling: While clear acrylic sheets can be recycled, the process is complex. Breaking down large pieces and using specialized methods like perspex recycling are just the first steps. This difficulty contributes to a global problem of acrylic waste harming ecosystems. In some areas, acrylic buildup disrupts the natural balance of CO2 and O2 exchange, hindering plant growth.

Conclusion:

The Polymethyl Methacrylate (PMMA) market has boomed in recent years, driven by its use in key industries like electronics, automotive, and construction. PMMA's unique properties, such as high durability and chemical resistance, suggest continued growth in the coming years. Rising urbanization, increasing demand for modern electronics, and projected growth in vehicle sales are all expected to fuel PMMA demand by 2034.

#PMMA#PMMAprices#PMMAmarket#PMMApricetrend#PMMApriceforecast#PMMAmarketprice#priceofPMMA#PMMAdemand#PMMASupply

1 note

·

View note

Text

Analyzing the Global Methyl Methacrylate Market: Trends, Growth Drivers, and Industry Insights

Methyl Methacrylate: Properties, Synthesis and Industrial Uses of Methacrylate Chemical Properties Methyl methacrylate, commonly known as MMA, is an organic compound with the formula C5H8O2. It is a colorless, volatile liquid with an acrid odor. MMA is moderately soluble in water but highly soluble in most organic solvents such as alcohol, ether, acetone and dichloromethane. The primary property of MMA is that it undergoes free radical polymerization, which leads to the formation of PMMA. During polymerization, the carbon double bonds in MMA monomers react to form long chains or polymers. This conversion of a low-molecular-weight liquid to a high-molecular-weight solid plastic through polymerization is the reason why MMA finds numerous industrial applications. MMA polymerizes via a free radical mechanism initiated by heat, light or chemicals like peroxides. The polymerization is exothermic and needs to be controlled carefully. During industrial production of PMMA, monomers, polymers and residual reactants must be kept separate to avoid premature or uncontrolled polymerization. Synthesis of MMA Commercially, MMA is produced through the acetone cyanohydrin process, which involves the reaction of acetone and hydrogen cyanide to form acetone cyanohydrin. This intermediate is then reacted with methanol in the presence of an acid catalyst to yield MMA. CH3COCH3 + HCN → CH3C(OH)CN + H2O CH3C(OH)CN + CH3OH → CH2=C(CH3)COOCH3 + H2O The overall reaction involves the replacement of the nitrile group in acetone cyanohydrin by a methoxy carbonyl group through acid-catalyzed esterification. Major process parameters are the selection of acid catalyst, temperature control and recovery of byproducts. MMA can also be synthesized through the methacrylic acid process, which involves the carbonylation of acetylene to methacrylic acid, followed by esterification with methanol. However, the acetone cyanohydrin process is preferred industrially due to lower costs. Industrial Uses of MMA Some of the major industrial applications of MMA and PMMA are: Plexiglas and Optical Materials - PMMA in the form of Plexiglas sheets finds widespread use as an alternative to glass in lighting fixtures, transport equipment, window panes and optical instruments. It offers advantages of lighter weight, thermal insulation and durability. Automotive and Aircraft Industries - MMA is used to manufacture canopies, light covers, glazing panels and translucent roof panels for aircraft, vehicles, trains and boats. PMMA offers crash resistance, high optical clarity and weatherability. Paints and Coatings - MMA or blends of MMA and styrene are used as monomers in paints and coatings for their resistance to solvents, weathering and aging. Applications include automotive finishes and industrial flooring. Adhesives - MMA based adhesives bond plastics, metals, wood, ceramics and composites. They offer high adhesion strengths along with heat, chemical and water resistance. Acrylic Fibers - Polymerization of MMA leads to acrylic fibers used in textiles and apparels. They mimic the feel and appearance of wool but are cheaper and easier to maintain. Medical Devices - PMMA is approved by FDA for applications such as bone cement, breast implants and contact lenses due to its biocompatibility and durability. In summary, methyl methacrylate serves as a vital building block monomer in the synthesis of PMMA, which then finds diverse industrial applications leveraging its outstanding material properties. Strict process control during MMA production and polymerization is needed for safety and maximal output.

0 notes

Text

India Butyl Acrylate Market Outlook, Report 2023-2030

BlueWeave Consulting, a leading strategic consulting and market research firm, in its recent study, estimated the India Butyl Acrylate Market size by value at USD 432.99 million in 2023. During the forecast period between 2024 and 2030, BlueWeave expects the India Butyl Acrylate Market size to expand at a CAGR of 7.85% reaching a value of USD 534.03 million by 2030. The Butyl Acrylate market in India is propelled by the increasing application as a solvent in the paints and coatings, as well as adhesive and sealants sectors, predominantly within the expanding construction and automotive industries. India has witnessed a rising trend in residential and commercial development in recent years, driven by increasing investments and evolving lifestyles. Also, butyl acrylate plays a crucial role as an ingredient in pressure-sensitive adhesives, widely employed by the textile and construction sectors. Its presence in PVC modifiers and molding or extrusion additives further enhances its application in the plastics sector. With the upswing in construction activities and infrastructure development, there is an anticipated surge in demand for commodities like paints & coatings and plastics, consequently boosting the overall demand for butyl acrylate over the forecast period.

By volume, BlueWeave estimated the India Butyl Acrylate Market size at 261.66 thousand tons in 2023. During the forecast period between 2024 and 2030, BlueWeave expects the India Butyl Acrylate Market size by volume is projected to grow at a CAGR of 7.01% reaching the volume of 301.09 thousand tons by 2030. The increasing use of butyl acrylate in the production of thermoplastic ethylene acrylate copolymers (EAC), containing up to 35% butyl acrylate, stands out as pivotal factor contributing to market expansion. The combination of butyl acrylate with other monomers, such as vinyl acetate, methyl methacrylate, acrylic acid, styrene, and other acrylate ester monomers, opens up possibilities for diverse copolymer compositions.

Sample Request @ https://www.blueweaveconsulting.com/report/india-butyl-acrylate-market/report-sample

Opportunity – Expanding automotive industry

The expanding automotive industry in India is anticipated to drive the need for butyl acrylate. The compound plays a crucial role in polymer manufacturing, specifically contributing to the production of car dashboards and leather seats. Additionally, butyl acrylate serves as a key component in the production of sealants, utilized in various automotive applications such as within the trunk, hood, doors, front dash, and on both the interior and exterior metal joints of vehicles. The global surge in motor vehicle production stands as a significant factor contributing to the anticipated growth of the butyl acrylate market in the coming years.

Impact of Escalating Geopolitical Tensions on India Butyl Acrylate Market

Increasing geopolitical tensions can have a multifaceted impact on the India Butyl Acrylate Market. The surge in upstream values, particularly crude oil, is exerting pressure on downstream derivatives, thereby elevating inflationary concerns for consumers. Butyl acrylate prices in the domestic market have responded with buoyancy, driven by multiple elements contributing to these fluctuations. A substantial driver for this upward trajectory is the notable increase in crude oil values, impacting critical feedstocks like n-Butanol and Acrylic Acid. The exponential rise in crude oil prices is a consequence of global uncertainties, with low inventories in the USA driving up spot prices of Brent. Simultaneously, geopolitical tensions between Russia and Ukraine have further heightened global contract purchases. Additionally, increased consumption in China, post-easing of the dual energy policy and winter Olympics-related restrictions, has influenced the overall pricing dynamics for crude oil globally. Also, heightened demand fundamentals for Butyl Acrylate in the downstream derivative segment contribute to the overall upward price trend in the Indian market.

India Butyl Acrylate Market

Segmental Information

India Butyl Acrylate Market – By Application

On the basis of application, the India Butyl Acrylate Market is divided into Paints & Coatings, Adhesives & Sealants, Chemical Synthesis, Plastic Additives, and Textiles segments. The paints & coatings segment holds the highest share in the India Butyl Acrylate Market by application closely followed by the adhesive & sealants segment. It is primarily due to their growing applications in the construction and automotive industries. Additionally, the rising trend of substituting old coatings with water-based alternatives in combination with the increased usage of adhesives further contributes to the sustained leadership of these industries in the market.

India Butyl Acrylate Market – By Region

Geographically, the India Butyl Acrylate Market is divided into North India, South India, East India, and West India regions. West India holds the highest market share and is expected to maintain its dominance during the forecast period. Its dominance is attributed to key consumption in states like Gujarat and Maharashtra, driven by prominent companies, such as Asian Paints. Until FY2022, India relied on imports to meet the demand for butyl acrylate.

Competitive Landscape

The India Butyl Acrylate Market is fragmented, with numerous players serving the market. The key players dominating the India Butyl Acrylate Market include Bharat Petroleum Corporation Limited, BASF, Vizag Chemical, Dhalop Chemicals, Dow, Arkema, Otto Chemie Pvt Ltd, KR Chemicals, and LG Chem. The key marketing strategies adopted by the players are facility expansion, product diversification, alliances, collaborations, partnerships, and acquisitions to expand their customer reach and gain a competitive edge in the overall market.

Contact Us:

BlueWeave Consulting & Research Pvt. Ltd

+1 866 658 6826 | +1 425 320 4776 | +44 1865 60 0662

0 notes

Text

Emerging Trends in the Methyl Methacrylate Market: A Detailed Study

Methyl Methacrylate: A Versatile and Widely Used Polymer Monomer Introduction

Methyl methacrylate, commonly referred to as MMA, is an organic compound that serves as the primary monomer in the production of a variety of plastics and polymers. Due to its ability to easily polymerize into strong and impact-resistant materials, MMA has become one of the most ubiquitous and versatile monomers in the modern chemical industry. In this article, we will explore the chemical and physical properties of MMA, its production methods, major applications and uses, as well as safety and environmental considerations regarding its handling and production. Chemical and Physical Properties

MMA is a colorless, volatile liquid at room temperature with a characteristic, unpleasant odor. Its chemical formula is C5H8O2 and it has a molecular weight of 100.12 g/mol. MMA is soluble in most common organic solvents like acetone, ethanol, benzene, and toluene. It exhibits low toxicity when ingested but can cause skin and eye irritation upon contact. When heated to its flame point of 210°C, MMA will ignite and burn. Its vapor is heavier than air and can travel considerable distances to an ignition source, posing a risk of flashback fires. Production

Nearly all MMA is produced through a two-step process involving acrolein or methacrolein as an intermediate. In the first step, propylene is oxidized to acrylic acid which is then dehydrated to acrolein. In the second step, acrolein undergoes an aldol condensation reaction with formaldehyde to yield MMA. The overall process typically takes place in the liquid phase with acid catalysts at mild temperatures and pressures. Annual global production capacity for MMA is estimated to be over 5 million tons and is continuing to grow along with its rising demand. Major Applications

By far, the biggest end use of methyl methacrylate market is in the production of polymethyl methacrylate (PMMA), commonly known as acrylic glass. Over 70% of MMA output goes into manufacturing this transparent thermoplastic that finds applications as transparent panels, glazing, decorative ornaments and diverse articles of daily use. Other common plastics derived from MMA include: acrylic fibers used in clothing and carpeting; extruded sheets for lighting panels and signage; and impact-resistant alloys blended with other polymers. MMA also serves as a reactive diluent for unsaturated polyester resins and acrylic paints and coatings, enhancing their application properties. Safety and Environmental Issues

Handling liquid MMA requires protective equipment like goggles, gloves, and masks due to its eye, skin and respiratory tract irritation potential. Its saturated vapors are denser than air and may collect in low-lying areas, so spaces should be well-ventilated. MMA is moderately toxic if ingested and is listed as a possible carcinogen by regulatory agencies. In the environment, it poses a low to moderate hazard as its hydrolyzes rapidly in water to non-toxic compounds. The main safety and health concerns arise during MMA production, where worker exposure to its fumes needs to be thoroughly controlled and monitored. Producers have also developed clean manufacturing techniques to minimize undesirable emissions and waste. Conclusions

Ever since its discovery in the late 19th century, MMA has emerged as one of the most widely produced organic compounds in the chemical industry. Its unique ability to readily polymerize into glass-clear, impact-resistant plastics like PMMA has enabled revolutionary applications across diverse fields from construction to consumer goods. With continued innovation around its production methods and further development of useful derivatives like co-polymers, the importance and utility of MMA is likely to grow in the coming decades. Proper safety precautions during its handling and manufacture also remain vital to protect human and environmental health.

0 notes

Text

0 notes

Text

https://www.maximizemarketresearch.com/market-report/methacrylate-monomers-market/2277/

0 notes

Text

Poly Methyl Methacrylate (PMMA) Price | Prices | Pricing | News | Database | Chart

Poly Methyl Methacrylate (PMMA), often referred to as acrylic or plexiglass, is a versatile thermoplastic with various applications across industries. PMMA is widely used in the automotive, construction, electronics, and medical sectors due to its excellent transparency, durability, and weather resistance. Given its importance, understanding the pricing dynamics of PMMA is essential for manufacturers, suppliers, and end-users alike. PMMA prices are influenced by several factors, ranging from raw material costs and supply-demand dynamics to market trends and regional variations. Like many other polymer materials, PMMA prices tend to fluctuate based on feedstock availability, especially the key monomer methyl methacrylate (MMA). The production process involves the polymerization of MMA, and the availability and pricing of this monomer directly impact the overall cost of PMMA.

Global market demand is a crucial determinant of PMMA prices. PMMA is used in various applications, including automotive lighting, LCD screens, signage, and medical devices. The increasing demand for lightweight and durable materials in the automotive and electronics industries has propelled the demand for PMMA. However, shifts in global economic conditions, such as economic slowdowns or trade disruptions, can lead to fluctuations in demand and, consequently, PMMA prices. For instance, during economic downturns, the reduced demand from key industries can lead to lower PMMA prices as suppliers adjust to the lower demand. Conversely, in periods of economic growth, rising demand can push prices upward as supply tightens.

Get Real Time Prices for Poly Methyl Methacrylate (PMMA): https://www.chemanalyst.com/Pricing-data/polymethyl-methacrylate-50

Regional variations in PMMA prices also play a significant role in the global market. Asia-Pacific, especially China and Japan, is one of the largest consumers of PMMA due to the booming automotive and electronics sectors. In this region, PMMA prices tend to be influenced by local supply and demand dynamics, government policies, and the availability of raw materials. In contrast, in Europe and North America, factors such as stricter environmental regulations and higher production costs can contribute to slightly higher PMMA prices. Moreover, transportation costs and trade tariffs between regions can lead to price disparities across different markets.

The cost of energy and labor also impacts PMMA prices. Since the production of PMMA is energy-intensive, fluctuations in energy prices, particularly oil and natural gas, can have a direct effect on the cost of production. Rising energy costs lead to higher production expenses, which are often passed on to the end consumers in the form of increased PMMA prices. Labor costs, especially in regions with high wages, can also add to the overall production costs. In countries where labor is more affordable, such as in parts of Asia, the production of PMMA can be more cost-effective, leading to lower prices compared to regions with higher labor costs.

Technological advancements and innovations in the production process can also affect PMMA prices. Improved manufacturing techniques and the development of new grades of PMMA that offer enhanced properties, such as increased impact resistance or UV protection, can influence the market. For example, specialty grades of PMMA that cater to specific industries, such as medical or aerospace, tend to command higher prices due to their specialized nature and the additional costs involved in their production. On the other hand, innovations that reduce production costs, such as more efficient polymerization processes or the use of alternative raw materials, can lead to lower PMMA prices over time.

Supply chain disruptions are another factor that can cause volatility in PMMA prices. Disruptions in the supply of raw materials, logistical challenges, or political instability in key manufacturing regions can lead to supply shortages, driving up PMMA prices. For instance, natural disasters, geopolitical tensions, or pandemics can impact the availability of methyl methacrylate and other essential inputs, leading to production delays and price increases. In addition, the COVID-19 pandemic had a significant impact on the global supply chain, leading to price fluctuations in many materials, including PMMA. As industries around the world experienced shutdowns and reduced production capacities, the demand for PMMA in sectors like automotive and electronics temporarily declined, causing prices to dip. However, as the global economy began to recover, demand surged, and PMMA prices experienced a corresponding increase due to supply chain constraints.

Sustainability concerns and environmental regulations are increasingly shaping the PMMA market and its pricing. As industries and governments worldwide focus on reducing carbon footprints and promoting sustainable practices, the demand for eco-friendly alternatives to conventional plastics has grown. PMMA, being recyclable and less harmful than some other polymers, is benefiting from this trend. However, stricter environmental regulations, especially in regions like Europe, can lead to increased production costs due to compliance requirements, thereby influencing PMMA prices. Producers may have to invest in cleaner production technologies or adopt more expensive processes to meet environmental standards, which can result in higher prices for PMMA.

In conclusion, the price of Poly Methyl Methacrylate is influenced by a multitude of factors, including the availability and cost of raw materials like methyl methacrylate, global and regional demand, energy and labor costs, technological advancements, supply chain disruptions, and environmental regulations. Understanding these factors is crucial for stakeholders in industries that rely on PMMA, as price fluctuations can significantly impact production costs and profit margins. As the global economy continues to evolve, with new challenges and opportunities emerging in various industries, the pricing of PMMA is likely to remain dynamic, reflecting the changing landscape of the materials market. Those involved in the supply chain of PMMA must stay attuned to these factors to navigate the market effectively and ensure cost-efficiency in their operations.

Get Real Time Prices for Poly Methyl Methacrylate (PMMA): https://www.chemanalyst.com/Pricing-data/polymethyl-methacrylate-50

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Poly Methyl Methacrylate#Poly Methyl Methacrylate Price#Poly Methyl Methacrylate Prices#Poly Methyl Methacrylate Pricing#Poly Methyl Methacrylate News

0 notes

Text

Methacrylate Monomers Market Size, Share, CAGR, Outlook, Competitive Landscape, Regional Analysis and Forecasts to 2027

APAC region is anticipated to lead the market during the forecast period due to the high obtainability of methacrylate monomers raw materials and the growing industrial applications in due to high consumption in China, Japan, India, South Korea, and others countries. Methacrylate monomers is highly used in automobiles, aerospace, construction, and other industries. The growth of Asia Pacific methacrylate monomers market is driven by the large rising demand of methacrylate monomers in construction and automotive industry. Methacrylate monomers used in various applications such as coatings, paints, inks, elastomers, adhesives, and others. Furthermore, Asia Pacific’s coatings industry is encompasses of huge and developing countries. China and India together considered as the largest coating market of this region. In addition to these countries, Asia Pacific is also included of many fast-growing countries in terms of coatings consumption such as Indonesia, Vietnam, Malaysia, Thailand, etc. The Asia Pacific region is developing economy owing to this the growth of construction industry, which is further accelerating demand of methacrylate monomers. On the other hand adhesives application of methacrylate monomers in growing industry such as in marine, automotive, aerospace, and construction will boost the consumption of methacrylate monomers in this region. The Asia Pacific region methacrylate monomers market is also segmented on the basis of derivatives, such as behenyl methacrylate, tert-butyl methacrylate, cyclohexyl methacrylate, iso-decyl methacrylate, stearyl methacrylate, and others. Whereas, North America holds second position for global methacrylate monomers market followed by Europe region. Moreover, Middle East, Latin America and South Africa is an emerging region for methacrylate monomers market due to increasing consumption of methacrylate monomers in various industries such as automotive, aerospace, construction, and other industries.

TABLE OF CONTENTS

1 Executive Summary

2 Scope Of The Report

2.1 Market Definition

2.2 Scope Of The Study

2.2.1 Research Objectives

2.2.2 Assumptions & Limitations

2.3 Markets Structure

3 Market Research Methodology

3.1 Research Process

3.2 Secondary Research

3.3 Primary Research

3.4 Forecast Model

4 Market Landscape

4.1 Five Forces Analysis

4.1.1 Threat Of New Entrants

4.1.2 Bargaining Power Of Buyers

4.1.3 Threat Of Substitutes

4.1.4 Segment Rivalry

4.2 Value Chain/Supply Chain Of Global Methacrylate Monomers Market

5 Industry Overview Of Global Methacrylate Monomers Market

5.1 Introduction

5.2 Growth Drivers

5.3 Impact Analysis

5.4 Market Challenges

5.5 Impact Analysis

Browse Full Report Here @

https://www.marketresearchfuture.com/reports/methacrylate-monomers-market-3245

Key Players: The Asia Pacific region methacrylate monomers market also provides an extensive range of manufacture including Japan and China based key players such as Mitsubishi Rayon Co. Ltd (Japan), Sumitomo Chemical Co., Ltd (Japan), Chi Mei Corporation (Taiwan), and others. Sumitomo Chemical Co., Ltd (Japan),

Segmentation The global methacrylate monomers market is majorly segmented on the basis of derivatives, application, end users and region. Based on derivatives of methacrylate monomers the market is segmented into behenyl methacrylate, tert-butyl methacrylate, cyclohexyl methacrylate, iso-decyl methacrylate, stearyl methacrylate, and others. Furthermore, based on application of methacrylate monomers the market is segmented into as coatings, paints, inks, elastomers, adhesives, and others. On the other hand, based on end user the market segmented into architectural, automotive¸ aerospace, marine, construction, and others, and based on region market is segmented into North America, Europe, APAC, Latin America, Middle East & Africa.

Request For Sample Report Here @

https://www.marketresearchfuture.com/sample_request/3245

About Market Research Future:

At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), & Consulting Services.

MRFR team have supreme objective to provide the optimum quality market research and intelligence services to our clients. Our market research studies by products, services, technologies, applications, end users, and market players for global, regional, and country level market segments, enable our clients to see more, know more, and do more, which help to answer all their most important questions.

In order to stay updated with technology and work process of the industry, MRFR often plans & conducts meet with the industry experts and industrial visits for its research analyst members.

Contact:

Market Research Future

Phone: +16468459312

Email: [email protected]

Read More Related Article:

https://www.marketresearchfuture.com/reports/printing-inks-market-5406

https://www.marketresearchfuture.com/reports/foam-blowing-agents-market-5487

https://www.marketresearchfuture.com/reports/self-healing-materials-market-5503

https://www.marketresearchfuture.com/reports/offshore-lubricants-market-5520

0 notes

Text

Methacrylate Monomers Market Size, Growth rate, Industry Challenges and Opportunities to 2027

This analysis of the Global Methacrylate Monomers Market aims to offer relevant and well-researched insights into the contemporary market scenario and the emergent growth dynamics. The report on Methacrylate Monomers Market also gives the market players and fresh contenders a holistic view of the global market landscape. The comprehensive study will help both established and emerging players formulate lucrative business strategies and realize their short-term and long-term goals. The Methacrylate Monomers industry has witnessed a stable growth rate in the past decade and is expected to continue on the same path in the forthcoming decades. Therefore, it is crucial to recognize all investment opportunities, potential market threats, restraining factors, challenges, market dynamics, and technological development to intensify footholds in the Methacrylate Monomers sector. This report has evaluated all the above mentioned aspects to present a detailed assessment to the reader to assist them in achieving the desired growth in their businesses.

This report covers the recent COVID-19 incidence and its impact on Methacrylate Monomers Market. The pandemic has widely affected the economic scenario. This study assesses the current landscape of the ever-evolving business sector and the present and future effects of COVID-19 on the market.

Request for FREE Sample Copy of This Research Report at: https://www.reportsanddata.com/sample-enquiry-form/1651

Key participants include Evonik Industries, The DOW Chemical Company, Mitsubishi Chemical, LG Chem, Sumitomo Chemical, BASF, Arkema, Nippon Shokubai, Eastman Chemical Company, Esstech, Estron Chemical, Fushun Anxin Chemical, Miwon Specialty Chemical, Kuraray, Gelest, Gantrade Corporation, Chi Mei Corporation, Asahi Kasei, Ted Pella, and Hitachi Chemical, among others.

To help gain the business owner further gain business intelligence the study on the Methacrylate Monomers market for the forecast period 2020 - 2027 brings to light data on production capability, consumption capacity, spending power, investment feasibility, and technology innovation. A thorough assessment of market performance across different regions is presented through self-explanatory graphic images, charts, and tables that add weight to corporate presentations and marketing materials. The study offers regional profiles of major vendors and extensive country-level break down to empower companies to make a wise investment decision when exploring new regions.

Application Outlook (Volume, Kilo Tons; and Revenue, USD Billion; 2016-2026)

Acrylic Sheets

Molding

Paints and Coatings

Additives

Adhesives

Others

Derivatives Outlook (Volume, Kilo Tons; and Revenue, USD Billion; 2016-2026)

Behenyl Methacrylate

Tert-Butyl Methacrylate

Cyclohexyl Methacrylate

Iso-Decyl Methacrylate

Stearyl Methacrylate

Others

Read Full Report Description at: https://www.reportsanddata.com/report-detail/methacrylate-monomers-market

Industry Vertical Outlook (Volume, Kilo Tons; and Revenue, USD Billion; 2016-2026)

Automotive

Architecture

Electronics

Advertisement & Communication

Building & Construction

Healthcare & Life Science

Aerospace

Marine

Others

Regional analysis: Based on geography, the market has been categorized into North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa.

Table of Contents:

Study Coverage: It includes key manufacturers covered, key market segments, the scope of products offered in the global Methacrylate Monomers market, duration considered, and objectives of the research. Additionally, it segments the market on the basis of product type and application.

Executive Summary: It offers a summary of other key studies, annual growth rate, competitive landscape, driving factors, market trends and issues, and macroscopic indicators.

Production by Region: Here, the report delivers information related to import and export, production, revenue, and key players of all regional markets inspected in the report.

Profile of Manufacturers: Each firm profiled in this segment is investigated by means of SWOT analysis, available products, global production, value, capacity, and other crucial factors.

Browse More Reports:-

Coated Fabric Market To Reach USD 32.55 Billion By 2026 | Reports And Data

Protein Hydrolysate Market To Reach USD 1013.2 Million By 2026 | Reports And Data

Highlights the following key factors:

1) Business description-Detailed description of a firm’s operations and business segments.

2) Corporate strategy – Analyst’s summarization of the company’s business strategy.

3) SWOT Analysis – A detailed analysis of the company’s strengths, weaknesses, opportunities, and challenges.

4) Company history – A company’s evolution, highlighting its key events through the years.

5) Major products and services – A list of flagship products, services, and brands of the company.

6) Key competitors – A list of key competitors of the company.

7) Important locations and subsidiaries – A list and contact details of key locations and subsidiaries of the company.

8) Detailed financial ratios for the past five years – The latest financial ratios derived from annual financial statements released by the company in the last five years.

The growth of this market across the globe is dependent on multiple factors; including consumer base of several Methacrylate Monomers products, inorganic growth models adopted by companies, price volatility of feedstocks, and product innovation, along with their economic prospects in both producer and consumer nations.

Overall, this report provides a clear view of every vital factor of the market without the need to refer to any other research reports or data sources. Our report will equip you with all the strategically vital facts about the past, present, and future of the market.

#Methacrylate Monomers Market#Methacrylate Monomers Market size#Methacrylate Monomers Market share#Methacrylate Monomers Market trends

0 notes

Text

Methyl Methacrylate Market Analysis: Trends and Growth Opportunities

Methyl Methacrylate: Properties, Uses and Potential Hazards Introduction Methyl methacrylate, commonly referred to as MMA, is an organic compound that is mainly used in the manufacturing of polymethyl methacrylate (PMMA), which is a transparent thermoplastic commonly known as acrylic glass. In this article, we will discuss the key properties of MMA, examine its widespread industrial applications as well as explore some potential hazards associated with its production and usage. Chemical and Physical Properties of Methyl Methacrylate MMA is a colorless volatile liquid that is slightly denser than water with a density of 0.94 g/cm3. Its molecular formula is C5H8O2 and it has a boiling point of 100.5°C. MMA has a characteristic irritating odor reminiscent of acrylic nails or glues. It is soluble in many organic solvents such as acetone, ethanol and ether but is non-soluble in water. MMA polymerizes readily, both through exposure to heat and when exposed to peroxides or other initiators at room temperature. The double bond in its structure makes it highly reactive. During polymerization, MMA molecules link up in long chains to form the plastic polymer known as PMMA. The properties of MMA include high reactivity, volatility, flammability and potential for explosion under certain conditions. Industrial Applications of Methyl Methacrylate Due to its ability to polymerize easily into strong, transparent plastics, MMA finds a wide array of industrial applications. Some key uses of MMA are: - Manufacture of PMMA sheets, also known by brand names such as Plexiglas and Acrylite. PMMA sheets formed have applications in signage, glazing, sanitary-ware and furnishing. - Production of PMMA casting/moulding resins used to manufacture various industrial and consumer products through mould casting techniques. Common products include bathroom fittings, automobile components, lenses and lighting equipment enclosures. - As a reactive monomer in the fabrication of polymethyl methacrylate concrete (PMMA concrete) which has advantages over traditional concrete such as transparency, UV resistance and superior tensile strength. - Used as a raw material for production of synthetic latexes that are employed as binders and modifiers in coatings, adhesives, sealants and more. - Enters as a monomer/intermediate in the chemical synthesis routes of numerous other industrially important polymers and resins.

0 notes