#Metalworking Fluid Market Trends

Explore tagged Tumblr posts

Text

Metalworking Fluids Market Dynamics, Growth Prospect and Consumption Analysis till 2030

The global metalworking fluids (MWFs) market, valued at USD 12.17 billion in 2023, is projected to grow at a compound annual growth rate (CAGR) of 4.9% from 2024 to 2030. This growth is expected to be fueled by rising demand for automotive and heavy industry machinery, as well as significant activity in sectors like machinery, metal fabrication, and transportation equipment. These industries are primary drivers of MWF demand, as they rely on these fluids for effective machining and metalworking processes. The production of MWFs involves crude oil as a fundamental raw material. Refined, processed, and blended from crude oil, the base oils in MWFs make up approximately 40% of the total cost of these fluids. Key products like neat cutting oils, soluble oils, and corrosion-preventive oils are developed from this crude oil refining and heating process, which is essential for producing motor oils, lubricants, and MWFs.

The MWF market benefits substantially from the growth of the automotive industry, where MWFs play a critical role in reducing friction between work pieces and tools, removing metal chips, ensuring high surface quality, and extending tool life. This ultimately increases the efficiency and productivity of machining processes, meeting high production demands. Consequently, the demand for MWFs is expected to remain steady as these industries expand.

In North America and Europe, manufacturing is a key sector, driving MWF demand due to advancements in manufacturing techniques for complex products and the high export rate of equipment for construction, power, agriculture, and automotive applications. The strong growth of end-use industries in Asia Pacific also contributes to MWF demand in North America and Europe, as more consumers in Asia Pacific increasingly opt for advanced machinery across sectors like automotive, agriculture, and construction.

Gather more insights about the market drivers, restrains and growth of the Metalworking Fluids Market

The global market is highly competitive, with the big international brands focusing on developing long-term relationships with end-users. With a rise in the manufacturing, automotive, and transportation sectors, the competition is also anticipated to increase in the coming years. Companies such as Houghton International Inc., BP plc, Exxon Mobil Corporation, and Total SA have a high degree of integration across the value chain as they are also engaged in producing various MWFs. These companies have established themselves as key manufacturers and focus on R&D for novel product uses.

The metalworking fluid market trend is being driven by increased demand for automotive and heavy industry, as well as the growing preference for lightweight components in high performance applications such as heavy machinery, transportation equipment, automotive and construction.

Product Segmentation Insights:

The mineral-based MWFs segment accounted for the largest market share in 2023, representing over 48.06% of total market revenue. Mineral oils are widely used due to their cost-effectiveness, making them popular among small- and medium-sized manufacturers who prioritize affordability. This trend is expected to support stable growth in mineral oil-based MWFs over the forecast period. Mineral oils find applications in various machining processes, including turning, grinding, broaching, drilling, and milling, due to their basic yet reliable performance characteristics.

On the other hand, synthetic MWFs are expected to experience the highest CAGR during the forecast period. These synthetic fluids offer several advantages, such as extending tool life, improving surface finishes, and minimizing friction, making them highly suitable for precision applications. Synthetic oils also provide benefits like reducing waste and extending sump life, which is critical in large-scale manufacturing. As a result, synthetic MWFs have seen a steady increase in adoption, particularly among large-scale manufacturers, and this growth is projected to continue as demand rises for higher-performance fluids.

In recent years, semi-synthetic MWFs have gained traction in many countries, contributing to the overall penetration of synthetic MWFs. Additionally, the growing concerns over environmental impacts associated with petroleum-based products have led to stringent environmental regulations and government initiatives promoting sustainable alternatives. Consequently, the production of bio-based MWFs has surged, offering a more environmentally friendly option that meets regulatory requirements and aligns with the industry's push toward sustainability.

Order a free sample PDF of the Metalworking Fluids Market Intelligence Study, published by Grand View Research.

#Metalworking Fluids Market Share#Metalworking Fluids Market Trends#Metalworking Fluids Market Growth#Metalworking Fluids Industry

0 notes

Text

Metalworking Fluids Market Analysis by Key Players, Sales Forecast and Supply Demand to 2030

The global metalworking fluids (MWFs) market, valued at USD 12.17 billion in 2023, is projected to grow at a compound annual growth rate (CAGR) of 4.9% from 2024 to 2030. This growth is expected to be fueled by rising demand for automotive and heavy industry machinery, as well as significant activity in sectors like machinery, metal fabrication, and transportation equipment. These industries are primary drivers of MWF demand, as they rely on these fluids for effective machining and metalworking processes. The production of MWFs involves crude oil as a fundamental raw material. Refined, processed, and blended from crude oil, the base oils in MWFs make up approximately 40% of the total cost of these fluids. Key products like neat cutting oils, soluble oils, and corrosion-preventive oils are developed from this crude oil refining and heating process, which is essential for producing motor oils, lubricants, and MWFs.

The MWF market benefits substantially from the growth of the automotive industry, where MWFs play a critical role in reducing friction between work pieces and tools, removing metal chips, ensuring high surface quality, and extending tool life. This ultimately increases the efficiency and productivity of machining processes, meeting high production demands. Consequently, the demand for MWFs is expected to remain steady as these industries expand.

In North America and Europe, manufacturing is a key sector, driving MWF demand due to advancements in manufacturing techniques for complex products and the high export rate of equipment for construction, power, agriculture, and automotive applications. The strong growth of end-use industries in Asia Pacific also contributes to MWF demand in North America and Europe, as more consumers in Asia Pacific increasingly opt for advanced machinery across sectors like automotive, agriculture, and construction.

Gather more insights about the market drivers, restrains and growth of the Metalworking Fluids Market

The global market is highly competitive, with the big international brands focusing on developing long-term relationships with end-users. With a rise in the manufacturing, automotive, and transportation sectors, the competition is also anticipated to increase in the coming years. Companies such as Houghton International Inc., BP plc, Exxon Mobil Corporation, and Total SA have a high degree of integration across the value chain as they are also engaged in producing various MWFs. These companies have established themselves as key manufacturers and focus on R&D for novel product uses.

The metalworking fluid market trend is being driven by increased demand for automotive and heavy industry, as well as the growing preference for lightweight components in high performance applications such as heavy machinery, transportation equipment, automotive and construction.

Product Segmentation Insights:

The mineral-based MWFs segment accounted for the largest market share in 2023, representing over 48.06% of total market revenue. Mineral oils are widely used due to their cost-effectiveness, making them popular among small- and medium-sized manufacturers who prioritize affordability. This trend is expected to support stable growth in mineral oil-based MWFs over the forecast period. Mineral oils find applications in various machining processes, including turning, grinding, broaching, drilling, and milling, due to their basic yet reliable performance characteristics.

On the other hand, synthetic MWFs are expected to experience the highest CAGR during the forecast period. These synthetic fluids offer several advantages, such as extending tool life, improving surface finishes, and minimizing friction, making them highly suitable for precision applications. Synthetic oils also provide benefits like reducing waste and extending sump life, which is critical in large-scale manufacturing. As a result, synthetic MWFs have seen a steady increase in adoption, particularly among large-scale manufacturers, and this growth is projected to continue as demand rises for higher-performance fluids.

In recent years, semi-synthetic MWFs have gained traction in many countries, contributing to the overall penetration of synthetic MWFs. Additionally, the growing concerns over environmental impacts associated with petroleum-based products have led to stringent environmental regulations and government initiatives promoting sustainable alternatives. Consequently, the production of bio-based MWFs has surged, offering a more environmentally friendly option that meets regulatory requirements and aligns with the industry's push toward sustainability.

Order a free sample PDF of the Metalworking Fluids Market Intelligence Study, published by Grand View Research.

#Metalworking Fluids Market Share#Metalworking Fluids Market Trends#Metalworking Fluids Market Growth#Metalworking Fluids Industry

0 notes

Text

Metalworking Fluids Market Dynamics, Technological Advancements, Environmental Impact and Effective Growth Strategies

The global metalworking fluids (MWFs) market is an essential component of the industrial manufacturing landscape. Metalworking fluids are used in machining processes to lubricate, cool, and protect both tools and workpieces, enhancing precision, extending tool life, and improving productivity. This market is highly dynamic, shaped by various economic, environmental, and technological factors. Understanding these dynamics and the strategies companies employ to navigate this landscape is critical for industry players seeking to stay competitive. This article delves into the key market dynamics and strategies driving the metalworking fluids market.

Key Market Dynamics

Rising Demand from End-Use Industries

The demand for metalworking fluids is closely tied to the growth of industries such as automotive, aerospace, machinery, and heavy equipment manufacturing. The automotive industry, in particular, is a major consumer of MWFs, as they are essential in precision machining processes used in manufacturing components like engines, transmissions, and chassis. As global vehicle production continues to rise, especially in emerging economies, demand for metalworking fluids will likely follow.

Additionally, the aerospace sector's increased focus on high-precision machining and high-performance materials like titanium and carbon composites is boosting demand for advanced metalworking fluids capable of supporting such challenging operations.

Technological Advancements

The metalworking industry is evolving with new technological advancements such as automation, CNC machines, and artificial intelligence-driven processes. These innovations require highly specialized MWFs that can withstand the demands of faster, more precise machining. The growing trend toward Industry 4.0 also influences the metalworking fluids market by pushing the need for smart fluids that enhance operational efficiency, optimize resource consumption, and improve overall process control.

Environmental Regulations

Environmental regulations play a significant role in shaping the metalworking fluids market. Government bodies, especially in Europe and North America, have imposed stringent regulations on the chemical composition and disposal of MWFs to reduce their environmental impact. For example, the European Union’s REACH regulations and the U.S. Environmental Protection Agency's (EPA) regulations on volatile organic compounds (VOCs) limit the use of certain hazardous chemicals.

These regulations are pushing manufacturers to develop biodegradable and environmentally friendly metalworking fluids, leading to a shift in market preferences toward products with reduced toxicity and improved sustainability.

Volatile Raw Material Prices

The metalworking fluids market is also influenced by fluctuations in the prices of raw materials such as base oils and additives. These materials are often derived from petroleum products, which are subject to price volatility based on global oil supply and demand, geopolitical tensions, and economic shifts. Rising raw material costs can directly impact the profitability of MWF manufacturers, forcing them to adjust prices or explore alternative materials.

Growing Focus on Sustainable Solutions

Sustainability has become a driving force across industries, including the metalworking fluids market. Companies are increasingly focused on reducing their carbon footprint by using eco-friendly MWFs, improving recycling practices, and minimizing waste generation. There is also a rising trend toward water-based MWFs as they are considered less harmful to the environment compared to traditional oil-based fluids.

The adoption of sustainable fluids can provide a competitive advantage, as companies and end-users seek to comply with regulatory requirements while meeting the growing demand for greener manufacturing processes.

Request Sample PDF for Metalworking Fluids Market Report

(The sample serves as a general overview and contents of the final report, without actual data. Accessing the facts and figures of the complete report will incur a cost.)

Key Market Strategies

Product Innovation and Differentiation

One of the most effective strategies in the metalworking fluids market is product innovation. Leading manufacturers are investing heavily in research and development (R&D) to create high-performance fluids that offer better lubrication, cooling, and corrosion protection while meeting the latest environmental standards. For example, the development of synthetic and semi-synthetic fluids has provided solutions with enhanced thermal stability, longer fluid life, and reduced microbial contamination.

Differentiation through specialized formulations, such as fluids tailored for specific machining applications (e.g., grinding, drilling, or turning), can also set a company apart from competitors.

Strategic Partnerships and Collaborations

Forming strategic partnerships with end-users, machine tool manufacturers, and other stakeholders in the metalworking value chain is another key strategy. Collaborations can lead to the co-development of fluids optimized for specific machines or processes, ensuring better performance and customer satisfaction. Such partnerships also facilitate knowledge sharing and allow companies to stay abreast of the latest trends and technological advancements in the industry.

Geographical Expansion

Expanding into emerging markets is a key growth strategy for metalworking fluids manufacturers. Asia-Pacific, in particular, represents a significant growth opportunity due to its rapidly expanding automotive, manufacturing, and construction sectors. Countries like China, India, and Vietnam are seeing increasing industrial activities, which is driving demand for metalworking fluids.

Companies are also focusing on establishing manufacturing facilities and distribution networks in these regions to cater to local demand more efficiently and reduce transportation costs.

Emphasis on Sustainability

Sustainability is not just a regulatory requirement but a strategic advantage. Companies are positioning themselves as leaders in environmental stewardship by promoting their eco-friendly products and sustainable manufacturing practices. Investing in the development of biodegradable and non-toxic MWFs can help companies tap into a growing segment of environmentally conscious consumers.

In addition to product innovation, manufacturers are improving the lifecycle management of their fluids, offering recycling programs or fluid maintenance services to minimize waste and environmental impact.

Cost Optimization

As raw material prices fluctuate, cost optimization becomes critical for manufacturers to maintain profitability. Companies are adopting strategies such as backward integration to secure raw material supply and reduce dependency on volatile markets. In addition, optimizing production processes and improving efficiency can help reduce overall costs, allowing companies to remain competitive while preserving margins.

#Metalworking Fluids Market#Metalworking Fluids Market szie#Metalworking Fluids Market share#Metalworking Fluids Market trends

1 note

·

View note

Text

#metalworking fluids market#metalworking fluids market trends#metalworking fluids market future#metalworking fluids market companies#metalworking fluids

0 notes

Text

Metalworking Fluids Market Analysis 2024 Fluctuating Business Scenario with CAGR Forecast by 2030

The Metalworking Fluids Market Research Report 2024 begins with an overview of the market and offers throughout development. It presents a comprehensive analysis of all the regional and major player segments that gives closer insights upon present market conditions and future market opportunities along with drivers, trending segments, consumer behaviour, pricing factors and market performance and estimation and prices as well as global predominant vendor’s information. The forecast market information, SWOT analysis, Metalworking Fluids Market scenario, and feasibility study are the vital aspects analyzed in this report.

The global metalworking fluids market is expected to grow at 4.2% CAGR from 2024 to 2030. It is expected to reach above USD 14.3 billion by 2030 from USD 8.65 billion in 2023.

Access Full Report:

https://exactitudeconsultancy.com/reports/3219/metalworking-fluids-market/

#Metalworking Fluids Market Size#Metalworking Fluids Market Share#Metalworking Fluids Market Report#Metalworking Fluids Market 2024-2030#Metalworking Fluids Market Forecast#Metalworking Fluids Market opportunity#Metalworking Fluids Market Scope#Metalworking Fluids Market Trends#Metalworking Fluids Market 2024#Metalworking Fluids Market 2030#Metalworking Fluids Market Analysis#Metalworking Fluids Market Technology#Metalworking Fluids Market Business#Metalworking Fluids Market South Korea#US Metalworking Fluids Market#French Metalworking Fluids Market#China Metalworking Fluids Market#Italy Metalworking Fluids Market#Europe Metalworking Fluids Market#Metalworking Fluids Market Outlook#Metalworking Fluids Market Research

0 notes

Text

#Metalworking Fluids Market#Metalworking Fluids Market Trends#Metalworking Fluids Market Growth#Metalworking Fluids Market Industry#Metalworking Fluids Market Research#Metalworking Fluids Market Report

0 notes

Text

Metalworking Fluids Market Size, Share, Trends And Forecast 2030

The global metalworking fluids market size is expected to reach USD 15.1 million by 2030, as per the new report by Grand View Research, Inc., registering a CAGR of 3.8% in the forecast period. The demand is attributed to arise in demand for automotive and industrial machinery. Individual end-use sectors, such as machinery, metal fabrication, and transportation equipment, are driving the expansion of the market.

The market is also expected to be driven by strong development in the machinery and transportation equipment end-use industries over the projected period. Manufacturing is one of the core industries in North America and Europe. Advances in the manufacturing methods for the production of sophisticated end-use products, coupled with the increase in the exports of construction machinery and power, agricultural, and automotive equipment, have fueled the market growth.

The sector is expected to benefit from increased production of construction machines and related parts for industrial, residential, and commercial construction. The rise in public-private partnerships is expected to boost the demand for a variety of construction components that use MWFs during their production. Because of the expanding building activities in these nations, emerging economies are likely to be critical for product growth.

The increasing demand for electricity and upgrading of the existing infrastructure for electricity generation, transmission, and distribution, is anticipated to fuel the market for electrical & power equipment and related components. These components are manufactured using ferrous and non-ferrous metal parts, which consume MWFs during manufacturing.

Request a free sample copy or view report summary: https://www.grandviewresearch.com/industry-analysis/metalworking-fluids-market

Metalworking Fluids Market Report Highlights

Mineral-based MWFs accounted for a revenue share of 48.1% in 2021 due to the increased consumption owing to their low cost

Water cutting oils application is anticipated to grow at the fastest CAGR over the forecast period due to product usage in operations, such as drilling, milling grinding, and mainly in heat dissipation for the proper machining process

The machinery segment dominated the market in 2021 due to the high demand for construction equipment and increased infrastructural development activities

The automobile industry is anticipated to witness a significant CAGR over the forecast period due to the high demand for automobile machinery

The growth of the construction and electrical & power equipment sectors in emerging economies is also expected to drive the product demand

Synthetic and mineral-based products aid in better tool performance, which has led to their high demand

Metalworking Fluids Market Segmentation

Grand View Research has segmented the metalworking fluids market report on the basis of product, application, end-use, industrial end-use, and region:

MWFs Product Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Mineral

Synthetic

Bio-based

MWFs Application Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Neat Cutting Oils

Water Cutting Oils

Corrosion Preventive Oils

Others

MWFs End-use Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Metal Fabrication

Transportation Equipment

Machinery

Others

MWFs Industrial End-use Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Construction

Electrical & Power

Agriculture

Automobile

Aerospace

Rail

Marine

Telecommunication

Healthcare

MWFs Regional Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

North America

U.S.

Canada

Mexico

Europe

Germany

Russia

France

Spain

Italy

U.K.

Switzerland

Denmark

Norway

Belgium

Poland

Czech Republic

Turkey

Sweden

Finland

Asia Pacific

China

India

Japan

South Korea

Singapore

Malaysia

Thailand

Australia

New Zealand

Central & South America

Brazil

Middle East & Africa

List of Key Players in Metalworking Fluids Market

Houghton International, Inc.

Blaser Swisslube AG

BP plc

Exxon Mobil Corp.

Total S.A.

FUCHS

Chevron Corp.

China Petroleum & Chemical Corp.

Kuwait Petroleum Corp.

Browse Full Report: https://www.grandviewresearch.com/industry-analysis/metalworking-fluids-market

#Metalworking Fluids Market#Metalworking Fluids Market Size#Metalworking Fluids Market Trends#Metalworking Fluids Market Forecast

0 notes

Text

#Metalworking Fluids Market#Metalworking Fluids Market Trends#Metalworking Fluids Market Growth#Metalworking Fluids Market Industry#Metalworking Fluids Market Research#Metalworking Fluids Market Report

0 notes

Text

The metalworking fluids market is expected to witness market growth at a rate of 16.80% in the forecast period of 2021 to 2028 and is expected to reach USD 14.50 billion by 2028. Data Bridge Market Research report on metalworking fluids market provides analysis and insights regarding the various factors expected to be prevalent throughout the forecast period while providing their impacts on the market’s growth. The increasing exploration and production activities of oil and gas are escalating the growth of metalworking fluids market.

#Metalworking Fluids Market#Metalworking Fluids Market Share#Metalworking Fluids Market Size#Metalworking Fluids Market Growth#Metalworking Fluids Market Trends#Metalworking Fluids Market Players#Metalworking Fluids Market Competitors#Metalworking Fluids Industry Size#Metalworking Fluids Industry Trends#Metalworking Fluids Industry Growth#Metalworking Fluids Industry Share#Metalworking Fluids Industry Players

0 notes

Text

Triethanolamine Prices, News, Trend, Graph, Chart, Monitor and Forecast

Triethanolamine (TEA) is a versatile chemical compound widely used in industries such as cosmetics, textiles, pharmaceuticals, and metalworking fluids. The pricing dynamics of triethanolamine are influenced by various factors, including raw material costs, supply-demand fluctuations, geopolitical influences, and regulatory changes. As the global economy continues to evolve, understanding the price trends of triethanolamine is crucial for businesses and stakeholders involved in its production and consumption.

The price of triethanolamine is largely dictated by the cost of its primary raw materials, ethylene oxide and ammonia. Ethylene oxide, a crucial precursor in TEA production, is subject to market volatility driven by crude oil prices, production constraints, and shifts in demand across different sectors. Any fluctuation in ethylene oxide pricing directly impacts triethanolamine production costs, leading to variations in market prices. Additionally, ammonia, another essential feedstock, is influenced by natural gas prices and seasonal demand shifts in the agricultural sector. When the costs of these raw materials rise, TEA manufacturers often pass on the increased expenses to buyers, thereby raising market prices.

Get Real time Prices for Triethanolamine: https://www.chemanalyst.com/Pricing-data/triethanolamine-1208

Supply and demand play a significant role in determining triethanolamine prices. The chemical industry experiences cyclical variations, with periods of high demand leading to price surges and phases of oversupply causing price declines. The growing applications of TEA in the cosmetics and personal care industry have been a major driver of demand, particularly in regions like North America, Europe, and Asia-Pacific. With consumers increasingly favoring high-quality personal care products, the demand for triethanolamine-based formulations continues to grow, sustaining upward pressure on prices. Similarly, the pharmaceutical sector's expansion, driven by rising healthcare needs, has contributed to TEA demand, further influencing pricing trends. On the supply side, production capacities of major manufacturers, plant shutdowns for maintenance, and disruptions in raw material availability significantly impact the market. Any unplanned outages or regulatory restrictions can lead to supply shortages, subsequently driving prices higher.

Geopolitical factors also exert considerable influence on triethanolamine pricing. Trade restrictions, tariffs, and geopolitical tensions among major chemical-producing nations affect the global supply chain, leading to price volatility. The imposition of tariffs on raw materials or finished products can increase production costs, compelling manufacturers to adjust their pricing strategies. Additionally, disruptions in global trade routes, such as port congestion and transportation challenges, can create supply chain bottlenecks, further influencing price movements. Economic conditions, including inflation rates and currency fluctuations, also play a role in determining the affordability and competitiveness of TEA in different markets.

The regulatory landscape surrounding triethanolamine usage and production significantly impacts its market prices. Governments worldwide have implemented stringent regulations regarding chemical safety, environmental impact, and occupational health standards. Compliance with these regulations often requires manufacturers to invest in advanced production technologies and sustainable practices, adding to operational costs. The shift toward greener and more eco-friendly chemicals has led to increased research and development efforts in alternative formulations, potentially impacting the long-term price trends of triethanolamine. Additionally, changes in classification standards by regulatory bodies such as the European Chemicals Agency (ECHA) and the U.S. Environmental Protection Agency (EPA) can influence the overall market outlook.

Regional variations in triethanolamine pricing are evident due to differences in production capacities, consumption patterns, and economic conditions. Asia-Pacific, being a major hub for chemical manufacturing, typically experiences lower production costs due to economies of scale and readily available raw materials. Countries like China and India play a dominant role in TEA production and export, often setting the tone for global price trends. In contrast, North America and Europe, where environmental regulations and labor costs are higher, tend to have relatively elevated prices for triethanolamine. Additionally, regional demand variations, such as higher consumption in personal care products in Europe or increased usage in the construction sector in the United States, contribute to localized pricing trends.

The impact of sustainability initiatives and technological advancements on triethanolamine pricing is becoming more pronounced. With growing concerns over environmental sustainability, many manufacturers are exploring bio-based alternatives and greener production methods for TEA. While these initiatives align with global sustainability goals, they also involve significant research and development investments, which may affect market prices in the short term. Furthermore, advancements in production efficiency, improved catalysts, and process optimization techniques are helping manufacturers achieve cost reductions, potentially stabilizing prices in the long run.

The future outlook for triethanolamine prices remains subject to multiple influencing factors, including market demand, regulatory changes, and raw material cost fluctuations. The continued expansion of end-user industries, particularly cosmetics, pharmaceuticals, and industrial applications, is expected to sustain demand growth. However, uncertainties in the global economy, supply chain disruptions, and evolving regulatory frameworks could contribute to price volatility. Businesses operating in the triethanolamine market must closely monitor these factors to make informed purchasing and production decisions.

Strategic sourcing and supply chain management have become critical for companies relying on triethanolamine. To mitigate price risks, businesses are increasingly diversifying their supplier base, securing long-term contracts, and exploring alternative raw materials. Additionally, leveraging digital technologies and data analytics to forecast price trends and optimize procurement strategies can provide a competitive edge in the market. By staying informed about market developments, businesses can navigate price fluctuations effectively and maintain cost efficiency in their operations.

Triethanolamine's price trends are shaped by a combination of supply-demand dynamics, raw material costs, geopolitical influences, and regulatory factors. As industries continue to evolve, understanding these pricing determinants is essential for stakeholders seeking to optimize their procurement and production strategies. With sustainability, technological advancements, and global economic conditions playing an increasing role in shaping the market, businesses must adapt to changing circumstances to remain competitive. By closely monitoring market trends and adopting strategic approaches, companies can effectively manage price fluctuations and ensure long-term sustainability in their operations.

Get Real time Prices for Triethanolamine: https://www.chemanalyst.com/Pricing-data/triethanolamine-1208

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Triethanolamine#Triethanolamine Price#Triethanolamine Prices#Triethanolamine Pricing#India#united kingdom#united states#Germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

0 notes

Link

0 notes

Text

Industrial Lubricants Market Report by Type, and Global Opportunity Analysis and Industry Forecast, 2024-2034

Industrial lubricants are essential for the smooth functioning of machinery and equipment across various industries. These lubricants help in reducing friction, wear and tear, and overheating, thereby extending the lifespan of equipment. The market for industrial lubricants has been growing steadily, driven by the increasing demand for efficiency and sustainability in industrial operations.

The industrial lubricants market is anticipated to increase at a compound annual growth rate (CAGR) of 3.8% from 2024 to 2033, reaching a value of USD 75.68 billion by that time. In 2023, the market is anticipated to be worth USD 55.34 billion.

Get a Sample Copy of Report, Click Here@ https://wemarketresearch.com/reports/request-free-sample-pdf/industrial-lubricants-market/1356

Industrial Lubricants Market Drivers

Increasing Industrialization: Growing industries in emerging economies are boosting the demand for high-performance lubricants.

Focus on Efficiency: Industries are increasingly adopting lubricants that enhance machine efficiency and reduce operational costs.

Technological Advancements: Innovations in synthetic and bio-based lubricants are creating new opportunities in the market.

Sustainability Trends: Rising awareness and regulations are pushing for eco-friendly and biodegradable lubricants.

Industrial Lubricants Market Challenges

Volatility in Raw Material Prices: Fluctuations in the prices of crude oil, the primary raw material for synthetic lubricants, pose a challenge.

Environmental Regulations: Strict guidelines for emissions and waste management require significant investment in R&D.

Competition from Alternatives: Emerging alternatives such as solid and dry lubricants may impact the market.

Industrial Lubricants Market Opportunities

Bio-Based Lubricants: Increasing demand for sustainable and biodegradable products is creating growth opportunities.

IoT and Smart Lubricants: Development of intelligent lubrication systems integrated with IoT is gaining traction.

Expansion in Emerging Economies: Untapped markets in developing regions offer potential for growth.

Industrial Lubricants Market Trends

Adoption of Synthetic Lubricants: Higher performance and longer life are driving the preference for synthetic options.

Digitalization in Maintenance: Predictive maintenance supported by data analytics is influencing lubricant requirements.

Rising Awareness of Bio-Lubricants: An increasing push for green industrial solutions is shaping product development.

Top companies in the Industrial Lubricants Market are,

Exxonmobil Corp; Fuchs Group; The Lubrizol Corporation; Royal Dutch Shell; Phillips 66; Lucas Oil Products, Inc.; Amsoil, Inc.; Bel-Ray Co., Inc.; Total S.A.; Kluber Lubrication; Valvoline International, Inc.; Chevron Corp.; Clariant; Quaker Chemical Corp.; Houghton International, Inc.; Castrol; Blaser Swisslube, Inc.; Calumet Specialty Products Partners, L.P.; Petronas Lubricant International; Idemitsu Kosan Co., Ltd.; Yushiro Chemical Industry Co., Ltd.

Market Segments

By Type

Mineral oils

Synthetic oils

Bio-based oils

By Application

Manufacturing

Transportation

Energy

Mining and construction

Food and beverage

Pharmaceutical

Others

By Product

General industrial oils

Process oils

Metalworking fluids

Industrial engine oils

Industrial greases

Regional Analysis of the Industrial Lubricants Market

Asia-Pacific: The largest and fastest-growing region due to rapid industrialization in countries like China and India.

North America: A mature market driven by technological advancements in manufacturing.

Europe: Growth driven by stringent regulations and the adoption of sustainable lubricants.

Latin America and Middle East & Africa: Moderate growth due to emerging industrialization.

Conclusion

The industrial lubricants market is on a steady growth trajectory, driven by the rising demand for efficient, high-performance, and sustainable solutions across diverse industries. Innovations in synthetic and bio-based lubricants, coupled with the push for eco-friendly practices, are reshaping the market landscape. Despite challenges such as fluctuating raw material prices and stringent environmental regulations, the sector continues to thrive, especially in emerging economies with rapid industrialization. Companies that prioritize sustainability, technological advancements, and strategic market expansion are well-positioned to capitalize on the evolving opportunities in this dynamic market.

0 notes

Text

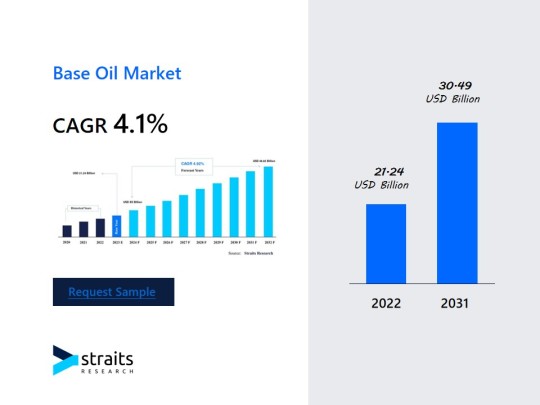

Base Oil Market Key Insights: Global Trends and Growth Forecasts by 2031

The global base oil market was valued at USD 21.24 billion in 2022. It is projected to grow from USD 22.76 billion in 2023 to USD 48.82 billion by 2031, registering a compound annual growth rate (CAGR) of 4.92% during the forecast period (2023–2031).

Overview of the Base Oil Market

The global base oil market is on a robust growth trajectory, driven by increasing demand for high-performance lubricants across various industries. Base oils, the primary ingredients in lubricants, play a crucial role in the formulation of oils used for automotive, industrial, and metalworking applications. As industrial activity ramps up worldwide and the automotive sector continues its evolution, base oils are expected to experience heightened demand in the coming years.

In 2022, the base oil market was valued at USD 21.24 billion and is forecasted to expand to USD 48.82 billion by 2031, growing at a CAGR of 4.92%. This growth is attributed to the increasing industrialization in emerging markets, rising demand for advanced lubricants, and a greater focus on energy-efficient solutions.

Market Definition

Base oils are refined from crude oil and used as the foundation for creating lubricants, oils, and other products, such as hydraulic fluids, metalworking fluids, and automotive oils. The classification of base oils is determined by their performance properties, with each type offering specific benefits based on application requirements. As key raw materials for a range of applications, base oils are essential to maintaining the smooth operation of machinery and vehicles.

Get a Full PDF Sample Copy of the Report @ https://straitsresearch.com/report/base-oil-market/request-sample

Market Dynamics: Key Trends, Drivers, and Opportunities

Key Trends:

Growing Adoption of Synthetic and High-Performance Oils: There is an increasing shift toward synthetic and high-performance base oils, particularly Group III and Group IV oils, which offer better oxidation stability, improved low-temperature performance, and longer-lasting protection for engines and industrial machinery. This trend is expected to accelerate as consumers and industries alike seek more efficient and durable oils.

Integration of Green and Sustainable Technologies: As environmental concerns continue to rise, there is a growing emphasis on the development of eco-friendly and sustainable base oils. The industry is witnessing innovations in bio-based oils and processes that use renewable feedstocks, reducing the overall carbon footprint of oil production and usage. This shift aligns with global sustainability goals and is likely to enhance market prospects.

Key Market Drivers:

Industrial Growth and Expansion in Emerging Markets: The expansion of industrial activities in emerging markets, particularly in Asia-Pacific, is one of the primary drivers for the base oil market. Rapid infrastructure development, increased manufacturing capacity, and growing demand for automotive lubricants are propelling the need for high-quality base oils. As industrial production ramps up, base oils will continue to be in high demand for applications ranging from hydraulic oils to industrial lubricants.

Technological Advancements in Lubricants and Oils: Advancements in lubricant technology, especially the demand for more energy-efficient and high-performance oils in automotive and industrial applications, are significantly driving the base oil market. Group II and Group III base oils, known for their superior properties, are gaining popularity due to their enhanced performance in high-temperature environments and longer service life.

Key Market Opportunities:

Expanding Automotive Sector and Electric Vehicle Production: As the automotive sector continues to grow, especially in emerging economies, the demand for lubricants is increasing. Additionally, the rise of electric vehicles (EVs) presents a unique opportunity for the base oil market. Even though electric vehicles require fewer oils and lubricants, the growing market for hybrid and electric vehicles will necessitate a shift toward specialized lubricants, creating new opportunities for base oil manufacturers.

Rising Demand for Metalworking Fluids and Hydraulic Oils: Base oils used in metalworking fluids, industrial oils, and hydraulic fluids represent a significant opportunity for market growth. As industries such as construction, mining, and manufacturing expand, the demand for high-performance industrial oils and lubricants is rising, offering strong growth prospects for the base oil market.

Market Segmentation

The base oil market is segmented based on type, application, and end-user industry. This segmentation helps understand the market's diverse needs and the opportunities available across various sectors.

By Type:

Group I

Group II

Group III

Group IV

Group V

By Application:

Hydraulic Oil

Automotive Fluid

Metalworking Fluids

Industrial Oil

Other

By End-User:

Industry

Construction

Automobile

Agriculture

Marine

Other

For more detailed segmentation and insights, visit: https://straitsresearch.com/report/base-oil-market/segmentation

Key Players in the Base Oil Market

The base oil market is highly competitive, with several global players leading the way in product innovation, capacity expansion, and market consolidation. The key players in the market include:

Royal Dutch Shell PLC

Exxon Mobil Corporation

H&R Ölwerke Schindler GmbH

Chevron Corporation

BP plc

Saudi Arabian Oil Co.

Petronas Pvt. Ltd.

Evonik Industries AG

Ergon Inc.

Nynas AB

Total S.A.

SK Lubricants Co. Ltd

S-Oil Corporation

Sinopec Group

Repsol S.A.

PetroChina Company Limited

Neste Oil

MOGoil GmbH

Lotos Oil SP. Z O.O.

GS Caltex Corporation

Calumet Specialty Products Partners Lp

Avista Oil AG

These companies are focusing on expanding their production capabilities, enhancing product quality, and exploring new geographic markets to tap into the growing demand for high-performance base oils.

Regional Analysis

Dominated Region: The Asia-Pacific region is the largest market for base oils, driven by the rapid industrialization in countries like China, India, and Japan. The region's booming automotive and manufacturing sectors, along with increasing infrastructure projects, are fueling the demand for base oils in various applications, such as automotive lubricants, industrial oils, and hydraulic fluids.

Fastest Growing Region: North America is expected to be the fastest-growing region for the base oil market. The U.S. and Canada are focusing on sustainable technologies and improving automotive and industrial production. Additionally, the rising demand for high-performance lubricants and oils is driving market growth in this region.

Conclusion

The base oil market is poised for significant growth, driven by industrial expansion, technological advancements, and the increasing need for high-performance lubricants. With a projected CAGR of 4.92%, the market is set to reach USD 48.82 billion by 2031. As demand grows across various industries, particularly in emerging markets, base oil manufacturers are well-positioned to capitalize on the opportunities in the automotive, industrial, and metalworking sectors.

For more information or to customize the report before purchasing, visit: https://straitsresearch.com/buy-now/base-oil-market

About Us:

StraitsResearch.com is a leading market research and market intelligence organization, specializing in research, analytics, and advisory services along with providing business insights & market research reports.

Contact Us:

Email: [email protected] Tel: +1 646 905 0080 (U.S.), +44 203 695 0070 (U.K.) Website: https://straitsresearch.com/

0 notes

Text

Lubricant Additives Market Growth, Drivers, Trends & Forecast 2024-2031

The global lubricant additives market is poised for significant growth, driven by the rising demand for high-performance lubricants across automotive, industrial, and marine sectors. According to SkyQuest Technology, the market is projected to reach a valuation of USD 24.1 billion by 2031, expanding at a CAGR of 4.3% from 2024 to 2031. Lubricant additives play a crucial role in enhancing the performance, durability, and efficiency of lubricants, making them indispensable across multiple industries.

Market Drivers: What’s Fueling the Growth?

The demand for lubricant additives is primarily driven by several key factors:

Rising Automotive Production and Sales The expanding automotive industry, especially in emerging markets, is a major growth driver. Additives such as dispersants, detergents, and viscosity modifiers improve engine performance and fuel efficiency, meeting modern vehicle requirements.

Stringent Environmental Regulations Increasing government regulations aimed at reducing emissions and improving fuel economy are pushing manufacturers to develop eco-friendly additives. Low-sulfur and high-performance additives are gaining traction.

Growth in Industrial Machinery Rapid industrialization and the increasing adoption of advanced machinery across sectors like manufacturing, construction, and energy have elevated the demand for high-quality lubricants with specialized additives.

Advancements in Additive Technologies Continuous R&D efforts have led to the development of innovative additives that enhance lubricant properties, such as anti-wear, anti-corrosion, and oxidation stability.

Request a Sample Report - https://www.skyquestt.com/sample-request/lubricant-additives-market

Market Segmentation: Key Categories

The lubricant additives market is segmented based on type, application, and end-use:

By Type

Dispersants: Prevent sludge formation by keeping contaminants in suspension.

Viscosity Index Improvers: Enhance the lubricant's viscosity stability under varying temperatures.

Detergents: Eliminate deposits and maintain engine cleanliness.

Anti-Wear Agents: Protect surfaces from frictional damage.

Others: Including antioxidants, rust inhibitors, and friction modifiers.

By Application

Engine Oils: The largest segment, essential for vehicles and machinery.

Gear Oils: Used in transmission systems for smooth operation.

Hydraulic Fluids: Widely utilized in industrial and mobile equipment.

Metalworking Fluids: Growing demand from manufacturing industries.

By End-Use Industry

Automotive: Leading the market due to growing vehicle fleets.

Industrial: Driven by the need for efficient machinery lubrication.

Marine and Aviation: Growing focus on enhancing equipment longevity.

Speak to an Analyst - https://www.skyquestt.com/speak-with-analyst/lubricant-additives-market

Regional Insights: Market Trends Across the Globe

North America North America leads the market due to strong demand for advanced lubricants in automotive and industrial applications. The U.S., in particular, is witnessing robust growth due to its large industrial base and stringent environmental policies.

Europe Europe remains a significant market, driven by automotive innovations and regulatory pressure to reduce carbon emissions. Countries like Germany and the UK are key contributors.

Asia-Pacific The Asia-Pacific region is the fastest-growing market, fueled by rapid urbanization, industrialization, and a growing automotive industry in China, India, and Japan. The rising demand for fuel-efficient vehicles further accelerates growth.

Rest of the World The Middle East, Latin America, and Africa are witnessing steady growth due to increasing industrial activities and infrastructure development projects.

Key Players in the Lubricant Additives Market

The lubricant additives market is competitive, with leading companies focusing on innovation, strategic partnerships, and sustainability:

Chevron Oronite Company LLC

The Lubrizol Corporation

BASF SE

Afton Chemical Corporation

Infineum International Limited

Evonik Industries AG

Croda International PLC

Lanxess AG

Dorf Ketal Chemicals

Chevron Corporation

Wuxi South Petroleum Additives Co., Ltd.

These players are developing advanced additive solutions that comply with environmental regulations while enhancing the efficiency and performance of lubricants.

Make a Purchase Inquiry - https://www.skyquestt.com/buy-now/lubricant-additives-market

Key Trends Shaping the Lubricant Additives Market

Focus on Bio-Based Lubricants The shift toward bio-based lubricants and additives is gaining momentum as industries prioritize sustainability and lower environmental impact.

Rising Adoption of High-Performance Lubricants With modern engines operating under extreme conditions, there is increasing demand for additives that enhance thermal stability and wear protection.

Technological Advancements Innovations in additive formulations, such as nanotechnology-based lubricants, are enhancing efficiency and extending lubricant lifespans.

Growing Use of Additives in Electric Vehicles (EVs) The rise of electric vehicles has opened new opportunities for additives designed to optimize cooling, lubrication, and system efficiency.

The Road Ahead for Lubricant Additives

The global lubricant additives market is on a steady growth trajectory, driven by advancements in automotive technology, stringent environmental regulations, and the rise of industrial activities. As the demand for fuel-efficient and eco-friendly solutions grows, market players are focusing on developing innovative, high-performance additives to meet evolving industry requirements.

With Asia-Pacific emerging as a hotspot for growth and bio-based solutions becoming a focal point, the lubricant additives market is set for transformative changes in the years to come.

#Lubricant Additives Market#Lubricant Additives Market Size#Lubricant Additives Market Share#Lubricant Additives Market Trends#Lubricant Additives Market Growth#Lubricant Additives Market Outlook#Lubricant Additives Market Key Players#Lubricant Additives Market Overview#Lubricant Additives Market Competitor#Lubricant Additives Market Insights#Lubricant Additives Market Forecast#Lubricant Additives Market Analysis#Lubricant Additives Market Statistics#Lubricant Additives Market Data#Lubricant Additives Market PDF#Lubricant Additives Market Excel#Lubricant Additives Market Strategy#Lubricant Additives Market Innovations

0 notes

Text

Exploring the Growing Industrial Lubricants Market: Trends and Innovations

The industrial lubricants market is a critical enabler of machinery efficiency across various sectors like manufacturing, construction, and mining. As industries evolve, the demand for high-performance lubricants to improve equipment lifespan, reduce maintenance costs, and enhance energy efficiency is surging.

Market Dynamics and Growth DriversThe industrial lubricants market is estimated to grow from USD 63.9 billion in 2024 to USD 74.3 billion by 2029, at a CAGR of 3.1%.The global market is fueled by industrialization, particularly in emerging economies, and advancements in lubricant formulations. Innovations like bio-based and synthetic lubricants, which offer superior performance and sustainability, are shaping the future. Additionally, demand for specialized lubricants tailored to sector-specific needs, such as hydraulic fluids or gear oils, is expanding rapidly.

Sustainability Takes Center StageAmid increasing environmental concerns, companies are adopting eco-friendly lubricants with lower carbon footprints. These products meet stringent regulatory standards while enhancing machine reliability. The push toward circular economies also fosters innovations in lubricant recycling and reuse.

Key Applications and Sectors The construction and automotive sectors dominate the industrial lubricants landscape, driven by the need for high-performing solutions under extreme operating conditions. Other industries, including energy, aerospace, and metalworking, are also witnessing significant growth in lubricant consumption.

To Know More Download PDF Brochure : As the market grows, key players are investing in R&D to meet the dual goals of performance and sustainability. By leveraging cutting-edge technologies, industrial lubricants are poised to remain integral to global industrial progress.

#Industrial Lubricants#Sustainable Lubricants#Machinery Efficiency#Lubricant Technology#Automotive Lubricants#Construction Lubricants#Bio-Based Lubricants

0 notes

Text

Synthetic Lubricants Market Industry Outlook: Forecasting Market Trends and Growth for the Coming Years

Synthetic Lubricants Market Strategies: Taking Advantage of Trends to Drive Growth in 2032

The Synthetic Lubricants Market Report provides essential insights for business strategists, offering a comprehensive overview of industry trends and growth projections. It includes detailed historical and future data on costs, revenues, supply, and demand, where applicable. The report features an in-depth analysis of the value chain and distributor networks.

Employing various analytical techniques such as SWOT analysis, Porter’s Five Forces analysis, and feasibility studies, the report offers a thorough understanding of competitive dynamics, the risk of substitutes and new entrants, and identifies strengths, challenges, and business opportunities. This detailed assessment covers current patterns, driving factors, limitations, emerging developments, and high-growth areas, aiding stakeholders in making informed strategic decisions based on both current and future market trends. Additionally, the report includes an examination of the Automatic Rising Arm Barriers sector and its key opportunities.

According to Straits Research, the global Synthetic Lubricants Market market size was valued at USD 17.2 Billion in 2022. It is projected to reach from USD XX Billion in 2023 to USD 22.9 Billion by 2031, growing at a CAGR of 3.28% during the forecast period (2023–2031).

Get Free Request Sample Report @ https://straitsresearch.com/report/synthetic-lubricants-market/request-sample

TOP Key Industry Players of the Synthetic Lubricants Market

Royal Dutch Shell

ExxonMobil

Sasol

Valvoline

British Petroleum

Chevron

Morris Lubricants

Dow

Indian Oil

Petronas

Lukoil

Idemitsu Kosan

Fuchs

Total Energies

Sinopec

Global Synthetic Lubricants Market: Segmentation

As a result of the Synthetic Lubricants market segmentation, the market is divided into sub-segments based on product type, application, as well as regional and country-level forecasts.

By Applications

Engine Oil

Transmission Fluids and Hydraulic Fluids

Metalworking Fluids

Greases

Others

By End-User

Power Generation

Automotive and Transportation

Heavy Equipment

Food and Beverage

Others

By Type

Polyalphaolefin

Esters

Polyalkylene Glycol

Browse Full Report and TOC @ https://straitsresearch.com/report/synthetic-lubricants-market/request-sample

Reasons for Buying This Report:

Provides an analysis of the evolving competitive landscape of the Automatic Rising Arm Barriers market.

Offers analytical insights and strategic planning guidance to support informed business decisions.

Highlights key market dynamics, including drivers, restraints, emerging trends, developments, and opportunities.

Includes market estimates by region and profiles of various industry stakeholders.

Aids in understanding critical market segments.

Delivers extensive data on trends that could impact market growth.

Research Methodology:

Utilizes a robust methodology involving data triangulation with top-down and bottom-up approaches.

Validates market estimates through primary research with key stakeholders.

Estimates market size and forecasts for different segments at global, regional, and country levels using reliable published sources and stakeholder interviews.

About Straits Research

Straits Research is dedicated to providing businesses with the highest quality market research services. With a team of experienced researchers and analysts, we strive to deliver insightful and actionable data that helps our clients make informed decisions about their industry and market. Our customized approach allows us to tailor our research to each client's specific needs and goals, ensuring that they receive the most relevant and valuable insights.

Contact Us

Email: [email protected]

Address: 825 3rd Avenue, New York, NY, USA, 10022

Tel: UK: +44 203 695 0070, USA: +1 646 905 0080

#Synthetic Lubricants Market#Synthetic Lubricants Market Share#Synthetic Lubricants Market Size#Synthetic Lubricants Market Research#Synthetic Lubricants Industry#What is Synthetic Lubricants?

0 notes