#Metalworking Fluids Market Growth

Explore tagged Tumblr posts

Text

Metalworking Fluids Market Dynamics, Growth Prospect and Consumption Analysis till 2030

The global metalworking fluids (MWFs) market, valued at USD 12.17 billion in 2023, is projected to grow at a compound annual growth rate (CAGR) of 4.9% from 2024 to 2030. This growth is expected to be fueled by rising demand for automotive and heavy industry machinery, as well as significant activity in sectors like machinery, metal fabrication, and transportation equipment. These industries are primary drivers of MWF demand, as they rely on these fluids for effective machining and metalworking processes. The production of MWFs involves crude oil as a fundamental raw material. Refined, processed, and blended from crude oil, the base oils in MWFs make up approximately 40% of the total cost of these fluids. Key products like neat cutting oils, soluble oils, and corrosion-preventive oils are developed from this crude oil refining and heating process, which is essential for producing motor oils, lubricants, and MWFs.

The MWF market benefits substantially from the growth of the automotive industry, where MWFs play a critical role in reducing friction between work pieces and tools, removing metal chips, ensuring high surface quality, and extending tool life. This ultimately increases the efficiency and productivity of machining processes, meeting high production demands. Consequently, the demand for MWFs is expected to remain steady as these industries expand.

In North America and Europe, manufacturing is a key sector, driving MWF demand due to advancements in manufacturing techniques for complex products and the high export rate of equipment for construction, power, agriculture, and automotive applications. The strong growth of end-use industries in Asia Pacific also contributes to MWF demand in North America and Europe, as more consumers in Asia Pacific increasingly opt for advanced machinery across sectors like automotive, agriculture, and construction.

Gather more insights about the market drivers, restrains and growth of the Metalworking Fluids Market

The global market is highly competitive, with the big international brands focusing on developing long-term relationships with end-users. With a rise in the manufacturing, automotive, and transportation sectors, the competition is also anticipated to increase in the coming years. Companies such as Houghton International Inc., BP plc, Exxon Mobil Corporation, and Total SA have a high degree of integration across the value chain as they are also engaged in producing various MWFs. These companies have established themselves as key manufacturers and focus on R&D for novel product uses.

The metalworking fluid market trend is being driven by increased demand for automotive and heavy industry, as well as the growing preference for lightweight components in high performance applications such as heavy machinery, transportation equipment, automotive and construction.

Product Segmentation Insights:

The mineral-based MWFs segment accounted for the largest market share in 2023, representing over 48.06% of total market revenue. Mineral oils are widely used due to their cost-effectiveness, making them popular among small- and medium-sized manufacturers who prioritize affordability. This trend is expected to support stable growth in mineral oil-based MWFs over the forecast period. Mineral oils find applications in various machining processes, including turning, grinding, broaching, drilling, and milling, due to their basic yet reliable performance characteristics.

On the other hand, synthetic MWFs are expected to experience the highest CAGR during the forecast period. These synthetic fluids offer several advantages, such as extending tool life, improving surface finishes, and minimizing friction, making them highly suitable for precision applications. Synthetic oils also provide benefits like reducing waste and extending sump life, which is critical in large-scale manufacturing. As a result, synthetic MWFs have seen a steady increase in adoption, particularly among large-scale manufacturers, and this growth is projected to continue as demand rises for higher-performance fluids.

In recent years, semi-synthetic MWFs have gained traction in many countries, contributing to the overall penetration of synthetic MWFs. Additionally, the growing concerns over environmental impacts associated with petroleum-based products have led to stringent environmental regulations and government initiatives promoting sustainable alternatives. Consequently, the production of bio-based MWFs has surged, offering a more environmentally friendly option that meets regulatory requirements and aligns with the industry's push toward sustainability.

Order a free sample PDF of the Metalworking Fluids Market Intelligence Study, published by Grand View Research.

#Metalworking Fluids Market Share#Metalworking Fluids Market Trends#Metalworking Fluids Market Growth#Metalworking Fluids Industry

0 notes

Text

Metalworking Fluids Market Analysis by Key Players, Sales Forecast and Supply Demand to 2030

The global metalworking fluids (MWFs) market, valued at USD 12.17 billion in 2023, is projected to grow at a compound annual growth rate (CAGR) of 4.9% from 2024 to 2030. This growth is expected to be fueled by rising demand for automotive and heavy industry machinery, as well as significant activity in sectors like machinery, metal fabrication, and transportation equipment. These industries are primary drivers of MWF demand, as they rely on these fluids for effective machining and metalworking processes. The production of MWFs involves crude oil as a fundamental raw material. Refined, processed, and blended from crude oil, the base oils in MWFs make up approximately 40% of the total cost of these fluids. Key products like neat cutting oils, soluble oils, and corrosion-preventive oils are developed from this crude oil refining and heating process, which is essential for producing motor oils, lubricants, and MWFs.

The MWF market benefits substantially from the growth of the automotive industry, where MWFs play a critical role in reducing friction between work pieces and tools, removing metal chips, ensuring high surface quality, and extending tool life. This ultimately increases the efficiency and productivity of machining processes, meeting high production demands. Consequently, the demand for MWFs is expected to remain steady as these industries expand.

In North America and Europe, manufacturing is a key sector, driving MWF demand due to advancements in manufacturing techniques for complex products and the high export rate of equipment for construction, power, agriculture, and automotive applications. The strong growth of end-use industries in Asia Pacific also contributes to MWF demand in North America and Europe, as more consumers in Asia Pacific increasingly opt for advanced machinery across sectors like automotive, agriculture, and construction.

Gather more insights about the market drivers, restrains and growth of the Metalworking Fluids Market

The global market is highly competitive, with the big international brands focusing on developing long-term relationships with end-users. With a rise in the manufacturing, automotive, and transportation sectors, the competition is also anticipated to increase in the coming years. Companies such as Houghton International Inc., BP plc, Exxon Mobil Corporation, and Total SA have a high degree of integration across the value chain as they are also engaged in producing various MWFs. These companies have established themselves as key manufacturers and focus on R&D for novel product uses.

The metalworking fluid market trend is being driven by increased demand for automotive and heavy industry, as well as the growing preference for lightweight components in high performance applications such as heavy machinery, transportation equipment, automotive and construction.

Product Segmentation Insights:

The mineral-based MWFs segment accounted for the largest market share in 2023, representing over 48.06% of total market revenue. Mineral oils are widely used due to their cost-effectiveness, making them popular among small- and medium-sized manufacturers who prioritize affordability. This trend is expected to support stable growth in mineral oil-based MWFs over the forecast period. Mineral oils find applications in various machining processes, including turning, grinding, broaching, drilling, and milling, due to their basic yet reliable performance characteristics.

On the other hand, synthetic MWFs are expected to experience the highest CAGR during the forecast period. These synthetic fluids offer several advantages, such as extending tool life, improving surface finishes, and minimizing friction, making them highly suitable for precision applications. Synthetic oils also provide benefits like reducing waste and extending sump life, which is critical in large-scale manufacturing. As a result, synthetic MWFs have seen a steady increase in adoption, particularly among large-scale manufacturers, and this growth is projected to continue as demand rises for higher-performance fluids.

In recent years, semi-synthetic MWFs have gained traction in many countries, contributing to the overall penetration of synthetic MWFs. Additionally, the growing concerns over environmental impacts associated with petroleum-based products have led to stringent environmental regulations and government initiatives promoting sustainable alternatives. Consequently, the production of bio-based MWFs has surged, offering a more environmentally friendly option that meets regulatory requirements and aligns with the industry's push toward sustainability.

Order a free sample PDF of the Metalworking Fluids Market Intelligence Study, published by Grand View Research.

#Metalworking Fluids Market Share#Metalworking Fluids Market Trends#Metalworking Fluids Market Growth#Metalworking Fluids Industry

0 notes

Text

#Metalworking Fluids Market#Metalworking Fluids Market Trends#Metalworking Fluids Market Growth#Metalworking Fluids Market Industry#Metalworking Fluids Market Research#Metalworking Fluids Market Report

0 notes

Text

#Metalworking Fluids Market#Metalworking Fluids Market Trends#Metalworking Fluids Market Growth#Metalworking Fluids Market Industry#Metalworking Fluids Market Research#Metalworking Fluids Market Report

0 notes

Text

The metalworking fluids market is expected to witness market growth at a rate of 16.80% in the forecast period of 2021 to 2028 and is expected to reach USD 14.50 billion by 2028. Data Bridge Market Research report on metalworking fluids market provides analysis and insights regarding the various factors expected to be prevalent throughout the forecast period while providing their impacts on the market’s growth. The increasing exploration and production activities of oil and gas are escalating the growth of metalworking fluids market.

#Metalworking Fluids Market#Metalworking Fluids Market Share#Metalworking Fluids Market Size#Metalworking Fluids Market Growth#Metalworking Fluids Market Trends#Metalworking Fluids Market Players#Metalworking Fluids Market Competitors#Metalworking Fluids Industry Size#Metalworking Fluids Industry Trends#Metalworking Fluids Industry Growth#Metalworking Fluids Industry Share#Metalworking Fluids Industry Players

0 notes

Text

Isoparaffin Solvents Market Size, Share, and Industry Analysis

Increasing Demand in Personal Care, Paints & Coatings, and Industrial Applications Drives Growth in the Isoparaffin Solvents Market.

The Isoparaffin Solvents MarketSize was USD 870 Million in 2023 and is expected to Reach USD 1185.7 Million by 2032 and grow at a CAGR of 3.5% over the forecast period of 2024-2032.

The global isoparaffin solvents market is driven by increasing demand from paints & coatings, personal care, pharmaceuticals, and industrial cleaning sectors. Isoparaffin solvents are low-odor, high-purity hydrocarbon solvents known for their excellent solvency, low toxicity, and environmental compliance. Their widespread use in metalworking fluids, adhesives, and agrochemicals is further fueling market expansion. Additionally, stringent environmental regulations favoring low-VOC (volatile organic compound) and eco-friendly solvents are driving the transition from traditional solvents to isoparaffin-based alternatives.

Key Players in the Isoparaffin Solvents Market

Chevron Phillips Chemical Company (Soltrol 130, Soltrol 145)

Braskem S.A. (IsoSolve, IsoPura)

Exxon Mobil Corporation (Isopar M, Isopar G)

TotalEnergies SE (Total Isane IP 140, Total Isane IP 160)

Idemitsu Kosan Co. Ltd (Isoparaffin H, Isoparaffin L)

Royal Dutch Shell plc (ShellSol D60, ShellSol T)

INEOS (Isopar E, Isopar K)

Luan Group (LuanSol IP, LuanSol MS)

RB Products (Isopar RC, Isopar HC)

Mehta Petro Refineries Ltd (Mehtol IP, Mehtol MC)

Future Scope and Emerging Trends

The isoparaffin solvents market is evolving with a strong emphasis on sustainability, regulatory compliance, and enhanced performance. With growing concerns over air pollution and workplace safety, industries are increasingly adopting low-VOC and biodegradable solvents to meet environmental standards. The cosmetics and personal care industry is witnessing a rise in the use of isoparaffin-based emollients and formulations, particularly in skincare and haircare products. Additionally, advancements in green chemistry are leading to the development of bio-based isoparaffin solvents, offering a sustainable alternative to petroleum-derived variants. The market is also benefiting from increasing industrialization in emerging economies, where demand for high-performance cleaning and degreasing solutions is on the rise.

Key Points

Growing Demand from Paints, Coatings, and Industrial Cleaning: Isoparaffin solvents are widely used in coatings, adhesives, and degreasers.

Rise in Personal Care and Cosmetic Applications: Increasing use in skincare, haircare, and fragrance formulations.

Shift Toward Low-VOC and Eco-Friendly Solvents: Regulations driving the adoption of sustainable alternatives.

Advancements in Bio-Based Isoparaffin Production: Emerging trends in green chemistry supporting sustainable solutions.

Expansion in Emerging Markets: Rapid industrialization fueling demand for high-purity solvents.

Conclusion

The isoparaffin solvents market is set for continued expansion, driven by regulatory shifts, sustainability initiatives, and increasing applications in industrial and personal care sectors. Companies investing in low-VOC solutions, bio-based formulations, and performance-enhancing solvent technologies will gain a competitive edge. As industries move toward eco-friendly and high-performance solvents, isoparaffin-based products will play a crucial role in ensuring safety, efficiency, and environmental compliance worldwide.

Read Full Report: https://www.snsinsider.com/reports/isoparaffin-solvents-market-3674

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Isoparaffin Solvents Market#Isoparaffin Solvents Market Size#Isoparaffin Solvents Market Share#Isoparaffin Solvents Market Report#Isoparaffin Solvents Market Forecast

0 notes

Text

Metalworking Fluids Market Key Insights And Technological Innovations Driving Industry Expansion

The metalworking fluids market is experiencing steady growth due to the rising demand for efficient machining and metal fabrication solutions. These fluids play a crucial role in reducing friction, improving tool life, and enhancing the quality of finished metal components. With industries such as automotive, aerospace, and manufacturing expanding their operations, the demand for advanced lubrication and cooling solutions is increasing. Technological innovations and the shift towards eco-friendly formulations are further shaping the future of the metalworking fluids market.

Market Size And Demand Trends

Global market valuation is expected to rise significantly by 2030, driven by industrialization

Increasing demand from automotive, aerospace, and construction industries influencing market growth

Expansion of metal fabrication and machining industries contributing to higher consumption rates

Growing investments in smart manufacturing and automation boosting product demand

Rising focus on enhancing machining efficiency driving adoption of high-performance fluids

Increasing R&D spending on innovative metalworking fluids enhancing product capabilities

Key Industry Growth Factors

Rapid urbanization and infrastructure development fueling demand for industrial machining solutions

High adoption of CNC machines requiring specialized lubrication solutions

Advancements in metal cutting and forming processes leading to new fluid formulations

Government regulations promoting sustainable and bio-based fluid alternatives

Growing awareness regarding workplace safety and reduced exposure to harmful chemicals

Demand for high-precision machining in electronics and medical device manufacturing supporting market expansion

Technological Innovations And Product Development

Development of water-soluble metalworking fluids enhancing cooling efficiency

Integration of nanotechnology for improved lubrication and heat dissipation properties

Formulation of hybrid fluids combining synthetic and bio-based elements for sustainability

Introduction of IoT-enabled monitoring systems for real-time fluid performance analysis

Advancements in anti-corrosion additives increasing fluid longevity and equipment protection

Innovations in low-foam and low-emission fluids improving workplace safety and air quality

End-User Industry Applications

Automotive Industry – Essential for precision machining of engine and transmission components

Aerospace Sector – Used in high-tolerance machining of aircraft parts and turbine blades

Construction Equipment Manufacturing – Applied in the production of heavy-duty structural components

General Manufacturing – Vital in machining operations for industrial tools and machinery parts

Electronics Industry – Required for precision metal cutting in semiconductor and circuit board production

Medical Device Manufacturing – Used in high-precision cutting of surgical tools and implants

Sustainability And Environmental Regulations

Global regulatory authorities enforcing stringent VOC and hazardous chemical restrictions

Shift towards bio-based fluids reducing carbon footprint and environmental impact

Development of biodegradable metalworking fluids aligning with green manufacturing policies

Companies investing in renewable raw materials for sustainable product development

Growing preference for water-based fluids minimizing hazardous waste disposal issues

Compliance with ISO standards and REACH regulations encouraging safer formulations

Regional Market Analysis

North America – Strong market presence due to advanced manufacturing and aerospace industries

Europe – High demand driven by stringent environmental regulations and industrial automation

Asia-Pacific – Rapidly growing market fueled by expanding automotive and construction sectors

Latin America – Increasing investments in infrastructure and heavy machinery production supporting market growth

Middle East And Africa – Emerging market with demand rising from mining and oil exploration industries

Challenges Impacting Market Expansion

Fluctuating raw material prices affecting production costs and market stability

Adoption of dry machining techniques reducing dependency on traditional fluids

High costs associated with developing eco-friendly formulations limiting affordability

Need for frequent fluid maintenance and monitoring increasing operational expenses

Growing concerns regarding disposal and recycling of used metalworking fluids

Competition from alternative lubrication technologies affecting market penetration

Future Growth Opportunities

Expansion of bio-based metalworking fluids market catering to sustainability trends

Increasing demand for smart lubrication systems with predictive maintenance capabilities

Collaboration between manufacturers and research institutions for advanced fluid technologies

Growth in electric vehicle manufacturing creating new application areas for specialized fluids

Digitalization of manufacturing processes integrating AI-driven fluid monitoring solutions

Rising investments in emerging economies driving new industrial applications for metalworking fluids

Competitive Landscape And Key Market Players

Major industry participants focusing on expanding product portfolios and sustainable innovations

Companies investing in strategic partnerships and acquisitions to strengthen market presence

Continuous development of cost-effective formulations ensuring affordability for SMEs

Competitive pricing strategies influencing market positioning and customer retention

Global players establishing regional production facilities for localized supply chain efficiency

Strong emphasis on R&D fostering the development of next-generation metalworking fluids

0 notes

Text

Future of the Industrial Lubricants Market: Innovations & Trends

Industrial Lubricants Market: Trends, Industry Analysis, Growth Factors

The Industrial Lubricants Market is expected to reach a value of USD 55.34 billion in 2023 and, with a linear growth pattern, reach USD 75.68 billion by 2033, with a compound annual growth rate (CAGR) of 3.8% from 2024 to 2033.

The Industrial Lubricants Market plays a vital role in various industries, ensuring the smooth operation of machinery and equipment. These lubricants help reduce friction, wear and tear, and overheating, thereby enhancing the efficiency and lifespan of industrial components. As industries continue to expand, the Industrial Lubricants Market Size is projected to grow steadily. This article provides an in-depth Industrial Lubricants Market Analysis, covering key trends, growth factors, challenges, and future opportunities.

Request Sample PDF Copy:https://wemarketresearch.com/reports/request-free-sample-pdf/industrial-lubricants-market/1356

Industrial Lubricants Market Segments

Market, By Type

Mineral oils

Synthetic oils

Bio-based oils

Market, By Application

Manufacturing

Transportation

Energy

Mining and construction

Food and beverage

Pharmaceutical

Others

Market, By Product

General industrial oils

Process oils

Metalworking fluids

Industrial engine oils

Industrial greases

Industrial Lubricants Market Trends and Analysis

Growing Demand for High-Performance Lubricants

One of the significant Industrial Lubricants Market Trends is the increasing demand for high-performance lubricants. These advanced lubricants offer superior protection, longer operational life, and enhanced efficiency in extreme conditions.

Expansion of the Manufacturing Sector

The rapid expansion of manufacturing industries worldwide is driving Industrial Lubricants Market Growth. As automation and heavy machinery usage increase, the need for efficient lubrication solutions is also rising.

Shift Towards Bio-Based Lubricants

Environmental concerns and regulatory pressures are encouraging industries to adopt eco-friendly alternatives. The rise of bio-based industrial lubricants is one of the major Industrial Lubricants Market Trends, reducing the carbon footprint while maintaining performance.

Digitalization and Smart Lubrication Systems

The integration of IoT and AI in lubrication systems is enhancing predictive maintenance. Smart lubricants and automated monitoring systems help industries optimize lubrication schedules, minimizing downtime and improving efficiency.

Industrial Lubricants Market Growth Factors

Increasing Industrialization and Urbanization

Rapid industrialization, especially in emerging economies, is driving the demand for lubricants. The growth of construction, automotive, and manufacturing industries directly contributes to Industrial Lubricants Market Growth.

Rising Demand from the Automotive Industry

The automotive sector is a major consumer of industrial lubricants. With increasing vehicle production and technological advancements, the demand for specialized lubricants is expected to rise.

Growing Energy and Power Sector

Industrial lubricants are essential in power generation, including wind, hydro, and thermal energy plants. The rising global energy demand is boosting Industrial Lubricants Market Potential.

Advancements in Lubricant Formulations

Ongoing research and development in synthetic and bio-based lubricants are leading to innovative products that enhance machinery efficiency, extend maintenance cycles, and reduce operational costs.

Key Companies in the Industrial Lubricants Market

ExxonMobil Corp

Fuchs Group

The Lubrizol Corporation

Royal Dutch Shell

Phillips 66

Lucas Oil Products, Inc.

Amsoil, Inc.

Bel-Ray Co., Inc.

Total S.A.

Kluber Lubrication

Valvoline International, Inc.

Chevron Corp.

Clariant

Quaker Chemical Corp.

Houghton International, Inc.

Castrol

Blaser Swisslube, Inc.

Calumet Specialty Products Partners, L.P.

Petronas Lubricant International

Idemitsu Kosan Co., Ltd.

Yushiro Chemical Industry Co., Ltd.

Key Points of the Industrial Lubricants Market Report

Comprehensive Industrial Lubricants Market Analysis covering trends, size, share, and forecast

Market segmentation based on product type, end-use industry, and application

Regional insights covering North America, Europe, Asia-Pacific, and Latin America

Key market players, competitive landscape, and strategic developments

Impact of regulations and environmental policies on the market

Benefits of This Report

Provides accurate Industrial Lubricants Market Forecast

Identifies key market drivers and challenges

Offers strategic insights for businesses and investors

Analyzes competitive landscape and key players in the industry

Helps stakeholders understand future market potential

Challenges in the Industrial Lubricants Market

Fluctuating Raw Material Prices

The Industrial Lubricants Market Price is influenced by the cost of raw materials such as base oils and additives. Price volatility poses challenges for manufacturers and consumers alike.

Stringent Environmental Regulations

Governments worldwide are implementing strict regulations regarding the use and disposal of industrial lubricants. Compliance with these regulations requires significant investments in research and development.

Increasing Competition from Alternative Technologies

The rise of self-lubricating materials and advanced coatings is posing a potential threat to the demand for traditional industrial lubricants.

Supply Chain Disruptions

Geopolitical tensions, trade restrictions, and global economic fluctuations can disrupt the supply chain, affecting Industrial Lubricants Market Share and availability.

Frequently Asked Questions (FAQs)

Q1: What is the current Industrial Lubricants Market Size?

Q2: Which industries drive Industrial Lubricants Market Growth?

Q3: What are the major Industrial Lubricants Market Trends?

Q4: How do environmental regulations impact the market?

Q5: What is the future Industrial Lubricants Market Forecast?

Related New Updated Research Report:

Antimicrobial-Coatings-Market

https://medium.com/@priteshwemarketresearch/antimicrobial-coatings-market-analysis-type-size-trends-key-players-and-forecast-2024-to-2034-f644d5e8f094

Heat-Transfer-Fluids-Market

https://medium.com/@priteshwemarketresearch/heat-transfer-fluids-market-industry-trends-and-forecast-to-2033-f6e6da647626

Global-Nanocomposites-Market

https://medium.com/@priteshwemarketresearch/global-nanocomposites-market-latest-trends-and-analysis-future-growth-study-by-2034-374bc36be5d6

Global-Green-Solvent-Market

https://medium.com/@priteshwemarketresearch/global-green-solvent-market-growth-trends-analysis-and-dynamic-demand-forecast-2024-to-2034-6cf30e39c8de

Industrial Lubricants Market:

https://wemarketresearch.com/reports/industrial-lubricants-market/1356

3D Printing Materials Market:

https://wemarketresearch.com/reports/3d-printing-materials-market/1338

Conclusion

The Industrial Lubricants Market is poised for significant growth, fueled by technological advancements, increasing industrialization, and rising demand from key industries. While Industrial Lubricants Market Challenges such as regulatory restrictions and raw material price fluctuations exist, the industry offers substantial opportunities for innovation and expansion.

#Industrial lubricants#Industrial lubricants Market#Industrial lubricants Market Scope#Industrial lubricants Market Growth#Industrial lubricants Market Overview#Industrial lubricants Market Size#Industrial lubricants Market Insight#Industrial lubricants Market Trends#Industrial lubricants Market Share#Industrial lubricants Market Industry Analysis

0 notes

Text

Industrial Lubricants Market Report by Type, and Global Opportunity Analysis and Industry Forecast, 2024-2034

Industrial lubricants are essential for the smooth functioning of machinery and equipment across various industries. These lubricants help in reducing friction, wear and tear, and overheating, thereby extending the lifespan of equipment. The market for industrial lubricants has been growing steadily, driven by the increasing demand for efficiency and sustainability in industrial operations.

The industrial lubricants market is anticipated to increase at a compound annual growth rate (CAGR) of 3.8% from 2024 to 2033, reaching a value of USD 75.68 billion by that time. In 2023, the market is anticipated to be worth USD 55.34 billion.

Get a Sample Copy of Report, Click Here@ https://wemarketresearch.com/reports/request-free-sample-pdf/industrial-lubricants-market/1356

Industrial Lubricants Market Drivers

Increasing Industrialization: Growing industries in emerging economies are boosting the demand for high-performance lubricants.

Focus on Efficiency: Industries are increasingly adopting lubricants that enhance machine efficiency and reduce operational costs.

Technological Advancements: Innovations in synthetic and bio-based lubricants are creating new opportunities in the market.

Sustainability Trends: Rising awareness and regulations are pushing for eco-friendly and biodegradable lubricants.

Industrial Lubricants Market Challenges

Volatility in Raw Material Prices: Fluctuations in the prices of crude oil, the primary raw material for synthetic lubricants, pose a challenge.

Environmental Regulations: Strict guidelines for emissions and waste management require significant investment in R&D.

Competition from Alternatives: Emerging alternatives such as solid and dry lubricants may impact the market.

Industrial Lubricants Market Opportunities

Bio-Based Lubricants: Increasing demand for sustainable and biodegradable products is creating growth opportunities.

IoT and Smart Lubricants: Development of intelligent lubrication systems integrated with IoT is gaining traction.

Expansion in Emerging Economies: Untapped markets in developing regions offer potential for growth.

Industrial Lubricants Market Trends

Adoption of Synthetic Lubricants: Higher performance and longer life are driving the preference for synthetic options.

Digitalization in Maintenance: Predictive maintenance supported by data analytics is influencing lubricant requirements.

Rising Awareness of Bio-Lubricants: An increasing push for green industrial solutions is shaping product development.

Top companies in the Industrial Lubricants Market are,

Exxonmobil Corp; Fuchs Group; The Lubrizol Corporation; Royal Dutch Shell; Phillips 66; Lucas Oil Products, Inc.; Amsoil, Inc.; Bel-Ray Co., Inc.; Total S.A.; Kluber Lubrication; Valvoline International, Inc.; Chevron Corp.; Clariant; Quaker Chemical Corp.; Houghton International, Inc.; Castrol; Blaser Swisslube, Inc.; Calumet Specialty Products Partners, L.P.; Petronas Lubricant International; Idemitsu Kosan Co., Ltd.; Yushiro Chemical Industry Co., Ltd.

Market Segments

By Type

Mineral oils

Synthetic oils

Bio-based oils

By Application

Manufacturing

Transportation

Energy

Mining and construction

Food and beverage

Pharmaceutical

Others

By Product

General industrial oils

Process oils

Metalworking fluids

Industrial engine oils

Industrial greases

Regional Analysis of the Industrial Lubricants Market

Asia-Pacific: The largest and fastest-growing region due to rapid industrialization in countries like China and India.

North America: A mature market driven by technological advancements in manufacturing.

Europe: Growth driven by stringent regulations and the adoption of sustainable lubricants.

Latin America and Middle East & Africa: Moderate growth due to emerging industrialization.

Conclusion

The industrial lubricants market is on a steady growth trajectory, driven by the rising demand for efficient, high-performance, and sustainable solutions across diverse industries. Innovations in synthetic and bio-based lubricants, coupled with the push for eco-friendly practices, are reshaping the market landscape. Despite challenges such as fluctuating raw material prices and stringent environmental regulations, the sector continues to thrive, especially in emerging economies with rapid industrialization. Companies that prioritize sustainability, technological advancements, and strategic market expansion are well-positioned to capitalize on the evolving opportunities in this dynamic market.

0 notes

Text

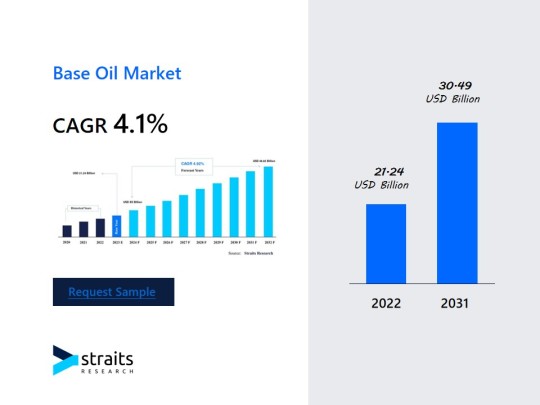

Base Oil Market Key Insights: Global Trends and Growth Forecasts by 2031

The global base oil market was valued at USD 21.24 billion in 2022. It is projected to grow from USD 22.76 billion in 2023 to USD 48.82 billion by 2031, registering a compound annual growth rate (CAGR) of 4.92% during the forecast period (2023–2031).

Overview of the Base Oil Market

The global base oil market is on a robust growth trajectory, driven by increasing demand for high-performance lubricants across various industries. Base oils, the primary ingredients in lubricants, play a crucial role in the formulation of oils used for automotive, industrial, and metalworking applications. As industrial activity ramps up worldwide and the automotive sector continues its evolution, base oils are expected to experience heightened demand in the coming years.

In 2022, the base oil market was valued at USD 21.24 billion and is forecasted to expand to USD 48.82 billion by 2031, growing at a CAGR of 4.92%. This growth is attributed to the increasing industrialization in emerging markets, rising demand for advanced lubricants, and a greater focus on energy-efficient solutions.

Market Definition

Base oils are refined from crude oil and used as the foundation for creating lubricants, oils, and other products, such as hydraulic fluids, metalworking fluids, and automotive oils. The classification of base oils is determined by their performance properties, with each type offering specific benefits based on application requirements. As key raw materials for a range of applications, base oils are essential to maintaining the smooth operation of machinery and vehicles.

Get a Full PDF Sample Copy of the Report @ https://straitsresearch.com/report/base-oil-market/request-sample

Market Dynamics: Key Trends, Drivers, and Opportunities

Key Trends:

Growing Adoption of Synthetic and High-Performance Oils: There is an increasing shift toward synthetic and high-performance base oils, particularly Group III and Group IV oils, which offer better oxidation stability, improved low-temperature performance, and longer-lasting protection for engines and industrial machinery. This trend is expected to accelerate as consumers and industries alike seek more efficient and durable oils.

Integration of Green and Sustainable Technologies: As environmental concerns continue to rise, there is a growing emphasis on the development of eco-friendly and sustainable base oils. The industry is witnessing innovations in bio-based oils and processes that use renewable feedstocks, reducing the overall carbon footprint of oil production and usage. This shift aligns with global sustainability goals and is likely to enhance market prospects.

Key Market Drivers:

Industrial Growth and Expansion in Emerging Markets: The expansion of industrial activities in emerging markets, particularly in Asia-Pacific, is one of the primary drivers for the base oil market. Rapid infrastructure development, increased manufacturing capacity, and growing demand for automotive lubricants are propelling the need for high-quality base oils. As industrial production ramps up, base oils will continue to be in high demand for applications ranging from hydraulic oils to industrial lubricants.

Technological Advancements in Lubricants and Oils: Advancements in lubricant technology, especially the demand for more energy-efficient and high-performance oils in automotive and industrial applications, are significantly driving the base oil market. Group II and Group III base oils, known for their superior properties, are gaining popularity due to their enhanced performance in high-temperature environments and longer service life.

Key Market Opportunities:

Expanding Automotive Sector and Electric Vehicle Production: As the automotive sector continues to grow, especially in emerging economies, the demand for lubricants is increasing. Additionally, the rise of electric vehicles (EVs) presents a unique opportunity for the base oil market. Even though electric vehicles require fewer oils and lubricants, the growing market for hybrid and electric vehicles will necessitate a shift toward specialized lubricants, creating new opportunities for base oil manufacturers.

Rising Demand for Metalworking Fluids and Hydraulic Oils: Base oils used in metalworking fluids, industrial oils, and hydraulic fluids represent a significant opportunity for market growth. As industries such as construction, mining, and manufacturing expand, the demand for high-performance industrial oils and lubricants is rising, offering strong growth prospects for the base oil market.

Market Segmentation

The base oil market is segmented based on type, application, and end-user industry. This segmentation helps understand the market's diverse needs and the opportunities available across various sectors.

By Type:

Group I

Group II

Group III

Group IV

Group V

By Application:

Hydraulic Oil

Automotive Fluid

Metalworking Fluids

Industrial Oil

Other

By End-User:

Industry

Construction

Automobile

Agriculture

Marine

Other

For more detailed segmentation and insights, visit: https://straitsresearch.com/report/base-oil-market/segmentation

Key Players in the Base Oil Market

The base oil market is highly competitive, with several global players leading the way in product innovation, capacity expansion, and market consolidation. The key players in the market include:

Royal Dutch Shell PLC

Exxon Mobil Corporation

H&R Ölwerke Schindler GmbH

Chevron Corporation

BP plc

Saudi Arabian Oil Co.

Petronas Pvt. Ltd.

Evonik Industries AG

Ergon Inc.

Nynas AB

Total S.A.

SK Lubricants Co. Ltd

S-Oil Corporation

Sinopec Group

Repsol S.A.

PetroChina Company Limited

Neste Oil

MOGoil GmbH

Lotos Oil SP. Z O.O.

GS Caltex Corporation

Calumet Specialty Products Partners Lp

Avista Oil AG

These companies are focusing on expanding their production capabilities, enhancing product quality, and exploring new geographic markets to tap into the growing demand for high-performance base oils.

Regional Analysis

Dominated Region: The Asia-Pacific region is the largest market for base oils, driven by the rapid industrialization in countries like China, India, and Japan. The region's booming automotive and manufacturing sectors, along with increasing infrastructure projects, are fueling the demand for base oils in various applications, such as automotive lubricants, industrial oils, and hydraulic fluids.

Fastest Growing Region: North America is expected to be the fastest-growing region for the base oil market. The U.S. and Canada are focusing on sustainable technologies and improving automotive and industrial production. Additionally, the rising demand for high-performance lubricants and oils is driving market growth in this region.

Conclusion

The base oil market is poised for significant growth, driven by industrial expansion, technological advancements, and the increasing need for high-performance lubricants. With a projected CAGR of 4.92%, the market is set to reach USD 48.82 billion by 2031. As demand grows across various industries, particularly in emerging markets, base oil manufacturers are well-positioned to capitalize on the opportunities in the automotive, industrial, and metalworking sectors.

For more information or to customize the report before purchasing, visit: https://straitsresearch.com/buy-now/base-oil-market

About Us:

StraitsResearch.com is a leading market research and market intelligence organization, specializing in research, analytics, and advisory services along with providing business insights & market research reports.

Contact Us:

Email: [email protected] Tel: +1 646 905 0080 (U.S.), +44 203 695 0070 (U.K.) Website: https://straitsresearch.com/

0 notes

Text

Lubricant Additives Market Growth, Drivers, Trends & Forecast 2024-2031

The global lubricant additives market is poised for significant growth, driven by the rising demand for high-performance lubricants across automotive, industrial, and marine sectors. According to SkyQuest Technology, the market is projected to reach a valuation of USD 24.1 billion by 2031, expanding at a CAGR of 4.3% from 2024 to 2031. Lubricant additives play a crucial role in enhancing the performance, durability, and efficiency of lubricants, making them indispensable across multiple industries.

Market Drivers: What’s Fueling the Growth?

The demand for lubricant additives is primarily driven by several key factors:

Rising Automotive Production and Sales The expanding automotive industry, especially in emerging markets, is a major growth driver. Additives such as dispersants, detergents, and viscosity modifiers improve engine performance and fuel efficiency, meeting modern vehicle requirements.

Stringent Environmental Regulations Increasing government regulations aimed at reducing emissions and improving fuel economy are pushing manufacturers to develop eco-friendly additives. Low-sulfur and high-performance additives are gaining traction.

Growth in Industrial Machinery Rapid industrialization and the increasing adoption of advanced machinery across sectors like manufacturing, construction, and energy have elevated the demand for high-quality lubricants with specialized additives.

Advancements in Additive Technologies Continuous R&D efforts have led to the development of innovative additives that enhance lubricant properties, such as anti-wear, anti-corrosion, and oxidation stability.

Request a Sample Report - https://www.skyquestt.com/sample-request/lubricant-additives-market

Market Segmentation: Key Categories

The lubricant additives market is segmented based on type, application, and end-use:

By Type

Dispersants: Prevent sludge formation by keeping contaminants in suspension.

Viscosity Index Improvers: Enhance the lubricant's viscosity stability under varying temperatures.

Detergents: Eliminate deposits and maintain engine cleanliness.

Anti-Wear Agents: Protect surfaces from frictional damage.

Others: Including antioxidants, rust inhibitors, and friction modifiers.

By Application

Engine Oils: The largest segment, essential for vehicles and machinery.

Gear Oils: Used in transmission systems for smooth operation.

Hydraulic Fluids: Widely utilized in industrial and mobile equipment.

Metalworking Fluids: Growing demand from manufacturing industries.

By End-Use Industry

Automotive: Leading the market due to growing vehicle fleets.

Industrial: Driven by the need for efficient machinery lubrication.

Marine and Aviation: Growing focus on enhancing equipment longevity.

Speak to an Analyst - https://www.skyquestt.com/speak-with-analyst/lubricant-additives-market

Regional Insights: Market Trends Across the Globe

North America North America leads the market due to strong demand for advanced lubricants in automotive and industrial applications. The U.S., in particular, is witnessing robust growth due to its large industrial base and stringent environmental policies.

Europe Europe remains a significant market, driven by automotive innovations and regulatory pressure to reduce carbon emissions. Countries like Germany and the UK are key contributors.

Asia-Pacific The Asia-Pacific region is the fastest-growing market, fueled by rapid urbanization, industrialization, and a growing automotive industry in China, India, and Japan. The rising demand for fuel-efficient vehicles further accelerates growth.

Rest of the World The Middle East, Latin America, and Africa are witnessing steady growth due to increasing industrial activities and infrastructure development projects.

Key Players in the Lubricant Additives Market

The lubricant additives market is competitive, with leading companies focusing on innovation, strategic partnerships, and sustainability:

Chevron Oronite Company LLC

The Lubrizol Corporation

BASF SE

Afton Chemical Corporation

Infineum International Limited

Evonik Industries AG

Croda International PLC

Lanxess AG

Dorf Ketal Chemicals

Chevron Corporation

Wuxi South Petroleum Additives Co., Ltd.

These players are developing advanced additive solutions that comply with environmental regulations while enhancing the efficiency and performance of lubricants.

Make a Purchase Inquiry - https://www.skyquestt.com/buy-now/lubricant-additives-market

Key Trends Shaping the Lubricant Additives Market

Focus on Bio-Based Lubricants The shift toward bio-based lubricants and additives is gaining momentum as industries prioritize sustainability and lower environmental impact.

Rising Adoption of High-Performance Lubricants With modern engines operating under extreme conditions, there is increasing demand for additives that enhance thermal stability and wear protection.

Technological Advancements Innovations in additive formulations, such as nanotechnology-based lubricants, are enhancing efficiency and extending lubricant lifespans.

Growing Use of Additives in Electric Vehicles (EVs) The rise of electric vehicles has opened new opportunities for additives designed to optimize cooling, lubrication, and system efficiency.

The Road Ahead for Lubricant Additives

The global lubricant additives market is on a steady growth trajectory, driven by advancements in automotive technology, stringent environmental regulations, and the rise of industrial activities. As the demand for fuel-efficient and eco-friendly solutions grows, market players are focusing on developing innovative, high-performance additives to meet evolving industry requirements.

With Asia-Pacific emerging as a hotspot for growth and bio-based solutions becoming a focal point, the lubricant additives market is set for transformative changes in the years to come.

#Lubricant Additives Market#Lubricant Additives Market Size#Lubricant Additives Market Share#Lubricant Additives Market Trends#Lubricant Additives Market Growth#Lubricant Additives Market Outlook#Lubricant Additives Market Key Players#Lubricant Additives Market Overview#Lubricant Additives Market Competitor#Lubricant Additives Market Insights#Lubricant Additives Market Forecast#Lubricant Additives Market Analysis#Lubricant Additives Market Statistics#Lubricant Additives Market Data#Lubricant Additives Market PDF#Lubricant Additives Market Excel#Lubricant Additives Market Strategy#Lubricant Additives Market Innovations

0 notes

Text

Exploring the Growing Industrial Lubricants Market: Trends and Innovations

The industrial lubricants market is a critical enabler of machinery efficiency across various sectors like manufacturing, construction, and mining. As industries evolve, the demand for high-performance lubricants to improve equipment lifespan, reduce maintenance costs, and enhance energy efficiency is surging.

Market Dynamics and Growth DriversThe industrial lubricants market is estimated to grow from USD 63.9 billion in 2024 to USD 74.3 billion by 2029, at a CAGR of 3.1%.The global market is fueled by industrialization, particularly in emerging economies, and advancements in lubricant formulations. Innovations like bio-based and synthetic lubricants, which offer superior performance and sustainability, are shaping the future. Additionally, demand for specialized lubricants tailored to sector-specific needs, such as hydraulic fluids or gear oils, is expanding rapidly.

Sustainability Takes Center StageAmid increasing environmental concerns, companies are adopting eco-friendly lubricants with lower carbon footprints. These products meet stringent regulatory standards while enhancing machine reliability. The push toward circular economies also fosters innovations in lubricant recycling and reuse.

Key Applications and Sectors The construction and automotive sectors dominate the industrial lubricants landscape, driven by the need for high-performing solutions under extreme operating conditions. Other industries, including energy, aerospace, and metalworking, are also witnessing significant growth in lubricant consumption.

To Know More Download PDF Brochure : As the market grows, key players are investing in R&D to meet the dual goals of performance and sustainability. By leveraging cutting-edge technologies, industrial lubricants are poised to remain integral to global industrial progress.

#Industrial Lubricants#Sustainable Lubricants#Machinery Efficiency#Lubricant Technology#Automotive Lubricants#Construction Lubricants#Bio-Based Lubricants

0 notes

Text

Enhancing Productivity: The Surging Demand for Metalworking Fluids

Metalworking Fluids Industry Overview

The global metalworking fluids market size is expected to reach USD 17.45 billion by 2030, as per the new report by Grand View Research, Inc., registering a CAGR of 4.9% in the forecast period. The demand is attributed to arise in demand for automotive and industrial machinery. Individual end-use sectors, such as machinery, metal fabrication, and transportation equipment, are driving the expansion of the market.

The market is also expected to be driven by strong development in the machinery and transportation equipment end-use industries over the projected period. Manufacturing is one of the core industries in North America and Europe. Advances in the manufacturing methods for the production of sophisticated end-use products, coupled with the increase in the exports of construction machinery and power, agricultural, and automotive equipment, have fueled the market growth.

Gather more insights about the market drivers, restrains and growth of the Metalworking Fluids Market

The sector is expected to benefit from increased production of construction machines and related parts for industrial, residential, and commercial construction. The rise in public-private partnerships is expected to boost the demand for a variety of construction components that use MWFs during their production. Because of the expanding building activities in these nations, emerging economies are likely to be critical for product growth.

The increasing demand for electricity and upgrading of the existing infrastructure for electricity generation, transmission, and distribution, is anticipated to fuel the market for electrical & power equipment and related components. These components are manufactured using ferrous and non-ferrous metal parts, which consume MWFs during manufacturing.

Browse through Grand View Research's Petrochemicals Industry Research Reports.

The global chemical distribution market size was estimated at USD 268.9 billion in 2024 and is anticipated to grow at a CAGR of 7.3% from 2025 to 2030.

The global biolubricants market size was valued at USD 2.95 billion in 2024 and is projected to grow at a CAGR of 13.7% from 2025 to 2030.

Metalworking Fluids Market Segmentation

Grand View Research has segmented the global metalworking fluid market report based on product, application, end-use, industrial end-use, and region:

Metalworking Fluids Product Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Mineral

Synthetic

Bio-Based

Metalworking Fluids Application Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Neat Cutting Oil

Water Cutting Oil

Corrosion Preventive Oil

Others

Metalworking Fluids End-use Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Metal Fabrication

Transportation Equipment

Machinery

Others

Metalworking Fluids Industrial End-use Outlook (Volume, Kilotons; Revenue, USD Million, 2018 – 2030)

Construction

Electric & Power

Agriculture

Automobile

Aerospace

Rail

Marine

Telecommunications

Health Care

Metalworking Fluids Regional Outlook (Volume, Kilotons; Revenue, USD Billion, 2018 - 2030)

North America

US

Canada

Mexico

Europe

Germany

France

UK

Russia

Italy

Spain

Turkey

Switzerland

Denmark

Norway

Belgium

Poland

Czech Republic

Sweden

Finland

Asia Pacific

China

Japan

South Korea

India

Singapore

Malayasia

Thailand

Australia

New Zealand

Central & South America

Brazil

Middle East & Africa

Key Companies profiled:

Houghton International, Inc.

Blaser Swisslube AG

BP plc

Exxon Mobil Corp.

Total S.A.

FUCHS

Chevron Corp.

China Petroleum & Chemical Corp.

Kuwait Petroleum Corp.

Key Metalworking Fluids Company Insights

Key companies are adopting several organic and inorganic growth strategies, such as capacity expansion, mergers & acquisitions, and joint ventures, to maintain and expand their market share.

On January 2023, Univar Solutions B.V. entered a distribution agreement with Graphics Services Ltd. for their products such as inks, rust preventive oils, coatings, lubricants, and metalworking fluids in Europe.

On September 2022, Clariant announced the extension of support for metalworking fluid manufacturers globally by offering their additives to develop high lubricity and fully-synthetic metalworking fluids.

Order a free sample PDF of the Metalworking Fluids Market Intelligence Study, published by Grand View Research.

0 notes

Text

Synthetic Lubricants Market Industry Outlook: Forecasting Market Trends and Growth for the Coming Years

Synthetic Lubricants Market Strategies: Taking Advantage of Trends to Drive Growth in 2032

The Synthetic Lubricants Market Report provides essential insights for business strategists, offering a comprehensive overview of industry trends and growth projections. It includes detailed historical and future data on costs, revenues, supply, and demand, where applicable. The report features an in-depth analysis of the value chain and distributor networks.

Employing various analytical techniques such as SWOT analysis, Porter’s Five Forces analysis, and feasibility studies, the report offers a thorough understanding of competitive dynamics, the risk of substitutes and new entrants, and identifies strengths, challenges, and business opportunities. This detailed assessment covers current patterns, driving factors, limitations, emerging developments, and high-growth areas, aiding stakeholders in making informed strategic decisions based on both current and future market trends. Additionally, the report includes an examination of the Automatic Rising Arm Barriers sector and its key opportunities.

According to Straits Research, the global Synthetic Lubricants Market market size was valued at USD 17.2 Billion in 2022. It is projected to reach from USD XX Billion in 2023 to USD 22.9 Billion by 2031, growing at a CAGR of 3.28% during the forecast period (2023–2031).

Get Free Request Sample Report @ https://straitsresearch.com/report/synthetic-lubricants-market/request-sample

TOP Key Industry Players of the Synthetic Lubricants Market

Royal Dutch Shell

ExxonMobil

Sasol

Valvoline

British Petroleum

Chevron

Morris Lubricants

Dow

Indian Oil

Petronas

Lukoil

Idemitsu Kosan

Fuchs

Total Energies

Sinopec

Global Synthetic Lubricants Market: Segmentation

As a result of the Synthetic Lubricants market segmentation, the market is divided into sub-segments based on product type, application, as well as regional and country-level forecasts.

By Applications

Engine Oil

Transmission Fluids and Hydraulic Fluids

Metalworking Fluids

Greases

Others

By End-User

Power Generation

Automotive and Transportation

Heavy Equipment

Food and Beverage

Others

By Type

Polyalphaolefin

Esters

Polyalkylene Glycol

Browse Full Report and TOC @ https://straitsresearch.com/report/synthetic-lubricants-market/request-sample

Reasons for Buying This Report:

Provides an analysis of the evolving competitive landscape of the Automatic Rising Arm Barriers market.

Offers analytical insights and strategic planning guidance to support informed business decisions.

Highlights key market dynamics, including drivers, restraints, emerging trends, developments, and opportunities.

Includes market estimates by region and profiles of various industry stakeholders.

Aids in understanding critical market segments.

Delivers extensive data on trends that could impact market growth.

Research Methodology:

Utilizes a robust methodology involving data triangulation with top-down and bottom-up approaches.

Validates market estimates through primary research with key stakeholders.

Estimates market size and forecasts for different segments at global, regional, and country levels using reliable published sources and stakeholder interviews.

About Straits Research

Straits Research is dedicated to providing businesses with the highest quality market research services. With a team of experienced researchers and analysts, we strive to deliver insightful and actionable data that helps our clients make informed decisions about their industry and market. Our customized approach allows us to tailor our research to each client's specific needs and goals, ensuring that they receive the most relevant and valuable insights.

Contact Us

Email: [email protected]

Address: 825 3rd Avenue, New York, NY, USA, 10022

Tel: UK: +44 203 695 0070, USA: +1 646 905 0080

#Synthetic Lubricants Market#Synthetic Lubricants Market Share#Synthetic Lubricants Market Size#Synthetic Lubricants Market Research#Synthetic Lubricants Industry#What is Synthetic Lubricants?

0 notes

Text

Metal Finishing Chemicals Market Analysis: Key Challenges and Opportunities

Rising Demand for Corrosion Resistance and Aesthetic Enhancement Fuels Growth in the Metal Finishing Chemicals Market.

The Metal Finishing Chemicals Market size was valued at USD 12.1 billion in 2023, and is expected to reach USD 18.8 billion by 2032, and grow at a CAGR of 5.1% over the forecast period 2024-2032.

The Metal Finishing Chemicals Market is driven by increasing demand from automotive, aerospace, electronics, and industrial manufacturing sectors. Metal finishing chemicals play a critical role in enhancing surface properties such as corrosion resistance, wear resistance, durability, and aesthetic appeal. With the rapid expansion of industrial production, advancements in surface treatment technologies, and stringent environmental regulations, the market is poised for sustained growth.

Key Players in the Metal Finishing Chemicals Market

A Brite Company (Brightener, Cleaner)

Advanced Chemical Company (Electrolytes, Surface Cleaners)

Atotech Deutschland GmbH (Plating Chemicals, Process Chemicals)

BASF SE (Plating Solutions, Surface Treatment Agents)

Chemetall (BASF Group) (Alodine, Oxsilan)

Element Solutions Inc. (Electroplating Solutions, Chemical Mechanical Polishing)

Houghton International Inc. (Metalworking Fluids, Cleaning Agents)

MacDermid Enthone (Electroplating Products, Surface Finishing Solutions)

Platform Specialty Products Corporation (Surface Treatment Chemicals, Plating Solutions)

Quaker Chemical Corporation (Metalworking Fluids, Coating Solutions)

These companies are investing in product innovation, eco-friendly formulations, and automation technologies to stay competitive in the global market.

Future Scope and Emerging Trends

The Metal Finishing Chemicals Market is expected to expand significantly due to increasing industrial applications, particularly in automotive coatings, semiconductor manufacturing, and aerospace components. The demand for high-performance coatings and nanotechnology-based metal finishing solutions is growing as manufacturers look for ways to enhance durability and efficiency while meeting regulatory requirements.

Sustainability is becoming a major focus, with companies shifting towards water-based, non-toxic, and eco-friendly metal finishing solutions to comply with environmental regulations such as REACH and RoHS. Additionally, the rise of automation and smart manufacturing is driving the development of AI-driven metal finishing processes that improve efficiency and reduce waste.

Key Market Points:

✅ Rising Demand in Automotive & Aerospace Industries: Increasing use of metal finishing chemicals for corrosion protection, wear resistance, and enhanced aesthetics. ✅ Growth in Electronics & Semiconductor Sectors: Essential for printed circuit boards (PCBs), connectors, and precision components. ✅ Advancements in Eco-Friendly Finishing Technologies: Shift towards non-toxic, water-based, and low-VOC solutions to comply with regulations. ✅ Increased Adoption of Smart Manufacturing: Use of automation, robotics, and AI-based quality control in metal finishing processes. ✅ Expanding R&D in Nanotechnology Coatings: Innovations in nano-coatings, self-healing surfaces, and high-durability protective films. ✅ Government Regulations Driving Market Transformation: Stricter policies on hazardous chemicals are pushing industries towards sustainable alternatives.

Conclusion

The Metal Finishing Chemicals Market is experiencing steady growth, fueled by technological advancements, industrial expansion, and sustainability initiatives. As industries increasingly focus on durability, corrosion resistance, and compliance with environmental regulations, the demand for innovative and eco-friendly metal finishing solutions will continue to rise. Companies that invest in advanced formulations, automation, and sustainable practices will be well-positioned to thrive in this dynamic and evolving market.

Read Full Report: https://www.snsinsider.com/reports/metal-finishing-chemicals-market-4602

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Metal Finishing Chemicals Market#Metal Finishing Chemicals Market Size#Metal Finishing Chemicals Market Share#Metal Finishing Chemicals Market Report#Metal Finishing Chemicals Market Forecast

0 notes

Text

Metalworking Fluids Market 2030 Size, Share, Business Growth, Demand and Applications

The global metalworking fluids market size was valued at USD 12.17 billion in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 4.9% from 2024 to 2030. This growth is primarily driven by the rising demand for automotive and heavy machinery across various industries, including machinery manufacturing, metal fabrication, and transportation equipment. These sectors rely on metalworking fluids for their ability to improve the machining and manufacturing process. The primary raw material used in producing MWFs is crude oil, which undergoes refining, treatment, and blending to produce key MWF types such as neat cutting oils, soluble oils, and corrosion-preventive oils. Base oil derived from crude oil represents around 40% of the overall MWF production cost and is essential for the manufacture of motor oils, lubricants, and MWFs.

The growth in the automotive industry is a significant factor boosting MWF demand, as these fluids help reduce friction between the tool and the workpiece, prevent metal chips, ensure high-quality surface finishes, and extend the lifespan of tools. These benefits contribute to more efficient machining processes, enhancing production rates. Consequently, the need for metalworking fluids is expected to remain stable, particularly in automotive applications, over the forecast period.

The manufacturing industry is a key economic sector in North America and Europe. Technological advancements in manufacturing processes for sophisticated products, alongside increased exports of construction machinery, power equipment, agricultural machinery, and automotive equipment, have contributed to the growth of the MWF market in these regions. Additionally, Asia Pacific’s demand for advanced machinery in agriculture, automotive, and construction industries supports MWF market expansion in both North America and Europe, as manufacturers in these regions continue to supply global demand.

Gather more insights about the market drivers, restrains and growth of the Metalworking Fluids Market

Application Segmentation Insights:

The neat-cutting oil segment led the MWF market, accounting for over 42% of the global revenue in 2023. Neat-cutting oils are widely used in machining processes across industries, including automotive, aerospace, marine, and construction, due to their effectiveness in cutting operations and high-volume manufacturing. Emerging economies in the Asia Pacific, where high-volume manufacturing is prevalent, have increased demand for neat-cutting oils, which offer a cost-effective solution in machining operations. The demand for neat-cutting oils is further supported by the use of high-alloy steels in heavy equipment manufacturing, which requires robust cutting fluids to optimize machining operations.

The water-cutting oil segment held the second-largest market share in 2023, driven by the increased consumption of these fluids in complex machining operations that require effective heat dissipation. Water-based cutting oils are diluted with water and applied in various procedures, such as drilling, milling, and grinding, to manage the high temperatures generated during machining. The ability of water-cutting oils to control the temperature during these processes makes them ideal for heavy equipment manufacturing.

The semi-synthetic cutting oil segment, a subset of water-cutting oils, is anticipated to grow at a significant CAGR from 2022 to 2030. Semi-synthetic oils are widely used in machining cast iron, aluminum components, and other operations like sawing, drilling, turning, and milling. The expanding applications for these oils are expected to propel the segment’s growth over the forecast period.

Corrosion-preventive fluids are another critical segment expected to grow steadily over the forecast period. These fluids are essential in machining processes where there is a risk of damaging the tools, as they help extend the lifespan of the sump, reducing overhead costs for manufacturers. Small-scale enterprises, which typically operate with lower production volumes and cost structures, increasingly rely on corrosion-preventive oils to maintain operational efficiency and protect their tools, further driving demand in this segment.

In summary, the MWF market is expected to see steady growth, fueled by the expansion of end-use industries and the increasing need for high-performance fluids that enhance machining efficiency, control temperature, and extend tool life. As manufacturing industries in North America, Europe, and Asia Pacific continue to grow, the demand for various MWF types, from neat-cutting oils to corrosion-preventive fluids, will likely rise, positioning MWFs as a key component in the global manufacturing and automotive industries.

Order a free sample PDF of the Metalworking Fluids Market Intelligence Study, published by Grand View Research.

0 notes