#Material Handling Equipment Manufacturers

Explore tagged Tumblr posts

Text

Selecting the right equipment can have a big impact on your operations' overall productivity, safety, and efficiency in the ever-changing field of material handling. Appropriate selection of material handling equipment is essential whether you oversee a manufacturing plant, warehouse, or distribution center. Bhupati Engineering is Best material handling equipment manufacturers in India. If you are facing any difficulty to choose material handling equipment. Contact us

#Material Handling Equipment Manufacturers in India#Material Handling Equipment Suppliers in India#Material Handling Equipment Manufacturers#Material Handling Equipment Suppliers#material handling

2 notes

·

View notes

Text

Exploring the Power of Material Handling Equipment in Modern Industries

Material Handling Equipment is not just a means to an end but a strategic investment for businesses seeking to stay competitive in today’s dynamic market landscape. From enhancing safety and efficiency to driving productivity gains, MHE is the cornerstone of modern industrial operations.

For more information click here: https://bit.ly/3xGgLtr

#Material Handling Equipment Rental#Material Handling Systems#Material Handling Tools#Heavy Duty material Handling Equipment#Material Handling Solutions Provider#Material Handling Equipment Suppliers#Material Handling Solutions#Material Handling Equipment manufacturers

0 notes

Text

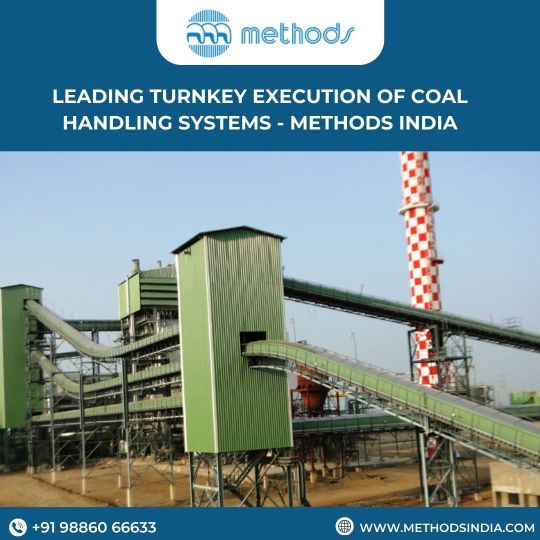

Leading Turnkey Execution of Coal Handling Systems - Methods India

In the realm of material handling, Methods India stands out as a leader in providing Turnkey execution of Coal Handling Systems. The products from Methods India are made with a focus on efficiency, safety, and simplicity. This allows for simple maintenance, which guarantees smooth operation. These turnkey solutions are designed to make moving and storing bulk materials easier.

The organization's dedication to quality has secured its standing as one of the top players in the bulk material handling sector. Find out how Methods India's innovative ideas can help you streamline your coal handling operations.

To contact us, Click on the link below- https://methodsindia.com/contact-information/

#Turnkey execution of Coal Handling Systems#Turnkey execution of Bulk Material Handling Systems#Independent Design House#Bagasse Handling Systems#Bulk material handling equipment manufacturers in Bangalore

2 notes

·

View notes

Text

15 Ton Overhead Cranes For Steel Slabs Handling

IntroductionManufacturing Process of Double Girder Overhead CranesUtilization of Double Girder Overhead Cranes in the Steel IndustryHow to Determine the Price of Your Crane ProjectConclusion Introduction In the world of industrial logistics, efficiency, strength, and reliability are the key characteristics that dictate the quality of equipment. We’re excited to bring forth a prime illustration…

View On WordPress

#coil handling#coil industry cranes#coil lifting#coil loading cranes#coil transport#crane design#crane manufacturing#crane operations#crane safety#girder cranes#heavy-duty cranes#high-capacity crane#hoisting equipment#industrial cranes#load management#material handling#overhead cranes#steel coil production#steel coil storage#steel coils

2 notes

·

View notes

Text

Material Handling Equipment Manufacturer in Ahmedabad Gujarat India

Weber Construction Machinery is a trusted material handling equipment manufacturer in Ahmedabad, Gujarat, India. We provide a builder hoist, concrete bucket, mini crane, and slab trolley with a rail that boosts efficiency, safety, and productivity in various industries.

#material handling#material handling equipment#material handling equipment manufacturer in ahmedabad#material handling equipment supplier#material handling equipment company#material handling system#builder hoist#concrete bucket#mini crane#slab trolley with rail

0 notes

Text

#Storage Systems Manufacturers#Heavy Duty Racks Manufacturers#Storage Racking Systems Suppliers#Material Handling Equipment Suppliers#Cable Trays Exporters#Supermarket Display Racks Exporters#Industrial Storage Rack#Pallet racks

1 note

·

View note

Text

Top Manufacturer of Material Handling Equipment | Nandan GSE

Explore Nandan GSE, a leading manufacturer of material handling equipment. We specialize in custom solutions for industries including aviation, logistics, and more. Discover high-quality equipment designed for efficiency and safety.

0 notes

Text

Tackling Challenges in Adhesive Powder Transfer with Scraper Rotary Valves

Rotary valves play a critical role in the transfer and handling of adhesive powder substances, especially in industries dealing with sticky or cohesive materials. These valves are designed to regulate the flow of bulk solids in various process applications, ensuring consistent material flow while preventing blockages and minimizing equipment downtime.

youtube

Challenges in Handling Adhesive Powder Substances

- Adhesive powders, due to their cohesive nature, often present challenges such as:

Material build-up

Clogging

Inefficient flow

leading to extended processing times and equipment wear. - Rotary valves may not be suitable for these materials as they are prone to blockages, especially at discharge points. - Adhesive powders can adhere to the internal surfaces of the valve, causing inefficiencies in metering and feeding processes.

Specialized Rotary Valves for Sticky Materials ( Scraper Type Valve )

Rotary valves designed for adhesive powders incorporate features to overcome these challenges. For instance, scraper-type rotary valves are equipped with internal scrapers that continuously clean the surfaces of the valve, preventing material build-up and ensuring consistent flow. These valves are particularly effective for handling sticky materials, reducing the risk of clogging and maintaining an uninterrupted process flow. The use of these valves can significantly reduce maintenance requirements and operational downtime, allowing for more efficient handling of adhesive substances.

Key Features of Rotary Valves for Adhesive Powders

a. Precision Metering: One of the main functions of rotary valves is to meter material from a supply into downstream processes. For adhesive powders, precision is crucial to avoid excess material flow, which can worsen sticking and build-up.

b. Scraper Mechanisms: The scraper type rotary valve remove material from the valve surfaces during operation. This prevents accumulation and ensures that the valve remains operational for extended periods without the need for frequent cleaning.

c. Sealing and Leakage Prevention: The Scraper rotary valves are designed to prevent leakage of powder or granules, which is critical for both product quality and environmental control.

Applications of Rotary Valves for a wide range of Industries:

Rotary valves designed for adhesive powders find applications in a variety of industries:

Food Processing: Rotary valves are used to control the flow of dry ingredients such as flour, sugar, and spices in food processing plants.

Chemical Industry: Rotary valves manage the flow of granular and powdered chemicals, enabling smooth transitions between different processing stages.

Plastic and Polymer Processing: Rotary valves facilitate the movement of plastic pellets or granules in manufacturing processes. They enable precise dosing of colorants and additives during polymer production.

Reducing Downtime and Maintenance

One of the major advantages of using Scraper rotary valves tailored for adhesive powders is the significant reduction in downtime. Traditional valves, when handling sticky materials, require frequent cleaning and maintenance to remove accumulated material. This not only interrupts the production process but also increases labor and maintenance costs.

Scraper-type rotary valves minimize the need for manual intervention. As a result, the process can run continuously, with minimal interruptions for cleaning or maintenance. This improves overall productivity and reduces operational costs. Moreover, by ensuring consistent material flow, these valves also contribute to better product quality and more efficient downstream processes.

Conclusion

Rotary valves are essential components in the efficient handling of adhesive powders. By selecting the right Rotary valves with features tailored to sticky materials, industries can: - Reduce Downtime - Improve material flow - Enhance process efficiency How does Aishin help in tackling challenges in Adhesive powder transfer: 1. Specially designed rotary valves for sticky materials with renowned Japanese Engineering 2. Their vacuum transfer systems for powders and granules further improve efficiency by ensuring reliable transfer without compromising material integrity 3. Seamless integration into existing production lines and improving overall process efficiency

#rotary valves#rotary valve manufacturer#rotary valve supplier#powder transfer system#equipment#material handling#Youtube

0 notes

Text

Electric Overhead Travel (EOT) Cranes

Introducing Avon Engineering advanced Electric Overhead Travel (EOT) Cranes – a pinnacle of innovation in material handling solutions. These cranes redefine the concept of heavy-duty lifting and movement, offering a seamless blend of efficiency, customization, safety, and durability for a wide range of industrial applications.

Key Features:

Experience the power of our EOT Cranes in efficiently lifting and transporting heavy loads with ease. Moreover, these cranes are designed to handle substantial weights, optimizing your material handling operations. Additionally, tailor your crane system to match your specific requirements. Avon Engineering Electric Overhead Travel EOT Cranes come in various configurations, including single girder, double girder, and underslung designs, ensuring a perfect fit for your workspace. Furthermore, achieve precise control over load movement with our advanced control systems. Safety is paramount, and our cranes are equipped with features like limit switches, overload protection, and emergency stop mechanisms to ensure secure and controlled operations. In addition, crafted for industrial environments, our EOT Cranes feature robust construction that can withstand the rigors of heavy usage. Lastly, built with quality materials and engineering expertise, they guarantee consistent performance and reliability over time. @avonengineering

Experience Cutting-Edge Material Handling: Our EOT Cranes introduce a new dimension of efficiency in material handling. Whether for manufacturing, construction, warehouses, or other sectors, these cranes deliver reliable, customizable, and safe load lifting and movement, optimizing your processes. They integrate technology, customization, safety, and durability, offering a forward-focused solution that aligns with your material handling goals. Elevate your material handling operations and invest in a product that ensures exceptional performance. Embrace a new era of material movement with our state-of-the-art EOT Cranes.

#Electric Overhead Travel Cranes#EOT Cranes#Industrial Lifting Equipment#Heavy-Duty Crane Systems#Overhead Crane Solutions#Electric Crane Technology#Material Handling Cranes#Customizable Crane Configurations#Precision Load Control#Safety Features for Overhead Cranes#Robust Construction for Industrial Use#High Capacity Lifting Solutions#Efficient Material Handling Equipment#Crane Automation Technology#EOT Crane Manufacturers

0 notes

Text

The Essential Role of Bucket Elevators

In today's industrial landscape, efficient material handling is paramount. Among the workhorses facilitating this movement are bucket elevators, tirelessly transporting bulk materials vertically. This blog delves into the essential role of bucket elevators, exploring their types, applications, and the benefits they offer.

The Mechanics of Movement

Bucket elevators are conveyor systems that utilize a continuous loop of buckets attached to a chain or belt to elevate bulk materials. As the loop rotates, buckets scoop up material from the bottom and carry it upwards, discharging it at the top into a chute or hopper. Their simple yet robust design makes them a reliable and efficient solution for vertical material handling.

Types of Bucket Elevators

Bucket elevators come in various configurations to suit diverse needs. Here are some common types:

Centrifugal Discharge Bucket Elevators: These utilize centrifugal force generated by the rotating chain or belt to discharge material at the top. They are ideal for free-flowing materials like grain or sand.

Gravity Discharge Bucket Elevators: Relying on gravity, these elevators discharge material as the buckets tip over at the top. They are suitable for materials with good flow characteristics.

Continuous Bucket Elevators: These feature overlapping buckets, creating a continuous flow of material without gaps. They are optimal for high-capacity applications.

Applications of Bucket Elevators

The versatility of bucket elevators makes them a ubiquitous presence across numerous industries. Here are some prominent applications:

Food and Beverage Processing: They efficiently elevate grain, flour, sugar, and other dry ingredients for further processing.

Chemical and Pharmaceutical Industries: These elevators handle various powders, granules, and flakes used in the production process.

Construction Industry: They transport sand, gravel, and cement for use in concrete mixing and other construction activities.

Agriculture: Elevators play a vital role in grain handling, transporting crops from storage bins to processing facilities.

Manufacturing Industries: They move a wide range of bulk materials used in various manufacturing processes, from plastic pellets to wood chips.

Benefits of Using Bucket Elevators

Several key advantages make bucket elevators a preferred choice for vertical material handling:

Efficiency: They offer a continuous and efficient method of transporting bulk materials, minimizing downtime and maximizing productivity.

Versatility: Their diverse configurations cater to a wide range of materials and capacities, ensuring a suitable solution for most applications.

Cost-Effectiveness: Bucket elevators offer a relatively low-maintenance and energy-efficient solution compared to other material handling methods.

Scalability: They can be designed in various sizes and capacities to handle small or large-scale material handling needs.

Finding the Right Bucket Elevator Manufacturers

Selecting the right bucket elevator manufacturer [bucket elevator manufacturer in India] is crucial for a successful installation. Look for a manufacturer with a proven track record, offering a variety of configurations, customization options, and reliable after-sales support.

Bucket elevators are the unsung heroes of industry, ensuring the smooth vertical flow of bulk materials. Understanding their types, applications, and benefits empowers you to leverage their efficiency and versatility in your industrial operations. Whether you need to move grain in a food processing plant or sand in a construction site, a well-chosen bucket elevator can play a key role in streamlining your material handling process.

#bucket elevators manufacturer in India#bulk material handling equipment manufacturers in India#chain conveyors manufacturer in India#paddle mixers manufacturer in India#pug mills manufacturer in India#Enviiro Bulkk

0 notes

Text

Exploring Top Industrial Material Handling Equipment Manufacturers

In the vibrant landscape of industrial sector, the pivotal role played by material handling equipment manufacturers cannot be overstated. These producers provide creative solutions that improve efficiency and streamline processes, making them the foundation of many different businesses. This article will examine Indian manufacturers of industrial material handling equipment, their importance, important figures, and the effect they have on the country’s industrial capacity.

If you want to know more about Industrial Material Handling Equipment Manufacturers. Bhupati Engineering is Best Industrial Material Handling Equipment Manufacturers & Suppliers in India.

Read more:

#industrial Material Handling Equipment Manufacturers#industrial Material Handling Equipment#Material handling Equipment manufacturers

0 notes

Text

Load Port Module: The Essential Link Between Wafer Transport System and Process Tool

A Load Port Module serves as the interface between a wafer transport system and a semiconductor process tool such as an etcher or deposition system. It facilitates the safe and ultra-clean transfer of wafers from cassettes stored in the transport system into the vacuum environment of the process chamber for semiconductor fabrication steps. Let's take a closer look at the key components and functions of this critical module. Wafer Cassette Access The front end of a loadlock in Load Port Module includes a cassette-loading station where standard 25mm wafer cassettes containing up to 25 wafers can be automatically loaded and unloaded. A robotic handler on the transport system sets the cassette into place and latches it securely. An environmentally sealed door then closes to maintain isolation of the cleanroom air from the vacuum system. Sensor inputs confirming cassette presence and door closure status are relayed to the process tool's control system. Vacuum-Compatible Design Since wafers must be transferred between the atmospheric cassette environment and high-vacuum process chambers, a Load Port Module needs vacuum-compatible construction. Chambers, bellows sections, and sealing joints are machined from non-outgassing stainless steel or aluminum alloys certified for ultra-high vacuum contact. Viton O-rings, metal gaskets, and precision actuators enable dependable closure and integrity testing of all interfaces down to vacuum pressures below 1x10^-7 Torr. Wafer Transfer Mechanisms Various transfer mechanisms are incorporated into load port designs depending on the specific process tool interface. Common configurations include a linear motor-driven blade that reaches into the cassette to pick wafers one at a time or a robotic arm capable of lifting an entire shelf of wafers simultaneously. Cameras and light sources aid alignment while sensors confirm contact and monitor for particles during extraction and placement into the loadlock chamber. Loadlock Chamber Contained within the load port housing is a small, sealable loadlock chamber where wafers can be coated or undergo vacuum bake-out procedures before entering the process chamber. Magnetic or mechanical end effectors gently grip wafers during transfer to stationary wafer pedestals inside the chamber. A turbo pump then evacuates air from the chamber to prepare for opening the valve to the process tool. Closing this valve isolates the loadlock to allow venting back to atmospheric pressure for wafer removal. Chemical Delivery Ports Some advanced load port designs accommodate ports for purge gas, chemical, or vapor delivery into the loadlock chamber or direct wafer surfaces. This enables pre-etch surface treatment, post-process cleaning, or thin film deposition capabilities directly on the wafers without needing to move them to a dedicated tool. Integrated mass flow controllers ensure precise chemical dosing and vacuum-safe plumbing routes all lines to the chamber.

Get More Insights On This Topic: Load Port Module

#Load Port Module#Semiconductor Industry#Manufacturing#Automation#Material Handling#Robotics#Semiconductor Equipment#Integrated Systems#Industrial Technology#Port Logistics#Container Handling

0 notes

Text

1 note

·

View note

Text

Titan material handling Pvt. Ltd provide Hydraulic Equipment, Hydraulic Equipment Manufacturer, Hydraulic Equipment Supplier, Material Handling Equipment at best cost, It Is the best Hydraulic Equipment, Hydraulic Equipment Manufacturer, Hydraulic Equipment Supplier, Material Handling Equipment Manufacturer company in Pune, Mumbai, India, Andhra Pradesh, Visakhapatnam, SriCity, Guntur, Goa, Margao, Haryana, Gurugram, Faridabad, Gujarat, Ahmedabad, Ankleshwar, Bharuch, Gandhinagar, Jamnagar, Rajkot, Vadodara, Himachal Pradesh, Baddi, Karnataka, Bangalore, Belagavi, Tumkur, Manglore, Hubli, Maharashtra, Navi Mumbai, Mumbai, Pimpri Chinchwad, Pune, Nashik, Aurangabad, Nagpur, Kolhapur, Rajnangaon, Madhya Pradesh, Pithampur, Indore, Tamil Nadu, Coimbatore, Chennai, Hosur, Uttar Pradesh, Noida, Telangana, Hyderabad, Chakan, Hinjawadi, Pirangut, Baramati, Ranjangaon, shirur

#Hydraulic Equipment#Hydraulic Equipment Manufacturer#Hydraulic Equipment Supplier#Material Handling Equipment#Andhra Pradesh#Visakhapatnam#SriCity#Guntur#Goa#Margao#Haryana#Gurugram#Faridabad#Gujarat#Ahmedabad#Ankleshwar#Bharuch#Gandhinagar#Jamnagar#Rajkot#Vadodara#Himachal Pradesh#Baddi#Karnataka#Bangalore#Belagavi#Tumkur#Manglore#Hubli#Maharashtra

0 notes

Text

Manufacturer of Material Handling Equipment | India

Before you start using a Flight Catering Hi Lift it's crucial to understand its features and specifications. Each model may have different weight limits, heights, and functions. Familiarizing yourself with the equipment will ensure you use it correctly and safely.

1 note

·

View note

Text

Katalyst Engineering: Pioneering Excellence in Engineering & Manufacturing

In the dynamic landscape of modern industry, Katalyst Engineering stands out as a beacon of innovation and excellence. Specializing in a comprehensive array of engineering disciplines, Katalyst has become synonymous with cutting-edge solutions in Engineering & Manufacturing, Contract Manufacturing, Mechanical Engineering, Electrical Engineering, and Civil Engineering.

1. Engineering & Manufacturing:

At the core of Katalyst's success is its unwavering commitment to engineering excellence and advanced manufacturing processes. The company seamlessly integrates engineering principles with state-of-the-art manufacturing technologies to deliver products that not only meet but exceed client expectations. Whether it's designing intricate components or optimizing production lines, Katalyst Engineering is a paragon of precision and efficiency.

2. Contract Manufacturing:

Katalyst's prowess extends to contract manufacturing, where the company's agile approach and adaptability shine. By offering end-to-end contract manufacturing solutions, Katalyst becomes a strategic partner for businesses looking to outsource their production needs. The company's commitment to quality control and timely delivery ensures that clients can focus on their core competencies while Katalyst handles the intricacies of manufacturing.

3. Mechanical Engineering:

In the realm of Mechanical Engineering, Katalyst is a trailblazer. From concept to realization, the company's mechanical engineering team tackles challenges with creativity and technical expertise. Whether it's designing robust machinery, optimizing existing systems, or developing innovative solutions, Katalyst's mechanical engineering division is the driving force behind many success stories.

4. Electrical Engineering:

The world is becoming increasingly electrified, and Katalyst Engineering stands at the forefront of this electrification revolution. The Electrical Engineering division leverages the latest advancements in technology to design and implement electrical systems that are not only efficient but also sustainable. Katalyst's electrical engineers are adept at navigating the complexities of power distribution, automation, and energy management. Visit here for more information: https://katalystengineering.com/

5. Civil Engineering:

Katalyst's influence extends to the foundations of our physical world through its Civil Engineering endeavors. From infrastructure projects to urban planning, the company's civil engineers bring a blend of creativity and technical acumen to the table. Katalyst's involvement in civil engineering projects spans the spectrum, ensuring that each endeavor contributes to the advancement of society.

In essence, Katalyst Engineering is not just a provider of engineering services; it is a catalyst for progress. The company's multidisciplinary approach, coupled with a relentless pursuit of excellence, has positioned Katalyst as a leader in the engineering and manufacturing landscape. As industries continue to evolve, Katalyst Engineering remains a reliable partner, driving innovation and shaping the future of engineering.

#engineering & manufacturing#agriculture equipment manufacturers#material handling systems#heavy machinery#Katalyst Engineering

0 notes