#ManufacturingSolution

Explore tagged Tumblr posts

Text

🚀 Want to elevate your manufacturing business in Bangladesh?Matiyas Solutions provides cutting-edge ERP software designed for manufacturing excellence. Our comprehensive services are now available in Bangladesh, helping you streamline operations and achieve Success.Partner with Matiyas Solutions and transform your manufacturing business today!If you want to ensure success for your manufacturing business in Bangladesh, look no further! 🌍Transform your business with Matiyas Solutions today! 🚀Request a demo now - lnkd.in/eAubdpnD

#Want to elevate your manufacturing business in Bangladesh?Matiyas Solutions provides cutting-edge ERP software designed for manufacturing ex#helping you streamline operations and achieve Success.Partner with Matiyas Solutions and transform your manufacturing business today!If you#look no further! 🌍Transform your business with Matiyas Solutions today! 🚀 Want to elevate your manufacturing business in Bangladesh?Matiyas#Manufacturing#ManufacturingSoftware#ManufacturingERP#ManufacturingSolution#ManufacturingIndustry#ManufacturingIndustrySoftware#ManufacturingIndustrySolution#ERP#ERPSoftware#ERPSolution#ERPsystem#CloudBasedERP#CloudBasedSoftware#CloudBasedSolutions#CloudBasedSystem#businesssoftware#ManufacturigERP#ERPNext#frappe#Bangladesh#matiyassolutions

0 notes

Text

Experience manufacturing excellence with Kechie's integrated solution. Seamlessly connecting inventory, production, and operations data, it offers comprehensive scheduling, reporting, and inventory management. Optimize your manufacturing processes with efficiency at every step.

0 notes

Text

Forge Ahead with Virat’s H13!

Virat Special Steels takes pride in offering high-quality Aluminium Extrusion Die Steel H13 – a true pinnacle of durability and performance in every extrusion process.

Application Areas:

Die Casting: H13 is highly recommended for aluminum pressure die casting due to its exceptional performance under high working temperatures and pressure.

Forging Dies: It withstands rapid cooling and early heat testing, making it suitable for forging applications.

Plastic Moulds: H13 is used in injection molding with high polishability.

Quality Assurance: Virat Special Steels ensures that H13 steel is fully ultrasonic inspected with 100% positive results as per NDT standards. It meets the requirements for safety and reliability.

Expertise and Inventory: With over five decades of experience, Virat Special Steels has a reputation for providing accurate and timely service. We maintain ready stock in their steel yards, offering immediate availability.

Choose VIRAT SPECIAL STEELS PVT. LIMITED , INDIA for your Aluminium Extrusion Die Steel needs, and experience quality and reliability!

Contact us today to learn more! https://www.viratsteel.in/materials/aluminium-extrusion-die-steel-supplier-in-india/

Any further queries feel free to contact us : 🌐https://www.viratsteels.com/ 📬 [email protected] ☎+91 98140-21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#steel#ExtrusionDies#AluminumProfiles#AluminumIndustry#ExtrusionProcess#ManufacturingSolutions

2 notes

·

View notes

Text

Discover the future of precision cutting with TradersFind's Laser Cutting Machines category! Explore top-quality machines designed to elevate your manufacturing process. Find the perfect match for your business needs and stay ahead in the competitive market. Unlock unparalleled precision and efficiency with our curated list of suppliers. Browse now and revolutionize your production line!

🛠️ Connect with us on WhatsApp at +971 56 977 3623 to discuss your Laser Cutting Machines requirements.

Visit our website now to explore our Laser Cutting Machines category in UAE! https://www.tradersfind.com/category/laser-cutting-machines

Laser Cutting Machines In UAE

#lasercutting#precisionengineering#manufacturingsolutions#tradersfind#b2b#uaebusiness#cuttingedgetechnology#businessgrowth#industrialmachinery#qualityassurance#innovationinmanufacturing#suppliernetwork#buyersparadise#explorenow

2 notes

·

View notes

Text

A Comprehensive Guide to Choosing the Right Equipment for Your Factory

🏗️ Dive into the world of lifting solutions! Our latest blog explores the intricacies of choosing the perfect lifting equipment for your factory. Electric chain hoists, customized solutions, safety inspections—unlock the secrets to streamlined operations. #FactoryTech #LiftingSolutions Mastering Industrial Lifting: A Comprehensive Guide to Choosing the Right Factory Equipment - KRC (krccranes.com)

#LiftingEquipment#FactoryAutomation#IndustrialSafety#ManufacturingSolutions#EquipmentSelection#FactoryOperations#TechInnovation#WorkplaceSafety#CustomizedSolutions#GlobalManufacturing#HeavyLifting#IndustrialEngineering#SafetyInspections#EfficiencyImprovement#TechGuide#WorkplaceProductivity#EquipmentMaintenance#OperationalEfficiency#FactoryManagement#SmartManufacturing

2 notes

·

View notes

Text

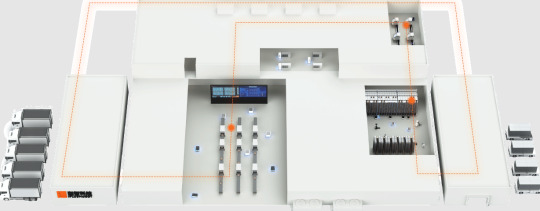

The Rise of Smart Factories: IPLUSMOBOT’s Cutting-Edge Manufacturing Solutions

As technology continues to evolve and disrupt traditional industries, manufacturing has been one of the most impacted. In recent years, smart factories have emerged as the future of manufacturing, enabling businesses to leverage the latest technological advancements to improve production efficiency, quality, and reduce costs. IPLUSMOBOT is at the forefront of this revolution, offering cutting-edge manufacturing solutions that help businesses stay ahead of the curve.

Smart factories are essentially manufacturing plants that rely on advanced technologies such as the Internet of Things (IoT), Artificial Intelligence (AI), and robotics to streamline production processes, enhance worker safety, and boost productivity. IPLUSMOBOT’s Futuristic Manufacturing Technologies have been developed with these technologies in mind, helping businesses overcome the challenges of traditional manufacturing.

One of the key benefits of IPLUSMOBOT’s smart manufacturing solutions is improved efficiency. The company’s state-of-the-art technology enables businesses to automate repetitive and mundane tasks, freeing up workers to focus on more strategic and creative work. This can significantly reduce production time and increase output, leading to a more efficient and profitable manufacturing process.

In addition to increased efficiency, IPLUSMOBOT’s solutions also enhance quality control. Smart factories rely on sensors and real-time monitoring to identify potential defects or issues in the production process, allowing businesses to take corrective action before products leave the factory floor. This leads to fewer defects, reduced waste, and improved customer satisfaction.

Another benefit of IPLUSMOBOT’s smart manufacturing solutions is increased safety for workers. By automating dangerous or hazardous tasks, businesses can minimize the risk of workplace accidents and injuries, protecting both their workers and their bottom line.

Finally, IPLUSMOBOT’s smart factories are highly flexible, enabling businesses to adapt quickly to changing customer demands and market trends. The company’s solutions can be easily reconfigured to accommodate new product lines or changes in production processes, allowing businesses to stay agile and responsive to market demands.

In conclusion, smart factories represent the future of manufacturing, and IPLUSMOBOT is leading the charge with its cutting-edge solutions. By leveraging advanced technologies such as IoT, AI, and robotics, the company’s smart factories offer businesses significant benefits in terms of efficiency, quality control, worker safety, and flexibility. With IPLUSMOBOT’s solutions, businesses can stay ahead of the curve and maintain a competitive edge in today’s fast-paced manufacturing environment.

2 notes

·

View notes

Text

✨ Custom Polypropylene Plastic Machining: Challenges & Solutions for Engineers ✨

🔹 Struggling with polypropylene machining? Discover expert insights on overcoming challenges and ensuring precision & efficiency in your projects. ⚙️

🔹 Whether you need large-scale orders or OEM plastic products, this guide provides tailored solutions to streamline your production. 🏭💡

#PolypropyleneMachining#customplastics#OEMSolutions#EngineeringChallenges#PlasticManufacturing#IndustrialDesign#PrecisionEngineering#ManufacturingSolutions#EngineeringTips#materialscience

0 notes

Text

#cncplasma#cncmachine#metalfabrication#CNCPlasma#MetalFabrication#HighSpeedCutting#PrecisionCutting#PlasmaTechnology#IndustrialCutting#SteelCutting#ManufacturingSolutions#AutomatedCutting#PipeFabrication#TubeCutting

0 notes

Text

At HiTech Machinery Middle East, we specialize in state-of-the-art plastic injection molding machinery for a wide range of applications.

Our advanced machines and comprehensive solutions serve industries such as automotive and mobility, advanced medical technology, innovative electronics, optimized packaging, and precision technical molding.

Partner with us for customized solutions that meet all your plastic manufacturing needs— all under one roof.

Visit: www.hitech-machinery.ae Contact Us: +971 54 247 6872 / +971 50 790 7424

#HiTechMachineryME#HITechMachinery#Middleast#HiTechmachineryMiddleeast#HiTechPlasticMachinery#IndustrialEquipment#ManufacturingSolutions#MachineryDistributor#PlasticManufacturing#PlasticMolding#InjectionMolding#ExtrusionBlowMolding#PETBlowMolding#AuxiliaryMachinery#Screwaircompressor#aircompressor#Blowmolding#Industrialequipment#plasticmachinery#injectionmoldingmachine#plasticinjection

1 note

·

View note

Text

Application for industrial machine tool includes levelling, minimized vibrations and secure mounting of the machines for maximum operational ability. Dynemech Wedge Mounts (DB Series) have been designed with these critical features in mind, making sure the machines stay stable, aligned and performing well during operations. These mounts cancel out most vibrations, allowing for even accuracy in machining, as well as prolonging the equipment's lifespan and parts.

Key Benefits of Dynemech Wedge Mounts – DB Series:

���️ Precision Levelling – Elevates accuracy for enhanced machining results.

✔️ Vibration Reduction – Reduces external interferences which help increase tool life and efficiency of machines.

✔️ Secure Mounting – Provides firm support for heavy industrial machines, preventing unwanted movement. ✔️ Durable & High-Performance Design – Built to withstand heavy loads and long-term industrial use.

Dynemech's expertise in engineering and advanced vibration control solutions makes us a partner of choice for industries across the globe. DB Series Wedge Mounts from Dynemech are used extensively in CNC/VMC machining centers, metal cutting machines, and other precision equipment that demands high stability and vibration isolation.

Smooth operations, improved productivity, and long-term performance of machinery with Dynemech's Wedge Mounts. Contact our experts today to find the best solution for your machinery!

🔗 To learn more about our products: https://www.vibrationmountsindia.com/products/

📞 Contact Us: +91-9810760131

📧 Email: [email protected]

🌐 Explore Our Solutions: vibrationmountsindia.com

#Dynemech#WedgeMounts#DBSeries#CNCPrecision#VibrationControl#MachineStability#IndustrialMounts#ManufacturingSolutions#CNCStability#IndustrialMachines#PrecisionLevelling#VibrationIsolation#MachinePerformance#EngineeringSolutions#MachinerySupport

0 notes

Text

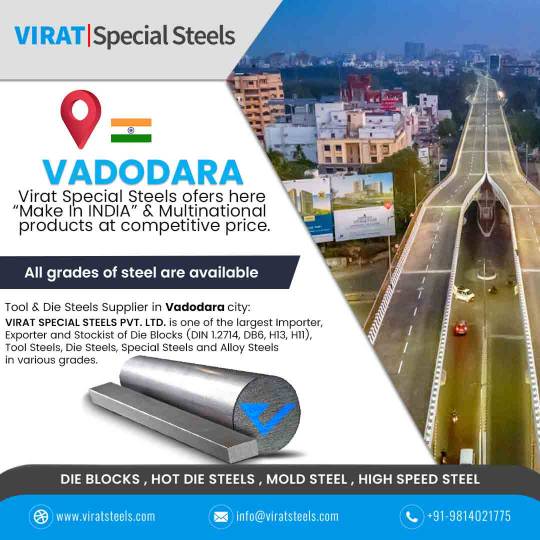

Are you looking for Tool and Die Steel Supplier in Vadodara, Gujarat?

Whether it’s tool steel, die steel, or any other steel requirement, Virat Special Steels stands out as a trusted supplier in Vadodara!

Today, Vadodara stands as a testament to industrial growth and innovation, particularly in the manufacturing and supply of tool and die steel components. The city's industrial clusters are a hive of activity, where small and medium-sized enterprises (SMEs) thrive on specialization in tool and die production. These clusters are not just local powerhouses but also vital cogs in the national supply chain, providing essential components to industries across India.

One of the best Tool & Die Steels Supplier in Vadodara city is: VIRAT SPECIAL STEELS PVT. LIMITED , INDIA . This is a company that deals in all kinds of tool steel, die steel, plastic mold steel, high speed steel, and alloy steel. They provide value added services, such as material machining, cut pieces, and tailor-made material.

They also offer metallurgical advice and quality assurance. They have a state-of-the-art plant in Gurugram and Ludhiana. They also have a strong distribution network across India.

For more information, you can explore here:

Any further queries feel free to contact us : 🌐https://www.viratsteels.com/ 📬 [email protected] ☎+91 98140-21775

#viratsteels#india#gurgaon#ludhiana#toolsteelsupplier#viratspecialsteels#iso9001#steel#Vadodara#Gujarat#DB6ToolSteel#H13Steel#H11Steel#IndustrialMaterials#ToolAndDie#ManufacturingSolutions#MetalIndustry

2 notes

·

View notes

Text

Trends Shaping the Future of Product Engineering: What to Expect by 2030

Advanced technologies are changing the way the designing, developing and delivering products evolve as product engineering is going through a monumental transition. The understanding of these trends is non-negotiable for businesses to stay ahead in a competitive market. Product engineering services companies in the USA are at an exciting stage of advancement, customer-centric design, and scalability. These transitions have the potential to revolutionize industries and create opportunities for growth.

1. The Rise of Artificial Intelligence and Machine Learning

In product engineering, Artificial Intelligence (AI) and Machine Learning (ML) play a very important role. For various organising processes of product lifecycles like the automation of complex processes, analysis of vast data sets, and allowance of predictive maintenance, AI and ML can be helpful.

2. Sustainability and Green Engineering

Sustainability is not avoidable anymore. Through the processes like renewing of materials and optimizing energy efficiency, green practices will be relevant in the engineering sector. It’s a must for all the product engineering services companies in the USA to invest in environmentally friendly practices.

3. Nanotechnology

Many stronger, lighter, and versatile products are created due to the development of advanced materials and nanotechnology, which helps increase durability and performance along with reducing costs. Product engineering services companies in the USA are already looking into fields like healthcare, electronics, and energy for incorporating nanotechnology to create many new products by 2030.

4. 5G and Edge Computing

Once 5G networks and edge computing come into play, the world of connectivity and data processing will experience a big transition. Smarter products and smooth IoT integrations are possible with faster internet speeds and real-time analytics. These new advancements provide opportunities for product engineering services companies in the USA that are supportive of connected ecosystems.

Product engineering services companies in the USA is going great heights with these technological innovations and it’s important for businesses to welcome those with open hands to stay relevant in the market. Engineering sector is indeed going to blow up in the coming years.

Discover More: https://www.veetechnologies.com/industries/engineering-services-and-solutions/product-engineering-manufacturing.htm

#ProductEngineering#Innovation#AI#MachineLearning#Sustainability#GreenEngineering#Nanotechnology#5G#EdgeComputing#TechTrends#SmartProducts#IoT#FutureOfEngineering#EngineeringServices#ProductDevelopment#AdvancedTechnology#BusinessGrowth#ManufacturingSolutions#VeeTechnologies#EngineeringInnovation

0 notes

Text

How ERP Optimizes Production Planning & Inventory in Manufacturing

The manufacturing world is changing quickly, and efficiency and accuracy are thought to maintain competitiveness. One of the most effective ways to achieve both is by using an ERP (Enterprise Resource Planning) system. ERP is a software application for integrating a variety of business processes into a singular system-such as production planning and inventory management. The focus of this blog is how an ERP optimizes these functional aspects in manufacturing and what benefits can be derived from it.

Optimizing Production Planning with ERP

One of the major benefits of ERP systems is their ability to improve production planning. ERP helps manufacturers create more accurate and efficient production plans by providing real-time visibility into inventory levels, raw material availability, and production schedules. The system automatically generates work orders, allocates resources, and schedules machine usage based on current demand and available capacity, thereby minimizing downtime and production delays. ERP also enhances the forecasting process because it analyzes history and trends so that production does not go above customer demand. This results in fewer disruptions and better resource utilization.

Enhancing Inventory Management

Another area where ERP makes a strong impact is on effective inventory management. ERP provides real-time tracking of inventory with automated tracking so that manufacturers have the right amount of materials in stock at any given time. The system, therefore, minimizes the effects of stock outs and overstocking, two common causes of production disruption and increased costs. ERP solutions further optimize reordering processes by automatically generating purchase orders when stock levels reach predefined thresholds. This reduces the chances of having more inventory and their associated storage costs while improving the cash flow.

Benefits of ERP for Manufacturing

Increased Efficiency: The routine work such as inventory tracking and production scheduling is automated by the ERP systems, freeing up valuable time for employees to focus on strategic decision-making.

Cost Savings :The manufacturer can reduce wastes, reduce holding costs of inventory, and increase profits with effective inventories and optimized production planning.

Better Decision-making: Realtime data and cutting-edge analytics create an opportunity in the manufacturing of better decision making that enhances their overall business performances.

Scalability: ERP systems scale with the business, so that manufacturers can increase operations without compromising efficiency.

Improved Customer Satisfaction: With efficient operations and precise production schedules, manufacturers can respond to customer demand promptly, leading to higher satisfaction and repeat business.

Final Thoughts

However, with the integration of real-time data, better forecasting, and synchronization of scheduling and inventory control, ERP solutions can help manufacturers improve their productivity, reduce costs, and improve their bottom lines. With the evolving nature of the manufacturing industry, ERP remains a hall mark of operating efficiently and effectively in business. Therefore, investing in an ERP system would be a shrewd and strategic decision for manufacturers to head away from competition.

#ERPSystems#ProductionPlanning#InventoryManagement#ManufacturingEfficiency#ERPForManufacturing#SupplyChainOptimization#ManufacturingSolutions#BusinessAutomation#LeanManufacturing#ManufacturingTechnology#RealTimeData#SupplyChainManagement#ERPImplementation#InventoryOptimization#BusinessSoftware

0 notes

Text

#PipeCutting#CNCPrecision#MetalFabrication#IndustrialCutting#HighSpeedCutting#AutomatedCutting#PipeFabrication#ManufacturingSolutions#SteelCutting#TubeCutting

0 notes

Text

Best Sheet Metal Fabrication Services – Precision & Quality Guaranteed

Looking for the Best sheet metal fabrication services? We offer top-notch metal fabrication solutions tailored to your needs, ensuring precision, durability, and superior craftsmanship. Our expert team specializes in custom metalwork, laser cutting, bending, welding, and CNC machining, delivering high-quality results for industries like automotive, construction, and manufacturing. Whether you need prototypes or bulk production, our advanced techniques and high-grade materials guarantee reliability and efficiency. Choose us for exceptional metal fabrication services that meet your exact specifications. Contact us today!

#SheetMetalFabrication#MetalFabrication#CustomMetalwork#CNCMachining#MetalWelding#PrecisionEngineering#ManufacturingSolutions

0 notes

Text

We specialize in Plastic Injection Molding Machines, Screw Air Compressors, PET Blow Molding Machines, Extrusion Lines, Extrusion Blow Molding Machines, and all other Auxiliary Machineries.

With over 1,000 satisfied customers both locally and internationally, we are renowned for our quality products, reasonably priced industrial solutions and reliable services.

#HiTechMachineryME#HITechMachinery#Middleast#HiTechmachineryMiddleeast#HiTechPlasticMachinery#IndustrialEquipment#ManufacturingSolutions#MachineryDistributor#PlasticManufacturing#PlasticMolding#InjectionMolding#ExtrusionBlowMolding#PETBlowMolding#AuxiliaryMachinery#Screwaircompressor#aircompressor#Blowmolding#Industrialequipment#plastic-machinery#injectionmoldingmachine#plasticinjection#business#industrial#technology#plastic injection moulding

0 notes