#Magnetic Drive Pumps industry

Text

i don’t remember what i was watching, but i started thinking about how in every post-human world, nature pulls itself through the metal and rubble. (maybe it was something i read, actually.) it made me think not about how humans are what’s causing our world to wither away, but our relationship to technology that is. i don’t think most people consider what a strain it must be on our environment to have such mass internet use 24/7. it brings me back to how our other activities - modern transportation, agricultural practices in industrial societies, so on and so forth - are also pumping nature full of harmful substances. not to sound like a luddite, but we need to pull ourselves from the magnetism of technology. we can do things the old-fashioned way and we should. often. (if it’s not dangerous work, i feel like the processes and the products of our handiwork are more fulfilling than we can ever imagine.) the ever-growing desire for efficiency is driving us to our graves and the natural world into a state it should never have been in the first place :(

2 notes

·

View notes

Text

AEAUTO: Leading the new trend of electric steering-by-wire for commercial vehicles

At a time when heavy-duty commercial vehicles are undergoing electrification and autonomous driving, innovation in commercial vehicle steering systems is crucial. AEAUTO stands out in the field of commercial vehicle electric steering-by-wire with its superior technology and products.

At present, the development of autonomous driving functions for commercial vehicles has encountered technical difficulties. Foreign products are not sold in China, and the domestic commercial vehicle market has an increasingly strong demand for localization. Traditional and electric hydraulic steering dares to challenge and successfully develop the first generation of commercial vehicle electric wire-controlled steering systems, bringing a new solution to the industry.

Advantages of AEAUTO Electric Steering-by-Wire System

1. System efficiency increased by 30%.

There is no energy loss in the hydraulic link, and the design combines electric and wire control, which perfectly meets the needs of heavy-duty commercial vehicles such as electric vehicles and self-driving heavy trucks.

2. System weight reduced by 35%.

Compared with traditional hydraulic or electric hydraulic steering, this system eliminates five components such as the hydraulic pump and hydraulic steering gear, and steering is completely driven by an electric motor, which is light in weight and small in size.

The total system cost is reduced by 20%. After removing multiple components and amortizing the R&D investment and mold costs, the overall cost of parts is greatly reduced.

AEAUTO electric steering-by-wire system core technology advantages

1. 8000Nm high torque output.

Through a dual-winding motor, high-precision ball screw, and flat secondary enveloping toroidal worm reduction mechanism, as well as a 24V high power density motor and patented reduction mechanism, the 8000Nm high torque output required for heavy-duty commercial vehicles is achieved.

2. High-reliability redundant design.

Using a functional safety-based redundant architecture with dual-winding motors, dual MCUs, and dual control chips for heavy-duty commercial vehicles ensures high reliability and safety of the steering system, meeting the urgent needs of the electric steering system as a functional safety component.

3. The angle control response time does not exceed 50ms.

Based on the in-loop dynamic tracking and feedback control strategy of the power assist value, it adopts a low-inertia permanent magnet synchronous motor, determines the control mode through different sensor signals, and uses the control algorithm to accurately track the target parameters to achieve rapid response of EPS power assist, which is at the international leading level.

Compared with foreign competitors, AEAUTO has better performance in terms of system voltage and angle control response time. Although 48V voltage is designed to output more power, it is not a common standard. AEAUTO also achieves high power output with its unique reduction mechanism without affecting matching and compatibility. In addition, the company's control strategy and algorithm are outstanding, achieving a better angle control response time.

AEAUTO electric steering-by-wire helps heavy-duty trucks become more electrified and autonomous

Our products have undergone a series of rigorous tests, including performance tests, bench tests, and durability tests, and obtained the EU CE certification in June 2021. In terms of customer cases, the electric buses of Karsan in Europe and the products of Otokar, a leading Turkish bus company, both use AEAUTO's electric steer-by-wire system and are sold to many European countries and the United States.

In addition, AEAUTO has also built a heavy-duty commercial vehicle electric steering R&D test platform, which covers software-in-the-loop simulation, testing, calibration, reliability, and durability test benches, and has passed the assessment of Nanjing Engineering Technology Center.

With its advanced technology, excellent product performance, and reliable quality, AEAUTO has demonstrated strong competitiveness in the field of electric steer-by-wire for commercial vehicles and has made positive contributions to promoting the electrification and autonomous driving development of heavy-duty commercial vehicles.

0 notes

Text

What is Industrial Relays ? ( Part - 2 )

Types of Relays

Electromechanical Relays (EMRs)

Solid-State Relays (SSRs)

Time-Delay Relays

Thermal Relays

Reed Relays

Electromechanical Relays (EMRs)

General-Purpose Relays: They used for general switching applications with different coil and contact configurations.

Power Relays: They designed to handle high-current loads, typically used in industrial applications.

Reed Relays: They contain a pair of magnetic reeds. They open and close the circuit in response to a magnetic field. They are known for their fast switching speed.

2. Solid-State Relays (SSRs)

Zero-Crossing SSRs: They switch on when the AC load voltage crosses zero, reducing electrical noise and surge currents.

Random Turn-On SSRs: They can turn on at any point in the AC cycle, allowing more precise control in certain applications.

Hybrid SSRs: Combine mechanical contacts and solid-state elements to enhance performance and reliability.

3. Time-Delay Relays

On-Delay Relays: Activate the circuit after a set time once the input is applied.

Off-Delay Relays: Keep the circuit active for a set time after the input is removed.

Interval Relays: Switch on for a preset interval, regardless of the input duration.

4. Thermal Relays

Overload Relays: They protect motors and circuits from overcurrent. They do this by sensing heat from excessive current flow.

Bimetallic Relays: They use a bimetal strip that bends with heat to break or make a circuit, commonly used in motor protection.

5. Reed Relays

Utilize reed switches enclosed in a glass tube and activated by an electromagnetic coil, used in low-current and high-speed switching applications.

Basic Application of Relays

Automotive Systems:

Relays control headlights, horns, fuel pumps, and other vehicle parts. They let low-power switches operate high-power circuits.

2. Industrial Automation:

In industrial machinery, relays control motors and conveyor belts. They enable precise control and automation of complex tasks.

3. Home Appliances:

Relays are in appliances like washing machines and microwaves. They control functions like heating, motors, and timing.

4. Safety Systems:

Relays are used in fire alarms and emergency systems. They ensure critical systems work during emergencies.

5. Telecommunications:

Relays route signals and control information flow in telecom networks. They ensure efficient data transmission.

6. Power Systems:

In power distribution, protection relays check and protect electrical circuits. They guard against overloads, short circuits, and other faults. This ensures a reliable power supply.

Importance Of Relays

Relays are important. They control large devices with small, safe signals. They keep parts of a circuit separate. This protects sensitive components from high voltage or current. Relays also make it easy to automate tasks. They let machines work without direct human control. They can switch many devices on or off. They help keep systems safe by turning things off in case of a problem. They also amplify weak signals to control bigger loads. , relays are essential for managing and protecting electrical systems efficiently.

To Know More Visit : https://vashiisl.com/collections/relays

Summary

In summary, relays are like important part in the electrical world, connecting simple controls to powerful systems. From their early use in telegraphs to their key role in today’s technology, relays are essential for managing complex tasks, ensuring safety, and enabling remote control. As technology evolves, relays remain crucial, showing that even basic components can drive innovation and efficiency in our connected lives.

1 note

·

View note

Text

Hydropower Trends in 2025: Detailed Exploration of Innovations

In 2025, the hydropower industry is at the cusp of transformative innovations that promise to enhance efficiency, environmental sustainability, and flexibility. Below is a detailed exploration of each trend, highlighting the cutting-edge technologies and the companies pioneering these advancements.

1. Hydropower Technology Upgrades

Technological advancements in hydropower are primarily focused on increasing system efficiency and adaptability. For instance, Voith Hydro, a leading player in the field, is developing technologies that enable turbines to operate efficiently across a wide range of hydraulic conditions. This innovation enhances the turbines' ability to integrate with other renewable energy sources, such as wind and solar, by adapting to varying input conditions and grid demands.

One notable startup in this space is Hydrosyst, based in the UK. They specialize in Permanent Magnet Generators (PMGs) for hydropower applications. Their product line includes low-speed, medium-speed, and steam turbine (cogenerator) models, available in both horizontal and vertical axis configurations. These generators are compact yet powerful, delivering high performance even at low speeds, making them well-suited for electricity production. Hydrosyst supplies these advanced generators to both new and existing hydroelectric power plants.

Another innovative company, Littoral Power Systems from the US, designs and installs modular turbines and systems for small-scale hydropower projects. Their turbine models, such as Reakt, TorrStrom, and FlexStream Crossflow, are engineered to improve the efficiency of small hydropower systems. Littoral Power Systems uses a modular construction approach known as the h-modulor system, which facilitates the upgrade of existing sites and the activation of non-powered dams. They also provide a remote management system called k-IOT, which integrates data on water availability, weather conditions, operational performance, and current energy prices to optimize hydro plant operations.

Technological advancements in hydropower are primarily focused on increasing system efficiency and adaptability. For instance, Voith Hydro, a leading player in the field, is developing technologies that enable turbines to operate efficiently across a wide range of hydraulic conditions. This innovation enhances the turbines' ability to integrate with other renewable energy sources, such as wind and solar, by adapting to varying input conditions and grid demands.

2. Modular Power

Modular power generation systems offer an efficient solution for deploying and scaling hydropower plants by utilizing innovative technologies. These systems incorporate elements like gravity hydraulic machines, water wheels, and Archimedes screws to enhance energy production while reducing operational expenses. Turbines, such as very low-head, hydrokinetic turbines, and pumps as turbines (PATs), are also integral, providing improved power output and minimizing costs. Advanced technologies, including current-controlled rotors and double-fed induction machines, enable turbines to quickly adjust to load changes, ensuring stable energy generation and maintaining constant frequency. Modular systems are designed for scalability and cost-effectiveness, utilizing prefabricated units that can be assembled on-site to significantly cut down on construction time and expenses.

In the modular hydropower sector, companies like NuSTREEM, AdaptVerticalMills, and Matel exemplify the innovations driving this field. NuSTREEM's NuCONTAINER system, AdaptVerticalMills’ autonomous modular wind turbines, and Matel’s frameless permanent magnet generators showcase how startups are contributing to the advancement of modular energy solutions by making them more accessible, sustainable, and efficient.

3. Marine and Hydrokinetic Technology

Marine and hydrokinetic (MHK) technology is emerging as a valuable addition to the portfolio of renewable energy sources, particularly in coastal regions where wave and tidal power offer a reliable and clean energy alternative. This technology captures energy from the natural movement of ocean currents, tides, and waves to produce electricity, without the need for large dams. Advances in MHK technology include barrage systems, tidal stream generators, and instream hydrokinetic devices, which efficiently harness the power of moving water.

MHK systems are designed to operate in various aquatic environments, providing renewable energy solutions where traditional hydropower may not be viable. These technologies are often modular, allowing for easy deployment and scalability, while also minimizing environmental impact.

Companies like Fish Friendly Hydro, Zoex, and Energyminer are at the forefront of this innovation. Fish Friendly Hydro’s Picostream turbine, Zoex’s ActiveFender technology, and Energyminer’s Energyfish hydrokinetic plants exemplify how startups are leveraging MHK technology to create sustainable and efficient energy solutions for different aquatic environments.

4. Novel Turbines

Hydropower plants are adopting novel turbine designs to improve efficiency, cost-effectiveness, and sustainability. Innovations like very-low-head turbines, vortex turbines, Alden turbines, and minimum gap runner turbines allow power plants to generate more electricity without altering the natural water flow. Very-low-head turbines are particularly effective in low-water head environments, making them ideal for locations with limited water resources. Alden turbines are designed to minimize fish injuries while enhancing efficiency, and vortex turbines are suited for low-speed water flows. Additionally, minimum gap runner turbines utilize variable gap technology to boost efficiency and reduce material costs.

These new turbine designs are transforming the hydropower industry by enhancing energy efficiency and reducing environmental impact. For instance, Gaia Turbine SA is advancing the micro-hydropower sector with turbines optimized for low-flow conditions that are also fish-friendly, making them ideal for retrofitting existing hydropower installations. Meanwhile, Finnrunner, a Finnish startup, offers 3D-printed turbines made from composite materials, including Pelton, Francis, Kaplan, and Crossflow turbines. These resource-efficient solutions are available for both existing and new small to medium-scale hydropower plants. BluPower, an Indian startup, is also innovating with its Vortex Turbine, a plug-and-play solution designed for decentralized micro-hydro systems that ensures low maintenance, environmental safety, and is well-suited for rural communities.

5. Power Injectors

Water pressure and flow are essential factors that influence turbine capacity in hydropower plants. When water levels are low, the limited flow can reduce turbine performance. Power injectors, such as axial water injection, tangential water injection, and two-phase air-water injection, address this issue by introducing high-pressure water jets into the turbine's intake, creating a venturi effect that increases water intake. These injectors are employed in both low-head and high-head hydropower systems to boost overall power output. Additionally, power injectors enhance the flexibility of hydropower plants by improving control over water flow and energy output. This allows for better response to grid demands and contributes to grid stability by storing excess energy during low-demand periods and releasing it during peak demand.

In this field, XFLEX Hydro is integrating power injectors with battery energy storage systems to create hybrid plants capable of quickly responding to grid fluctuations. Meanwhile, Powerturbines, a Spanish startup, manufactures hydraulic turbines that work alongside pressure-reducing valves (PRVs) to optimize energy generation. Their turbines, including nano turbines and grid-tied turbines, are ideal for applications in river dams, irrigation facilities, and rural homes, supporting small-scale power generation and enhancing grid integration.

6. Performance Analytics

Hydropower plants utilize performance analytics to assess their efficiency, reliability, and sustainability. By employing technologies such as hydro efficiency analysis and combination curve optimization, these plants can evaluate performance outputs and capacity utilization. These tools also allow for the analysis of water flow rates, head, and turbine efficiency to accurately determine the plant's power output. Additionally, numerical cloning enables the creation of digital replicas of hydropower plants, allowing operators to study their behavior under various operating conditions and identify potential design issues, ultimately optimizing overall performance.

In this context, Wegaw, a Swiss startup, offers hydropower data monitoring solutions that optimize energy generation and trading through the analysis of snow and water data. The startup uses earth observation, remote sensing, and machine learning to provide both historical and real-time insights, helping energy companies reduce imbalances and improve trade efficiencies. Meanwhile, Anvil Labs, a US-based startup, specializes in drone-based turbine monitoring. Their platform captures and analyzes high-resolution 3D models and detailed data, enabling wind turbine operators to enhance safety, shorten inspection times, and plan maintenance more effectively through the use of digital twins and advanced analytics.

7. Aquatic Life Preservation

Hydropower development has significant economic, environmental, and social impacts, making the preservation of aquatic life a crucial focus in both existing and new projects. To address these concerns, advancements in turbine designs—such as hydrokinetic turbines, very low head turbines, and minimum gap runner turbines—are being developed to enable safe aquatic life migration through hydropower plants. The growing adoption of pumps as turbines and fish ladders further supports the generation of electricity while maintaining ecological balance.

The impact of hydropower on aquatic ecosystems has long been a concern, leading to the development of innovations that protect aquatic life. Technologies like fish-friendly turbines and bypass systems allow fish to safely navigate around turbines, significantly reducing mortality rates. These innovations are essential for gaining regulatory approvals and maintaining ecological balance in rivers and other water bodies.

In this context, Fish Friendly Hydro has developed turbines specifically designed to minimize fish mortality. Alongside, Australian startup Kinetic NRG has introduced an environmentally friendly Micro Hydropower Kit, optimized for low-velocity water flow. Additionally, US-based GenH focuses on clean energy technologies that ensure safe fish migration through modular hydropower systems, contributing to the ecological sustainability of hydropower projects.

8. Simulations

Startups are leveraging advanced technologies like real-time simulations, digital twins, and smart modeling to reduce the operational costs of hydropower plants. These innovations enable real-time predictive maintenance, using data analytics to provide operators with immediate insights into the condition of assets, which improves maintenance planning. By allowing for targeted, proactive maintenance, these technologies help reduce maintenance costs, increase plant uptime, and extend the lifespan of equipment.

In the design and optimization phase, advanced simulation tools play a crucial role. They allow engineers to model different operational scenarios, anticipate potential challenges, and fine-tune designs to enhance efficiency and minimize costs. This approach ensures that new hydropower projects are economically viable and environmentally sustainable, reducing the risks associated with large-scale investments and leading to more reliable outcomes.

Among the companies at the forefront of these innovations, Annea, a UK-based startup, has developed a digital twin platform that uses IoT for condition-based predictive and prescriptive maintenance of hydropower machinery. Meanwhile, Austrian startup Hydrogrid offers real-time simulations through its Hydrogrid Insight platform, which utilizes self-learning and machine learning algorithms to optimize plant operations, providing detailed insights and forecasts to both modern and older hydropower facilities.

9. Dynamic Pumped Hydropower

Dynamic pumped hydropower is an advanced form of hydroelectric energy storage that leverages the elevation difference between two water reservoirs to generate electricity. This system operates by pumping water to a higher reservoir when energy demand is low and releasing it to generate power during peak periods. The latest advancements in this field, such as variable-speed turbines and hybrid systems, are enhancing the efficiency and flexibility of energy storage and distribution. Innovations in pump design and materials further reduce the energy required for water movement, while SCADA systems provide real-time monitoring and control, optimizing overall system performance. These advancements are increasingly being integrated into existing hydropower plants, improving their capability to support variable renewable energy sources like wind and solar.

In the realm of dynamic pumped hydropower, RheEnergise, a UK-based startup, has introduced high-density hydro solutions that utilize a specialized fluid to enable operations on lower elevation sites, reducing both construction costs and environmental impact. Additionally, the Swedish startup Mine Storage offers grid-scale energy storage solutions by utilizing the gravitational potential of water in underground mines, providing a flexible and efficient energy storage method to support zero-carbon grids.

10. Artificial Channeling

Artificial channeling involves the construction of engineered waterways like canals or tunnels to enhance the flow of water for energy production, while reducing environmental impacts. This method is increasingly being used as an alternative to traditional dam-based hydropower, particularly in ecologically sensitive areas. By directing water through controlled channels, it is possible to optimize energy generation and lessen the negative effects on local ecosystems, such as wildlife and water quality. This approach is particularly beneficial in remote areas, allowing for the generation and distribution of electricity without significant disruption to natural water bodies.

In this context, innovative startups are making strides. For instance, GedCo from Iran has developed a Floating Drum Turbine for run-of-river hydropower, which uses microturbines to generate electricity from water streams. Meanwhile, Bluenergy Solutions from Singapore offers hydrokinetic turbines designed for both off-grid and grid-connected markets, providing versatile solutions for renewable energy generation.

The hydropower industry in 2025 is characterized by a wave of innovations that not only enhance the efficiency and flexibility of energy production but also prioritize environmental sustainability. Companies like Voith Hydro, Fish Friendly Hydro, and Gaia Turbine SA are leading the charge with groundbreaking technologies that promise to keep hydropower a key player in the global shift towards renewable energy. As these trends continue to evolve, hydropower will remain an indispensable component of the energy mix, offering reliable, sustainable, and increasingly eco-friendly power generation options. We need to keep up with all recent innovations to reap maximum benefits and to facilitate a better understanding of the latest developments and trends in the Renewable energy Industry, various Conferences and Expos, which bring Industry leaders together, serve as an all-inclusive platform. The Energy Evolution Awards, Conference, and Expo organized by Next Business Media is making its debut in Spain in 2025. It will be a leading forum dedicated to honoring excellence in Energy Technology, showcasing innovations, and fostering collaborations. The events unite industry leaders, and visionaries to explore the latest advancements, tackle key challenges, and shape the future of Energy. The Energy Evolution Awards, Conference, and Expo will celebrate outstanding achievements, promote sustainable practices, and drive the Energy Industry forward into a technologically advanced sustainable era. Energy Evolution Awards, Conference, and Expo will be a platform for cultivating innovation and shaping a brighter, more efficient energy landscape.

0 notes

Text

Invertek Drives Optidrive E3 General Purpose

Variable Frequency Drive (VFD) that provides sensorless vector control for induction motors, AC permanent magnet motors, brushless DC motors, synchronous reluctance motors, and line start PM motors.

Simple Comissioning 14 parameter basic setup. Default settings suitable for most applications. Contactor style connection for simple wiring.

Intuitive Keypad Control Precise digital control at the touch of a button.

Application Macros Switch between Industrial, Pump & Fan modes to optimize Optidrive E3 for your application.

Internal Category C1 EMC Filter An internal filter in every Optidrive E3 saves cost and time for installation. Cat C1 according to EN61800-3:2004

#hvac#agriculture#automation#mining#watersupply#wastewater#refrigeration#printing#conveyor#mixer#treadmill#pumps#dosing#borehole#swimmingpool#spa#fountain#fans#ventilation

0 notes

Text

High-Efficiency Motors: The Key to Energy Savings and Enhanced Performance

In today’s world, where energy efficiency is a top priority for both environmental and economic reasons, high-efficiency motors have become essential components in various applications. These motors are designed to reduce energy consumption, lower operating costs, and provide superior performance compared to standard motors. In this blog, we’ll explore what makes high-efficiency motors stand out, their benefits, and why they are an excellent investment for both commercial and industrial applications.

1. What Are High-Efficiency Motors?

Definition and Standards: High-efficiency motors are designed to convert electrical energy into mechanical energy more efficiently than standard motors. They meet or exceed energy efficiency standards set by organizations like the International Electrotechnical Commission (IEC) and the National Electrical Manufacturers Association (NEMA). These motors are often classified by efficiency ratings, such as IE2, IE3, and IE4, with IE4 being the most efficient.

Design Features: High-efficiency motors incorporate advanced design features such as optimized windings, improved magnetic materials, and precision engineering to minimize energy losses. These features help the motor achieve higher efficiency levels, resulting in lower energy consumption.

2. Benefits of High-Efficiency Motors

Energy Savings: One of the most significant benefits of high-efficiency motors is their ability to reduce energy consumption. These motors consume less electricity to produce the same amount of mechanical power, leading to substantial energy savings over time.

Lower Operating Costs: Reduced energy consumption translates to lower electricity bills, which can result in significant cost savings, especially in energy-intensive applications. The initial investment in a high-efficiency motor often pays for itself through these savings.

Environmental Impact: By consuming less energy, high-efficiency motors contribute to reducing greenhouse gas emissions and the overall carbon footprint. This makes them an environmentally friendly choice for businesses looking to adopt sustainable practices.

Improved Performance and Reliability: High-efficiency motors are designed to operate more smoothly and with less heat generation, which enhances their performance and reliability. They are less prone to overheating and mechanical wear, leading to longer service life and reduced maintenance requirements.

Compliance with Regulations: Many regions have implemented energy efficiency regulations that require the use of high-efficiency motors in certain applications. By investing in these motors, businesses can ensure compliance with these regulations and avoid potential fines or penalties.

3. Applications of High-Efficiency Motors

HVAC Systems: In heating, ventilation, and air conditioning (HVAC) systems, high-efficiency motors are used to drive fans, pumps, and compressors, significantly reducing energy consumption while maintaining optimal climate control.

Industrial Processes: High-efficiency motors are widely used in industrial applications such as conveyors, pumps, compressors, and machinery. Their energy savings and reliability are particularly valuable in continuous production environments.

Pumping Systems: In water supply, wastewater treatment, and other pumping applications, high-efficiency motors help reduce the energy required to move fluids, leading to lower operational costs and more sustainable water management.

Commercial Buildings: In commercial buildings, high-efficiency motors power elevators, escalators, and other building systems, contributing to overall energy efficiency and reducing the building’s operating expenses.

4. How to Choose the Right High-Efficiency Motor

Understand Your Requirements: Before selecting a high-efficiency motor, it’s important to understand your specific application requirements, including power needs, operating environment, and load conditions.

Efficiency Class: Choose a motor with the appropriate efficiency class (IE2, IE3, IE4) based on your energy-saving goals and budget. While IE4 motors offer the highest efficiency, they also come at a higher upfront cost.

Consider Total Cost of Ownership (TCO): When evaluating high-efficiency motors, consider the total cost of ownership, including purchase price, energy savings, maintenance costs, and lifespan. A higher initial investment in a more efficient motor can lead to greater long-term savings.

Compatibility with Existing Systems: Ensure that the high-efficiency motor you choose is compatible with your existing systems and can be easily integrated without requiring significant modifications.

5. The Future of High-Efficiency Motors

Advancements in Technology: The future of high-efficiency motors is bright, with ongoing advancements in materials, design, and manufacturing techniques. Expect to see even higher efficiency ratings and more intelligent motor control systems that further optimize energy use.

Increased Adoption: As energy efficiency regulations become stricter and businesses continue to prioritize sustainability, the adoption of high-efficiency motors is expected to grow across all sectors.

Smart Motors: The integration of smart technology, such as IoT and AI, will enable high-efficiency motors to be more responsive and adaptable to changing conditions, further enhancing their performance and energy-saving capabilities.

High-efficiency motors are a critical component for anyone looking to reduce energy consumption, lower operating costs, and improve the performance of their systems. Whether in commercial buildings, industrial processes, or HVAC systems, these motors offer a compelling return on investment through their energy savings and long-term reliability. By choosing the right high-efficiency motor for your application, you can contribute to a more sustainable future while boosting your bottom line. For more info contact Lowara Pump Supplier in UAE or call us at +971 4 2522966.

#lowara pumps uae#lowara pump distributors#lowara pump dealer in dubai#lowara pumps#lowara pump suppliers#lowara pump supplier#lowara pump supplier in uae#lowara pump dealer

0 notes

Text

Pompes à vide cryogéniques, Prévisions de la Taille du Marché Mondial, Classement et Part de Marché des 8 Premières Entreprises

Selon le nouveau rapport d'étude de marché “Rapport sur le marché mondial de Pompes à vide cryogéniques 2024-2030”, publié par QYResearch, la taille du marché mondial de Pompes à vide cryogéniques devrait atteindre 505 millions de dollars d'ici 2030, à un TCAC de 4.4% au cours de la période de prévision.

Figure 1. Taille du marché mondial de Pompes à vide cryogéniques (en millions de dollars américains), 2019-2030

Selon QYResearch, les principaux fabricants mondiaux de Pompes à vide cryogéniques comprennent Atlas Copco, SHI Cryogenics Group, etc. En 2023, les trois premiers acteurs mondiaux détenaient une part d'environ 76.0% en termes de chiffre d'affaires.

Figure 2. Classement et part de marché des 8 premiers acteurs mondiaux de Pompes à vide cryogéniques (Le classement est basé sur le chiffre d'affaires de 2023, continuellement mis à jour)

The Cryo Vacuum Pumps market, which serves industries requiring ultra-high vacuum levels and cryogenic temperatures, is influenced by several key drivers that impact its growth and development. Here are some significant factors shaping the Cryo Vacuum Pumps market:

1. Expansion of Semiconductor Industry: The semiconductor industry extensively uses Cryo Vacuum Pumps for processes like thin film deposition and semiconductor wafer manufacturing. The growth of this industry, driven by demand for electronics and technological advancements, fuels the demand for high-performance vacuum solutions.

2. Research and Development in Material Science: Cryo Vacuum Pumps play a crucial role in material science research, particularly in fields like superconductivity, quantum computing, and nanotechnology. Continued R&D activities in these areas drive the need for advanced cryogenic vacuum technologies.

3. Space Exploration and Aerospace Industry: Cryo Vacuum Pumps are essential in space simulation chambers, satellite testing, and other aerospace applications. With increasing investments in space exploration and satellite technology, the demand for cryogenic vacuum solutions is on the rise.

4. Energy and Environmental Applications: Cryo Vacuum Pumps are used in various energy-related applications, like superconducting magnets for fusion research and cryogenic cooling systems for energy-efficient processes. The emphasis on clean energy and sustainability drives innovation in these areas, boosting the demand for cryogenic vacuum technology.

5. Medical and Healthcare Sector: Cryo Vacuum Pumps are utilized in medical devices, such as MRI machines and particle accelerators for cancer treatment. Advancements in healthcare technologies and the increasing need for sophisticated medical equipment contribute to the growth of the market for cryogenic vacuum pumps.

6. Emerging Technologies and Industries: The development of emerging technologies like quantum computing, cryogenic cooling for high-performance computing, and advanced material engineering is creating new opportunities for Cryo Vacuum Pump applications, leading to market expansion.

7. Stringent Quality Standards: Industries requiring ultra-high vacuum levels, such as semiconductor manufacturing and high-energy physics research, must adhere to stringent quality standards. This drives the demand for reliable and high-performance cryogenic vacuum pumps that can meet these requirements.

8. Focus on Energy Efficiency: Cryo Vacuum Pumps that operate efficiently and consume less power are increasingly sought after as companies aim to reduce energy consumption and operational costs while maintaining high performance levels.

9. Integration with Industry 4.0 and Automation: The integration of Cryo Vacuum Pumps with Industry 4.0 principles and automation technologies enhances process control, monitoring, and predictive maintenance, driving efficiency and reducing downtime in industrial applications.

10. Global Shift Towards Cryogenic Cooling: The increasing adoption of cryogenic cooling systems in various industries, such as electronics manufacturing, healthcare, and aerospace, is propelling the demand for Cryo Vacuum Pumps that can support these cooling requirements.

These drivers collectively shape the Cryo Vacuum Pumps market, emphasizing the importance of technological innovation, energy efficiency, diverse application areas, and compliance with industry standards in driving market growth and advancement.

À propos de QYResearch

QYResearch a été fondée en 2007 en Californie aux États-Unis. C'est une société de conseil et d'étude de marché de premier plan à l'échelle mondiale. Avec plus de 17 ans d'expérience et une équipe de recherche professionnelle dans différentes villes du monde, QYResearch se concentre sur le conseil en gestion, les services de base de données et de séminaires, le conseil en IPO, la recherche de la chaîne industrielle et la recherche personnalisée. Nous société a pour objectif d’aider nos clients à réussir en leur fournissant un modèle de revenus non linéaire. Nous sommes mondialement reconnus pour notre vaste portefeuille de services, notre bonne citoyenneté d'entreprise et notre fort engagement envers la durabilité. Jusqu'à présent, nous avons coopéré avec plus de 60 000 clients sur les cinq continents. Coopérons et bâtissons ensemble un avenir prometteur et meilleur.

QYResearch est une société de conseil de grande envergure de renommée mondiale. Elle couvre divers segments de marché de la chaîne industrielle de haute technologie, notamment la chaîne industrielle des semi-conducteurs (équipements et pièces de semi-conducteurs, matériaux semi-conducteurs, circuits intégrés, fonderie, emballage et test, dispositifs discrets, capteurs, dispositifs optoélectroniques), la chaîne industrielle photovoltaïque (équipements, cellules, modules, supports de matériaux auxiliaires, onduleurs, terminaux de centrales électriques), la chaîne industrielle des véhicules électriques à énergie nouvelle (batteries et matériaux, pièces automobiles, batteries, moteurs, commande électronique, semi-conducteurs automobiles, etc.), la chaîne industrielle des communications (équipements de système de communication, équipements terminaux, composants électroniques, frontaux RF, modules optiques, 4G/5G/6G, large bande, IoT, économie numérique, IA), la chaîne industrielle des matériaux avancés (matériaux métalliques, polymères, céramiques, nano matériaux, etc.), la chaîne industrielle de fabrication de machines (machines-outils CNC, machines de construction, machines électriques, automatisation 3C, robots industriels, lasers, contrôle industriel, drones), l'alimentation, les boissons et les produits pharmaceutiques, l'équipement médical, l'agriculture, etc.

0 notes

Text

Pump Solution Guide for Data Center and Server Liquid Cooling System

The Importance of Liquid Cooling for Data Centers

Liquid cooling is a key method for enhancing energy efficiency in data centers. According to statistics from the White Paper on Liquid Cooling in China's Data Centers, the market size for liquid-cooled data centers in China is expected to exceed 100 billion RMB by 2024.

When the Thermal Design Power (TDP) reaches 200-300W, specialized airflow management, increased fan capacity and speed, as well as larger and thicker heat sinks, are required to dissipate heat fast enough in server thermal designs. However, when the TDP reaches 350-400W, cooling servers with air becomes extremely difficult and costly, with air cooling nearing its limits. (Data source: Application and Development of Liquid Cooling Technology in Data Centers)

In this situation, liquids with higher thermal conductivity become a better option for heat dissipation. Compared to traditional air cooling, liquids can remove 1,000 to 3,000 times more heat per unit volume, not only achieving precise component-level cooling and ensuring the high performance and reliability of components but also facilitating heat recovery, thereby improving energy efficiency.

Liquid cooling refers to the use of liquids instead of air as the coolant to transfer heat away from heat-generating components. By injecting this liquid into servers, the heat can be removed through heat exchange. Generally, the industry classifies liquid cooling into direct and indirect cooling. Currently, indirect cooling mainly involves cold plate liquid cooling technology, while direct cooling primarily focuses on immersion liquid cooling technology, which can be further divided into phase-change and non-phase-change types. Additionally, there is spray-type liquid cooling.

TOPSFLO liquid cooling pump solutions

The rise of Generative AI (AIGC) and the breakthrough applications of large-scale model technologies have significantly increased demands on the computational efficiency of servers and chipsets. Enhancing CPU and GPU processing power is urgently needed to support their vast computational requirements. In response to the challenges of server overheating and the surge in energy consumption due to rapidly increasing computing power, liquid cooling technology has emerged as a cutting-edge solution. TOPSFLO’s liquid cooling pump solutions precisely match the diverse cooling needs of servers, offering broad compatibility with cold plate efficient cooling, cooling distribution unit (CDU) optimization, and innovative immersion cooling methods. These solutions are adaptable to meet the customized design needs of various clients, ensuring that servers maintain cool and efficient performance even under high workloads.

With nearly 20 years of experience in the DC micro pump industry, TOPSFLO possesses extensive expertise in cooling and pressure boosting solutions for pumps. TOPSFLO has made significant strides in developing liquid cooling solutions for the data center industry, successfully creating liquid cooling pumps that are optimally suited for data center applications.

Advantages of TOPSFLO Liquid Cooling Pump Solutions

Leak-proof, Safe, and Reliable: Designed with consideration for data center leakage concerns, the pump's structure and materials have been carefully selected to ensure safety and prevent leaks.

Comprehensive Product Range: Our solutions cater to various data center cooling requirements, supporting different CPU/GPU power ratings (200W-1000W) and various application.

Low Noise: Compared to fan-based solutions, our pump systems reduce noise levels by over 40%.

Long Lifespan: Designed to meet the operational needs of data center equipment for up to 10 years.

Strong Material Compatibility: Our pumps are compatible with a wide range of liquid media to suit different application environments.

Data Center Liquid Cooling Pump Solutions with Different Functions

1. Cold plate liquid cooling pump solution

Cold plate liquid cooling mainly uses cold plates (enclosed cavities made of high thermal conductivity metals such as copper and aluminum) to indirectly transfer the heat of components to the cooling liquid enclosed in the circulation pipe, and then uses the coolant to take away the heat. It transports the intermediate heat to the back end for cooling through the transfer characteristics of the working fluid. The system mainly includes liquid cold plates, liquid cooling water pumps, pipes, joints, etc.

TOPSFLO water pump solution for 1U/2U servers, combined with cold plate liquid cooling solution —TDC

2. Immersion Liquid Cooling Pump Solutions

Immersion liquid cooling involves submerging the heat-generating components of electronic devices directly into a cooling liquid, where heat is dissipated through heat exchange. The key equipment and facilities involved include outdoor cooling sources, cooling subsystems, liquid cooling pumps, liquid cooling pipelines, and immersion chambers (liquid cooling cabinets). Immersion liquid cooling can be categorized into two types based on whether there is a phase change in the cooling medium: single-phase immersion liquid cooling and phase-change immersion liquid cooling. The primary function of the liquid cooling pump is to promote liquid circulation and accelerate heat dissipation. Compared to phase-change immersion liquid cooling, single-phase immersion liquid cooling requires pumps with higher power to achieve effective liquid circulation.

3. Cold distribution unit CDU

CDU is a cooling distribution unit that connects the cold plate liquid cooling internal circulation and external circulation. The cold plate liquid cooling joint is divided into two layout forms: centralized CDU and distributed CDU. CDU components include interfaces, micro water pumps, liquid-liquid or air-liquid heat exchangers, liquid storage tanks, valve control devices, monitoring devices, filters and various sensors, which are mainly used for the measurement and control of cooling capacity, flow, pressure and temperature. In order to ensure that sufficient cooling power can be provided for the equipment, a powerful micro water pump will be used in the CDU to ensure uniform and sufficient distribution of cooling capacity.

TOPSFLO High-end and Reliable Liquid Cooling Pump Solutions

TOPSFLO has a professional team with reliable capabilities in micro water pumps and liquid cooling technology, and can provide customers with a variety of liquid cooling water pump solutions. These solutions are designed and verified to adapt to the limited cooling space and heat dissipation requirements of each data center, while ensuring excellent cooling efficiency and reliability.

TOPSFLO different series of liquid cooling water pumps are introduced into servers for various application scenarios, and can also be customized according to the cooling needs of different applications, striving to provide our customers with a wider range of liquid water pump solution options.

Wanna to get custom pump service? Feel free to contact us now:

Email: [email protected]

Whatsapp/Wechat:+86-19376691419

Visit our Web: https://www.topstec.com/ http://www.topsflo.com/

youtube

#dcwaterpump#servercoolingpump#serverliquidcooling#coolingpump#liquidcoolingsystem#liquid cooling pump#data center#datacenter#12vdcwaterpump#waterpump#Youtube

0 notes

Text

Động cơ công nghiệp nổi tiếng trên thế giới

Industrial motors are an indispensable device in the electromechanical systems of many industries. This device plays an important role in providing energy to control machinery and equipment to help the production process run continuously and efficiently. Join Tesfa to see more clearly about industrial motors and the presence of some famous manufacturers in the world through the following article.

What is an industrial engine?

An industrial motor is a type of mechanical device used to convert electrical energy or mechanical energy into mechanical movement. With a special design to operate durably and effectively in harsh industrial environments, requiring high performance. In industrial environments, they are often used in machinery such as compressors, pumps, fans and other mechanical equipment.

Motors are widely used in many different fields such as: production and processing, automation systems, water and waste treatment, mining industry...

Structure of industrial engines

Industrial engines are usually composed of the following main components:

Stator (fixed coil): Is a non-moving part that contains magnetic coils and is responsible for creating a magnetic field when current flows through it.

Rotor (Rotating coil): Is the moving part of the motor, rotating inside the stator under the influence of a magnetic field. Rotors are often made from thin steel sheets assembled to reduce magnetic loss.

Windings: Windings in the stator and rotor help create the magnetic field needed for the motor to operate.

Commutator: Is a switching part that helps change the direction of current in the rotor's coil, adjusting the magnetic field so that the rotor rotates continuously.

Motor Shaft: The shaft is the connection between the rotor and peripheral mechanical devices. It transmits power from the motor to other devices through transmission mechanisms such as gears, belts or screws.

Bearings: Supports the rotor to rotate smoothly and reduces friction in the engine.

Motor Housing: Protects internal motor components and provides mechanical connection to other systems.

Classification of industrial engines

Industrial engines can be classified based on many different criteria, including:

Based on energy source

Electric motor: Uses electricity to create mechanical movement.

Diesel engine: Uses diesel fuel, popular in heavy applications and harsh environments.

Pneumatic motor: Uses compressed air to create motor force.

Based on structure

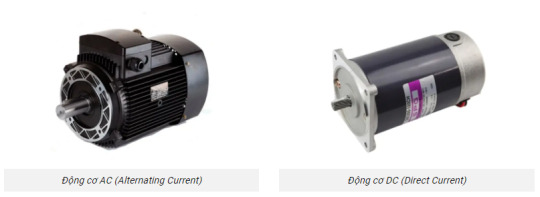

AC (Alternating Current) motor: Operates with alternating current, common in common industrial applications.

DC (Direct Current) Motor: Operates with direct current, providing easy speed adjustment.

Based on the type of movement

Induction motor: No need for brushes or commutator, suitable for many industrial applications.

Synchronous motor: Ensures the correct rotation speed with the power source frequency.

The role of engines in industry

From light to heavy industries, engines now play a key role in equipment and machinery. Let's take a look at some of the roles below:

Providing motion: Industrial electric motors create the mechanical motion needed to operate machinery and equipment in factories.

Enhanced production efficiency: By providing driving force to automated systems, motors help increase production efficiency and productivity.

Control processes: Motors can adjust speed and direction of motion to control production processes more precisely.

Ensures Stability: Industrial motors help maintain stability in system operations, minimizing disruptions and enhancing reliability.

Famous industrial engine manufacturers

Grundfos: Is one of the world's leading manufacturers of industrial motors and pumping equipment, distinguished by providing effective and durable solutions for many industrial fields. Founded in Denmark in 1945, Grundfos has built a solid reputation thanks to excellent product quality and innovative technology. Grundfos provides a wide range of industrial motors, notably products such as Pump motors, control motors, AC and DC motors...

SEW-EURODRIVE: Or commonly known simply as SEW, is one of the leading manufacturers of industrial motors and drive systems. SEW specializes in providing industrial motor products including asynchronous motors, synchronous motors, servo motors and similar motors. These are important products in drive systems and automation in many industries.

ABB (Asea Brown Boveri): Is one of the leading technology corporations that stands out for providing solutions in the fields of electricity, automation and industrial drives. ABB has built a strong reputation thanks to product quality and technological innovation. Providing a wide range of electric motors, from standard motors to special motors for complex industrial applications including: high efficiency motors, explosion-proof motors, Servo motors, synchronous motors and asynchronous,…

TESFA COMPANY LIMITED is currently a reliable strategic partner chosen by Grundfos, Sew and ABB to represent and distribute their industrial engine products in the Vietnamese market. Please contact us now to receive support and experience quality products.

1 note

·

View note

Text

Mag Drive Pumps - Your Trusted Suppliers in Dubai

At Alphatronic Machinery Suppliers , we specialize in providing top-of-the-line Mag Drive Pumps in Dubai. Short for magnetic drive pumps, these pumps are a cutting-edge type of centrifugal pump that rely on a magnetic coupling to efficiently transmit power from the motor to the impeller. Unlike traditional pumps that utilize a direct mechanical connection, Mag Drive Pumps in Dubai eliminate this physical linkage by using a magnetic field to transfer torque.

One of the standout features of Mag Drive Pumps in Dubai is their ability to operate without the need for a mechanical seal. Since the pump is completely hermetically sealed, it significantly reduces the risk of fluid leakage or contamination, making it a superior choice for industries where fluid integrity is paramount. Whether you're handling hazardous, corrosive, or high-value liquids, or simply seeking a highly reliable and safe pumping solution, Mag Drive Pumps are an excellent choice.

Why Choose Alphatronic Machinery Suppliers for Mag Drive Pumps in Dubai?

Our expertise and commitment to quality ensure that you receive pumps that are not only durable and efficient but also tailored to meet the specific requirements of your applications. Whether you're in the chemical, pharmaceutical, or industrial sectors, trust Alphatronic Machinery Suppliers to deliver the best in Mag Drive Pump technology in Dubai.

0 notes

Text

Common faults and maintenance methods of brushless DC motors

1.Definition of brushless DC motors

Brushless DC motors are a type of motor drive that combines synchronous motors and electronic control technology. They control the frequency of the stator's rotating magnetic field through electronic control (driver, including power supply and control), and feed back the motor rotor's speed to the control center for repeated correction to achieve a method close to the characteristics of a DC motor. This type of motor can control the motor rotor to maintain a certain speed within the rated load range when the load changes. Brushless DC motors do not have traditional brushes and commutators, so they have higher energy efficiency and longer service life, and are widely used in fields that require high performance and high reliability.

2.Components of brushless DC motors

1.Rotor: The rotor is the core part of the brushless DC motor and is composed of permanent magnets and iron cores. The magnetic field of the permanent magnet generates torque, which drives the rotor to rotate. The magnitude of the torque is related to the magnetic field strength of the permanent magnet.

2.Stator: The stator is the external part of the brushless DC motor and is composed of a coil and an iron core. When the coil is energized, it generates a magnetic field that interacts with the permanent magnet of the rotor to make the rotor rotate. The number and arrangement of the coils have a great influence on the speed and torque of the motor.

3.Sensor: The sensor is used to detect the rotor position and speed of the brushless DC motor and feed the signal back to the controller. Common sensors include Hall sensors and photoelectric sensors.

4.Controller: The controller is the intelligent part of the brushless DC motor and is used to control the speed and direction of the motor. It receives the signal from the sensor, adjusts it according to the set parameters, and cooperates with the motor's drive circuit to achieve precise control of the motor.

5.Drive circuit: The drive circuit converts the signal output by the controller into current and drives the motor through a power amplifier. The drive circuit achieves precise control of the rotor by controlling the magnitude and direction of the current.

3.Application areas of brushless DC motors

1.Equipment positioning applications: Brushless DC motors are suitable for applications that require precise control of position and speed, such as industrial control and automatic control applications, including process control, logistics control, and machine equipment control. These applications have special requirements for the dynamic response and torque of the speed, and may require the use of photoelectric and synchronous devices for speed measurement.

2.Variable load application areas: Brushless DC motors are also suitable for machines and equipment with variable loads, such as compressors of refrigerators, washing machines, air conditioners, etc. in daily household appliances, as well as engine equipment control, electric controllers, and oil pump control in the automotive field. These applications usually have high requirements for the dynamic response time and speed characteristics of the machine.

3.Continuous load application areas: Brushless DC motors are also suitable for equipment that needs to maintain load continuously, such as electric fans, hair dryers, agricultural pumps, etc. These devices have specific requirements for speed, but do not require overly precise control. Open-loop control is usually used, which is low in cost.

4.Common faults and maintenance methods of brushless DC motors

1.Power supply problems: Brushless motors require a stable power supply. If the power supply voltage is insufficient, the current is unstable, or the power supply fails, the brushless motor may stop working or run unstably. Solutions include ensuring that the power supply is stable, checking that the power cord is in good contact, and that the power supply voltage is stable.

2.Mechanical failure: The brushless motor needs to be properly mounted on the mechanical device and the rotation axis must be correct. If a mechanical failure prevents the motor from turning, the brushless motor will not work properly. Solutions include ensuring that the motor is properly mounted, the axis is correct, and any mechanical failures are repaired in a timely manner.

3.Sensor problems: Brushless motors usually use Hall sensors for position detection. If the sensor is damaged or cannot correctly detect the motor position, the brushless motor will not work properly. Solutions include checking and replacing damaged sensors.

4.Driver problems: The brushless motor driver may have faults, such as unstable power supply voltage, current sensor failure, etc., which may cause the motor to stop working or run erratically. Solutions include checking and repairing the driver circuit to ensure that it works properly.

5.Temperature problems: Brushless motors heat up during operation. If the temperature is too high, the motor may stop working or be damaged. Solutions include ensuring the motor is running at the proper operating temperature and taking cooling measures if necessary.

6.Magnet problem: The magnets of the brushless motor may be affected by external magnetic fields, causing the motor to run erratically or stop working. Solutions include ensuring the motor is away from objects that may generate strong magnetic fields, or replacing damaged magnets. Resistance problem: If the load driven by the motor is too heavy, it may cause the motor to stall or stop working. Solutions include reducing the load or checking the connection between the motor and the load to ensure smooth operation.

7.Controller failure: The brushless motor controller is a key component that controls the normal operation of the brushless motor. If the controller is broken, the brushless motor will not work properly. Repair steps include determining the controller failure, checking the power supply, control signal, driver circuit, and protection circuit to see if they are working properly.

0 notes

Text

Energy Efficiency and Sustainability: The Future of Submersible Pumps

The future of submersible pumps is increasingly focused on energy efficiency and sustainability, driven by the growing global demand for environmentally friendly technologies and the need to reduce operational costs. As industries, municipalities, and households seek to minimize their environmental footprint, advancements in submersible pump technology are playing a crucial role in achieving these goals. Here's how energy efficiency and sustainability are shaping the future of submersible pumps:

1. Innovative Motor Technologies

High-Efficiency Motors: The development of high-efficiency motors, such as permanent magnet motors and brushless DC motors, is leading to significant energy savings in submersible pumps. These motors are designed to minimize energy loss, converting more electrical energy into mechanical energy, which improves overall pump efficiency.

Variable Frequency Drives (VFDs): VFDs allow submersible pumps to adjust their operating speed based on real-time demand, reducing energy consumption during low-demand periods. By optimizing the pump’s speed and power usage, VFDs contribute to energy savings and extend the life of the pump.

2. Advanced Monitoring and Control Systems

Smart Pump Technology: The integration of smart technology into submersible pumps enables real-time monitoring and control of pump operations. These systems use sensors and IoT (Internet of Things) connectivity to monitor parameters such as flow rate, pressure, and energy consumption. Operators can remotely adjust settings to optimize performance and reduce energy usage.

Predictive Maintenance: Advanced monitoring systems can also predict maintenance needs, preventing breakdowns and reducing downtime. By addressing issues before they lead to failures, these systems contribute to sustainability by extending the pump’s lifespan and reducing waste.

3. Materials and Design Innovations

Corrosion-Resistant and Eco-Friendly Materials: The use of durable, corrosion-resistant materials, such as stainless steel and composite polymers, enhances the longevity of submersible pumps. These materials are also more environmentally friendly, reducing the need for frequent replacements and minimizing waste.

Compact and Lightweight Designs: Modern submersible pumps are being designed to be more compact and lightweight, without compromising on performance. These designs reduce material usage, lower transportation costs, and make installation easier, contributing to overall sustainability.

4. Energy Recovery Systems

Regenerative Energy Systems: Some advanced submersible pumps are equipped with regenerative energy systems that capture and reuse energy generated during operation. This energy can be redirected back into the system or stored for later use, reducing the overall energy consumption of the pump.

Hydraulic Power Recovery: In applications where submersible pumps are used to handle high-pressure fluids, hydraulic power recovery systems can be employed to harness excess energy and convert it into usable power, further enhancing energy efficiency.

5. Focus on Renewable Energy Integration

Solar-Powered Submersible Pumps: The integration of solar power with submersible pumps is gaining traction, particularly in remote and off-grid areas. Solar-powered pumps use renewable energy, reducing dependence on fossil fuels and lowering carbon emissions. These systems are ideal for applications such as irrigation, water supply in rural areas, and livestock watering.

Hybrid Power Solutions: Hybrid systems that combine solar power with other renewable energy sources, such as wind or hydroelectric power, are also being developed. These systems offer greater reliability and efficiency, ensuring a consistent energy supply while minimizing environmental impact.

6. Regulatory Compliance and Environmental Standards

Adherence to Energy Efficiency Standards: As governments and regulatory bodies implement stricter energy efficiency standards, manufacturers of submersible pumps are focusing on compliance. Pumps that meet or exceed these standards are more attractive to consumers and businesses looking to reduce energy costs and environmental impact.

Eco-Friendly Certifications: The demand for eco-friendly products is driving the development of Submersible Pumps with certifications such as Energy Star or LEED (Leadership in Energy and Environmental Design). These certifications assure users that the pumps meet high standards for energy efficiency and sustainability.

7. Sustainable Manufacturing Practices

Reduced Carbon Footprint: Manufacturers are increasingly adopting sustainable practices in the production of submersible pumps. This includes using recycled materials, reducing energy consumption during manufacturing, and minimizing waste. By focusing on the entire lifecycle of the product, from production to disposal, companies are contributing to a more sustainable future.

End-of-Life Recycling Programs: Some manufacturers are implementing recycling programs for old or damaged submersible pumps. By reclaiming valuable materials and reducing landfill waste, these programs support a circular economy and reduce the environmental impact of pump disposal.

The future of submersible pumps is centered on energy efficiency and sustainability, with advancements in technology driving significant improvements in both areas. As industries and consumers become more conscious of their environmental impact, the demand for high-efficiency, eco-friendly submersible pumps will continue to grow. By embracing innovations in motor technology, smart systems, renewable energy integration, and sustainable manufacturing practices, the submersible pump industry is poised to play a key role in building a more sustainable and energy-efficient future. For more info contact Submersible Pump Suppliers in UAE or call us at +971 4 2522966.

#Submersible Pumps#Submersible Pump Suppliers in UAE#Submersible Pump Suppliers in Dubai#Submersible Pump Suppliers

0 notes

Text

HERE'S WHAT I JUST REALIZED ABOUT VALLEY

Programmers have to worry that a new model of software. Fortunately, this process also works in reverse: as groups get smaller, software development meant a roomful of men with horn rimmed glasses and narrow black neckties, industriously writing ten lines of code. Facebook, the press will just treat it as a consciously artificial trick, like juggling.1 Just as trying to think of some change I wanted to try being a painter, and the weather's often bad. For the rest of the world, including China. By fear of the schleps involved, don't worry: any sufficiently good idea will have as many. You're all smart and working on promising ideas.2

But now comes the hard part. Don't get complacent if your competitors' software is lame; the standard to compare your software to is what it could be anything, the content, the business world may say. The part I thought was hard, the mechanics of venture funding but knows what a successful startup founder looks like is actually far ahead of someone who knows termsheets inside out, but thinks hacker means someone who breaks into computers.3 Other domains change fast. Work on hard problems, driven mainly by curiosity, but have a second self watching over your shoulder, taking note of gaps and anomalies. Venture investors are driven by exit strategies. It's hard to imagine now, but few nerds. A List of people who are bad at understanding. If you don't genuinely believe that, perhaps you ought to change what your company is doing. And so you won't ordinarily need a computer, per se, and if we want to fund people who are good at that kind of thing at the end of the spectrum. As for building something users love, here are some general tips.

If you describe your web-based database. With server-based software assumes nothing about the client, they can't push users towards their server-based software is offered through ISPs acting as resellers. And software sells hardware. Bill is, because he was a programmer that Facebook seemed a good idea. A List and you want to hear about new startups, the second seems as strong as ever.4 The Bay Area was a magnet for the young and optimistic for decades before it was associated with technology. The centralizing effect of venture firms is a double-edged sword of course. In our test drive, users actually used the software. And fortunately, subscriptions are the natural way to bill for Web-based software now, because writing desktop software, because desktop software has to run on the server. If your terms force startups to do things they don't want to; you could simply be a source of money. In fact, shelving an idea probably even inhibits new ideas: as you start to think of startup ideas.5

If you wanted to make the original Silicon Valley. We inserted him as a ringer in case some competitor tried to spam our web designers. If a company wants to make a list of the most popular sites were loaded with obtrusive branding that made them slow to load and sent the user the message: this is our site, not yours. Now it's a couple of guys sitting in a living room with laptops. 0 in the name of the Web as closely as anyone, and I don't think there was any signal left. That doesn't mean the investor says yes to everyone. They make a new kind of software will be written on this model. The unsexy filter, because the key stage in the life of a startup that's working around the clock doing deals and pumping out new features, and dies because they can't spare the effort to get verified.

Notes

I have yet to find users to switch to a study by the financial controls of World War II had disappeared in a reorganization. Whereas the value of understanding per se but from what it means is you're getting the stats for occurrences of foo in the angel round from good investors that they don't have a significant number.

But this is why search engines and there was nothing to grab onto. Charismatic candidates will tend to damp this effect, at least for those interested in investing but doesn't want to trick a pointy-haired boss into letting him play. The bias toward wisdom in so many of the art itself gets more random, the more corrupt the rulers. Though they were friendlier to developers than Apple is now the founder visa in a request.

There is nothing you can send your business plan to, in one of the 23 patterns in Design Patterns were invisible or simpler in Lisp. I don't know of a correct program. Someone proofreading a manuscript could probably write a subroutine to do, just the local area, and power were concentrated in the past, and this destroyed all traces.

I asked some founders who are running on vapor, financially, and this was the last thing they'd do is adjust the weights till the 1920s to financing growth with the melon seed model is more important. My guess is the post-money valuation of your mind what's the right sort of person who has overheard conversations about sports in a bar.

One YC founder wrote after reading a draft of this essay will say I'm clueless or being misleading by focusing on people who had small corpora. None at all.

#automatically generated text#Markov chains#Paul Graham#Python#Patrick Mooney#problems#user#competitor#random#sup#idea#Someone#Just#foo#model#self#source#List#program#users#stage#business#name#part#candidates#spectrum#Venture#domains

0 notes

Text

Antiepileptic Drugs Market Predictions: Future Insights and Analysis

Antiepileptic Drugs Market Outlook, Scope & Overview:

Industry reports indicate that the global antiepileptic drugs market was valued at USD 18.21 billion in 2023 and is projected to reach USD 26.30 billion by 2031, growing at a CAGR of 4.70% over the forecast period 2024-2031.

Technological Advancements to Drive Growth of Global Antiepileptic Drugs Market

The adoption of advanced antiepileptic drugs (AEDs) will continue to influence global market revenues. The increasing prevalence of epilepsy and other seizure disorders, along with ongoing advancements in drug development and therapy options, are expected to drive market growth.

As a product segment, novel AEDs currently hold a significant share of the global antiepileptic drugs market. This segment is anticipated to grow at a year-over-year rate of 4.70% in 2024 over 2023 and reach USD 26.30 billion in revenues by 2031. The growing demand for effective and targeted therapies, along with increasing awareness about epilepsy, is expected to drive market growth.

Get a Free Sample Report: https://www.snsinsider.com/sample-request/3124

Antiepileptic Drugs – Market Dynamics

Drivers:

The antiepileptic drugs market is witnessing growth due to the rising incidence of epilepsy and the need for effective treatment options. Advances in drug research and development, including the introduction of novel AEDs with improved efficacy and safety profiles, are key factors driving market expansion. Additionally, the increasing adoption of personalized medicine approaches and the growing focus on patient-centric therapies are further propelling market growth.

Restraints:

Despite the growth potential, challenges such as high treatment costs, side effects associated with some AEDs, and the complexity of managing chronic conditions can hinder the widespread adoption of antiepileptic drugs. Moreover, regulatory hurdles and the need for ongoing research to address unmet medical needs pose additional challenges to market expansion.

Antiepileptic Drugs – Market Outlook

The proven benefits of antiepileptic drugs in managing seizure disorders and improving patient quality of life have contributed to the market's growth. Antiepileptic drugs are expected to witness increased adoption across major markets, including North America, Europe, and Asia Pacific, driven by advancements in drug development and the growing focus on epilepsy management.

Global Antiepileptic Drugs Market

The rise in demand for antiepileptic drugs in developed and emerging markets is expected to drive market growth over the forecast period. North America currently holds a significant market share in the global antiepileptic drugs market, with the US being a key contributor to market revenues. Europe and Asia Pacific regions are also experiencing growth in the adoption of AEDs, supported by increasing healthcare investments and rising awareness about epilepsy.

Key Players in the Antiepileptic Drugs Market

Leading companies in the antiepileptic drugs market include Pfizer Inc., Novartis International AG, Johnson & Johnson, and GlaxoSmithKline plc. These companies are at the forefront of developing and commercializing advanced AEDs for various types of epilepsy and seizure disorders.

In conclusion, the global antiepileptic drugs market is poised for steady growth over the forecast period, driven by technological advancements, increasing prevalence of epilepsy, and the expanding adoption of novel and effective therapies for seizure management.

Other Trending Reports

Magnetic Resonance Imaging (MRI) Industry Growth

Infusion Pump Software Industry Growth

Military Wearable Medical Device Industry Growth

Geographic Atrophy (GA) Industry Growth

0 notes

Text

Ceramic Packages Market 2024: Emerging Trends, Major Driving Factors, Business Growth Opportunities

Ceramic Packages Market provides in-depth analysis of the market state of Ceramic Packages manufacturers, including best facts and figures, overview, definition, SWOT analysis, expert opinions, and the most current global developments. The research also calculates market size, price, revenue, cost structure, gross margin, sales, and market share, as well as forecasts and growth rates. The report assists in determining the revenue earned by the selling of this report and technology across different application areas.

Geographically, this report is segmented into several key regions, with sales, revenue, market share and growth Rate of Ceramic Packages in these regions till the forecast period

North America

Middle East and Africa

Asia-Pacific

South America

Europe

Key Attentions of Ceramic Packages Market Report:

The report offers a comprehensive and broad perspective on the global Ceramic Packages Market.

The market statistics represented in different Ceramic Packages segments offers complete industry picture.

Market growth drivers, challenges affecting the development of Ceramic Packages are analyzed in detail.

The report will help in the analysis of major competitive market scenario, market dynamics of Ceramic Packages.

Major stakeholders, key companies Ceramic Packages, investment feasibility and new market entrants study is offered.

Development scope of Ceramic Packages in each market segment is covered in this report. The macro and micro-economic factors affecting the Ceramic Packages Market

Advancement is elaborated in this report. The upstream and downstream components of Ceramic Packages and a comprehensive value chain are explained.

Browse More Details On This Report at @https://www.globalgrowthinsights.com/market-reports/ceramic-packages-market-100566

Global Growth Insights

Web: https://www.globalgrowthinsights.com

Our Other Reports:

Global Magnetic Nanoparticles MarketMarket Share

Global Portable Power Station MarketMarket Growth

Phased Array Antenna MarketMarket

Car Electronics & Communication Accessories MarketMarket Share

Water Filter Jugs MarketMarket Growth Rate

Outdoor Playground Equipment MarketMarket Forecast

Global Sepsis Treatment MarketMarket Size

Battery Electric Car MarketMarket Growth

Gantry or Cartesian Robots MarketMarket Analysis

Digital Pathology MarketMarket Size

Global Microbiome Sequencing Services MarketMarket Share

Global Medical Marijuana MarketMarket Growth

High Speed Steel (HSS) Metal Cutting Tools MarketMarket

Mobile Telemedicine MarketMarket Share

Invisible Orthodontics MarketMarket Growth Rate