#MIGWeldingMachine

Explore tagged Tumblr posts

Text

The Essential Guide to Choosing the Right Welding Machine and Accessories

When welding, having the right tools and accessories is critical. Whether you are working in manufacturing, construction, or repair, your welding machine and accessories can directly impact the quality, safety, and efficiency of your work. In this guide, we’ll explore key considerations for choosing the best welding machine and accessories to fit your needs.

1. Types of Welding Machines

Selecting the right welding machine starts with understanding the different types available and their applications. Here’s a quick overview of the most common types: MIG (Metal Inert Gas) Welding Machines: Ideal for beginners, MIG welding is relatively easy to learn and works well for welding thinner metals, like aluminum and steel. This type is widely used in automotive repair and light manufacturing.

Tungsten Inert Gas (TIG) Welding Machines: TIG welding machines are more versatile, producing cleaner welds with more precision. These machines are popular in industries that demand high-quality welds, such as aerospace and metal fabrication.

Stick Welding Machines: Also known as arc welding, stick welding is robust, affordable, and effective for outdoor projects or thicker metals. It is suitable for heavy-duty welding tasks and commonly used in construction and industrial sectors.

Multi-Process Welders: A versatile option, multi-process welders combine multiple welding methods (like MIG, TIG, and stick) into one machine. They are ideal for workshops that need flexibility without investing in multiple machines.

2. Key Factors to Consider When Choosing a Welding Machine

After determining the type of welding machine, consider these essential factors to ensure you’re making the right investment: Power Supply: Check if your workspace supports the power requirements of your chosen welding machine. Some machines are designed for 110V outlets, while others require 220V. Duty Cycle: The duty cycle represents the amount of continuous welding time before the machine needs to cool down. Higher-duty cycles are better for industrial projects as they minimize downtime. Material Compatibility: Different machines are better suited for specific metals. Make sure your welding machine is compatible with the types of metals you work with regularly. Portability: For on-site or fieldwork, consider the portability of the machine. Portable welders are often smaller and lighter, allowing you to transport them easily to different job locations.

3. Must-Have Welding Accessories for Optimal Performance

In addition to the welding machine, having the right accessories enhances the safety, productivity, and quality of the welds. Here are a few essential accessories every welder should have: Welding Helmets: A high-quality helmet is crucial for protecting your face and eyes from sparks, heat, and harmful radiation. Look for auto-darkening helmets that automatically adjust to the brightness of the arc, allowing you to see your work clearly. Welding Gloves and Jackets: These protect your hands and body from sparks, heat, and UV radiation. Choose gloves and jackets made from durable, fire-resistant materials like leather. Welding Clamps: Clamps secure your metal workpieces in place, reducing the risk of accidents and ensuring a clean, accurate weld. Choose clamps that are heat-resistant and easy to adjust. Welding Carts: Carts make it easy to move your welding machine and accessories around your workspace. Look for carts with wheels that can handle the weight of your welding setup. Welding Wire and Electrodes: Choose high-quality wires and electrodes compatible with your welding machine. The right materials will improve the quality and strength of your welds. Fume Extractors: Welding generates fumes and particles that can be hazardous to health. Fume extractors help ensure a safe and clean working environment by removing harmful emissions from the air.

4. Maintenance Tips for Prolonging Your Welding Equipment’s Lifespan

Regular maintenance ensures that your welding equipment remains in peak condition. Here are a few tips for keeping your machine and accessories in top shape: Clean Regularly: Dust and debris can accumulate in your welding machine. Regular cleaning helps prevent blockages and overheating. Inspect Cables and Connections: Frequently check your machine’s cables and connections for any signs of wear or damage. Replace damaged components promptly to avoid electrical issues. Store in a Dry Place: Moisture can cause rust and corrosion, affecting your welding machine’s performance. Store your equipment in a cool, dry place when not in use. Calibrate Periodically: For accuracy, periodically calibrate your welding machine to ensure consistent performance and high-quality welds.

5. Partnering with a Reliable Welding Equipment Supplier

Choosing the right supplier for your welding machines and accessories can make all the difference. A reliable supplier not only provides high-quality products but also offers valuable insights and guidance in selecting the right equipment for your needs. Look for suppliers with industry experience, a wide product range, and responsive customer service to help you make informed decisions. Final Thoughts The right welding machine and accessories can significantly impact the quality and efficiency of your work. Whether you are a professional welder or a DIY enthusiast, taking the time to choose equipment that matches your project’s requirements will yield excellent results and help you achieve optimal performance.

1 note

·

View note

Text

Power up your welding projects with our MIG Welding Machine (MAG/CO2)! Equipped with a constant potential power source, wire feeder, gas-cooled torch, and more, this machine is built for precision and reliability. From the pressure regulator to the welding cable, every component ensures a seamless welding experience.

For more details, visit - https://www.yashmachine.com/product/welding/mig

0 notes

Text

Rajlaxmi Machine Tools offers HMP | Ramato | Roent Make Anodizing Rectifier, Electro Plating Rectifier, DC Rectifier, Dimmer, Transformer based MIG Co2 Welding Machine, IGBT Based Plating Rectifier, 3 Phase Thyristor Control Regulator, Air Cooled Rectifier, Oil Cooled Rectifier, Fan Cooled Rectifier, AC Rectifier, DC Rectifier Machine, and All Type of CED Coating Equipments Exporter From Rajkot Gujarat Bharat (INDIA).

#HMPRectifier#RamatoRectifier#RoentRectifier#AnodizingRectifier#ElectroPlatingRectifier#DCRectifier#Dimmer#TransformerBasedMIGWeldingMachine#MIGWeldingMachine#CO2WeldingMachine#IGBTBasedPlatingRectifier#3PhaseThyristorControlRegulator#AirCooledRectifier#OilCooledRectifier#FanCooledRectifier#ACRectifier#DCRectifierMachine#CEDCoatingEquipments#RectifierExporter#RajkotRectifier#GujaratRectifier#IndiaRectifier#RectifierManufacturers#PlatingRectifier#WeldingMachine#RectifierSystems#RectifierSolutions#RectifierTechnology#RectifierDesigns#RectifierProducts

0 notes

Text

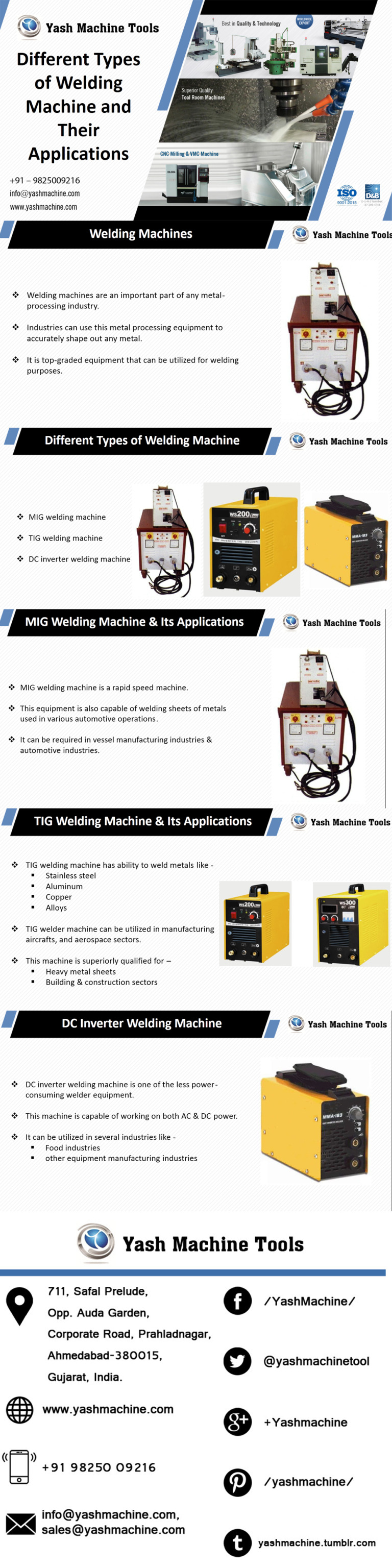

Different Types of Welding Machine & Their Applications

Welding machines are an important part of any metal-processing industry, as they have the ability to produce heat in order to melt down the metal, so that the metal can be constructed into a specific structure. Industries can use this metal processing equipment to accurately shape out any metal. Now, welding machines like MIG welding machine, TIG welding machine & DC inverter welding machine are top-graded equipment that can be utilized for welding purposes. Hence, the detailed information mentioned below can explain about different types of welding machines & their applications.

Key Tips for A Utilizing Welding Machine

There are several important aspects that can be followed while utilizing a welding machine for accurate welding of the metals. One of the prior tips that can be followed while welding is that, the welding equipment needs to be operated on a heavy force, when the metal is either dirty or has rustic layers on it. Tips like flux-cored welding techniques can also be applied to the thick metal surface for welding. Mainly this technique is helpful at places like construction sectors as well as dockyards, where metals of the ships are thicker, and requires heavy metal welding.

The exporters of MIG, TIG & DC inverter welding machines can benefit the industries in which the welding of metals are demanded for different purposes. These welding equipment can also offer advantages like less-power consumption, rapid & top-grade welding force & other features like rapid cool down of the equipment as soon as the welding operation is executed. Therefore, industries with the requirement of a welding machine can get their suitable type of welding equipment from the MIG, TIG & DC inverter welder machine manufacturers.

Know about Welding Machines visit- https://www.yashmachine.com/product/welding

Follow us on-

Facebook: https://www.facebook.com/YashMachine/

Pinterest: http://pinterest.com/yashmachine/

Tumblr: http://yashmachine.tumblr.com/

Twitter: https://twitter.com/yashmachinetool

#WeldingMachine#TIGWeldingMachine#MIGWeldingMachine#MAGWeldingMachine#CO2WeldingMachine#MMAWeldingMachine#DCInverterWeldingMachine

0 notes

Video

instagram

Test mesin las after service #perbaikanmesin #servicemesinimdustri #migweldingmachine

0 notes

Text

Mig Welding Machine

9016903132, 9426526762

www.hmpdrills.com

#hmp #mig #welding #machine #migwelding #migweldingmachine #welder #mag #magwelding #co2 #co2welding #co2weldingmachine #weldingmachine #250a #400a #singlephase #threephase #rajkot #gujarat #india #manufacturer #dealer

0 notes

Text

MigWeldingMachine Mig Welding Machine http://ping.fm/RwzBc Online Shopping For Mig Welding Machine & Comparison Shopping For Mig Welding Machine.

0 notes

Text

MigWeldingMachine Mig Welding Machine http://ping.fm/Objdh Compare And Buy Best Mig Welding Machine We Offers Best Deal To Buy Mig Welding Machine On Mig Welding Machine.

0 notes

Text

Rajiv Machine Tools is a leading supplier of high-quality welding machines, including TIG welding machines, MIG welding machines, MMA Welding machines, and submerged arc welding as well as a comprehensive range of welding accessories and welding consumables. Over the years, we have expanded our reach and expertise, now offering 1,100+ products to a growing base of 500+ clients through a robust 100+ dealer network across Ahmedabad and Gujarat.

MIG Welding Machine (Metal Inert Gas)

Overview: MIG welding machines use a continuous wire electrode fed through a welding gun. The process involves shielding the weld with an inert or semi-inert gas to protect it from atmospheric contamination.

Features

High deposition rate.

Easy to learn and operate.

Suitable for welding thin and thick materials.

Applications: Automotive industry.

Construction and structural welding.

Repair and maintenance work.

Advantages:

Faster welding speeds.

Clean and spatter-free welds.

Minimal post-weld cleaning required.

0 notes

Text

Rajlaxmi Machine Tools offers HMP | Ramato | Roent Make All Type of Welding Series Like Transformer Based Welding Machine (Air Cooled, Fan Cooled & Oil Cooled), Stud Type Welding, Regulator Type Welding Machine, Arc Welding Machine, MMA Welding Machine, Tig Welding Machine, Argon Gas Welding Machine, Mig Welding Machine, Mag Welding Machine, CO2 Gas Welding Machine, Gasless Mig Welding Machine, Air Plasma Cutting Machine, Spot Welding Machine, Butt Welding Machine, Projection Welding Machine, Resistance Welding Machine, Pneumatic Welding Machine, Laser Welding Machine and All Type of Welding Accessories From Rajkot Gujarat Bharat (INDIA).

#MIGWeldingMachine#MAGWeldingMachine#CO2WeldingMachine#MIGWelding#MAGWelding#CO2Welding#WeldingMachine#MIGWeldingTech#MAGWeldingTech#CO2WeldingTech#WeldingEquipment#MIGWeldingEquipment#MAGWeldingEquipment#CO2WeldingEquipment#WeldingTools#MIGWeldingProcess#MAGWeldingProcess#CO2WeldingProcess#MIGWeldingMachineFeatures#MAGWeldingMachineFeatures#CO2WeldingMachineFeatures#WeldingMachineApplications#MIGWeldingApplications#MAGWeldingApplications#CO2WeldingApplications#MIGWeldingMachineParts#MAGWeldingMachineParts#CO2WeldingMachineParts#WeldingMachineComponents#MIGWeldingMachineComponents

0 notes

Text

The welding process includes exposing the components to elevated temperatures that melt the parts and when left for cooling these parts fuse together.

To know more, visit: https://www.yashmachine.com/mig/

#yashmachinetools#migwelding#migweldingmachine#weldingmachine#Fabricationwork#vesselbuilding#heavystructurework#bodybuilding

0 notes

Text

MIG, TIG, and DC Inverter Welder Machines are a few examples of the best #WeldingMachine that may be used to conduct rational welding over job materials that are frequently challenging to manage using traditional equipments.

For more details, visit us at https://www.yashmachine.com/product/welding

#yashmachinetools#weldermachine#migwelding#migwelder#migweldingmachine#tigwelder#tigwelding#TigWeldingMachine#dcinverterweldermachine#inverterweldingmachine

0 notes

Text

#MIGWeldingMachine are used in industries like #AutomotiveIndustry, #Construction and #ManufacturingIndustries due to their high efficiency of #Welding process. Visit https://www.yashmachine.com/product/welding/mig

#yashmachinetools#yashmachine#weldingmachine#automotiveindustry#constructionindustry#manufacturingindustry

0 notes

Text

#MIGWeldingMachine are used in industries like #AutomotiveIndustry, #Construction and #ManufacturingIndustries due to their high efficiency of #Welding process.

Visit https://www.yashmachine.com/product/welding/mig to know more about Welding Machines.

#yashmachinetools#yashmachine#weldingmachine#automotiveindustry#constructionindustry#manufacturingindustry

0 notes

Text

#MIGWeldingMachine are used in industries like #AutomotiveIndustry, #Construction and #ManufacturingIndustries due to their high efficiency of #Welding process.

Visit https://www.yashmachine.com/product/welding/mig to know more about Welding Machines.

#yashmachinetools#yashmachine#weldingmachine#automotiveindustry#constructionindustry#manufacturingindustry

0 notes

Text

youtube

Different types of #WeldingMachines have different applications that are used in metal-processing Industries. Watch out our video to know more - https://www.youtube.com/watch?v=ZxW8ehFRhMo&t=3s

0 notes