#tigwelder

Explore tagged Tumblr posts

Text

The Essential Guide to Choosing the Right Welding Machine and Accessories

When welding, having the right tools and accessories is critical. Whether you are working in manufacturing, construction, or repair, your welding machine and accessories can directly impact the quality, safety, and efficiency of your work. In this guide, we’ll explore key considerations for choosing the best welding machine and accessories to fit your needs.

1. Types of Welding Machines

Selecting the right welding machine starts with understanding the different types available and their applications. Here’s a quick overview of the most common types: MIG (Metal Inert Gas) Welding Machines: Ideal for beginners, MIG welding is relatively easy to learn and works well for welding thinner metals, like aluminum and steel. This type is widely used in automotive repair and light manufacturing.

Tungsten Inert Gas (TIG) Welding Machines: TIG welding machines are more versatile, producing cleaner welds with more precision. These machines are popular in industries that demand high-quality welds, such as aerospace and metal fabrication.

Stick Welding Machines: Also known as arc welding, stick welding is robust, affordable, and effective for outdoor projects or thicker metals. It is suitable for heavy-duty welding tasks and commonly used in construction and industrial sectors.

Multi-Process Welders: A versatile option, multi-process welders combine multiple welding methods (like MIG, TIG, and stick) into one machine. They are ideal for workshops that need flexibility without investing in multiple machines.

2. Key Factors to Consider When Choosing a Welding Machine

After determining the type of welding machine, consider these essential factors to ensure you’re making the right investment: Power Supply: Check if your workspace supports the power requirements of your chosen welding machine. Some machines are designed for 110V outlets, while others require 220V. Duty Cycle: The duty cycle represents the amount of continuous welding time before the machine needs to cool down. Higher-duty cycles are better for industrial projects as they minimize downtime. Material Compatibility: Different machines are better suited for specific metals. Make sure your welding machine is compatible with the types of metals you work with regularly. Portability: For on-site or fieldwork, consider the portability of the machine. Portable welders are often smaller and lighter, allowing you to transport them easily to different job locations.

3. Must-Have Welding Accessories for Optimal Performance

In addition to the welding machine, having the right accessories enhances the safety, productivity, and quality of the welds. Here are a few essential accessories every welder should have: Welding Helmets: A high-quality helmet is crucial for protecting your face and eyes from sparks, heat, and harmful radiation. Look for auto-darkening helmets that automatically adjust to the brightness of the arc, allowing you to see your work clearly. Welding Gloves and Jackets: These protect your hands and body from sparks, heat, and UV radiation. Choose gloves and jackets made from durable, fire-resistant materials like leather. Welding Clamps: Clamps secure your metal workpieces in place, reducing the risk of accidents and ensuring a clean, accurate weld. Choose clamps that are heat-resistant and easy to adjust. Welding Carts: Carts make it easy to move your welding machine and accessories around your workspace. Look for carts with wheels that can handle the weight of your welding setup. Welding Wire and Electrodes: Choose high-quality wires and electrodes compatible with your welding machine. The right materials will improve the quality and strength of your welds. Fume Extractors: Welding generates fumes and particles that can be hazardous to health. Fume extractors help ensure a safe and clean working environment by removing harmful emissions from the air.

4. Maintenance Tips for Prolonging Your Welding Equipment’s Lifespan

Regular maintenance ensures that your welding equipment remains in peak condition. Here are a few tips for keeping your machine and accessories in top shape: Clean Regularly: Dust and debris can accumulate in your welding machine. Regular cleaning helps prevent blockages and overheating. Inspect Cables and Connections: Frequently check your machine’s cables and connections for any signs of wear or damage. Replace damaged components promptly to avoid electrical issues. Store in a Dry Place: Moisture can cause rust and corrosion, affecting your welding machine’s performance. Store your equipment in a cool, dry place when not in use. Calibrate Periodically: For accuracy, periodically calibrate your welding machine to ensure consistent performance and high-quality welds.

5. Partnering with a Reliable Welding Equipment Supplier

Choosing the right supplier for your welding machines and accessories can make all the difference. A reliable supplier not only provides high-quality products but also offers valuable insights and guidance in selecting the right equipment for your needs. Look for suppliers with industry experience, a wide product range, and responsive customer service to help you make informed decisions. Final Thoughts The right welding machine and accessories can significantly impact the quality and efficiency of your work. Whether you are a professional welder or a DIY enthusiast, taking the time to choose equipment that matches your project’s requirements will yield excellent results and help you achieve optimal performance.

0 notes

Text

MIG, TIG, and DC Inverter Welder Machines are a few examples of the best #WeldingMachine that may be used to conduct rational welding over job materials that are frequently challenging to manage using traditional equipments.

For more details, visit us at https://www.yashmachine.com/product/welding

#yashmachinetools#weldermachine#migwelding#migwelder#migweldingmachine#tigwelder#tigwelding#TigWeldingMachine#dcinverterweldermachine#inverterweldingmachine

0 notes

Text

Rajlaxmi Machine Tools offers HMP | Ramato | Roent Make All Type of Welding Series Like Transformer Based Welding Machine (Air Cooled, Fan Cooled & Oil Cooled), Stud Type Welding, Regulator Type Welding Machine, Arc Welding Machine, MMA Welding Machine, Tig Welding Machine, Argon Gas Welding Machine, Mig Welding Machine, Mag Welding Machine, CO2 Gas Welding Machine, Gasless Mig Welding Machine, Air Plasma Cutting Machine, Spot Welding Machine, Butt Welding Machine, Projection Welding Machine, Resistance Welding Machine, Pneumatic Welding Machine, Laser Welding Machine and All Type of Welding Accessories From Rajkot Gujarat Bharat (INDIA).

#ArgonWeldingMachine#TIGWeldingMachine#GasWeldingMachine#WeldingMachine#ArgonWelding#TIGWelding#GasWelding#WeldingEquipment#IndustrialWeldingMachine#ArgonWeldingTech#TIGWeldingTech#GasWeldingTech#WeldingTools#ArgonWeldingEquipment#TIGWeldingEquipment#GasWeldingEquipment#WeldingMachineFeatures#ArgonWeldingMachineFeatures#TIGWeldingMachineFeatures#GasWeldingMachineFeatures#WeldingMachineApplications#ArgonWeldingApplications#TIGWeldingApplications#GasWeldingApplications#ArgonWeldingMachineParts#TIGWeldingMachineParts#GasWeldingMachineParts#WeldingMachineComponents#ArgonWeldingMachineComponents#TIGWeldingMachineComponents

0 notes

Video

youtube

TIG Welding in Hyderabad | Vishnupiryaindustries | TIG Welding services ...

#youtube#TIGWelding TIGWeldingservices TIGWeldingservicesinhyderabad Vishnupriyaindustries VishnupriyaindustriesbrandisINNofab vishnupriyaindustries

0 notes

Text

Stainless Steel Hollow Bars

Need lightweight strength for your project? Look no further than stainless steel hollow bars. SS hollow sections or tubes offer a compelling combination of strength, corrosion resistance, and lightweight design. These versatile bars, available in various sizes and shapes, including stainless steel hollow square bars, cater to diverse applications across industries. They are made from various grades of stainless steel, such as 304, 316, and 430, each with its own unique properties and applications. These versatile tubes, available in various sizes like square bars and hollow tubes, offer impressive strength without the weight. It is used in construction (railings, columns) and automotive (roll cages, exhaust systems) due to their strength-to-weight ratio.

To know more details you can check out this link:https://onetouchexim.com/stainless-steel-hollow-bars-applications-uses/

#stainlesssteel#steel#stainless#jewelry#handmade#welding#fabrication#design#tigwelding#stainlesssteeljewelry#metal#interiordesign#tig#custom#kitchen#earrings#manufacturing

0 notes

Text

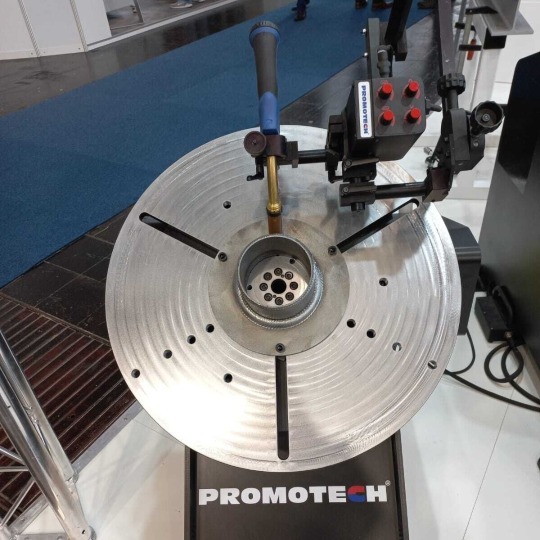

Promotech 𝐌𝐎𝐃𝐔𝐋𝐀𝐑 𝐖𝐄𝐋𝐃𝐈𝐍𝐆 𝐏𝐎𝐒𝐈𝐓𝐈𝐎𝐍𝐄𝐑💪🏻, now equipped with an innovative new feature. Simplify your welding process with precision and efficiency. Experience improved stability and control as you work on your projects. Get the most out of every weld with this cutting-edge positioner. . ▶️ 𝐏𝐫𝐨𝐝𝐮𝐜𝐭 𝐍𝐚𝐦𝐞: ▪️ Positioner 300 Premium ▪️ Positioner 750 Premium ▶️ 𝐅𝐞𝐚𝐭𝐮𝐫𝐞𝐬 𝐚𝐧𝐝 𝐁𝐞𝐧𝐞𝐟𝐢𝐭𝐬: ▪️ Automatic strat/stop ▪️ Automatic Arc ignition control ▪️ Intermittent (stitch) welding with the adjustment of weld length ▪️ Display of actual welding speed ▪️ Settings of total weld length or the rotation angle ▪️ Overlap length adjustment ▪️ Back welding ▪️ Crater fill ▪️ Clading ▪️ Smart HMI pendant controller . Get to know more about the product by mailing us at [email protected] or call us @ +91 844 838 5808

#PromotechIndia#weldingpositioner#welding#tigwelding#weldlife#weldeverydamnday#welder#fabrication#weld#weldernation#metalwork#weldinglife#steel#metal#migwelding#metalfabrication

0 notes

Text

How to Tig Weld? Mastering the Art of TIG Welding: A Comprehensive Guide

#TIGWelding#WeldingGuide#WeldingTechniques#GasTungstenArcWelding#WeldingTips#TIGWeldingBasics#Fabrication#Manufacturing#WeldingSkills#WeldingEquipment#WeldingSafety#WeldingAr

0 notes

Text

Rajiv Machine Tools is a leading supplier of high-quality welding machines, including TIG welding machines, MIG welding machines, MMA Welding machines, and submerged arc welding as well as a comprehensive range of welding accessories and welding consumables. Over the years, we have expanded our reach and expertise, now offering 1,100+ products to a growing base of 500+ clients through a robust 100+ dealer network across Ahmedabad and Gujarat.

MIG Welding Machine (Metal Inert Gas)

Overview: MIG welding machines use a continuous wire electrode fed through a welding gun. The process involves shielding the weld with an inert or semi-inert gas to protect it from atmospheric contamination.

Features

High deposition rate.

Easy to learn and operate.

Suitable for welding thin and thick materials.

Applications: Automotive industry.

Construction and structural welding.

Repair and maintenance work.

Advantages:

Faster welding speeds.

Clean and spatter-free welds.

Minimal post-weld cleaning required.

0 notes

Text

A Comprehensive Guide to TIG Welding

TIG welding, which stands for Tungsten Inert Gas welding, is a welding technique that uses a non-consumable tungsten electrode to heat and melt metal workpieces together. The weld area is protected from atmospheric contamination by an inert shielding gas, typically argon, which flows around the weld area to prevent oxidation and other types of contamination. TIG welding is a precise welding process that produces high-quality welds with minimal spatter, making it ideal for welding thin materials and for applications that require a clean and aesthetically pleasing weld. TIG welding is commonly used in the aerospace, automotive, and electronics industries, as well as for welding stainless steel, aluminum, and other non-ferrous metals.

Equipment and Safety

To begin TIG welding, you will need a few essential pieces of equipment, such as a TIG torch, power source, TIG electrode, and a shielding gas like argon. You will also need a welder's helmet, welding gloves, and protective clothing. Before starting your project, make sure your workspace is clean, organized, and free of any flammable materials or potential hazards. Always follow proper safety procedures, such as grounding your equipment and wearing proper protective gear.

Setting up Your Equipment

Before starting to weld, set up your equipment and adjust the settings according to the material you will be welding. You must have a clean and polished TIG electrode for your welding project. The electrode must be the correct size, type, and amperage for the material you are welding. For example, the amperage and electrode size used for welding aluminum will differ from that used for welding steel.

TIG Welding Techniques

Here are some of the techniques used in TIG welding: Torch Angle: The torch angle is important in TIG welding because it affects the weld's appearance and penetration. A torch angle of about 10-15 degrees from vertical is generally recommended. Filler Rod Placement: The filler rod should be placed in the heat of the arc, just ahead of the molten pool. This helps ensure the proper fusion of the base metal and the filler material. Shielding Gas Flow: The shielding gas flow should be adjusted to ensure adequate coverage of the weld area. The gas flow rate is typically around 15-20 cubic feet per hour. Arc Length: Maintaining the proper arc length is critical in TIG welding. The arc should be kept as short as possible to prevent oxidation and ensure good penetration. Welding Speed: The welding speed should be consistent to ensure a consistent weld bead. It is important to maintain a steady pace to prevent overheating the base metal or creating cold welds. Pulse Frequency: Pulse TIG welding is a technique that involves alternating the welding current between high and low frequencies. This can be used to control the heat input and improve weld quality. Post-Weld Cleaning: After welding, the weld area should be cleaned to remove any oxidation or contamination that could weaken the weld. This can be done with a wire brush or grinder.

Common Problems and Solutions

As with any welding technique, TIG welding can present some issues that can affect the quality of your weld. One common problem is porosity, which results from gas pockets forming inside the weld. Porosity can be caused by contaminated shielding gas or a dirty workpiece. You can rectify this by using clean gas and ensuring your workpiece is clean and polished before you start welding. TIG welding is an excellent method for producing high-quality, precise, and aesthetically pleasing welds. However, it is essential to have the right equipment, follow safety guidelines, and master the techniques to ensure a successful outcome. With patience, practice, and attention to detail, you can become an expert TIG welder and produce welds that will stand up to even the most demanding applications. Photo by Heber Davis on Unsplash Read the full article

0 notes

Text

Make Welding Projects Easy With a TIG Machine at Canaweld

TIG welding is an amazing way to provide your next project with the best precision, sleek design and professionalism. For years, these welders have done wonders in transforming projects into things of beauty.

Here at Canaweld we offer these machines in a quality you won't find anywhere else.

If you're interested in learning more about our TIG Welders in Canada, be sure to visit our official website linked below and get in touch with our team of welding experts today! We look forward to hearing from you/working with you soon.

🌎 Learn More: https://www.canaweld.com

📞 Phone: (416) 548-5650

📬 Email: [email protected]

📍 Location: 155 Drumlin Circle, Vaughan, ON L4K 3E7

#TIG#welderMachine#weldingMachines#Welder#WeldersSupplies#TIGWelding#MultiProcessWelders#TIGWelders#TIGWelder#CanadaWeldingSupply

0 notes

Text

5 notes

·

View notes

Text

📢𝗜𝗺𝗺𝗲𝗱𝗶𝗮𝘁𝗲 𝗛𝗶𝗿𝗶𝗻𝗴: 𝗧𝗜𝗚 𝗪𝗲𝗹𝗱𝗲𝗿𝘀 – 𝗔𝘁𝗵𝗹𝗼𝗻𝗲, 𝗜𝗿𝗲𝗹𝗮𝗻𝗱!

We are looking for certified TIG Welders to join our team in Athlone, Ireland for an urgent project.

🔹𝗥𝗲𝗾𝘂𝗶𝗿𝗲𝗺𝗲𝗻𝘁𝘀:

✅Must be certified in TIG welding

✅Minimum 3 years of experience in welding

✅Expertise in 6mm thick carbon pipe welding

✅Ability to work in a fast-paced environment

✅Available to start immediately

📩 Apply now! Don't miss this opportunity—send your CV today.

🌐 www.awilli-ag.ch

#Hiring #TIGWelders #AthloneJobs #WeldingJobs #ImmediateStart #TigWelding #Irelandjobs #HireTIGWelders

0 notes

Text

Tecoustics also offers experts welding services, including Tig Welding and Mig Welding, ensuring strong and durable joints for various metal fabrication projects.

#MetalLaserCutting

#TigWelding

#MigWelding

#CustomMetalCutting

https://bit.ly/3uTecDF

0 notes

Text

Revolutionize your welding process ✌️ with our welding positioners💪🏻! Designed to rotate 🌀 round or tubular metal pieces effortlessly, they enhance weld seam accessibility and ensure high-quality welds 🧑🏻🏭. Experience increased ⬆️ deposition rates and improved productivity. Level up your welding game today! . Visit https://bit.ly/43hzDcr for more details . #PromotechIndia #weldingpositioner #welding #tigwelding #weldlife #weldeverydamnday

#promotechindia#fabrication#india#beveling#metalindustry#metal#automationsolution#welding#automation#bevellingmachine

0 notes

Text

"Harmony" 316L stainless steel sheet Modern Sculpture

2 notes

·

View notes

Video

tumblr

That’s a real welder and a real life situations for tax on the pipe welded up with your legs crossed

2 notes

·

View notes