#Lubricants For The Mining Industry

Explore tagged Tumblr posts

Text

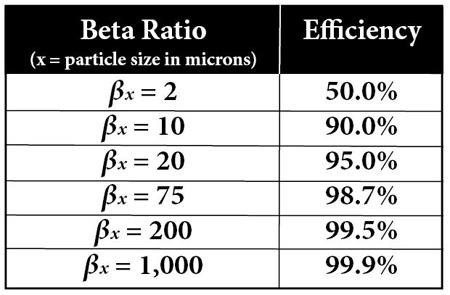

Understanding of the BETA factor

What is the Beta Ratio?

The beta ratio refers to the efficiency in which a given filter element removes the particle of a given size. The Beta Ratio is calculated using the ISO multi-pass test standard 16889:1999.

How is it measured?

Get your filter check today, Call +91 7030901266

So, to purchase a filter with a beta ratio of 2-10 is considered poor, it is advised to use filters with at least a Beta factor of 75 and 98.7% effectiveness. High quality, efficient filter assemblies can achieve 200 to 2000 Beta Ratio for given particle size and should be ideal to achieve a low level of contamination.

Also read: https://www.linkedin.com/pulse/you-buying-right-oil-filter-anshuman-agrawal-mlt-1-/

We at Minimac Systems Pvt Ltd. provide services of Total Lubrication Management and Lubrication Consulting that helps you optimize your Lubrication needs. Minimac stands for MINImum MAChinery Maintenance.

#frf#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#lube oil filter#hydraulic oil filter#contamination#oil purification system#oil purification machine#oil contamination#oil purification#oil testing#oil filter machine#oil filter systems#oil filters#oil industry#oil and gas#turbine oilanalysis maintenance lubrication reliability contaminationcontrol oil powerplants oilfiltration rotatingequipment mechanical bre#turbinemaintenance#wind turbines#gas turbine#steam turbine#steel#metal#mining#oil dehydration systems

2 notes

·

View notes

Text

United States industrial lubricants market size reached USD 7.8 Million in 2024. Looking forward, IMARC Group expects the market to reach USD 10.5 Million by 2033, exhibiting a growth rate (CAGR) of 3.3% during 2025-2033. The growing utilization in the production of vehicles and the maintenance of manufacturing equipment, rising adoption of industrial automation, and increasing investments in research and development (R&D) represent some of the key factors driving the market.

#United States Industrial Lubricants Market Report by Product Type (Hydraulic Fluid#Metal Working Fluid#Gear Oil#Grease#and Others)#Base Oil (Mineral Oil#Synthetic Oil#Bio-based Oil)#End Use Industry (Construction#Metal and Mining#Cement Production#Power Generation#Automotive#Chemical Production#Oil and Gas#Textile Manufacturing#Food Processing#Agriculture#Pulp and Paper#and Region 2025-2033

0 notes

Text

What Lubricant Should You Use for Mining Machines?

In the demanding world of mining, machinery is subjected to harsh conditions, including extreme temperatures, heavy loads, and constant exposure to dust and debris. Proper lubrication is essential for protecting this equipment, preventing costly downtime, and ensuring efficient operation.

Choosing the Right Lubricant for Peak Performance in Mining Operations

In the demanding world of mining, machinery is subjected to harsh conditions, including extreme temperatures, heavy loads, and constant exposure to dust and debris. Proper lubrication is essential for protecting this equipment, preventing costly downtime, and ensuring efficient operation.

GS Caltex India, a leading supplier of lubricants for mining industry, has factors to consider when selecting the right lubricant for your mining equipment.

Factors to Consider When Choosing a Lubricant

When selecting a lubricant for your mining equipment, several crucial factors need to be considered:

Equipment type: Different types of mining equipment require specific lubricants formulated to meet their unique operating conditions and demands.

Operating conditions: Factors such as temperature, load, and exposure to water and dust will influence the type of lubricant needed.

Performance requirements: Consider the desired properties of the lubricant, such as viscosity, oxidation resistance, and anti-wear characteristics.

Compatibility: Ensure the chosen lubricant is compatible with your equipment's materials and other lubricants being used.

GS Caltex India: Your Trusted Partner in Mining Lubrication

GS Caltex India offers a comprehensive range of high-performance lubricants specifically designed for the demanding requirements of the mining industry. Their lubricants are formulated with advanced technologies to deliver:

0 notes

Text

I feel really sorry for whales on account of the whole "driving them to near extinction" thing but in retrospect it's extremely funny to me that we figured out "create an entire industry out of extremely dangerous hunting of a limited number of giant sea mammals" before mastering the whole "hydrocarbons that shoot right out of the fucking ground in unimaginable quantities" thing. There were entire factories of steam engines running machines powered by coal mined from the ground but they were lubricated entirely with foul smelling cetacean juice instead of like, fossil fuel oil that literally shoots out of the ground.

90 notes

·

View notes

Text

On October 17th 1850 James Young obtained the patent for the extraction of paraffin from shale.

The following year the world's first commercial oil refinery followed opened.The chemist-cum-businessman James Young, later known as "Paraffin" Young, opened a works near Bathgate that produced lubricating oils and naphtha (for use as a cleaning solvent) from the shale found among West Lothian's coal deposits.

Soon he developed technologies that produced paraffin for lights – Bathgate oil lit a quarter of London's lamps – and paraffin wax for candles. In the 1860s, when many of Young's patents expired, Scotland became gripped by oil mania as dozens of hastily established companies dug pits and erected retorts and refineries in a small stretch of countryside to the south of the Forth.

During its first boom, the shale oil industry employed more than 30,000 people, many of them migrants from elsewhere in Britain. Existing villages grew at a rate bewildering to those who lived in them – Broxburn's population went from 660 to 5,898 in 30 years – while entirely new settlements of brick cottages, with perhaps a store or a working men's institute at their centre, appeared suddenly where no one had previously thought to live. By the 1910's West Lothian shale produced 27.5m barrels of crude oil, which was roughly 2% of then world production.

As the 20th century progressed oil from the Persian gulf became more abundant and cheaper to produce, the second world war and oil shortages prolonged the shale business but the writing was on the wall. The last shale mine closed in 1962, and then it was gone. The pitheads, the retorts, the refineries and the narrow-gauge electric railway that connected them: all vanished, leaving the spoil heaps, the bings, as the most visible evidence that industry had ever existed.

Just north of my home town of Loanhead lays Straiton, not retail parks and most famous for the large Ikea there, but back in the day it was part of the shale works that stretched across the Lothians, all that is left of the Straiton Oil Company are a row of cottages, the head office was in a building that eventually was converted into a pub, The Callyr Inn, sadly the people that bought it years after it closed let it rot, deliberately making it so unsafe that it was pulled down to be replaced by more warehouse type units.

Two of the bings remain, Greendyke and Five Sisters, as industrial monuments protected in law against excavation and reshaping by road builders who want their red waste as hardcore. Whether you love them or hate them the bings are there to stay, as a reminder to a once thriving mining industry around the lothians,, my fave is Greendyke, if you like a good walk, apparently they call it Bing Bashing, it offers great views, you can see the Ochils to the north and the Pentlands to the south, the strange cone of North Berwick Law away to the east and it's possible to make out the shape of Ben Lomond to west, on a clear day. Edinburgh Castle and the Forth bridges are easily picked out and if you walk to the northern edge,you can look down on Niddry Castle, a 15th-century keep where Mary Queen of Scots once spent a night.

There's loads of history, first is the official Shale Oil Museum webpage, promoting the museum itself, it will take you weeks to get through everything here https://www.scottishshale.co.uk/index.html

Pics are James "Parafin" Young, some old pics of the industrialisation, an old Farm eaten up by the plants and pics of the Greendyke bing, with Niddry Castle and Five Sisters Bing from the air

11 notes

·

View notes

Text

Back on my Wheels Bullshit Again

Some thoughts about why Menos are probably not a good replacement candidate for whale oil; and why the Seireitei should have an extremely racist (ghost-ist?) World's Fair

Yesterday I drove 500+ miles to see someone perform, among other things, as a seagull in a James and the Giant Peach musical. EXCELLENT, would recommend, but this also meant I had a good amount of time on the road to think about some absolute bullshit. As a result of the Great Summer Conspiracy (road construction, hours and hours), I'm also feeling dehydrated and mentally addled, so this will be word vomit I may come back to more seriously, or maybe not! Who knows!

But I was thinking about the Soul Society wheels situation. Wheels exist, if not in great numbers (filler wheels in deep Rukongai; Mayuri's Hueco Mundo caravan; the casters on the Zombie Pods, the wheels on Yachiru's sheathe). But if they wanted more wheels (transportation wheels, but any other kind of wheels or spinning thing--like, in a computer or other mechanized object), what would they use for lubricant? Is there oil they can drill for? Is the ocean close and fecund enough to have whale oil (or I guess... some other oily fish, in abundance)? There doesn't seem to be a lot of domestic animal husbandry to be using them for tallow/lard in addition to occasional food. Does the 12th have a lubricants division, and if so, what kinds of things do they develop, and what raw materials are available? I guess they probably do, but the fact remains they have way fewer wheels and spinny things than we do.

I feel like Menos would not be a good substitute for whale oil, because, despite having made a joke about Menos leather jackets once, I don't think they use Hollows like that, due to the stigma (and/or concerns over spiritual contamination). And also because it may not be that....stable? Like, it seems equally likely that a Menos body might stick around to be harvested, or would just poof into reishi motes. Maybe there's some finesse to whichever of these happens, but the whole otherworldly spirit flesh thing introduces some complications here, is what I'm saying.

Which made me think about the fact of most of the population of Soul Society not needing to eat, and the need for food production not acting as a driver for agricultural/industrial change, because the eating population is pretty small. So who needs wheels, or agriculture at scale, or orphan chimney sweeps? As long as you have enough criminals to mine for seki-sekki, you're gucci!

In terms of things shinigami would have spent time on instead, we have kidou/kaidou and killing Hollows (see above). That got interesting to me just because there does seem to be a kind of dichotomy between what we'll call military technologies and "other stuff." Like, there seem to be spiritual/ritual reasons that zanpakutou powers tend to be used only in battle/warfare applications (excepting some omake/omake-like instances). Kidou might be a little looser, but only slightly--in the sense that it seems like it's probably involved in some of their electrical/technological stuff--the worm TV, Rin's Noo-Noo thing (linked because I realize that my ~natural Teletubbies patois might not be shared, LOL). But they haven't gone, like, fully Harry Potter with what they think kidou/magic should be user for. So there's also not necessarily that same driver where military/non-military technologies are a lot more incestuous for us than they seem to be for them.

And that's all without thinking about the timescale at which they're operating, re: aging. Or the fact that thinking about shinigami specifically, they don't really have trading partners or other societies to swap ideas with (that we know of), aside from cribbing off the Living World--which certainly has made its mark on the palimpsestic cultural/technological life of Soul Society, though it's not all just stolen from the Living World, being that Sasakibe's been rocking rapiers since time immemorial, and Shinji's TBTP speaker setup, etc.

I feel like if the Seireitei were interested enough in ethnographic studies of Rukongai, there'd be some extremely interesting stuff out there. Like, sure, from what we've seen it's fairly resource-poor, and the somewhat high turnover rate from people getting eaten by monsters could go either way in terms of whether that's uhhhh helpful in driving cultural change. But there's a lot of souls out there with a lot of fragments of all kinds of weirdo memory, maybe, and a lot of different groups of people thinking about things largely independently of one another--but with some opportunity for cultural cross-pollination still. And we know they've got the hottest wheels AND the snake wine out there. I feel like there's all kinds of cool regional stuff going down out there, and it's just shinigami who are like

"Ah yes, the cultureless, primitive, flatlands of Rukongai"

"Actually, out in East 56 we have a rich history of--"

"woe are the half-lives of the ghostly"

"we have 42 lunar calendar systems and 35 linguistic sub-families--"

"nary a dinglehopper with which to entertain themselves as they await death"

8 notes

·

View notes

Text

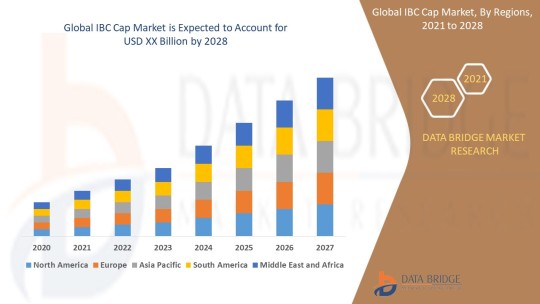

IBC Cap Market Size, Share, Trends, Growth and Competitive Analysis

"IBC Cap Market – Industry Trends and Forecast to 2028

Global IBC Cap Market, By Product Type (Flange, Plugs, Vent-in Plug, Vent-out Plug and Screw closure), Type (Plastic IBC, Metal IBC and Composite IBCs), Material Type (Plastics, Metal, Aluminium and Steel), End Use (Chemicals & Fertilizers, Petroleum & Lubricants, Paints, Inks & Dyes, Food & Beverage, Agriculture, Building & Construction, Healthcare & Pharmaceuticals and Mining), Application (Food And Drinks, Chemical Industry, Oil and Agriculture), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, U.A.E, Saudi Arabia, Egypt, South Africa, Israel, Rest of Middle East and Africa) Industry Trends and Forecast to 2028

Access Full 350 Pages PDF Report @

The global IBC cap market is expected to witness significant growth over the forecast period due to the increasing demand for intermediate bulk containers (IBCs) in various industries such as chemicals, food and beverages, pharmaceuticals, and others. The IBC caps play a crucial role in ensuring the safe storage and transportation of liquid products. The market growth is also being driven by technological advancements in IBC cap designs, such as tamper-evident seals and spouts for easy dispensing. Additionally, the growing focus on sustainability and recyclability of packaging materials is further boosting the adoption of IBC caps made from eco-friendly materials.

**Segments**

- Based on material type, the IBC cap market can be segmented into plastic, metal, and others. Plastic caps are widely used due to their lightweight nature and cost-effectiveness. - By cap type, the market can be categorized into screw caps, snap-on caps, and flip-top caps. Screw caps are preferred for their secure sealing properties. - On the basis of end-user industry, the market can be divided into chemicals, food and beverages, pharmaceuticals, and others. The chemicals segment is anticipated to hold a significant market share due to the widespread use of IBCs for storing chemical products.

**Market Players**

- TPS Industrial Srl - Schuetz GmbH & Co. KGaA - Mauser Packaging Solutions - Time Technoplast Ltd - Berry Global Inc. - THIELMANN UCON AG - Precision IBC, Inc. - Peninsula Packaging LLC

These market players are actively involved in strategic initiatives such as product launches, partnerships, and acquisitions to strengthen their market presence and expand their product offerings. The competitive landscape of the IBC cap market is characterized by intense competition, prompting companies to focus on innovation and quality to gain a competitive edge.

The Asia-Pacific region is expected to witness substantial growth in the IBC cap market, driven by the rapid industrialization and the increasing adoption of IBCsThe Asia-Pacific region represents a significant growth opportunity for the global IBC cap market due to several key factors. With rapid industrialization and the expanding manufacturing sector in countries like China, India, and Southeast Asia, there is a growing demand for efficient storage and transportation solutions, including IBCs and their associated caps. The increased focus on chemical production, food processing, and pharmaceutical manufacturing in the region further fuels the need for reliable packaging solutions like IBC caps. As these industries continue to grow, the adoption of IBC caps is expected to rise, driving market expansion in the Asia-Pacific region.

Moreover, the emphasis on enhancing safety standards and ensuring product integrity is a crucial factor contributing to the growth of the IBC cap market in Asia-Pacific. Regulations regarding the safe handling and transportation of hazardous chemicals and pharmaceuticals necessitate the use of high-quality caps that can effectively seal and protect the contents of IBCs. As companies in the region strive to comply with stringent regulatory requirements, the demand for advanced and secure IBC caps is projected to increase significantly.

Additionally, the shift towards sustainability and eco-friendly practices is another trend shaping the IBC cap market in Asia-Pacific. With growing environmental concerns and increasing awareness about plastic pollution, there is a rising preference for IBC caps made from recyclable and biodegradable materials. Market players in the region are focusing on developing sustainable packaging solutions to meet the evolving consumer demands and align with global sustainability goals. This shift towards eco-friendly IBC caps not only addresses environmental concerns but also presents market players with opportunities to differentiate their offerings and attract environmentally conscious customers.

Furthermore, the competitive landscape of the IBC cap market in Asia-Pacific is characterized by the presence of both local manufacturers and international players. Local companies often have a strong understanding of regional market dynamics and customer preferences, giving them a competitive advantage in catering to specific industry needs. On the other hand, multinational companies bring technological expertise and a wide product portfolio, which can appeal to a broader customer base seeking innovative and**Global IBC Cap Market, By Product Type**

- Flange - Plugs - Vent-in Plug - Vent-out Plug - Screw closure

**Type**

- Plastic IBC - Metal IBC - Composite IBCs

**Material Type**

- Plastics - Metal - Aluminium - Steel

**End Use**

- Chemicals & Fertilizers - Petroleum & Lubricants - Paints, Inks & Dyes - Food & Beverage - Agriculture - Building & Construction - Healthcare & Pharmaceuticals - Mining

**Application**

- Food And Drinks - Chemical Industry - Oil and Agriculture

The Global IBC Cap market is experiencing significant growth due to the rising demand for intermediate bulk containers across various industries. Plastic caps are increasingly preferred for their lightweight and cost-effective nature, driving market growth within the material type segment. Screw caps, known for their secure sealing properties, dominate the cap type category. The chemicals segment is anticipated to hold a substantial market share among end-user industries, attributed to the widespread use of IBCs for chemical storage. The market players in the industry are focusing on strategic initiatives like product launches and partnerships to enhance their market presence and offerings. The competitive landscape is intense, spurring companies to innovate and prioritize quality for a competitive advantage.

In Asia-Pacific, the IBC cap market is poised for robust growth fueled by rapid industrialization and the expanding manufacturing sector, particularly in countries like China,

Countries Studied:

North America (Argentina, Brazil, Canada, Chile, Colombia, Mexico, Peru, United States, Rest of Americas)

Europe (Austria, Belgium, Denmark, Finland, France, Germany, Italy, Netherlands, Norway, Poland, Russia, Spain, Sweden, Switzerland, United Kingdom, Rest of Europe)

Middle-East and Africa (Egypt, Israel, Qatar, Saudi Arabia, South Africa, United Arab Emirates, Rest of MEA)

Asia-Pacific (Australia, Bangladesh, China, India, Indonesia, Japan, Malaysia, Philippines, Singapore, South Korea, Sri Lanka, Thailand, Taiwan, Rest of Asia-Pacific)

Key Coverage in the IBC Cap Market Report:

Detailed analysis of IBC Cap Market by a thorough assessment of the technology, product type, application, and other key segments of the report

Qualitative and quantitative analysis of the market along with CAGR calculation for the forecast period

Investigative study of the market dynamics including drivers, opportunities, restraints, and limitations that can influence the market growth

Comprehensive analysis of the regions of the IBC Cap industry and their futuristic growth outlook

Competitive landscape benchmarking with key coverage of company profiles, product portfolio, and business expansion strategies

TABLE OF CONTENTS

Part 01: Executive Summary

Part 02: Scope of the Report

Part 03: Research Methodology

Part 04: Market Landscape

Part 05: Pipeline Analysis

Part 06: Market Sizing

Part 07: Five Forces Analysis

Part 08: Market Segmentation

Part 09: Customer Landscape

Part 10: Regional Landscape

Part 11: Decision Framework

Part 12: Drivers and Challenges

Part 13: Market Trends

Part 14: Vendor Landscape

Part 15: Vendor Analysis

Part 16: Appendix

Browse Trending Reports:

Calcium Glycinate Market Retinal Biologics Market Facial Fat Transfer Market Angio Suites Diagnostic Imaging Market Adoption Of Benelux Power Tools Market De Quervains Tenosynovitis Treatment Market Biodetectors And Accessories Market Colposcope Market Sports Medicine Market Automotive Adhesives Market Infrared Imaging Market Vapour Deposition Market Professional Diagnostics Market Ct Scanner Market Programmable Application Specific Integrated Circuit Asic Market Hospital Operating Room Or Products And Solutions Market Castor Oil Market Zika Virus Infection Drug Market Toluene Diisocynate Market Antibiotic Resistance Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: [email protected]"

2 notes

·

View notes

Text

A Whovian Watches Star Trek for the First Time: Part 008 - The Meddling Shopkeeper

Star Trek: Enterprise - Season 1 Episode 9 - Civilisation

So, we've found another habitable planet, this time with enough life signs to qualify as an undiscovered civilisation!

T'Pol is against making planetfall, and to be honest, I agree with her on this one. But, Archer decides to go down with Hoshi, Trip and T'Pol anyways

Seeing Hoshi having fun with the languages, and we got a cute in-universe explanation for crop circles.

Now, we have a mystery: There appears to be an anti-matter reactor on this planet, which seems to be in all other respects pre-industrial. The ground crew narrow down it's location to some kind of antiques shop, but seem to be seen while breaking into it. We came finding various other pieces of technology from this antiques shop: Magnetic force fields, Dampening fields et cetera.

Archer and Trip return during the day, and indeed find the shopkeeper, Garos, isn't from this planet. I noticed a few similarities between this episode, and the classic Doctor Who serial, The Time Meddler, and while their philosophy isn't exactly the same, Garos does share a lot in common with the Monk from that same serial. Both interfere with a low technology civilisation, while using technology far in advance of what they should have

Garos is running a mining operation, that has caused an industrial lubricant to seep into the town's water supply, and as a result the locals are being poisoned.

The ship crew transporting the reactor into space, then using it as a weapon to break down the other ship's shield was genius!

I was kind of hoping Riaan would get to see inside the enterprise and have something akin to a Doctor Who "It's Bigger on the Inside" moment, but that never happened. Archer and Riann's brief romance was cute, but I doubt we're going to see much more of it.

On the whole, I think this is my favourite episode so far. It was very Doctor Who, which obviously for me is a good thing.

#whovian watching star trek#star trek enterprise#star trek#star trek ent#star trek: enterprise#enterprise#ENT#For the Record I could 100% the guy who played Garos playing a regenerated version of the Monk in Doctor Who

14 notes

·

View notes

Text

How to Maintain Your Dewatering Pumps for Longevity and Performance

Dewatering pumps are a critical tool for any industry, particularly construction, mining, and municipal projects. For dewatering pumps to perform well and operate for a long time, maintenance is essential. With a few critical maintenance practices in mind, you can keep your dewatering pumps running well, avoiding expensive repairs and downtime.

One of the first steps in maintaining your dewatering pump is regular inspection. Always check for any signs of wear or damage, such as cracks in the casing or any loose parts. Cleaning the pump regularly is another essential practice. Dirt and sediment can accumulate in the pump over time, leading to clogging or reduced efficiency. Make sure to clean the pump and remove any blockages in the intake and discharge areas.

Lubrication plays a critical role in the smooth operation of the pump’s moving parts. Bearings, seals, and shafts must be lubricated for reduced friction and wear. Moreover, check on the motor for overheating as excessive heat may cause it to deteriorate considerably and reduce the life of the pump.

Proper storage is equally important. When the pump is not in use, store it in a dry, sheltered environment to prevent rusting and corrosion, which can damage the pump’s components.

Lastly, always follow the manufacturer's guidelines for operation and maintenance. Regular servicing and replacing worn-out parts promptly can extend the life of your dewatering pump.

As an established manufacturer, Darling Pumps stands out for anyone looking for dependable, high-quality pumps. One of the top pump manufacturers in Indore, Darling Pumps provides long-lasting, high-quality dewatering pumps that guarantee every project will function well over the long run.

0 notes

Text

The Role of Wire Rope in Heavy Lifting Operations

When it comes to heavy lifting operations, wire ropes are indispensable. From construction sites to shipping yards, these robust cables serve as the backbone of lifting machinery, ensuring safety and efficiency. With their unparalleled strength and versatility, wire ropes enable industries to handle massive loads with ease. Understanding their role, construction, and application is essential for anyone involved in heavy lifting tasks.

What is a Wire Rope?

A wire rope is a complex assembly of wires twisted into strands and laid around a core. This design provides it with the flexibility, strength, and durability needed to handle heavy loads. Manufactured using high-grade steel, wire ropes are engineered to withstand extreme stress and harsh environmental conditions.

Why Are Wire Ropes Crucial in Heavy Lifting?

Wire ropes are essential in heavy lifting operations because of their ability to distribute loads evenly across multiple strands. This design minimizes wear and tear, ensuring a longer lifespan even under constant use. Industries such as construction, mining, and shipping rely heavily on wire ropes for their ability to handle loads safely and efficiently.

Applications of Wire Rope in Heavy Lifting

Construction: Wire ropes are used in cranes to lift and transport heavy materials.

Shipping and Ports: These ropes are essential for mooring, towing, and lifting cargo.

Mining: Wire ropes are crucial in hoisting equipment and extracting minerals.

Elevators and Lifts: Wire ropes ensure smooth and reliable operation in high-rise buildings.

How to Choose the Right Wire Rope

Selecting the right wire rope depends on various factors, including the load, environment, and type of operation. Consulting reputable wire rope suppliers in India is a good starting point to ensure you get a product tailored to your specific needs. A reliable wire rope manufacturer will provide guidance on materials, construction, and safety standards.

Maintenance and Safety Tips

To maximize the lifespan and ensure the safety of wire ropes:

Regular Inspection: Check for fraying, corrosion, or broken strands.

Proper Lubrication: Minimize friction and prevent rust.

Correct Usage: Avoid overloading and ensure proper alignment during operations.

The Importance of Trusted Suppliers

High-quality wire ropes are crucial for safety and efficiency in heavy lifting operations. Partnering with reputable wire rope suppliers in India ensures you receive products that meet industry standards. From construction projects to industrial applications, a trusted wire rope manufacturer provides not only durable products but also expert advice on maintenance and usage.

Future Trends in Wire Rope Technology

As industries evolve, so does the technology behind wire ropes. Modern advancements focus on enhancing strength, reducing weight, and improving corrosion resistance. Innovations like synthetic cores and advanced coatings are transforming the capabilities of wire ropes, making them even more reliable in demanding environments.

Conclusion

Wire ropes are the unsung heroes of heavy lifting operations, offering unmatched strength, durability, and versatility. Their role in industries like construction, shipping, and mining underscores their importance in modern infrastructure and logistics. By partnering with a reliable wire rope manufacturer or trusted wire rope suppliers in India, businesses can ensure operational efficiency and safety. As technology advances, the future of wire ropes looks promising, paving the way for even more efficient heavy-lifting solutions.

0 notes

Text

Reclamation of FRF

A 1200 MW coal-fired thermal power plant using Indo-Chinese Turbine EHC System in Southern India

Synopsis

Problems

Failure of Moog valve: This was the main reason for the trip of the turbine and breakdown in the power plant.

Poor Oil Analysis Program: An oil analysis is supposed to be done monthly for Particle count & TAN (weekly if the trend is negative) and weekly test for water content but the customer has scheduled these indefinitely.

Inadequate Operation Practices: The solenoid valve of the LVDH (oil purification machine) vacuum line was only 20% closed which failed to generate vacuum.

Solutions

Benefits

1) Extended oil life 2) Reduced TAN value 3) Elimination of oil Replacement cost 4) Protection of Turbine against hunting 5) Increased Turbine reliability.

Subscribe to our WhatsApp Community and be a part of our Journey - Click Here

#frf#oil filtration machine#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#lube oil filter#contamination#hydraulic oil filter#oil filtration systems#oil testing#oil analysis#oil filters#oil industry#oil and gas#turbine oilanalysis maintenance lubrication reliability contaminationcontrol oil powerplants oilfiltration rotatingequipment mechanical#turbinemaintenance#gas turbine market trends#power industry#metal#mining#oil purification system#oil purification machine#oil filtration system#transformer oil#transformer oil cleaning#transformation oil purification#transformer oil filtration

0 notes

Text

Everything You Need to Know About Bentonite Drilling Mud

When it comes to drilling operations, one of the most crucial elements is the drilling fluid, which helps to lubricate the drill bit, control pressure, and remove debris from the borehole. Among the various types of drilling fluids, bentonite drilling mud is widely recognized for its effectiveness and versatility in the industry. Whether you're involved in oil drilling, water well drilling, or civil engineering, bentonite drilling mud plays a vital role in ensuring a smooth and efficient operation.

In this blog, we’ll explore the essential features, benefits, and applications of bentonite drilling mud, providing you with a comprehensive understanding of why it’s the preferred choice in various drilling activities.

What is Bentonite Drilling Mud?

Bentonite drilling mud is a water-based slurry made from bentonite clay, which is a natural, absorbent, and swelling clay mineral. Bentonite's unique properties allow it to form a thick, stable gel when mixed with water, making it an excellent choice for drilling operations. It can effectively suspend drill cuttings, cool the drill bit, and stabilize the borehole. This makes it an indispensable component in many drilling applications.

Bentonite’s primary use in drilling is as a thickening agent. It can create a fluid that is viscous enough to lift debris from the borehole while still remaining fluid enough to flow easily. These properties make bentonite drilling mud highly effective in providing essential lubrication to the drilling tools, preventing the borehole from collapsing, and maintaining pressure control.

Key Benefits of Bentonite Drilling Mud

Enhanced Lubrication Bentonite drilling mud acts as an effective lubricant, reducing friction between the drill bit and the formation. This lubrication reduces the wear and tear on drilling equipment and helps to improve the overall efficiency of the drilling process.

Hole Stability One of the significant advantages of bentonite drilling mud is its ability to provide excellent hole stability. As it forms a gel-like structure when mixed with water, it helps to maintain the integrity of the borehole. This is especially crucial in unstable formations where there is a high risk of the hole collapsing.

Efficient Cuttings Removal Drilling creates cuttings that need to be removed from the borehole to ensure smooth progress. Bentonite drilling mud has excellent carrying capacity for these cuttings, preventing them from accumulating at the bottom of the hole and obstructing further drilling.

Cost-Effective Bentonite is an affordable and readily available material, making bentonite drilling mud a cost-effective solution for drilling projects. The combination of cost-effectiveness and efficiency has made it a popular choice in industries like oil and gas, mining, and construction.

Environmental Safety Bentonite is a natural clay, which makes bentonite drilling mud more environmentally friendly compared to other synthetic alternatives. It is non-toxic and biodegradable, ensuring that it has a minimal environmental impact when used correctly.

Applications of Bentonite Drilling Mud

Bentonite drilling mud is used in a wide variety of drilling applications across different industries. Here are some of the primary uses:

Oil and Gas Drilling: Bentonite drilling mud is a staple in oil and gas exploration. It helps control the pressure in the wellbore, stabilizes the hole, and carries cuttings to the surface.

Water Well Drilling: In water well drilling, bentonite drilling mud is used to create a stable borehole while protecting underground water sources.

Civil Engineering Projects: For trenchless technology, such as Horizontal Directional Drilling (HDD), bentonite drilling mud ensures smooth, uninterrupted drilling through rock and soil.

How Bentonite Drilling Mud Works

The effectiveness of bentonite drilling mud stems from its ability to interact with water and form a thick gel-like structure. When bentonite is added to water, it absorbs water and swells, forming a viscous slurry. This slurry serves several functions:

Suspension of Cuttings: The viscosity of the mud allows it to lift and suspend cuttings, preventing them from settling back into the hole.

Cooling and Lubrication: The slurry cools the drill bit and reduces friction, ensuring that the equipment doesn’t overheat.

Pressure Control: By forming a thin but impermeable layer on the borehole walls, the bentonite mud helps to prevent the influx of fluids from surrounding formations.

Why Choose Amrfeo for Your Bentonite Drilling Mud Needs?

When it comes to sourcing bentonite drilling mud, quality and reliability are of the utmost importance. That’s where Amrfeo comes in. As a leading provider of high-quality bentonite drilling mud, Amrfeo offers products that meet the rigorous demands of the drilling industry. Whether you are working on oil exploration, water well drilling, or large-scale civil engineering projects, Amrfeo ensures that you get the right product for your needs.

With a commitment to excellence and customer satisfaction, Amrfeo is your trusted partner for high-performance drilling fluids. Our bentonite drilling mud is formulated for maximum efficiency, helping you reduce costs, improve productivity, and ensure the success of your drilling projects.

Conclusion

Bentonite drilling mud is an essential component in modern drilling operations, offering numerous benefits like improved lubrication, hole stability, and efficient cuttings removal. Its widespread use across industries such as oil and gas, water well drilling, and civil engineering makes it a go-to choice for many drilling professionals.

When looking for top-quality bentonite drilling mud, trust Amrfeo to deliver superior products that meet the demands of your drilling projects. With Amrfeo’s bentonite solutions, you can ensure that your drilling operations are safe, efficient, and cost-effective.

0 notes

Text

Electromagnetic Vibrating Feeder: Applications and Maintenance

The electromagnetic vibrating feeder is widely used in various industries, including mining, metallurgy, coal, building materials, light industry, electric power, machinery, and food. It functions to transport bulk, granular, and powdered materials from storage bins or hoppers to receiving devices in a uniform, continuous, or precise manner.

Main Features

1. Intelligent Electrical Control

The feeder uses a half-wave rectification circuit, allowing for stepless adjustment of the feeding amount. This feature supports automatic control in production processes, promoting automation.

2. Simple Structural Design

The device contains no rotating parts and requires no lubrication. Its simple structure makes maintenance easy, reducing operational complexity.

3. Low Wear Operation

The materials move in a micro-throwing motion within the feeder, resulting in minimal wear on the trough. This design extends the equipment's lifespan.

4. High-Temperature and Corrosion Resistance

The trough is made of alloy steel plates, enabling it to handle materials that are high-temperature, highly abrasive, or corrosive.

Maintenance Points

1.Regular Inspections: Frequently check the amplitude of the trough and the coil current. Pay attention to any unusual noises. If you notice a sudden increase in noise or any impact sounds, analyze the cause immediately and stop the machine.

2.Maintain Balanced Air Gap: Keep the air gap between the core and the armature balanced. Regularly inspect bolts for looseness and ensure the gap is within normal limits. If the spring bolt is loose or the spring is broken, address these issues promptly.

3.Check the Lifting Device: Regularly inspect the lifting device for looseness. A loose lifting device can cause imbalance at the corners of the feeder, affecting the feeding quality. Tighten it immediately if necessary.

4.Clean the Sealing Cover: Ensure the sealing cover of the vibrator is intact to prevent dust from entering and clogging the gaps between the springs. Regularly clean any dust buildup on the sealing cover.

Common Fault Analysis

1. Machine Does Not Vibrate After Power On

Cause: Blown fuse or shorted coil wires.

Solution: Replace the fuse and check the resistance to repair any breaks.

2. Material Transport Direction Is Off

Cause: The centerline of the trough and the line of excitation force are not in the same vertical plane.

Solution: Adjust them to be in the same vertical plane.

3. Weak Vibration

Cause: The thyristor is damaged or the air gap is blocked.

Solution: Replace the thyristor and remove any blockages.

4. Loud and Irregular Noise

Cause: Broken spring or loose connection bolts.

Solution: Replace the spring and tighten the bolts.

5. Torsional Vibration Occurs

Cause: The line of excitation force is not aligned with the center of the trough.

Solution: Adjust the excitation force line to pass through the center of the trough.

6. Current Fluctuates

Cause: Damaged coil or poor contact.

Solution: Inspect the coil for shorts or loose connections in the control box.

7. Normal Operation with High Current

Cause: The air gap may be too large.

Solution: Adjust the air gap to about 2 mm.

8. Insufficient Feeding

Cause: The trough's vibration does not meet the required amplitude.

Solution: Check if the hopper load directly compresses the feeder trough. Adjust the air gap and ensure proper spring tension.

9. Rectifier Failure During Operation

Cause: Short-circuited coil or leakage (grounding).

Solution: Replace the thyristor and coil, and fix the leakage issue.

10. Excessive Vibration of the Foundation

Cause: The stiffness of the isolation springs may be too high.

Solution: Reduce the stiffness of the isolation springs.

Conclusion

The electromagnetic vibrating feeder offers a simple structure, low noise, and lightweight design. It operates easily and consumes little power. It supports automation in production processes with stepless adjustment capabilities. The feeder can frequently start and operate continuously under rated voltage and amplitude conditions, making it widely applicable across various industries. Regular maintenance and inspections will effectively extend the equipment's lifespan and ensure efficient and stable production.

If you have any questions or need further support, please feel free to contact us. We look forward to providing you with professional service and solutions!

0 notes

Text

Common Challenges in Belt Conveyor Maintenance and How to Overcome Them

Belt conveyors are indispensable in various industries, from mining and manufacturing to logistics and food processing. However, maintaining these essential systems can present significant challenges. Effective maintenance is crucial to ensure smooth operations, minimize downtime, and extend the lifespan of conveyor systems. Here, we discuss some common challenges in belt conveyor maintenance and offer practical solutions to overcome them.

1. Belt Misalignment

Challenge: Belt misalignment occurs when the conveyor belt deviates from its intended path. This can lead to increased wear and tear, material spillage, and even complete system failure.

Solution: Regularly inspect the alignment of the belt and its components. Install self-aligning idlers or guiding systems to correct minor deviations. Ensure proper tensioning of the belt to prevent misalignment caused by slack.

2. Material Spillage

Challenge: Spillage of materials can lead to workplace hazards, loss of product, and additional cleaning costs.

Solution: Install appropriate skirting systems and sealing mechanisms to minimize gaps between the belt and the conveyor structure. Regularly inspect these components and replace them when worn out. Optimize loading procedures to ensure materials are placed centrally on the belt.

3. Belt Wear and Tear

Challenge: Over time, conveyor belts can suffer from wear and tear due to heavy loads, sharp materials, or improper handling.

Solution: Use belts made from durable materials suitable for the specific application. Conduct routine inspections to identify signs of damage early. Repair minor damages with adhesive patches or consider hot vulcanizing for larger repairs.

4. Roller and Idler Failures

Challenge: Faulty rollers and idlers can lead to excessive belt wear, increased energy consumption, and operational inefficiencies.

Solution: Implement a regular maintenance schedule to inspect and clean rollers and idlers. Replace worn-out components promptly. Consider using high-quality rollers with low-friction seals to reduce maintenance needs.

5. Carryback Issues

Challenge: Carryback, where materials stick to the conveyor belt and are carried back along the return path, can cause buildup and damage to the system.

Solution: Install efficient belt cleaners, such as scrapers and brushes, at appropriate locations. Use specialized coatings or belts with anti-stick properties for sticky materials.

6. Tracking Problems

Challenge: Poor belt tracking can lead to uneven wear, increased energy usage, and potential damage to the conveyor structure.

Solution: Regularly check and adjust tracking components. Ensure the conveyor frame and rollers are aligned correctly. Employ automated tracking systems for continuous monitoring and adjustments.

7. Overloading

Challenge: Overloading a conveyor system can cause excessive strain, leading to belt slippage, motor overheating, and structural damage.

Solution: Adhere to the conveyor’s load capacity guidelines. Use sensors and automated systems to monitor and control load levels. Train personnel on proper loading practices.

8. Insufficient Lubrication

Challenge: Lack of proper lubrication in moving parts can lead to increased friction, overheating, and component failures.

Solution: Develop a lubrication schedule based on the manufacturer’s recommendations. Use high-quality lubricants suitable for the operating environment. Automate lubrication processes where feasible to ensure consistency.

Proactive Maintenance: The Key to Longevity

To address these challenges effectively, adopting a proactive maintenance strategy is essential. This includes:

Regular Inspections: Conduct visual and mechanical inspections at regular intervals to identify and address potential issues early.

Training: Equip maintenance personnel with the skills and knowledge to handle conveyor systems efficiently.

Documentation: Maintain detailed records of inspections, repairs, and replacements to track the system’s health and plan future maintenance activities.

Predictive Technologies: Leverage advanced technologies like IoT sensors and condition monitoring systems to detect anomalies and predict failures before they occur.

Conclusion

While belt conveyor maintenance poses various challenges, implementing a structured approach can significantly enhance system reliability and performance. By addressing issues such as misalignment, spillage, wear, and overloading with targeted solutions, industries can minimize downtime and maximize productivity. A combination of regular maintenance, proper training, and advanced monitoring technologies ensures that belt conveyor systems continue to operate at their best.

0 notes

Text

PP FRP Blower Supplier in Uttar Pradesh

Sunfiber is a Manufacturer, Exporter, and Supplier of PP FRP Blower in Uttar Pradesh, India. Our Manufacturing Unit is in Ahmedabad, Gujarat, India. Sunfiber provides high-quality PP (Polypropylene) FRP (Fiberglass Reinforced Plastic) blowers, designed to deliver optimal performance in demanding environments. It combines the durability of polypropylene with the strength of fiber-reinforced plastic to deliver superior air movement in various applications. We engineer these blowers to handle a variety of industrial processes, ensuring reliability and high efficiency. PP FRP Blowers are highly resistant to moisture and corrosion, making them ideal for high-humidity environments like textile plants or other industrial applications where moisture or chemical exposure is common. Why Choose PP FRP Blower? Durability: PP FRP blowers are highly resistant to corrosion, making them ideal for industries that deal with corrosive gases and particles. Cost-effective: The use of polypropylene and fiber-reinforced plastic makes these blowers a cost-effective solution compared to metal blowers without compromising performance. Energy Efficiency: These blowers are designed to consume less energy while delivering superior airflow, helping you reduce operational costs. Versatility: With a range of sizes and configurations, these blowers can be customized for a wide variety of industrial applications. Low Maintenance: The non-corrosive nature of the materials used ensures a longer lifespan and minimal maintenance needs. Applications: Chemical Industries Wastewater Treatment Plastic Manufacturing Pharmaceutical Industry Mining & Construction Food Processing FAQs: How do I maintain a PP FRP Blower? Regular cleaning of the blower, inspecting the fan blades, and ensuring proper lubrication and component checks are essential for maintaining its optimal performance. Can PP FRP Blowers handle high air volumes? We design PP FRP blowers to handle high air volumes and provide consistent performance, even in demanding industrial environments. Sunfiber is Supplier of PP FRP Blower in Uttar Pradesh, India including location like Kanpur, Lucknow, Ghaziabad, Agra, Meerut, Varanasi, Prayagraj, Bareilly, Aligarh, Moradabad, Saharanpur, Gorakhpur, Noida, Firozabad, Jhansi, Muzaffarnagar, Mathura-Vrindavan, Ayodhya, Rampur, Shahjahanpur, Farrukhabad-Fatehgarh, Budaun, Maunath Bhanjan, Hapur, Etawah, Mirzapur-Vindhyachal, Bulandshahr, Sambhal, Amroha, Hardoi, Fatehpur, Raebareli, Orai, Sitapur, Bahraich, Modinagar, Unnao, Jaunpur, Lakhimpur, Hathras, Banda, Pilibhit, Barabanki, Khurja, Gonda, Mainpuri, Lalitpur, Etah, Deoria, Ghazipur, Sultanpur, Azamgarh, Bijnor, Sahaswan, Basti, Chandausi, Akbarpur, Ballia, Tanda, Greater Noida, Shikohabad, Shamli, Awagarh, Kasganj. Contact us today for inquiries or to place an order! View Product: Click Here Read the full article

#Agra#Ahmedabad#Akbarpur#Aligarh#Amroha#Awagarh#Ayodhya#Azamgarh#Bahraich#Ballia#Banda#Barabanki#Bareilly#Basti#Bijnor#Budaun#Bulandshahr#Chandausi#Deoria#Etah#Etawah#Exporter#ExporterofPPFRPBlower#Farrukhabad-Fatehgarh#Fatehpur#Firozabad#Ghaziabad#Ghazipur#Gonda#Gorakhpur

0 notes

Text

Industrial Oil Purification Systems: Essential for Clean Oil in Africa and India

Introduction to Industrial Oil Purification Systems

Industrial Oil Purification Systems are crucial for maintaining the quality and longevity of oils used in various industrial applications, including manufacturing, energy production, and transportation. These systems efficiently remove contaminants such as water, dirt, and other impurities from oils, ensuring smooth operation of machinery and reducing maintenance costs. Oil purification is a critical process to ensure that lubricants and industrial oils continue to perform at their optimal levels.

In this article, we explore how Industrial Oil Purification Systems are used in countries like Botswana, Ethiopia, Kenya, Namibia, Nigeria, South Africa, Zambia, Zimbabwe, and India. We will also dive into the significance of Oil Purification Systems and Industrial Oil Filter Machines in keeping industries running smoothly and efficiently.

What Are Industrial Oil Purification Systems?

An Industrial Oil Purification System is designed to purify industrial oils, ensuring they remain free of contaminants that could degrade performance. These systems are widely used in various sectors such as manufacturing, automotive, mining, and energy generation to purify oils like lubricants, hydraulic oils, and transformer oils.

Key Benefits of Industrial Oil Purification:

Improved Oil Performance: Purifying oil helps maintain its viscosity and lubricating properties, ensuring that machines run smoothly without wear and tear.

Reduced Maintenance Costs: Clean oil reduces the frequency of maintenance required for industrial machinery, thereby reducing operational costs and downtime.

Extended Equipment Lifespan: By preventing contaminants from causing damage, oil purification helps extend the lifespan of machines and equipment.

Environmentally Friendly: Oil purification reduces the need for frequent oil disposal, making it a more sustainable solution for industries.

Oil Purification Systems in Africa

In Africa, the demand for efficient and reliable Oil Purification Systems is growing across countries like Botswana, Ethiopia, Kenya, Namibia, Nigeria, South Africa, Zambia, and Zimbabwe. As industries expand and modernize, there is an increasing need to improve the quality of industrial oils to boost the productivity and longevity of machinery.

Industrial Oil Purification Systems in Botswana, Ethiopia, and Kenya:

In Botswana, Ethiopia, and Kenya, industries such as mining, manufacturing, and power generation rely on Industrial Oil Purification Systems to ensure their equipment operates at peak efficiency. These systems remove contaminants from oil, which prevents machinery breakdowns and costly repairs. The growing industrial base in these countries has made oil purification an essential part of their maintenance programs.

Industrial Oil Purification Systems in Nigeria, South Africa, Zambia, and Zimbabwe:

Countries like Nigeria, South Africa, Zambia, and Zimbabwe face the challenge of maintaining their large industrial sectors, which depend heavily on clean oil to ensure smooth operations. Oil Purification Systems play a key role in improving the reliability and performance of industrial equipment. These systems are crucial in sectors such as energy production, mining, and manufacturing, where machinery is exposed to harsh conditions and needs constant care.

Industrial Oil Filter Machines: Ensuring High-Quality Purification

Industrial Oil Filter Machines are essential components in Oil Purification Systems. These machines remove solid contaminants from oil, ensuring that only clean, pure oil is circulated through machinery. By using advanced filtration technologies, Industrial Oil Filter Machines help extend the life of both the oil and the machinery, reducing the risk of damage caused by impurities.

Industrial Oil Filter Machines in Africa:

In Botswana, Ethiopia, Kenya, Namibia, Nigeria, South Africa, Zambia, and Zimbabwe, Industrial Oil Filter Machines are being used in various industries to maintain the quality of industrial oils. These machines remove particles such as dirt, rust, and other debris from oil, ensuring that machinery runs smoothly without clogging or damage.

Industrial Oil Filter Machines in India:

In India, where industries such as automotive, power generation, and steel manufacturing are expanding rapidly, Industrial Oil Filter Machines play an important role in ensuring the longevity of industrial equipment. By keeping oils free of contaminants, these machines improve the overall efficiency of industrial processes and contribute to the sustainability of operations.

The Role of Oil Purification in Industrial Efficiency

The importance of Oil Purification cannot be overstated. Clean oil is critical to maintaining the smooth operation of machinery and preventing downtime. In industries across Africa and India, the use of Oil Purification Systems has been shown to significantly reduce maintenance costs, prevent equipment failures, and extend the operational lifespan of critical machinery.

Oil Purification Systems in Botswana, Ethiopia, and Kenya:

In Botswana, Ethiopia, and Kenya, industries are increasingly adopting Oil Purification Systems to improve oil quality and reduce the wear and tear on machinery. These systems help companies avoid the high costs associated with premature equipment failure and ensure that industrial processes run efficiently.

Oil Purification Systems in Nigeria, South Africa, Zambia, and Zimbabwe:

In countries like Nigeria, South Africa, Zambia, and Zimbabwe, oil purification has become essential for industries that rely heavily on machinery and equipment. Whether it's in the mining, manufacturing, or energy sectors, Industrial Oil Purification systems help businesses reduce operational downtime and ensure machinery is operating at its best.

Why Choose Industrial Oil Purification Systems?

Cost Savings: By reducing the frequency of oil changes and maintenance, Oil Purification Systems provide significant cost savings for industries.

Increased Efficiency: Cleaner oil results in more efficient machinery, which can improve productivity and reduce energy consumption.

Environmentally Friendly: Purification reduces the need for disposal of used oil, promoting sustainability.

Enhanced Equipment Reliability: Clean oil extends the life of equipment, preventing failures caused by contamination.

Conclusion

Industrial Oil Purification Systems are essential for industries across Africa and India to maintain the performance, efficiency, and longevity of their machinery. Countries like Botswana, Ethiopia, Kenya, Namibia, Nigeria, South Africa, Zambia, Zimbabwe, and India are increasingly adopting oil purification solutions to keep their industries running smoothly.

With the use of advanced Oil Purification Systems and Industrial Oil Filter Machines, industries can reduce maintenance costs, prevent equipment failure, and promote sustainability. As industries continue to grow and modernize in these regions, the demand for high-quality oil purification will only increase.

For more information on Industrial Oil Purification Systems, Oil Purification processes, and Industrial Oil Filter Machines, visit Transformeroilfilterplant.com. Discover how our cutting-edge purification systems can help you improve your industrial operations and achieve long-lasting performance.

0 notes