#Low VOC Adhesives Market Outlook

Explore tagged Tumblr posts

Text

Expansion of Construction Sector Boost Consumption of Low VOC Adhesives

VOCs include a group of chemicals found in adhesives. These chemicals pose a health threat and also cause air pollution such as smog.

The low VOC adhesives industry has garnered $47.6 billion in 2021, and it is projected to generate $81.1 billion, advancing at a rate of 6.1% in the coming years.

Over the last few decades, the consumption of adhesives has increased in the construction sector. They are widely utilized in furniture assembly, upholstery, carpeting, flooring, crating, and packaging. The construction of several homes involves around a half-ton of glue.

Due to growing awareness of the potential drawbacks of VOC-containing adhesives, the demand for safer and eco-friendlier alternatives is growing. Therefore, environmentally friendly low-VOC adhesives are introduced in the industry.

The Camie 573 and Camie 500 mist sprays are such examples, as they have less than 30% VOC content. There are several other low VOC adhesives offered in the market, which are highly safe as they can be applied on several surfaces only.

To receive free sample pages of this report@ https://www.psmarketresearch.com/market-analysis/low-voc-adhesives-market/report-sample

The stringent government regulations encourage manufacturers to introduce environmentally friendly adhesives. Industry leaders are focusing on launching products that meet the standard regulations. The low VOC adhesives are such eco-friendly solutions.

Numerous companies have developed low VOC adhesives which are safe for both public and the environment, as well as ensure high performance. The eco-friendly and sustainable adhesives provide opportunities to manufacturing companies operating in the industry, due to implementation of the stringent regulations for low carbon emissions.

Moreover, the advent of advanced low VOC adhesives in various industries, such as building and construction, automotive and transportation, and paper and packaging provides an opportunity for industry players.

Furthermore, the companies operating in the industry are focusing on launching new products and establishing manufacturing facilities to stay ahead of their competitors.

For instance;

Toyochem Co. Ltd., the subsidiary of the Tokyo Ink Group of Japan, launched Oribain EXK 21-046, a new low-odor, low-VOC acrylic pressure-sensitive adhesive in March 2022, for its usage in enclosed spaces including building interiors and vehicles.

Sika announced to set up of a new technology center and manufacturing facility for producing high-quality adhesives and sealants, in Pune, India, in December 2021.

#Low VOC Adhesives Market#Low VOC Adhesives Market Size#Low VOC Adhesives Market Share#Low VOC Adhesives Market Growth#Low VOC Adhesives Market Trends#Low VOC Adhesives Market Outlook

0 notes

Text

Exploring the Growth Potential of the Construction Adhesive Tapes Industry: Key Trends and Innovations Driving the Market

The construction adhesive tapes industry has been gaining significant momentum in recent years, becoming an essential component in modern construction projects. From residential buildings to large-scale infrastructure, adhesive tapes are revolutionizing how structures are assembled, sealed, and protected. In this blog, we’ll explore the factors driving the industry's growth, the latest innovations, and the benefits that construction adhesive tapes offer over traditional bonding methods.

1. Market Growth and Demand Drivers

The global construction adhesive tapes market is expanding rapidly, driven by rising demand for more efficient, cost-effective, and sustainable construction materials. Factors contributing to the market's growth include:

Increased construction activities in developing regions

A growing emphasis on sustainable and green building practices

The need for faster, labor-saving solutions on construction sites

Technological advancements in adhesive formulation, ensuring stronger and more durable bonds

2. Types of Construction Adhesive Tapes

Adhesive tapes in the construction industry come in a variety of forms, each designed for specific applications. Some of the most popular types include:

Duct tapes: Known for their versatility and strength in temporary bonding.

Double-sided tapes: Ideal for permanent bonding in installations like flooring or wall paneling.

Foil tapes: Used in HVAC applications, offering excellent resistance to temperature and moisture.

Masking tapes: Perfect for precise painting and surface protection.

Each type serves a critical function, whether it's sealing, joining, or protecting surfaces.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=222451392

3. Key Innovations in the Industry

Recent developments in the construction adhesive tapes industry have focused on improving adhesion strength, environmental resistance, and ease of application. Some innovations include:

Heat-resistant and waterproof tapes for extreme conditions

Low-VOC (volatile organic compound) adhesives that contribute to healthier building environments

Eco-friendly options using recyclable materials and biodegradable adhesives

Smart tapes that change color to indicate correct application or curing

These advancements ensure that adhesive tapes not only perform better but also contribute to more sustainable building practices.

4. Benefits Over Traditional Bonding Methods

Compared to conventional fastening systems like nails, screws, or liquid adhesives, construction adhesive tapes offer several advantages:

Quick application: Tapes require minimal equipment and can be applied faster than traditional methods.

Clean worksite: Adhesive tapes eliminate the need for liquid adhesives, reducing mess and cleanup time.

Strong and flexible bonding: Tapes provide long-lasting bonds that can withstand the stresses of construction environments.

Minimal damage to materials: Tapes cause less structural damage compared to drilling or nailing into surfaces.

These benefits are making adhesive tapes the go-to choice for many contractors and builders.

5. Future Outlook for the Industry

As construction projects continue to evolve with advancements in building materials and methods, the construction adhesive tapes industry is poised for continued growth. Innovations like smart adhesives, sustainable materials, and more specialized tapes tailored for unique construction needs will play a vital role in the industry's future. Moreover, as green building regulations become stricter, the demand for eco-friendly adhesive solutions will continue to rise.

#construction additives tapes industry#construction additives tapes#construction additives tapes market#construction#construction additives#construction additives industry#construction industry#business#news

2 notes

·

View notes

Text

Water Based Lithography Inks Market, Global Outlook and Forecast 2025-2032

Water-based lithography inks are specially formulated inks that utilize water as a primary solvent, making them an environmentally friendly alternative to solvent-based inks. These inks are primarily used in the printing industry for newspapers, packaging, magazines, and promotional materials. They are known for their excellent adhesion, fast drying times, and low volatile organic compound (VOC) emissions, making them ideal for sustainable printing solutions.

Market Size

Download FREE Sample of this Report @ https://www.24chemicalresearch.com/download-sample/287067/global-water-based-lithography-inks-forecast-market-2025-2032-604

0 notes

Text

Global Interior Wall Putty Powder Market Poised for Growth Amid Rising Demand for High-Quality Finishing Solutions

Global Interior Wall Putty Powder Market Poised for Growth Amid Rising Demand for High-Quality Finishing Solutions

Market Overview

The Global Interior Wall Putty Powder Market is experiencing significant growth, driven by the increasing demand for smooth, durable, and aesthetic wall finishes in residential, commercial, and industrial construction. Interior wall putty powder is a pre-coated material used to create a uniform, crack-free surface before painting or wallpaper application, enhancing the durability and appearance of walls.

With rapid urbanization, expanding real estate projects, and a growing focus on premium interior aesthetics, the demand for high-performance putty powders is on the rise. Manufacturers are innovating eco-friendly, quick-drying, and multi-purpose putty solutions to meet evolving consumer and industry requirements.

Free Sample Report:- https://www.researchallied.com/request-sample/61412-global-interior-wall-putty-powder-market

Market Insights & Trends

Growing Adoption in Residential & Commercial Construction: With a rise in home renovations, smart homes, and corporate interior design projects, the demand for high-quality wall finishing products is increasing.

Technological Advancements in Putty Formulations: The development of water-resistant, anti-fungal, and high-adhesion wall putties is enhancing their durability and performance.

Shift Towards Eco-Friendly & Low-VOC Putty Powders: Environmental concerns are driving manufacturers to create non-toxic, sustainable, and dust-free putty solutions that comply with green building standards.

Increasing Popularity of White Cement-Based Putty: Due to its superior adhesion, crack resistance, and enhanced finish, white cement-based putty is becoming the preferred choice for interior walls.

Growing Demand in Developing Economies: Expanding urban infrastructure in Asia-Pacific, the Middle East, and Latin America is fueling market growth, with a focus on cost-effective, high-strength wall putty powders.

Key Players in the Market

The Global Interior Wall Putty Powder Market is highly competitive, with key manufacturers investing in product innovations, improved formulations, and sustainability initiatives. Major players include:

Asian Paints Ltd.

JK Cement Ltd.

Birla White (UltraTech Cement Ltd.)

Nippon Paints

Berger Paints India Ltd.

Dulux (AkzoNobel)

Mapei S.p.A.

Sika AG

Walplast Products Pvt. Ltd.

V V Paints

These companies are focused on developing waterproof, fast-setting, and premium-grade wall putty solutions to meet growing customer demands.

Full Report:- https://www.researchallied.com/report/61412-global-interior-wall-putty-powder-market/

Regional Insights

Asia-Pacific: The largest and fastest-growing market, led by India, China, and Japan, due to rapid urbanization, increasing real estate development, and government initiatives for smart cities.

North America: The United States and Canada are witnessing steady growth due to rising home renovation projects, commercial construction, and demand for eco-friendly putty solutions.

Europe: Countries like Germany, the UK, and France are experiencing a demand surge for premium, weather-resistant, and sustainable putty powders in both residential and commercial applications.

Middle East & Africa: Expanding construction activities in Saudi Arabia, the UAE, and South Africa are driving the adoption of moisture-resistant and high-strength putty powders.

South America: Growth is driven by increasing housing projects and infrastructure modernization efforts in Brazil, Argentina, and Chile.

Market Outlook & Growth Prospects

The Global Interior Wall Putty Powder Market is projected to grow at a CAGR of over 5% from 2018 to 2028, driven by:

Increasing demand for smooth, long-lasting wall finishes in residential and commercial spaces

Rising preference for eco-friendly, low-VOC, and moisture-resistant putty formulations

Technological advancements in quick-drying, crack-resistant, and anti-microbial wall putty powders

Expansion of construction activities, smart cities, and urban housing projects worldwide

Growing investment in home renovation and interior design upgrades

Enquire Before Buy:- https://www.researchallied.com/enquire-before/61412-global-interior-wall-putty-powder-market

Top Trending Reports

Global More Electric Aircraft Market

Nigeria Oil and Gas Upstream Activities Market

Global Industrial Plastic Bags Market

0 notes

Text

Water Resins Market: Growth Opportunities, Key Trends, and Forecast 2025

Introduction

The global Water Resins Market is experiencing significant growth due to rising demand across various industries such as construction, automotive, and coatings. Water resins are essential for enhancing durability, water resistance, and chemical stability in end products. This blog provides a comprehensive overview of the market, highlighting key trends, drivers, challenges, and future growth opportunities.

Market Overview

The Water Resins Market is expanding rapidly, driven by increasing awareness of sustainable materials and the adoption of water-based solutions across industries. Water resins, such as acrylic, epoxy, and polyurethane resins, are widely used in paints, coatings, adhesives, and sealants due to their eco-friendly properties.

Key Market Segments

By Type: Acrylic Resins, Epoxy Resins, Polyurethane Resins, Alkyd Resins

By Application: Paints & Coatings, Adhesives, Construction, Automotive, Electronics

By Region: North America, Europe, Asia-Pacific, Latin America, Middle East & Africa

Regional Insights

1. North America

North America holds a significant market share due to the presence of leading manufacturers and growing demand for water-based coatings in the construction and automotive industries.

2. Europe

Europe is witnessing steady growth, driven by stringent environmental regulations promoting the use of low-VOC (volatile organic compound) products. The demand for water resins in the construction and automotive sectors is also contributing to market expansion.

3. Asia-Pacific

Asia-Pacific is the fastest-growing region, with countries like China, India, and Japan leading the market. Rapid urbanization, infrastructure development, and increased adoption of eco-friendly products are key growth factors in this region.

4. Middle East & Africa

The Middle East & Africa region is expected to witness moderate growth, with rising construction activities and increasing awareness of sustainable materials driving demand for water resins.

Key Market Drivers

Growing Demand for Eco-friendly Products: Increasing environmental concerns have driven the shift toward sustainable and water-based solutions in paints and coatings.

Expansion in the Construction Sector: The construction industry's growth, especially in emerging economies, is boosting the demand for water resins in concrete additives and coatings.

Rising Use in Automotive Coatings: Water resins are gaining popularity in automotive coatings for their low environmental impact and high-performance properties.

Leading Players in the Water Resins Market

Several key players are driving innovation and competitiveness in the water resins market. Some of the prominent companies include:

BASF SE

Dow Chemical Company

Arkema Group

Huntsman Corporation

Wacker Chemie AG

Allnex Group

These companies focus on developing high-performance, eco-friendly water resins to meet the growing demand across various industries.

Challenges in the Water Resins Market

Despite its growth potential, the water resins market faces some challenges:

High Production Costs: Manufacturing water resins can be expensive compared to traditional materials, affecting profit margins for producers.

Lack of Awareness in Emerging Markets: In some developing regions, limited awareness and availability of water-based solutions can hinder market growth.

Stringent Regulatory Requirements: Compliance with environmental and safety standards can be complex and time-consuming for manufacturers.

Future Outlook

The global Water Resins Market is poised for continued growth, driven by rising environmental awareness and increased adoption of eco-friendly products. The market is expected to witness innovations in resin formulations and expanded applications in the construction, automotive, and electronics industries. With key players focusing on R&D and strategic partnerships, the market is set to offer numerous opportunities for stakeholders.

Conclusion

The Water Resins Market is on an upward trajectory, with significant growth opportunities driven by the increasing demand for sustainable materials and expanding industrial applications. Companies investing in eco-friendly water resins and innovative product development will be well-positioned to capitalize on this growing market.

Contact Us

Looking to stay ahead in the evolving Water Resins Market? Mark & Spark Solutions offers expert insights and customized market research services to help your business thrive. Contact us today for more information and strategic guidance!

0 notes

Text

Chlorinated Rubber Coatings Market Companies, Overview, Outlook, CAGR, Growth, Share

"Chlorinated Rubber Coatings Market Size And Forecast by 2028

The chlorinated rubber coatings market is expected to gain market growth in the forecast period of 2021 to 2028. Data Bridge Market Research analyses the market to reach at an estimated value of USD 1,533.7 million by 2028 and grow at a CAGR of 7.5% in the above-mentioned forecast period.

Lastly, the study emphasizes the broader implications of these companies’ contributions to the Chlorinated Rubber Coatings Market growth and evolution. Their strategies, technological advancements, and market influence not only define current industry trends but also set the stage for future developments. By providing a comprehensive overview of the leading players, the report equips stakeholders with critical insights to understand competitive positioning, identify opportunities for collaboration, and develop strategies to thrive in this dynamic industry.

Get a Sample PDF of Report - https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-chlorinated-rubber-coatings-market

Which are the top companies operating in the Chlorinated Rubber Coatings Market?

The Top 10 Companies in Chlorinated Rubber Coatings Market operating in the Chlorinated Rubber Coatings Market are recognized for their innovation, market leadership, and strong presence across key regions. These companies invest heavily in research and development, driving continuous product innovation to meet evolving customer demands. Their extensive distribution networks, brand reputation, and technological expertise have solidified their positions as industry leaders. Additionally, these top companies are expanding through strategic partnerships, mergers, and acquisitions, enabling them to strengthen their market share and enhance their competitive advantages.

**Segments**

- Based on type, the chlorinated rubber coatings market can be segmented into solvent-based and water-based coatings. Solvent-based coatings have been traditionally used due to their excellent adhesion and resistance properties, but with increasing environmental regulations, water-based coatings are gaining popularity for their low VOC content and eco-friendly nature. - In terms of application, the market can be divided into marine, industrial, automotive, and others. The marine segment is anticipated to witness significant growth, driven by the increasing demand for anti-corrosive coatings in shipbuilding and offshore structures. The industrial segment is also expected to grow as chlorinated rubber coatings offer protection against harsh chemicals and abrasion. - Geographically, the market is categorized into North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. Asia Pacific is expected to dominate the market due to the growing industrial and construction activities in countries like China and India. North America and Europe are mature markets for chlorinated rubber coatings, with a focus on innovation and sustainability driving growth in these regions.

**Market Players**

- Some of the key players in the chlorinated rubber coatings market include PPG Industries, Inc., Sherwin-Williams, Akzo Nobel, Hempel A/S, Jotun, RPM International Inc., Nippon Paint Holdings Co., Ltd., Kansai Paint Co., Ltd., Axalta Coating Systems, and BASF SE. These companies are focusing on product development, strategic partnerships, and acquisitions to expand their market presence and meet the evolving customer demands. The competitive landscape of the market is characterized by intense competition, with players vying for market share through technological advancements and quality enhancements.

For more detailed insights on the global chlorinated rubber coatings market, visit: https://www.databridgemarketresearch.com/reports/global-chlorinated-rubber-coatings-market The global chlorinated rubber coatings market is poised for significant growth in the coming years, driven by several key factors across various segments. One emerging trend in the market is the increasing shift towards water-based coatings over traditional solvent-based options. This transition can be attributed to the rising environmental concerns and stringent regulations aimed at reducing volatile organic compound (VOC) emissions. Water-based chlorinated rubber coatings offer lower VOC content and are considered more eco-friendly, positioning them as a preferred choice for environmentally conscious consumers and industries.

Moreover, the application segment is witnessing notable developments, with robust demand expected in the marine and industrial sectors. The marine segment, in particular, is projected to experience substantial growth, primarily due to the escalating need for anti-corrosive coatings in shipbuilding and offshore structures. As the marine industry continues to expand globally, the demand for high-performance coatings that provide protection against harsh marine environments is expected to drive the adoption of chlorinated rubber coatings. Similarly, the industrial segment is forecasted to grow steadily as these coatings offer exceptional resistance to chemicals and abrasion, making them ideal for various industrial applications.

From a regional perspective, Asia Pacific emerges as a dominant force in the global chlorinated rubber coatings market, fueled by the rapid industrialization and infrastructure development in countries like China and India. The region's surging construction activities, coupled with the increasing focus on corrosion-resistant coatings, are expected to drive significant growth opportunities for market players. On the other hand, North America and Europe represent mature markets for chlorinated rubber coatings, characterized by a strong emphasis on innovation and sustainability. Market players in these regions are concentrating on product enhancements and sustainability initiatives to maintain their competitive edge and cater to evolving customer preferences.

In terms of market players, leading companies such as PPG Industries, Inc., Sherwin-Williams, Akzo Nobel, and Jotun are actively engaging in product development, strategic collaborations, and acquisitions to strengthen their market position and address the changing market dynamics. The competitive landscape of the chlorinated rubber coatings market is intense, with a focus on technological advancements and quality improvements to capture a larger market share. Overall, the market is poised for continued expansion, driven by evolving industry requirements, regulatory changes, and the strategic initiatives of key market players to meet the ever-changing needs of customers globally.**Segments**

Global Chlorinated Rubber Coatings Market, By Type (High Temperature, Low Temperature), Application (Paints, Lacquers, Adhesives, Printing Inks), End Users (Architecture, Automotive, Aerospace, Electronics, Others), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, U.A.E, Saudi Arabia, Egypt, South Africa, Israel, Rest of Middle East and Africa) Industry Trends and Forecast to 2028

The global chlorinated rubber coatings market is witnessing significant growth driven by various factors across different segments. One notable trend is the increasing preference for water-based coatings over traditional solvent-based options due to environmental concerns and stringent regulations on VOC emissions. Water-based chlorinated rubber coatings, with their lower VOC content and eco-friendly nature, are gaining traction among environmentally conscious consumers and industries. In terms of applications, the marine and industrial segments are expected to experience strong growth. The marine sector's increasing demand for anti-corrosive coatings in shipbuilding and offshore structures is a key driver, while the industrial segment benefits from the coatings' protection against harsh chemicals and abrasion.

From a regional perspective, Asia Pacific is set to lead the global chlorinated rubber coatings market, thanks to rapid industrialization and infrastructure development in countries like China and India. The surge in construction activities in the region, coupled with the focus on corrosion-resistant coatings, presents substantial growth opportunities. Meanwhile, North America and Europe are mature markets with a focus on innovation and sustainability. Market players in these regions are enhancing products and implementing sustainability initiatives to stay competitive and meet evolving customer needs.

**Market Players**

Some of the major players operating in the chlorinated rubber coatings market report are BASF SE, DIEFFENBACHER GMBH Maschinen- und Anlagenbau, JNC Corp, DOW, Koninklijke Dsm N.V, 3M Co, Heubach Color, The Magni Group, Wacker Chemie AG, SK Formulations India, Bluechem Group, Ancatt Inc., S.M. Adhesives., Renner Herrmann S.a, PPG Industries, Inc., Akzonobel N.V., The Sherwin-Williams Company, Axalta Coating Systems Ltd, Kingfa Science & Technology (India) Limited., Owens Corning, TORAY INDUSTRIES, INC., Momentive, LANXESS, SABIC, PPG Industries, Inc, Avient Corporation, Daicel Corporation among others.

These market players are actively engaged in product development, strategic collaborations, and acquisitions to strengthen their market positions and adapt to changing market dynamics. The competitive landscape of the chlorinated rubber coatings market is intense, with a focus on technological advancements and quality enhancements to capture a larger market share. Overall, the market is poised for continued expansion driven by evolving industry requirements, regulatory changes, and strategic initiatives of key market players to meet the shifting customer demands globally.

Explore Further Details about This Research Chlorinated Rubber Coatings Market Report https://www.databridgemarketresearch.com/reports/global-chlorinated-rubber-coatings-market

Key Insights from the Global Chlorinated Rubber Coatings Market :

Comprehensive Market Overview: The Chlorinated Rubber Coatings Market is expanding rapidly, fueled by technological innovation and increasing global demand.

Industry Trends and Projections: Automation, sustainability, and digital solutions are key trends, with the market projected to grow at a significant rate.

Emerging Opportunities: New opportunities are arising in green technologies and personalized solutions, especially in emerging markets.

Focus on R&D: Companies are heavily investing in R&D to drive innovation, focusing on AI, IoT, and sustainability.

Leading Player Profiles: Market leaders like Company A and Company B maintain dominance through strong portfolios and extensive networks.

Market Composition: The market is fragmented, with a mix of established players and emerging startups targeting various segments.

Revenue Growth: The market is experiencing steady revenue growth, driven by both consumer and commercial demand.

Commercial Opportunities: Key commercial opportunities lie in expanding into new regions, leveraging digital transformation, and strategic collaborations.

Find Country based languages on reports:

https://www.databridgemarketresearch.com/jp/reports/global-chlorinated-rubber-coatings-markethttps://www.databridgemarketresearch.com/zh/reports/global-chlorinated-rubber-coatings-markethttps://www.databridgemarketresearch.com/ar/reports/global-chlorinated-rubber-coatings-markethttps://www.databridgemarketresearch.com/pt/reports/global-chlorinated-rubber-coatings-markethttps://www.databridgemarketresearch.com/de/reports/global-chlorinated-rubber-coatings-markethttps://www.databridgemarketresearch.com/fr/reports/global-chlorinated-rubber-coatings-markethttps://www.databridgemarketresearch.com/es/reports/global-chlorinated-rubber-coatings-markethttps://www.databridgemarketresearch.com/ko/reports/global-chlorinated-rubber-coatings-markethttps://www.databridgemarketresearch.com/ru/reports/global-chlorinated-rubber-coatings-market

Data Bridge Market Research:

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC: +653 1251 975

Email:- [email protected]"

0 notes

Text

Latin America Rail Turnout Market Outlook and Forecast 2025-2032

UV curable resins are specialized polymeric materials designed for rapid curing when exposed to ultraviolet (UV) light. These resins play a crucial role in various industries, including coatings, adhesives, printing, and packaging, due to their ability to enhance durability, efficiency, and environmental sustainability. Unlike traditional solvent-based systems, UV curable resins offer a low-VOC (volatile organic compound) alternative, making them an eco-friendly choice in industrial applications.

Download FREE Sample of this Report @ https://www.24chemicalresearch.com/download-sample/286478/latin-america-uv-curable-resin-market-2025-2032-366

0 notes

Text

Floor Adhesives Market Trends From Eco-Friendly to High Performance Solutions

The global floor adhesives market is witnessing significant growth as construction activities surge and consumer preferences shift toward sustainable and high-performance products. This article delves into the market’s key dynamics, highlighting trends, challenges, and future prospects for this vital industry.

Introduction

Floor adhesives play a crucial role in modern construction, providing durable and secure bonding for a variety of flooring materials, such as wood, vinyl, and tiles. With increasing urbanization, rising demand for innovative flooring solutions, and growing environmental concerns, the floor adhesives market has become a focal point for both manufacturers and consumers.

Key Market Insights

Rising Demand for Sustainable Adhesives As governments enforce stricter environmental regulations and consumers become more eco-conscious, the demand for low-VOC, solvent-free, and bio-based adhesives is rising. These products not only align with sustainability goals but also offer superior performance and safety.

Technological Advancements Innovations in adhesive technology, such as hybrid polymers and self-leveling adhesives, are reshaping the market. These advancements provide faster curing times, improved strength, and compatibility with diverse flooring materials, making them attractive to contractors and homeowners.

Boom in Construction Activities The construction industry’s expansion, particularly in emerging economies, is driving the demand for floor adhesives. Urbanization and the need for residential and commercial spaces are significant contributors to this growth.

Regional Market Trends

Asia-Pacific: Leading the market due to rapid urbanization and infrastructure development in countries like China and India.

North America and Europe: Experiencing steady growth driven by sustainable building practices and technological innovation.

Latin America and the Middle East: Emerging markets showing potential due to increasing construction projects.

Diverse Applications Floor adhesives cater to various applications, including residential, commercial, and industrial settings. The rise in remodeling and renovation projects is further boosting demand in mature markets.

Challenges Facing the Market

Despite robust growth, the floor adhesives market faces challenges such as:

Volatility in Raw Material Prices: Fluctuating prices of petroleum-based products impact manufacturing costs.

Awareness Gap: Limited awareness among consumers about advanced adhesive solutions can hinder adoption.

Environmental Compliance: Adhering to stringent regulations while maintaining cost-effectiveness remains a challenge for manufacturers.

Opportunities for Growth

Expansion in Emerging Markets Unexplored regions with growing construction activities offer immense potential for market players.

Focus on Innovation Developing adhesives tailored for specific applications, such as heat-resistant or moisture-tolerant solutions, can open new revenue streams.

Sustainability Initiatives Investing in research and development for eco-friendly adhesives and recyclable packaging aligns with global sustainability goals, enhancing brand reputation.

Competitive Landscape

Major players in the floor adhesives market are focusing on product innovation, mergers, and acquisitions to strengthen their market position. Companies are also emphasizing customer-centric strategies, such as offering customized solutions and robust technical support.

Future Outlook

The future of the floor adhesives market is poised for sustained growth, driven by technological innovation and a strong emphasis on sustainability. Smart adhesives equipped with advanced features, such as thermal insulation and anti-microbial properties, are likely to gain traction. Additionally, the integration of digital solutions, such as Building Information Modeling, could influence adhesive applications in construction projects.

Conclusion

The floor adhesives market is on a promising growth trajectory, shaped by trends like sustainability, technological advancements, and rising construction activities. While challenges such as raw material volatility and compliance persist, opportunities in emerging markets and innovation provide significant growth avenues. By prioritizing eco-friendly solutions and leveraging technological advancements, industry stakeholders can achieve sustainable success in this evolving landscape.

0 notes

Text

C10 Solvent Prices: Current Trends and Market Dynamics

C10 solvents, a group of hydrocarbons derived primarily from petroleum refining, are essential in a variety of industries, including paints and coatings, adhesives, and industrial cleaning. These solvents are valued for their high solvency power, low evaporation rates, and compatibility with many formulations. However, like other petrochemical products, the pricing of C10 solvents is subject to multiple factors, including raw material costs, global supply-demand balances, and market-specific dynamics.

Recent Price Trends

The prices of C10 solvents have seen significant fluctuations over the past year. This volatility is largely tied to crude oil prices, as C10 solvents are derived from petroleum feedstocks. In 2023, the global oil market experienced price surges due to geopolitical tensions, OPEC production cuts, and increased energy demand post-pandemic. These factors directly impacted the cost of petrochemical intermediates, including C10 solvents.

As of the fourth quarter of 2024, C10 solvent prices are stabilizing but remain on the higher end compared to historical averages. This stabilization is attributed to several factors:

Moderating Crude Oil Prices: After peaking earlier in the year, crude oil prices have eased slightly due to improved supply dynamics and slower economic growth in major markets like China and Europe.

Seasonal Demand Variations: Demand for C10 solvents typically fluctuates based on seasonal activity in the coatings and construction sectors. The autumn months often see a dip as these sectors wind down.

Currency Fluctuations: The strengthening of the U.S. dollar in recent months has made imports of petrochemical products more expensive for countries with weaker currencies, impacting global trade flows.

Get Real time Prices for C10 solvent: https://www.chemanalyst.com/Pricing-data/c10-solvent-1466

Supply Chain Dynamics

The global supply chain for C10 solvents has faced disruptions in recent years due to logistical bottlenecks, particularly during the COVID-19 pandemic. While supply chains have largely normalized, occasional disruptions continue to occur, particularly in regions prone to natural disasters or political instability.

Additionally, the global transition towards greener energy and stricter environmental regulations have placed pressure on the petrochemical industry. Producers are increasingly focusing on sustainable practices, which may lead to higher production costs for traditional solvents like C10. Some manufacturers are also exploring bio-based alternatives, which could eventually impact the market share and pricing dynamics of conventional C10 solvents.

Outlook for 2025

Market analysts forecast a steady demand for C10 solvents, particularly in emerging economies where industrial growth remains robust. However, potential challenges include:

Environmental Regulations: Stricter emissions standards and sustainability initiatives could limit the use of traditional solvents, encouraging a shift towards low-VOC or bio-based alternatives.

Raw Material Prices: Crude oil and naphtha prices will continue to play a pivotal role in determining the cost of C10 solvents.

Technological Innovations: Advances in solvent recovery and recycling technologies may reduce overall demand for virgin solvents, impacting market dynamics.

Conclusion

The C10 solvent market remains a critical component of the global petrochemical industry, with its pricing influenced by a complex interplay of macroeconomic factors, raw material availability, and regulatory changes. Stakeholders, including manufacturers, distributors, and end-users, must stay attuned to these dynamics to navigate the market effectively. As the industry evolves, adapting to environmental trends and technological advancements will be crucial for long-term sustainability and profitability.

Get Real time Prices for C10 solvent: https://www.chemanalyst.com/Pricing-data/c10-solvent-1466

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#C10 Solvent#C10 Solvent Price#C10 Solvent Prices#C10 Solvent Pricing#india#united kingdom#united states#germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

0 notes

Text

Construction Adhesive market is predicted to develop at a compound annual growth rate (CAGR) of 5.1% from 2024 to 2034, when it is projected to reach USD 17.75 Million in 2034, based on an average growth pattern. Construction adhesive market is estimated to reach a value of USD 10.85 Million in 2024. Construction adhesive is a type of adhesive specifically formulated to bond construction materials together. It is used in a variety of construction and building applications to provide a strong and durable bond. These adhesives can bond materials such as wood, metal, concrete, glass, plastic, and composites. They are designed to meet the demands of different environments and applications, providing properties such as strength, flexibility, and resistance to weather and chemicals.

The construction adhesive market is evolving rapidly, shaped by technological advancements, sustainability initiatives, and shifting construction practices. Key trends include the rise of smart adhesives with monitoring capabilities, a shift towards low-VOC and bio-based products to meet environmental regulations, and increased adoption in modular construction methods. Energy efficiency remains a focal point, driving demand for adhesives in insulation and solar panel installations. Emerging markets in Asia-Pacific and Latin America are seeing significant growth, while innovations in digitalization and resilience are enhancing application precision and durability.

Construction Adhesive Market Dynamics:

Growth Drivers: Increasing construction activities globally, urbanization, and infrastructure development.

Technological Advancements: Continuous innovation in adhesive formulations to improve performance and meet environmental standards.

Environmental Regulations: Demand for eco-friendly and low-VOC adhesives due to regulatory requirements.

Regional Variances: Market growth influenced by regional construction trends, economic conditions, and regulatory landscapes.

The report presents an in-depth assessment of the ‘Global Construction Adhesive Market’. This includes enabling technologies, key trends, market drivers, challenges, standardization, regulatory landscape, deployment models, competitive analysis, operator case studies, opportunities, future trends, value chains, ecosystem player profiles, and strategies included. The report also presents a SWOT analysis and forecast for Construction Adhesive industry investments from 2024 to 2034.

Construction Adhesive Market Regional Outlook:

The construction adhesive market shows diverse regional dynamics. North America and Europe emphasize sustainability and advanced technologies, driving demand for eco-friendly adhesives. Asia-Pacific leads growth with rapid urbanization and infrastructure projects, particularly in China and India. Latin America and Middle East & Africa exhibit rising construction activities, boosting market expansion. Each region adapts to local regulations and construction trends, influencing adhesive preferences. Overall, the market's regional outlook reflects a blend of technological innovation, sustainability initiatives, and varying construction demands across developed and emerging economies.

The construction adhesive market is expected to witness continued growth, driven by technological innovations, environmental considerations, and expanding construction activities globally. The focus will increasingly be on developing sustainable, high-performance adhesives that meet the evolving needs of the construction industry while complying with environmental regulations. Companies that can balance innovation with sustainability will likely lead the market in the coming years.

Key Companies profiled in this research Study are:

Henkel AG & Co. KGaA

3M Company

Sika AG

H.B. Fuller Company

Bostik (Arkema Group)

Dow Inc.

Illinois Tool Works Inc.

Avery Dennison Corporation

Pidilite Industries Limited

Huntsman Corporation

Franklin International

LORD Corporation

Wacker Chemie AG

Mapei Corporation

Akzo Nobel N.V.

Other

Construction Adhesive Market Segmentation:

By Resin Type

Acrylic

Polyurethanes

Polyvinyl Acetate

Epoxy

Others

By Application

Residential

Commercial

Industrial

By Technology

Water-based

Solvent-based

Reactive & Others

Construction Adhesive Market Growth:

The construction adhesive market is experiencing significant growth, driven by multiple factors, including technological advancements, rising construction activities, and increasing demand for sustainable building practices. Rapid urbanization and population growth are driving the demand for new housing. The construction of residential buildings, both new and renovated, significantly contributes to the demand for construction adhesives. The expansion of commercial infrastructure such as office buildings, shopping malls, and hotels fuels the market growth. Ongoing industrialization in developing economies leads to the construction of factories, warehouses, and other industrial facilities, boosting the demand for durable adhesives

Conclusion: The construction adhesive market is experiencing robust growth driven by advancements in technology and increasing emphasis on sustainability. Key trends include the development of high-performance adhesives and eco-friendly formulations to meet stringent environmental standards. Regional dynamics vary, with North America and Europe focusing on advanced technologies, while Asia-Pacific leads with rapid urbanization and infrastructure projects. The market's expansion into modular construction and energy-efficient applications further enhances its growth prospects. Challenges such as raw material costs and regulatory compliance necessitate ongoing innovation. Overall, the market is poised for significant expansion as companies leverage these trends to meet evolving construction needs globally.

#construction adhesives market#construction adhesives market size#construction adhesives market report#construction adhesives market analysis#construction adhesives market growth#construction adhesives market trends#construction adhesives market scenario

0 notes

Text

Polyurethane Adhesive for Windshields Market, Global Outlook and Forecast 2025-2032

Polyurethane adhesive for windshields is a high-performance bonding material designed specifically for automotive windshields. It consists primarily of polyurethane resin and a curing agent, providing excellent adhesion, flexibility, and durability. This adhesive ensures a strong bond between the windshield and the vehicle body, enhancing safety and structural integrity. It also contributes to vehicle stability during high-speed travel and impacts, making it a preferred choice in the automotive industry.

Market Size

Download FREE Sample of this Report @ https://www.24chemicalresearch.com/download-sample/287322/global-polyurethane-adhesive-for-windshields-forecast-market-2025-2032-469

The global polyurethane adhesive for windshields market was valued at USD 452 million in 2023 and is projected to reach USD 657.51 million by 2030, reflecting a CAGR of 5.50% during the forecast period.

The North American market alone accounted for USD 117.78 million in 2023, with an anticipated CAGR of 4.71% from 2025 to 2030. The market’s growth is attributed to increasing automobile production, stringent safety regulations, and rising demand for high-performance adhesives in the automotive sector.

Market Dynamics (Drivers, Restraints, Opportunities, and Challenges)

Drivers

Growing Automotive Production: The rising production of vehicles worldwide directly fuels the demand for high-quality windshield adhesives.

Stringent Safety Regulations: Governments and regulatory bodies impose strict safety standards, requiring the use of reliable adhesives for windshield bonding.

Technological Advancements: Continuous innovations in polyurethane adhesive formulations improve their strength, durability, and curing time.

Increasing Consumer Preference for Durable and Lightweight Vehicles: Polyurethane adhesives contribute to reducing vehicle weight, enhancing fuel efficiency.

Growing Automotive Production: The rising production of vehicles worldwide directly fuels the demand for high-quality windshield adhesives.

Stringent Safety Regulations: Governments and regulatory bodies impose strict safety standards, requiring the use of reliable adhesives for windshield bonding.

Technological Advancements: Continuous innovations in polyurethane adhesive formulations improve their strength, durability, and curing time.

Increasing Consumer Preference for Durable and Lightweight Vehicles: Polyurethane adhesives contribute to reducing vehicle weight, enhancing fuel efficiency.

Restraints

High Costs of Raw Materials: Polyurethane adhesives are more expensive than conventional alternatives, impacting cost-sensitive markets.

Stringent Environmental Regulations: Environmental concerns over solvent-based adhesives lead to regulatory challenges.

Limited Awareness in Developing Regions: Some developing markets still rely on traditional bonding techniques, slowing polyurethane adhesive adoption.

High Costs of Raw Materials: Polyurethane adhesives are more expensive than conventional alternatives, impacting cost-sensitive markets.

Stringent Environmental Regulations: Environmental concerns over solvent-based adhesives lead to regulatory challenges.

Limited Awareness in Developing Regions: Some developing markets still rely on traditional bonding techniques, slowing polyurethane adhesive adoption.

Opportunities

Expansion in Emerging Markets: Rapid urbanization and growing automotive industries in Asia-Pacific and Latin America offer growth potential.

Eco-friendly and Low-VOC Adhesives: Manufacturers investing in sustainable adhesive solutions can tap into the increasing demand for eco-friendly products.

R&D in Quick-Curing Adhesives: Faster curing times can reduce assembly time and labor costs, attracting more manufacturers.

Expansion in Emerging Markets: Rapid urbanization and growing automotive industries in Asia-Pacific and Latin America offer growth potential.

Eco-friendly and Low-VOC Adhesives: Manufacturers investing in sustainable adhesive solutions can tap into the increasing demand for eco-friendly products.

R&D in Quick-Curing Adhesives: Faster curing times can reduce assembly time and labor costs, attracting more manufacturers.

Challenges

Fluctuating Raw Material Prices: Variability in petroleum-based raw material costs can affect profit margins.

Supply Chain Disruptions: Dependence on specific raw materials and supply chain challenges can impact production.

Fluctuating Raw Material Prices: Variability in petroleum-based raw material costs can affect profit margins.

Supply Chain Disruptions: Dependence on specific raw materials and supply chain challenges can impact production.

Regional Analysis

North America

Dominates the market with USD 117.78 million in 2023

Strong automotive industry and stringent safety regulations drive demand.

Key players focus on R&D for improved adhesives.

Dominates the market with USD 117.78 million in 2023

Strong automotive industry and stringent safety regulations drive demand.

Key players focus on R&D for improved adhesives.

Europe

High adoption of advanced adhesives due to strict safety and environmental regulations.

Strong presence of major automobile manufacturers.

High adoption of advanced adhesives due to strict safety and environmental regulations.

Strong presence of major automobile manufacturers.

Asia-Pacific

Rapid urbanization and growing vehicle production make it the fastest-growing market.

Countries like China, Japan, and India play key roles in market expansion.

Rapid urbanization and growing vehicle production make it the fastest-growing market.

Countries like China, Japan, and India play key roles in market expansion.

Latin America & Middle East & Africa

Moderate growth due to increasing automobile sales.

Economic fluctuations impact market stability.

Moderate growth due to increasing automobile sales.

Economic fluctuations impact market stability.

Competitor Analysis

The polyurethane adhesive for windshields market is highly competitive, with major companies focusing on product innovation and strategic partnerships. Some key players include:

3M Company

Henkel AG & Co. KGaA

Sika AG

Dow Inc.

Bostik SA

H.B. Fuller Company

3M Company

Henkel AG & Co. KGaA

Sika AG

Dow Inc.

Bostik SA

H.B. Fuller Company

Global Polyurethane Adhesive for Windshields: Market Segmentation Analysis

This report provides a deep insight into the global polyurethane adhesive for windshields market, covering all its essential aspects. This ranges from a macro overview of the market to micro details of market size, competitive landscape, development trends, niche market growth, key market drivers and challenges, SWOT analysis, and value chain analysis.

The analysis helps readers understand industry competition and develop strategies for navigating the competitive landscape. Furthermore, it provides a structured framework for evaluating business opportunities and identifying market positioning. The report introduces in detail the market share, product performance, operational strategies, and financial status of major industry players, helping stakeholders grasp the market dynamics.

Market Segmentation (by Application)

OEMs (Original Equipment Manufacturers)

Aftermarket Replacement

OEMs (Original Equipment Manufacturers)

Aftermarket Replacement

Market Segmentation (by Type)

One-Component Polyurethane Adhesive

Two-Component Polyurethane Adhesive

One-Component Polyurethane Adhesive

Two-Component Polyurethane Adhesive

Key Company

3M Company

Henkel AG & Co. KGaA

Sika AG

Dow Inc.

Bostik SA

H.B. Fuller Company

3M Company

Henkel AG & Co. KGaA

Sika AG

Dow Inc.

Bostik SA

H.B. Fuller Company

Geographic Segmentation

North America

Europe

Asia-Pacific

Latin America

Middle East & Africa

North America

Europe

Asia-Pacific

Latin America

Middle East & Africa

FAQ Section

What is the current market size of the polyurethane adhesive for windshields market?

As of 2023, the global polyurethane adhesive for windshields market was valued at USD 452 million and is projected to reach USD 657.51 million by 2030, growing at a CAGR of 5.50%.

Which are the key companies operating in the polyurethane adhesive for windshields market?

Major players in this market include 3M Company, Henkel AG & Co. KGaA, Sika AG, Dow Inc., Bostik SA, and H.B. Fuller Company.

What are the key growth drivers in the polyurethane adhesive for windshields market?

Rising automotive production

Stringent safety regulations

Technological advancements in adhesives

Increasing demand for durable and lightweight vehicles

Rising automotive production

Stringent safety regulations

Technological advancements in adhesives

Increasing demand for durable and lightweight vehicles

Which regions dominate the polyurethane adhesive for windshields market?

North America and Europe are leading markets due to strict safety regulations and a strong automotive industry, while Asia-Pacific is witnessing rapid growth due to increasing vehicle production.

What are the emerging trends in the polyurethane adhesive for windshields market?

Development of eco-friendly and low-VOC adhesives

Increasing R&D in quick-curing polyurethane adhesives

Growing demand in emerging markets

Development of eco-friendly and low-VOC adhesives

Increasing R&D in quick-curing polyurethane adhesives

Growing demand in emerging markets

Get the Complete Report & TOC @ https://www.24chemicalresearch.com/reports/287322/global-polyurethane-adhesive-for-windshields-forecast-market-2025-2032-469 Table of content

Table of Contents 1 Research Methodology and Statistical Scope 1.1 Market Definition and Statistical Scope of Polyurethane Adhesive for Windshields 1.2 Key Market Segments 1.2.1 Polyurethane Adhesive for Windshields Segment by Type 1.2.2 Polyurethane Adhesive for Windshields Segment by Application 1.3 Methodology & Sources of Information 1.3.1 Research Methodology 1.3.2 Research Process 1.3.3 Market Breakdown and Data Triangulation 1.3.4 Base Year 1.3.5 Report Assumptions & Caveats 2 Polyurethane Adhesive for Windshields Market Overview 2.1 Global Market Overview 2.1.1 Global Polyurethane Adhesive for Windshields Market Size (M USD) Estimates and Forecasts (2019-2030) 2.1.2 Global Polyurethane Adhesive for Windshields Sales Estimates and Forecasts (2019-2030) 2.2 Market Segment Executive Summary 2.3 Global Market Size by Region 3 Polyurethane Adhesive for Windshields Market Competitive Landscape 3.1 Global Polyurethane Adhesive for Windshields Sales by Manufacturers (2019-2025) 3.2 Global Polyurethane Adhesive for Windshields Revenue Market Share by Manufacturers (2019-2025) 3.3 Polyurethane Adhesive for Windshields Market Share by Company Type (Tier 1, Tier 2, and Tier 3) 3.4 Global Polyurethane Adhesive for Windshields Average Price by Manufacturers (2019-2025) 3.5 Manufacturers Polyurethane Adhesive for Windshields Sales Sites, Area Served, Product Type 3.6 Polyurethane Adhesive for Windshields Market Competitive Situation and Trends 3.6.1 Polyurethane Adhesive for WindshiCONTACT US: North Main Road Koregaon Park, Pune, India - 411001. International: +1(646)-781-7170 Asia: +91 9169162030

Follow Us On linkedin :- https://www.linkedin.com/company/24chemicalresearch/

0 notes

Text

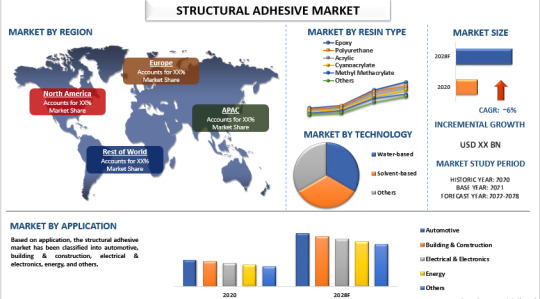

Structural Adhesive Market: Trends, Growth, and Future Outlook

The structural adhesive market has been experiencing significant growth in recent years, driven by increasing demand across various industries including automotive, aerospace, construction, and electronics. Structural adhesives are essential for creating strong, durable bonds between different materials, offering numerous advantages such as enhanced performance, reduced weight, and improved aesthetics. This article provides a comprehensive overview of the structural adhesive market, exploring key trends, growth factors, and future prospects.

Market Overview

Structural adhesives are high-performance bonding agents used to join load-bearing structures. These adhesives are designed to provide long-lasting bonds and withstand various environmental conditions such as temperature fluctuations, moisture, and chemical exposure. Common types of structural adhesives include epoxy, polyurethane, acrylic, and cyanoacrylate, each offering unique properties tailored to specific applications.

Key Trends Driving Market Growth

1. Rising Demand in Automotive Industry: The automotive sector is one of the largest consumers of structural adhesives. The shift towards lightweight materials to improve fuel efficiency and reduce emissions has led to increased use of adhesives for bonding different substrates such as metals, plastics, and composites. Structural adhesives are crucial in manufacturing processes, contributing to vehicle safety, durability, and performance.

2. Advancements in Aerospace Applications: The aerospace industry requires adhesives that can withstand extreme conditions while ensuring the integrity of critical components. Structural adhesives are extensively used in aircraft manufacturing for bonding metals and composites, enhancing structural strength and reducing weight. Innovations in adhesive formulations have led to improved performance, making them indispensable in modern aerospace engineering.

3. Growing Construction Activities: The construction sector is witnessing a surge in the adoption of structural adhesives for various applications, including bonding concrete, metals, and insulation materials. These adhesives offer superior bonding strength and durability, making them ideal for demanding construction projects. The trend towards sustainable construction practices further boosts the demand for eco-friendly adhesive solutions.

4. Electronics and Consumer Goods: Structural adhesives play a vital role in the electronics industry, where they are used to assemble components and protect delicate circuits from environmental factors. The miniaturization of electronic devices and the increasing complexity of assemblies drive the need for high-performance adhesives that provide reliable bonds and thermal management.

For a comprehensive analysis of the market drivers:- https://univdatos.com/report/structural-adhesive-market/

Market Dynamics

Drivers

- Technological Advancements: Ongoing research and development activities have led to the introduction of advanced adhesive formulations with enhanced properties such as faster curing times, higher bond strength, and improved resistance to environmental factors. These innovations drive market growth by meeting the evolving needs of various industries.

- Environmental Regulations: Stringent regulations aimed at reducing volatile organic compounds (VOCs) and promoting sustainable practices have led to the development of eco-friendly adhesives. Manufacturers are focusing on producing low-VOC and solvent-free adhesives, aligning with global environmental standards and catering to environmentally conscious consumers.

- Increasing Infrastructure Development: Rapid urbanization and infrastructure development, especially in emerging economies, create a significant demand for structural adhesives. The need for efficient bonding solutions in construction projects, including bridges, tunnels, and high-rise buildings, fuels market expansion.

Challenges

- High Cost of Advanced Adhesives: While advanced structural adhesives offer superior performance, their high cost can be a barrier to widespread adoption, particularly in price-sensitive markets. Balancing cost and performance remains a challenge for manufacturers.

- Technical Limitations: Despite advancements, certain technical limitations such as limited heat resistance and difficulties in bonding specific substrates can hinder market growth. Continuous research and development efforts are essential to address these challenges and expand the application range of structural adhesives.

For a sample report, visit:- https://univdatos.com/get-a-free-sample-form-php/?product_id=31065

Future Outlook

The structural adhesive market is poised for robust growth in the coming years, driven by technological advancements, increasing industrial applications, and the push for sustainable solutions. The development of new adhesive formulations with improved properties and the expansion of applications in emerging sectors such as renewable energy and medical devices present significant opportunities for market players.

In conclusion, the structural adhesive market is evolving rapidly, with increasing demand across various industries due to their ability to provide strong, durable bonds and enhance overall performance. Continued innovation and a focus on sustainability will be key to unlocking new growth avenues and maintaining the upward trajectory of the market.

Contact Us:

UnivDatos Market Insights

Email - [email protected]

Contact Number - +1 9782263411

Website -www.univdatos.com

#Structural Adhesive Market#Structural Adhesive Market Growth#Structural Adhesive Market Share#Structural Adhesive Market Forecast

0 notes

Text

Emulsion Polymer Market: A Sustainable Revolution in Coatings, Adhesives, and Packaging

Introduction

The global emulsion polymer market is projected to grow from $38.5 billion in 2023 to $56.2 billion by 2030, at a CAGR of 5.5%. Emulsion polymers are widely used in paints & coatings, adhesives, textiles, and paper production, offering low VOC emissions and superior durability. The increasing demand for eco-friendly and water-based coatings is a major factor driving market growth.

Market Overview

1. Market Drivers

Growing Demand for Water-Based Coatings: Rising environmental concerns and stringent regulations are shifting the market towards low-VOC and eco-friendly emulsion polymers.

Expanding Construction and Automotive Industries: The surge in infrastructure development and automotive production is increasing the demand for paints, adhesives, and coatings, all of which use emulsion polymers.

Technological Advancements in Polymer Production: Innovations in bio-based and high-performance emulsion polymers are boosting market penetration.

Rising Demand in Packaging & Paper Industry: The growing need for flexible packaging, food-grade coatings, and printing inks is fueling market expansion.

2. Market Restraints

Volatility in Raw Material Prices: Fluctuations in petrochemical-based feedstocks may impact production costs.

Availability of Alternative Polymers: Increasing competition from solvent-based and UV-cured polymers could challenge market growth.

Segmentation Analysis

1. By Type

Acrylics: Widely used in paints & coatings, adhesives, and textiles.

Styrene-Butadiene (SB) Latex: Key component in paper coatings and carpets.

Vinyl Acetate Polymers: Used in wood adhesives and architectural coatings.

Others: Hybrid polymers and specialty emulsions for high-performance applications.

2. By End-Use Industry

Paints & Coatings: Largest segment due to demand for decorative and protective coatings.

Adhesives & Sealants: Emulsion-based adhesives offer high bonding strength and environmental compliance.

Paper & Packaging: Growth in eco-friendly packaging is boosting demand.

Textiles: Used for fabric finishes, waterproofing, and dyeing processes.

Regional Insights

1. North America

✅ Stringent environmental regulations favoring water-based coatings over solvent-based alternatives.

2. Europe

✅ Sustainability initiatives driving the adoption of bio-based emulsion polymers.

3. Asia-Pacific

✅ China, India, and Japan are leading in construction, automotive, and industrial applications, boosting market growth.

4. Middle East & Africa

✅ Growing infrastructure projects are increasing demand for paints, adhesives, and coatings.

Competitive Landscape

Leading companies in the emulsion polymer market include:

BASF SE

Dow Inc.

Arkema Group

Trinseo

Synthomer Plc

These firms are investing in R&D for sustainable and high-performance polymers, mergers & acquisitions, and expanding production capacity.

Future Outlook

The emulsion polymer market is expected to continue expanding with innovations in bio-based polymers, low-VOC formulations, and high-performance applications. As industries shift towards sustainable solutions, emulsion polymers will play a critical role in shaping the future of coatings, adhesives, and packaging materials.

✅ The bio-based emulsion polymer segment is projected to grow at 7.2% CAGR, reinforcing the trend toward sustainability.

Conclusion

The emulsion polymer market is evolving with advancements in eco-friendly materials, innovative production techniques, and regulatory compliance. With increasing applications in construction, automotive, and packaging, emulsion polymers remain a crucial component in modern industrial and commercial applications.

0 notes

Text

The construction flooring chemicals market is projected to grow from USD 1699.04 million in 2023 to USD 2371.98 million by 2032, at a CAGR of 3.60%.In the realm of construction, flooring plays a pivotal role not only in aesthetics but also in functionality and durability. Behind the scenes, there exists a market dedicated to providing the necessary chemicals for various flooring applications. From concrete sealers to epoxy coatings, these chemicals are essential for enhancing the strength, resilience, and longevity of floors across different sectors. This article delves into the nuances of the construction flooring chemicals market, exploring its current landscape and future prospects.

Browse the full report at https://www.credenceresearch.com/report/construction-flooring-chemicals-market

Market Overview: The construction flooring chemicals market has been witnessing steady growth globally, driven by the burgeoning construction industry and increasing demand for durable and aesthetically pleasing flooring solutions. According to recent market analyses, the market is expected to experience a compound annual growth rate (CAGR) of around X% over the forecast period. This growth can be attributed to several factors, including rapid urbanization, infrastructural developments, and the adoption of advanced flooring technologies.

Key Players and Products: Several prominent players operate in the construction flooring chemicals market, offering a diverse range of products tailored to meet the specific requirements of different applications. These products encompass various chemical formulations such as epoxy resins, polyurethane coatings, sealers, adhesives, and additives. Some of the leading players in the market include BASF SE, Sika AG, RPM International Inc., and The Dow Chemical Company, among others. These companies continually innovate to develop advanced formulations that cater to evolving customer needs while adhering to stringent regulatory standards.

Market Segmentation: The construction flooring chemicals market can be segmented based on product type, application, end-user industry, and geographical regions. Product segmentation includes epoxy, polyurethane, acrylic, and others. Applications range from residential to commercial, industrial, and institutional sectors. End-user industries encompass construction, automotive, healthcare, and manufacturing, among others. Geographically, the market is divided into North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa.

Trends and Drivers: Several trends are shaping the construction flooring chemicals market landscape. One prominent trend is the growing preference for environmentally sustainable and low VOC (Volatile Organic Compound) products. As environmental consciousness increases, manufacturers are focusing on developing eco-friendly formulations without compromising performance. Additionally, advancements in technology, such as self-leveling compounds and moisture mitigation systems, are gaining traction in the market, offering enhanced efficiency and durability.

Moreover, the rapid expansion of the construction industry, particularly in emerging economies, is fueling market growth. Infrastructure projects, urban development initiatives, and the construction of commercial and residential buildings contribute to the rising demand for high-quality flooring solutions. Furthermore, the increasing focus on renovation and remodeling activities in the existing infrastructure is driving the adoption of flooring chemicals for restoration and enhancement purposes.

Challenges and Opportunities: Despite the optimistic outlook, the construction flooring chemicals market faces certain challenges, including fluctuating raw material prices and regulatory constraints. The volatility in raw material costs can impact profit margins and pricing strategies of manufacturers. Moreover, stringent regulations pertaining to product safety, environmental impact, and VOC emissions necessitate compliance, adding to operational complexities.

However, these challenges also present opportunities for market players to innovate and diversify their product portfolios. Collaborations with research institutions and investment in R&D activities can lead to the development of novel formulations with improved performance and sustainability credentials. Additionally, strategic partnerships and expansion into untapped regions offer avenues for growth and market expansion.

Key Player Analysis

AkzoNobel

BASF

Borealis Ag

Dow Chemical

Dupont

Exxon Mobil

Forbo Holding

Huntsman Corp

LG Chemical

Lyondellbasell Industry

Segments:

Based on Product:

Epoxy Floor Coating

Grout Chemicals

Admixtures Chemicals

Floor Hardeners

Curing and Sealing Compounds

Primers

Polyurethane Coating

Others

Based on Application:

Industrial Flooring

Residential Flooring

Waterproofing

Repair and Protection

Anti-skid

Anti-slip Flooring

Others

Based on End-Use Industry:

Building and construction

Residential

Independent Houses

Apartments

Row Houses

Commercial

Office Building

Hospitals

Retailers

Hotel/Hospitality

Restaurants

Educational Institutions

Others

Industrial

Infrastructural

Airports

Highways

Others

Based on the Geography:

North America

The U.S.

Canada

Mexico

Europe

Germany

France

The U.K.

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of the Middle East and Africa

About Us:

Credence Research is committed to employee well-being and productivity. Following the COVID-19 pandemic, we have implemented a permanent work-from-home policy for all employees.

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

0 notes

Text

Latin America UV Curable Resin Market Outlook and Forecast 2025-2032

UV curable resins are specialized polymeric materials designed for rapid curing when exposed to ultraviolet (UV) light. These resins play a crucial role in various industries, including coatings, adhesives, printing, and packaging, due to their ability to enhance durability, efficiency, and environmental sustainability. Unlike traditional solvent-based systems, UV curable resins offer a low-VOC (volatile organic compound) alternative, making them an eco-friendly choice in industrial applications.

Download FREE Sample of this Report @ https://www.24chemicalresearch.com/download-sample/286478/latin-america-uv-curable-resin-market-2025-2032-366

0 notes

Text

Exploring the Key Players in PF Resin Supply Chain: Suppliers, Innovations, and Market Trends

Introduction: Phenol-formaldehyde (PF) resin is a versatile and widely used synthetic resin with applications ranging from wood adhesives to molded products. As industries seek sustainable and high-performance materials, the demand for PF resin continues to grow. Central to meeting this demand are the suppliers who provide the raw materials, expertise, and innovations driving the PF resin market forward. This article delves into the world of PF resin suppliers, exploring their roles, innovations, and the evolving landscape of this essential industry.

The Role of PF Resin Suppliers: PF resin suppliers play a crucial role in the supply chain by providing manufacturers with the raw materials needed to produce Pf Resin Manufacturer in India adhesives, coatings, and other products. These suppliers typically offer a range of PF resin grades tailored to specific applications, including:

Adhesive Grade PF Resins: These resins are formulated to provide strong and durable bonds in wood products, laminates, and composite materials, making them indispensable in the furniture, construction, and automotive industries.

Molding Grade PF Resins: Molding grade PF resins are used in the production of molded products such as electrical components, appliance parts, and decorative items, offering excellent heat resistance and dimensional stability.

Coating Grade PF Resins: PF resins designed for coatings and surface treatments provide protection against moisture, chemicals, and abrasion, making them ideal for applications in marine, aerospace, and industrial sectors.

Innovations in PF Resin Technology: Driven by the demand for sustainable and high-performance materials, PF resin suppliers are continually innovating to improve product quality, environmental sustainability, and application versatility. Key innovations in PF resin technology include:

Low-Formaldehyde Formulations: Suppliers are developing PF resin formulations with reduced formaldehyde emissions to meet stringent regulatory requirements and address consumer preferences for eco-friendly products.

Bio-Based PF Resins: Bio-based PF resins derived from renewable feedstocks such as lignin or agricultural residues offer a sustainable alternative to traditional petroleum-based resins, reducing reliance on fossil fuels and mitigating environmental impact.

Waterborne PF Resins: Waterborne PF resin formulations provide improved safety, handling, and environmental benefits compared to solvent-based resins, contributing to lower VOC emissions and reduced environmental footprint in coating and adhesive applications.

High-Performance Additives: The integration of advanced additives such as crosslinking agents, antioxidants, and UV stabilizers into PF resin formulations enhances product performance, durability, and application versatility in various end-use industries.

Market Trends and Outlook: The PF resin market is characterized by steady growth driven by expanding applications in construction, automotive, electronics, and consumer goods sectors. Key market trends shaping the industry include:

Growing Demand for Engineered Wood Products: The increasing adoption of engineered wood products such as plywood, particleboard, and MDF (medium-density fiberboard) fuels demand for PF resins in wood adhesive applications, particularly in construction and furniture manufacturing.

Shift Towards Sustainable Materials: Consumer preferences for sustainable and environmentally friendly products drive the demand for bio-based and low-formaldehyde PF resin formulations, prompting suppliers to invest in green technologies and product development.

Technological Advancements in Manufacturing: Advances in resin synthesis, process Pf Resin Manufacturer in India optimization, and quality control enable suppliers to enhance product consistency, performance, and cost-effectiveness, driving competitiveness in the global PF resin market.