#Linear Actuator works

Explore tagged Tumblr posts

Text

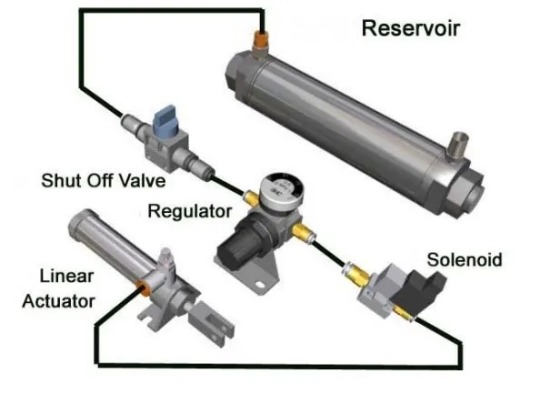

How pneumatic linear actuators work

Pneumatic linear actuators are devices that convert compressed air into linear motion. They are widely used in various industrial applications due to their simplicity, reliability, and affordability. The basic principle behind their operation lies in the conversion of potential energy stored in compressed air into mechanical work.

A pneumatic linear actuator consists of several key components, including a cylinder, a piston, and valves. The cylinder is a hollow tube that houses the piston and provides a sealed environment for the movement of the piston. The piston, which is a solid cylindrical object, is positioned inside the cylinder and is connected to a rod that extends outside the actuator. The valves, located at the inlet and outlet ports of the actuator, control the flow of compressed air into and out of the cylinder Pneumatic Linear Actuator.

When compressed air is supplied to the actuator, it enters the cylinder through the inlet valve, pushing the piston and the attached rod forward. This movement is facilitated by the difference in pressure between the compressed air and the atmosphere. As the piston moves forward, the air behind it is vented through the outlet valve, allowing for continuous motion. To reverse the direction of the actuator, the flow of compressed air is redirected through the valves, causing the piston to move in the opposite direction.

Pneumatic linear actuators offer precise and controlled linear motion, making them suitable for applications that require repetitive and accurate movements. Their design allows for high-speed operation and high-force output, making them ideal for tasks such as clamping, lifting, pushing, and pulling. Furthermore, their modular nature enables easy integration into existing systems, making them a versatile choice for various industries.

In summary, pneumatic linear actuators work by converting compressed air into linear motion through the interaction of a piston, cylinder, and valves. Their simple yet effective design allows for reliable and efficient operation, making them a popular choice in industrial automation.

0 notes

Text

god i really do need to work on the mechanical goggles while im energetic

#at least just to get a functional prototype#proof of concept and all#i need light sensors and figure out is linear actuators or servos would work better#i think servos would react faster but the motion i need is back and forth#ig i could turn rotation into linear motion through gears but thats a lotta failure points

19 notes

·

View notes

Text

[image description: chart titled Talk Like A Technician: The Use of Technobabble.

Technology in Star Trek is complex and works in scientific concepts and principles that are far beyond what the majority of Players and Gamemasters are knowledgeable in. Throughout the collected media, Starfleet officers discuss technology using terms that most Players are not going to know. Instead of expecting Players to study and memorize technical manuals and reference books that have been published over the years we've provided an easy way to talk like a Starfleet engineer. Anyone can do "technobabble"!

To use the chart simply gather and roll d20s and consult the chart below for technical new terms and concepts.

Occasionally portions of the chart may not be applicable to the scene or circumstance. In that case simply omit that portion of technobabble!

The chart has six columns, Roll, Action, Descriptor, Source, Effect, and Device. Each has 20 rows.

Roll: numbers 1-20

Action: refocus, amplify, synchronize, redirect, recalibrate, modulate, oscillate, intensify, nullify, boost, reverse, reconfigure, actuate, focus, invert, reroute, modify, restrict, reset, extend

Descriptor: microscopic, macroscopic, linear, non-linear, isometric, multivariant, nano, phased, master, auxiliary, primary, secondary, tertiary, back-up, polymodal, multiphasic, tri-fold, balanced, oscillating

Source: Quantum, positronic, thermionic, osmotic, neutrino, spatial, resonating, thermal, photon, ionic, plasma, nucleonic, verteron, gravimetric, nadion, subspace, baryon, tetryon, polaron, tachyon

Effect: flux, reaction, field, particle, gradient, induction, conversion, polarizing, displacement, feed, imagining, reciprocating, frequency, pulse, phased, harmonic, interference, distortion, dampening, invariance

Device: inhibitor, equalizer, damper, chamber, catalyst, coil, unit, grid, regulator, sustainer, relay, discriminator, array, coupling, controller, actuator, harmonic, generator, manifold, stabilizer.

/end id]

269 notes

·

View notes

Text

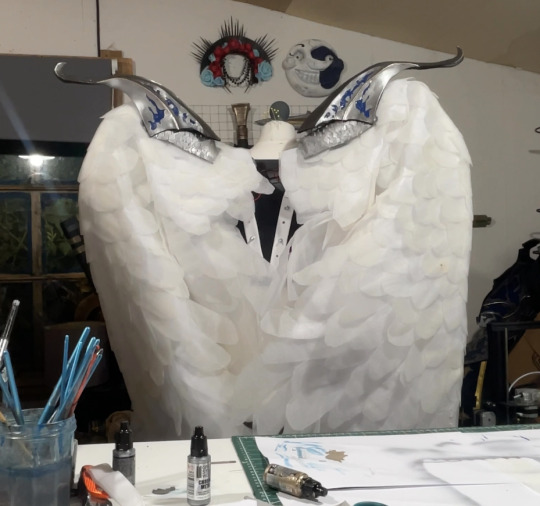

How to Make: Electronic Wings for Cosplay

Hello Everyone! It's been a while since I last uploaded a written tutorial on here and since I just finished and wore my Dame Aylin cosplay this last weekend it seemed appropriate to jump back in with a tutorial on one of the costume pieces!

Her wings were the star of the show this weekend and I know a lot of people were curious about how I made them! A huge source of knowledge and inspiration behind these wings was this video by Axceleration, I made a few changes to the frame shape and electrical circuitry for mine but her tutorial was a huge stepping stone to give me the confidence to tackle them myself!

Health and Safety:

When working with Sintraboard (as well as other thermoplastics) it is incredibly important you wear a respirator as well as goggles when heating, moulding and cutting it. The fumes this plastic will give off when heated up are no joke! Make sure you're in a well-ventilated space!

Basic tool safety knowledge is also really important! wearing gloves when using power tools can be more dangerous in most situations, so always be aware of where your hands are vs where the tools are. Always cut away from yourself and take things slowly, don't panic.

Electrical safety! You're working with live wires and circuitry! make sure your hands are dry, you aren't touching the bare wires at any point when they are connected to a power source, and if you choose to solder anything, make sure you're wearing heat-proof gloves and a mask in a ventilated space!

Tools

Wire stripper

Screwdriver and wrench

Dremel - I recommend the Dremel 3000 rotary tool personally! Some essential Dremel bits you'll need for this include, a sanding bit, drill bit (smaller or same size as your screws/bolts), and a small/narrow cutting bit. These will usually come with the Dremel!

Heat Gun (A hairdryer will not get hot enough to heat the Sintraboard!!)

Pipe cutter (alternatively you can use a hacksaw for this!)

Hacksaw

Ruler

Scissors (for cutting fabric straps)

Materials

Heat shrink Tubing

2 core electrical wire

switch (you want a three position, six pin switch, like this one, even better if it has the Screws on the pins! otherwise you'll need a soldering kits to solder the wires to the pins.

2x 8AA 12v Battery Holders

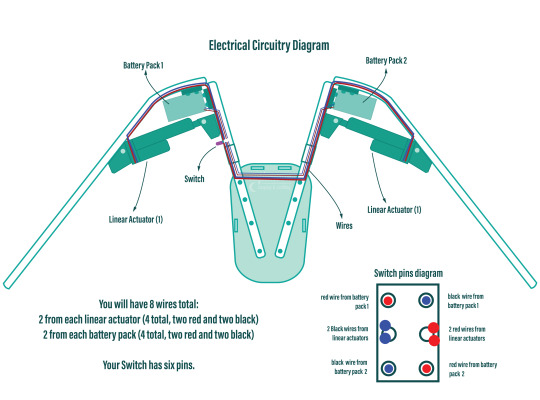

2x 12v Linear Actuators (Mine had a stroke length of 100mm)

21.5mm PVC Pipes (I got 2x 3m Lengths)

2x 21.5mm PVC Pipe straight couplers

6mm 8"x12" Sintraboard

Nuts/Bolts/Screws (I used M5 bolts for the base & Actuator connectors and M6 screws to attach the hinges to the pipes! You'll need Washers for every Nut & Bolt!)

Hinges (I used 2.5cm wide hinges that were skinny but long so they would just about fit along the PVC pipe! 3" gate hinges would work!)

50 metre Polythene Jiffy foam roll (in retrospect this was ALOT of foam, you could definitely get away with maybe a 20-30 metre roll! I now have a load leftover XD)

16 AA Batteries (I used 16 and had enough for the whole day with them on, I think They'd probably be enough for another half a day-full day too! but have spares just in case!)

Webbing strap ( I went for grey to match my base suit colour!)

Buckle - as wide as the webbing strap you use!

3 metres of white cotton fabric (or whatever colour wings youre going for!)

Optional

Zipties (for cleaning up the wires)

Lets Go!

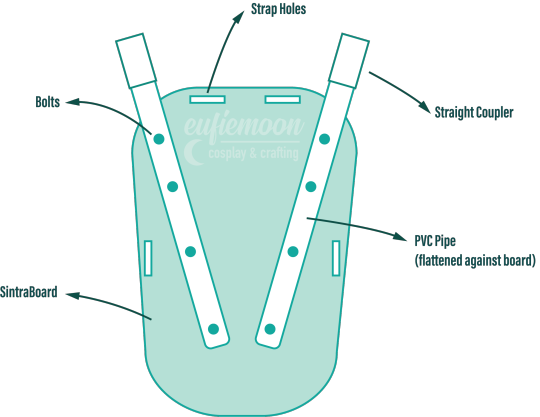

Sintraboard is this wonderfully stable thermoplastic that is relatively easy to cut into (with the right tools) and when heated allows you to mould its shape! I started by using a mannequin and heating the Sintraboard with a heat gun for a few minutes to make it pliable, I recommend using gloves for this part as the materials gets VERY HOT! Press the board into the shape of the mannequin's back, taking note of the edges especially! you want this board to sit as comfortably to your body shape as possible as it makes a huge difference to how long you can wearing the wings for in this backplate is comfy!

Once shaped, I placed it against my back to make sure it was a good fit, heating again and making any alterations I needed (again don't place bright hot plastic to your bare skin! wear protective clothes and wait till its slightly cooler to do this, with the help of a friend!). I then took a hacksaw and rounded the corners, before sanding the edges with my Dremel! Try to avoid cutting off loads, just enough to make things less likely to snag.

3. I then cut in four holes, wide enough to feed my webbing strap through, two at the top and one on either side below where my arms would sit! I measured the webbing strap by firstly feeding them through the top holes and pinning them, and then bring the strap over my should to everything sits where it should and seeing where the strap hits the side hole and cutting the length there! you'll also want a strap that attaches across the chest, meeting in the centre with a buckle!

4. After sewing the straps closed I was able to move onto the PVC pipe structure! This may change slightly depending on the finished shape you want but I needed the PVC pipes to come out from inside a breastplate so had a particularly angle as well as character references to work with! I began by heating the pipe over my heat gun and flattening a portion of it under a heavy object so it would sit much more flush against the backboard and sit better underneath my breastplate before moving onto securing the first portion of the structure to the backplate. This mainly involved lots of try-ons and measuring to make sure the angles were correct and symmetrical and was quite fiddly but well-worth the effort! I'll include a diagram of the general shape I went with below:

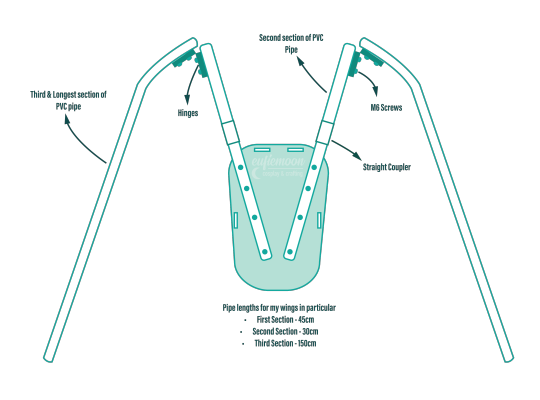

5. I wanted my wings to be relatively modular for ease of travel so I needed to make sure certain portions of them could come away from other parts easily, so I popped a straight coupler on the top of the pipes that were attach to the breastplate, this also meant I could slot the breastplate over these shorter pipes and wear everything correctly! Then these second pipes slot on and at the other end they are attached via hinges to the longest portion of the pipe 'skeleton', Diagram below:

6. Now that the skeleton was put together, it's time for the electrical stuff! It's a good idea to figure out where your circuit is going to lay on the skeleton - consider if you want the battery packs mounted the the backplate or, like me, put them inside the actual wings in removeable pockets for easy access and removal for battery changes. all your wires will go through the switch so deciding where you want to place that is very important! Mine was placed just over my shoulder on the front side, mounted to the PVC pipe with a metal cover I drilled a hole into to slip the switch through and then drill through the pipe.

I've included another diagram below that explains all the electrical circuitry, including which wires go on which pins on the switch!

Important to note: The linear actuators need to be placed and bolted into the PVC pipes at *exactly* the same angle on each side, any slight deviation will lead to the wings going up wonkily! So take your time and make as many adjustments as necessary.

7. You can extend your wires by adding on the electrical wire, just match the colours, and put heat shrink tubing over the connections to hide the live wires! I ended up zip-tying the wires into organised bundles once the wings were done to help keep everything safe from snags.

8. Now its time for the Wings themselves! I drafted my base pattern by just draping the white cotton fabric I had over the wing when it was fully extended. I then pinned the wings to the shape I wanted them to be along the bottom before cutting along the pins. I ran the fabric through my sewing machine to close the bottom edge, leaving a gap wide enough by the wing base so I could slip the wing on and off, closing it with velcro. I also added little fabric pockets inside of these to hold my battery packs, which also connected via velcro for easy removal!

9. Now that I had a wing base I was able to begin making feathers! I cut out a total of 800 feathers out of polythene jiffy roll for these wings, in 6 different styles and using real life bird wings to dictate the shapes I used and where I placed them. I ended up hot gluing every individual feather onto the white fabric base, going row by row until every side was covered, the wing covers themselves are super light because of the foam feathers and they shine light through them in a really magical way!

Optional: I also ended up going over these feathers with my airbrush and some super light beige paint to help darken the shadows, this is entirely optional and may change depending on the wings you're looking to make!

When in neutral position and in extended position the wings looks like this:

Mine had a wingspan of about 7ft total when fully extended but when in neutral position they were fairly close to my own proportions! mainly staying behind me and weren't much of a problem in a packed con hall!

Photo by: Helloimfran (on Instagram and Twitter)

I hope this tutorial helped and if there are any questions about anything in specific don't hesitate to reach out at [email protected] or on my instagram or twitter (@eufiemoon)

Happy Crafting!

#cosplay#cosplayer#cosplaying#baldurs gate iii#baldur’s gate 3#baldurs gate 3#bg3#dame aylin#aylin x isobel#bg3 aylin#cosplay tutorial#Wings#fantasy#tutorial#cosplay help#cosplay tips

168 notes

·

View notes

Text

Southern Jimmy, The Fanfic

Jimmy and the gang had a rare day off, so they decided to relax in their own ways around Jimmy’s lab. Timmy and Manny decided to play video games, with a promise not to get out of hand again like last time. (Call Of Duty is still banned after half the lab got destroyed.) Spongebob was cooking a feast for a village for lunch, the smells coming out of the kitchen was making everyone relax even more. Jenny and Danny was sitting on another nearby couch, talking about space and discussing theories of alien life. Jimmy has his playlist playing on a low volume as he works on Goddard. It was about time for another update for him after the last mission.

Everyone was enjoying themselves in their own happy little bubbles. “Eres tan patético, que resultas entrañable! You seriously think you can pass me as Luigi?” Manny taunts as he throws a blueshell at Bowser and makes it to first place. Timmy, on the other hand, his stuck in third place and quickly taking advantage of Bowser still out to score second. “Dude! You’re luck is about to run out!” Cosmo and Wanda stayed silent as they sat on his shoulder and watched. “You keep papando moscas because you are never going to-HEY!” Manny was interrupted by a Bullet Bill. Timmy quickly shot past and made it over the finish line, finishing in first place. “HA! I told you could never beat me! I’m the Mario Kart champion!”

Jenny and Danny paused their conversation about the differences of their solar system when they looked over to the duo on the couch in amusement. “Perdí la partida! Danny, heal my wounds! El Niño hada beat my by a bullet, I’m wounded.” Manny dramatically draped himself over Danny and the couch. Danny did nothing; he wrapped his arms around the dramatic boy and continued talking to Jenny. “Anyways, our Land Rover went silent June 2018 due to a global dust storm on Mars. It wasn’t until eight months later that the Land Rover was declared dead on February 13.” Jenny gasps in shock. “What?!” Danny nods in understanding, “There was a global dust storm that blocked sunlight from reaching the rover’s solar panels, preventing it from recharging.”

Timmy sighs after losing his gaming partner, he turned to the boy genius, who was still focused on Goddard with his music playing on a low hum. Timmy leaned in close and heard 200 Digits of PI playing from his phone. Jimmy wasn’t paying attention to how close Timmy was leaning into his personal space. He was focused on making sure he had the linear actuator, which was lining up just right with the electrical circuits. The rest of the leg lay in front of him as he tested to make sure the valve leading to the piston cylinder had no more faults. “Oi, el niño hada! I demand a rematch!” Manny declared as he stood on the table. Timmy quickly diverted his attention to the buff guy on the table. Before anyone could stop them, a guitar song started playing.

Cheater, cheater where'd you meet her

Down at Ernie's Bar?

Did she smile your way, twirl her hair and say how cute your dimples are?

Did she use that line "Your place or mine?" while you danced with her real slow?

Tell me cheater, cheater where'd you meet that no good, white trash ho?

Everyone was in a state of shock and utter confusion. They understood that Jimmy was from Texas, but no one thought that he had a southern accent. Let alone knew any southern songs. So when Jimmy mindlessly started to sing, in perfect rhythm and twang, nobody was ready.

Liar, liar did you buy her whiskey all night long?

Did you hide your ring in the pocket of your jeans or did you just keep it on?

When the deed was done and you had your fun did you think I wouldn't know?

Tell me cheater, cheater where'd you meet that no good, white trash ho?

“Guys, he has a southern accent?” Timmy whispers. Like he wasn’t sure whether what he was facing was reality or one of his secret fantasies. “Dude, that is what you’re focused on? Like, don’t get me wrong, I know people love a good accent. But are we not going to talk about how Jimmy knows this song word by word?” Jenny asks. “No, no. He has a point,” Danny hushes, and Manny nods to back him up. “El chico has a point.”

Now I'm not one to judge someone that I ain't never met

But to lay your hands on a married man is bout as low as a gal can get

Hey I wish her well as she rots in hell and you can tell her I said so

Cheater, cheater where'd you meet that no good, white trash ho?

“Mi amor, you are from Illinois right? Please tell me you have the same accent,” Manny all but begged as he looked at Danny with puppy eyes. The ghost boy smirked and winked at him, “Maybe you will find out later?”

Jenny rolled her eyes as the two boys mindlessly flirted with each other like they are the only ones in the room. She glances over towards Timmy and realizes he’s not much better, as Jimmy decides to start slightly moving his body as if to dance to the music. Jimmy glanced up to see where all the commotion is and noticed almost everyone is looking at him.

Loser, loser hope you love her cuz your stuck with her now

Take your sorry butt, load up all your stuff, and get the hell out of my house

But I just wish you'd tell me this one thing before you go

Cheater, cheater where'd you meet that no good, white trash ho?

Now I'm not one to judge someone that I ain't never met

But to lay your hands on a married man is bout as low as a gal can get

Hey I wish her well as she rots in hell and you can tell her I said so

Cheater, cheater where'd you meet that no good, white trash ho?

Yeah I just wish you'd tell me this one thing before you go

Cheater, cheater where'd you meet that low down, up town, slept with every guy around, pressed on eyelash, no good, white trash ho?

Jimmy stayed frozen when the song ended, as he couldn’t believe everyone just heard him. “Jim, JimJam, Jimberly, the Jim to my heart. Why didn’t you tell me you had a southern accent? Do you realize how hot that is? Holy shit babe, why didn;t you ever tell me?!” Timmy exclaimed, successfully flustering the boy genius. “Look-wait-how long-” Jimmy stuttered. “So, fellow southern boy, when were ya goin to tell me yer southern as well?” Danny teased. Jimmy sank his face into his hands. “Danny, please?”

Manny hopped over the couch, “Dude! Do you realize how amazing an accent is? Think about all the things you can do, the people you can confuse, mi amigo del sur! The world is at your fingertips!” SpongeBob chose this instant to pop out of the kitchen, “Lunch is ready, come get it!” Jimmy had never been so happy to hear those words and was the first one up and in the kitchen before anyone else. “Wait, I still have a lot of questions!” Timmy shouted and ran after him. Jenny shared a look with Danny, and she handed him a fifty. “ I can’t believe you were right. How on Earth did you know he was southern?” Danny chuckled but didn’t say anything, just letting Manny drag him into the kitchen after the lovers. Jenny was close behind, bugging him to finally answer him.

~~~~~~~Footnotes~~~~~~~~

A linear actuator is a device that transforms rotational motion into linear (straight-line) motion, typically using a motor, a lead screw, and a nut. It's used in applications requiring controlled pushing, pulling, or lifting, such as in medical equipment, adjustable furniture, and industrial automation.

The actuators are all wired to electrical circuits. The circuits power electrical motors and solenoids directly and activate hydraulic systems by manipulating electrical valves. The valves determine the pressurized fluid's path through the machine. To move a hydraulic leg, for example, the robot's controller would open the valve leading from the fluid pump to a piston cylinder attached to that leg. The pressurized fluid would extend the piston, swiveling the leg

Eres tan patético, que resultas entrañable- You’re so pathetic, you’re actually entertaining

papando moscas- Day dreaming

Perdí la partida- I lost the game

El Niño hada- The fairy boy

El chico- The boy

Mi amigo del sur- My southern friend (masculine)

15 notes

·

View notes

Text

Terms and definitions that you can maybe apply to your fan works

I don't know anything about computer or mechanical engineering (it's very funny to me that I am in the Transformers fandom and I don't even care about cars), but I do care about improving my writing. I have gathered a list of terms that sound very sciencey and applicable to mechs, some from Martha Wells's "Murderbot Diaries," some from fanfiction/fandom (shout-out to the Crime in Crystals series by Aard_Rinn and Baebeyza, they wrote Transformers better than any Transformers comic/TV show did), and a lot from just surfing through Google and going, "well, what the hell is this? Okay, but what the hell is THAT?".

Also, as I was writing this post, I ended up getting sucked into this article:

And this really bloated my already long list of terms. Very easy to read if you want to glance it over yourself.

It's not an exhaustive list and who knows if it will be useful to you - but maybe you can reblog with your own add-ons of terms and definitions you think make a Transformers fan work just that much better.

The list is below the cut:

100% CPU Load - CPU is fully occupied with too many processors/applications/drivers/operations - not necessarily synonymous with an overload.

Actuators* - A device that causes a machine or other device to operate (Ex: a computerized unit instructs the actuator how to move the tires on a vehicle); create linear and rotary movement (Ex: A hydraulic actuator on a valve will move that valve in response to a sensor/signal); Linear actuators "move a piston back and forth inside a cylinder to build pressure and 'actuate', or complete an action".

* Think of actuators as devices that help produce linear motion and motors as devices that help produce rotational movement. Hence, some consider actuators as a type of motor. But a motor is not a type of actuator (jhfoster.com).

Alternator - Converts mechanical energy to electrical energy with an alternating current. The stator and rotor inside the alternator work as magnets and rotate to generate the alternating current. Then the alternating current (AC) is transformed into a direct current (DC) that charges the battery.

Archive (Archive files) - used to collect multiple data files together into a single file for easier portability and storage, or simply to compress files to use less storage space.

Arithmetic Log Unit (ALU) - the part of a central processing unit that carries out arithmetic and logic operations on the operands in computer instruction words. In some processors, the ALU is divided into two units: an arithmetic unit (AU) and a logic unit (LU).

Augment - Make something greater; increase.

Auxiliary Battery - Designed to run as a backup to the starting battery and provide power to some essential equipment like engine start/stop and other systems that require power while the engine is off to put less strain on the main battery and alternator.

Bandwidth - A measurement indicating the maximum capacity of a wired or wireless communications link to transmit data over a network connection in a given amount of time.

Behavioral Coding - A term used in Martha Wells' Murderbot Diaries; essential, code for behaviors.

Branch Instructions - Use programming elements like if-statements, for-loops, and return-statements; used to interrupt the program execution and switch to a different part of the code.

Branch Predictors - Track the status of previous branches to learn whether or not an upcoming branch is likely to be taken or not.

Buffer - A region of memory used to store data temporarily while it is being moved from one place to another.

Cathodes vs Anodes - Cathodes are the positive electrode while the anode is the negative electrode; electrons flow from the anode to the cathode and this creates the flow of electric charge in a battery or electrochemical cell.

Catastrophic Failure - Complete, sudden and unexpected breakdown in a machine, indicating improper maintenance.

Central Processing Unit (CPU) - Primary component of a computer that acts as its "control center"; complex set of circuitry that runs the machine's operating systems and apps; the brains of the computer. * Components: Instruction Set Architecture (ISA), Control Unit (CU), Datapath, Instruction Cycle, Registers, Combinational Logic, the Arithmetic Logic Unit (ALU), etc...

Clock - Determines how many instructions a CPU can process per second; increasing its frequency through overclocking will make instructions run faster, but will increase power consumption and heat output.

Combustion Chambers - An enclosed space in which combustion takes place, such as an engine; jet engines also have combustion chambers.

Condition Codes - Extra bits kept by a processor that summarize the results of an operation and that affect the execution of later instructions.

Control Bus - Manages the communication between the computer's CPU and its other components.

Control Unit (CU) - Manages the execution of instructions and coordinates data flow within the CPU and between other computer components.

Cybermetal - Element native to Cybertron and Cybertron alone.

Datapath - The path where data flows as it is processed; receives input, processes it, and sends it out to the right place when done processing; datapaths are told how to operate by the CU; depending on instructions, a datapath can route signals to different components, turn on and off different parts of itself, and monitor the state of the CPU.

Diagnostic and Data Repair Sequence - Term used in Martha Wells' Murderbot Diaries; exactly what it sounds like.

Diode - A semiconductor device with two terminals (a cathode and an anode), typically allowing the flow of current in one direction only.

Discrete Circuit vs Integrated Circuit- Single device with a single function (ex: Transistor, diode) vs Devices with multiple functional elements on one chip (ex: Memories, microprocessor IC and Logic IC).

Drivers - A set of files that help software (digital components, such as Microsoft Office) interface/work with hardware (physical components, such as a keyboard); allows an operating system and a device to communicate.

Electromagnetic (EM) Field - A combination of invisible electric and magnetic fields of force; used in fandom by mechs to broadcast emotions to others.

Flags - A value that acts as a signal for a function or process. The value of the flag is used to determine the next step of a program; flags are often binary flags which contain a boolean value (true or false).

Full Authority Digital Engine Control (FADEC) - Consists of an electronic control unit (ECU) and related accessors that control aircraft engine performances.

Gestation Tank - Used in mech pregnancies, you can pry it from my cold, dead hands.

Heads Up Display (HUD) - A part of the user interface that visually conveys information to the player during gameplay.

Heat Spreader - Often used in computer processors to prevent them from overheating during operation; transfers energy as heat from a hotter source to a colder heat sink or heat exchanger.

HUB - A device that connects multiple computers and devices to a local area network (LAN).

Inductive Charging - How I imagine berths work; wireless power transfer (ex: Wireless charger or charging pad used for phones).

Instruction Cycle - Also known as fetch-decode-execute cycle; basic operation performed by a CPU to execute an instruction; consists of several steps, each of which performs a specific function in the execution of the instruction.

Instruction Set Architecture (ISA) - The figurative blueprint for how the CPU operates and how all the internal systems interact with each other (I think of it like a blueprint for the brain).

Irising - Term used in fanfiction (specifically the Crime in Crystals series) to describe the action of the of the spark chamber opening ("The Talk", chapter 6, my absolute favorite chapter out of the entire series). I just really liked how the word sounded in that context.

Life Codes - "For those of us who were forged, Primus, through Vector Sigma, generated a pulse wave. Each one a data-saturated life code faster than thought, brighter than light, racing across Cybertron, sowing sparks..." (~Tyrest/Solomus, Volume 5 of More Than Meets the Eye)

Memory Hierarchy - Represents the relationship between caches, RAM, and main storage; when a CPU receives a memory instruction for a piece of data that it doesn't yet have locally in its registers, it will go down the memory hierarchy until it finds it.

Levels: L1 cache (usually smallest and fastest), L2 cache, L3 cache, RAM, and then main storage (usually biggest and slowest); available space and latency (delay) increase from one level to the next

Depending on the multi-core (a core is usually synonymous with a CPU) system, each core will have its own private L1 cache, share an L2 with one other core, and share an L3 with more or more cores.

Motors* - Any power unit that generates motion; electric motors work by converting electrical energy into mechanical energy... when this happens within a magnetic field, a force is generated which causes shaft rotation.

Multitasking Operating System - Allows users to run multiple programs and tasks almost simultaneously without losing data; manage system resources (such as computer memory and input/output devices), allocate resources, enable multiple users, and eliminate long wait times for program execution.

Network - A set of computers sharing resources located on or provided by network nodes. Computers use common communication protocols over digital interconnections to communicate with each other.

Network Feed - The continuously updating stream of content that users encounter on networking platforms.

Neural Network - A type of machine learning process that uses interconnected nodes (like neurons) to teach computers to process data in a way similar to the human brain; a form of deep learning that can help computers learn from their mistakes and improve their time.

Nimbus - A luminous cloud or a halo surrounding a supernatural being or a saint; has been used in fanfiction synonymously or in junction with the corona of the spark.

Nodes - A connection point between devices that allows data to be sent and received between them.

Oil Sump/Oil Pan - Don't forget to change your mech's oil.

Out-Of-Order Execution - A paradigm used to minimize downtime while waiting for other instructions to finish; allows a CPU to choose the most timely instructions to execute out of an instruction queue.

Overload - Orgasm; an electrical overload occurs when too much electricity passes through a circuit, exceeding its capacity; an information overload is when a system receives more input than it can process, or a state of being overwhelmed by the amount of data presented for processing.

Pedes - Feet

Pipelining - A technique used in computer architecture that allows a processor to execute multiple instructions simultaneously, improving overall performance.

Processing Capacity - The ability and speed of a processor, and how many operations it can carry out in a given amount of time.

Program Counter - A special register in a computer processor that contains the memory address (location) of the next program instruction to be executed.

Programmable Nanobots/Nanites - Cybertronian microbots programmed to do work at the molecular level; used popularly for surface healing and pigment in mechs.

Protected Storage - Provides applications with an interface to store user data that must be kept secure or free from modification; a storage method; a function in mainframe hardware.

Protoform - Formed of an ultra-dense liquid metal and are extremely hard to damage; the most basic Cybertronian form of raw, free-flowing living metal; first stage of Cybertronian life cycle

To create a Cybertronian, you need the protoform, the life-giving spark, and alt-form information.

Register - A type of computer memory built directly into the processor or CPU that is used to store and manipulate data during the execution of instructions.

Ex: "When you run a .exe on Windows... the code for that program is moved into memory and the CPU is told what address the first instruction starts at. The CPU always maintains an internal register that holds the memory location of the next instruction to be executed [the Program Counter]"...

Resource Allocations - The process of identifying and assigning available resources to a task or project to support objectives.

Risk Assessment - Focus on identifying the threats facing your information systems, networks, and data and assessing the potential consequences should these adverse events occur.

Routine - A component of a software application that performs a specific task (ex: Saving a file).

Servomechanism - A powered mechanism producing motion or force at a higher level of energy than the input level (ex: In the brakes and steering of large motor vehicles) especially where feedback is employed to make the control automatic.

Servos - Hands

Shellcode - A small piece of executable code used as a payload, built to exploit vulnerabilities in a system or carry out malicious commands. The name comes from the fact that the shellcode usually starts a command shell which allows the attacker to control the compromised machine.

Semiconductor - A material used in electrical circuits and components that partially conduct electricity.

Semiconductor materials include silicon, germanium, and selenium.

Struts - Bones; A rod or bar forming part of a framework and designed to resist compression.

System/System Unit (in computers) - A setup that consists of both hardware and software components organized to perform complex operations/The core of your computer where all the processing happens.

Task Specific Accelerator - Circuits designed to perform one small task as fast as possible (ex: Encription, media encoding & machine learning).

Teek - Used in Transformers fandom in conjunction with EM Fields; when a mech "teeks" another mech's field, they are feeling the emotions that mech is broadcasting.

Transistor - Enables a computer to follow instructions to calculate, compare and copy data.

Universal Serial Bus (USB) - A standard plug-and-play interface that allows computers and peripheral devices to connect with each other, transfer data, and share a power source; allows data exchange and delivery of power between many types of electronics; plug-and-play interface is also a type of sexual activity used in fandom.

Warren - Used to refer to a group of minibots with their own social hierarchy and culture (Seriously, read the Crime in Crystals series, it's better than canon).

#transformers#macaddam#world building#Terms and Definitions#Transformers Terms#Computer Terms#Please Add Your Own Terms and Definitions as you see fit

21 notes

·

View notes

Note

how can an IC fab stepper motor move only 10nm per ste

for reference, this question is talking about machines called steppers that are used in the production of integrated circuits (you know, computer chips)

integrated circuit fabrication is, without a doubt, the most complex and involved behaviour humans have ever exhibited, and we're not going to go into it today, it is way too much. it happens in fabrication facilities which are vast campuses of buildings on the order of dozens and dozens of city blocks. to even get in most of those buildings you even need to wear a special bunny suit. anyways, there is obviously a lot of complicated, expensive equipment involved, but the one that takes the cake is the stepper. it's where the magic happens.

when people talk about chip sizes and moore's law and all that, they're talking about the smallest features we can print onto a chip, usually the transistor gate length. this is on the order of tens of nanometers currently. in order to achieve that, we have to have some device capable of working accurately & precisely down to the tens of nanometers. this is the stepper. it aligns photomasks accurately to such a degree for exposure. that is "the magic" i mentioned

the good modern steppers used in the production of, e.g. the intel i7 CPU in your computer are made by one company. they run about $200mm USD. lol:

with the cowling off:

inside this thing, photomasks are physically aligned, and their alignment has to be accurate to within nanometers, like i said. the straightforward answer to this question, is that such alignment is done with linear motors. we just build them to an insane degree of precision, and then control and drive them with ultra-high-accuracy electronics. fundamentally speaking, just like with a normal induction motor, you can measure the electrical characteristics of the windings during operation and deduce details about your rotor (or in this case, where your actuator is in space). if you use ultra-high-precision electronics, you get accordingly precise details. (like, where on the X axis your actuator is sitting)

these sorts of extremely niche motors, of course, also need a whole daughter industry to design and manufacturer. the stepper vendor doesn't just do that in-house. i found one such company. these things, or, these other things would be examples

139 notes

·

View notes

Text

compact drawer mechanism

I've been tinkering with a compact drawer mechanism for a hidden bar setup inside my kitchen cabinet, but space is super limited — like, I'm working with just under 4 inches of clearance. I know linear actuators can be really versatile, but I’m not sure which compact models are reliable and quiet enough for a small home setup like this. Anyone had luck with something similar? I don’t need it to lift anything heavy linear actuator 12v https://progressiveautomations.com.au/collections/linear-actuators just smooth, discreet motion.

2 notes

·

View notes

Text

How to Choose the Right Keyboard: A Comprehensive Guide

Choosing the right keyboard is crucial for comfort, productivity, and even gaming performance. With countless options available, understanding your needs and preferences is key. Here's a guide to help you find the perfect keyboard for your setup.

1. Understand Your Purpose

The first step is to determine how you’ll use the keyboard. Are you a gamer, a professional typist, or a casual user? Gamers might prioritize features like low latency, customizable RGB lighting, and mechanical switches, while professionals and writers might value comfort, durability, and typing speed.

2. Choose Between Mechanical and Membrane Keyboards

Keyboards generally fall into two categories: mechanical and membrane.

Mechanical Keyboards: These are known for their tactile feedback, durability, and precise keystrokes. They come in various switch types, such as Cherry MX, Razer, or Logitech switches, each offering distinct actuation points and feel. Mechanical keyboards are ideal for gamers and typists who value accuracy and speed.

Membrane Keyboards: These are quieter, more affordable, and lightweight. They lack tactile feedback, but they work well for casual users and those on a budget.

3. Switch Types Matter

If you choose a mechanical keyboard, pay attention to the switch type.

Linear Switches (e.g., Cherry MX Red): Smooth and consistent, great for gaming.

Tactile Switches (e.g., Cherry MX Brown): Offer a bump for feedback, ideal for typing.

Clicky Switches (e.g., Cherry MX Blue): Provide tactile feedback with an audible click, preferred by enthusiasts and typists.

4. Ergonomics and Comfort

Ergonomics is critical, especially if you spend long hours typing. Look for keyboards with wrist rests, adjustable height, and ergonomic designs. Split keyboards or those with curved layouts can reduce strain on your wrists and fingers.

5. Keyboard Layout and Size

Keyboards come in different sizes, such as full-size, tenkeyless (TKL), and compact (60% or 75%).

Full-Size Keyboards: Include a numeric keypad and all standard keys.

Tenkeyless Keyboards: Omit the number pad for a smaller footprint.

Compact Keyboards: Save space but may sacrifice functionality. Choose based on desk space and personal preferences.

6. Connectivity Options

Decide between wired and wireless options.

Wired Keyboards: Offer a reliable connection and no need for charging.

Wireless Keyboards: Provide flexibility and a cleaner desk setup, though you’ll need to charge or replace batteries periodically.

7. Additional Features

Look for extra features like backlighting (RGB or monochrome), programmable keys, and media controls. Gamers may benefit from anti-ghosting and N-key rollover for precise input recognition.

8. Budget and Build Quality

Set a budget and consider build quality. Higher-end keyboards often use premium materials, like aluminum, for durability.

In conclusion, the best keyboard is the one that aligns with your needs, preferences, and budget. Whether you’re typing essays or conquering virtual worlds, investing in the right keyboard can significantly enhance your experience.

3 notes

·

View notes

Text

Monthly Roundup [Nov. 30th, 2023]

I liked his pitch-disorted, creepy laugh in the movie. I absolutely did!

Hey everyone, and welcome to the Reddit roundup for this month.

For all the new folks seeing one of our posts for the first time:

Hello, this is Teal from this project, dedicated to creating real-life robots of the animatronics of the Five Nights At Freddy’s franchise.

Here, we post our short little monthly update in regards to the progress of our robot(s). Enjoy!

-

ROBOT!

-

Nov. 11 – Lower leg 3D renders, for where the foot will be attached to the linear actuator.

Nov. 29 – Boss has unfortunately hit a major hurdle with the current foot iteration. This one will be hard to explain, but hopefully with some pictures you might see the issue yourself, and the description of said issue written here, will be present in there as well so you can follow along:

The problem lies in the matter that as the lower leg and the foot was about to be combined, the ankle and heel do not line up with each other. In the middle is the ankle, with the rear part connecting to the linear actuator for the lower leg.

Both of those pieces having been rotated towards the camera, they show the ankle "rolling" - aka tilting from side-to-side. The hollowed box of the heel, would not line up properly with the middle hollow U shape. Due to this, when the ankle piece from the other robot part is connected, will literally get stuck in a neutral position (base starting position of a movement), meaning the "rolling" motion cannot even be started at all, and the ankle does not properly work.

This issue is still getting addressed, so updates are coming as soon as a solution is found!

-

That’s all for this monthly roundup. If you like what you see in these posts, or what you see from us in general, tell your friends and donate Here if you'd like to! Every little penny helps the robot.

- Thank you so much, and we hope to see you all next month!

1 note

·

View note

Text

What are classifications of pressure transmitters?

Pressure transmitter is a pressure signal into a standardized output signal available instrumentation, and the output signal and the pressure variable has a given continuous function relationship (usually linear function). Because of its reliable operation, high accuracy level, stable performance, strong anti-interference ability and measuring signal transmission distance and other advantages, so it is widely used in industrial field four. Its standardized output signal is mainly (0 ~ 10) mA, (4 ~ 20) mA and (1 ~ 5) V DC signal, according to different types of pressure measurement, can be divided into positive (negative) pressure transmitter, differential pressure transmitter, absolute pressure transmitter.

Common Types of Pressure Transmitters

Pressure transmitter is able to convert the pressure variable into a standard output signal instrumentation, there is a certain function relationship between the pressure variable and the output signal. According to different working principles, pressure transmitters can be divided into the following types.

Piezoresistive Pressure Transmitter

(1)Piezoresistive Pressure Transmitter is the pressure to the front surface of the diaphragm, the diaphragm under pressure will appear a certain deformation, the back of the pressure-sensitive diaphragm is printed with a thick-film resistor, which in turn forms a Wheatstone bridge, in the piezoresistive effect, the bridge will produce the corresponding voltage signals, which are proportional to the excitation voltage.

(2) Piezoelectric pressure transmitter

Piezoelectric pressure transmitter is the use of positive piezoelectric effect developed, the positive piezoelectric effect is a certain amount of external force on the electrolyte so that it deforms, the electrolyte will be polarized inside the phenomenon, and in the two surfaces of the positive and negative charges will be generated, the external force ceases to act, the electrolyte is restored to the state of the electrolyte is not charged. The polarity of the charge changes with the direction of the force. When an electric field is applied in the direction of polarity of the electrolyte, the electrolyte will be deformed, and the deformation of the electrolyte will disappear after the withdrawal of the force, which is the inverse piezoelectric effect.

(3)Strain pressure transmitter

adopts special adhesive to bond the strain gauges together to produce mechanical strain, in the body of the force changes, the resistance of the strain gauges will be followed by a certain amount of deformation, which affects the magnitude of the resistance value, the voltage on the resistor changes. But this case the resistance value of the change is small, usually composed of strain bridge, in the instrumentation amplifier under the action of the larger, and finally transmitted to the processing line display or actuator.

(4) capacitive pressure transmitter

capacitive pressure transmitter electric and pneumatic two types, the former standardized input signal for the DC signal, the latter output signal for the gas pressure. The two types of pressure of the medium to be measured were input into the high and low pressure chamber, acting on both sides of the isolation diaphragm of the sensitive element. Measuring diaphragm and both sides of the electrodes on the insulating sheet to form a capacitor, in the two sides of the pressure size is different, the module will produce displacement, the two sides of the current size is different, in the oscillation and regulation of the role of the formation of the current, voltage or digital output signal.

Pressure transmitter is an important part of the automatic control system. It is mainly used for the measurement and control of pressure parameters in industrial processes. It is widely used in the fields of petroleum, chemical industry, electric power, etc. There are many types of pressure transmitters, and they are classified in different ways according to their working principles and uses. Pressure transmitters are mainly used for remote display and control of pressure. They often work in high temperature, low pressure, corrosion, vibration and other environments, and the probability of failure is relatively high. Therefore, it is very meaningful to study the influencing factors and common failures of pressure transmitters.

0 notes

Text

Hydraulic Cylinder Exporter

Understanding the Role of a Hydraulic Cylinder Exporter in the Global Industrial Supply Chain

In the realm of heavy machinery and industrial equipment, hydraulic systems play a crucial role in delivering the power needed for various mechanical tasks. At the heart of these systems lies the hydraulic cylinder — a robust component that converts fluid power into linear motion and force. As industrial demand grows across sectors like construction, agriculture, mining, and manufacturing, so does the need for reliable hydraulic cylinders. This global demand has given rise to a dynamic and competitive market of hydraulic cylinder exporters.

What Is a Hydraulic Cylinder?

Before diving into the role of exporters, it's important to understand what a hydraulic cylinder is. A hydraulic cylinder is a mechanical actuator used to provide unidirectional force through a unidirectional stroke. It consists of a cylindrical barrel, a piston, and a piston rod. Hydraulic fluid — typically oil — is pushed into the cylinder under pressure, which moves the piston and extends or retracts the rod.

Hydraulic cylinders are valued for their strength, precision, and ability to handle heavy loads. They are essential components in a wide range of machinery, including excavators, cranes, loaders, forklifts, and presses.

The Growing Global Demand

As global infrastructure projects expand and industries become increasingly mechanized, the demand for hydraulic cylinders has surged. Emerging markets are investing heavily in agriculture and construction, while developed countries continue to modernize manufacturing with automation and robotics — both of which rely on hydraulic technology.

The increased demand for these components has turned the spotlight on hydraulic cylinder exporters, who serve as the crucial link between manufacturers and global buyers. Whether it's standard off-the-shelf products or customized solutions tailored for specific machinery, exporters help bridge geographical and logistical gaps.

What Does a Hydraulic Cylinder Exporter Do?

A hydraulic cylinder exporter is responsible for supplying hydraulic cylinders to international markets. Their role is multifaceted, involving procurement, quality assurance, logistics, compliance, and customer support. Below are some key responsibilities:

1. Sourcing and Procurement

Exporters often work with multiple manufacturers to source hydraulic cylinders of various types — including single-acting, double-acting, telescopic, tie-rod, and welded cylinders. Their procurement decisions are influenced by quality standards, client specifications, pricing, and production capacity.

2. Customization and Engineering Support

Many international buyers require customized hydraulic cylinders tailored to specific applications. Exporters often provide technical assistance, either in-house or through their manufacturing partners, to design and supply cylinders that meet exact performance requirements.

3. Compliance and Standards

International trade of hydraulic components involves strict adherence to safety and performance standards. Exporters ensure that products comply with international regulations such as ISO, CE, and other regional certifications. They also handle export documentation, tariffs, and customs procedures.

4. Logistics and Distribution

Efficient logistics is crucial in the export business. Exporters coordinate the shipping, warehousing, and distribution of hydraulic cylinders across borders, ensuring timely delivery and minimal disruption to their clients’ operations.

5. After-Sales Support

Global clients often require ongoing support. Exporters provide warranty services, technical documentation, maintenance guidance, and spare parts to build long-term relationships and ensure customer satisfaction.

Challenges Faced by Exporters

Like any business involved in international trade, hydraulic cylinder exporters face several challenges:

Quality Assurance: Ensuring consistent quality from different manufacturers, especially when dealing with customized solutions.

Regulatory Hurdles: Navigating the complex and often changing import/export regulations across different countries.

Competition: Intense global competition, particularly from low-cost manufacturing hubs, can pressure pricing and margins.

Logistics Disruptions: Events like pandemics, geopolitical tensions, or supply chain breakdowns can delay shipments and increase costs.

Currency Fluctuations: Dealing with multiple currencies introduces financial risks that need to be carefully managed.

Key Markets for Hydraulic Cylinder Exporters

Hydraulic cylinder exporters serve a global market, but some regions have a higher concentration of demand:

North America: Driven by large-scale infrastructure projects and a mature manufacturing sector.

Europe: Known for its engineering excellence and stringent quality standards.

Asia-Pacific: Rapid industrialization in countries like India, China, and Southeast Asian nations is creating booming markets.

Africa and the Middle East: Increasing investment in agriculture, mining, and construction is generating growing demand.

Exporters often tailor their strategies depending on the target market, considering factors like technical requirements, language barriers, shipping infrastructure, and trade agreements.

The Role of Technology in Hydraulic Cylinder Exports

Digital transformation is reshaping the export landscape. Exporters are increasingly adopting technology to streamline operations and enhance customer experience. Some key trends include:

Online Catalogs and E-Commerce: Providing buyers with easy access to product specifications and online ordering.

Supply Chain Management Software: Enhancing visibility and efficiency in sourcing and logistics.

Data Analytics: Leveraging data to forecast demand, optimize pricing, and monitor quality control.

Virtual Collaboration Tools: Facilitating remote design consultations and support across time zones.

Sustainability and the Future of Exporting

As sustainability becomes a priority across industries, hydraulic cylinder exporters are being pushed to consider the environmental impact of their operations. This includes sourcing from eco-conscious manufacturers, reducing packaging waste, and optimizing shipping routes to minimize carbon emissions.

Furthermore, the shift toward electric and hybrid machinery may influence future demand for different types of hydraulic systems, requiring exporters to adapt their product offerings and expertise.

Conclusion

Hydraulic cylinder exporters play a vital role in keeping global industries moving. By connecting manufacturers with international buyers, ensuring quality and compliance, and managing complex logistics, they form the backbone of the hydraulic component supply chain. As technology advances and global markets evolve, these exporters will need to remain agile, innovative, and customer-focused to meet the growing and changing demands of industrial automation and infrastructure development.

Whether serving a small agricultural equipment supplier or a multinational construction giant, the work of a hydraulic cylinder exporter is essential, impactful, and poised for growth in the years to come.URL: For more information, visit Suvera Fluid Power: Hydraulic Cylinder Exporter

0 notes

Text

What Does a Camshaft Do? The Heart of Your Engine's Performance Explained

https://autorepairlebanontn.com/?p=4006 What Does a Camshaft Do? The Heart of Your Engine's Performance Explained Ever wondered about that mysterious component under your car’s hood that helps create the powerful roar of your engine? The camshaft is one of the unsung heroes of your vehicle’s performance, quietly orchestrating the precise dance of valves that keeps your engine running smoothly. We’ll take you through everything you need to know about this crucial engine component. From how it controls the timing of valve openings to its direct impact on your vehicle’s power output and fuel efficiency, understanding your camshaft can help you make better maintenance decisions and even unlock hidden performance potential in your engine. Table of Contents Toggle What Is a Camshaft and Where Is It LocatedThe Basic Function of a Camshaft in an EngineHow Camshafts Control Valve TimingThe Relationship Between Camshafts and Engine PerformanceDifferent Types of CamshaftsOverhead Camshafts vs. Pushrod DesignsVariable Valve Timing CamshaftsCommon Camshaft Problems and SymptomsSigns of a Failing CamshaftMaintenance Tips for Prolonging Camshaft LifePerformance Upgrades and Aftermarket CamshaftsHow Camshaft Modifications Affect Engine PowerModificationsConfigurationsConclusionFrequently Asked QuestionsWhat is a camshaft and why is it important in a car engine?How does a camshaft affect engine performance?What are the different types of camshaft designs?What are common symptoms of a failing camshaft?How can I maintain my camshaft for longer life?Can I upgrade my camshaft for better performance?How does the camshaft work with the crankshaft?What’s the difference between OHC and DOHC engines? What Is a Camshaft and Where Is It Located A camshaft is a rotating cylindrical shaft with egg-shaped lobes (cams) that convert rotational motion into linear motion to operate the engine’s valves. These precision-engineered shafts feature carefully designed lobes that push against valve lifters or rockers as the shaft rotates. The camshaft’s lobe profile determines critical valve timing parameters including when valves open, how long they stay open, and how far they open. Most modern passenger vehicles use overhead camshaft designs where the camshaft is positioned above the cylinder head, directly actuating the valves. This configuration, known as OHC (Overhead Camshaft), offers improved efficiency and performance over older pushrod designs. Performance engines often employ DOHC (Dual Overhead Camshaft) systems with separate camshafts for intake and exhaust valves, allowing for optimized valve timing on both sides. In older or some current truck engines, the camshaft sits within the engine block. These pushrod engines use long metal rods to transfer the camshaft’s motion up to the valves. While this design creates more moving parts, it allows for a more compact engine height and sometimes simpler maintenance. The camshaft connects to the crankshaft through timing chains, belts, or gears and rotates at precisely half the speed of the crankshaft in four-stroke engines. This synchronized relationship ensures valves open and close at the exact right moment during each piston’s cycle, maintaining the proper sequence of intake, compression, power, and exhaust strokes. The Basic Function of a Camshaft in an Engine A camshaft serves as a critical component in internal combustion engines, converting rotational motion into reciprocating motion through its distinctive lobed design. This shaft features a row of pointed cams or lobes that push against valves as it rotates, creating the mechanical action necessary for engine operation. During rotation, these lobes open and close the engine’s intake and exhaust valves, allowing air-fuel mixture to enter combustion chambers and exhaust gases to exit. How Camshafts Control Valve Timing Camshafts control valve timing through their precisely engineered lobe profiles and synchronization with the crankshaft. The exact shape and positioning of each lobe on the camshaft dictates exactly when valves open and close during the engine cycle. Connected to the crankshaft via a timing belt or chain, the camshaft typically rotates at half the crankshaft’s speed, maintaining perfect coordination between valve operations and piston movement. This synchronized relationship ensures that air and fuel enter cylinders and exhaust gases exit at optimal moments for combustion efficiency. The Relationship Between Camshafts and Engine Performance Camshaft design directly impacts horsepower, torque, and emissions in every internal combustion engine. The camshaft’s valve control and timing capabilities are fundamental to the four-stroke cycle—intake, compression, power, and exhaust—which determines an engine’s efficiency and performance characteristics. Engineers develop camshaft profiles to match exact performance goals, balancing factors like power delivery, fuel economy, and emissions compliance. Performance enthusiasts often upgrade camshafts to enhance engine output, though such modifications require careful consideration of related components including rocker arms, valvetrain parts, and fuel management systems to maintain reliability. Without proper camshaft function, an engine simply can’t deliver optimal performance regardless of other enhancements. Different Types of Camshafts Camshafts come in several distinct designs, each with unique characteristics that affect engine performance, efficiency, and maintenance requirements. Let’s explore the main types of camshafts used in modern and traditional internal combustion engines. Overhead Camshafts vs. Pushrod Designs Overhead camshaft (OHC) systems position the camshaft directly above the cylinders for more precise valve control. Single overhead cam (SOHC) designs use one camshaft to operate both intake and exhaust valves, while dual overhead cam (DOHC) configurations employ separate camshafts for intake and exhaust valves, allowing for more refined valve timing and potentially higher performance. These overhead designs create a more direct connection to the valves, reducing moving parts and potential points of failure. Pushrod designs, in contrast, locate the camshaft within the engine block, operating valves through a system of lifters, pushrods, and rocker arms. This traditional configuration appears in many classic engines and some modern V8s, offering a compact engine height and simplified maintenance access. The additional components in the valve train can create more mechanical complexity, but many manufacturers have refined these systems to deliver reliable performance in exact applications. Variable Valve Timing Camshafts Variable valve timing (VVT) camshafts represent a important advancement in engine technology, dynamically adjusting valve operation based on engine conditions. These sophisticated systems use hydraulic or electronic actuators to modify the camshaft’s phase relative to the crankshaft, optimizing performance across different RPM ranges and load conditions. VVT technology allows engines to deliver better low-end torque while maintaining high-end power, improving fuel efficiency and reducing emissions. Advanced VVT systems can adjust not only valve timing but also lift and duration, creating an engine that effectively changes its personality based on driving conditions. These adaptable camshaft designs have become increasingly common in modern vehicles as manufacturers seek to balance performance demands with stringent emissions regulations. The ability to precisely control when and how valves open transforms what was once a fixed mechanical component into a ever-changing system that responds to real-time engine needs. Common Camshaft Problems and Symptoms Camshaft issues can significantly impact engine performance and longevity. Worn or damaged camshafts often lead to a cascade of engine problems that require prompt attention to prevent costly repairs. Signs of a Failing Camshaft Engine misfires frequently indicate camshaft problems, occurring when valves don’t open and close at the proper times. Poor engine performance, including reduced power, decreased fuel efficiency, and sluggish acceleration, points to potential camshaft failure. Unusual noises such as tapping, clattering, or grinding from the engine area typically suggest worn cam lobes, damaged lifters, or other camshaft-related components. Modern vehicles will activate the check engine light when the onboard computer detects issues with camshaft timing or performance. Hydraulic lifters or followers that ride on cam lobes can wear out, producing distinct tapping sounds that are especially noticeable when the engine is cold. Bent or damaged camshafts cause improper valve timing, resulting in misfires and potentially causing extensive engine damage if not addressed promptly. Maintenance Tips for Prolonging Camshaft Life Regular oil changes serve as the foundation of camshaft maintenance, ensuring proper lubrication of this critical component. High-quality oil matching manufacturer specifications provides optimal protection against wear on camshaft lobes and lifters. Avoiding extreme temperature conditions helps reduce thermal stress on the camshaft and related components. Monitoring engine performance allows for early detection of potential issues before they escalate into major problems. Following the manufacturer’s recommended maintenance schedule ensures all engine components, including the camshaft, receive appropriate inspection and service at optimal intervals. Addressing timing issues immediately prevents poor engine performance and increased emissions that result from improper camshaft-to-crankshaft synchronization. Listening for unusual engine sounds during startup can help identify potential camshaft problems in their early stages, saving important repair costs. Performance Upgrades and Aftermarket Camshafts Aftermarket camshafts represent one of the most effective ways to enhance engine performance through precise valve timing modifications. These specialized components can dramatically transform how an engine breathes and performs across different RPM ranges. How Camshaft Modifications Affect Engine Power Camshaft modifications directly influence an engine’s power output by altering three critical aspects: valve lift, duration, and timing. Performance camshafts typically feature more aggressive lobe profiles that keep valves open longer and lift them higher, allowing more air-fuel mixture into the combustion chambers. These design changes can significantly increase horsepower, particularly at higher RPMs where racing and performance applications benefit most. Many aftermarket camshafts optimize valve overlap—the period when both intake and exhaust valves are simultaneously open—creating a scavenging effect that improves cylinder filling efficiency. The exact lobe design determines where in the RPM range the engine will develop peak power, with some configurations favoring low-end torque while others maximize top-end horsepower. Performance enthusiasts must carefully select camshaft specifications that match their driving goals, as modifications that increase high-RPM power often sacrifice low-speed drivability and fuel economy. Modifications Aftermarket camshafts come with various modifications designed to enhance exact performance characteristics. Lobe design alterations change the shape and size of the camshaft’s lobes, affecting valve timing patterns to achieve particular power delivery goals. Engineers adjust the lift and duration parameters to control how far valves open and how long they remain open during each cycle. High-performance applications often use increased lift to maximize airflow into the combustion chamber, while extended duration keeps valves open longer to support higher RPM operation. Modern dual overhead cam (DOHC) configurations allow for more precise valve control compared to single cam designs, enabling complex camshaft profiles that optimize both intake and exhaust flow independently. These modifications must be carefully balanced to maintain proper engine operation, as excessive valve overlap can reduce vacuum and affect idle quality. Performance camshafts frequently incorporate advanced materials and manufacturing techniques to withstand the increased stress from higher valve spring pressures and engine speeds. Configurations The physical arrangement of camshafts within an engine significantly impacts performance potential and upgrade options. DOHC engines use separate camshafts for intake and exhaust valves, offering greater flexibility for performance tuning compared to single overhead cam designs. This configuration allows performance camshafts to optimize valve timing events independently for each valve train, resulting in more precise control over the combustion process. Variable valve timing systems add another dimension to camshaft performance, with some aftermarket upgrades designed to work with or enhance these factory systems. Performance camshafts for DOHC applications often feature asymmetric lobe profiles that apply different timing strategies to intake and exhaust valves, maximizing both power and efficiency. Racing-oriented configurations may employ radical cam profiles with extremely high lift and duration values that wouldn’t be practical for street use due to rough idle qualities and poor low-speed response. When selecting aftermarket camshafts, compatibility with existing engine components like valve springs, lifters, and rockers must be carefully considered to ensure reliable operation. Conclusion The camshaft stands as the unsung hero of your engine’s performance maintaining the critical rhythm that keeps your car running smoothly. Understanding this vital component helps us make better maintenance decisions and recognize potential issues before they become expensive problems. Whether you’re seeking better fuel economy or maximum horsepower upgrading your camshaft can be a game-changer when done properly. Remember that regular maintenance including timely oil changes is essential for preserving your camshaft’s functionality. By listening to your engine and addressing unusual sounds or performance issues promptly you’ll extend not just your camshaft’s life but your entire engine’s longevity. Your camshaft may be hidden inside your engine but its impact on your driving experience is undeniable. Frequently Asked Questions What is a camshaft and why is it important in a car engine? A camshaft is a rotating cylindrical shaft with egg-shaped lobes that converts rotational motion into linear motion to operate the engine’s valves. It’s crucial because it controls the timing of valve openings, directly affecting power output and fuel efficiency. Without proper camshaft function, an engine cannot achieve optimal performance regardless of other enhancements. How does a camshaft affect engine performance? The camshaft directly impacts horsepower, torque, and emissions through precise valve timing. Its lobe shape and positioning determine when and how long valves stay open, affecting combustion efficiency. Engineers develop specific camshaft profiles to meet performance goals, balancing power delivery, fuel economy, and emissions compliance. What are the different types of camshaft designs? Modern vehicles commonly use Overhead Camshaft (OHC) and Dual Overhead Camshaft (DOHC) systems for improved efficiency and performance. Older vehicles may have pushrod designs with the camshaft located in the engine block. DOHC systems allow independent optimization of intake and exhaust valve timing, while variable valve timing systems enhance overall performance. What are common symptoms of a failing camshaft? Signs of camshaft problems include engine misfires, poor performance, unusual noises (particularly ticking or knocking sounds), and an illuminated check engine light. You might also notice reduced power, decreased fuel efficiency, or rough idling. Addressing these symptoms promptly can prevent more extensive and costly engine damage. How can I maintain my camshaft for longer life? Maintain your camshaft by changing oil regularly with the manufacturer-recommended type, avoiding extreme temperature operation, monitoring engine performance, and following the maintenance schedule. Check timing components periodically, listen for unusual sounds, and address any performance issues immediately. Proper maintenance prevents premature wear and expensive repairs. Can I upgrade my camshaft for better performance? Yes, aftermarket performance camshafts can enhance engine output through more aggressive lobe profiles that improve airflow and increase horsepower. However, choose specifications that match your driving goals, as modifications can impact low-speed drivability and fuel economy. Consider that installation may require additional component upgrades and professional installation for optimal results. How does the camshaft work with the crankshaft? The camshaft operates in synchronized timing with the crankshaft, typically rotating at half the crankshaft’s speed in four-stroke engines. This precise synchronization ensures valves open and close at the correct moments during the engine cycle. Timing belts, chains, or gears maintain this relationship, and proper timing is critical for engine operation. What’s the difference between OHC and DOHC engines? An Overhead Camshaft (OHC) engine has one camshaft controlling both intake and exhaust valves. A Dual Overhead Camshaft (DOHC) engine features separate camshafts for intake and exhaust valves, allowing for more precise valve control and typically better performance. DOHC designs generally permit higher RPM operation and improved breathing, resulting in increased power output. https://autorepairlebanontn.com/?p=4006 Absolute Auto Repair

0 notes

Text

How Transducers Power Modern Automation Systems?

In today’s fast-paced industrial landscape, automation systems are the backbone of efficiency, safety, and productivity. But what connects the physical world to digital control systems? Transducers - the often-unsung heroes of automation - play a vital role in this transformation.

Let’s explore how transducers power modern automation systems, what types are commonly used, and why they are so essential in today’s industries.

What Is a Transducer?

A transducer is a device that converts one form of energy into another. In automation, it usually refers to a sensor that converts a physical quantity (such as temperature, pressure, or displacement) into an electrical signal. This signal is then interpreted by a controller, display, or monitoring system to take action.

How Transducers Work in Automation Systems?

Automation systems rely on feedback loops to perform operations accurately. These loops consist of:

1. Input – A physical change (temperature, motion, pressure, etc.)

2. Transducer/Sensor – Detects the change and converts it to an electrical signal.

3. Controller – Processes the signal and decides on action.

4. Actuator – Takes physical action (e.g., turning on a fan, moving a valve).

5. Feedback – Monitors the outcome to maintain control.

Transducers are critical at the input stage, providing real-time data to control units and enabling automated responses.

Types of Transducers Used in Automation

1. Temperature Transducers

Example: Thermocouples, RTDs

Use: In HVAC, food processing, plastic molding, and chemical plants.

Function: Measure heat and help maintain temperature stability in processes.

2. Pressure Transducers

Example: Strain gauge-based sensors

Use: Oil & gas, hydraulic systems, marine equipment.

Function: Monitor and control fluid or air pressure in real-time.

3. Displacement/Position Transducers

Example: LVDTs (Linear Variable Differential Transformers)

Use: Robotics, CNC machines, packaging.

Function: Track motion or position of machine parts for precision control.

4. Force Transducers

Example: Load cells

Use: Weighing systems, industrial presses, material testing.

Function: Convert force or load into measurable signals.

5. Flow Transducers

Example: Turbine meters, magnetic flow meters

Use: Water treatment, chemical flow, oil pipelines.

Function: Measure flow rate of liquids or gases for volume control.

6. Light/Photoelectric Transducers

Example: Photodiodes, phototransistors

Use: Conveyor belt item detection, safety doors, counting systems.

Function: Convert light intensity into electrical signals.

Applications Across Industries

Transducers are used in virtually every industry:

1. Manufacturing

In smart factories, transducers track everything from spindle speed to ambient humidity, helping to maintain optimal production conditions.

2. Marine & Offshore