#Large diameter pipe

Explore tagged Tumblr posts

Text

Best Large Diameter Pipe Manufacturers in India

Nova Steel Corporation is a major Large Diameter Pipe Manufacturers in India. Large diameter pipes are essential for industries that require high-capacity fluid or gas transfer, such as water treatment, oil and gas extraction, and infrastructure construction. These pipes, which are often made of steel, concrete, or thermoplastics, are designed to transfer large volumes of liquids or gases across long distances, making them ideal for high-demand applications. We are also a renowned Pipes and Tubes Manufacturers in India.

India is a major hub for large diameter pipe production, with several producers offering a diversified range of options to fulfill a wide range of industrial needs. Large Diameter Pipe Suppliers in India are well-known for their innovative production techniques, adherence to international standards, and ability to produce high-quality goods that meet the specific demands of many sectors throughout the world.

#Large Diameter Pipe Manufacturers in India#Large Diameter Pipe#Large Diameter Pipe Suppliers in India#Pipes and Tubes Manufacturers in India

0 notes

Text

Discover a wide array of tubular offerings including IS 9292 pipes, Special ERW sections, pre-galvanised pipes, CR full hard pipes, CRCA pipes, CR soft pipes, IS 3183 pipes, API pipes, column pipes, and large diameter pipes. These robust solutions cater to diverse industrial requirements, ensuring reliability and performance. Experience the epitome of quality and versatility with our comprehensive tubular range, promising unparalleled excellence in every application.

#is 9292 pipes#Special ERW sections#pre galvanised pipes#cr full hard pipe#crca pipes#cr soft pipe#large diameter pipe#column pipe

0 notes

Text

Tube Trading is a trusted ERW pipe dealer in Gujarat, offering high-quality ERW pipes for a variety of industrial applications. As a leading ERW pipe distributor in Gujarat and a reliable ERW pipe supplier in Vadodara, we ensure timely delivery and exceptional service to meet the needs of our clients across diverse sectors. Our commitment to quality and customer satisfaction makes us a preferred partner for ERW pipe solutions in the region.

#ERW pipe dealer in Gujarat#ERW Pipe distributor in Gujarat#ERW Pipe supplier in Vadodara#India#Daman#Uttar Pradesh#Gujarat#Maharashtra#Madhyapradesh#Rajasthan#Steel company#Steel industries#Business#Civil Work#construction strucutre#industries#stainless steel#large diameter pipes

6 notes

·

View notes

Text

1 note

·

View note

Text

All About Large Diameter Steel Pipes

Large Diameter Steel Pipes are an essential component of civil engineering and construction projects. Large Diameter Steel Pipes offer superior strength and durability in comparison to other materials such as concrete or plastic, making them ideal for large-scale projects. But what exactly are Large Diameter Steel Pipes and why should you use them? Read on to learn more about this popular building material.

What Are Large Diameter Steel Pipes?

Large Diameter Steel Pipes are long-length pipes that are usually made from steel. They come in a variety of sizes and can be used for a variety of purposes, including water supply lines, gas pipelines, sewage systems, drainage systems, foundation supports, structural supports, roadways, bridges, and much more. Because they’re so strong and durable they’re often the preferred choice when constructing large-scale projects such as bridges or buildings.

How Are Large Diameter Steel Pipes Made?

LDSPs are created using a process called continuous welding. This process involves continuously welding together small pieces of steel until the desired length is achieved. The pipe is then cut to size before being tested for strength and quality control. Once it passes inspection the pipe is ready to be installed on site.

The Benefits of Using Large Diameter Steel Pipes

As previously mentioned LDSPs offer superior strength compared to other materials such as concrete or plastic pipes. This makes them perfect for large-scale projects where reliability is paramount. In addition to their strength they also have superior corrosion resistance which means that they will last longer than other materials in corrosive environments like coastal regions or near chemical plants. They’re also easier to install than some other materials because they require less equipment or tools due to their shape and size. Lastly, LDSPs are relatively inexpensive when compared with other materials making them an economical choice for many projects.

Conclusion:

Large diameter steel pipes provide civil engineers with a reliable building material that offers superior strength and corrosion resistance while remaining economical at the same time. Their ease of installation makes them perfect for all kinds of large-scale projects ranging from bridges to sewage systems and everything in between! If you need reliable building material that won't break the bank then look no further than large diameter steel pipes!

0 notes

Text

An Overview of Stainless Steel 304 Large Diameter Pipes

Stainless steel 304 large diameter pipes are an incredibly versatile and durable material that can be used in a variety of applications. From industrial settings to residential use, stainless steel pipes have come a long way since their introduction in the early 20th century. Let’s take a look at the properties of Stainless Steel 304 Large Diameter Pipes and why they are so popular today.

Durability and Strength

Stainless steel 304 large diameter pipes are made from one of the most durable metals on earth - stainless steel. This special grade of stainless steel is particularly resistant to corrosion, making it ideal for both indoor and outdoor use. It also has superior strength, allowing it to withstand higher temperatures and pressures than other materials without compromising its structural integrity.

Versatility

Due to its high strength-to-weight ratio, stainless steel 304 large diameter pipes can be bent or shaped into any form needed without sacrificing structural integrity. This makes them especially useful in situations where tight spaces or complex configurations are required. Furthermore, due to their resistance to corrosion, these pipes can also be used in more corrosive environments than other types of metal piping such as copper or aluminum.

Cost Effective Solution

In addition to being one of the most durable materials available for use in piping systems, stainless steel 304 large diameter pipes are also one of the most cost effective solutions for many industrial applications. They can be produced quickly with minimal waste, resulting in lower production costs than other types of metal piping. Furthermore, due to their superior strength, these pipes require less maintenance over their lifetime which further reduces operating costs associated with them over time.

Conclusion: As you can see, stainless steel 304 large diameter pipes have many unique properties that make them an ideal choice for many industrial applications. Their durability makes them suitable for both indoor and outdoor use while their versatility allows them to be bent or shaped into any form needed without compromising structural integrity or requiring additional support structures like other materials do. Furthermore, their cost effectiveness makes them a great choice for those looking for an affordable solution with maximum longevity and reliability over time. If you’re looking for a durable and cost effective material for your industrial piping project - look no further than stainless steel 304 large diameter pipes!

#Stainless Steel 304 Large Diameter Pipes#Large Diameter Steel Pipe#STAINLESS STEEL PIPE DIAMETERS#LARGE DIAMETER STEEL PIPE MANUFACTURERS

0 notes

Text

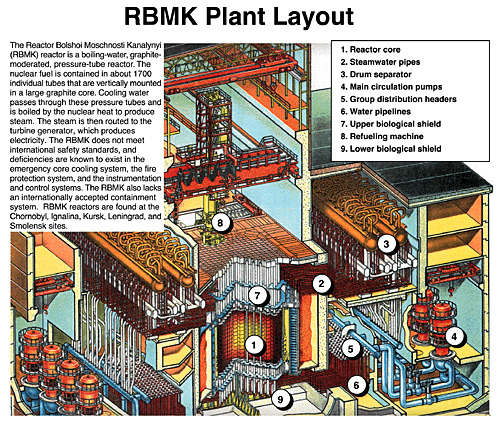

Principles of the RBMK Reactor

The RBMK-1000 Boiling Water Reactor is a Soviet-designed nuclear reactor capable of generating 1,000 megawatts of electricity. The core of the reactor is a short, wide cylinder. The active zone is contained inside a large metal drum, known as the core shroud. The reactor assembly is supported by a large metal disk known as the Lower Biological Shield. This sits on top of a larger metal cross labeled “Structure S”. On top of all this rests the 2,000 ton Upper Biological Shield of the reactor, known as "Structure E". The reactor sits in a large reinforced concrete shell which provides structural support and shields plant personnel from radiation.

The core region of the reactor is a large pile of graphite 14.52m × 9.7m. This pile is composed of graphite blocks 25cm by 25cm, with a height of between 20 and 60cm depending on its location in the reactor. Drilled through these blocks is a 11.4cm diameter hole, through which a zirconium alloy tube (known as a ‘technological channel’) is inserted. These contain either a fuel assembly, a control rod, or reactor monitoring equipment. These channels can be opened in situ or removed completely to replace any fuel or equipment inside them. Zirconium is used due to its high melting point and because it allows the neurons that produce the fission reaction in the core to pass through it far easier than other alloys such as stainless steel.

These metal technological channels have water pumped into them from the bottom by the Main Circulation Pumps. The entire reactor vessel is pressurized with a helium-nitrogen mixture, to prevent the oxidization of the graphite. Graphite is flammable in oxygen, but removed from it it can become quite an efficient thermodynamic conductor.

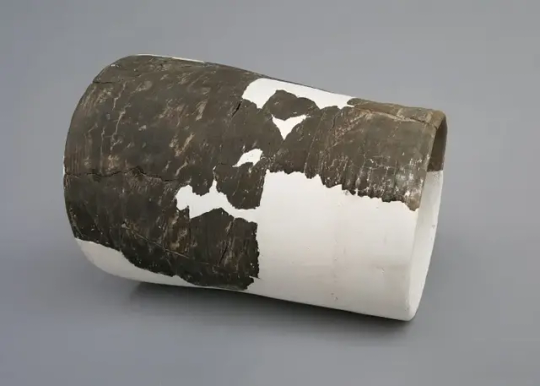

Below: A photo of RBMK technological channels at Chernobyl Unit 2. The length of these gives a good idea as to how massive the core of the RBMK is.

This picture is a screencap from this video.

The fuel of an RBMK is small uranium oxide pellets, stacked into small metal pipes and bundled together into fuel assemblies. Uranium oxide is a ceramic material composed of Uranium 235. This element, under special conditions, can create a nuclear chain reaction which generates heat. The RBMK has three primary components that help create these special conditions to create the controlled fission reactions in the core. These are graphite, water, and boron.

Graphite is used in the core of an RBMK as a moderator. Basically, it slows down the neutrons discarded by U-236 atoms (a U 235 atom which a neutron has collided with) when they split apart. When they are released they are travelling at a tremendous speed, and have very little chance of coming into contact with another atom of uranium. Slowing them down, however, creates a higher chance of the neutrons coming into contact with an atom of U-235, creating the unstable U-236 and then pulling itself apart, thereby creating more neutrons (as well as several other elements) and sustaining a nuclear chain reaction. This sustained reaction is what creates the heat in the core of a nuclear reactor. The more neutrons there are in the core, the more reactivity (and therefore heat) is created. It should be noted that graphite is combustible at high temperatures. The core contained 1,700 tons of graphite.

Water in the core of an RBMK serves as a coolant. Because the core of a nuclear reactor gets extremely hot, it becomes necessary to cool its components if you wish to avoid destructive melting within the core region. Water is the most common coolant in nuclear reactors, as it is cheap and abundant. The water is pumped in under high pressure at about 265 C by the Main Circulation Pumps from the bottom of the reactor up into the technological channels containing the fuel and other components of the reactor. After passing through the channels and heating up to about 284 C, the water is piped out of the top of the reactor. Some of the coolant water heats up so much that it forms into steam bubbles inside the reactor. When the water is pumped out of the core it is then sent into four steam separator drums, where the steam is separated from the water. The water is then pumped back into the reactor, while the steam is sent to the turbine generators of the plant to create electricity. After this, the steam is condensed back into water using cool water from the plant cooling pond and recirculated into the cooling system.

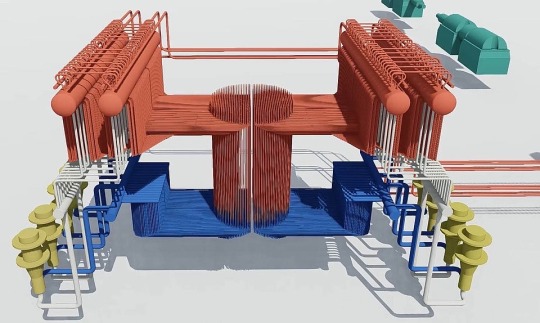

Below: A model showing the circulation system of an RBMK-1000 reactor. Coolant water is in blue and hot water/steam is in red. The yellow structures are the main cooling pumps, and the green structures are steam turbines. This model is spatially to scale, essentially what you would see if you removed every part of the reactor except for the coolant circuit.

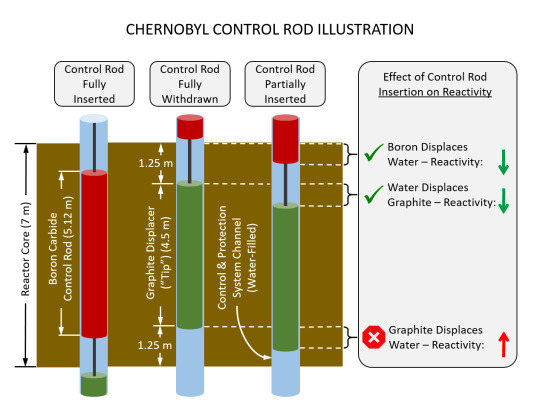

Some of the channels in the RBMK contain control rods (large boron carbide rods) that move up and down in the channel as necessary to keep the reactor within operational limits. Boron is a neutron sponge. It absorbs neutrons and can effectively eliminate a chain reaction. It functions as the brakes on a human made nuclear reaction, useful both in making sure a chain reaction does not become a runaway criticality and also in being the off switch on a nuclear reactor. The RBMK has 211 of these control rods, some of which are under operator control and some of which are under the control of a computer. A design quirk of the RBMK is that at the end of each standard control rod was a 14ft 9in graphite displacer. When a control rod was withdrawn out of the core it left behind a space that would be filled with water, a neutron absorber. Since more water in the core would kill reactivity, the designers of the reactor hung this displacer from the control rods to replace the space left by the control rod with something that would increase reactivity rather than kill it. This was a sound design choice, but it was a major factor in the events of the accident at Chernobyl.

Below: An illustration of the control rod displacers in an RBMK.

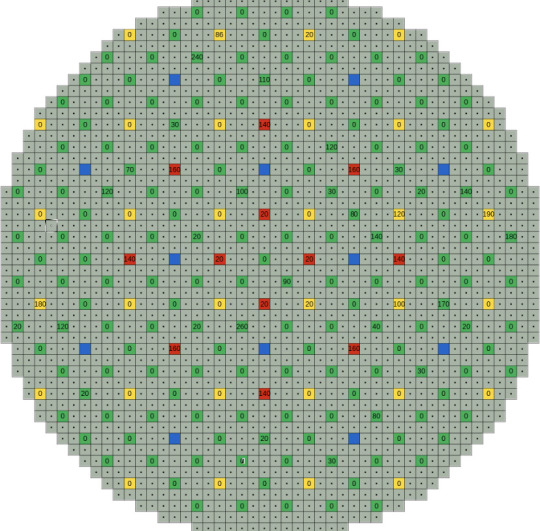

Below: A top down view of the channels of an RBMK. You can see the layout of the control rods (green), neutron detectors (blue), shortened control rods inserted from below the reactor (yellow), automatic control rods (red), and the fuel channels (grey). The number on the green, yellow, and red squares are the last recorded insertion depths of control rods in Chernobyl Unit 4 1m 30s before the explosion. Only one is fully inserted.

Below: A cutaway of the RBMK system layout.

Two additional factors also come into play regarding the water. Water is naturally a neutron absorber, albeit a far less effective one than boron. The more water in the core, the less neutrons are present and therefore the lower the reactivity. However, when transformed into steam, water loses nearly all of its neutron absorbing properties. The more steam in the core, the higher reactivity is. This is called a ‘positive void coefficient’, and it was a known quirk of the RBMK and indeed several other reactor designs. However, the RBMK had a much higher level of this effect in its core due to its design. This is important to the accident sequence.

It is also important to note that the RBMK is an enormous construction. It is temperamental, unstable unless operating at full power, and requires constant monitoring and guidance from its operators. It requires three operators just to run it normally, and it was notoriously difficult to operate. The core region is so large that the equipment used to monitor it could not accurately read a large portion of it, and hotspots of reactivity would often form resulting in alarming and unexplained jumps in power output and temperature. While in theory not a bad design, the RBMK was a deeply flawed machine.

An enormous thank you is owed to @nicotinebeige , who was extremely helpful in the creation of this post. If you like film photography, you should check out their blog!

This is a technical explanation of the RBMK design. For a history of the RBMK, check out this post. Apologies for any mistakes! I’m most definitely not an expert on nuclear physics, and if anything is unclear you should absolutely check out other sources for more info. As always, thank you for your interest!

#chernobyl#nuclear reactor#history#radiation#accidents and disasters#nuclear power#autism#nuclear#reactor#chnpp#rbmk#rbmk 1000

134 notes

·

View notes

Text

4,000-Year-Old Ceramic Drainage System Discovered in China

The people of Pingliangtai built and operated the system without any help from a central state government.

China’s Longshan period which lasted from about 2600 to 2000 BCE is best known for its sophisticated pottery shapes, but their sophisticated plumbing is getting some well-deserved attention. A team of archaeologists found the oldest known ceramic water pipes in China, demonstrating that locals were capable of major feats of engineering without a centralized state government. The findings are described in a study published August 14 in the journal Nature Water.

The newly unearthed network of ceramic water pipes and drainage ditches were found at the ancient walled city of Pingliangtai, located in what is now the Huaiyang District of Zhoukou City in central China. The town was home to roughly 500 people during neolithic times and had protective walls and a surrounding moat. It sits on the Upper Huai River Plain on the vast Huanghuaihai Plain, and the climate 4,000 years ago saw large seasonal climate shifts. Summer monsoons could dump a foot and a half of rain on the region every month.

With all this rain, it was critical for the region to manage floodwaters. The people of Pingliangtai appear to have built and operated a two-tier drainage system to help mitigate the rainy season’s excessive rainfall. Simple but coordinated lines of drainage ditches ran parallel to the rows of houses to divert water from the residential area to a series of ceramic water pipes that carried the water into the surrounding moat, and away from the village.

The team says that this network of pipes shows that the community cooperated with one another to build and maintain this drainage system.

“The discovery of this ceramic water pipe network is remarkable because the people of Pingliangtai were able to build and maintain this advanced water management system with stone age tools and without the organization of a central power structure,” study co-author and University College London archaeologist Yijie Zhuang said in a statement. “This system would have required a significant level of community-wide planning and coordination, and it was all done communally.”

The network is made of interconnecting individual segments which run along roads and walls that divert rainwater. According to the team, it shows an advanced level of central planning and is the oldest complete system discovered in China to date.

The team was also surprised by this find because the Pingliangtai settlement shows little evidence of a social hierarchy. The homes within it were uniformly small and there aren’t any signs of social stratification or significant inequality amongst the population. Digs at the town’s cemetery also didn’t reveal any evidence of a social hierarchy in burials the way excavations at other nearby towns have.

The level of complexity that these pipes demonstrate also undermines some earlier understanding of archaeological finds that believe only a centralized state power could organize and provide the resources for such a complex water management system. Other ancient societies that used advanced water systems tended to have a stronger, more centralized government, but Pingliangtai shows that that centralized power was possibly not always needed.

“Pingliangtai is an extraordinary site. The network of water pipes shows an advanced understanding of engineering and hydrology that was previously only thought possible in more hierarchical societies,” study co-author and Peking University archaeologist Hai Zhang said in a statement.

The ceramic water pipes also show an advanced level of technology for this period in time. Like with Longshan pottery, there was some variety of decoration and styles, but each pipe segment was about 7.8 and 11.8 inches in diameter and about 11.8 to 15.7 inches long. Multiple segments were slotted into one another to transport the water over long distances.

According to the study, the team can’t say specifically how the labor to build this infrastructure was organized and divided. A similar level of communal coordination would also have been necessary to build the earthen walls and moat that surround Pingliangtai.

By Laura Baisas.

#4000-Year-Old Ceramic Drainage System Discovered in China#ancient city of Pingliangtai#Zhoukou City#ancient artifacts#archeology#archeolgst#history#history news#ancient history#ancient culture#ancient civilizations#ancient china#chinese history

36 notes

·

View notes

Text

Top Large Diameter Pipe Manufacturers in India

Nova Steel Corporation is the largest Large Diameter Pipe Manufacturers in India.

Large diameter pipes are critical in businesses that demand high-capacity fluid or gas transportation, such as water treatment, oil and gas extraction, and infrastructure development. These pipes, which are often composed of steel, concrete, or thermoplastics, are intended to transport enormous amounts of liquids or gases across long distances, making them perfect for high-demand applications. We are also a leading Pipes and Tubes Manufacturers in India.

India is a key hub for large diameter pipe production, with various manufacturers providing a diverse range of alternatives to meet a variety of industrial requirements. Large Diameter Pipe Suppliers in India are known for their advanced manufacturing processes, adherence to international standards, and ability to create high-quality items that fit the unique needs of numerous industries throughout the world.

#Large Diameter Pipe Manufacturers in India#Large Diameter Pipe#Large Diameter Pipe Suppliers in India#Pipes and Tubes Manufacturers in India

0 notes

Text

"Unravelling the Diversity of Steel Pipes and Tubes: A Comprehensive Guide"

Steel pipes and tubes are indispensable components in various industries, serving as conduits for transporting fluids, gases, and solids. From construction to manufacturing, agriculture to infrastructure, the versatility of steel pipes and tubes makes them essential for countless applications. In this blog, we'll delve into the diverse world of steel pipes and tubes, exploring their different types, specifications, and uses.

IS 9292 Pipes and Tubes:

IS 9292 refers to Indian Standard specifications for steel pipes and tubes. These pipes and tubes adhere to stringent quality standards, ensuring durability, reliability, and performance. Whether it's IS 9292 pipes or tubes, they are commonly used in structural applications, fabrication, and general engineering purposes.

Special ERW Sections:

Special Electric Resistance Welded (ERW) sections are designed to meet specific requirements, offering versatility and customization options. These sections can be tailored to various shapes and sizes, making them ideal for architectural, automotive, and industrial applications.

Pre Galvanised Pipes:

Pre galvanized pipes are coated with a layer of zinc before being formed into pipes, providing corrosion resistance and extended longevity. These pipes are commonly used in outdoor structures, fencing, and agricultural equipment where exposure to harsh environments is prevalent.

CR Full Hard Pipe and CR Soft Pipe:

CR (Cold Rolled) full hard pipes and CR soft pipes differ in their level of hardness and ductility. Full hard pipes are rigid and suitable for applications requiring stiffness and strength, while soft pipes offer flexibility and ease of bending, making them ideal for intricate installations and plumbing systems.

IS 3183 Pipes and API Pipes:

IS 3183 pipes conform to Indian Standard specifications for line pipes used in the transportation of oil, gas, and water. API pipes, on the other hand, adhere to standards set by the American Petroleum Institute and are widely used in the oil and gas industry for drilling, production, and distribution purposes.

Column Pipes and Large Diameter Pipes:

Column pipes are designed to withstand vertical loads and are commonly used in borewell and pump installations. Large diameter pipes, on the other hand, are used in infrastructure projects, water supply systems, and industrial applications where high flow rates and structural integrity are paramount.

GI Pipes and Galvanised Pipes:

GI (Galvanized Iron) pipes are coated with a layer of zinc to protect against corrosion and rust. These pipes are commonly used in plumbing, water supply, and construction applications. Galvanized pipes offer enhanced durability and longevity, making them suitable for outdoor and corrosive environments.

GP Tubes, CDW Tubes, and DOM Tubes:

GP (Galvanized Pipes) tubes, CDW (Cold Drawn Welded) tubes, and DOM (Drawn Over Mandrel) tubes cater to different requirements in terms of surface finish, dimensional accuracy, and mechanical properties. While GP tubes are coated with zinc, CDW and DOM tubes offer superior precision and consistency in dimensions and tolerances.

Carbon Steel Tubes and Mild Steel Sections:

Carbon steel tubes and mild steel sections are widely used in structural applications, fabrication, and machinery manufacturing. These materials offer excellent weldability, machinability, and versatility, making them indispensable in various industries.

ERW Tubes, Rectangular Tubes, Round Tubes, and Square Tubes:

ERW tubes (Electric Resistance Welded), rectangular tubes, round tubes, and square tubes are available in a variety of sizes, shapes, and specifications to suit diverse applications. Whether it's structural framing, furniture manufacturing, or automotive components, these tubes offer unmatched versatility and performance.

MS Pipes and Mild Steel Tubes:

MS (Mild Steel) pipes and tubes are known for their affordability, ease of fabrication, and wide availability. These materials find applications in construction, agriculture, and general engineering where cost-effectiveness and reliability are paramount.

In conclusion, steel pipes and tubes form the backbone of modern infrastructure and industry, offering unmatched durability, versatility, and performance. Whether it's IS 9292 pipes, pre galvanized pipes, API pipes, or ERW tubes, the diversity of options available caters to a wide range of applications, making steel pipes and tubes indispensable in various sectors.

#api pipe#column pipe#large diameter pipe#gi pipe#galvanised pipe#gp tube#cdw tubes#dom tubes#carbon steel tubes#Mild steel section

0 notes

Link

Tube Trading Co. is the most prominent Stainless steel pipes supplier in vadodara gujarat. Tube Trading CO provides IBR approved pipes and we supplied across the India with a trustworthy level. IBR pipes which are supplied by us are supplied by us are the top quality of raw material. These products are presented in different shape as per the client requirement and sizes and they are applicable both for engineering and industrial purpose.

If you are looking for the most reputed as well as noteworthy Stainless steel pipes Dealer in vadodara gujarat, Tube Trading Co. is the best pick for you.

#Stainless steel pipes Dealer in vadodara gujarat#Stainless steel pipes supplier in vadodara gujarat#MSERW Pipe Supplier in Gujarat#MSERW Pipe Provider in Gujarat#Stainless steel pipes distributor in vadodara gujarat#MS steel#SS large diameter pipes

9 notes

·

View notes

Text

1 note

·

View note

Text

which lab tunnel ends connect?

here's the opening One shows El, in the HNL basement.

"this will lead you out beyond the lab fence to the woods," he says.

and here's the Mr. Clarke opening, where he finds the scrap of El's hospital gown.

thinking maybe Will crawled into this tunnel, the cops try to follow it to see where he'd have come out the other end, and run into the HNL perimeter fence. so the Mr. Clarke opening is very much Beyond The Lab Fence In The Woods.

pairing One's dialogue (if he's telling the truth) and that scrap of hospital gown, it seems very likely that the basement opening truly does connect to Mr. Clarke's, right?

so then what is this third tunnel opening that the lab's Head Of Security takes the cops to - claiming it to be where the Mr. Clarke tunnel leads?

Hopper knew the lab was lying because of the lack of rain in the surveillance footage of the HOS opening, which suggests the tape they showed him wasn't really from the night they said.

but are they also lying to him about this even being where the Mr. Clarke tunnel leads? ifthey just don't wanna let the cops into the HNL basement where that tunnel really leads, why fake the tape? what's there to cover up if this isn't even the same tunnel?

is this a wholly unrelated tunnel? could all three Y connect?

while we're here, why does the basement have that huge pipe at all? it's definitely a larger diameter than the outdoor ends, not that that proves anything, but why does it have to be so big? is it just like how in every movie the air ducts are large enough to crawl in for plot reasons?

#random observations#mine#lab stuff#also we're just assuming it's a straight level tunnel#what if little El crawls in there and then surprise!!! 90 degree ten foot drop in pitch black

19 notes

·

View notes

Text

Saguaro National Park

That's such a cute little dude you've got there Organ Pipe Cactus National Monument 🌵 21 cute little arms and all. Maybe one day, it will get close to our prize-winning Saguaro, the Granddaddy Saguaro!

This massive Saguaro holds the record as the most massive Saguaro in the park. While some may have been taller, this Saguaro had the most mass, estimated to weigh over 30,000 pounds. The trunk was nearly two and a half feet in diameter at chest height. It had a total of 45 arms, all raised high towards the sky. It also was believed to be nearly 300 years old! Unfortunately, this green giant fell victim to bacterial necrosis in 1992. While not quite as massive, many large giants like this can be found in and around the eastern district of the park. Generally, the western district has a higher density of Saguaros per acre, whereas the east side will have more enormous cacti with more arms on average.

What is the largest Saguaro you have encountered?

(JC; 📸, NPS)

#SaguaroSkirmish #OrganPipeNationalMonument #SaguaroNationalPark

35 notes

·

View notes

Text

BIOMECH TOWER:

Now that I can add bent pipe, I can't stop. Spending a lot of time walking back and forth between the work bench and the model table, dry fitting and adjusting and finally adhering the shaped pipes to the model. One of the last things I will do before painting is to attach the gun subassembly to the cryopak cube; who knows what other accommodations will need to be made?

Another bit of work is adding details to the pipes to add visual interest and to hide joints. It's aggravating to make fittings for every pipe, but I can't stand a blunt pipe end simply hot-glued to any other component.

Went out today and got some 3/4" PVC pipe for other subassembly pipe work, also some 2" ABS that I will use to add large diameter pipes to the base.

I must remain patient, I do sloppy work otherwise. I'm getting a little burnt out, I think; the enormity of remaining work is bumming me out. Maybe I'm just tired, I don't know. Probably I should just watch movies or play games for a day or two, get my creative urge up again.

10 notes

·

View notes

Text

Discover the exceptional performance of copper nickel pipe fittings, high alloy pipe fittings, Hastalloy pipe fittings, and super duplex fittings in demanding industrial applications. This article highlights the importance of these specialized fittings, ideal for fertilizer service plants and large diameter, heavy-wall pipe fittings. Learn how these advanced materials ensure durability, reliability, and optimal performance for critical systems.

#copper nickel pipe fittings#high alloy pipe fittings#Hastalloy pipe fittings#heavy-wall pipe fittings#japan#fertilizer service plants#super duplex fittings

2 notes

·

View notes