#Juice Pet Bottles Manufacturer

Text

Trusted Juice Pet Bottles Manufacturer in Delhi, India

Are you looking for reliable Juice Pet Bottles Manufacturer in Delhi, India? You are at the right place, we are Teknobyte India is a trusted plastic pet bottles manufacturers in Delhi specializing in Juice Pet Bottles.

With their state-of-the-art facilities and expertise in the packaging industry, they deliver high-quality bottles that ensure the freshness and integrity of your juices.

Whether…

#Juice Pet Bottles#Juice Pet Bottles Manufacturer#Juice Pet Bottles Manufacturer in Delhi#Juice Pet Bottles Manufacturer in India#plastic bottles manufacturers in delhi#plastic pet bottles manufacturers in Delhi

0 notes

Photo

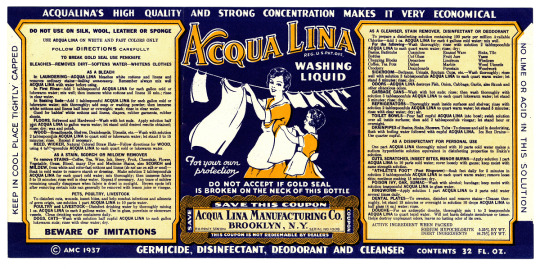

Product label for Acqua Lina Washing Liquid, 10/19/1937.

(It’s bleach.)

Series: Case Files for Registered Product Labels , 1874 - 1940

Record Group 241: Records of the Patent and Trademark Office, 1836 - 1978

Transcription:

[sample label]

[vertical text on sideS of label] KEEP IN COOL PLACE TIGHTLY CAPPED | NO LIME OR ACID IN THIS SOLUTION [/vertical text]

ACQUALINA'S HIGH QUALITY AND STRONG CONCENTRATION MAKES IT VERY ECONOMICAL

[capitalized] Do Not Use on Silk, Wook, Leather, or Sponge | Use Acqua Lina on White and Fast Colors Only | Follow DIRECTIONS Carefully | To Break Gold Seal Use Penknife | Bleaches -- Removes Dirt -- Softens Water -- Whitens Clothes | As a Bleach in LAUNDERING -- ACQUA LINA[ [/capitilzation] bleaches white cottons and linens and removes ordinary stains -- boiling unnecessary. Remember always mix well ACQUA LINA with water before using. In First Rinse -- Add 1 tablespoonful ACQUA LINA for each gallon cold or lukewarm water; mix well; then immerse white cottons and linens 15 min.; rinse in clear water. In Soaking Suds -- Add 1 tablespoonful ACQUA LINA for each gallon cold or lukewarm water; mix thoroughly; add soap or washing powder; then immerse white cottons and linens half hour or overnight; wash; rinse in clear water. Good for babies' white cotton and linens, diapers, rubber garments, rubber sheets. FLOORS, Softwood and Hardwood -- Wash with hot suds. Apply solution half pint ACQUA LINA to gallon warm water; let stand until desired results obtained; rinse; dry; wax and polish. WOOD -- Breadboards, Shelves, Drainboards, Utensils, etc. -- Wash with solution 2 tablespoonfuls ACQUA LINA to quart cold or lukewarm water; let stand 5 to 15 minutes; rinse. Repeat if necessary. REED, WICKER, Natural Colored Straw Hats -- Follow directions for WOOD, using 4 tablespoonfuls ACQUA LINA to each quart cold or lukewarm water. AS A STAIN, SCORCH OR MILDEW REMOVER To remove STAINS -- Coffee, Tea, Wine, Ink, Berry, Fruit, Chocolate, Flower, Vegetable, Grass, Blood, many Dye and Medicine Stains, also SCORCH and MILDEW, from white and color-fast cottons and linens (do not use on silk or wool) -- Soak in cold water to remove starch or dressing. Make solution 2 tablespoonfuls ACQUA LINA for each quart cold water; mix thoroughly; then immerse fabric 5 to 15 minutes; rinse well in clear water. Repeat if necessary. Any trace of mildew remaining usually disappears when fabric is dried in sunlight. Brown spots left after removing certain inks can generally be removed with lemon juice or vinegar. PETS, POULTRY, LIVESTOCK To disinfect cuts, wounds, insect bites, and help combat infections and ailments of germ origin, use solution 1 part ACQUA LINA to 10 parts water. POULTRY and LIVESTOCK -- Disinfect drinking water by thoroughly mixing 1 oz. ACQUA LINA to each 5 gallons water. Use in glass, porcelain or stoneware vessels. Clean drinking water containers daily. DOGS, CATS -- Wash with solution half cupful ACQUA LINA to each gallon lukewarm suds; rinse with clear water; dry. BEWARE OF IMITATIONS

ACQUA LINA REG. U.S. PAT. OFF. WASHING LIQUID [image of mother and daughter hanging up laundry] For your own protection DO NOT ACCEPT IF GOLD SEAL IS BROKEN ON THE NECK OF THIS BOTTLE

[coupon] SAVE THIS COUPON [vertical text: SAVE COUPON] ACQUA LINA MANUFACTURING CO. BROOKLYN, N.Y. SERIAL NO. 1008 THIS COUPON IS NOT REDEEMABLE BY DEALER

AS A CLEANSER, STAIN REMOVER, DISINFECTANT OR DEODORANT To prepare a disinfecting solution containing 100 parts per million Available Chlorine -- Add 1 oz. ACQUA LINA for each 4 gallons cold water; mix well. For the following -- Wash thoroughly; rinse with solution 2 tablespoonfuls ACQUA LINA to each quart warm water; rinse; dry;

Basins, Bathtubs Cuspidors Enamel Ware Sinks, Tile

Bottles Cut Glass Fruit Jars Vases

Chopping Blocks Decanters Linoleum Windows

Coffee, Tea Pots Dishes Marble Wood Utensils

Crockery Drainboards Porcelain Woodwork

SICKROOM -- Bedpans, Urinals, Sputum Cups, etc. -- Wash thoroughly; rinse well with solution 3 tablespoonfuls ACQUA LINA to each quart warm water; let stand 5 minutes; rinse; dry. ODORS - ACQUA LINA destroys Fish, Onion, Cabbage, Garlic, also Skunk and other obnoxious odors. GARBAGE CANS -- Wash with hot suds; then wash thoroughly with solution 3 tablespoonfuls ACQUA LINA to each quart lukewarm water; let stand 5 minutes; rinse; dry. REFRIGERATORS -- Thoroughly wash inside surfaces and shelves; rinse with solution 2 tablespoonfuls ACQUA LINA to quart warm water; let stand 5 minutes; rinse with clear water; dry; air. TOILET BOWLS -- Pour half cupful ACQUA LINA into bowl; swish solution over all inside surfaces; then add 2 tablespoonfuls vinegar; let stand hour or overnight. DRAINPIPES of Basins, Sinks, Showers, Tubs -- To cleanse and aid in deodorizing, flush with boiling water followed with cupful ACQUA LINA. Ice Box Drains -- Use quarter cupful. AS A DISINFECTANT FOR PERSONAL USE One part ACQUA LINA thoroughly mixed with 10 parts cold water makes a sodium hypochlorite solution equivalent in disinfection properties to Dakin's solution. CUTS, SCRATCHES, INSECT BITES, MINOR BURNS -- Apply solution 1 part ACQUA LINA to 10 parts cold water; cover loosely with gauze; keep moist with same strength solution. "ATHLETE'S FOOT" (Foot Ringworm) -- Soak feet daily for 5 minutes in solution 2 tablespoonfuls ACQUA LINA to each quart warm water; remove loose skin; continue soaking 15 minutes; dry. POISON IVY, OAK, SUMAC -- Wash with alcohol; bandage; keep moist with solution teaspoonful ACQUA LINA to glass water. RINGWORM--Apply solution 1 part ACQUA LINA to 5 parts cold water several times daily. DENTAL PLATES -- To sweeten, disinfect and remove stains -- Cleanse thoroughly, let stand 15 minutes or overnight in solution 10 drops ACQUA LINA to half glass (4 oz.) water; rinse. DOUCHE -- For an antiseptic douche, thoroughly mix 1 to 2 teaspoonfuls ACQUA LINA to quart tepid water. Will not harm delicate membrane or tissue. Helps destroy unpleasant odors, leaves no lasting odor of its own. ACTIVE INGREDIENT WHEN PACKED SODIUM HYPOCHLORITE 5.25% Y WT. | INERT INGREDIENTS 94.75% BY WT.

© AMC 1937 GERMICIDE, DISINFECTANT, DEODORANT AND CLEANSER CONTENTS 32 FL. OZ.

19 notes

·

View notes

Text

Manufacturer of Juice Pet Bottle Capping Machine

Shiv Shakti Machtech is a Manufacturer of Juice Pet Bottle Capping Machine in Ahmedabad.

Our Manufacturing Unit is in Ahmedabad, Gujarat, India.

PET bottle capping machine for juice is an automated system designed to securely seal plastic PET bottles with caps, ensuring the preservation of juice quality and extending shelf life.

This machine is essential for high-efficiency bottling lines in the beverage industry.

Automatic Operation streamlines the capping process, boosting throughput while reducing manual labor.

Adjustable speed lets you customize the capping rate, and high precision ensures consistent, tight seals to prevent leakage.

The user-friendly interface and integrated safety mechanisms make operation and maintenance easy and safe.

Working Process:

Bottle Loading: Bottles are automatically fed into the capping machine through a conveyor system.

Cap Placement: Caps are positioned over the bottles using a cap feeder or vibratory bowl system.

Capping Mechanism: The machine uses a capping head to apply and tighten the caps onto the bottles. You can achieve this using various methods, such as screw-on, snap-on, or pressure-sensitive sealing.

Inspection: Some machines incorporate sensors or cameras to check the integrity of the seal and ensure proper cap placement.

Discharge: The capping machine ejects sealed bottles onto a conveyor belt for further processing or packaging.

Application:

Juice Bottling

Beverage Industry

Food Processing

Shiv Shakti Machtech is a Manufacturer of Juice Pet Bottle Capping Machine in Ahmedabad, Gujarat, India Including Kathwada, Vadodara, Changodar, Gota, Naroda, Nikol, Mehsana, Palanpur, Deesa, Patan, Vapi, Surendranagar, Bhavnagar, Jamnagar, Junagadh, Rajkot, Amreli, Mahuva, Surat, Navsari, Valsad, Silvassa, Porbandar, Mumbai, Vasai, Andheri, Dadar, Maharashtra, Aurangabad, Kolhapur, Pune, Rajasthan, Jaipur,

Udaipur, Kota, Bharatpur, Ankleshwar, Bharuch, Ajmer, Delhi, Noida, Baddi, Solan, Himachal Pradesh, Una, Jammu Kashmir, Haryana, Hisar, Gurgaon, Gurugram, Madhya Pradesh, Indore, Bhopal, Ratlam, Jabalpur, Satna, New Delhi, Kolkata, West Bengal, Assam, Asansol, Siliguri, Durgapur, Bhubaneswar, Odisha, Brahmapur, Puri, Goa, Amaravati, Andhra Pradesh, Visakhapatna, Hyderabad, Guntur, Chittoor, Kurnool,

Vizianagaram, Srikakulam, Karimnagar, Ramagundam, Suryapet, Telangana, Medak, Bengaluru, Bangalore, Mangaluru, Hubballi, Vijayapura, Davanagere, Kalaburagi, Chitradurga, Ballari, Kolar, Chennai, Coimbatore, Madurai, Tiruchirapalli, Tiruppur, Salem, Erode, Tirunelveli, Tamil Nadu, Kerala, Kochi, Thiruvananthapuram,

Kozhikode, Thrissur, Kollam, Alappuzha, Kottayam, Kannur, Malappuram, Bharatpur, Jodhpur, Bikaner, Alwar, Bhilwara, Nagpur, Amravati, Solapur, Malegaon, Navi Mumbai, Thane, Wardha, Vasai-Virar, Gondia, Hinganghat, Barshi, Ulhasnagar, Nandurbar, Bhusawal, Pimpri-Chinchwad, Kalyan, Satara, Yamuna Nagar, Chhachhrauli.

For more information or to request a quote, please reach out to us.

View Product: Click Here

Read the full article

0 notes

Text

The resin code covers the six main plastics used in packaging:

#1 refers to PET;

#2 indicates high-density polyethylene (HDPE), the plastic used in milk and juice containers and T-shirt bags;

#3 is polyvinyl chloride (PVC), which in packaging gets deployed in juice bottles, blister packs for electronics, and some cling wraps;

#4 is low-density polyethylene, used for frozen-food bags, squeezable bottles, and sometimes cling films and the flexible lids of containers;

#5 is polypropylene, the plastic of yogurt containers, margarine tubs, bottle caps, and microwavable ware.

#6 refers to polystyrene, either in a foamed version that’s used in egg cartons and takeout containers or in a hard, clear incarnation, which is increasingly being used in clamshell containers for produce, consumer goods, and takeout foods.

The last category, #7, was intended as a catchall for any other plastic. In recent years, its association with bisphenol A-containing polycarbonate, found in those hard water bottles, has made consumers leery, tainting the designation for the makers of other plastics. No manufacturer wants a #7 on its product anymore.

0 notes

Text

How plastic containers and bottles have contributed to the convenience of modern living?

In today's fast-paced world, convenience is a paramount concern for both consumers and businesses. The advent of plastic containers and bottles has revolutionized the way we store, transport, and consume a wide range of products, making them indispensable in modern living. From food and beverages to personal care and industrial chemicals, plastic containers and bottles have found applications in nearly every aspect of daily life. This composition explores the various types of plastic containers and bottles, such as round bottles, square bottles, juice bottles, supplement and vitamin bottles, pet supplies bottles and jars, garden and hydroponics bottles, skincare bottles and jars, hotel amenity bottles, chemical industrial bottles, and BBQ & hot sauce bottles, and their contributions to the convenience of modern living.

The versatility of plastic containers and bottles

One of the most significant contributions of plastic containers and bottles to modern living is their versatility. Plastic, as a material, is incredibly flexible, allowing manufacturers to mold it into various shapes and sizes to suit different purposes. For example, round bottles are commonly used for liquids like beverages, oils, and cleaning products. Their shape makes them easy to hold and pour, contributing to user convenience. Square bottles, on the other hand, are favored for their efficient use of space during storage and transport, making them ideal for bulk products like laundry detergents or industrial chemicals.

Juice bottles are a prime example of how plastic containers have made everyday life more convenient. These juice bottles are designed to be lightweight, shatterproof, and resalable, ensuring that consumers can easily carry their favorite beverages on the go without worrying about spills or breakages. The durability of plastic also extends the shelf life of juices by providing an effective barrier against air and light, preserving the freshness and flavor of the contents.

Enhancing health and wellness

The health and wellness industry has greatly benefited from the use of plastic containers, particularly in the packaging of supplements and vitamins. Supplement and vitamin bottles are typically made from high-density polyethylene (HDPE) or polyethylene terephthalate (PET), both of which are known for their strength and resistance to moisture. These bottles are often designed with child-resistant caps and tamper-evident seals, ensuring that the contents remain secure and uncontaminated. The convenience of plastic bottles in this context cannot be overstated, as they provide consumers with a safe and practical way to store and transport their health supplements.

In the realm of personal care, skincare bottles and jars have become a staple. The beauty industry relies heavily on plastic packaging to deliver products that are both aesthetically pleasing and functional. Skincare bottles and jars are designed to protect sensitive formulations from environmental factors such as light, air, and moisture, all of which can degrade the effectiveness of the products. Additionally, the lightweight nature of plastic makes these containers ideal for travel, allowing consumers to maintain their skincare routines even when they are on the move.

Convenience in pet care and gardening

The use of plastic containers has also extended into the realm of pet care and gardening, offering convenience to pet owners and gardeners alike. Pet supply bottles and jars are used to store a variety of products, from shampoos and conditioners to supplements and treats. These containers are designed to be easy to open and close, ensuring that pet owners can quickly access what they need without any hassle. The durability and moisture resistance of plastic also ensure that pet supplies remain fresh and effective for longer periods.

In gardening and hydroponics, plastic bottles are used to store fertilizers, pesticides, and other essential liquids. The use of plastic in this context offers several advantages, including resistance to corrosion, ease of handling, and the ability to precisely dispense liquids. Gardeners and hydroponics enthusiasts appreciate the convenience of plastic bottles for their lightweight, portable, and reusable nature. Moreover, the transparency of many plastic bottles allows for easy monitoring of the contents, helping users keep track of their supplies.

Hospitality and industrial applications

The hospitality industry has also seen the benefits of plastic containers, particularly in the form of hotel amenity bottles. These small, single-use bottles are used to package toiletries such as shampoo, conditioner, body wash, and lotion for guests. Plastic amenity bottles are not only convenient for guests but also for hotel staff, as they are easy to stock, store, and dispose of. The use of plastic in this context ensures that hotels can offer a hygienic and cost-effective solution for providing personal care products to their guests.

In the industrial sector, chemical industrial bottles are widely used to store and transport a variety of chemicals, from cleaning agents to hazardous materials. The strength and chemical resistance of plastic makes it an ideal material for these applications, as it can safely contain substances that might otherwise react with or degrade other materials. The convenience of plastic chemical bottles lies in their lightweight nature, which reduces shipping costs, and their durability, which minimizes the risk of leaks or spills during transport.

Culinary convenience

The culinary world has also embraced the convenience of plastic containers, particularly in the form of BBQ and hot sauce bottles. These bottles are designed to be squeezable, allowing for easy and controlled dispensing of sauces, marinades, and dressings. The resalable nature of plastic bottles ensures that the contents remain fresh, while their durability makes them ideal for both indoor and outdoor use. Whether at a backyard barbecue or in a professional kitchen, plastic sauce bottles provide a practical and user-friendly solution for condiment storage and application.

The environmental perspective

While the convenience of plastic containers and bottles is undeniable, it is important to acknowledge the environmental concerns associated with their widespread use. Plastic waste has become a significant global issue, with millions of tons of plastic ending up in landfills and oceans each year. However, the plastics industry has been making strides toward more sustainable practices, including the development of biodegradable plastics and the promotion of recycling programs.

Recycling plays a crucial role in mitigating the environmental impact of plastic containers and bottles. Many of the plastic bottles mentioned earlier, such as those used for juices, supplements, and skincare products, are made from PET, a highly recyclable material. When properly recycled, PET bottles can be turned into new containers, clothing, carpeting, and even automotive parts. The increased emphasis on recycling and the development of eco-friendly plastics represent important steps toward balancing the convenience of plastic with the need for environmental stewardship.

Innovations and the future of plastic packaging

The future of plastic containers and bottles is likely to be shaped by ongoing innovations aimed at enhancing both convenience and sustainability. For example, manufacturers are increasingly exploring the use of recycled and plant-based plastics, which offer the same benefits as traditional plastics but with a reduced environmental footprint.

Smart packaging, in particular, represents an exciting frontier in the world of plastic containers. This technology integrates sensors and indicators into the packaging to monitor the condition of the contents, such as freshness or temperature. In the case of juice bottles or supplement bottles, smart packaging could provide real-time information to consumers about the quality of the product, further enhancing the convenience and safety of plastic containers.

Conclusion

In conclusion, plastic containers and bottles have made significant contributions to the convenience of modern living across various sectors. Whether in the form of round bottles for beverages, square bottles for industrial chemicals, or specialized containers for skincare, supplements, and pet supplies, plastic has become an integral part of our daily lives.

However, as we continue to rely on plastic for convenience, it is essential to address the environmental challenges it poses. Through innovations in recycling, the development of eco-friendly materials, and responsible consumer behavior, we can ensure that plastic containers and bottles continue to serve us well while minimizing their impact on the planet.

Some plastic bottles are gaining fame around the world day by day. Where to buy this bottle at the lowest price and highest quality is mentioned below:

Plastic bottles are increasingly becoming a popular choice worldwide due to their versatility, durability, and convenience. Whether it's for beverages, personal care products, or household items, the demand for high-quality plastic bottles continues to grow. However, finding a reliable source that offers these bottles at the lowest prices without compromising on quality can be a challenge.

For those seeking premium plastic bottles at competitive prices, Oh Yes Plastics stands out as a trusted supplier. They provide a wide range of plastic bottles, including specialized designs like the Cosmo Round and Boston Round bottles, tailored to meet various industry needs. Each bottle is crafted from high-grade materials to ensure durability and safety, making them a preferred choice for businesses looking to package their products effectively.

At Oh Yes Plastics, you can shop with confidence, knowing you're getting the best value for your money. Their commitment to quality, combined with affordable pricing, makes them the go-to destination for purchasing plastic bottles. Visit Oh Yes Plastics to explore their extensive selection and find the perfect bottle for your needs at the most competitive prices.

16 oz Mia Round Plastic Juice Bottles 38-DBJ | Oh Yes Plastics

Buy now:

Elevate your juice game with our high-quality 16 oz Miami Round Plastic Juice Bottles and cold press juice containers, available exclusively at Oh-Yes.org. Designed for small business owners, juice enthusiasts, and eco-conscious consumers, these premium wholesale plastic bottles meet all your packaging needs. Experience the convenience and quality that enhance your juice presentation while promoting sustainability. Shop now at Oh-Yes.org to elevate your juice experience!

With our 16 oz Miami Round Plastic Juice Bottles by Oh Yes Plastics, you gain more than just a container; you receive a versatile, reliable, and stylish packaging solution that complements your premium juices. Visit Oh-Yes.org and join the movement towards sustainable, high-quality juice packaging today!

Are you ready to make the switch?

Explore the unmatched benefits of our plastic bottles wholesale at Oh-Yes.org and place your order now. We are a leading plastic bottle manufacturer, offering wholesale options for businesses aiming to boost their brand with our eco-friendly packaging solutions.

Discover the 16 oz MIA Round Plastic Juice Bottles 38-DBJ, a perfect solution for all your juice storage needs at Oh Yes Plastics. Whether you're looking to store fresh-squeezed juice or planning to freeze orange juice for later use, these high-quality plastic bottles are designed to preserve the freshness and flavor of your beverages.

Wondering if you can freeze orange juice in a plastic bottle?

The answer is yes, these bottles are perfect for it! Shop now and enjoy the convenience and quality that our plastic juice bottles provide.

16 oz bullet Cosmo Round Clear 28-400 l Oh Yes Plastics

Buy now:

Our Cosmo Bullet Round Bottle, packaged conveniently and crafted from durable PET, ensures reliable storage for various liquids. The 28-400 neck finish provides compatibility with a range of closures, offering versatility in all bottle caps. Cosmo Bullet Round Bottles come in a large variety of colors and sizes. and are great for shampoos, lotions, personal care products, cleaning supplies, and many other applications.

These bottles offer practicality and functionality, whether for dispensing liquids or storing cleaning solutions. Their sleek, bullet-round design maximizes storage space while maintaining a compact footprint. Perfect for home, industrial, or commercial use, these bottles are essential for any packaging needs. Elevate your storage solutions with our 16 fl oz PET Cosmo Bullet Round Bottle 28-400, a must-have for every household or business.

Discover the versatility and elegance of the 16 oz Bullet Cosmo Round Clear 28-400 bottles at Oh Yes Plastics. Perfectly designed for a wide range of uses, these Cosmo bottles are ideal for packaging personal care products, cosmetics, and more. The sleek, clear design allows for easy product visibility, making them a popular choice for brands that value both functionality and style.

How are Cosmo round bottles used? These bottles are commonly used for lotions, shampoos, conditioners, and other liquid products. Their durable plastic construction ensures the contents are protected, while the 28-400 neck finish provides compatibility with a variety of closures, including pumps, sprays, and caps.

Elevate your packaging with Oh Yes Plastics' Cosmo round bottles, where quality meets design.

16 oz Bullet Cosmo Round Amber 28-400 l Oh Yes Plastics

Buy now:

Explore the superior functionality and stylish design of the 16 oz Bullet Cosmo Round Amber 28-400 bottle from Oh Yes Plastics. This elegant amber bottle is a perfect choice for packaging various products, from essential oils and serums to skincare and pharmaceutical items. Its amber color offers excellent protection against UV rays, preserving the integrity and efficacy of light-sensitive contents.

Cosmo round bottles are renowned for their sleek, modern appearance and practicality. The 28-400 neck finish ensures a secure fit with many closures, including pumps, sprayers, and caps, providing versatile packaging solutions for your needs.

How are Cosmo round bottles used? Ideal for both personal and professional use, these bottles are perfect for showcasing your products while offering durability and style. Enhance your brand's presentation with the 16 oz Bullet Cosmo Round Amber bottle—where aesthetics and functionality come together.

These bottles offer practicality and functionality, whether for dispensing liquids or storing cleaning solutions. Their sleek Bullet Round design maximizes storage space while maintaining a compact footprint. Perfect for home, industrial, or commercial use, these bottles are essential for any packaging needs. Elevate your storage solutions with our 16 fl oz PET Cosmo Bullet Round Bottle 28-400 a must-have for every household or business.

Specifications

Capacity: 16 fl oz

Neck Finish: 28-400

16 oz Bullet Cosmo Round Black 28-400 l Oh Yes Plastics

Buy now:

Unveil the bold sophistication of the 16 oz Bullet Cosmo Round Black 28-400 bottle, available at Oh Yes Plastics. Perfect for a range of products, from luxurious lotions to high-end hair care items, this sleek black bottle adds a touch of elegance to any brand. The striking black color not only enhances the product's visual appeal but also offers protection from harmful UV rays, ensuring the longevity and quality of your content. Cosmo round bottles are known for their ergonomic design and versatility. The 28-400 neck finish is compatible with various closures, including pumps, sprayers, and caps, making it an ideal choice for diverse packaging needs.

How are Cosmo round bottles used?

These bottles are widely used in the beauty, wellness, and personal care industries. Their modern design and durable construction make them a preferred choice for brands looking to make a statement with their packaging.

Elevate your product line with the 16 oz Bullet Cosmo Round Black bottle, where style meets functionality. These bottles offer practicality and functionality, whether for dispensing liquids or storing cleaning solutions. Their sleek Bullet Round design maximizes storage space while maintaining a compact footprint. Perfect for home, industrial, or commercial use, these bottles are essential for any packaging needs. Elevate your storage solutions with our 16 fl oz PET Cosmo Bullet Round Bottle 28-400 a must-have for every household or business.

Specifications

Capacity: 16 fl oz

Neck Finish: 28-400

16 oz PET Boston Round 28-400 | Oh Yes Plastics

Buy now:

Experience the classic design and reliability of the 16 oz PET Boston Round 28-400 bottle, available at Oh Yes Plastics. Crafted from high-quality PET plastic, this bottle is lightweight yet durable, making it an ideal choice for a wide range of products, including personal care items, beverages, and household solutions. The traditional Boston Round shape, with its rounded shoulders and base, adds a timeless aesthetic to your product line.

The 28-400 neck finish offers compatibility with various closure types, such as pumps, caps, and sprayers, providing flexibility in your packaging options. PET plastic is not only known for its strength but also for its recyclability, making these bottles an eco-friendly choice for brands committed to sustainability. Enhance your product's presentation and protection with the 16 oz PET Boston Round bottle from Oh Yes Plastics, where classic design meets modern functionality.

These bottles offer practicality and functionality, whether for dispensing liquids or storing cleaning solutions. Their sleek Bullet Round design maximizes storage space while maintaining a compact footprint. Perfect for home, industrial, or commercial use, these bottles are essential for any packaging needs. Elevate your storage solutions with our 16 fl oz Boston Round PET Plastic Bottles 28-400 a must-have for every household or business.

Specifications

Capacity: 16 fl oz

Neck Finish: 28-400

12 oz Black PET Boston Round 24-410 | Oh Yes Plastics

Buy now:

Discover the modern elegance of the 12 oz Black PET Boston Round 24-410 bottle, available at Oh Yes Plastics. This sleek black bottle is crafted from high-quality PET plastic, offering both durability and style. Perfect for a variety of applications, from personal care products to household solutions, the Boston Round shape provides a timeless look with its rounded shoulders and base, ensuring your product stands out on the shelf.

The 24-410 neck finish is designed to accommodate a range of closures, including pumps, sprayers, and caps, allowing for versatile packaging options. The black PET material not only adds a touch of sophistication but also protects the contents from light exposure, ensuring the quality and longevity of your product. Elevate your packaging with the 12 oz Black PET Boston Round bottle from Oh Yes Plastics, where aesthetics and functionality come together.

These bottles offer practicality and functionality, whether for dispensing liquids or storing cleaning solutions. Their sleek Round design maximizes storage space while maintaining a compact footprint. Perfect for home, industrial, or commercial use, these bottles are essential for any packaging needs. Elevate your storage solutions with our 8 fl oz Boston Round PET Plastic Bottles 24-410 a must-have for every household or business.

Specifications

Capacity: 8 fl oz

Neck Finish: 24-410

16 oz Square Plastic Juice Bottle | Oh Yes Plastics

Buy now:

Introducing the Oh Yes Plastics 16 oz Square Plastic Juice Bottle, the perfect solution for all your juice and beverage packaging needs. As a leading plastic bottle manufacturer, we offer a versatile container that combines functionality with an appealing design, making it an essential addition to your product lineup.

The Oh Yes Plastics 16 oz Square Plastic Juice Bottle is a reliable, versatile, and stylish packaging solution tailored for the beverage industry. As a dedicated plastic bottle manufacturer, we offer these containers for wholesale and bulk orders, making them perfect for businesses seeking high-quality, eco-friendly packaging options. Ready to enhance your beverage packaging? Visit Oh-Yes.org to order your Oh-Yes Plastics Square Plastic Juice Bottles today and experience the impact of quality packaging!

Benefits of the Unique Design:

The square shape of this container maximizes shelf space while enhancing portability, making it a favorite in the industry. The straight sides and wide-body panel provide ample space for label application, allowing you to create standout branding.

Specifications

Material: High-quality PET (Polyethylene Terephthalate)

Color Options: Clear, with custom colors available upon request

Capacity: 16 oz

Neck Finish: 38-400 tamper-evident

Shape: Sleek square design for modern appeal

8 oz Clear PET Juice Round Wide-Mouth Beverage 38-DBJ

Buy now:

Introducing our premium 12 oz Round PET Clear Juice Bottles, boxed for your convenience with 24 bottles per pack. Crafted for optimal functionality, these bottles are perfect for energy drinks, cold-pressed juices, or any refreshing beverage. Made from high-quality PET plastic, they offer both durability and clarity, ensuring your drinks look as good as they taste.

The round design facilitates easy handling and storage, while the secure cap guarantees leak-proof transportation. Whether you're a juice bar owner or a health-conscious consumer, these bottles are essential for keeping your beverages fresh and delicious. Elevate your drink experience with our 12 oz Round PET Clear Juice Bottles.

Specifications

Material: PET

Capacity: 12 oz

Packaging: Boxed

Ready to elevate your juice packaging? Click below to purchase your 12 oz Round Juice Bottles today! The 8 oz Clear PET Juice Round Wide-Mouth Beverage 38-DBJ bottle offers several unique design benefits that make it a standout choice for beverage packaging. Its clear PET construction ensures excellent product visibility, allowing consumers to see the contents clearly, which is essential for showcasing the freshness and quality of juices and other beverages. The wide-mouth design makes it easy to fill and pour, reducing spillage and making the bottle more user-friendly.

12 oz LA Round Plastic Juice Bottles 38-DBJ | Oh Yes Plastics

Buy now:

Boost your juice business with our premium 12 oz LA Round Plastic Juice Bottles, available exclusively at Oh-Yes.org. These bulk juice containers are ideal for small business owners, juice enthusiasts, and eco-conscious consumers. Crafted to enhance your juice presentation, our bottles not only offer convenience and quality but also promote sustainability. Plus, we provide custom label options and label services to make your brand shine!

With our 12 oz LA Round Plastic Juice Bottles, you don't just get a container; you gain a versatile, reliable, and stylish packaging solution that enhances your premium juices. Visit Oh-Yes.org today to discover the benefits of custom labeling and elevate your juice brand with our eco-friendly packaging solutions!

Ready to make the switch?

Explore our range of bottles at Oh-Yes.org and place your order now. Wholesale options are available for businesses looking to enhance their branding with our sustainable juice packaging!

The 12 oz LA Round Plastic Juice Bottles 38-DBJ feature a unique design that offers several benefits, making them ideal for beverage packaging. The round shape provides a comfortable grip, enhancing the user experience while also ensuring easy handling during filling, storage, and transport. The clear plastic construction allows consumers to see the contents clearly, which is crucial for highlighting the freshness and vibrant colors of juices. The wide-mouth 38-DBJ neck finish facilitates easy filling and pouring, reducing the risk of spills and making it more convenient for both manufacturers and end-users.

8 oz MIA Round Plastic Juice Bottles 38-DBJ | Oh Yes Plastics

Buy now:

Elevate your juice game with our premium 8 oz Miami Round Plastic Juice Bottles and cold press juice containers, available exclusively at Oh-Yes.org. Designed for small business owners, juice enthusiasts, and eco-conscious consumers, these high-quality wholesale plastic bottles meet all your juice packaging needs. Experience the convenience and quality that enhance your juice presentation while promoting sustainability. Shop now at Oh-Yes.org to elevate your juice experience!

Ready to make the switch?

Explore the unmatched benefits of our plastic bottles wholesale at Oh-Yes.org and place your order now. We are a leading plastic bottle manufacturer, offering wholesale options for businesses aiming to boost their brand with our eco-friendly packaging solutions. Discover how our sustainable juice bottles can transform your product offerings!

Order wholesale plastic bottles at Oh-Yes.org! As a top plastic bottle manufacturer, we provide 8 oz MIA Plastic Juice Bottles (38-DBJ) to fulfill all your packaging needs. Boost your business with our quality products!

The 8 oz MIA Round Plastic Juice Bottles 38-DBJ are designed to offer practical benefits that enhance the overall user experience. The round shape of the bottle provides a comfortable grip, making it easy to hold and pour, which is especially important for on-the-go consumption. The clear plastic material allows for excellent visibility of the contents, showcasing the product's freshness and appealing color, which can be a significant selling point. Additionally, the wide-mouth 38-DBJ neck design ensures easy filling, reducing spillage and making the bottling process more efficient. This thoughtful combination of functionality and visual appeal makes the bottle an ideal choice for both manufacturers and consumers looking for a reliable and attractive packaging solution.

Our Global Impact

The global packaging industry has both positive and negative impacts on the environment. While packaging is essential for protecting and preserving products, it also generates waste and contributes to environmental concerns. However, we can make a difference with intelligent design, data-driven research, and a collective responsibility to drive change.

Positive Aspects:

1. Product Protection: Packaging is crucial in protecting products from damage, spoilage, and contamination during transportation and storage. This helps reduce food waste and ensures the quality and safety of goods.

2. Convenience: Packaging provides convenience for consumers by allowing easy handling, storage, and transportation of products. It also facilitates portion control and extends the shelf life of various items.

3. Information and Marketing: Packaging serves as a means to convey important information about products, including ingredients, nutritional facts, and usage instructions. It also plays a significant role in marketing and branding.

Efforts are being made to address the negative impacts of packaging through sustainable practices and innovations. This includes developing eco-friendly packaging materials, recycling initiatives, and promoting circular economy principles. Many companies and industries are adopting more sustainable packaging practices to reduce their environmental footprint. Additionally, consumers increasingly seek products with minimal and eco-friendly packaging, driving positive changes in the industry.

Who We Are?

Oh Yes Plastics is a leading independently owned manufacturer specializing in high-quality plastic bottles, innovative custom bottle design molds, and creative bottle decoration. As a trusted packaging partner in the competitive packaging sector, we have years of experience as a prominent wholesale plastic bottle manufacturer. Our reputation is built on outstanding service and consistent quality in the blow molding field. We offer customized packaging solutions, including custom labels and comprehensive label services, catering to diverse needs with our versatile plastic bottles for juices and durable juice bottles. Discover the difference with Oh Yes Plastics, your go-to source for innovative, reliable packaging partners.

Contact US

Website: https://www.oh-yes.org/

Email:

Phone: +13055043425

Direction: https://maps.app.goo.gl/DwvvDQHCMQbZxGDU6

Address: 14931 NW 27th Ave Miami, FL 33054

Hours of Operation:

9 am - 5 pm (Monday - Thursday)

9 am - 3 pm (Friday)

1 note

·

View note

Text

Understanding Multilayer Pet Bottles Market: Regional Dynamics 2024

The Multilayer PET Bottles Market is becoming one of the crucial markets in the packaging industry, especially for food, beverage and pharmaceutical products that require high protection standards. These bottles designed with multiple layers, offer exceptional barrier properties, safeguarding contents from oxygen, moisture, and UV light while also being lightweight and durable. As consumer awareness around sustainability grows, the market for these bottles is expected to see a strong CAGR of 4.00% over the next few years. Recent innovations, such as the use of bio-based PET and advanced coatings, are pushing the boundaries of what these bottles can do making them more eco-friendly without compromising on performance. Asia-Pacific has emerged as a key player in this market being driven by the expanding food and beverage industry. Notably, major companies are now committing to using higher percentages of recycled PET (rPET) in their multilayer bottles aiming for 50-100% rPET content by 2030, in response to regulatory pressures and consumer demand for greener packaging solutions.

The Multilayer PET Bottles Market is an ever-growing industry with a valuation of over USD 6.2 Billion in 2023.

Multilayer PET Bottles Market - Key Segment by Type

The Multilayer PET Bottles Market is thriving, with different bottle sizes catering to a wide range of applications each designed to meet specific consumer and industry needs. Whether you're in the beverage industry, pharmaceuticals or household goods, choosing the right bottle size can significantly impact your product's success.

1. Up to 500 ml: Perfect for Portability and Convenience -

In the world of small-volume packaging, the up to 500 ml segment is a go-to choice for products like personal care items, single-serving beverages, and pharmaceuticals. These smaller bottles are all about convenience—easy to carry, perfect for on-the-go consumption and ideal for trial-sized products. They're popular in industries like cosmetics and health, where maintaining the freshness and quality of the product is crucial. This segment is where you’ll find significant demand for innovative packaging solutions that combine portability with advanced barrier protection to keep products at their best.

2. 500-1000 ml: The Sweet Spot for Versatility -

The 500-1000 ml bottle segment is the workhorse of the beverage packaging industry. It’s the perfect size for everything from juices and sodas to water and cooking oils. These bottles hit the sweet spot between single and multiple servings, making them a favourite among consumers. The versatility of this size means it's also used in household products like detergents. Manufacturers rely on the multilayer technology in these bottles to protect against contamination, spoilage, and flavour loss, ensuring their products stand out on the shelves. Keywords like "best beverage packaging solutions" and "versatile PET bottles" are crucial for businesses looking to capitalize on this popular segment.

3. More Than 1000 ml: Built for Bulk and Durability -

When it comes to bulk packaging, bottles with more than 1000 ml are where durability meets practicality. These larger bottles are essential for family-sized beverages, bulk cooking oils and large-volume household cleaners. Designed to hold heavier and larger quantities, these bottles must be strong enough to handle the pressure without compromising on protection. This is where the money-making keywords like "bulk packaging solutions" and "durable PET bottles" come into play as they highlight the key selling points that manufacturers and consumers alike are looking for.

Prominent Companies in the Multilayer PET Bottles Market This Year include :

Amcor

ALPLA

Plastipak

RPC Group

RETAL

Zhongfu Enterprise

Indorama Ventures

Taiwan Hon Chuan Enterprise

Resilux

Zijiang Enterprise

Manjushree

PDG Plastiques

Global Multilayer PET Bottles Market Key Segment by Application Into :

Sauces

Beer & Alcoholic Drink

Juice & Tea

Dairy Products

Edible Oils... etc

Important Market Regions Covered

North America

Europe

Asia Pacific

Latin America

the Middle East

Africa

Concluding the Multilayer PET Bottles Market [2024-2031]

Each size segment in the Multilayer PET Bottles Market offers unique benefits tailored to specific industries and consumer needs. Whether you're targeting the on-the-go market with smaller bottles, appealing to versatile use with mid-sized options or focusing on bulk sales with larger bottles, the right choice can drive your product's success. With growing demand for sustainable, durable and efficient packaging, businesses in this market can leverage these size segments to meet consumer expectations and maximize their reach.

Contact Us for more information on the Multilayer PET Bottles Market Research 2023-2030 Forecast :

Mail your queries to - [email protected]

Or Phone Call us :

USA - +1 507 500 7209 | India - +91 750 648 0373

Browse more reports in "Packaging Category" :

Lamination Adhesives For Flexible Packaging Market

Aseptic Packaging Market Forecast 2023-2030

Sterile Medical Packaging Market Regional Dynamics

Reusable Packaging Market Segmentation

Molded Fiber Pulp Packaging Market Trends

Stretch Film Packaging Market Size

Fruit Juice Packaging Market Overview

Glass Packaging Market Size

Market Research by Report Prime.

#MultilayerPetBottles #MultilayerPetBottlesMarket #MultilayerPetBottlesMarketSize #MultilayerPetBottlesMarketGrowth #MultilayerPetBottlesMarketTrends #MultilayerPetBottlesMarketOpportunities #MultilayerPetBottlesMarketResearch #MultilayerPetBottlesMarketReport #MultilayerPetBottlesMarketRegionalDynamics #MultilayerPetBottlesLandscape #MarketResearch #MarketReports #ReportPrime

0 notes

Text

The Complete Show Info for BrauBeviale Nuremberg 2024

BrauBeviale Nuremberg 2024 will be an ideal location for all professionals working in the field of beverages. The bottlers and producers of soft drinks, beer, mineral water, and juices, along with sparkling wine, wine and spirits, are expected to gather for a discussion about the future of the industry. Braubeviale Nuremberg 2024 dates have been set, and the prestigious event in the field of beverage will take place from November 26 to 28, 2024, at the Nuremberg Exhibition Centre.

Vendors display their products, solutions, and services at every step in the beverage manufacturing process, from raw materials to packaging, bottling, and point-of-sale marketing. This text will provide information about the show and will be read until the final.

BrauBeviale Nuremberg 2024: Detailed Show Info

In BrauBeviale 2024 Nurnberg, You will get to know colleagues and business partners with similar interests, as well as beer enthusiasts across Germany, Europe, and across the globe. The show will bring together a range of brewing-related interests. Hobbyists, craft brewers, historical family breweries, and international beer clubs will be represented in the exhibit. The brewing industry is a thriving community that is able to address the most pressing issues, including sustainability, climate change and energy issues, and regulations regarding packaging. Nearly all the participants in BrauBeviale 2024, which will be held in Nuremberg, will showcase products, solutions, services, or products for brewery owners. The event will function as a platform to share ideas and gain an idea.

The range of products includes the raw materials and brewhouse technologies to bottling facilities, and finally, sales, marketing as well as beverage logistics will all be showcased at this trade show. Also, you will be able to see the entire range of products and services that are available to the cellar industry during BrauBeviale 2024 Germany. Fermentation and maturation through to marketing and bottling are a few examples. Seventy percent of exhibitors offer solutions for wine and cellar trade along with distilleries. Professional tasters are also expected to show high-end spirits during the event.

BrauBeviale has offered for a long time an extensive selection of non-alcoholic beverages. About 60 percent of our exhibitors provide solutions for bottlers and manufacturers of non-alcoholic drinks and mineral water. In this collection, BrauBeviale Nuremberg 2024 will highlight the latest developments in beverage production, bottling facilities, packaging accessories marketing and distribution for soft drinks, fruit juices, and mineral water.

What Products You Will See at Exhibition Areas at BrauBeviale Nuremberg 2024?

BrauBeviale 2024 Nurnberg will showcase products and solutions for marketing. Here are the most important areas of the show:

Raw materials and refinement of the sensory

Systems and machines to produce beverages

Systems and equipment used for packaging and filling drinks

Packaging for products closure systems, labeling and other aids.

Automation and IT

Equipment for operating and laboratory use Operating and auxiliary equipment

Energy systems including compressed air/gases, workplace safety and environmental technology

Logistics and intralogistics

Catering and marketing facilities

Institutes, services education establishments, services and media

Exhibitors will showcase unique products that contain raw materials like malt and hops, as well as ingredients such as syrups, flavourings, syrups, sweeteners and so on. and also equipment to manufacture beverages and packaging. Glass bottles for packaging, PET bottle containers, composite packaging bags-in-box solutions, as well as bottles that are not returnable or non-returnable are popular. Closure systems, labels, and packaging tools complete the scope of this exhibition sector.

Automatization and IT technology will also be showcased, which can meet the increasing demands for efficiency. In addition, the latest insights into catering and marketing strategies and logistical issues are covered. BrauBeviale Nuremberg 2024 is an important gathering for experts in the beverage industry due to its networking opportunities as well as access to the latest developments and trends.

Get Your Exhibition Stand Booked With Stands Pro

BrauBeviale is an essential event to attend and a mood gauge for the beverage industry. It is the place where small-sized companies meet the most prominent players in the global market, conventional companies meet startups, and fresh talents meet experienced professionals to help develop the beverage industry with future-proof solutions.

Join BrauBeviale Nuremberg 2024 by booking your stand at the exhibition with Stands Pro. We are an established exhibition stand design business in Nuremberg that offers eye-catching exhibits and everything associated with exhibitions.

Connect us to discuss your needs for your exhibition stand should you plan to exhibit your products. We’re ready to help you any time, ensuring your exhibit is a smooth and unforgettable experience. We’re the ones who will take your Braubeviale Nuremberg 2024 tickets to the top of the list of priorities.

Exhibitor Profile: BrauBeviale attracts exhibitors from various sectors of the beverage industry, including:

Brewing Equipment Manufacturers: Leading manufacturers of brewing equipment, machinery, and systems for beer production, including brewhouses, fermenters, filtration systems, and packaging equipment.

Beverage Packaging Solutions: Suppliers of beverage packaging materials, containers, bottles, cans, labels, closures, and packaging machinery for breweries and beverage companies.

Ingredients and Raw Materials Suppliers: Providers of brewing ingredients such as malt, hops, yeast, and adjuncts, as well as suppliers of water treatment solutions, flavorings, and additives for beverage production.

Technology and Automation Providers: Companies offering technology solutions, automation systems, process control equipment, and software solutions for optimizing brewing and beverage production processes.

Beverage Industry Services: Providers of consulting services, laboratory analysis, quality control, logistics, and marketing services for breweries and beverage companies.

Why Attend the Show:

Product Showcase: Explore a comprehensive range of brewing equipment, beverage packaging solutions, ingredients, and technologies from leading industry suppliers, gaining insights into the latest innovations and trends in the beverage industry.

Networking Opportunities: Connect with brewers, beverage producers, suppliers, and industry professionals from around the world, fostering collaborations, partnerships, and business opportunities.

Educational Seminars and Workshops: Attend seminars, workshops, and panel discussions featuring industry experts and thought leaders discussing brewing techniques, beverage trends, market insights, and sustainability in the beverage industry.

Market Insights: Gain valuable market insights into consumer preferences, emerging beverage trends, regulatory developments, and sustainability initiatives shaping the future of the beverage industry.

International Platform: BrauBeviale provides an international platform for companies to showcase their products and innovations, attracting visitors and exhibitors from across the globe, and facilitating global business connections.

Organiser Website Link for More Info: For more information about BrauBeviale 2024, including registration details, exhibitor information, and the event program, please visit the official website: BrauBeviale

In summary, BrauBeviale 2024 is a premier event for professionals and businesses in the brewing and beverage industry, offering valuable networking opportunities, product showcases, educational resources, market insights, and international business connections.

#exhibition stand#exhibition stand design#exhibition stand builders#exhibition stand builders in germany#Best exhibition stand builders in germany#exhibition stand contractors#modular exhibition stands#custom exhibition stands#portable exhibition stands#double decker exhibition stand#stand construction companies in germany#exhibition booth contractor#exhibition stand manufacturers#exhibition stand design company#exhibition stand builders company#modular display stands#Custom stand design solutions#Custom exhibition stand design solutions in Germany#Messebau#Europaplein#Messe nuremberg#stand building company#exhibition construction companies#best exhibitions in europe 2024#exhibition stands uae#exhibition stand companies

0 notes

Text

"From Costs to Sustainability: Why PET is a Game-Changer for Packaging"

As global markets expand, the demand for efficient, cost-effective packaging solutions has skyrocketed. This raises a crucial question: how can industries meet these growing needs while ensuring product safety and sustainability? Enter PET (Polyethylene Terephthalate), a material that is rapidly replacing glass in packaging. Why is PET the ultimate choice for modern packaging, and what are its key benefits? Now let's explore PET's transformational potential and how it will influence packaging going forward.

The Rise of PET: A New Era in Packaging

In recent years, PET has emerged as a game-changer in the packaging industry. But what exactly makes PET stand out from traditional materials like glass? PET is extremely lightweight, durable, and indestructible in contrast to glass.It is a more affordable option for packing food and drinks because of these features.For example, PET’s high barrier properties ensure that products remain fresh longer, which is a significant advantage in the competitive market of packaged goods.

Strength and Durability: PET vs. Glass

When comparing PET to glass, strength and durability are where PET truly shines. Glass, while classic, is heavy and prone to breakage, which can lead to costly losses during transportation. PET, on the other hand, drastically reduces transportation costs due to its lightweight nature. The almost zero breakage rate of PET ensures that products arrive at their destination intact, making it a reliable choice for manufacturers and distributors alike.

Economy of Cost and Adaptability

PET's cost-effectiveness is one of its greatest benefits. PET is not only reasonably priced but also pliable in a broad range of forms and dimensions because of its durability and resilience to chemicals. The product's visual attractiveness is improved by adaptability, which fosters greater creativity in packaging design. PET is also reasonably priced for its production method, which makes it a cost-effective option for packaging requirements involving large volumes.

Environmental Advantages: PET's Recyclability

PET's recyclability is a big plus at a time when environmental sustainability is a major concern. In contrast to glass, which may be recycled but needs a lot of energy to do so, PET is easily recycled into new products. In addition to having zero environmental impact, this 100% recyclable product also satisfies consumer demand for environmentally responsible goods. PET's capacity to be made in a variety of colors and transparency makes it suitable for use in a variety of industries.

SEPPA SOLUTIONS: Leading the Charge in PET Packaging Solutions

For those seeking advanced PET packaging solutions, SEPPA stands at the forefront. SEPPA offers a comprehensive range of PET blowing machines, from semi-automatic to fully automatic models. Whether your needs are for low-speed or high-speed production lines, Seppa equipment caters to various industries, including water, sparkling water, CSD (carbonated soft drinks), juice, milk, beer, liquor, and wine. Seppa Solutions offers full line solutions for PET bottles and jars in addition to PET blowing equipment.

This includes rinser fillers, cappers, labelers, date and batch coders, shrink/carton packaging equipment, palletizers, and stretch wrappers. Selecting Seppa Solutions means investing in a strong and adaptable packaging solution that satisfies market demands.

Why PET is the Best Option for Contemporary Packaging

To summarize, PET is not only a fad but a revolution in the packaging sector. It is the best option for many different items because of its durability, affordability, adaptability, and environmental advantages. PET plays an increasingly important role in providing effective, sustainable packaging solutions as the world's markets continue to expand. A more efficient and environmentally responsible future is only a few steps away for companies that embrace PET and invest in cutting-edge solutions like those provided by Seppa Solutions.

#automatic pet bottle blowing machine#pet blowing machine#pet bottle blowing machine#bottle blowing machine#pet bottle making machine#pet making machine#pet bottle blow machine#pet blower machine#pet blowing machine manufacturer in india#automatic pet blowing machine#bottle blower machine#bottle blow machine#pet blowing machine manufacturer

0 notes

Text

Water Treatment Plants: Ensuring Clean Water for Every Industry

Introduction

Water treatment plants play a crucial role in ensuring that the water we consume and use in various industries is safe, clean, and fit for purpose. From drinking water to industrial processes, the quality of water directly impacts health, safety, and efficiency. This article explores the different types of water treatment plants and their specific roles in various industries.

Mineral Water Plant

Mineral Water Plant is designed to purify water and infuse it with essential minerals, making it safe and healthy for consumption. The process involves several stages, including filtration, reverse osmosis, UV treatment, and ozonation. These plants are essential in producing bottled water, which is widely consumed around the world. The purity of the water is maintained through rigorous quality checks, ensuring that the final product is free from contaminants.

Juice Production Plant

Juice production plants are specialized facilities where fruit juices are extracted, processed, and packaged for distribution. The process begins with the selection of fresh fruits, which are then washed, peeled, and juiced. The juice is pasteurized to kill any harmful bacteria, and additives like vitamins and minerals may be included to enhance its nutritional value. Finally, the juice is filled into bottles or cartons using advanced filling machines, ensuring that it remains fresh and flavorful.

Soft Drink Plant

Soft drink plants are complex facilities that produce carbonated beverages enjoyed by millions. The production process starts with water purification, followed by the mixing of various ingredients, including sweeteners, flavorings, and carbon dioxide. The mixture is then chilled, carbonated, and filled into bottles or cans. These plants are equipped with state-of-the-art machinery that ensures consistency, quality, and safety in every bottle.

PET Bottle Plant

PET bottles are ubiquitous in the beverage industry due to their durability, lightweight, and recyclability. PET bottle plant is where these bottles are manufactured. The process involves the use of preforms, which are heated and blown into the desired bottle shape using blow molding machines. These bottles are then used to package a wide range of beverages, from water to soft drinks, providing a convenient and safe packaging solution.

Commercial RO Plant

Commercial Reverse Osmosis (RO) plants are designed to purify water on a larger scale, suitable for commercial establishments such as hotels, restaurants, and offices. These plants use a multi-stage filtration process, including sediment filtration, activated carbon filtration, and reverse osmosis, to remove impurities and contaminants from water. The result is clean, safe water that meets the needs of businesses and their customers.

Industrial RO Plant

Industrial RO plants are similar to commercial RO plants but are designed to handle much larger volumes of water. These plants are used in industries such as pharmaceuticals, food and beverage, and chemical manufacturing, where water purity is critical. Industrial RO plants are highly efficient, capable of removing up to 99% of dissolved salts, bacteria, and other impurities, ensuring that the water used in industrial processes is of the highest quality.

Water Softener

Water softeners are essential in areas where water hardness is a problem. Hard water contains high levels of calcium and magnesium, which can cause scale buildup in pipes and reduce the efficiency of appliances. A water softener works by exchanging these minerals with sodium or potassium ions, effectively "softening" the water. This process extends the life of appliances, reduces energy costs, and improves the overall quality of the water.

Carbonated Soft Drink Filling Machine

The filling process for carbonated soft drinks is a delicate one, requiring precise control over pressure and temperature. Carbonated soft drink filling machines are designed to handle this process with efficiency and accuracy. These machines fill bottles or cans with the carbonated beverage, ensuring that the carbonation level is maintained and the drink remains fresh. Different types of filling machines are available, including volumetric and gravity filling machines, each suited to specific production needs.

Juice Bottle Filling Machine

Juice bottle filling machines are used to fill bottles with juice in a hygienic and efficient manner. These machines are designed to handle different types of juices, including those with pulp or other particulates. The filling process is carefully controlled to prevent spillage and contamination, ensuring that the juice retains its quality and freshness from the production line to the consumer.

Water Bottle Filling Machine

Water bottle filling machines are critical in the production of bottled water. These machines are designed to fill bottles with purified water quickly and accurately, minimizing waste and ensuring consistent quality. Modern water bottle filling machines are highly automated, reducing the need for manual labor and increasing production efficiency. These machines are also equipped with sensors and controls to monitor the filling process and detect any issues in real-time.

Automatic and Semi-Automatic Blow Moulding Machine

Blow molding is a process used to create hollow plastic containers, such as bottles. Automatic blow molding machinesand semi-automatic blow molding machines are used in this process to shape plastic preforms into bottles. Automatic machines offer higher efficiency and consistency, while semi-automatic machines provide more flexibility and control. Both types of machines are essential in the production of PET bottles, contributing to the packaging needs of the beverage industry.

BOPP Labeling Machine

BOPP (Biaxially Oriented Polypropylene) labels are widely used in the packaging industry due to their durability, clarity, and resistance to moisture. BOPP labeling machines apply these labels to bottles, cans, and other containers with precision and speed. These machines are designed to handle high-speed production lines, ensuring that labels are applied consistently and accurately, enhancing the appearance and shelf appeal of the products.

Sticker Labeling Machine

Sticker labeling machines are versatile machines used to apply stickers or labels to a wide range of products. These machines can handle different shapes and sizes of containers, making them ideal for various industries, including food and beverage, pharmaceuticals, and cosmetics. The technology behind sticker labeling machines ensures that labels are applied smoothly and securely, enhancing the overall presentation of the product.

Sleeve Applicator

A sleeve applicator is a machine used to apply shrink sleeves or labels to containers. These sleeves are then heat-shrunk to fit tightly around the container, providing a tamper-evident seal and a 360-degree label. Sleeve applicators are commonly used in the beverage industry, where they help enhance the visual appeal of products and provide additional space for branding and information.

Automatic and Semi-Automatic Shrink Wrapping Machine

Shrink wrapping is a packaging process where a plastic film is wrapped around a product and then heat-shrunk to create a tight seal. Automatic and semi-automatic shrink wrapping machines are used in this process to package products quickly and efficiently. Automatic machines are ideal for high-volume production lines, while semi-automatic machines offer more flexibility for smaller operations. Both types of machines are essential in protecting products during transportation and storage.

Jar Washing Machine

Jar washing machines are used to clean jars before they are filled with products such as jams, sauces, or beverages. These machines use a combination of water, detergent, and mechanical agitation to remove dirt, residues, and contaminants from the jars. The clean jars are then ready for filling, ensuring that the final product is safe and free from any contaminants.

Water Pouch Filling Machine

Water pouch filling machines are used to fill pouches with purified water, providing a convenient and cost-effective packaging solution. These machines are commonly used in areas where bottled water is not practical or affordable. The pouches are filled, sealed, and packaged in one continuous process, ensuring that the water remains clean and safe for consumption.

Auto Batch Coding Machine

Auto batch coding machines are used to print batch numbers, expiration dates, and other important information on products. These machines are essential in ensuring product traceability and compliance with regulatory requirements. The codes are printed clearly and accurately, providing vital information to consumers and enabling manufacturers to track products through the supply chain.

Water ATM

A Water ATM is a kiosk or vending machine that dispenses clean drinking water to the public. These machines are particularly useful in areas where access to clean water is limited. Users can purchase water at an affordable price, making it accessible to a wider population. Water ATMs are a significant innovation in providing safe drinking water to communities and reducing the reliance on bottled water.

Water Chiller

Water chillers are used to cool water for various industrial processes. These machines remove heat from water, lowering its temperature to the desired level. Water chillers are commonly used in industries such as food and beverage, pharmaceuticals, and manufacturing, where precise temperature control is essential. Different types of water chillers are available, including air-cooled and water-cooled models, each suited to specific applications.

Conclusion

Water treatment plants and related machinery play a vital role in ensuring that water used in various industries is clean, safe, and suitable for its intended purpose. From mineral water production to industrial processes, the quality of water directly impacts the success and efficiency of operations. As technology continues to evolve, we can expect further advancements in water treatment and packaging solutions, helping to meet the growing demands of consumers and industries alike.

youtube

0 notes

Text

Rotary Four Head Bottle Capping Machine

Rotary Four Head Bottle Capping Machine or Bottle Capper is state-of-art machine for screw capping glass, plastic, PET & HDPE bottles. It has an adjustable height system for convenience of use and is self-supported. Four capping heads perform capping operation simultaneously in order to do screw tightening operations.

Adinath is renowned bottle capping machine manufacturers in India with more than 16 models of bottle capping machines available. Our machine is uses in dry syrup, edible oils, shampoo, ready-to-drink juice, bleach powder, talcum powder, electrical components, glues, cosmetics, lip balm, hair strengtheners, hand sanitizers, lotions, hair wash, and stationery items. Our four-head bottle capping machine is widely uses across variety of industries for a plethora of applications. Our single head bottle capping machine can reach a maximum speed of 40 bottles per minute, while our six head and eight head machines can reach up to 120 and 180 bottles per minute, respectively. All our machine model made from high grade steel materials for long lasting sturdy operations. Machine design is simple to use that even semi skilled operator can operate the machine.

#Bottle Capper#bottle capping machine#four-head bottle capping machine#single head bottle capping machine

0 notes

Text

#teknobyte india#JuicePetBottles#JuicePetBottlesManufacturer#JuicePetBottlesManufacturerInDelhi#JuicePetBottlesManufacturerInIndia

1 note

·

View note

Text

Crafting Quality: Awanti Polymoulds’ Precision moulds for PET

Plastic bottles and containers serve a diverse range of purposes across industries such as beverages, food processing, pharmaceuticals, liquor, and home care products. They are utilized for packaging water, soda, juice, oil, jams, medicines, liquor, as well as personal and home care items, with sizes varying from small volumes to several litres.

At Awanti, we specialize in manufacturing blow moulds for PET bottles, employing advanced designing, high precision manufacturing and accelerated testing. Established in 1990, Awanti Polymoulds has been at the forefront of designing, manufacturing, and testing PET blow moulds to meet international standards. Precision and accuracy are paramount in our manufacturing process to ensure consistent, high-quality bottles that meet our customers’ expectations.

Our commitment to customer satisfaction extends both domestically and internationally, driving our continuous efforts to excel. Our moulds are engineered for durability, precision, and longevity. Properly matched with moulding machines, they have the capacity to endure for years and produce millions of bottles. We prioritize precision, customization, and attention to detail throughout the bottle designing, mould manufacturing, and testing phases.

With a longstanding presence in the beverage industry and tooling industry, Awanti Polymoulds has been a trusted supplier of blow moulds for brands like Coca-Cola, Unilever, Parle Agro, Bisleri, Pepsi, AJE and many more. Whether it’s fruit juices, carbonated beverages, natural mineral water, packaged drinking water, personal care products, or edible oils, Awanti has consistently delivered, always aiming for customer satisfaction.

0 notes

Text

Plastic jar manufacturer Malaysia

High-Quality Plastic Bottle Manufacturing in Malaysia: Westone.com.my Commitment to Excellence

In today's competitive market, the demand for high-quality plastic bottles is ever-increasing. Whether for beverages, personal care products, or industrial applications, manufacturers need to deliver products that meet stringent quality standards and customer expectations. Westone.com.my, a premier plastic bottle manufacturer based in Malaysia, has positioned itself as a leader in this industry, offering exceptional products and services to a diverse clientele.

The Premier Plastic Bottle Manufacturer in Malaysia

At the core of Westone.com.my operations is a dedication to excellence and innovation. As a trusted plastic bottle manufacturer in Malaysia, the company utilizes state-of-the-art technology and advanced manufacturing processes to produce a wide range of plastic bottles that cater to various needs. From small cosmetic bottles to large industrial containers, Westone.com.my ensures that every product is crafted with precision and care.

Leading the Beverage Bottle Manufacturing Sector

Westone.com.my stands out in the beverage bottle manufacturing sector with its ability to create high-quality, durable, and aesthetically pleasing bottles. The company understands the importance of packaging in the beverage industry—where the right bottle can enhance the product's appeal and ensure its integrity from production to consumption. Using food-grade materials and adhering to international safety standards, Westone.com.my beverage bottles are designed to preserve the freshness and taste of beverages, whether it's water, juice, or soft drinks.

Expertise in PET Bottle Manufacturing

Polyethylene Terephthalate (PET) bottles are a popular choice for many products due to their strength, light weight, and recyclability. As a leading PET bottle manufacturer, Westone.com.my leverages its expertise to produce bottles that meet the highest standards of quality and sustainability. The company employs cutting-edge PET manufacturing techniques, ensuring that each bottle is not only robust and lightweight but also environmentally friendly. Westone.com.my commitment to sustainability is evident in their efforts to minimize waste and promote recycling, contributing to a greener planet.

Why Choose Westone.com.my?

Quality Assurance: Westone.com.my prioritizes quality at every stage of production. Each bottle undergoes rigorous testing to ensure it meets the required specifications and standards.

Customization: Understanding that different clients have unique needs, Westone.com.my offers extensive customization options. Clients can choose from various shapes, sizes, colors, and designs to match their brand identity and functional requirements.

Advanced Technology: The company invests in the latest manufacturing technologies, which allows for efficient production processes and consistent high-quality output.

Sustainability: With a strong focus on environmental responsibility, Westone.com.my implements eco-friendly practices in its manufacturing processes, aiming to reduce its carbon footprint and support recycling initiatives.

Customer Service: Westone.com.my prides itself on providing exceptional customer service. The company works closely with clients to understand their needs and deliver solutions that exceed expectations.

Conclusion

Westone.com.my is more than just a plastic bottle manufacturer; it is a partner dedicated to helping businesses succeed by providing top-tier packaging solutions. Whether you need a reliable beverage bottle manufacturer or a specialized PET bottle manufacturer, Westone.com.my offers the expertise, technology, and commitment to quality that can meet and exceed your expectations. Visit Westone.com.my website today to learn more about their products and services, and discover how they can help your business thrive.

Contact Info

Address: Lot 33, Jalan CJ3, Taman Cheras Jaya, 43200 Selangor.

Email: [email protected]

Phone: 03 – 9075 6161

0 notes

Text

Rising Demand for Polyethylene Terephthalate Market is estimated to Witness High Growth

The global polyethylene terephthalate (PET) market is primarily driven by its increasing usage in the production of plastic bottles for packaging beverages and other liquids. PET is a lightweight yet strong plastic resin that provides durability and shatter resistance to bottles. It helps preserve drinks for a longer time without contaminations and allows clear visibility of the contents. PET bottles are widely adopted by beverage producers due to their affordability, sustainability credentials, and high recycling rates.

The Global polyethylene terephthalate (PET) Market is estimated to be valued at US$ 53.53 Bn in 2024 and is expected to exhibit a CAGR of 8.6% over the forecast period 2024 to 2031.

Key Takeaways

Key players operating in the polyethylene terephthalate (PET) market are Medtronic, Abbott Laboratories, Boston Scientific, Biotronik, Koninklijke Philips, Nihon Kohden, Fukuda Denshi, Hill-Rom Holdings. PET resin manufacturers like DAK Americas and Indorama Ventures are investing heavily in capacity expansions to meet the rising demand from beverage producers.