#Isoprene Monomer Market Share

Explore tagged Tumblr posts

Text

Isoprene Monomer Market Evolution: Historical Perspective and Future Direction

Isoprene Monomer Market: Unlocking Growth Opportunities

Isoprene, a volatile liquid hydrocarbon, holds significant importance in the global chemical industry as a vital monomer. It serves as a building block for the synthesis of various high-value products, including synthetic rubber, adhesives, and specialty chemicals. The Isoprene Monomer market has witnessed notable growth in recent years, owing to its versatile applications and the increasing demand for eco-friendly alternatives in various industries. In this article, we delve into the Isoprene Monomer market, exploring its current landscape, key drivers, challenges, and future prospects.

Understanding Isoprene Monomer

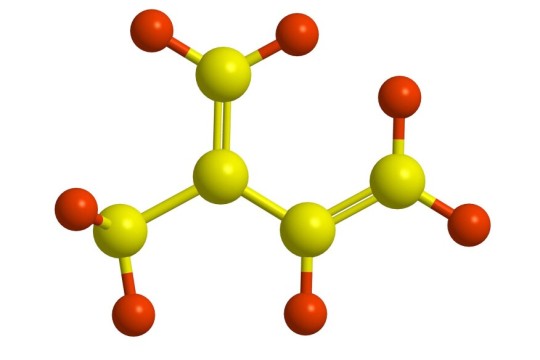

Isoprene monomer market, chemically known as 2-methyl-1,3-butadiene, is a colorless, volatile liquid with a pungent odor. It is naturally found in trace amounts in plants, making it a renewable resource. However, the majority of isoprene used in industries is derived from petroleum-based feedstocks through the cracking of naphtha.

One of the primary uses of isoprene is in the production of synthetic rubber, particularly polyisoprene rubber. This rubber is highly sought after for its properties such as high tensile strength, elasticity, and resistance to abrasion. It finds applications in the manufacturing of tires, medical devices, footwear, and a wide range of industrial products.

The Isoprene Monomer Market Landscape

Market Size and Trends

The Isoprene Monomer market has experienced steady growth over the years. The global demand for synthetic rubber, fueled by the automotive and construction industries, has been a significant driver of this market. Additionally, the increasing adoption of bio-based isoprene as a sustainable alternative has opened up new avenues for growth.

Key Players

Several prominent players dominate the Isoprene Monomer market, including:

Sibur: A Russian petrochemical company, Sibur is a leading producer of isoprene monomer.

Nizhnekamskneftekhim: This Russian company is another major player in the isoprene market, known for its high-quality isoprene production.

Goodyear Chemicals: As a subsidiary of the Goodyear Tire and Rubber Company, Goodyear Chemicals is a significant player in the synthetic rubber industry, relying on isoprene as a key raw material.

Kuraray: This Japanese company is known for its innovative technology in bio-based isoprene production.

ZEON Corporation: ZEON is another Japanese company that plays a vital role in the isoprene monomer market.

Applications

The Isoprene Monomer market caters to a diverse range of applications, including:

Synthetic Rubber Production: The largest consumer of isoprene monomer, the synthetic rubber industry, relies on it for producing high-quality tires and various rubber products.

Adhesives and Sealants: Isoprene-based adhesives and sealants offer excellent bonding and sealing properties, making them valuable in construction and automotive applications.

Specialty Chemicals: Isoprene is used in the synthesis of specialty chemicals such as antioxidants, flavorings, and fragrances.

Bio-based Products: With the growing emphasis on sustainability, bio-based isoprene is gaining traction as a green alternative for various applications.

Driving Forces in the Isoprene Monomer Market

Several factors contribute to the growth of the Isoprene Monomer market:

Automotive Industry Expansion The automotive industry's growth, particularly in emerging economies, has boosted the demand for synthetic rubber. Isoprene monomer, as a key component in synthetic rubber production, directly benefits from this expansion.

Sustainability and Bio-based Isoprene Environmental concerns and sustainability goals are driving the development and adoption of bio-based isoprene. Companies are investing in research and development to create bio-sourced isoprene, which has a lower carbon footprint compared to its petroleum-derived counterpart.

Technological Advancements Advancements in isoprene production technologies are leading to higher yields and improved product quality. These innovations are helping manufacturers meet the increasing demand for isoprene and its derivatives.

Challenges and Future Outlook

While the Isoprene Monomer market demand shows promise, it is not without its challenges:

Price Volatility The market is susceptible to price fluctuations, primarily due to the volatility in crude oil prices, as isoprene is derived from petroleum feedstocks.

Environmental Concerns The environmental impact of traditional isoprene production raises concerns. Companies are under pressure to adopt greener production methods to align with sustainability objectives.

Regulatory Hurdles Stringent regulations regarding emissions and environmental impact can pose challenges for isoprene manufacturers.

Looking ahead, the Isoprene Monomer market is expected to continue growing, driven by the expanding automotive industry and the shift toward sustainable practices. Bio-based isoprene is likely to play a more significant role in the market as companies strive to reduce their environmental footprint. Technological advancements and innovation will remain crucial in meeting the rising demand for isoprene and its derivatives.

In conclusion, the Isoprene Monomer market offers promising opportunities in a world where sustainability and innovation are driving factors. As industries seek eco-friendly alternatives and synthetic rubber continues to be in high demand, isoprene's versatile applications ensure its relevance and growth in the chemical industry.

#Isoprene Monomer Market Share#Isoprene Monomer Market Growth#Isoprene Monomer Market Demand#Isoprene Monomer Market Trend#Isoprene Monomer Market Analysis

0 notes

Text

0 notes

Text

Isoprene Rubber Price Trend, Monitor, Supply & Demand, Forecast | ChemAnalyst

Isoprene rubber Prices a synthetic elastomer derived from isoprene monomers, has witnessed dynamic fluctuations in its market prices, influenced by a myriad of factors. The isoprene rubber market is a critical component of the global rubber industry, serving diverse applications such as tires, automotive parts, medical devices, and consumer goods. The pricing trends in this market are intricately linked to the broader economic landscape, raw material costs, and geopolitical factors.

One of the primary drivers affecting isoprene rubber prices is the demand-supply dynamics within the industry. As the automotive sector constitutes a significant consumer of isoprene rubber, any fluctuations in the global automotive market can have a direct impact on prices. For instance, periods of economic growth often lead to increased demand for vehicles, subsequently driving up the demand for isoprene rubber in tire manufacturing. Conversely, economic downturns can result in reduced demand, creating downward pressure on prices.

Raw material costs play a pivotal role in determining isoprene rubber prices. Isoprene, the key monomer used in its production, is derived from petrochemical sources. Thus, fluctuations in crude oil prices can have a cascading effect on isoprene rubber costs. Additionally, factors affecting the production of isoprene, such as disruptions in the supply chain or changes in feedstock availability, can contribute to price volatility. Producers closely monitor these factors, adjusting prices to reflect the underlying cost structure.

Get Real Time Prices of Isoprene Rubber: https://www.chemanalyst.com/Pricing-data/isoprene-rubber-1501

Geopolitical events and trade policies also exert a substantial influence on isoprene rubber market prices. Tariffs, trade agreements, and diplomatic relations impact the cost of raw materials, transportation, and overall market dynamics. For instance, trade tensions between major economies can lead to increased costs due to tariffs on critical inputs or disruptions in supply chains. Conversely, favorable trade agreements and stable geopolitical conditions can contribute to a more predictable pricing environment.

Environmental regulations and sustainability initiatives have emerged as critical determinants of isoprene rubber prices in recent years. As the global focus on reducing carbon emissions intensifies, there is a growing demand for eco-friendly alternatives in various industries. Isoprene rubber, being a synthetic material, faces scrutiny in terms of its environmental impact. Consequently, regulatory changes or increased consumer preference for sustainable products can influence the market, affecting both demand and prices.

The global nature of the isoprene rubber market means that currency exchange rates play a vital role in shaping pricing trends. Fluctuations in currency values, especially those of major trading currencies like the US Dollar and Euro, can impact the competitiveness of isoprene rubber producers in different regions. Currency devaluations or appreciations can influence export-import dynamics, leading to adjustments in prices to maintain market share.

Technological advancements and innovations within the rubber industry also contribute to pricing trends. Improvements in manufacturing processes, the development of new formulations, and enhanced performance characteristics can affect the demand for isoprene rubber. Producers that invest in research and development to create innovative products may command premium prices, driving overall market dynamics.

In conclusion, the isoprene rubber market is characterized by a complex interplay of factors that collectively influence pricing trends. From demand-supply dynamics and raw material costs to geopolitical events and environmental considerations, each element contributes to the overall volatility in isoprene rubber prices. Stakeholders in this market must navigate these multifaceted influences to make informed decisions and adapt to the ever-evolving landscape of the isoprene rubber industry.

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

0 notes

Text

Embracing Eco-Friendly Solutions: The Growing Polyisoprene Latex Market

Polyisoprene latex is a type of synthetic latex that is derived from the polymerization of isoprene monomers. It shares similarities with natural latex derived from rubber trees but offers certain advantages in terms of consistency, purity, and reduced allergenic potential. Polyisoprene latex is widely used in various industries, including healthcare, automotive, and consumer goods.

One of the primary applications of polyisoprene latex is in the production of medical gloves. These gloves offer excellent barrier protection and tactile sensitivity, making them suitable for use in healthcare settings. Polyisoprene latex gloves are a popular choice because they provide a similar feel and elasticity to natural rubber latex gloves, without the risk of allergic reactions associated with proteins found in natural latex.

Polyisoprene latex is also used in the manufacturing of condoms. Condoms made from polyisoprene latex provide reliable protection against sexually transmitted infections and unintended pregnancies. They offer a comfortable and natural sensation due to their elasticity and thinness, and are a suitable alternative for individuals with latex allergies.

Additionally, polyisoprene latex finds applications in various consumer goods such as balloons, adhesive tapes, and rubber bands. Its excellent elasticity, durability, and resistance to tearing make it a versatile material for a wide range of products. Polyisoprene latex is also used in the automotive industry for the production of rubber components like seals, gaskets, and vibration dampers.

Furthermore, the production of polyisoprene latex offers certain advantages in terms of sustainability and environmental impact. It can be manufactured without the need for natural rubber, reducing dependence on rubber tree plantations and minimizing the associated deforestation. Additionally, polyisoprene latex can be produced with lower levels of residual chemicals and allergenic proteins compared to natural latex, contributing to improved worker and consumer safety.

For More Info @ https://www.persistencemarketresearch.com/market-research/polyisoprene-latex-market.asp

In conclusion, polyisoprene latex is a valuable synthetic latex with diverse applications in various industries. Its use in medical gloves and condoms offers enhanced safety and comfort compared to natural latex, particularly for individuals with latex allergies. The versatility and sustainability of polyisoprene latex make it an attractive choice for the production of consumer goods and automotive components. Continued research and development in this field will contribute to further improvements and innovations in latex-based products.

0 notes

Text

Isoprene Monomer Market,Forecast to 2022

Isoprene Monomer Market,Forecast to 2022

Isoprene Monomer or 2-methyl-1, 3-butadiene, is a common organic compound with the formula CH2=C(CH3)CH=CH2. In its pure form, it is a colorless volatile liquid.

Date Published: 2017/08/02

Region: Europe

Delivery Format: PDF

Pages: 116

Category: Chemical

Scope of the Report:

This report focuses on the Isoprene Monomer in Europe market, especially in Germany, UK, France, Russia, and Italy. This…

View On WordPress

#Global Isoprene Monomer Market#Isoprene Monomer Market analysis#Isoprene Monomer Market data#Isoprene Monomer Market discount#Isoprene Monomer Market economic value#Isoprene Monomer Market efficiency#Isoprene Monomer Market opportunity#Isoprene Monomer Market research reports#Isoprene Monomer Market risk#Isoprene Monomer Market share

0 notes

Text

Global Isoprene Monomer Market 2017- Nizhnekamskneftekhim, Sibu, Synthez-Kauchuk, Shell

Worldwide Isoprene Monomer Market 2017 Research report is an in-depth analysis of 2017 global Isoprene Monomer market on the current state.

First of all, the report (2017 Isoprene Monomer Market) provides a basic overview of the Isoprene Monomer industry 2017 including – definitions, classifications, Isoprene Monomer market by applications and Isoprene Monomer industry chain structure. The 2017’s…

View On WordPress

#Isoprene Monomer#Isoprene Monomer Industry#Isoprene Monomer Market#Isoprene Monomer Market 2017#Isoprene Monomer Market Share

0 notes

Text

Furfural Market Statistics, Overview ,Revenue, Demand, Share, Size, Analysis and Research Report 2020

Reports and Data has published a new study on the Global Furfural Market comprising of exclusive insights, growth prospects, market size and share estimation, and opportunities. Global Furfural Market report is a comprehensive and top-notch market report which offers the professionals and businesses critical insights into the market and industry.

The global Furfural Market is forecasted to reach USD 793.3 Million by 2027, according to a new report by Reports and Data. Growing demand for the market is due to the rise in demand for green chemicals. An increase in concern for the environment and shift to renewable alternatives to replace fossil fuels will propel the growth of the industry. The growing demand in the pharmaceutical sectors will also propel the demand for the product.

The driving factor of the market is the stringent regulations with regards to the air pollution standards. The market products are extracted from the lignocellulosic and agricultural feedstock. The adhesives segment is witnessing increased demand due to its usage in the automotive industry as weight-reducing components. Moreover, the demand for non-toxic Furfural in petroleum refineries is also encouraging the growth of the market. High demand from the food and beverage industries is also supporting market demand.

However, slow technological advancement and lack of production process frameworks are expected to fuel the demand for the market. Moreover, the development of new technologies is also creating ample opportunities for growth. Raw materials for Furfural are available in Asia Pacific regions such as India, China, Malaysia, and Indonesia, and the cost of production is also quite low.

Top Companies Listed in the Furfural Market Report:

Pennakem, Lenzing, Central Romana Corporation, Illovo Sugar Africa, Transfurans Chemicals, Hongye Holding Group Corporation, Silvateam, Shandong Crownchem Industries Limited, KRBL, and Laxmi Furals Private Limited, among others.

To receive a sample copy of the global Furfural market report, visit @ https://reportsanddata.com/sample-enquiry-form/3461

The study offers key insights into the strengths and weaknesses of the prominent players through an extensive SWOT analysis and Porter’s Five Forces analysis. It further segments the market on the basis of product type, application spectrum, med-use, and geography. The Furfural industry analysis report assesses the industry in terms of market size, market share, and revenue. The key regional markets covered in the report include North America, Asia Pacific, Europe, Latin America, and Middle East & Africa. Furthermore, the report sheds light on the presence of the global Furfural market in the major regions with regards to market share, market size, revenue contribution, sales statistics, distribution channels, and various other key elements.

To know more about the report @ https://www.reportsanddata.com/report-detail/furfural-market

Raw Material Outlook (Revenue, USD Billion; 2017-2027)

Sugarcane Bagasse

Rice Husk

Corncob

Sunflower Hull

Others

Application Outlook (Revenue, USD Billion; 2017-2027)

Solvent

Furfuryl alcohol

Intermediate

Others

Request a customized copy of the report @ https://reportsanddata.com/request-customization-form/3461

Thank you for reading our report. To know more about the customization or any query about the report contents, please connect with us and our team will ensure the report is tailored to meet your requirements.

Key Questions Answered by the Report:

What are the key market trends influencing the growth of the Furfural market?

Who are the prominent players of the Furfural market?

What is the impact of the COVID-19 pandemic on the Furfural market?

What are the key growth driving and restraining of the Furfural market?

What are the strengths and weaknesses of the prominent players of the Furfural market?

What are the key outcomes of the SWOT analysis and Porter’s Five Forces analysis

Read More Related Reports:

Isoprene Monomer Market Projections

Perfluorooctanoic Acid (PFOA) Market Top Companies

About Reports and Data

Reports and Data is a market research and consulting company that provides syndicated research reports, customized research reports, and consulting services. Our solutions purely focus on your purpose to locate, target and analyze consumer behavior shifts across demographics, across industries and help client’s make a smarter business decision. We offer market intelligence studies ensuring relevant and fact-based research across a multiple industries including Healthcare, Technology, Chemicals, Power and Energy. We consistently update our research offerings to ensure our clients are aware about the latest trends existent in the market. Reports and Data has a strong base of experienced analysts from varied areas of expertise.

Contact Us:

John W

Head of Business Development

Reports and Data | Web: www.reportsanddata.com

Direct Line: +1-212-710-1370

E-mail: [email protected]

Read Our Innovative Blogs @ https://www.reportsanddata.com/blogs

Check our upcoming research reports @ https://www.reportsanddata.com/upcoming-reports

0 notes

Text

Elastomers Market Size, Segment | Value Share, Leading Players and Forecast to 2027

Market Synopsis

According to the MRFR analysis, the Global Elastomers Market is expected to reach over ~USD 107.1 Billion by the end of 2025 at a CAGR of ~4.8%.

Elastomers are amorphous polymers exhibiting characteristics of rubber in terms of flexibility and elasticity. Various elastomeric products on the account of their high abrasion and heat resistance are used in numerous industrial applications. For instance, TPUs offer excellent mechanical strength and low creep thus are used to manufacture conveyor belts. The rising demand for high-performance elastomers in the automotive and medical industries are the key factors favoring the growth of the elastomers market.

Pricing and Regulatory Analysis

In 2018, the price of Elastomers Market increased from USD 0.19 to USD 0.40 between 2016 and 2018 and is likely to observe a gradual upsurge during the forecast period owing to fluctuating raw material and crude oil prices.

The stringent standards for elastomer analysis may favor the demand for elastomers during the review period. Some of the standards are American Society for Testing and Materials - ASTM D412, ASTM D624, ASTM D3182 ”and International Standard - ISO 34-1:2015.

SEGMENTATION

By Type

Thermoset Elastomers: These polymers belong to the group of elastomers that cannot be molded once they have been cured. Thus, on the account of their structural integrity thermoset elastomers are widely used in high-temperature applications.

Synthetic Rubber: The segment held the largest market share in 2018 on account of its excellent strength and flexibility. These elastomers are artificially synthesized and derived from petroleum-based monomers.

Styrene-Butadiene Rubber (SBR): On account of its good abrasion and elasticity, it is widely used in pneumatic tires. SBR on reinforcement exhibits higher strength and durability.

Isobutylene-Isoprene Rubber (IIR): Owing to its low gas permeability and high resistance finds applications in inner tires of cars, bicycles and other high-pressure tubes.

Nitrile rubber (NBR): It is used in the applications that demand oil and heat resistance. Modified nitrile rubber such as carboxylated nitrile rubbers (XNBR) and hydrogenated nitrile rubbers (HNBR) exhibit high tensile strength and weather resistance.

Polybutadiene (PBR): It is extensively used in various parts of automobile tires including sidewall of truck tires and heavy vehicles for abrasion resistance.

Others: The segment includes acrylic rubber (ACM) and ethylene-propylene rubber (EPM), among others.

Natural Rubber: It is a bio-based elastomer obtained from the rubber trees. It is commonly known as Natural Rubber Latex (NBL) and find wide applications in friction tapes, cement, and adhesives. However, the natural rubber is usually vulcanized to enhance the chemical properties.

Thermoplastic Elastomers: It is projected to be the fastest-growing segment during the forecast period due to significant advantages over conventional thermosetting elastomers. These elastomers are recyclable and are capable of being remolded.

Thermoplastic Polyurethane (TPU): On account of excellent flexibility over a wide temperature range and high abrasion resistance, it is extensively used in a foray of industrial applications such as seals and gaskets, sealants, andconveyor belts.

Thermoplastic Styrenic elastomers (TPS): They are styrene block copolymers with excellent flexibility and elasticity and commonly used in footwear, belts, and adhesives.

Others: The segment includes thermoplastics polyester-ether elastomer (TPE-E) and thermoplastic polyamide elastomers (TPE-A), among others.

Browse Full Research Report @

https://www.marketresearchfuture.com/reports/elastomers-market-8342

By End-Use Industry

Automotive: The automotive segment accounted for more than 62% market share in 2018. This is primarily due to the increased use of elastomers in various applications such as airbags, tires, gaskets, bumpers, and HVAC systems. In the automotive industry, the demand for elastomers in interior applications is expected to increase at a significant rate during the forecast period.

Medical: It is projected to be the fastest-growing segment during the review period. The increasing use of elastomers on account of hydrolytic stability and ease of sterilization in variety of applications such as peristaltic pump catheters, needleless syringes, and valves is fueling the demand for elastomers in the medical industry. Additionally, the rising innovations to develop bio-based elastomers offers a wide range of opportunities to produce artificially synthesized biocompatible organs.

Electronics: A variety of elastomers exhibit low electrical conductivity and thus are suitable for insulation purposes. For instance, ethylene-propylene rubber is used to insulate indoor and outdoor high voltage cables.

Textiles: Elastomeric fabrics on the account of their lightweight and stretchability are used in a variety of garments including cycling shorts, swimsuits, and athletic wear.

Others: The segment includes aerospace & defense, oil & gas, and construction.

By Region

Asia-Pacific: The regional market held a dominant share in 2018 and is expected to maintain its dominance during the review period. The increasing disposable income coupled with expanding automotive and textile industries in the region are fueling the regional market growth.

North America: The market growth is driven by the demand for high-performance elastomers in the aerospace and medical industries.

Europe: A firm market owing to the demand for elastomers in the automotive industry. Additionally, the rising automobile exports from the region is aiding market growth.

Latin America: The growing healthcare and electronics industries is driving the demand for elastomers in Latin America.

Middle East & Africa: The expanding automotive industry and rising constructional activities in the region are contributing to the regional market growth.

Get a Sample Copy of This Report @

https://www.marketresearchfuture.com/sample_request/8342

About Market Research Future:

At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), & Consulting Services.

MRFR team have supreme objective to provide the optimum quality market research and intelligence services to our clients. Our market research studies by products, services, technologies, applications, end users, and market players for global, regional, and country level market segments, enable our clients to see more, know more, and do more, which help to answer all their most important questions.

In order to stay updated with technology and work process of the industry, MRFR often plans & conducts meet with the industry experts and industrial visits for its research analyst members.

Contact:

Market Research Future

Phone: +16468459312

Email: [email protected]

Read More Related Article:

https://www.marketresearchfuture.com/reports/medical-device-coatings-market-2120

https://www.marketresearchfuture.com/reports/smart-polymers-market-4719

https://www.marketresearchfuture.com/reports/architectural-coatings-market-4753

0 notes

Text

Elastomers Market Size, Segment | Value Share, Leading Players and Forecast to 2027

Elastomers Market Synopsis

According to the MRFR analysis, the Global Elastomers Market is expected to reach over ~USD 107.1 Billion by the end of 2027 at a CAGR of ~4.8%.

Elastomers are amorphous polymers exhibiting characteristics of rubber in terms of flexibility and elasticity. Various elastomeric products on the account of their high abrasion and heat resistance are used in numerous industrial applications. For instance, TPUs offer excellent mechanical strength and low creep thus are used to manufacture conveyor belts. The rising demand for high-performance elastomers in the automotive and medical industries are the key factors favoring the growth of the Elastomers Market.

Pricing and Regulatory Analysis

In 2018, the price of elastomers increased from USD 0.19 to USD 0.40 between 2016 and 2018 and is likely to observe a gradual upsurge during the forecast period owing to fluctuating raw material and crude oil prices.

The stringent standards for elastomer analysis may favor the demand for elastomers during the review period. Some of the standards are American Society for Testing and Materials - ASTM D412, ASTM D624, ASTM D3182 ”and International Standard - ISO 34-1:2015.

Get Free Sample Copy of “Elastomers Market” @ https://www.marketresearchfuture.com/sample_request/8342

SEGMENTATION

By Type

Thermoset Elastomers: These polymers belong to the group of elastomers that cannot be molded once they have been cured. Thus, on the account of their structural integrity thermoset elastomers are widely used in high-temperature applications.

Synthetic Rubber: The segment held the largest Market in 2018 on account of its excellent strength and flexibility. These elastomers are artificially synthesized and derived from petroleum-based monomers.

Styrene-Butadiene Rubber (SBR): On account of its good abrasion and elasticity, it is widely used in pneumatic tires. SBR on reinforcement exhibits higher strength and durability.

Isobutylene-Isoprene Rubber (IIR): Owing to its low gas permeability and high resistance finds applications in inner tires of cars, bicycles and other high-pressure tubes.

Nitrile rubber (NBR): It is used in the applications that demand oil and heat resistance. Modified nitrile rubber such as carboxylated nitrile rubbers (XNBR) and hydrogenated nitrile rubbers (HNBR) exhibit high tensile strength and weather resistance.

Polybutadiene (PBR): It is extensively used in various parts of automobile tires including sidewall of truck tires and heavy vehicles for abrasion resistance.

Others: The segment includes acrylic rubber (ACM) and ethylene-propylene rubber (EPM), among others.

Natural Rubber: It is a bio-based elastomer obtained from the rubber trees. It is commonly known as Natural Rubber Latex (NBL) and find wide applications in friction tapes, cement, and adhesives. However, the natural rubber is usually vulcanized to enhance the chemical properties.

Thermoplastic Elastomers: It is projected to be the fastest-growing segment during the forecast period due to significant advantages over conventional thermosetting elastomers. These elastomers are recyclable and are capable of being remolded.

Thermoplastic Polyurethane (TPU): On account of excellent flexibility over a wide temperature range and high abrasion resistance, it is extensively used in a foray of industrial applications such as seals and gaskets, sealants, andconveyor belts.

Thermoplastic Styrenic elastomers (TPS): They are styrene block copolymers with excellent flexibility and elasticity and commonly used in footwear, belts, and adhesives.

Polyether Block Amide (PEBA): It is a high-performance thermoplastic elastomer. Due to its high flexibility and low density, PEBA is used in sports applications such as racquet grommets, golf balls, basketballs, and ski boots.

Others: The segment includes thermoplastics polyester-ether elastomer (TPE-E) and thermoplastic polyamide elastomers (TPE-A), among others.

Get More Professional and Technical Industry Insights @ https://www.marketresearchfuture.com/reports/elastomers-market-8342

By End-Use Industry

Automotive: The automotive segment accounted for more than 62% Market in 2018. This is primarily due to the increased use of elastomers in various applications such as airbags, tires, gaskets, bumpers, and HVAC systems. In the automotive industry, the demand for elastomers in interior applications is expected to increase at a significant rate during the forecast period.

Medical: It is projected to be the fastest-growing segment during the review period. The increasing use of elastomers on account of hydrolytic stability and ease of sterilization in variety of applications such as peristaltic pump catheters, needleless syringes, and valves is fueling the demand for elastomers in the medical industry. Additionally, the rising innovations to develop bio-based elastomers offers a wide range of opportunities to produce artificially synthesized biocompatible organs.

Electronics: A variety of elastomers exhibit low electrical conductivity and thus are suitable for insulation purposes. For instance, ethylene-propylene rubber is used to insulate indoor and outdoor high voltage cables.

Textiles: Elastomeric fabrics on the account of their lightweight and stretchability are used in a variety of garments including cycling shorts, swimsuits, and athletic wear.

Others: The segment includes aerospace & defense, oil & gas, and construction.

By Region

Asia-Pacific: The regional market held a dominant share in 2018 and is expected to maintain its dominance during the review period. The increasing disposable income coupled with expanding automotive and textile industries in the region are fueling the regional market growth.

North America: The market growth is driven by the demand for high-performance elastomers in the aerospace and medical industries.

Europe: A firm market owing to the demand for elastomers in the automotive industry. Additionally, the rising automobile exports from the region is aiding market growth.

Latin America: The growing healthcare and electronics industries is driving the demand for elastomers in Latin America.

Middle East & Africa: The expanding automotive industry and rising constructional activities in the region are contributing to the regional market growth.

NOTE: Our Team of Researchers is Studying Covid19 and its Impact on Various Industry Verticals and wherever required we will be considering Covid19 Footprints for Better Analysis of Market and Industries. Cordially get in Touch for More Details.

0 notes

Text

0 notes

Text

Embracing Eco-Friendly Solutions: The Growing Polyisoprene Latex Market

Polyisoprene latex is a type of synthetic latex that is derived from the polymerization of isoprene monomers. It shares similarities with natural latex derived from rubber trees but offers certain advantages in terms of consistency, purity, and reduced allergenic potential. Polyisoprene latex is widely used in various industries, including healthcare, automotive, and consumer goods.

One of the primary applications of polyisoprene latex is in the production of medical gloves. These gloves offer excellent barrier protection and tactile sensitivity, making them suitable for use in healthcare settings. Polyisoprene latex gloves are a popular choice because they provide a similar feel and elasticity to natural rubber latex gloves, without the risk of allergic reactions associated with proteins found in natural latex.

Polyisoprene latex is also used in the manufacturing of condoms. Condoms made from polyisoprene latex provide reliable protection against sexually transmitted infections and unintended pregnancies. They offer a comfortable and natural sensation due to their elasticity and thinness, and are a suitable alternative for individuals with latex allergies.

Additionally, polyisoprene latex finds applications in various consumer goods such as balloons, adhesive tapes, and rubber bands. Its excellent elasticity, durability, and resistance to tearing make it a versatile material for a wide range of products. Polyisoprene latex is also used in the automotive industry for the production of rubber components like seals, gaskets, and vibration dampers.

Furthermore, the production of polyisoprene latex offers certain advantages in terms of sustainability and environmental impact. It can be manufactured without the need for natural rubber, reducing dependence on rubber tree plantations and minimizing the associated deforestation. Additionally, polyisoprene latex can be produced with lower levels of residual chemicals and allergenic proteins compared to natural latex, contributing to improved worker and consumer safety.

For More Info@ https://www.persistencemarketresearch.com/market-research/polyisoprene-latex-market.asp

In conclusion, polyisoprene latex is a valuable synthetic latex with diverse applications in various industries. Its use in medical gloves and condoms offers enhanced safety and comfort compared to natural latex, particularly for individuals with latex allergies. The versatility and sustainability of polyisoprene latex make it an attractive choice for the production of consumer goods and automotive components. Continued research and development in this field will contribute to further improvements and innovations in latex-based products.

0 notes

Text

Polymerization Catalysts Market Overview: 2020-2027

ThePolymerization Catalysts Market was valued at US$ xx Mn in 2019 is expected to reach US$ xx Mn by the end of 2027 at a CAGR of 4.7% from 2019 to 2027.

The report includes an analysis of the impact of COVID-19 lockdown on the revenue of market leaders, followers, and disruptors. Since the lockdown was implemented differently in various regions and countries; the impact of the same is also seen differently by regions and segments. The report has covered the current short-term and long-term impact on the market, and it would help the decision-makers to prepare the outline and strategies for companies by region.

Global Polymerization Catalysts Market:

Traditionally, polymerization of a-olefins was done by radical polymerization. The problem with the technique was the formation of undesired allylic radicals leading to the branched polymers. For example, radical polymerization of propene gave branched polymers with large molecular weight distribution. Also, radical polymerization had no control over stereochemistry. The ZN catalyst overcomes these problems. The catalyst can give linear a-olefin polymers with high and controllable molecular weights. In addition, it makes the fabrication of polymers with specific tacticity possible. By controlling the stereochemistry of products, either syndiotactic or isotactic polymers can be achieved.

For more info, Get PDF at: https://www.trendsmarketresearch.com/report/sample/13505

They catalyze a-olefins to produce various commercial polymers, like polyethylene, polypropylene, and Polybutene-1. Polyethylene and polypropylene are reported to be the top two widely used synthetic plastics globally. Among the polyethylene fabricated by ZN catalysts, there are three major classes which include high-density polyethylene (HDPE), linear low-density polyethylene (LLDPE), and ultra-high molecular weight polyethylene (UHMWPE).

HDPE, a linear homopolymer, is widely applied in garbage containers, detergent bottles, and water pipes because of its high tensile strength. Compared with HDPE, whose branching degree is quite low, LLDPE has many short branches. Its better toughness, flexibility, and stress-cracking resistance make it suitable for materials like cable coverings, bubble wrap.

UHMWPE is polyethylene with a molecular weight between 3.5 and 7.5 million. This material is extremely tough and chemically resistant. Therefore, it is often used to make gears and artificial joints. Increasing production of polymer resin is the primary factor that is driving the market growth.

ZN catalysts are effective for polymerization of a-Olefins (ethylene, propylene) and some dienes (butadiene, isoprene). However, they don’t work for some other monomers, such as 1.2 disubstituted double bonds. Vinyl chloride cannot be polymerized by ZN catalyst either because free radical vinyl polymerization is initiated during the reaction. Another situation where ZN catalysts don’t work is when the substrate is an acrylate. The reason is, ZN catalysts often initiate anionic vinyl polymerization in those monomers.

The report has profiled ten-key players in the market from different regions. However, the report has considered all market leaders, followers, and new entrants with investors while analyzing the market and estimation the size of the same. The manufacturing environment in each region is different and focus is given on the regional impact on the cost of manufacturing, supply chain, availability of raw materials, labor cost, availability of advanced technology, trusted vendors are analysis and report has come up with recommendations for a future hot spot in the Asia Pacific region. Major countries' policies about manufacturing and their impact on Polymerization Catalysts' demands are covered in the report.

Global Polymerization Catalysts Market Segment Analysis:

The polyethylene segment is expected to grow at a CAGR of xx % during the forecast period

By Applications, in 2019, the global polyethylene segment was xx % and is estimated to reach USD $ XX Mn by 2027. The polyethylene segment is dominating as they are lightweight and durable thermoplastic. Continuous demand for polyethylene from the electrical, packaging, automotive industry is also a major factor. It is used in applications ranging from tubes, laminates, films, and plastic parts.

You can Buy This Report from Here @ https://www.trendsmarketresearch.com/checkout/13505/Single

The polypropylene segment is the second-largest segment which is expected to grow at a CAGR of xx % during the forecast period. The major end-users of polypropylene are the packaging industry, which consumes about 30% of the total, followed by electrical and equipment manufacturing, which uses about 13% each. Household appliances and automotive industries both consume 10% each and construction materials follow with 5% of the market. Other applications together make up the rest of the global polypropylene consumption.

Global Polymerization Catalysts Market Regional Insights:

Asia Pacific is expected to grow at a CAGR of xx % during the forecast period and is expected to reach xx % market share by 2027

In the Asia Pacific, the market growth is fuelled by the increasing demand from the petrol chemical industry. In China and India, the growth in the polymer, refining, chemical industry, and urbanization is likely to drive the polymerization catalyst market. In the Middle East and Africa, increasing production of the oil & gas industry and increasing investment by large-scale producers of oil & gas for building new refining petroleum are expected to drive the market.

The objective of the report is to present a comprehensive analysis of the global Polymerization Catalysts market including all the stakeholders of the industry. The past and current status of the industry with forecasted market size and trends are presented in the report with the analysis of complicated data in simple language. External as well as internal factors that are supposed to affect the business positively or negatively have been analyzed, which will give a clear futuristic view of the industry to the decision-makers.

The report also helps in understanding the global Polymerization Catalysts market dynamics, structure by analyzing the market segments and project global Polymerization Catalysts market clear representation of competitive analysis of key players by price, financial position, by detection and equipment portfolio, growth strategies, and regional presence in the global Polymerization Catalysts market make the report investor’s guide.

Get Discount on This Report: https://www.trendsmarketresearch.com/report/discount/13505

0 notes

Text

Elastomers Market Size Forecast to 2027 Available in New Report

Elastomers Market Size Synopsis

According to the MRFR analysis, the Global Elastomers Market Size is expected to reach over ~USD 107.1 Billion by the end of 2027 at a CAGR of ~4.8%.

Elastomers are amorphous polymers exhibiting characteristics of rubber in terms of flexibility and elasticity. Various elastomeric products on the account of their high abrasion and heat resistance are used in numerous industrial applications. For instance, TPUs offer excellent mechanical strength and low creep thus are used to manufacture conveyor belts. The rising demand for high-performance elastomers in the automotive and medical industries are the key factors favoring the growth of the Elastomers Market Size.

Pricing and Regulatory Analysis

In 2018, the price of elastomers increased from USD 0.19 to USD 0.40 between 2016 and 2018 and is likely to observe a gradual upsurge during the forecast period owing to fluctuating raw material and crude oil prices.

The stringent standards for elastomer analysis may favor the demand for elastomers during the review period. Some of the standards are American Society for Testing and Materials - ASTM D412, ASTM D624, ASTM D3182 ”and International Standard - ISO 34-1:2015.

SEGMENTATION

By Type

Thermoset Elastomers: These polymers belong to the group of elastomers that cannot be molded once they have been cured. Thus, on the account of their structural integrity thermoset elastomers are widely used in high-temperature applications.

Synthetic Rubber: The segment held the largest market share in 2018 on account of its excellent strength and flexibility. These elastomers are artificially synthesized and derived from petroleum-based monomers.

Styrene-Butadiene Rubber (SBR): On account of its good abrasion and elasticity, it is widely used in pneumatic tires. SBR on reinforcement exhibits higher strength and durability.

Isobutylene-Isoprene Rubber (IIR): Owing to its low gas permeability and high resistance finds applications in inner tires of cars, bicycles and other high-pressure tubes.

Nitrile rubber (NBR): It is used in the applications that demand oil and heat resistance. Modified nitrile rubber such as carboxylated nitrile rubbers (XNBR) and hydrogenated nitrile rubbers (HNBR) exhibit high tensile strength and weather resistance.

Polybutadiene (PBR): It is extensively used in various parts of automobile tires including sidewall of truck tires and heavy vehicles for abrasion resistance.

Others: The segment includes acrylic rubber (ACM) and ethylene-propylene rubber (EPM), among others.

Natural Rubber: It is a bio-based elastomer obtained from the rubber trees. It is commonly known as Natural Rubber Latex (NBL) and find wide applications in friction tapes, cement, and adhesives. However, the natural rubber is usually vulcanized to enhance the chemical properties.

Thermoplastic Elastomers: It is projected to be the fastest-growing segment during the forecast period due to significant advantages over conventional thermosetting elastomers. These elastomers are recyclable and are capable of being remolded.

Thermoplastic Polyurethane (TPU): On account of excellent flexibility over a wide temperature range and high abrasion resistance, it is extensively used in a foray of industrial applications such as seals and gaskets, sealants, andconveyor belts.

Thermoplastic Styrenic elastomers (TPS): They are styrene block copolymers with excellent flexibility and elasticity and commonly used in footwear, belts, and adhesives.

Polyether Block Amide (PEBA): It is a high-performance thermoplastic elastomer. Due to its high flexibility and low density, PEBA is used in sports applications such as racquet grommets, golf balls, basketballs, and ski boots.

Others: The segment includes thermoplastics polyester-ether elastomer (TPE-E) and thermoplastic polyamide elastomers (TPE-A), among others.

Get More Professional and Technical Industry Insights @ https://www.marketresearchfuture.com/reports/elastomers-market-8342

By End-Use Industry

Automotive: The automotive segment accounted for more than 62% market share in 2018. This is primarily due to the increased use of elastomers in various applications such as airbags, tires, gaskets, bumpers, and HVAC systems. In the automotive industry, the demand for elastomers in interior applications is expected to increase at a significant rate during the forecast period.

Medical: It is projected to be the fastest-growing segment during the review period. The increasing use of elastomers on account of hydrolytic stability and ease of sterilization in variety of applications such as peristaltic pump catheters, needleless syringes, and valves is fueling the demand for elastomers in the medical industry. Additionally, the rising innovations to develop bio-based elastomers offers a wide range of opportunities to produce artificially synthesized biocompatible organs.

Electronics: A variety of elastomers exhibit low electrical conductivity and thus are suitable for insulation purposes. For instance, ethylene-propylene rubber is used to insulate indoor and outdoor high voltage cables.

Textiles: Elastomeric fabrics on the account of their lightweight and stretchability are used in a variety of garments including cycling shorts, swimsuits, and athletic wear.

Others: The segment includes aerospace & defense, oil & gas, and construction.

By Region

Asia-Pacific: The regional market held a dominant share in 2018 and is expected to maintain its dominance during the review period. The increasing disposable income coupled with expanding automotive and textile industries in the region are fueling the regional market growth.

North America: The market growth is driven by the demand for high-performance elastomers in the aerospace and medical industries.

Europe: A firm market owing to the demand for elastomers in the automotive industry. Additionally, the rising automobile exports from the region is aiding market growth.

Latin America: The growing healthcare and electronics industries is driving the demand for elastomers in Latin America.

Middle East & Africa: The expanding automotive industry and rising constructional activities in the region are contributing to the regional market growth.

Get Free Sample Copy of “Elastomers Market Size” @ https://www.marketresearchfuture.com/sample_request/8342

NOTE: Our Team of Researchers is Studying Covid19 and its Impact on Various Industry Verticals and wherever required we will be considering Covid19 Footprints for Better Analysis of Market and Industries. Cordially get in Touch for More Details.

0 notes

Text

Isoprene Monomer Market Report, Top Key Players, and Industry Statistics

Reports and Data has recently added an investigative study report on the Global Isoprene Monomer Market. The report assesses the Isoprene Monomer Market with regards to the profit margin, value chain analysis, recent developments, opportunities, year-on-year growth along with SWOT analysis, Porter’s Five Forces analysis, and PESTEL analysis. It also provides market estimates, size, and forecast for key segments and sub-segments for the period of 2020-2026. An in-depth analysis of the growth tactics and expansion undertaken by the prominent players of the market are covered in the report.

This detailed report on the Isoprene Monomer market provides an in-depth analysis of the demand, growth, gross profits, earnings and revenue of the Isoprene Monomer industry. The report considers the years 2016 and 2017 for historical data, 2018 as the base year and the years 2019 to 2026 as the forecast period. It gives an extensive outlook of the industry by evaluating the sales, demand, trends, pricing, revenue, total earnings, gross profit and potential opportunities in the business. The forecast predicts the demand and growth rate for the business in the upcoming years.

Get a sample of the report @ https://www.reportsanddata.com/sample-enquiry-form/1580

The report covers the market dynamics analysis, company profiles, production and manufacturing capacity, product specifications, product value, and key players. The report also offers an insight into the growth prospects during the forecast period. The Isoprene Monomer Market report also offers detailed data on the key market players to impart a deeper understanding of the competitive landscape. The report focuses on the key market elements to ensure the readers gain a competitive advantage and maximum benefit of the market data to assist them in achieving substantial growth and an advantageous position in the global market.

The major companies profiled in the report are:

· Nizhnekamskneftekhim

· Sibur

· Synthez-Kauchuk

· Shell

· JSR

· Goodyear Chemical

· Kuraray

On the basis of the product type, the market is segmented into:

· Polymerization Grade

· Chemical Grade

On the basis of the application, the market is segmented into:

· IR

· SIS

· IIR

· Fine Chemicals

Request a discount on the report @ https://www.reportsanddata.com/discount-enquiry-form/1580

The report further provides an extensive analysis of the key geographical regions where the market is spread and offers a comprehensive overview of the market size, market share, revenue generation, production and consumption patterns, supply and demand ratio, and import/export ratio, among others.

Based on the regions, the report covers the following regions:

• North America (U.S.A., Canada)

• Europe (U.K., Italy, Germany, France, Rest of EU)

• Asia-Pacific (India, Japan, China, South Korea, Australia, Rest of APAC)

• Latin America (Chile, Brazil, Argentina, Rest of Latin America)

• The Middle East & Africa (Saudi Arabia, U.A.E., South Africa, Rest of MEA)

To know more about the report, visit @ https://www.reportsanddata.com/report-detail/isoprene-monomer-market

Key Coverage of the Report:

· An in-depth analysis of the historical years and the forecast period has been offered in the report

· Isoprene Monomer Market dynamics, including key drivers, challenges, restraints, threats, and growth opportunities have been analyzed in reports

· SWOT analysis and Porter’s Five Forces analysis with feasibility analysis and investment return analysis

· Competitive landscape benchmarking along with a comprehensive overview of their company profiles, product portfolios, strategic business decisions, and financial standings

· The report covers mergers and acquisitions, product launches and brand promotions, joint ventures, collaborations, and partnerships among few

· Pictorial representation of the key statistical data into graphs, tables, charts, diagrams, and figures

· An in-depth analysis of the current and emerging market trends and developmental patterns

Request customization of the report @ https://www.reportsanddata.com/request-customization-form/1580

Thank you for reading our report. To know more about customization options, please get in touch with us. Our team will ensure the report is tailored to suit your requirements.

0 notes

Text

Automotive Elastomers Market - Future Analysis, Share, Growth, Trends, Company Profiles and Forecast 2025

Automotive Elastomers are useful for various manufacturing operations. A new report on the Global Automotive Elastomers Market, published by Market Research Future (MRFR), predicts that this market could grow between 2016 and 2023. In terms of value, the market can be worth USD 4,317.10 Mn by the end of the forecast period.

The primal market driving factor for the Global Automotive Elastomers Market growth is the use of Automotive Elastomers as sealants, adhesives, and flexible molded parts in automotive manufacturing. Surging sales of passenger cars in emerging economies have created growth opportunities for Automotive Elastomers. Other market driving factors include increasing purchasing power of the consumers, the rising standard of living, strict emission regulations in developed economies, subsequent increasing usage of high-performance, lightweight materials in the automotive industry, and lastly, the rapid rise in demand for both commercial and passenger vehicles.

Key Players:

Prominent players in the Global Automotive Elastomers Market include Arlanxeo (Netherlands), BASF SE (Germany), The Dow Chemical Company (USA), Exxon Mobil Corp. (USA), Kraiburg TPE GmbH & Co. Kg (Germany), Kuraray Co. Ltd. (Japan), LG Chem Ltd. (South Korea), Mitsui Chemicals Inc. (Japan), Nizhnekamskneftekhim PJSC (Russia), Saudi Basic Industries Corporation (Saudi Arabia), Solvay S.A. (Belgium), Sumitomo Chemical Co. Ltd. (Japan), Teknor Apex Company Inc. (USA), and Versalis S.P.A (Italy).

Latest Industry News:

Mitsubishi Chemical has developed thermoplastics elastomer material called extrusion-grade styrenic copolymer (TPS). It is a single auto-foamable core grade that can be extruded at around 190 to produce foamed-core profiles. 8 AUG 2019

Get Free Sample @ https://www.marketresearchfuture.com/sample_request/4992

Market Segmentation:

Global Automotive Elastomers Market segmentation encompasses Application, Type, and Vehicle Type. MRFR's take on the market explores various facets of the market in-depth.

The Application-Based Segmentation of this market covers exterior application, interior application, and tire application. The exterior segment has been sub-segmented into bumper fascia, front end body panel, rocker panel, and roof molds & window shields. The interior application has been sub-segmented into airbags, breaks & suspensions, dashboards, door panels, hoses & seals, instrument & soft-touch panels, seatings, and transmission & conveyor belts. The tire segment holds 61.4% of the market share.

By Type, the market has been segmented into thermoplastic elastomers (TPE) and thermoset elastomers (TSE). The TSE segment has been sub-segmented into acrylic rubber or alkyl acrylate copolymer (ACM), butyl rubber or isobutylene isoprene rubber (IIR), chlorinated elastomers, ethylene propylene diene monomer (EPDM), fluoroelastomers, natural rubber, nitrile butadiene rubber (NBR), polybutadiene rubber (BR), silicone rubber (Q), and styrene butadiene rubber (SBR). The TPE segment has been sub-segmented into copolyamides (COPA), copolyesters (COPE), polyether block amide (PEBA), styrene block copolymer (SBC), thermoplastic olefins (TPO), thermoplastic polyurethane (TPU), and thermoplastic vulcanizates (TPV).

Based on Vehicle Type, light commercial vehicle (LCV), medium & heavy commercial vehicle (M/HCV), and passenger cars.

Regional Segmentation:

A Geographical Outlining of the Global Automotive Elastomers Market covers Asia Pacific, Europe, North America, Latin America, and the Middle East & Africa (MEA).

Browse Key Industry Insights spread across 449 pages with 327 market data tables & 26 figures & charts from the report, “Automotive Elastomers Market Information: By Type, Application and Region – Growth Potential, Price Trends, Competitive Market Share & Forecast 2025” in detail along with the table of contents: https://www.marketresearchfuture.com/reports/automotive-elastomers-market-4992

During the forecast period, the Asia Pacific region has the strongest chance to stand tall as the principal regional market due to the growing standards of living and rising disposable income of the consumers in developing economies namely China, India, and South Korea. These economies are incentivizing automotive production to meet the increasing demand in their respective countries. Japan is another major country-specific market as some important market players in the Asia Pacific region are based in Japan. Indonesia is another sizable country-specific market in this region. An analysis of the remaining countries in the Asia Pacific region featured in this report estimates the huge contribution to market revenue from some other countries.

Europe is the second-largest regional market due to technological advancement and a strong automotive industry in countries like Germany. Some of the key market players are based in Europe. Other critical country-specific markets in this region are France, Italy, Poland, Russia, and the UK. An observation of the remaining countries in Europe featured in this report speculate the huge addition to market revenue from some other countries.

North America is another important regional market due to the strong automotive industry, strong economy, technological advancement, and the presence of most of the key market players. USA and Canada generate maximum revenue in this market.

Latin America and the MEA region, hold the smallest market shares in the global market. Latin America is a bigger market than the MEA region as the automotive industry is stronger in this region. Argentina, Brazil, and Mexico are the biggest country-specific market in this region. An audit of the remaining countries in Latin America featured in this report speculate the huge addition to market revenue from some other countries. In the MEA region, market is limited due to limited scope for the automotive industry. In this region, the biggest country-specific markets are Saudi Arabia, Turkey, and UAE. A scrutiny of the remaining countries in the MEA region featured in this report calculates the increase to market revenue from some other countries.

Read our Blogs @ http://mrfrblog.com

Related Chemicals and Materials Market Research Report @ https://www.marketresearchfuture.com/categories/chemicals-market-report

NOTE: Our team of researchers are studying Covid19 and its impact on various industry verticals and wherever required we will be considering covid19 footprints for a better analysis of markets and industries. Cordially get in touch for more details.

About Market Research Future:

At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), Raw Research Reports (3R), Continuous-Feed Research (CFR), and Market Research & Consulting Services.

MRFR team have supreme objective to provide the optimum quality market research and intelligence services to our clients. Our market research studies by Components, Application, Logistics and market players for global, regional, and country level market segments, enable our clients to see more, know more, and do more, which help to answer all their most important questions.

Contact: Market Research Future +1 646 845 9312 Email: [email protected]

0 notes