#Isoprene Monomer

Explore tagged Tumblr posts

Text

Isoprene Monomer Market Evolution: Historical Perspective and Future Direction

Isoprene Monomer Market: Unlocking Growth Opportunities

Isoprene, a volatile liquid hydrocarbon, holds significant importance in the global chemical industry as a vital monomer. It serves as a building block for the synthesis of various high-value products, including synthetic rubber, adhesives, and specialty chemicals. The Isoprene Monomer market has witnessed notable growth in recent years, owing to its versatile applications and the increasing demand for eco-friendly alternatives in various industries. In this article, we delve into the Isoprene Monomer market, exploring its current landscape, key drivers, challenges, and future prospects.

Understanding Isoprene Monomer

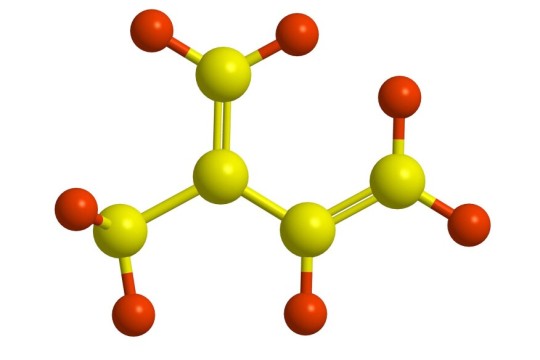

Isoprene monomer market, chemically known as 2-methyl-1,3-butadiene, is a colorless, volatile liquid with a pungent odor. It is naturally found in trace amounts in plants, making it a renewable resource. However, the majority of isoprene used in industries is derived from petroleum-based feedstocks through the cracking of naphtha.

One of the primary uses of isoprene is in the production of synthetic rubber, particularly polyisoprene rubber. This rubber is highly sought after for its properties such as high tensile strength, elasticity, and resistance to abrasion. It finds applications in the manufacturing of tires, medical devices, footwear, and a wide range of industrial products.

The Isoprene Monomer Market Landscape

Market Size and Trends

The Isoprene Monomer market has experienced steady growth over the years. The global demand for synthetic rubber, fueled by the automotive and construction industries, has been a significant driver of this market. Additionally, the increasing adoption of bio-based isoprene as a sustainable alternative has opened up new avenues for growth.

Key Players

Several prominent players dominate the Isoprene Monomer market, including:

Sibur: A Russian petrochemical company, Sibur is a leading producer of isoprene monomer.

Nizhnekamskneftekhim: This Russian company is another major player in the isoprene market, known for its high-quality isoprene production.

Goodyear Chemicals: As a subsidiary of the Goodyear Tire and Rubber Company, Goodyear Chemicals is a significant player in the synthetic rubber industry, relying on isoprene as a key raw material.

Kuraray: This Japanese company is known for its innovative technology in bio-based isoprene production.

ZEON Corporation: ZEON is another Japanese company that plays a vital role in the isoprene monomer market.

Applications

The Isoprene Monomer market caters to a diverse range of applications, including:

Synthetic Rubber Production: The largest consumer of isoprene monomer, the synthetic rubber industry, relies on it for producing high-quality tires and various rubber products.

Adhesives and Sealants: Isoprene-based adhesives and sealants offer excellent bonding and sealing properties, making them valuable in construction and automotive applications.

Specialty Chemicals: Isoprene is used in the synthesis of specialty chemicals such as antioxidants, flavorings, and fragrances.

Bio-based Products: With the growing emphasis on sustainability, bio-based isoprene is gaining traction as a green alternative for various applications.

Driving Forces in the Isoprene Monomer Market

Several factors contribute to the growth of the Isoprene Monomer market:

Automotive Industry Expansion The automotive industry's growth, particularly in emerging economies, has boosted the demand for synthetic rubber. Isoprene monomer, as a key component in synthetic rubber production, directly benefits from this expansion.

Sustainability and Bio-based Isoprene Environmental concerns and sustainability goals are driving the development and adoption of bio-based isoprene. Companies are investing in research and development to create bio-sourced isoprene, which has a lower carbon footprint compared to its petroleum-derived counterpart.

Technological Advancements Advancements in isoprene production technologies are leading to higher yields and improved product quality. These innovations are helping manufacturers meet the increasing demand for isoprene and its derivatives.

Challenges and Future Outlook

While the Isoprene Monomer market demand shows promise, it is not without its challenges:

Price Volatility The market is susceptible to price fluctuations, primarily due to the volatility in crude oil prices, as isoprene is derived from petroleum feedstocks.

Environmental Concerns The environmental impact of traditional isoprene production raises concerns. Companies are under pressure to adopt greener production methods to align with sustainability objectives.

Regulatory Hurdles Stringent regulations regarding emissions and environmental impact can pose challenges for isoprene manufacturers.

Looking ahead, the Isoprene Monomer market is expected to continue growing, driven by the expanding automotive industry and the shift toward sustainable practices. Bio-based isoprene is likely to play a more significant role in the market as companies strive to reduce their environmental footprint. Technological advancements and innovation will remain crucial in meeting the rising demand for isoprene and its derivatives.

In conclusion, the Isoprene Monomer market offers promising opportunities in a world where sustainability and innovation are driving factors. As industries seek eco-friendly alternatives and synthetic rubber continues to be in high demand, isoprene's versatile applications ensure its relevance and growth in the chemical industry.

#Isoprene Monomer Market Share#Isoprene Monomer Market Growth#Isoprene Monomer Market Demand#Isoprene Monomer Market Trend#Isoprene Monomer Market Analysis

0 notes

Text

Hydrogenated Isoprene Polymer(EP)

Zhongli EP series products are (ethylene-alt-propylene) star polymers made from isoprene as a monomer after polymerization and hydrogenation. It has a narrow molecular weight distribution and very low carbon-carbon double-bond residues. Hydrogenated Isoprene Polymer has compatibility with polypropylene and synthetic/mineral base oils. It can be used as a viscosity index improver for high-grade lubricants with strict shear stability requirements, and can also be used to modify polyolefin membranes and other products.

Phone: +86-15268315011

Email: [email protected]

0 notes

Text

Butyl Rubber: A Comprehensive Guide

Butyl rubber is a versatile material that has earned a prominent place in the roofing and sealing industries. Known for its exceptional durability, flexibility, and resistance to harsh weather conditions, butyl rubber is a preferred choice for residential, commercial, and industrial applications. Whether you are repairing a leaking roof, sealing cracks, or enhancing the lifespan of your roofing system, butyl rubber offers reliable solutions.

This article explores the key features of butyl rubber, its benefits, and its common applications, with a focus on its role in roofing and sealing projects.

What is Butyl Rubber?

Butyl rubber is a synthetic elastomer made by polymerizing isobutylene with small amounts of isoprene. This unique composition gives it several desirable properties, such as:

Weather Resistance: It can withstand extreme heat, cold, and UV rays.

Flexibility: It remains pliable over a wide temperature range, making it ideal for roofing.

Waterproofing: It forms a tight seal, preventing water penetration.

These properties make it a popular choice for roofing materials and sealants.

Applications of Butyl Rubber in Roofing

Liquid Rubber Roof Coatings

One of the most innovative uses of butyl rubber is in liquid rubber roof coatings. This liquid application allows for seamless coverage, eliminating gaps and cracks where water can seep through.

Liquid rubber roof coatings are particularly beneficial for flat or low-slope roofs. Once applied, the coating creates a protective membrane that extends the lifespan of the roof while enhancing its resistance to weather damage.

EPDM Liquid Rubber Roofing

Butyl rubber is also a key ingredient in EPDM liquid rubber roofing systems. EPDM (ethylene propylene diene monomer) is a synthetic rubber material widely used for roofing. Combining EPDM with butyl rubber results in a roofing solution that is:

Highly durable and long-lasting.

Resistant to UV rays and ozone.

Easy to install and maintain.

EPDM liquid rubber roofing is often used for commercial buildings, RVs, and trailers because of its cost-effectiveness and superior performance.

Rubber Roof Patch Kits

Roofing issues like cracks, holes, or leaks can be effectively addressed with rubber roof patch kits made from butyl rubber. These kits are easy to use and provide an instant fix for minor roof repairs.

Rubber roof patch kits can be applied to various surfaces, including:

Metal roofs.

Flat roofs.

RV roofs.

With a simple application process, these patches create a watertight seal, protecting the roof from further damage.

Benefits of Using Butyl Rubber in Roofing

Durability

Butyl rubber coatings and patches can last for years without cracking or peeling. Their ability to withstand heavy rain, snow, and high winds makes them a reliable roofing material.

Flexibility

Roofing systems often expand and contract due to temperature changes. Butyl rubber remains flexible, preventing cracks and maintaining a tight seal.

Ease of Application

Liquid rubber roof coatings and patch kits are simple to apply, even for DIY enthusiasts. With minimal tools, you can complete the repair or coating process efficiently.

Cost-Effective

Using butyl rubber can save you money in the long run by reducing the need for frequent repairs or replacements.

Environmentally Friendly

Many butyl rubber products are non-toxic and environmentally friendly, making them a sustainable choice for roofing projects.

Common Issues Addressed with Butyl Rubber

Leaking Roofs

A leaking roof can cause severe damage to your property. Butyl rubber creates a seamless barrier, effectively stopping leaks and preventing future issues.

Cracked Roof Surfaces

Over time, roofing materials may develop cracks due to wear and tear. Liquid rubber roof coatings fill these cracks, restoring the roof’s integrity.

Damaged Seams

Seams and joints are common weak points in roofs. Butyl rubber patch kits can reinforce these areas, ensuring they remain watertight.

How to Apply Butyl Rubber Products

For Liquid Rubber Roof Coatings:

Clean the Surface: Remove dirt, debris, and old coatings from the roof.

Prepare the Product: Mix the liquid rubber thoroughly for an even application.

Apply the Coating: Use a roller, brush, or sprayer to apply the coating evenly.

Let It Cure: Allow the coating to dry and cure completely for maximum effectiveness.

For Rubber Roof Patch Kits:

Locate the Damage: Identify the area that needs repair.

Clean the Area: Ensure the surface is clean and dry.

Apply the Patch: Place the butyl rubber patch over the damaged area and press firmly.

Seal the Edges: Use additional sealant if necessary to secure the patch.

Conclusion

Butyl rubber is a game-changer in the roofing industry, offering durable, flexible, and cost-effective solutions for roof repairs and maintenance. From liquid rubber roof coatings to EPDM liquid rubber roofing and rubber roof patch kits, butyl rubber provides versatile options to keep your roof in top condition.

Whether you’re dealing with a leaking roof, cracked surfaces, or damaged seams, butyl rubber products can help you achieve a long-lasting and reliable fix. With easy application methods and exceptional performance, butyl rubber continues to be a preferred choice for homeowners and professionals alike.

0 notes

Text

0 notes

Text

Synthetic Rubber for Medical Applications: Safety and Performance Features

Synthetic rubber has revolutionized various industries, and its role in the medical field is particularly noteworthy. With its versatile properties, durability, and resistance to various chemicals and temperatures, synthetic rubber is a vital material in manufacturing medical devices, tools, and equipment. From gloves to seals in medical machinery, synthetic rubber ensures safety, reliability, and performance in critical healthcare applications.

This article delves into the applications of synthetic rubber in the medical field, its safety features, and the properties that make it indispensable.

What is Synthetic Rubber?

Synthetic rubber is a man-made polymer created through the polymerization of monomers such as butadiene, isoprene, and styrene. Unlike natural rubber, synthetic rubber is engineered to exhibit specific properties, making it suitable for diverse applications. Types of synthetic rubber commonly used in the medical industry include:

Nitrile Rubber (NBR): Widely used in disposable gloves and seals due to its resistance to oils, chemicals, and punctures.

Silicone Rubber: Known for its biocompatibility, flexibility, and ability to withstand extreme temperatures.

Ethylene Propylene Diene Monomer (EPDM): Popular for tubing and seals due to its resistance to chemicals and heat.

Applications of Synthetic Rubber in the Medical Field

Synthetic rubber plays a crucial role in ensuring the safety and functionality of various medical tools and equipment. Its applications include:

1. Medical Gloves

Nitrile gloves, made from nitrile rubber, are a cornerstone of healthcare safety. These gloves are:

Resistant to punctures, ensuring protection against needle injuries.

Impermeable to a wide range of chemicals and pathogens, providing a safe barrier during medical procedures.

Hypoallergenic, making them a preferred alternative to latex gloves for individuals with latex allergies.

2. Medical Tubing

Synthetic rubber, particularly silicone and EPDM, is extensively used in medical tubing for devices such as catheters, IV lines, and ventilators. Tubing made from synthetic rubber is:

Flexible, ensuring ease of use and patient comfort.

Resistant to heat and sterilization processes, maintaining hygiene standards.

Biocompatible, reducing the risk of adverse reactions during use.

3. Seals and Gaskets in Medical Equipment

Seals and gaskets made from synthetic rubber are integral to the functionality of medical devices such as ventilators, dialysis machines, and infusion pumps. These components provide:

Leak-proof performance, ensuring the safe operation of medical equipment.

Resistance to chemicals and sterilization, maintaining durability under rigorous conditions.

4. Implants and Prosthetics

Silicone rubber is commonly used in implants and prosthetics due to its:

Biocompatibility, ensuring compatibility with human tissue.

Flexibility and comfort, enhancing the usability of prosthetics.

Durability, allowing long-term use without degradation.

5. Medical Device Components

Synthetic rubber is used in various other medical device components, including syringes, diaphragms, and seals, to ensure precision and reliability in critical healthcare applications.

Safety Features of Synthetic Rubber in Medical Applications

Synthetic rubber is engineered to meet stringent safety standards required in the healthcare sector. Key safety features include:

1. Biocompatibility

Silicone rubber and other biocompatible synthetic rubbers are non-toxic and do not react with bodily tissues, making them suitable for implants, tubing, and other applications in direct contact with patients.

2. Sterilization Resistance

Synthetic rubber materials can withstand repeated sterilization processes, including autoclaving, chemical cleaning, and gamma irradiation, ensuring hygiene and safety in medical environments.

3. Hypoallergenic Properties

Unlike latex, which can cause allergic reactions, synthetic rubbers like nitrile and silicone are hypoallergenic, making them safer for both healthcare providers and patients.

4. Chemical Resistance

Synthetic rubber is highly resistant to various chemicals, ensuring its integrity when exposed to cleaning agents, disinfectants, and bodily fluids.

5. Durability Under Stress

Synthetic rubber maintains its performance under extreme conditions, such as high pressure, temperature fluctuations, and prolonged use, ensuring reliability in critical medical applications.

Performance Features of Synthetic Rubber in Medical Applications

The performance of synthetic rubber is tailored to meet the demanding requirements of the medical field. Key performance features include:

1. Flexibility and Elasticity

Synthetic rubber's ability to stretch and retain its shape ensures usability in gloves, tubing, and other medical tools.

2. High Temperature and Pressure Resistance

Materials like silicone rubber are capable of withstanding extreme temperatures, making them ideal for autoclaving and high-pressure environments.

3. Customization

Synthetic rubber can be manufactured with specific properties such as varying hardness, elasticity, and color, making it adaptable to a wide range of medical applications.

4. Longevity

Synthetic rubber’s resistance to wear and tear ensures that medical devices remain functional for extended periods, reducing maintenance and replacement costs.

Conclusion

Synthetic rubber has become an indispensable material in the medical field due to its unmatched safety and performance features. From ensuring protection through gloves to enhancing the functionality of medical devices, its versatility and reliability make it a cornerstone of modern healthcare.

As technology advances, the development of new synthetic rubber formulations will continue to meet the evolving demands of the medical industry. With its ability to combine safety, durability, and adaptability, synthetic rubber remains a critical component in improving healthcare outcomes worldwide.

0 notes

Text

0 notes

Text

Isoprene Rubber Prices | Pricing | Price | News | Database | Chart | Forecast

Isoprene Rubber prices have been a topic of considerable interest and fluctuation within the global market due to various influencing factors. As a synthetic elastomer that closely mimics natural rubber, isoprene rubber is extensively utilized in various industries including automotive, medical, and consumer goods, leading to significant demand fluctuations. The pricing dynamics of isoprene rubber are influenced by several key factors including raw material costs, production technology, market demand, and geopolitical events.

The primary raw material for isoprene rubber is isoprene monomer, which is derived from petrochemical sources. Thus, the price of isoprene rubber is closely tied to the fluctuations in crude oil prices. When crude oil prices increase, the cost of producing isoprene monomer rises, thereby pushing up the price of isoprene rubber. Conversely, when oil prices decrease, the cost of isoprene rubber typically follows suit, though this relationship can be moderated by other factors.

Production technology also plays a critical role in determining the price of isoprene rubber. Advances in manufacturing processes can lead to more efficient production methods, reducing costs and potentially lowering prices. Conversely, if new technologies require significant investment or lead to higher production costs, the prices of isoprene rubber may increase. Additionally, production capacity and the number of operational facilities can influence supply levels, thereby impacting prices. A high production capacity with numerous operational plants can help stabilize prices, while production constraints or plant closures can lead to price increases due to reduced supply.

Market demand is another major factor affecting isoprene rubber prices. The demand for isoprene rubber is largely driven by its applications in various sectors. In the automotive industry, for example, isoprene rubber is used in tire manufacturing due to its excellent performance characteristics, including abrasion resistance and flexibility. Fluctuations in automotive production and sales can directly affect the demand for isoprene rubber, thereby impacting its price. Similarly, demand from the medical sector, where isoprene rubber is used in products such as gloves and medical tubing, also influences price trends. High demand in any of these sectors can drive up prices, while reduced demand can lead to price declines.

Get Real Time Prices for Isoprene Rubber: https://www.chemanalyst.com/Pricing-data/isoprene-rubber-1501

Geopolitical events and trade policies can also have a significant impact on isoprene rubber prices. Trade restrictions, tariffs, and sanctions imposed by governments can affect the cost and availability of raw materials, including those used in isoprene rubber production. For example, if a major producer of isoprene monomer faces trade barriers, the global supply chain can be disrupted, leading to increased prices for isoprene rubber. Additionally, geopolitical instability in key producing regions can lead to supply disruptions, further impacting prices.

Supply chain dynamics, including transportation costs and logistics, also play a role in determining the price of isoprene rubber. Transportation costs can fluctuate based on fuel prices and logistical challenges, which in turn affect the overall cost of isoprene rubber. Any disruptions or inefficiencies in the supply chain can lead to increased costs, impacting the final price of isoprene rubber products.

Furthermore, environmental regulations and sustainability concerns are becoming increasingly important in the production of isoprene rubber. Stricter environmental regulations can lead to higher production costs as manufacturers invest in cleaner technologies and processes. This can contribute to higher prices for isoprene rubber as companies pass on the increased costs to consumers. On the other hand, the growing emphasis on sustainability and the development of bio-based alternatives to traditional isoprene rubber could influence future price trends, potentially leading to shifts in the market as new products become more prevalent.

Overall, the prices of isoprene rubber are subject to a complex interplay of factors including raw material costs, production technology, market demand, geopolitical events, and supply chain dynamics. As these factors continue to evolve, they will shape the future pricing trends of isoprene rubber, making it essential for industry stakeholders to stay informed about these influences to navigate the market effectively.

Get Real Time Prices for Isoprene Rubber: https://www.chemanalyst.com/Pricing-data/isoprene-rubber-1501

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Isoprene Rubber#Isoprene Rubber Price#Isoprene Rubber Prices#Isoprene Rubber Pricing#Isoprene Rubber News

0 notes

Text

0 notes

Text

Embracing Eco-Friendly Solutions: The Growing Polyisoprene Latex Market

Polyisoprene latex is a type of synthetic latex that is derived from the polymerization of isoprene monomers. It shares similarities with natural latex derived from rubber trees but offers certain advantages in terms of consistency, purity, and reduced allergenic potential. Polyisoprene latex is widely used in various industries, including healthcare, automotive, and consumer goods.

One of the primary applications of polyisoprene latex is in the production of medical gloves. These gloves offer excellent barrier protection and tactile sensitivity, making them suitable for use in healthcare settings. Polyisoprene latex gloves are a popular choice because they provide a similar feel and elasticity to natural rubber latex gloves, without the risk of allergic reactions associated with proteins found in natural latex.

Polyisoprene latex is also used in the manufacturing of condoms. Condoms made from polyisoprene latex provide reliable protection against sexually transmitted infections and unintended pregnancies. They offer a comfortable and natural sensation due to their elasticity and thinness, and are a suitable alternative for individuals with latex allergies.

Additionally, polyisoprene latex finds applications in various consumer goods such as balloons, adhesive tapes, and rubber bands. Its excellent elasticity, durability, and resistance to tearing make it a versatile material for a wide range of products. Polyisoprene latex is also used in the automotive industry for the production of rubber components like seals, gaskets, and vibration dampers.

Furthermore, the production of polyisoprene latex offers certain advantages in terms of sustainability and environmental impact. It can be manufactured without the need for natural rubber, reducing dependence on rubber tree plantations and minimizing the associated deforestation. Additionally, polyisoprene latex can be produced with lower levels of residual chemicals and allergenic proteins compared to natural latex, contributing to improved worker and consumer safety.

For More Info @ https://www.persistencemarketresearch.com/market-research/polyisoprene-latex-market.asp

In conclusion, polyisoprene latex is a valuable synthetic latex with diverse applications in various industries. Its use in medical gloves and condoms offers enhanced safety and comfort compared to natural latex, particularly for individuals with latex allergies. The versatility and sustainability of polyisoprene latex make it an attractive choice for the production of consumer goods and automotive components. Continued research and development in this field will contribute to further improvements and innovations in latex-based products.

0 notes

Text

Global Global Isoprene Monomer Market Analysi, Size, Shares, Production, Export, Import, Revenue, Price, Cost and Gross Margin - Future Forecast To 2027

0 notes

Text

Isoprene Monomer Market Report, Top Key Players, and Industry Statistics

Reports and Data has recently added an investigative study report on the Global Isoprene Monomer Market. The report assesses the Isoprene Monomer Market with regards to the profit margin, value chain analysis, recent developments, opportunities, year-on-year growth along with SWOT analysis, Porter’s Five Forces analysis, and PESTEL analysis. It also provides market estimates, size, and forecast for key segments and sub-segments for the period of 2020-2026. An in-depth analysis of the growth tactics and expansion undertaken by the prominent players of the market are covered in the report.

This detailed report on the Isoprene Monomer market provides an in-depth analysis of the demand, growth, gross profits, earnings and revenue of the Isoprene Monomer industry. The report considers the years 2016 and 2017 for historical data, 2018 as the base year and the years 2019 to 2026 as the forecast period. It gives an extensive outlook of the industry by evaluating the sales, demand, trends, pricing, revenue, total earnings, gross profit and potential opportunities in the business. The forecast predicts the demand and growth rate for the business in the upcoming years.

Get a sample of the report @ https://www.reportsanddata.com/sample-enquiry-form/1580

The report covers the market dynamics analysis, company profiles, production and manufacturing capacity, product specifications, product value, and key players. The report also offers an insight into the growth prospects during the forecast period. The Isoprene Monomer Market report also offers detailed data on the key market players to impart a deeper understanding of the competitive landscape. The report focuses on the key market elements to ensure the readers gain a competitive advantage and maximum benefit of the market data to assist them in achieving substantial growth and an advantageous position in the global market.

The major companies profiled in the report are:

· Nizhnekamskneftekhim

· Sibur

· Synthez-Kauchuk

· Shell

· JSR

· Goodyear Chemical

· Kuraray

On the basis of the product type, the market is segmented into:

· Polymerization Grade

· Chemical Grade

On the basis of the application, the market is segmented into:

· IR

· SIS

· IIR

· Fine Chemicals

Request a discount on the report @ https://www.reportsanddata.com/discount-enquiry-form/1580

The report further provides an extensive analysis of the key geographical regions where the market is spread and offers a comprehensive overview of the market size, market share, revenue generation, production and consumption patterns, supply and demand ratio, and import/export ratio, among others.

Based on the regions, the report covers the following regions:

• North America (U.S.A., Canada)

• Europe (U.K., Italy, Germany, France, Rest of EU)

• Asia-Pacific (India, Japan, China, South Korea, Australia, Rest of APAC)

• Latin America (Chile, Brazil, Argentina, Rest of Latin America)

• The Middle East & Africa (Saudi Arabia, U.A.E., South Africa, Rest of MEA)

To know more about the report, visit @ https://www.reportsanddata.com/report-detail/isoprene-monomer-market

Key Coverage of the Report:

· An in-depth analysis of the historical years and the forecast period has been offered in the report

· Isoprene Monomer Market dynamics, including key drivers, challenges, restraints, threats, and growth opportunities have been analyzed in reports

· SWOT analysis and Porter’s Five Forces analysis with feasibility analysis and investment return analysis

· Competitive landscape benchmarking along with a comprehensive overview of their company profiles, product portfolios, strategic business decisions, and financial standings

· The report covers mergers and acquisitions, product launches and brand promotions, joint ventures, collaborations, and partnerships among few

· Pictorial representation of the key statistical data into graphs, tables, charts, diagrams, and figures

· An in-depth analysis of the current and emerging market trends and developmental patterns

Request customization of the report @ https://www.reportsanddata.com/request-customization-form/1580

Thank you for reading our report. To know more about customization options, please get in touch with us. Our team will ensure the report is tailored to suit your requirements.

0 notes

Text

Hydrogenated Isoprene Polymer(EP)

Zhongli EP series products are (ethylene-alt-propylene) star polymers made from isoprene as a monomer after polymerization and hydrogenation. It has a narrow molecular weight distribution and very low carbon-carbon double-bond residues. Hydrogenated Isoprene Polymer has compatibility with polypropylene and synthetic/mineral base oils. It can be used as a viscosity index improver for high-grade lubricants with strict shear stability requirements, and can also be used to modify polyolefin membranes and other products.

Phone: +86-15268315011 Email: [email protected]

0 notes

Text

0 notes

Text

Global Isoprene Monomer Market 2019 | Manufacturers In-Depth Analysis Report to 2024

The latest trending report Global Isoprene Monomer Market 2019-2024 added by DecisionDatabases.com

Isoprene Monomer or 2-methyl-1, 3-butadiene, is a common organic compound with the formula CH2=C(CH3)CH=CH2. In its pure form, it is a colorless volatile liquid.

The worldwide market for Isoprene Monomer is expected to grow at a CAGR of roughly 6.0% over the next five years, will reach 3120 million US$ in 2024, from 2330 million US$ in 2019.

This report focuses on the Isoprene Monomer in global market, especially in North America, Europe and Asia-Pacific, South America, Middle East and Africa. This report categorizes the market based on manufacturers, regions, type and application.

Browse the complete report and table of contents @ https://www.decisiondatabases.com/ip/25017-isoprene-monomer-market-analysis-report

Market Segment by Manufacturers, this report covers

· Nizhnekamskneftekhim

· Sibur

· Synthez-Kauchuk

· Shell

· JSR

· Goodyear Chemical

· Kuraray

· ZEON CORPORATION

· SINOPEC

· Jinhai Chenguang

· Zibo Luhua Hongjin New Material

· Shandong Yuhuang Chemical

· Kaixin

· Yikesi

· Yuangang Petrochemical

Market Segment by Regions, regional analysis covers

· North America (United States, Canada and Mexico)

· Europe (Germany, France, UK, Russia and Italy)

· Asia-Pacific (China, Japan, Korea, India and Southeast Asia)

· South America (Brazil, Argentina, Colombia etc.)

· Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria and South Africa)

Market Segment by Type, covers

· Polymerization Grade

· Chemical Grade

Market Segment by Applications, can be divided into

· IR

· SIS

· IIR

· Fine Chemicals

Download Free Sample Report of Global Isoprene Monomer Market @ https://www.decisiondatabases.com/contact/download-sample-25017

The content of the study subjects, includes a total of 15 chapters: Chapter 1, to describe Isoprene Monomer product scope, market overview, market opportunities, market driving force and market risks. Chapter 2, to profile the top manufacturers of Isoprene Monomer, with price, sales, revenue and global market share of Isoprene Monomer in 2017 and 2018. Chapter 3, the Isoprene Monomer competitive situation, sales, revenue and global market share of top manufacturers are analyzed emphatically by landscape contrast. Chapter 4, the Isoprene Monomer breakdown data are shown at the regional level, to show the sales, revenue and growth by regions, from 2014 to 2019. Chapter 5, 6, 7, 8 and 9, to break the sales data at the country level, with sales, revenue and market share for key countries in the world, from 2014 to 2019. Chapter 10 and 11, to segment the sales by type and application, with sales market share and growth rate by type, application, from 2014 to 2019. Chapter 12, Isoprene Monomer market forecast, by regions, type and application, with sales and revenue, from 2019 to 2024. Chapter 13, 14 and 15, to describe Isoprene Monomer sales channel, distributors, customers, research findings and conclusion, appendix and data source.

Purchase the complete Global Isoprene Monomer Market Research Report @ https://www.decisiondatabases.com/contact/buy-now-25017

Other Reports by DecisionDatabases.com:

Global Styrene Monomer (SM) Market 2019 by Manufacturers, Regions, Type and Application, Forecast to 2024 @ https://www.decisiondatabases.com/ip/41567-styrene-monomer-sm-industry-analysis-report

Global Polycarboxylate Superplasticizer Monomers Market 2019 by Manufacturers, Regions, Type and Application, Forecast to 2024 @ https://www.decisiondatabases.com/ip/26217-polycarboxylate-superplasticizer-monomers-market-analysis-report

About-Us: DecisionDatabases.com is a global business research reports provider, enriching decision makers and strategists with qualitative statistics. DecisionDatabases.com is proficient in providing syndicated research report, customized research reports, company profiles and industry databases across multiple domains.

Our expert research analysts have been trained to map client’s research requirements to the correct research resource leading to a distinctive edge over its competitors. We provide intellectual, precise and meaningful data at a lightning speed.

For more details: DecisionDatabases.com E-Mail: [email protected] Phone: +91 9028057900 Web: https://www.decisiondatabases.com/

#Isoprene Monomer Market#Isoprene Monomer Market Report#Isoprene Monomer Industry Report#Isoprene Monomer Market Analysis#Isoprene Monomer Market Growth#Isoprene Monomer Market Trends#Isoprene Monomer Market Outlook#Global Isoprene Monomer Industry Report

0 notes

Text

Isoprene Rubber Prices Trend | Pricing | Database | Index | News| Chart

Isoprene Rubber Prices a synthetic rubber known for its similar properties to natural rubber, has seen fluctuating prices influenced by various market dynamics. The pricing trends of isoprene rubber are closely linked to factors such as raw material costs, supply chain disruptions, demand fluctuations, and broader economic conditions. The production of isoprene rubber involves the polymerization of isoprene, a hydrocarbon derived from petroleum, making its price sensitive to changes in crude oil prices. When oil prices rise, the cost of producing isoprene rubber tends to increase, leading to higher prices for the end product. Conversely, a drop in oil prices can reduce production costs and consequently lower isoprene rubber prices.

Demand for isoprene rubber is another critical factor affecting its price. It is widely used in various industries, including automotive, manufacturing, medical devices, and consumer goods. The automotive industry, in particular, is a significant consumer of isoprene rubber, using it for tires, belts, hoses, and other components. An increase in automobile production or a surge in the replacement tire market can drive up demand, putting upward pressure on prices. Similarly, any slowdown in the automotive sector can lead to reduced demand and lower prices. The medical industry also relies on isoprene rubber for products like gloves and medical tubing, so shifts in healthcare demands can impact prices as well.

Get Real Time Prices of Isoprene Rubber: https://www.chemanalyst.com/Pricing-data/isoprene-rubber-1501

Supply chain stability plays a crucial role in the pricing of isoprene rubber. Disruptions caused by geopolitical tensions, natural disasters, or logistical challenges can restrict the supply of raw materials or finished products, leading to price volatility. For instance, if a major isoprene rubber manufacturing facility experiences a shutdown due to technical issues or natural calamities, the supply can be significantly affected, resulting in price spikes. Additionally, the global nature of the supply chain means that international trade policies and tariffs can influence prices. Trade restrictions or tariffs on raw materials like crude oil or isoprene monomer can increase production costs, thereby raising the price of isoprene rubber.

Technological advancements and innovation in production processes can also impact isoprene rubber prices. Improvements in manufacturing efficiency, alternative sourcing of raw materials, and advancements in synthetic rubber technology can lead to cost reductions, which may be passed on to consumers through lower prices. Conversely, investment in new technologies or compliance with stringent environmental regulations can increase production costs, leading to higher prices. The balance between technological progress and regulatory compliance is therefore a key factor in determining isoprene rubber pricing trends.

Global economic conditions significantly influence the pricing of isoprene rubber. During periods of economic growth, increased industrial activity and consumer spending typically boost demand for products that use isoprene rubber, leading to higher prices. In contrast, economic downturns can result in reduced industrial output and consumer spending, lowering demand and prices. Inflationary pressures, currency fluctuations, and changes in interest rates can also impact the cost structure of isoprene rubber production and pricing. For example, a weaker currency can make imports of raw materials more expensive, thereby increasing production costs and prices.

Environmental and sustainability considerations are becoming increasingly important in the rubber industry, including the production of isoprene rubber. There is growing pressure on manufacturers to adopt sustainable practices and reduce the environmental impact of their operations. This can include investing in renewable energy sources, improving waste management practices, and developing more environmentally friendly production processes. While these initiatives are crucial for long-term sustainability, they can also lead to higher production costs in the short term, potentially increasing the price of isoprene rubber.

Market competition also plays a significant role in determining isoprene rubber prices. The presence of multiple suppliers in the market can lead to competitive pricing strategies, benefiting consumers with lower prices. However, if the market is dominated by a few large players, they may have greater pricing power and can influence market prices to their advantage. Mergers and acquisitions in the industry can also impact competition and pricing dynamics. Increased consolidation can reduce competition and lead to higher prices, while the entry of new players can enhance competition and drive prices down.

In summary, isoprene rubber prices are influenced by a complex interplay of factors including raw material costs, demand from various industries, supply chain stability, technological advancements, global economic conditions, environmental considerations, and market competition. Understanding these factors is essential for stakeholders in the isoprene rubber market to navigate price fluctuations and make informed decisions. The future pricing trends of isoprene rubber will continue to be shaped by these multifaceted influences, making it a dynamic and challenging market to predict.

Get Real Time Prices of Isoprene Rubber: https://www.chemanalyst.com/Pricing-data/isoprene-rubber-1501

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Isoprene Rubber#Isoprene Rubber Price#Isoprene Rubber Prices#Isoprene Rubber Pricing#Isoprene Rubber News

0 notes

Text

Embracing Eco-Friendly Solutions: The Growing Polyisoprene Latex Market

Polyisoprene latex is a type of synthetic latex that is derived from the polymerization of isoprene monomers. It shares similarities with natural latex derived from rubber trees but offers certain advantages in terms of consistency, purity, and reduced allergenic potential. Polyisoprene latex is widely used in various industries, including healthcare, automotive, and consumer goods.

One of the primary applications of polyisoprene latex is in the production of medical gloves. These gloves offer excellent barrier protection and tactile sensitivity, making them suitable for use in healthcare settings. Polyisoprene latex gloves are a popular choice because they provide a similar feel and elasticity to natural rubber latex gloves, without the risk of allergic reactions associated with proteins found in natural latex.

Polyisoprene latex is also used in the manufacturing of condoms. Condoms made from polyisoprene latex provide reliable protection against sexually transmitted infections and unintended pregnancies. They offer a comfortable and natural sensation due to their elasticity and thinness, and are a suitable alternative for individuals with latex allergies.

Additionally, polyisoprene latex finds applications in various consumer goods such as balloons, adhesive tapes, and rubber bands. Its excellent elasticity, durability, and resistance to tearing make it a versatile material for a wide range of products. Polyisoprene latex is also used in the automotive industry for the production of rubber components like seals, gaskets, and vibration dampers.

Furthermore, the production of polyisoprene latex offers certain advantages in terms of sustainability and environmental impact. It can be manufactured without the need for natural rubber, reducing dependence on rubber tree plantations and minimizing the associated deforestation. Additionally, polyisoprene latex can be produced with lower levels of residual chemicals and allergenic proteins compared to natural latex, contributing to improved worker and consumer safety.

For More Info@ https://www.persistencemarketresearch.com/market-research/polyisoprene-latex-market.asp

In conclusion, polyisoprene latex is a valuable synthetic latex with diverse applications in various industries. Its use in medical gloves and condoms offers enhanced safety and comfort compared to natural latex, particularly for individuals with latex allergies. The versatility and sustainability of polyisoprene latex make it an attractive choice for the production of consumer goods and automotive components. Continued research and development in this field will contribute to further improvements and innovations in latex-based products.

0 notes