#Iron Casting

Explore tagged Tumblr posts

Text

Shivalik Engineering: Your Trusted Partner in Water Works & Pipe Fitting Castings

Shivalik Engineering is a leading manufacturer of high-quality water works and ductile pipe fitting castings, ensuring durability and reliability. Shivalik Group is in a very strategic position to provide Ductile Iron Pipe fittings for water works Industries of various sizes of Bends, Tee, Reducers, Wyes, Cross, Caps & Plugs, Laterals, Adaptors and other components as per customer specification and requirements.

0 notes

Text

A Complete Guide to Choosing the Right Manifold Casting Materials

The selection of manifold-casting material forms one of those critical decisions at the foundry, as doing so would directly translate to some modification in part performance and durability apart from its cost. Manifolds are among the main components in many industries, such as aeronautics and machinery. These components are very often expected to withstand very high pressures, sometimes even corrosive environmental temperatures, and it is this that makes material selection one of the crucial aspects of the design and manufacturing process. Material selection will be discussed in this guide, with critical considerations placed on a manifold cast product with the intent of ensuring that the cost and performance expectations are met.

Understanding Manifold Casting

Manifold casting is considered to refer to the casting of sophisticated parts associated with controlling the flow and dispersion of any gases and liquids within a particular system. Manifolds, being active components, need to be made of materials that can survive the specified operating conditions. This means material choice determines the manifold resistance against wear, corrosion, and thermal shock; therefore, material selection is actually the very foundation of the whole casting process.

Critical Factors of Material Selection

1. Application-Specific Requirements

Of course, the first step toward the selection of the proper material for manifold casting is understanding the specific demands of the application. Different applications make different demands on the manifold. For example, a manifold in an automotive exhaust system has to put up with severe temperatures and corrosive gases in the exhaust. A manifold Utilise in hydraulic pressure would need a resisting capability and durability at much higher pressures.

2. Material Properties

Each manifold casting material has its peculiar strength, resistance to heat, and corrosion. Commonly used ones are:

Grey Iron: Due to good machinability and low cost, grey iron finds wide applications in places where no pronounced degree of strength and elasticity is required.

Ductile Iron: Since ductile iron has greater tensile strength and flexibility, its use is preferred where toughness and resistance against impact are called for.

Stainless Steel: Applications where the material is vulnerable to moisture or strong chemicals are recommended for its use.

Aluminum Alloys: The alloying of aluminium makes the material lightweight and resistant to corrosion; hence, this is applied in weight-reduction industries like aeronautical and automobile industries.

3. Environmental Conditions

Operational conditions in the environment are also another vital consideration for material selection for the manifold. Those operating in the marine environment, for example, must be able to resist the salinity present in the water. For those operating at high temperatures, these must be made of material that can withstand thermal stresses.

Temperature Resistance: The ductile iron and some grades of stainless steel resisted high temperatures without strength loss.

4. Cost Considerations

While performance is the central issue, material cost counts as an essential consideration, too. If high-performance materials like stainless steel or special alloys are used, then the manufacturing cost will increase considerably. A trade-off should be considered concerning the material performance regarding the cost issue. An economically feasible solution can be to use less expensive material with diverse surface treatments or coatings without compromising the quality.

5. Manufacturing Complexity

The manifold complexity of the design may also make a difference in material choice. Materials differ in their castability and their ease of machining, with a significant impact on production time and attendant costs. Gray iron is very easily machined and, hence, a cheap material for complicated designs.

Conclusion

The selection of material for manifold casting is a complex decision based on various considerations. For us at AKP Ferrocast, the choice of appropriate materials calls for prudent consideration of a variety of elements like performance requirements, characteristics of materials, operating environments, and material economy. Only then can we ensure that manifold castings produced by us exhibit high-performance qualifications and economical durability.

0 notes

Text

Chocolate Chip Cookie Skillet (x)

#food#food porn#cookies#cookie skillet#chocolate chip cookies#cast iron skillet#ice cream#dessert#vanilla#chocolate#food stim#food gif#gifset#gif#lustingfood

7K notes

·

View notes

Text

Iron Casting Manufacturer- Mahadev Ferro Cast

Since its inception in 1969, Mahadev Ferrocast, rapidly became the leader of high quality Ductile and Grey Iron castings.

One of the most significant differentiation that distinguishes us from others is high level performance and precision work. Adding more feathers to the cap, the meticulous quality control, capacity of production, expertise of technicians and engineers plays a major role in standing out from the crowd. We have in-house state of the art Machine Shop which gives us a added advantage of providing the casting in properly finished condition.

ustomer Satisfaction is our first priority and we attain it with the help of complete integration of quality systems and latest technological equipment. We are customers’ first choice not just because of the quality, reliability and delivery but we are also certified with ISO BS OHSAS 18001. With years of experience and expertise in manufacturing and supplying components to various standards and specifications, Mahadev, is the one name you want to hear again and again.

We have the mammoth capacity to produce casting upto 3000 kg single part piece. Our fundamental production facility includes Induction, Fast Loop No-Bake Moulding Line, Green Sand Plant, Knock Out, Shot Blasting, Machine Shop with Latest HMC’s, VMC’s, CNC VTL’s and CNC milling machines.

Link: https://www.mahadevferrocast.com/

#iron casting#casting iron#cast iron#iron cast#iron casting manufacturer#iron casting foundry#casting foundry

1 note

·

View note

Text

Forging Excellence: Todeco Group's Mastery in Iron Casting Parts

Introduction: In the world of metal manufacturing, iron casting stands as an age-old technique that has been refined and perfected over centuries. Todeco Group, a prominent player in the industry, brings a contemporary touch to this ancient craft, showcasing unparalleled expertise in producing high-quality iron casting parts.

The Art of Iron Casting: Iron casting is a metallurgical process that involves melting iron and pouring it into a mold to create a desired shape. The versatility of iron casting allows for the production of intricate and durable parts, making it a pivotal method in various industries.

Todeco Group's Mastery in Iron Casting:

Versatility in Iron Alloys: Todeco Group's proficiency in iron casting extends across a range of iron alloys, including gray iron, ductile iron, and alloyed iron. This versatility enables the group to cater to diverse industry needs, offering components with specific material properties and characteristics.

State-of-the-Art Foundry Facilities: At the heart of Todeco Group's iron casting excellence lies its state-of-the-art foundry facilities. Equipped with modern technology and advanced machinery, the foundries ensure precision, efficiency, and the capability to handle complex casting projects.

Customization and Design Expertise: Understanding that each project is unique, Todeco Group collaborates closely with clients to provide customized iron casting solutions. Their team of skilled engineers and technicians optimize designs for manufacturability, ensuring that the final components meet both functional and aesthetic requirements.

Quality Assurance: Quality is paramount in Todeco Group's iron casting process. Rigorous quality assurance measures are implemented at every stage, from raw material inspection to the final casting. This commitment guarantees that the iron casting parts meet or exceed industry standards.

Applications Across Industries: Todeco Group's mastery in iron casting finds applications across a spectrum of industries. From automotive components and machinery parts to construction materials and infrastructure components, the versatility of iron casting meets the demands of diverse sectors.

Environmental Responsibility: In addition to delivering quality products, Todeco Group places a strong emphasis on environmental responsibility in the iron casting process.

Efforts are made to optimize energy consumption and minimize waste, aligning with the group's commitment to sustainability.

Conclusion: Todeco Group stands as a beacon of excellence in the art of iron casting, combining tradition with innovation. Their proficiency in diverse iron alloys, investment in advanced technology,

dedication to customization, and unwavering commitment to quality assurance position them as a reliable partner for industries seeking top-tier iron casting solutions.

As manufacturing landscapes evolve, Todeco Group remains at the forefront, forging excellence in every iron casting part they produce.

0 notes

Text

Grey Iron Casting Manufacturer West Bengal, India | HUSTON (INDIA) PVT. LTD.

We follow global standards to design, make, and test our products, making them stand out in the market. Our team of experts checks the quality of our products at every step to make sure they work perfectly for customers.

0 notes

Text

Elphaba: WHO WROTE THE GRIMMERIE

*cocks shotgun*

I JUST WANNA TALK.

-

Fiyero's not salty at Elphaba per se, but damn, sometimes when you read something that quirks your eyebrow, you gotta take a step back and reconsider.

Elphaba didn't exactly have time to do that so can we really blame her?

We can, however, blame the absolute masochist that wrote the Grimmerie.

No but for real, whoever created that spellbook was an absolute troll. Just sheer genie level of manipulation and word-twisting and "you better cross your T's and dot your I's because I can and will exploit every vague unclear word you speak to be as horrific as possible."

#wicked#wicked movie#wicked musical#wicked spoilers#fiyero#elphaba#fiyero tigelaar#fiyero tiggular#elphaba thropp#wicked witch of the west#oz#wizard of oz#scarecrow#you just KNOW elphaba was bracing for whatever bullshit this spell was gonna pull on her#considering what happened to the Monkeys and Boq#ironically the only spell that seemed to go off without a hitch was the one she cast on Nessa's shoes#maybe that's part of why she wants the shoes so bad#the one spell that DIDN'T blow up horrifically in her face

2K notes

·

View notes

Text

The light-filled kitchen received the same attention to detail as the rest of the house. The staff quarters can be seen through the doorway.

The Los Angeles House: Decoration and Design in America's 20th-Century City, 1995

#vintage#vintage interior#interior design#home#architecture#home decor#style#1990s#kitchen#cast iron#stove#sunroom#subway tile#bungalow#craftsman#woodwork#California#Los Angeles

1K notes

·

View notes

Text

Just remember: whatever level of insane you are about Wicked, you will still NEVER be as insane as Stephanie J Block and Sebastian Arcelus running down to a NYC courthouse one early morning to elope before their wedding day, just so they could perform As Long As You’re Mine on Broadway that night as a married couple

#*allegedly* (<- story is very famous and widely told on Broadway)#stephanie j block#sebastian arcelus#wicked#they literally met while playing the characters in the National Tour#and their WEDDING WAS PERFORMING A LOVE SCENE ON BROADWAY WHEN SJB WAS CAST AS THE LEAD#Stephanie being the true OG Elphaba and also having the craziest lore in relation to her 2007-2008 run#she was the moment#ironically not too far off the plot of#fiyeraba

791 notes

·

View notes

Text

i’m literally never buying anybody new shit ever again. there’s so much cool shit on ebay. buy somebody a weird beautiful item off ebay today

851 notes

·

View notes

Text

#foundry#automotive casting#pipe fittings#pipe castings#iron casting#Ductile Iron Pipe Fittings#castingsupplier

0 notes

Text

Quality Assurance in Cast Iron Supply: Ensuring Consistency and Reliability

In the manufacturing industry, cast iron remains a vital material due to its durability, machinability, and excellent thermal properties. However, the quality of cast iron can vary significantly, making it essential for manufacturers to source materials from reliable cast iron suppliers. To maintain high production standards and minimise defects, it is important to ensure the consistency and reliability of cast iron supplies.

The Importance of Quality Assurance for Cast Iron Suppliers

Quality assurance (QA) in cast iron supply involves a systematic process of ensuring that the iron meets specific standards and requirements. This process is vital for several reasons:

Consistency: Consistent quality in cast iron is essential for maintaining the integrity of manufactured products. Variations in quality can lead to defects, product failures, and increased costs due to rework and scrap.

Reliability: Reliable cast iron ensures that the final products meet performance expectations, particularly in applications where safety and durability are critical.

Customer Satisfaction: High-quality materials lead to high-quality products, which in turn result in satisfied customers. This satisfaction is crucial for building a solid reputation and customer loyalty.

Critical Aspects of Quality Assurance in Cast Iron Supply

Material Selection and Specification

The first step in quality assurance is the careful selection of raw materials. Cast iron suppliers must source high-quality raw materials and adhere to strict specifications regarding the composition and properties of the iron. This includes ensuring the correct balance of carbon, silicon, manganese, and other alloying elements that affect the iron's characteristics.

Manufacturing Processes and Control

Cast iron quality is determined by the manufacturing process. The following are key processes:

Melting: The melting process must be carefully controlled to achieve the desired chemical composition and avoid impurities. This involves precise temperature control and the use of clean, high-quality materials.

Moulding and Casting: The quality of the moulds and casting methods directly impacts the surface finish, dimensional accuracy, and internal soundness of the cast iron. Using advanced moulding techniques and high-quality moulds can minimise defects.

Inspection and Testing

Quality assurance includes both inspection and testing. Cast iron suppliers must implement strict inspection protocols to detect any defects. Standard inspection methods include:

Visual Inspection: Surface defects, such as cracks and porosity.

Dimensional Inspection: Ensuring that the cast iron components meet the specified dimensions and tolerances.

Non-Destructive Testing (NDT): Techniques like ultrasonic testing, radiography, and magnetic particle inspection help detect internal defects without damaging the product.

Chemical and Mechanical Property Testing

To ensure that the cast iron meets the required specifications, suppliers must conduct tests to determine its chemical composition and mechanical properties. Key tests include:

Chemical Analysis: Determines the composition of the iron, ensuring it meets the specified alloying elements' content.

Tensile and Hardness Testing: Assess mechanical properties such as tensile and hardness to ensure that the materials meet the required standards.

Certification and Documentation

Reliable cast iron suppliers provide certification and documentation for their products. This includes material test reports (MTRs) and certificates of compliance, which verify that the cast iron meets the required specifications and standards. Proper documentation is essential for traceability and accountability, providing manufacturers with the assurance that they are using high-quality materials.

Conclusion

To ensure consistency and reliability, AKP Ferrocast must adhere to strict quality assurance standards. From material selection and manufacturing control to inspection and testing, every step must be carefully managed to maintain high standards. Manufacturers need to partner with reputable suppliers of cast iron, such as AKP Ferrocast, in order to obtain materials that meet performance and specification criteria. Suppliers and manufacturers who prioritise quality assurance can create reliable, high-quality goods that meet the expectations of customers and are able to withstand various applications.

0 notes

Text

Steak and Eggs with Chimichurri (x)

#food#food porn#steak#steak and potatoes#breakfast#brunch#potatoes#eggs#meat#grill#bbq#cast iron#cast iron skillet#outdoor cooking#food gif#food gifs#lustingfood#gif#gifset#mine#chimichurri#green onion

3K notes

·

View notes

Text

don't wash the cast iron skillet

#the song is cast iron skillet by jason isbell!#warrior cats#warrior cats art#warrior cats designs#mothwing#riverclan#wc designs#warriors#wc

2K notes

·

View notes

Text

Jaime Lorente as Néstor & Joel Bosqued as Álex 📺MANO DE HIERRO (IRON REIGN) · S1·EP5 · Crime/Thriller

#GO SHORT KING GO! just remembering jaime wanting to fuck ander the most in the elite cast during their press tour#jaime lorente#iron reign#mano de hierro#netflixedit#queer#lgbt#joel bosqued#couple#kiss#affection#intimacy#desire#yearning#longing#beautiful men

2K notes

·

View notes

Text

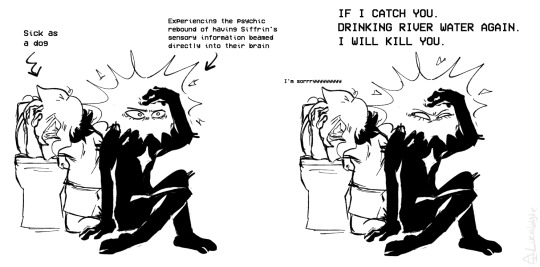

traveller tips! you can drink from any standing body of water. it's fine.

#its a cute headcanon that loop's ability to watch/hear via siffrin as a guide extends to their other senses too#but its also got some funny fucking implications if you broaden your concept of 'senses' to 'general bodily experience'#isat#in stars and time#isat fanart#isat siffrin#isat loop#doodlebyte#anyway this joke entered my brain completely fully formed theres like no further thoughts behind it.#im just a staunch believer that siffrin probably has a cast-iron stomach from their eating habits pre-party#but cast iron doesnt mean immune. so watch out!

1K notes

·

View notes