#Insulator Warehouse Curtain Manufacturers

Explore tagged Tumblr posts

Photo

Insulator Warehouse Curtain Manufacturers: For separating temperature zones in a range of applications, Insulator Warehouse Curtain Manufacturers are a practical and affordable option. They may be utilised, among other things, in applications for food storage, cooler-to-cooler, freezer-to-ambient, and freezer-to-ambient. We are the top producer of Insulator Warehouse Curtains in India. Our Insulator Warehouse curtains are lightweight, adaptable, and can be opened and closed to a third of their original size to allow heavy gear or equipment access to temperature-controlled areas.

0 notes

Text

Aluminium Roller Shutters: A Modern Solution for Enhanced Property Protection

Introduction to Aluminium Roller Shutters for Commercial and Industrial Spaces

Aluminium roller shutters are a popular and reliable choice for both commercial and industrial applications. Designed with horizontal steel or aluminium slats, these shutters roll around a barrel to open and close seamlessly. They can be operated through various mechanisms like springs, chains, or electric motors, and are fully customizable to meet specific requirements.

Customization and Operation

Aluminium roller shutters feature side guides to keep the curtain securely in place. Built for vertical operation, they are compact and take up minimal space when fully open, with the curtain’s top space varying between 200–500mm based on the door height and slat type.

Many modern shutters use electric motors for ease and efficiency, especially in high-traffic areas, as they are cost-effective and more practical than manual options.

Heavy-Duty Requirements for Industrial and Commercial Use

In commercial and industrial settings, roller shutters are often required to handle frequent use. Heavy-duty 3-phase electric motors are common for shutters that need to open and close over 15–20 times daily, or for larger and heavier shutters. This setup ensures durability, strength, and a longer service life.

Versatile and Durable Aluminium Roller Shutters

Our aluminium roller shutters are a versatile, lightweight, and durable option suitable for a range of settings, from shopping centers and storefronts to bottle shops and canteens.

They provide excellent protection, style, and resistance to wear, making them ideal for both aesthetics and security in any commercial environment. Their custom design also enhances protection against extreme weather conditions and potential break-ins.

Why Choose Aluminium?

Aluminium is known for being lightweight, strong, and resistant to rust. It ensures a quiet, smooth operation, efficient insulation, and lasting durability.

Additionally, aluminium’s high-quality surface finish maintains its appearance over time, making it a reliable choice for long-term use.

Enhanced Privacy, Light Control, and Noise Reduction

These roller shutters offer more than security; they add privacy, control over light, and noise reduction, making them a suitable solution for both commercial and residential spaces.

Aluminium roller shutters are perfect for homes that want both functionality and style in their design.

Expanding Applications Beyond Industrial Use

Traditionally used in factories and warehouses, aluminium roller shutters have gained popularity in retail, schools, and healthcare settings, proving their versatility beyond industrial buildings. They offer a practical and secure solution for various commercial uses.

Added Security and Energy Efficiency

Aluminium roller shutters act as a solid barrier when closed, providing high-level protection against intruders. Their tight, gap-free design offers a clean and professional appearance, giving businesses a secure, polished look.

Some shutters even include automatic locking systems for extra security, further safeguarding the premises.

Streamlining Operations in Warehouses

In warehouse settings, roller shutters help streamline workflow by creating organized zones for different types of stock or activities. This organization can improve efficiency by separating temperature zones, preserving product quality, and managing stock effectively.

Built to Last with Quality Craftsmanship

Aluminium is well-suited to withstand twisting and minimal expansion, even in high temperatures, making it ideal for precision manufacturing.

When combined with professional craftsmanship, these qualities make aluminium roller shutters a top-quality, reliable option for commercial and industrial spaces.

Boosting Protection with Wind Locking Mechanisms

For areas prone to strong winds or storms, a wind-locking mechanism is a valuable addition to ensure shutters stay secure. This added feature helps protect your shutters from damage in extreme weather, enhancing their longevity and performance.

Conclusion

Aluminium roller shutters offer a range of sizes and customization options, making them suitable for any commercial or industrial setting, from small stores to large warehouses. With benefits like durability, security, and efficient operation, aluminium roller shutters are a valuable addition for any property seeking style, protection, and ease of use.

For expert guidance on installing aluminium roller shutters, contact Able Door Services today.

#Aluminium roller shutters#aluminium security shutters#aluminium roller shutter price#aluminium shutter door#aluminium roller door#aluminium roller shutter door#extruded aluminium roller shutters#steel door rollers

0 notes

Text

Low-e Insulated Glass For Curtain Wall

Custom manufacturer of insulating glass for architectural and specialty industries. Features include exterior noise reduction.Thriking glass is insulating glass manufacturer,supplier,We will assist you to complete the entire process of ordering, production, and transportation, and follow up the order 24 hours until the glass is safely delivered to your warehouse.

0 notes

Text

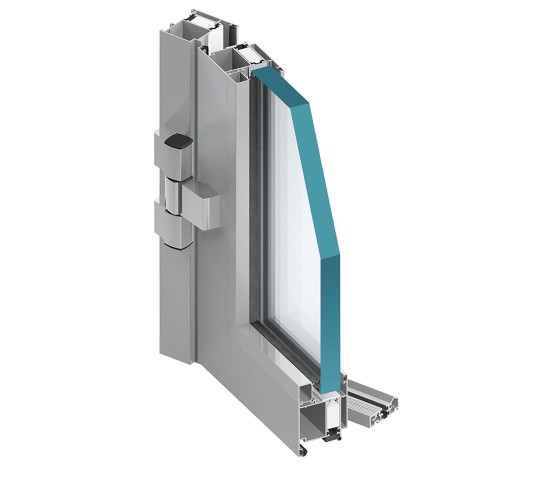

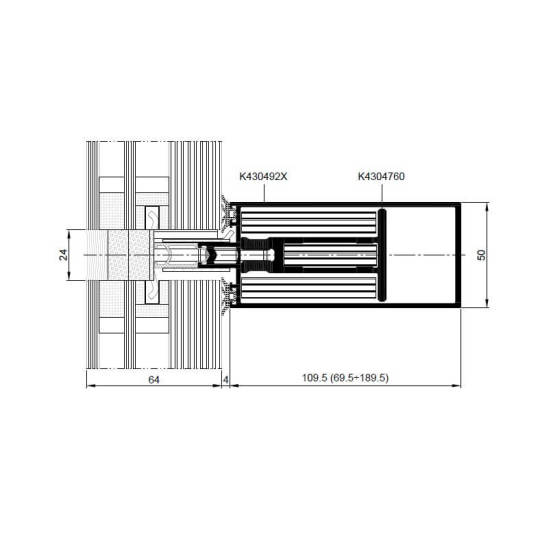

Aluprof - A Vertically Integrated Systems Supplier

Elzbieta Kantor - Aluprof Operations Director

What is ‘vertical integration?’ and why is it important to the specifier when choosing suppliers? Vertical integration for any business is gaining control of upstream processes, normally by bringing them in-house to gain more control and consolidate costs. It is important from a specification process viewpoint as it offers many advantages in ease of supply, quality and costs.

An architectural aluminium systems company designs windows, doors, curtain wall systems and other products for use in building construction. These products are supplied in system form to fabricators and installers who manufacture and install under contract. Each system is extensively tested and carries the appropriate standards and performance levels for various applications.

When single systems are shared among several fabricators, the cost of development, testing, and updating is divided among them, with the systems company handling these tasks.

Many systems companies supply warehouse stock to their customers for ‘off-the-shelf’ windows, doors and curtain walls. As projects become more complex and expect higher performance levels, a systems company that looks to become more vertically integrated offers many advantages to the specifier. Vertical integration can include the ability to smelt aluminium, the design of dies to extrude profiles, inserting thermal breaks in profiles and offering finished profiles, either powder coating or anodised.

Only a few of the leading systems companies operating across the UK and Europe are vertically integrated. Having control of each process that completes a window door or curtain wall system helps limit risk. Between separate suppliers, such as between an extruder and a systems company, conflict can arise when the extrusion supplied does not meet expectations from the systems company, for various reasons, this poses risk, both on supply time and costs.

Following extrusion, main profiles often require thermal breaks to be inserted by first knurling the profile, inserting the thermal break, often made of polyamide along with additional insulation materials and then rolling the profile to create a single section. Being able to integrate a thermal break also allows the systems company to develop special designs of polyamide profiles that can enhance the performance both in thermal and weathering characteristics. In-house finishing of profiles further enhances system allowing for single or bespoke dual colour profiles to be created. All systems companies now offer QUALICOAT powder coated profiles as a standard which is recognised globally. Powder coating all profiles in-house reduces both time and transport requirements.

Vertical process integration can improve safety in the workplace by removing many of the operations where transport is required between businesses. Fewer loadings and unloading of profiles not only reduce potential health and safety issues, but also reduces the risk of profile damage in transit. A further consideration is the reduction in packaging need when profiles require protection when shipped between companies for processing.

Reduced handling of profiles allows for optimisation of processes and improvement in logistics. For example, batches of profiles of various sizes can more easily be processed economically rather than having to opt for the advantages of scale to save costs. With the reduction of minimum process quantities comes the benefit of speed of production thereby reducing order lead times for customers.

With the advantages of vertical integration mentioned above, a further benefit to the specifier is a reduction in carbon emissions. Reduced handling requirements and carbon miles automatically save energy, but linking the processes can also allow for further reductions to be accommodated when processing in a single location. With less handling and closer communication up and down the supply chain can lead to a more consistent profile quality. A single company that controls the entire process from start to finish has a vested interest in reducing wastage, minimising energy use and providing an optimised system, often bespoke on a project per project basis.

Aluprof, as a vertically integrated systems supplier encompass the development and production of various systems for applications in a wide range of building projects. In the UK & Ireland Aluprof UK offers local support to specifiers and contractors. Aluprof UK place more emphasis on flexibility with their ‘Tailored Solutions’ approach. For example, by having an experienced and extensive design team in Poland, Aluprof UK can quickly create bespoke profiles to suit any project. With an experienced design team in the UK Aluprof will collectively work with architects and fabricators to agree a solution which carries Aluprof’s warranty into the project which is passed onto the client.

All customers in the UK & Ireland enjoy weekly deliveries direct from Aluprof’s distribution centre based in Poland. Delivering directly to the customer reduces lead times, reduces handling damage and saves carbon, compared to double-handle project-specific material, such as delivering to a UK warehouse and then onto a further delivery vehicle for final delivery. Aluprof also ship orders complete, which enables the fabricator to schedule fabrication from delivery, rather than having to check and wait for all the materials to arrive. Both these approaches to supply, significantly reduce lead times allowing the fabricator to get products installed on site quicker and hopefully help improve cash flow throughout a contract.

Aluprof also recognised that not all fabricators can put on extra shifts to meet busy times as production facilities often utilise a lean working ethic to maintain competitiveness. To assist fabricators, Aluprof introduced a fabrication facility in Poland that can support fabricators in manufacturing some of the supplies at their request. This has proven to be a real benefit to customers who contract and often use this facility to manufacture the more difficult constructions required on a project.

Value Management, which encompasses Value Engineering, looks at every process from order through to completion. To begin with, an overview of the complete project programme is needed, with each of the processes and deadlines for completion itemised. It is at this stage that options are discussed. One of the obvious choices is that of the systems to be used for the windows, doors or facade. As a high end systems company, Aluprof offer their systems in various designs to meet the exact needs of the building. An example of this can be seen in Aluprof's popular MB-SR50N Curtain Wall system, far from being a single system there are many options to choose from, these include various insulation levels, capping options or structural arrangements, each choice represents a cost or a cost saving. It's a little like specifying options on a new car taking the base model of choice as a starting point.

A further consideration is the optimisation of aluminium profile cutting. To reduce wastage on fabrication, profiles can be extruded to special lengths which offer high levels of cutting optimisation which in turn reduces material waste, which then reduces costs. These are just some of the important issues that are reviewed in the Value Management process which ensures that the completed project performs exactly as specified and perfectly meets with the clients' expectations.

So, from specification through to installation, the Aluprof team in the UK ‘partners’ with specifiers and customers to ensure that system supply is value managed, minimising cost and carbon footprint. Aluprof UK believe this ‘Value Management’ strengthens the relationship with customers who then often request Aluprof to partner them on projects that they have secured.

Aluprof are proud to be one of Europe's largest aluminium systems companies. Specification support is available through the company’s website at aluprof.co.uk, directly from their UK head office in Altrincham or from their London office at the Building Design Centre by phoning +44 (0) 161 941 4005.

0 notes

Text

Enhancing Your Business Environment with PVC Strip Curtains

In today’s fast-paced business world, maintaining an efficient and organized workspace is crucial. One of the simplest yet most effective tools for achieving this is the PVC strip curtain. Whether you're looking to improve energy efficiency, hygiene, or workflow, PVC strip curtains offer a versatile solution that can be tailored to your specific needs. Here’s everything you need to know about the benefits and applications of PVC strip curtains.

What are PVC Strip Curtains?

PVC strip curtains are made from flexible polyvinyl chloride (PVC) strips that hang vertically and overlap to form a barrier. These curtains are designed to separate different areas within a facility while allowing easy passage for people and equipment. The transparency and flexibility of PVC strip curtains make them an ideal solution for a variety of commercial and industrial environments.

Key Benefits of PVC Strip Curtains

Energy Efficiency

One of the most significant advantages of PVC strip curtains is their ability to conserve energy. By acting as a barrier between different temperature zones, PVC strip curtains help maintain the desired climate in specific areas. This is especially beneficial for businesses with refrigerated sections or heated workspaces, as it reduces the strain on HVAC systems and lowers energy costs.

Improved Hygiene and Cleanliness

PVC strip curtains are an excellent way to keep out dust, dirt, insects, and other contaminants. This makes them ideal for use in environments where cleanliness is paramount, such as food processing plants, pharmaceutical facilities, and healthcare settings. By maintaining a cleaner environment, PVC strip curtains help businesses comply with hygiene standards and regulations.

Noise Reduction

In noisy industrial settings, managing sound levels is essential for maintaining a safe and productive workspace. PVC strip curtains act as sound barriers, helping to reduce noise pollution and create a quieter work environment. This can enhance employee comfort and productivity, particularly in manufacturing and assembly areas.

Enhanced Workflow and Accessibility

Unlike solid doors, PVC strip curtains allow for easy and quick access between different areas without the need to open and close doors. This seamless transition is especially beneficial in high-traffic zones where efficiency is critical. Workers and equipment can pass through with minimal disruption, thereby improving overall workflow.

Versatility and Customization

PVC strip curtains are highly versatile and can be customized to fit any size or type of opening. Whether you need a small curtain for a doorway or a large partition for a loading dock, PVC strip curtains can be tailored to meet your specific requirements. Various options are available in terms of strip width, thickness, and color to suit different applications.

Common Applications of PVC Strip Curtains

PVC strip curtains are used across a wide range of industries due to their adaptability and effectiveness. Some common applications include:

Warehouses and Distribution Centers: To separate different zones and maintain temperature control.

Food Processing and Storage: To ensure hygiene and temperature stability in cold storage rooms.

Retail and Supermarkets: To divide storage areas from sales floors while maintaining accessibility.

Factories and Workshops: To reduce noise and prevent cross-contamination of materials.

Restaurants and Kitchens: To maintain cleanliness and separate kitchen areas from dining spaces.

Choosing the Right PVC Strip Curtains

When selecting PVC strip curtains for your business, consider the following factors:

Quality of Material: Ensure that the PVC strip curtains are made from high-quality, durable PVC that can withstand the demands of your environment.

Appropriate Size and Thickness: Choose the right size and thickness of the strips based on the level of insulation and durability required.

Ease of Installation and Maintenance: Opt for PVC strip curtains that are easy to install and maintain. Look for systems that allow for quick replacement of individual strips if needed.

Customization Options: Work with suppliers who offer customization to tailor the PVC strip curtains to your specific needs.

Conclusion

PVC strip curtains provide a cost-effective and practical solution for improving energy efficiency, hygiene, noise reduction, and workflow in various business environments. Their versatility and ease of use make them a valuable investment for any industry looking to optimize operations and create a more organized and efficient workspace.

By choosing high-quality PVC strip curtains and implementing them effectively, you can enhance the overall functionality and productivity of your facility. Whether you’re managing a bustling warehouse, a busy kitchen, or a temperature-sensitive storage area, PVC strip curtains are an indispensable tool for modern businesses.

0 notes

Text

Pre-Engineered Steel Building Manufacturer in Uttar Pradesh

To work with a pre-engineered steel building Manufacturer in Uttar Pradesh is a modern technology where the complete designing is done at the factory and the building components are brought to the site in CKD (completely knock down condition) and then fixed/jointed at the site and raised with the help of cranes.

An efficiently designed pre-engineered building can be lighter than conventional steel buildings by up to 30%. Lighter weight equates to less steel and potential price savings in the structural framework.

Advantages of Work With Best Pre Engineered Steel Building Manufacturer in Uttar Pradesh

Reduction in Construction Time Buildings are typically delivered in just a few weeks after approval of drawings. Foundation and anchor bolts are cast parallel with finished, ready for the site bolting. In India, the use of PEB will reduce the total construction time of the project by at least 50%. This also allows for faster occupancy and earlier realization of revenue.

Lower Cost

Due to the systems approach, there is a significant saving in design, manufacturing and on-site erection cost. The secondary members and cladding nest together reducing transportation cost.

Flexibility of Expansion

Buildings can be easily expanded in length by adding additional bays. Also, expansion in width and height is possible by pre-designing for future expansion.

Larger Spans

Buildings can be supplied to around 80M clear spans.

Quality Control

As buildings are manufactured completely in the factory under controlled conditions the quality is assured.

Low Maintenance

Buildings are supplied with high-quality paint systems for cladding and steel to suit ambient conditions at the site, which results in long durability and low maintenance costs.

Energy-Efficient Roofing and Wall Systems

Buildings can be supplied with polyurethane insulated panels or fiberglass blankets insulation to achieve required “U” values.

Architectural Versatility

The building can be supplied with various types of fascia, canopies, and curved eaves and are designed to receive precast concrete wall panels, curtain walls, block walls, and other wall systems.

Single Source Availability

As the complete building package is supplied by a single vendor, compatibility with all the building components and accessories is assured. This is one of the major benefits of pre-engineered building systems.

Application of Pre-Engineered Steel Building

Factories

Warehouses

Cold Storage

Houses & Living Shelters

Sports Halls ( Indoor and Outdoor)

Aircraft Hangers

Supermarkets

Workshops

Office Buildings

Labor Rooms

Petrol Pumps/Service Buildings

Schools

Community center

Hospital

Bus Stand

Railway Station

Originally published at https://creativepeb.com/pre-engineered-steel-building-manufacturer.html

0 notes

Text

Aluminium Rolling Shutter Manufacturers In Chennai

Aluminium Rolling Shutters and Features

The roller shutter or roller door or sectional door is a type of door or window shutter that consists of many horizontal slats (rod or net systems) connected by hinges. The door is opened by lifting it and closed by bringing down it. For large doors, the movement can be motorized. The rolling shutter provides protection from wind and rain. In the form of roller shutters, they are used in front of windows to protect them from vandalism and break-in attempts.

Aluminum roller doors are the ideal solution for industries where excellent insulation values, operational reliability, and lasting quality are paramount. Olympic Shutters Company is one of the most reliable aluminium rolling shutter manufacturers in Chennai that fully meet these requirements and also provide protection against burglary, vandalism, and storms.

Features of Aluminum Rolling Shutters

· Safety - Roller doors are made of sturdy metals such as steel or aluminum.

· Visual deterrent

· Weather protection

· Fire protection

· User friendly

· Insulation

· You can control the amount of light in your building.

· Rust and scratch protection

Aluminum roller shutters are widely used in a variety of applications such as windows, doors, service areas, kitchens, parking lots, offices, stores, warehouses, and other facilities. Being one of the best aluminium rolling shutter manufacturers in Chennai, the aluminum roller shutters offered by us are aesthetically designed and manufactured using high-quality raw materials and advanced technology, strictly adhering to defined industry standards and guidelines.

Its designed insulated aluminum roller shutters for customers have the objective of saving energy resources. It is designed for those who need to save on utility bills as it retains heat and cools. Also used as "premium" curtains, they block almost 100% of all light. This is perfect for the people who live in big cities. Its products are highly praised for their corrosion resistance, durability, robust construction, long service life, and high strength.

0 notes

Text

What are Industrial Impact Doors?

Industrial impact doors or crash doors are used in industries that require easy access between two areas, for workers, products, and machinery such as forklifts. What makes these doors different from your ordinary door, is the fact that they're more heavy-duty, and designed to withstand the roughest of environments. Not only do they offer visibility for users, but they are one of the most practical and economical solutions to reducing noise pollution and temperature control. In this blog post, I am going to list the top types of impact doors available on the market and what materials they are made out of. Have you noticed any impact doors on your premises? If not, now might be the time to benefit from them!

Leading Impact Door Suppliers UK

If you type impact doors into the search panel of your browser, there will be hundreds of companies that will appear, but which one do you choose? From my personal experience, I recommend Rayflex Group, one of the UK's leading manufacturers of high-quality and robust PVC products, doors, and curtains. All of their goods can be made-to-measure making them excellent for those awkwardly shaped or hard to get to places. It is definitely worth checking them out if you're looking for any industrial products!

Each type of door is suitable for different environments, so it is important that you purchase the best one for you. The door material will depend on the size of the entranceway, the level of traffic, and the traffic type such as people or machinery. However, there is one specification that you should all consider, and that is the environment where you are installing the doors. Impact doors are popular for cold store rooms, supermarkets, hospitals, warehouses, manufacturing plants, and many more!

Common Designs

PVC

For light and medium-duty locations, PVC doors are an excellent choice for full visibility and temperature control. As PVC is relatively lightweight, both people and products can easily pass through the doors with little force. These are commonly used in supermarkets and cold store rooms where more visibility is required, plus, as they don't need to be opened by hand, they are great for workers holding food goods and pallets. As they close by themselves, they help to regulate temperatures by keeping the heat in or out, also offering a range of economical and energy-saving benefits.

Coloured

You can also find colourful impact doors to purchase, which tend to be made from coloured PVC and stainless steel hinges. Even though these could be installed just for aesthetics, they can also help to denote areas of high or low-risk operations, which helps visitors and workers to avoid certain areas if necessary.

Insulating

Heavy-duty insulating doors are great for their cost-effectiveness, as you may have guessed, they are designed for energy-saving purposes to act as a thermal barrier in industrial locations.

You can acquire these doors with a combination of panel formats, which you can request depending on how much visibility you need. For example for locations which experience a substantial volume of traffic, you will need an incredibly durable and robust door. To make sure the door will withstand the test of time, the bottom of the door can be made out of thick material, whilst you can have window-like panels made out of clear PVC for users to see through.

Utilising these kinds of doorways can be very beneficial to your business, and as a bonus, they do not cost a lot!

https://rayflexgroup.co.uk

0 notes

Text

Insulator Warehouse Curtain Manufacturers

Insulator Warehouse Curtain Manufacturers - The insulated warehouse curtain wall, helps warehouses and distribution centers create temperature-controlled areas, conserve energy, and maximize their space. InsulWall is the only flexible, insulated curtain wall manufactured with recycled insulation making it a LEED-contributing product. With the ability to move, reconfigure, and adjust quickly to seasonal inventory, learn how InsulWall is being used in a variety of industries and applications to separate space, temperature, and humidity.

#Birds Entry Control Strip Curtain Manufacturers#Pvc Industrial Strips For Factory Gates Manufacturers#Climate Control Strip Curtain Manufacturers#Dock Levelers Shelter Manufacturers#Industrial Curtain Hanger Manufacturers

1 note

·

View note

Text

WHAT IS A CLEANROOM?

A clean room is a controlled environment where pollutants like dust, airborne microbes, and aerosol particles are filtered out in order to provide the cleanest area possible. Most cleanrooms are used for manufacturing products such as electronics, pharmaceutical products, and medical equipment. A cleanroom can be classified into different levels of contamination depending on the amount of particles allowed in the space, per cubic meter. Cleanrooms also control variables like temperature, air flow, and humidity.

HOW DOES IT WORK?

Essentially, cleanrooms work to remove pollutants, particles, and contaminants from outside ambient air. Outside air is first circulated to a filter system. The filters (either HEPA or ULPA) then clean and decontaminate this outside air according to their specifications. The filtered air is then forced into the cleanroom. Additionally, contaminated air within the cleanroom is forced outside the room by registers, or it is recirculated back into the filters, and the process restarts.

WHO NEEDS A CLEANROOM?

There are a wide variety of reasons that a company may need a cleanroom. If you’re manufacturing something that is easily affected by contaminants or particles in the air for example, it’s likely that you’ll need a cleanroom. If you’re not sure, or if you’d like an estimate, give the experts at Angstrom a call. Here are a few common reasons you might need a cleanroom, and some common industries that regularly use cleanrooms:

Manufacturing Companies

Research Facilities

Pharmaceutical Companies

Medical Laboratories

Electronic Part Production

What is a sandwich panel?

A sandwich panel is a product used to clad the walls and roofs of buildings. Each panel comprises a core of thermoinsulating material, skinned on both sides with sheet metal. Sandwich panels are not structural materials but curtain materials. The structural forces are carried by the steel framework or other carrier frame to which the sandwich panels are attached.

The types of sandwich panel are generally grouped by the thermoinsulating material used as the core. Sandwich panels with cores of EPS (expanded polystyrene), mineral wool and polyurethane (PIR, or polyisocyanurate) are all readily available.

The materials mainly vary in their thermal insulating performance, sound insulating performance, reaction to fire and weight.

Why use sandwich panels anyway?

Sandwich panels are widely acclaimed due to a number of benefits, mainly those related to cost. Comparisons between frame or stud partition technology (frames lined with sandwich panels) and traditional building technologies based on masonry walls reveal advantages of sandwich panels in three key areas:

1. Direct costs

Construction of a building in either technology requires similar capital expenditure levels. The comparison in this area includes the costs of construction materials, labour and shipping.

2. Construction time

A building based on a traditional masonry process may take 6 to 7 months to complete. A building of the same volume utilising stud partitions takes just 1 month to complete. The construction time is business-critical. The sooner a production building or warehouse is commissioned for use, the sooner a return on the investment can be achieved.

Stud partition buildings are assembled rather than “built”. The finished structural parts and cladding components arrive on site, and are then assembled like a house of toy bricks. Another plus is that there is no need to wait for the building shell to lose excess moisture.

3. Construction processes

In some sectors of industry, the construction requirements can be critical for a building project. Stud partition construction is a ‘dry process’, with no water needed for the construction materials. A dry process requires only the assembly of the structure and fixing of the cladding (here, the sandwich panels) with screws.

Traditional masonry construction uses ‘wet processes’, which require significant amounts of water to make the mortar for bricklaying, concrete for casting or the plaster for rendering.

Some sectors of industry, like wood processing or pharmaceutical manufacture, require fixed and controlled relative humidity levels, which preclude wet construction processes.

Pass box is one of the cleanroom systems, which is used to transfer materials from one side to other side through controlled environment in order to avoid airborne cross contamination. As the name states itself, the primary and only work of a pass box is to pass material from one side to other without raising contamination concern and if any particulate matter presents on the material surface, it swipes away during the operation. Interlocking door mechanism is the prime feature of a pass box, when door at one side is open the door at other side remains closed. It is popular with other names such as cleanroom pass through, clean transfer window and transfer hatch; in addition, it is widely used in microbiology laboratories in food, pharmaceutical and chemical industries.

A pass box is designed in two different types; static and dynamic, it is the user specific requirement which decides the right design configuration. The difference between these two is explained as:

DYNAMIC PASS BOX (DPB)

A dynamic pass box is fitted between classified and non-classified areas. Material is passed through vertically HEPA filtered air.

STATIC PASS BOX

Static pass box on the other hand is fitted only between two clean room areas and has no air supply or extract. It is also known as passive pass box and equipped with UV light.

We are ISO certified pass box manufacturers in India. Our pass boxes deliver low noise and easy to use operation, rugged construction promises long service life. Standard size is 2 x 2 x 2 ft. or 60 x 60 x 60 cm, we also make customized pass through boxes to any customer provided size. Every box is made to comply international standards and supplied at industry leading price in India.

What Is a Clean Bench?

A

clean bench

is an enclosed laboratory bench that is designed to prevent pollution and contamination by controlling and keeping the air cleanliness level at a certain point. A clean bench is a type of laminar airflow cabinet (also known as a tissue culture hood).

Clean benches are frequently used in laboratories across a wide range of industries all over the world. These hoods utilize state-of-the-art technology in order to provide the laboratory with a clean, safe, bacteria-free environment for sensitive biological substances. The hood ensures that the operating environment is 99% free of .3 micron particles.

What Exactly Does a Clean Bench Do?

Clean benches prevent dust, smoke, bacteria, microorganisms, and other undesired dirt in the air from contaminating the biological materials and samples that the lab worker is currently working on. The HEPA filter, which is a high-efficiency mechanical filter, lets the air through, cleaning it and directing the air flows right to the substances. A clean bench can maintain a high level of air cleanliness even in a significantly polluted environment.

Does a Clean Bench Protect the Worker Too?

A clean bench only provides protection for samples, substances, and materials that are being worked on, as it directs the filtered air across the operating surface towards the worker. These hoods can be used for particular cleaning operations, such as the dust-free assembly of sterile facilities or electronic devices. A clean bench must never be used while working with drugs, highly infectious substances, or other dangerous samples. The lab worker will be exposed to the substances, which could lead – depending on the material – to poisoning, infection, contamination, or toxicity. So, a clean bench should not be mixed up with a biosafety cabinet.

What Are the Different Types of Clean Benches?

Circulation bench: this hood allows clean air to circulate.

Light table clean bench: the workstation is made of glass or acrylic; plus, it has a fluorescent lamp.

Drainage bench: the workstation also includes a sink with a tap.

Drying bench: the infrared light allows the materials to dry quickly.

Built-in bench: floor-standing units are built into the equipment.

Exhaust bench: the air can be sucked in from the workstation or just a part of it.

Vibration-free bench: the gap between the main unit and the workstation prevents the hood from vibrating.

Why Choose Laminar Flow?

Laminar flows are used in all industries where there are high demands on the purity of the air environment. Clean benches for particular environments are equipped with either horizontal or vertical laminar flow. This means that the air flows in one direction and at one speed in parallel lines without backflow. This type of protection and the right enclosure design ensures that the laminar flow protects the work on the clean bench surface. Laminar flow can carry contaminants away from the clean bench to where they can be efficiently collected by filtration and disposed of in another, even more convenient location.

Clean room doors are an essential part of cleanrooms since they are responsible for sealing the controlled environment. If they do not work properly, the cleanroom is exposed to a higher risk of contamination.

Here, Kleanlabs provide 10 key considerations when choosing a cleanroom door based on its many years in the cleanroom construction industry.

1. Completely flat surface

Opt for a door that has a completely flat surface on both sides. If there are no edges for the dust to settle in, it becomes very easy to clean and maintain exceptional hygiene. The best option is a door that has smoothly embedded windows and is completely flush with clean room walls.

2. Easy to integrate

Be aware of system dependence of cleanroom doors. Many manufacturers market doors that can only be integrated into their systems. This makes it difficult to change parameters within the facility without the cleanroom door integrity being compromised. System independent doors however, can be installed into any cleanroom regardless of the manufacturer. Kleanlabs have designed bezels that fit into any wall structure.

3. Thick door panels

Choose a door that is resistant to bending and shock. Kleanlabs recommend a thickness of 60 mm which provides both strength and reliability under most industrial circumstances. Aluminum is a particularly durable material.

4. High level of air tightness

What level of appropriate air tightness should the door have? 3,5 m3/hm2 measured at 200 Pa pressure is a reliable and good value. Some doors can be equipped with double gasket technology and an integrated sink gasket, improving air tightness even more.

5. Resistance to cleaning products

Cleanrooms are exposed to intense cleaning every day with a variety of strong chemicals to assure high levels of hygiene. Cleanroom doors, as any other cleanroom surfaces, need to be resistant to the regular usage of any cleaning products and any reaction between the door and the chemicals need to be avoided. Kleanlabs have carried out several tests to make sure that its own brand of doors resist any cleaning product used within the industry.

6. Safety glazing

In a cleanroom, safety comes first. Therefore, every part of the product should be designed to meet the highest safety requirements. Kleanlab doors are equipped with shatter proof, safety glazing, meaning if the window breaks, it stays in place and there is no risk of scatter.

0 notes

Text

Fenestration that Offers Fire and Smoke Protection

Aluminium remains the most widely specified material for commercial windows, doors and curtain wall so it should come as no surprise that leading European systems company, Aluprof, offer a comprehensive range of fire rated systems.

Until a few years ago, material choices were limited to timber and steel systems, but with advances in design and materials, aluminium framed products are now quickly becoming the specifiers choice. Aluprof have designed each of their fire rated products to perfectly complement their standard systems. So, for any part of any screen, window, door or curtain wall aluminium framing can be fire rated and can still retain the slim sight lines of standard systems. Some solutions are unique to the industry and available only from Aluprof such as the fire rated, capless silicon joint curtain wall system, MB SR50NEI EFEKT tested to EI60 class.

Aluprof’s technical brochure entitled, 'Fire Rated and Smoke Exhaust Systems', explains in detail each product and rating. Aluprof systems offer some of the highest fire protection ratings in Europe, some reaching EI120 - that's two hours fire and smoke protection. Each system has been tested according to UK industry standards with various specialist glasses and most are fully covered by the UK's 'Certifire' certificate of approval.

The company’s fire rated MB-60E EI system offers a cost effective solution for fire doors. With just a 60mm frame depth, the MB-60E EI can achieve a fire resistance class of EI15 or a EI30 according to DIN EN 13501-2 + A1. Complete with polyamide thermal breaks, the door system is ideal for use in both external or internal applications. Door sets can be manufactured with both fixed lights and opening, single or double doors, to create extensive screen assemblies.

For specification flexibility, the MB-60E EI door can be specified with glazing thicknesses of between 5 to 41 mm and can be manufactured up to 2,300 x 1,300 mm in size per door leaf. Being fully compatible with Aluprof ‘MB’ systems, specifiers do not have to sacrifice constant sight-lines between fire rated areas and normal glazing requirements.

The competitively priced MB-60E EI system joins a wide range of windows, doors, screens and curtain wall systems which can achieve ratings of up to EI60. Aluprof also offer a comprehensive RIBA approved CPD for specifiers titled ‘The Use of Glazed Screens to Control the Spread of Smoke and Fire in Buildings’.

Bringing together more than eight decades of technical industry experience, fire glass experts Pyroguard have completed an ambitious testing programme in partnership with Aluprof a new, cost-efficient, non-insulated, slimline fire-resistant glazing system for the UK and European market.

Following two years of collaboration, the new MB-45EW framing system has been developed and rigorously tested for applications where non-insulated screens and doors are required. A first for the UK market, the slim system exceeds the current ratings of E30 and EW requirements with additional radiation reduction. Suitable for internal applications, the framing system also offers a smoke-proof screen arrangement with doors, compliant with EN13502-2. Pyroguard Integrity Plus glass is the first fire glazing tested and certified for the new system delivering El 15 and EW30 fire performance along with 1B1 impact protection.

Wojciech Brozyna, Managing Director at Aluprof UK, commented: “As we strive to deliver a solution which is effective, cost-efficient and aesthetically pleasing to suit the needs of specifiers today, we had to overcome several challenges. The expertise of Pyroguard has been invaluable and by combining our efforts throughout the testing phase we have created a solution which exceeds current safety requirements to deliver advanced protection.”

“Glazing often plays a vital role in modern buildings, but meeting functional safety requirements needn’t come at the expense of aesthetics,” says Vince Crook, Technical Director at Pyroguard. “By collaborating with Aluprof, we’ve been able to develop a fully-accredited and certified framing solution which utilises the key characteristics of our high-performing products – namely design and 1B1-classified impact protection, in addition to essential EI 15 and EW30 safety requirements.”

In what is believed to be a first for the industry, the cap-less, fire rated curtain wall system MB-SR50N EI EFKT has recently been specified on a refurbishment development in Manchester. The project, known as ‘The Core’, is located at 24-30 Brown Street in Manchester city centre.

Originally built in the mid-1980s as the headquarters for law firm Halliwells, the building, also formerly known as St James’s Court, has been given an £8 million overhaul to replace the facade and re-fit the internals. The Core comprises 48,000 sq.ft of office space over six floors including a new 7,500 sq.ft roof-top extension. It is this new upper floor that proved a challenge for the architects PRP as the planners insisted on parts of the new facade would need to be fire rated due to the proximity of other buildings and future developments.

A fire rating of EI60 was required on part of the new cap-less, curved glass facade on the top floor. Aluprof’s new system, MB-SR50N EI efekt, enabled the architect to have a cap-less fire rated system whilst at the same time seamlessly blending in with areas which did not require a fire rating. Dan Holden of facade specialists Casu Consulto who designed and installed the facade takes up the story, “We were going down the route of a steel system for this project until we were introduced to this new system by Aluprof. To achieve a cap-less fire rated curtain wall system is a big development for the industry, but to be able to have the fire rated system on one side of a mullion and non-fire rated on the other side in a seamless transition, is truly impressive.”

With the old heavy red brick facade removed and window openings made much larger, the new office development has been finished to shell to allow tenants to customise their space, following the trend for more individually designed workspaces. The central light-well has been opened up and windows enlarged to further add light into all floors.

The project team for the refurbishment, managed by OBI, included PRP Architects, Russells Construction, Tier Consult as structural engineer, and REDS, M&E advisor.

Serving the whole of the UK and Ireland, Aluprof UK’s head office and warehouse facility is located in Altrincham, Cheshire. Aluprof systems are increasingly being specified on a wide range of residential and commercial projects across the UK. Systems are designed, fabricated and installed by selected, specially trained local companies, to ensure each fabricated product meets Aluprof’s exacting standards. Further information is available on the company’s website at www.aluprof.co.uk and specialist advice is available directly from Aluprof’s UK head offices on +44 (0) 161 941 4005 or from their London office, based at the Business Design Centre, Islington, on +44 (0) 207 288 6415.

1 note

·

View note

Text

Keep Your Workplace Spick and Span With PVC Strip Curtains!

PVC Strip Curtains - What Are They?

Industrial areas often use polyvinyl chloride Strip Curtains because these long and thick strips provide thermal and acoustic insulation. These strips are overlapping in such a way that they serve to regulate the temperature of an enclosed area in addition to providing a shield that absorbs high decibel noises generated at workstations.

The application of PVC Strip Curtains in various industries has expanded greatly in recent years. Using them will help keep the area within the strip clean by preventing dust and flies from entering. These strips are highly recommended in environments where hygiene is key. Pestology introduces Phthalates free PVC strips, also known as non-phthalate PVC strip curtains, which are food-grade quality, safe for humans, and environmentally friendly.

When used outdoors, they have a relatively long lifespan of three-plus years, whereas indoors, they are capable of lasting for four to five years. Employees and workers can easily push equipment through these strips during their daily work hours because the strips are highly flexible.

When a client purchases PVC Strip Curtain, the process of installation and maintenance is of primary concern. Fortunately, the installation takes just a couple of minutes per strip. Maintaining the strips is very straightforward.

PVC Strip Curtains - which industries need them?

Strip Curtains For Home create a suitable environment as a boundary between two areas. These areas may be indoors or outdoors.

1. The manufacturing of dairy products that rely on chillers, blast freezers, and refrigerated trucks can benefit from Polar Grade (Cold Storage) PVC strip curtains because they can withstand freezing temperatures of 30 degrees Celsius to 45 degrees Celsius.

2. The color amber yellow helps to preserve the temperature in restaurants, manufacturing facilities, and supermarkets. Yellow strips made from non-Phthalates are also known as anti-insect strips because of the way the color makes them appear opaque, making them repel insects.

3. Ribbed strips are used in warehouses, automobiles, textiles, and packaging industries, for example, wherever moving trucks and forklifts rub against strips. PVC Curtain Strip curtains made from non-Phthalate materials help to keep the desired temperature and prevent any pollutants from entering.

4. Transparent non-phthalate PVC strip curtains are ideal for clean rooms, pharmaceuticals, and health care facilities that require a transparent view through their curtains. You can pass through them easily and keep an eye on the other side while you are doing so.

5. A Welding Area in Research and Development Laboratories requires welded grade Non-Phthalate Plastic Door Curtains to prevent contamination and the effects of strong radiation. Employees are protected from harmful radiation exposure.

6. Checking baggage at an airport can be made easier by using Opaque Non-Phthalate PVC Strip Curtains that block out the light and give access to scanning bags and individuals.

Strip curtains made of PVC have a wide range of applications in and around industrial settings. With numerous advantages, non-phthalate Strip Curtains PVC is a great option.

#PVC Curtain Direct#pvc curtain direct#pvc strip curtains#PVC Strip Curtain#Plastic Door Curtains#Strip Curtains#PVC Curtain Strip#Strip Curtains For Home#PVC Curtains UK#Strip Curtains PVC#PVC Strip Curtains#Plastic Strip Curtains#Plastic Curtains#PVC Curtain

1 note

·

View note

Text

Loading Dock Equipment, Commercial Door Products, and Installation Services

Overhead Door Company of Charlotte, a division of DuraServ, provides Charlotte, Concord, Davidson, Fort Mill, Gastonia, Huntersville, Lake Wylie, Monroe, Mooresville, Rock Hill, and Weddington, NC with loading dock equipment, commercial door products, and installation services. We are a distributor and installer of McGuire loading dock, and Overhead Doors, LiftMaster, and TKO Dock Doors commercial doors.

Call Overhead Door Company of Charlotte today at 704-594-5094 or connect with us online to find out how we can help you.

Commercial Products

Dock Levelers & Lifts

McGuire loading dock levelers include industry-leading features which increase productivity and improve safety to the loading dock.

Mechanical Dock Levelers

McGuire mechanical dock levelers set the industry standard for durability, dependability, and safe operation. Mechanical dock levelers have a single-point adjustment extension spring counterbalance, unlimited float hold-down, an integral maintenance strut, and lip support latch features.

MP Mechanical Leveler

Hydraulic Dock Levelers

Hydraulic dock levelers provide the highest capacity rating and are designed for busy loading docks. McGuire hydraulic dock levelers are high-performance, low-maintenance, fast, safe, and have an easy push-button operation.

Autodok® H Series Hydraulic Leveler

HP Hydraulic Leveler

Air Powered Dock Levelers

McGuire Air Powered dock levelers are safe, easy to operate, and with advanced technology used in heavy-lifting industries. It offers a low-maintenance solution and operational efficiency. A simple push-button activation rises the deck effortlessly.

CentraAir® Air Powered Leveler

MA Air Powered Leveler

Specialty Dock Levelers

McGuire specialty dock levelers deliver reliable powered up and powered down performance.

VSH Vertical Storing Leveler

Portable Steel Yard Ramp

RRH Hydraulic Rail Ramp

Edge of Dock Levelers

Edge of dock levelers provide accessibility to docks and permit the safe and efficient transfer of products.

HED Hydraulic EOD Leveler

MEDLF Mechanical EOD Leveler

Dock Seals & Shelter

Dock seals or shelters cover the gap between a dock and a trailer by creating an extension of a facility that seals the top, sides, and back of a trailer.

Dock Seals

McGuire dock seals create an airtight seal between a dock system and trailer.

TS101 Fixed Head

TS103 Curtain Head

TS500 CWT Adjustable Head

Dock Shelters

McGuire dock shelters enclose trailer tops and sides for ultimate sealing efficiency. Dock shelters offer reliable performance and protection from compression and reversing trailers.

TC300 Flexible Steel Frame

TC400 Rigid Wood Frame

TC900 Soft Sided

TC1000 Weather Sentry™

Safety Equipment & Truck Restraints

Loading dock safety equipment prevents dock accidents during loading and unloading.

Vehicle Restraints

Vehicle restraints keep a truck or trailer stationed at the dock.

Hold-Tite® Push Button Vehicle Restraint

Stop-Tite® Manually Operated Vehicle Restraint

Stop-Tite® Push Button Vehicle Restraint

TPR® Automatic Vehicle Restraint

TPR UniLock® Automatic Vehicle Restraint

Light Communication System

Light communication systems improve security and productivity at the loading dock.

Edge Lights

Light Communication System (LCS)

Safety Barriers

Safety barriers protect personnel, goods, and equipment from accidentally rolling off the dock.

Bar Lift Barrier

Barrier Lip Leveler

Commercial Door Products

Rolling Steel Doors

Overhead Door carries a full line of rolling steel doors including coil-away rolling steel service doors, rolling fire counter doors, rolling steel fire doors, insulated rolling steel fire doors, rolling steel service doors, and rolling sheet doors. Rolling steel doors provide long-lasting performance and are reliable solutions for self-storage facilities, warehouses, pharmacies, hospitals, offices, schools, and retail businesses.

Overhead Door – Fireking 630 Series – Insulated Rolling Steel Fire Rated Service Door

Overhead Door – Fireking 630 Series – Rolling Steel Fire Rated Service Door

Overhead Door – Fireking 631 Series – Rolling Steel Fire Rated Service Door

Overhead Door – Fireking 634 Series – Rolling Steel Fire Rated Service Door

Overhead Door – Model 600 Coil–Away Rolling Steel Service Door

Overhead Door – Model 610 Rolling Steel Service Door

Overhead Door – Model 620 Stormtite Rolling Steel Service Door

Overhead Door – Model 625 Stormtite Insulated Rolling Steel Service Door

Overhead Door – Model 640 Rolling Fire Counter Door

Overhead Door – Model 641 Stainless Steel Rolling Fire Counter Door

Overhead Door – Model 660 Integral Frame Rolling Fire Counter Door

Sectional Doors

Overhead Door Company of Charlotte carries Overhead Door commercial sectional doors include aluminum full view sectional doors, insulated sectional doors, steel sectional doors, screen doors.

Overhead Sectional Doors

Overhead Door™ sectional steel and insulated steel doors are economical, durable, and reliable. An assortment of door panel profiles, track and hardware, and specialized options allows the further customization of doors to your specific project requirements.

Overhead Door – Model 416 Steel Sectional Door

Overhead Door – Model 430 Steel Sectional Door

Overhead Door – Model 418 Insulated Steel Sectional Door

Overhead Door – Model 420 Steel Sectional Door

Overhead Door – Model 422 Insulated Steel Sectional Door

Overhead Door – Model 424 Steel Sectional Door

Overhead Door – Model 426 Insulated Steel Sectional Door

Overhead Door – Model 432 Insulated Steel Sectional Door

Overhead Door – Model 511 Aluminum Sectional Door

Overhead Door – Thermacore 591 Insulated Sectional Door

Overhead Door – Thermacore 592 Insulated Sectional Door

Overhead Door – Thermacore 593 Insulated Sectional Door

Overhead Door – Thermacore 594 Insulated Sectional Door

Overhead Door – Thermacore 595 Insulated Sectional Door

Overhead Door – Thermacore 598 Insulated Sectional Door

Overhead Door – Thermacore 599 Insulated Sectional Door

Screen Doors

Screen doors are an economical solution for screening bugs, birds, and other unwanted pests from your industrial facility.

Bug Blocker Sectional Screen Door

Screen Pro Roll-Up Bug Door

Knock Out Doors

Knock out doors, the most rugged option, are designed to prevent damage to door panels and tracks when impacted. Knock out doors are the best solution for damaged dock doors in busy loading docks.

Pflow Model M Vertical Lift System

TKO Cruiserweight Knock-Out Door

TKO Thermalweight Knock-Out Door

TKO Welterweight Knock-Out Door

High-Performance Doors

Overhead Door high-performance doors optimize efficiency, improve production flow, operate quickly, raise the number of opening and closing cycles, and require less maintenance and repair cost.

High Speed Exterior Rubber Door – 990

High Speed Exterior Rubber Door – 991

High Speed Exterior Rubber Door – 992

High Speed Exterior Rubber Door – 993

High Speed Exterior Rubber Door – 994

High Speed Exterior Rubber Door – 995

Door Operators

Commercial door operators provide security and reliability for business facilities. Overhead Door and LiftMaster door operators have a compact design, an emergency chain hoist with an electric interlock, and with adjustable friction clutch.

Liftmaster 115v Hoist Logic Operator

Overhead Door RHX™ Heavy Duty Commercial Operators

Overhead Door RMX™ Medium-Duty Commercial Operator

Overhead Door RSX™ Standard Duty Commercial Operator

Aftermarket Products

Aftermarket products prevent energy loss and ensure dock personnel and equipment are protected from accidents.

Energy Saving Products

APS LED Guide Lights

APS E-Saver LED Bulb

APS Turbo-ES™ Fan

ENERGY GUARD® Retrofit Kit

G-Flex LED Dock Light™

High Impact LED™ Dock Light

Rytec Turbo Seal INSULATED Door

Serco Energy Guard™

Serco S1000 Ultra Seal w/ fixed head pad

Equipment Upgrades

APS Air Bag Conversion Kit

APS Flexback Panel

APS Hydraulic Conversion Kit

Industrial Fans

Industrial fans are High-Volume, Low-Speed Fans that efficiently move air through an industrial space. HVLS fans are ideal in climate-controlled and non-conditioned areas.

Aeratron

AirVolution

AirVolution-D 370

AirVolution-D 550

AirVolution-D 780

Loading Dock Equipment and Commercial Doors Uses

Auto Dealers

Cold Storage

Distribution Centers

Energy Efficient Facilities

Food & Beverage Plants

High Security Areas

Industrial Operations

Manufacturing Facilities

Parking Garages

Pharmaceutical Facilities

Retail Businesses

Service Centers

Transportation & Transit

Warehousing Facilities

North Carolina’s Most Trusted Loading Dock and Commercial Door Distributor and Installer

Overhead Door Company of Charlotte, a division of DuraServ, supplies loading dock equipment and commercial doors products to Charlotte, Concord, Davidson, Fort Mill, Gastonia, Huntersville, Lake Wylie, Monroe, Mooresville, Rock Hill, and Weddington, NC. With skilled technicians, fully equipped service trucks, and an expansive loading dock equipment and door parts inventory, Overhead Door Company of Charlotte is a company you can depend on.

Whether you need a simple part or searching for efficiency and safety improvements to a current loading dock design, turn to Overhead Door Company of Charlotte!

Call Overhead Door Company of Charlotte today at 704-594-5094 or connect with us online to discover safe, smooth, and cost-effective loading dock equipment, commercial door products, and installation services.

#loading dock system Charlotte#McGuire mechanical dock levelers Charlotte#McGuire hydraulic dock levelers Charlotte#McGuire air powered dock levelers Charlotte#McGuire specialty dock levelers Charlotte#mechanical dock levelers Charlotte#hydraulic dock levelers Charlotte#air powered dock levelers Charlotte#specialty dock levelers Charlotte#edge of dock levelers Charlotte#dock seals Charlotte#dock shelters Charlotte#McGuire dock seals Charlotte#McGuire dock shelters Charlotte#vehicle restraints Charlotte#light communication systems Charlotte#safety barriers Charlotte#McGuire vehicle restraints Charlotte#McGuire light communication systems Charlotte#McGuire safety barriers Charlotte#aftermarket products Charlotte#industrial fans Charlotte#commercial sectional doors Charlotte#rolling up doors Charlotte#high speed doors Charlotte#door operators Charlotte#Overhead Door rolling doors Charlotte#Overhead Door sectional doors Charlotte#Overhead Door high speed doors Charlotte

0 notes

Text

Aluminum angle of medical equipment aluminum profile Medical grade aluminum guangyuan-alum.com profile

Product Introduction

Aluminum angle of instrument aluminum profile_ 24-hour telephone / wechat: 13143881116 manager

the online price is for reference only. The actual price is subject to the following list on the same day, welcome to discuss!!!

Guangdong Zhongya Aluminum Co., Ltd. (brand: Yaya brand) is located in Dawang high tech Industrial Development Zone, Zhaoqing, Guangdong Province, adjacent to the Asian industrial city. It is one of the current aluminum profile manufacturers. The plant covers an area of 806 mu, which is 6 times larger than that of the old plant. The total investment of the project is 80 million US dollars, and the annual output is 150000 tons.

1. The company's products mainly include: aluminum alloy anodized profiles, guangyuan-alum.com</a> electrophoretic coating profiles, powder spraying profiles, fluorocarbon paint spraying profiles, wood grain profiles, threading insulation profiles, cast insulation profiles, and various industrial aluminum alloy profiles.

2. The factory has complete production equipment, including 38 extruders from 500 tons to 6000 tons, 8 powder / fluorocarbon spraying lines, 2 oxidation electrophoresis workshops, deep processing workshops, mold center, quality inspection center, environmental protection and energy-saving melting and casting furnace, aluminum rod homogenizing furnace, long ingot shearing machine, double traction machine, polishing machine, sanding machine and other new equipment.

aluminium frame solar panel</a>

process flow

< common questions]

﹥ br >

< 1;

2. Alloy model: 6063-T5, 6061-T6, etc.

3. Production cycle: 10-15 working days shall prevail when the formal order is issued, and the special situation shall be subject to the confirmation of both parties;

2

4. Ordering requirements: the order quantity of conventional profiles is 500kg (except for the first sample sheet);

5. Packaging method: adopt national standard packaging, including shrink film inside, paper wrapping and other packaging methods;

and 6. Pricing method: according to the actual weighing weight (the weight difference is calculated according to the national standard of 3 ‰) or the actual delivery quantity of finished products;

delivery requirements 8. Mold matters: after both parties confirm the mold drawing, if we have conventional mold, we can directly receive the order production. If the mold drawing needs to be confirmed by both parties, and the mold opening will be arranged after our company receives the full mold fee from your company. The mold opening time is 10-12 working days. The blank head within 1 meter will be provided free of charge to your company for confirmation. If it is more than one meter, it will be sold according to the normal unit price.

after the mold test, the blank 9. Payment method: 30% of the total payment should be paid in advance to our company when the formal order is issued. After the profile production is completed, the remaining payment shall be paid with the product warehouse receipt, and the relevant shipment shall be arranged immediately.

10. Quotation method: aluminum ingot price + processing fee (the price of aluminum ingot is subject to the quotation of Nanhai Lingtong information on the same day) or the quotation of finished products according to the drawings.

11. The length of profile: generally controlled at 3-6M, and other lengths shall be subject to the confirmation of both parties.

[contact information]

﹤ br > { Company Name: Shenzhen Zhongya Aluminum Co., Ltd

Contact: Mr. Fang (Manager)

Tel: 0755 89554859

Mobile: 13632919686

Fax: 0755 89554659

address: 19 / F, Rongchao financial building, Dayun new town, Longgang District, Guangdong

Central Asia Aluminum is committed to the R & D and pursuit of product quality, product quality is our guarantee for every customer. Whether it is modern buildings, commercial and residential buildings, or common civil doors and windows, industrial profiles, our company has done a good job: all levels of aluminum profiles to meet the needs of its customers, to provide customers with cost competitive advantage of high-quality aluminium extrusion heat sink profiles</a> profiles!

Welcome to our company's door and window, curtain wall profile atlas, oxidation electrophoresis color plate atlas.

Welcome users to send letters, calls, orders, samplesIt's customized.

We are looking forward to your coming!

..................................................................................................

0 notes

Text

Tips in Developing Your Warehouse Food Safety Plan in Texas

A warehouse or distribution center that caters food is very sensitive that mandatory requires utmost care and protection.

The pieces of equipment to be installed in a food warehouse or distribution should be assembled particularly for this specific purpose only. Otherwise, your food will be subjected to food contamination.

A contamination risk has always been experienced by the different food manufacturers including the functions that carry or load food products. This undertaking should always be in line with the guidelines being observed by the Food and Drug Administration (FDA) Food Safety Modernization Act (FSMA) to be considered compliant. This process is been formulated to prevent the proliferation of foodborne illnesses.

With the serious observance of FSMA, it elevates the safety level of these facilities into a safe zone against contamination. For instance, in the presence of a broken door in Texas, the owner of the facility must undertake a corresponding spring repair in Texas.

DuraServ is the leading service provider in the loading dock, door and equipment industry across the United States and Canada.

What is a warehouse or distribution center?

A warehouse or distribution center is a specialized demand-driven building that is engineered to integrate a refrigeration system or air-conditioning, which stocked goods for redistribution purposes to the retailers and wholesalers.

This facility is designed for perishable goods only and a special door is highly recommended to be installed to sustain and promote the freshness of the products.

What is STHAF rule?

The Sanitary Transport of Human and Animal Food (STHAF) is one of the reforms being advocated by FSMA and as a matter of fact, it is one of the latest regulations being undertaken to get hold of the enforcement phase.

What kind of roll-up door suitable for the warehouse or distribution facility?

There are several types of roll-up doors designed for this facility. The best ones are being offered by DuraServ Corp and they are as follow but not limited to:

1. Wayne Dalton – Model 800 Rolling Steel Service Door The Wayne Dalton Model 800 Rolling Service Door is designed to meet the tough requirements of virtually any commercial or industrial application. Model 800 offers flexibility in substrate materials with choices of galvanized or prime steel, stainless steel, or aluminum.

Common Applications · Distribution Operations · Retails Outlets · Industrial Operations

2. Wayne Dalton – Model 900 Rolling Steel Service Door

Wayne Dalton’s Model 900 Rolling Service Door is ideal for jobs where an economical solution, as well as durability and strength, are needed. This door offers flexibility in curtain materials with choices of galvanized steel, stainless steel, or aluminum.

Common Applications · Warehouse and Industrial spaces · Manufacturing facilities · Food and Beverage facilities

3. Model 625 Stormtite Insulated Rolling Steel Service Door

The Model 625 rolling steel doors are an insulated, heavy-duty rolling service door that is an ideal choice for applications requiring a moderate level of thermal protection.

· Designed in sizes up to 30’4″ wide and 28’4″ high (9246 mm and 8636 mm) · Constructed with a CFC-free · Foamed-in-place polyurethane insulation · Vinyl weatherstripping on the bottom bar · Exterior curtain-side guide · Hood baffle provides additional protection against air infiltration.

Common Applications · Distribution Operations · Safety and Security · General Warehousing · High-Security Facilities

4. Overhead Door- Model 640 Rolling Fire Counter Door

This fire-rated counter door features 22-gauge primed galvanized steel and is ideal for applications where safety is as important as style. A host of standard and optional features further improve the performance of these doors beyond the norm in fire-rated applications. This fire-rated counter door has exposed components made of primed galvanized steel.

Common Applications · Grocery Store · High-Security Facilities · Manufacturing · Safety and Security · Food and Beverages · General Warehousing

For the complete list of commercial rolling steel doors, click here.

DuraServ Corp offers comprehensive loading dock, leveler, and door service coverage. Fully trained and certified technicians. 24/7/365 availability. We deliver service on a national scale to customers with large facilities, often in multiple locations, across the United States, and in Canada. Some of our key employees have over 40 years of experience and represent some of the most knowledgeable people you’ll find in the loading dock and door industry.

We carry a wide array of high-quality products including the commercial door and fire doors in Texas. Also we undertake the fire door repair, ramp service in Texas and emergency service in Texas.

Our company is the best option in cases your need arises to get hold of the emergency parts and service of roll-up doors including the broken spring in Texas.

Further, we undertake a professional repair service of a broken overhead door in Austin. For more details, please visit our official website to learn more.

If you have a question about our products and services, you may contact us at the telephone number 800-994-2361. You may also reach us online.

We have several service centers to provide you with the utmost assistance. Service areas include Fort Worth, TX, Houston, TX, Austin, TX, Dallas, TX, San Antonio, TX, Shreveport, LA, Baton Rouge, LA, New Orleans, LA, Atlanta, GA, Savannah, GA, Orlando, FL, Tampa, FL, Jacksonville, FL, Fort Myers, FL, Naples, FL, Miami, FL, Charlotte, NC, Angier, NC, Farmville, NC, Greater Hickory, NC, Sterling, VA, Baltimore, MD, Jamesburg, NJ, South Windsor, CT, Phoenix, AZ, Philadelphia, PA, and Toronto, CA.

0 notes

Text

Tailored Solutions

by Wojciech Brozyna - MD of Aluprof UK

Buying from a systems company offers an immediate partnership between the fabricator and supplier. This bond can become very strong over time as both systems company and fabricator work together to gain specification and supply architectural aluminium installations. Typically the systems company supplies an ‘off the shelf’ tried and tested aluminium system, be it a door system, windows or curtain wall, complete with detailed fabrication information which can include tooling and even fabrication software.

The procurement process is mainly one way, from systems company to fabricator, with system construction being prescriptive in order to meet the outline of the tests that the systems comply with. The benefit to the systems company is that they can share all the legislative and testing costs across many projects and customers, this keeps costs down. For the fabricator, to have a range of systems off the shelf is certainly much more competitive than having to try and design their own bespoke systems.

At Aluprof we have placed more emphasis on flexibility with our ‘Tailored Solutions’ approach. For example, by having an experienced and extensive design team in Poland, coupled with our own Polish extrusion facility we can quickly create bespoke profiles to suit any project. Our design team here in the UK will work with architect and fabricator to agree a solution which then becomes part of the overall Aluprof warranty provided on any project. But that is just part of the story.

Minimal profile and hardware stock is held here in the UK and we rely on twice weekly deliveries direct from Poland to anywhere in the UK. It did not seem sensible, when we set up in the UK some fifteen years ago, to double-handle project specific material; delivery to a UK warehouse and then onto another delivery vehicle for final delivery. This way material will often travel further to get to the fabricator with increased lead times. We also pride ourselves in shipping orders complete, this enables the fabricator to schedule fabrication from delivery, rather than having to check and wait for all the materials to arrive. Both these approaches to supply significantly reduces lead times allowing the fabricator to get products installed on site quicker, with an improved cash flow.

We also recognised that not all fabricators can put on extra shifts to meet busy times as production facilities often utilise a lean working ethic to maintain competitiveness. To assist fabricators, Aluprof introduced a fabrication facility in Poland that can manufacture some or all of the supply at the request of the fabricator. This has proven to be a real benefit to our customers and we have often seen the more difficult constructions within a project being made by us.

From specification through to installation, our team in the UK ‘partners’ with our customers to ensure that system supply is value managed, maximising profit for our customer. We believe this ‘Value Management’ strengthens our relationship with our customers who then often ask us to partner them on projects they have secured.

Value Management encompasses Value Engineering as it looks at every process from order through to completion. To begin with, an overview of the complete project programme is needed, with each of the processes and deadlines for completion itemised. It is at this stage that options are discussed. One of the obvious choices is that of the systems to be used for the windows, doors or facade. As with other high end systems companies, Aluprof offer their systems in various designs to meet the exact needs of the building. An example of this can be seen in Aluprof's popular MB-SR50N Curtain Wall system, far from being a single system there are many options to choose from, these include various insulation levels, capping options or structural arrangements, each choice represents a cost or a cost saving. It's a little like specifying options on a new car taking the base model of choice as a starting point.

A further consideration is the optimisation of aluminium profile cutting. To reduce wastage on fabrication, profiles can be extruded to special lengths which offer high levels of cutting optimisation which in turn reduces material waste, which then reduces costs. These are just some of the important issues that are reviewed in the Value Management process which ensures that the completed project performs exactly as specified and perfectly meets with the clients expectations.

To ensure that any installation meets exacting site requirements, new profiles can form part of the Value Management process. New profiles could offer not just a better detail, but new profiles can reduce the time taken to install on site. At the extreme end of Value Management is the option of developing an entirely new system to meet a projects requirement. The experience within the technical team at Aluprof makes this option entirely possible, it has been done before. On this point, we do have some exciting news shortly with a new system for the UK being launched very soon.