#Injection mold 3D design

Explore tagged Tumblr posts

Text

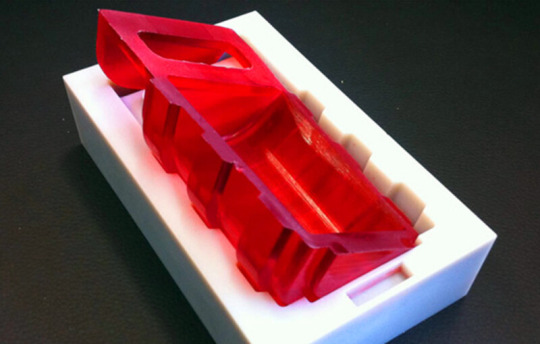

Injection mold 3D design sequence and design key points summary

1. Front and rear molds and mechanism parting Design points: can extend but not stretch, can stretch but not connect, can be flat but not beveled, can be beveled but not curved(1) Shrinkage: All products are shrunk and aligned, such as placing multiple products on different layers to facilitate subsequent design(2) Front and rear mold parting: If surface connecting product and parting is more…

View On WordPress

#Auxiliary parts design#ejector design#Front and rear mold parting#Gate and runner design#Gate design#Injection mold 3D design#lifter design#Mechanism parting#mold base design#Slider Design#three-plate mold#Waterway design

0 notes

Text

So I have fully jumped on the claw clip bandwagon, in large part because they are less damaging to my hair than elastics and also because they actually hold my fine-with-lots-of-curly-body hair very securely, especially if I want to put the full length up

(Also as a 90's kid there is also no small amount of nostalgia tied to them, hello tiny rainbow butterfly clips)

However, in my hunt for fun and whimsical designs, I have found plenty of cottagecore-esque plant designs as well as some animals, but have noticed a near total lack of Western/winged dragon claw clips (as well as my own more niche interests like ravens and German Shepherds and maybe a feather/quill pen).

...I'm gonna have to break out the modeling software and find a 3D printer to rectify this, aren't I.

#life with ladytemeraire#resident craft gremlin#I'm guessing outsourcing like you would for enamel pins would be HORRENDOUSLY expensive#injection molding usually is because you need a dedicated mold for each design and there's generally a minimum order quantity#soooooo 3D printing and or resin to the rescue!

9 notes

·

View notes

Text

What are the classification of Rapid Prototyping Technologies?

Rapid prototyping is a group of techniques used to quickly fabricate a scale model of a physical part or assembly using three-dimensional computer aided design (CAD) data.

The Common Technical Classification in Processing Techniques

CNC Machining

2. 3D Printing

3. Vaccum Casting

4. Sheet Metal

5. Low-volume Manufacturing

#design#autos#business#cnc machining#precision machining#prototype machining#prototyping#machining parts#prototype#rapid prototyping#3d printing#vacuum casting#injection molding#sheet metal fabrication#sheet metal manufacturing#sheet metal services tauranga#sheet metal work contractor financing

1 note

·

View note

Text

I think 2024 will have more text musings from me. Idk tho.

But here is one anyways:

The dream would be 3d modeling on pc and producing 3d print works like figurines but painting is legit impossible for me due to health now lol, guess I have to wait until the Statasys PolyJet/BJP patent expires in a decade+, so that consumer level color/transparency/multimaterial printers can become available. $50,000 for the base machine is not affordable lmafo.

Honestly with the rate at which certain tech advances, it truely feels like patents in those specific fields stunt global advancement for decades. Feels criminal.

For things like 3d printers that are able to print with different materials, colors, and transparencies, it could truely save lives and at minimum drastically improve livelihoods, so it is so bizarre that tech like this is gatekept and not shared to be expanded on and innovated on by others.

This is also a problem in the gaming industry, (albeit at less severity, but still ridiculous). Tell me why there was a DECADES long patent on "mini games during loading screens" that was barely even used before it expired? And the nemesis system...

Obviously, patents have a use and can be very important in making sure creators are not taken advantage of or ripped off (in fact it will likely be a saving grace for taking down unethically sourced data for the current scummy unregulated generative ai models out there), but in certain situations like 3d printing it is straight up detrimental gatekeeping that benefits no one.

#text#musings#certified old fart yells at clouds#tell me that 3d printing full color flexible or transparent merch that looks like mold injection quality at home wouldn't be cool as hell.#with the bs 2d ink printers have now with subscriptions and other bs... i am not looking forward#to that monetization model.#designing and wearing 3d printed shoes that accommodate you sounds cool as hell too.#3d printing

1 note

·

View note

Text

3D printing service near me | injection mold designer

Looking for a 3D printing service near me? Our expert team offers top-quality 3D printing solutions. We also specialize in injection mold designer. Whether you need prototypes or final products, we've got you covered. With cutting-edge technology and experienced designers, we ensure precision and efficiency in every project. Get in touch today for all your 3D printing and injection mold design needs!

0 notes

Text

#Injection molding mold design#Single Cavity Mold Design#Die Casting Mold Design#SolidWorks Injection Mold Design#3D CAD software#V bending die design

0 notes

Text

North American Combine Minotaur Howitzer

I did a art! This is the NAC's Minotaur Howitzer, from the 1977 wargame OGRE by Steve Jackson Games. This was a commission, and took about seven hours from start to finish. It still needs textures, but half the fun of wargaming is the minis, or so I'm told.

If you're personally familiar with OGRE, and you're trying to figure out which specific run of figures I've based this on, the answer is kind of a mix of all and none of them! I took inspiration from images I found of a whole bunch of different variants, but I also made sure to include an extent of my own modifications, especially given that this thing is in no way designed for 3d printing let alone injection molding, which let me play around with the geometry in ways seldom permissible by the laws of physics.

If you're a fan of my work, and have a few spare bucks to chuck in the general direction of a dorkass loser of nondescript provenance vis a vis queerness or ethnicity, you can support me over on my Ko-Fi! And if you're interested in commissioning something from me, you can DM me right here on Tumblr, or email me at [email protected].

19 notes

·

View notes

Text

I watched a video by a guy who made a dupe of a very expensive all-plastic chair and had done one other video and he was like "guys i am NOT providing the file i do NOT want them to sue me"

and i thought that was pretty funny cause

1. as people pointed out in the comments the design was very easy to replicate in almost any 3D modeling program. The guy kind of struggled with it because he was new to 3D modeling (no shame! we all start somewhere) but... yeahhhh an experienced artist could make that fairly easily.

2. duplicating 3D models and providing the designs to people is what i do. (although tbf a very "fancy" business might be more s.l.a.p. happy than a business who stopped producing those molds ages ago)

3. although i support paying designers/artists well, there is something a touch... say, ironic... about selling something that is just an injection molded plastic lawn chair for $1200

#shutupotter#luxury goods#lmfao#also it doesnt look comfortable at all#granted it is made out of 25% recycled plastic so thats nice#unfortunately for them a bunch of other people#already make lawn chairs for much cheaper that are 100% recycled plastic#theyre still somewhat pricey like $200+ but at least they arent over a thousand

3 notes

·

View notes

Text

3rd party resin print tomb kings horse archers vs. the official gw plastic models.

I'm not a fan of the official gw tomb kings skeleton cavalry. They have a goofy toyetic charm that isn't entirely lost on my, and they were certainly good enough for their time, but that time passed long ago. So when my planned horse archer conversion using black knight bits didn't pan out, I broke down and tried resin 3d printed models, ordered from an online shop since my small apartment doesn't have the space to deal with resin safely.

So on the left are 10 3rd party horse archers - 'Second Dynasty Knights' designed by Lost Kingdom, ordered from online printing house Coveted Forge, with a special request to replace spears & shields with more bows & quivers.

The designs by Lost Kingdom are fantastic, much better proportioned, very dynamic, and the large sideways quivers give the riders a distinct silhouette. I will say the skinny bones, bows, and arrows feel super fragile though, and its not always entirely clear how or which hooves are supposed to glue to the base.

The prints from coveted forge took about a month to arrive, and came packaged super well. There was one quiver missing, which they're re-sending. I've been very happy with fdm printed bases & unit trays from Coveted Forge, this is my first time ordering resin prints. The pieces had no misprints and were cleaned cleaned with just a few leftover supports or studs to trim from where supports were removed, & everything was intact despite how fragile it all is. The scale was a bit larger than advertised - i purchased '28mm' scale, but the skeleton riders are about 34mm tall. The size is still fine for what I'm using them for, so it's fine. I've come to expect minis will usually be a bit larger scale than advertized, plus the pieces came in parts so the actual scale wouldn't have been obvious when printing.

Unfortunately, I'm just not a fan of resin as a material. Details are a bit soft, and the material feels both softer and less fragile, which is more an issue for skinny skeletons than most other stuff. Different printers or different resin might give a better result, but fundamentally I just don't think resin printing will ever be on the same level as GW's modern injection molded plastic.

I don't think I want to make resin prints a regular part of my minis collection, but in this case I like the sculpts ~so much~ better than the official models that I'm willing to deal with it, even if I have to keep backups of the official models anyway in case i ever play Old World at a GW store or event.

2 notes

·

View notes

Text

Learn About the Basics of Vacuum casting

Within the dynamic realm of production and prototyping, urethane casting is a unique technology that provides cost-effectiveness, accuracy, and diversity. Urethane casting has become the industry standard for a variety of applications, from complex prototypes to small-batch production runs, including consumer electronics, medical equipment, and the automotive and aerospace sectors.

Gratitude Casting of Urethane

The first step in the procedure is to create a master pattern, which is usually done via fast prototyping techniques like CNC machining or 3D printing. The silicone molds that are made from this master pattern are used to pour polyurethane resin into. The resin mimics the fine features of the master design once it has dried, producing pieces that are excellent and ready for manufacturing.

Flexibility throughout Sectors

The adaptability of urethane casting across sectors is one of its most noteworthy benefits. Urethane casting may be used for a variety of purposes, including the production of end-use components and prototypes for new product development. For instance, urethane casting makes it possible to quickly iterate ideas for dashboard panels, interior trim, and lighting fixtures in the car industry. Similar to this, urethane casting makes it easier and faster to produce unique medical device housings, surgical instruments, and prosthetic components in the medical profession. Vacuum casting also offers flexibility.

Benefits Compared to Conventional Approaches

When compared to conventional production techniques like CNC machining and injection molding, urethane casting has several significant benefits. The most important factor is cost-effectiveness. Because urethane casting requires less tooling up front, it's a great option for low-volume production runs if standard tooling costs are too high. Urethane casting also has a short turnaround time, which enables companies to quickly develop and refine ideas without having to wait for long lead periods.

Additionally, the design freedom provided by urethane casting makes it feasible to produce intricate surface details, undercuts, and complicated geometries that would be difficult or impossible to accomplish with alternative manufacturing processes. This versatility also applies to the choice of material, since a variety of polyurethane resins are available to satisfy certain performance needs, including those related to hardness, flexibility, and chemical resistance. You can Explore vacuum casting also.

Follow our Facebook and Twitter for more information about our product.

#vacuum casting#vacuum casting services#Urethane Casting#Explore vacuum casting#Custom Vacuum Casting Services

2 notes

·

View notes

Text

Improve LSR injection molding mold temperature and warpage with special-shaped oil circuit and mold

Due to rapid development of 3D printing technology, designers can use 3D metal printing to design more in line with requirements of oil circuit, which can be close to contour of product when designing, so as to solve dead angle and heat accumulation of product. The more complex geometric shape of product will be more obvious, and this type of waterway design is usually called Conformal…

View On WordPress

#3D printing#Conformal Cooling#injection molding mold#injection molding process#mold flow analysis#Moldex3D analysis#oil circuit designs#plastic part#special-shaped oil circuit mold

0 notes

Text

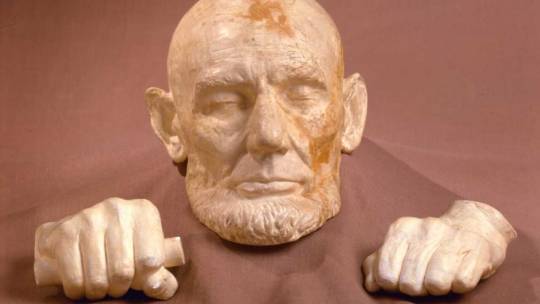

Volk, L. (1860). Abraham Lincoln. [Death Mask]. The Henry Ford Museum.

DEATH MASKS

The making of a death mask is a practice that has evidence of dating back as early as Ancient Egypt, over 5,000 years ago, where a mask is created of the deceased's face, either sculpted or directly cast, in order to preserve their image. The Ancient Egyptian process was to sculpt a stylised representation of the face of the dead, cast in gold with gemstone adornments, which was then placed on the mummified body of the individual in order to guard them from evil spirits in their journey to the afterworld. Roman death masks were cast directly from the face but while they were still alive, and used during funerals. This practice has maintained to the modern age, and has evolved into contemporary creative practice. Historically, the process involves making a mold of the deceased person's face and sometimes other body parts like hands in plaster or wax, which is then cast in either plaster, wax, or bronze to create a statuette of the death mask. These masks were used for a variety of reasons, either for funerary practices, to create sculptures in the likeness of the individual, scientific purposes or even in unsolved criminal cases where the victim's unidentified face would be made as a death mask in order to display to the wider public for information and identification. In contemporary methods, alginate is used directly on the face, which then plaster bandages are layered on top in order to create a secure hard backing for the alginate so it can remain stable and not rip or fall apart.

Reynolds, N. (2007). Death Mask of John Joe Armador. [Death Mask]. The Terrestrial. Historic death masks directly cast have survived for hundreds of years, with some being over 500 years old. While there were many made of criminals, most have been made of famous individuals throughout the western world, with most surviving masks being from the 1700-1900's. Masks of Oliver Cromwell, Ludvig Van Beethoven, Abraham Lincoln and Napoleon Bonaparte still survive, with even two separate masks attributed to Mary Queen of Scots that are made in wax. Nick Reynolds, the son of British criminal Bruce Reynolds, is a sculptor who specialises in contemporary death masks. He has made the mask of his own father. His death mask of John Joe Armador, a man who was executed by lethal injection for his conviction of armed robbery and murder, was made into a sculpture in protest against capital punishment in the United States. We also have the work of Neri Oxman as featured in my artist research, a bioartist/designer who has worked on three series of Vesper masks. These masks are 3D printed from grown biological material and while each series has a slightly different intention, but are linked in that "Each mask represents an imaginary martyr going through a metamorphosis from life to death or death to life". I feel that the death mask is such a heavy and significant symbol of death objects and liminality. The visage, especially when preserved after death of the individual, retains the person's image for eternity and exists in the physical world with a presence that is not matched by many other types of objects in this realm. In the way that a human skeleton or skull evokes curious perception of the individual past their lifespan, the death mask is the face itself, and tells a story of their life and death such a visceral way. While death masks have been used as a way to immortalise figures of their time, they also mirror the practice of the reliquary, where an important religious figure's remains are enshrined or entombed within ornate housing to be displayed within their place of worship. This link within religious iconography, death and the shrine are some very interesting threads that I would like to follow to continue from last year.

Unidentified Maker. (1587). Death Mask of Mary Queen of Scots. [Death Mask]. Lennoxlove House.

2 notes

·

View notes

Note

i like your 3D printed stuff, what program do you use? can I ask what gaps (in the market/husbandry) that made you decide to design this kind of stuff? and i found you through people who are interested in advancing husbandry, so wondering how you (or anyone you follow) think that reptile accessories might be evolving, if you want to talk about it consider this an opportunity :3

ty! I use fusion 360, which is just standard CAD software. honestly I think my main niche is just providing things that are user friendly. like. nowadays a LOT of products have "how can we make people buy more and more stuff" as their backbone rather than "how can we make a good and serviceable product" and I think that's pretty shitty. things like planned obsolescence and turning necessary accessories into additional purchases. for my hides with the integrated thermometers and hygrometers, I could've just glued them in place permanently, and it would've saved MANY many hours of designing. but instead I wanted people to be able to replace it if they wanted or needed, so I glued them into cutouts instead that can be put on or taken off with a standard allen wrench. and instead of making people buy the cover (that turns it into a normal hide again) separately, I wanted to include it as is

it definitely helps that I'm using 3d printing as my manufacturing process too tho! it costs absurd amounts of money to prototype and manufacture stuff like this with typical injection molding methods, but for me it's like. idk. takes a few hours of designing and then a couple dollars in filament to test stuff :o in turn, the costs to produce each thing is a little higher but I don't mind!

4 notes

·

View notes

Text

Expert mechanical design engineering company offering services such as 3D moulding products design, plastic mould design, 2D drafting DFM for mould manufacturing CNC programming for machines

Thiram is capable of providing product development and design. Our three decades of experience in the engineering field have helped us develop unmatched expertise in the market. Our strong material technology has helped us serve time and distance for the customers.

2 notes

·

View notes

Text

0 notes

Photo

I actually work as a volunteer assistive device designer

This kind of low demand situation along with the more obvious benefits for customization are big reasons for using things like 3d printing and such

but the reality is that mass production usually with industrial methods like mold injection or whatever are the most efficient but also require a larger scale

which is possible for some common assistive devices like grippable silverware

but random able-bodied people adding to a consumer base really does help, both in directly contributing to the demand for a product and supporting the businesses that generally produce assistive devices

the future is now

580K notes

·

View notes