#Industrial RCC

Explore tagged Tumblr posts

Text

Premium Industrial RCC for Rent in IMT Manesar – Contact Property4Sure

Industrial RCC in IMT Manesar offers excellent options for businesses seeking reliable spaces in a prime location. If you're interested in Industrial RCC for Rent in IMT Manesar, we provide cost-effective solutions with great connectivity and essential infrastructure. Explore our wide range of rental spaces and find the perfect fit for your business needs. For more details, contact us at 8178749372 or 9910902063. Let Property4Sure assist you in securing the ideal industrial space.

#property4sure#properties for rent#industrial rcc for rent in imt manesar#industrial rcc#imt manesar

0 notes

Text

Role Of TMT Saria and Dowel Bars in Modern Pavement Construction

It takes more than merely pouring concrete to create long-lasting, sturdy pavements. The strategic use of premium materials, especially those provided by reliable TMT Saria manufacturers, and the accurate installation of dowel bars form the foundation of outstanding pavement construction. The lifetime and structural integrity of the pavement are greatly dependent on this cooperative interaction.

Understanding the Foundation: TMT Saria in Pavement Projects

TMT Saria, produced by specialized TMT Saria manufacturers, forms the critical reinforcement structure within concrete pavements. These steel bars provide essential tensile strength, preventing crack formation and ensuring uniform load distribution across the pavement surface. The quality of TMT Saria directly influences pavement durability, making manufacturer selection a pivotal decision in construction planning.

The binding wire used to secure TMT Saria must meet specific strength requirements. High-grade binding wire ensures reinforcement components remain firmly in place during concrete pouring, preventing displacement that could compromise structural integrity. Quality binding wire also resists corrosion, maintaining its grip strength throughout the pavement's lifetime.

Dowel Bars: The Load Transfer Champions

Dowel bars serve as vital load transfer devices between concrete pavement slabs. These smooth steel bars facilitate proper load distribution, preventing differential movement between adjacent slabs and ensuring smooth transitions at joints. When combined with properly installed TMT Saria, dowel bars create a robust system that significantly extends pavement life and reduces maintenance requirements.

Quality Considerations in Material Selection

Selecting materials from a reliable TMT Saria manufacturer impacts several crucial aspects of pavement performance:

Structural Integrity

Premium TMT Saria exhibits consistent mechanical properties

Higher yield strength ensures better crack resistance

Uniform chemical composition guarantees predictable performance

Durability Factors

Superior coating on dowel bars prevents corrosion

High-quality binding wire maintains reinforcement positioning

Well-manufactured TMT Saria resists environmental degradation

Cost-Effectiveness

Premium materials reduce long-term maintenance expenses

Quality dowel bars minimize joint deterioration

Professional-grade binding wire ensures reliable reinforcement fixing

Real-World Applications and Benefits

Modern infrastructure projects demonstrate the advantages of using premium materials. Highway pavements constructed with high-grade TMT Saria and precisely installed dowel bars show significantly reduced maintenance requirements and extended service life. Airport runways, which face extreme load conditions, particularly benefit from this optimal material combination.

The Science Behind the Synergy

The interaction between TMT Saria and dowel bars creates a comprehensive reinforcement system. While TMT Saria provides overall structural strength, dowel bars manage load transfer at critical joint locations. This partnership prevents common pavement issues such as:

Corner cracking

Slab displacement

Joint deterioration

Surface spalling

Installation Best Practices

Proper installation maximizes the benefits of quality materials. Precise spacing of dowel bars, coupled with correctly positioned TMT Saria, ensures optimal load distribution. Professional-grade binding wire secures reinforcement components, maintaining their designed positions during concrete placement.

Long-Term Performance Benefits

Pavements constructed using materials from reputable TMT Saria manufacturers, coupled with quality dowel bars, demonstrate superior performance metrics:

Extended service life

Reduced maintenance frequency

Better ride quality

Enhanced structural stability

Improved load-bearing capacity

Making the Right Choice

Selecting construction materials requires careful consideration of manufacturer credentials, product specifications, and quality certifications. Leading TMT Saria manufacturers invest in rigorous quality control processes, ensuring consistent product performance. When combined with properly specified dowel bars and binding wire, these materials create pavements that stand the test of time.

Taking Action for Quality Construction

For construction professionals planning pavement projects, partnering with established TMT Saria manufacturers represents a crucial first step toward project success. Evaluate potential suppliers based on their track record, quality control measures, and product specifications. Remember that initial material quality determines long-term pavement performance, making careful supplier selection essential for project success.

#TMT Saria#dowel bars#pavement construction#road reinforcement#concrete durability#load transfer bars#highway construction#TMT bars#road strength#crack prevention#binding wire#infrastructure development#RCC roads#pavement joints#structural stability#steel reinforcement#construction materials#long-lasting roads#heavy-load pavements#industrial flooring

0 notes

Text

RCC Breaking Services in Maharashtra | Concrete Breaking Service 9923437177

SB Demolition Offers Safe And Efficient RCC Breaking Concrete cutting Services in Maharashtra. Trust Our Experts For Reliable Solutions in Construction And Demolition Projects.

#RCC breaking services Pune#RCC breaking services Maharashtra#RCC demolition Pune#SB Demolition#RCC breaking contractors in Maharashtra#concrete breaking in Maharashtra#RCC structure removal in Maharashtra#construction demolition in Maharashtra#safe RCC breaking in Maharashtra#Concrete breaking services Pune#RCC structure demolition Pune#RCC removal contractors Pune#Professional RCC breaking in Maharashtra#Safe RCC breaking services in Maharashtra#Construction RCC breaking Pune#Industrial RCC breaking services in Maharashtra#Residential RCC demolition Pune#RCC slab breaking Pune#RCC breaking for renovations in Maharashtra#Cost-effective RCC breaking Pune#Concrete demolition contractors in Maharashtra

0 notes

Text

Industrial Screw Chillers, Industrial Screw Chiller Manufacturer India

Industrial Screw Chillers, Industrial Screw Chiller Supplier, Industrial Screw Chiller Exporter, Industrial Screw Chiller Manufacturers Mumbai, India.

Cooling Towers, Frp Cooling Towers, Pultruded Cooling Towers, Timber Cooling Towers, Rcc Cooling Towers, Ice Plant, Block Ice Plant, Ammonia Block Ice Plant, Freon Ice Plant, Flake Ice Plant, Tube Ice Plant, Chilling Plants, Air Cooled Chilling Plants, Water Cooled Chilling Plants, Brine Chilling Plants, Oil Chillers, Air Blast Coolers, Industrial Screw Chillers, Multi Compressor Chillers, Brine Process Cooling System, Water Process Cooling System, Water Cooled Screw Chillers, Atmospheric Type Condenser, Ammonia Cooling Coil, Trunk Coil, Ammonia Receiver, Ammonia Refrigerant Liquid Storing Tank, Ice Can, Cooling Tower Film Fills, Frp Fan Stack, Water Distribution System Frp Fan Stack, Drift Eliminators, Cooling Tower Services, Mumbai, India.

#Cooling Towers#Frp Cooling Towers#Pultruded Cooling Towers#Timber Cooling Towers#Rcc Cooling Towers#Ice Plant#Block Ice Plant#Ammonia Block Ice Plant#Freon Ice Plant#Flake Ice Plant#Tube Ice Plant#Chilling Plants#Air Cooled Chilling Plants#Water Cooled Chilling Plants#Brine Chilling Plants#Oil Chillers#Air Blast Coolers#Industrial Screw Chillers#Multi Compressor Chillers#Brine Process Cooling System#Water Process Cooling System#Water Cooled Screw Chillers#Atmospheric Type Condenser#Ammonia Cooling Coil#Trunk Coil#Ammonia Receiver#Ammonia Refrigerant Liquid Storing Tank#Ice Can#Cooling Tower Film Fills#Frp Fan Stack

0 notes

Text

RCC Buildings in industrial projects

Reinforced concrete (RCC) buildings are common in industrial projects due to their strength and durability. They offer resistance to harsh environments and heavy loads, ensuring long-term structural integrity and safety. Read more at:

0 notes

Text

Top premier Manufacturer of RCC Jacking Pipes - Kalokhe

A reputable brand in the sector, Kalokhe Pipes Pvt Ltd is well known for producing RCC jacking pipes of the highest caliber. Our pipes are designed to be durable and precise, making them perfect for a range of building tasks. You may rely on us for dependable answers and unrivaled knowledge in the field of RCC jacking pipes.

For more Information Contact US: +91 96074 22525

Email: [email protected]

0 notes

Text

3000SQ.FT RCC SPACE AVAILABLE ON RENT IN BHIWANDI IDEAL FOR STATIONARY STORAGE

3000SQ.FT RCC SPACE AVAILABLE ON RENT IN BHIWANDI IDEAL FOR STATIONARY STORAGE #rcc #warehouse #multipurpose #rent #bhiwandi PROPERTY Code : AJJK345AREA : 3000 sq ftFLOOR : SECOND FLOORLOCATION: BHIWANDIPOSSESSION: 1-07-23RENT : 12.50 /- PER SQFTSHUTTER : SINGLE SHUTTERPOWER : SINGLE SHUTTERHEIGHT : 12′ ftFlooring : TRIMIXFIRE HYDRANT: NOT AVAILABLEINSULATION: NOT…

View On WordPress

0 notes

Text

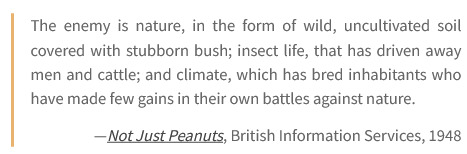

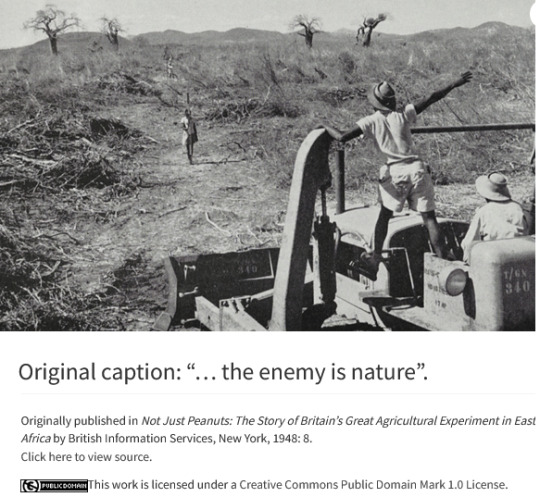

The link between warfare and technological innovation has been well documented [...]. World War II was a particularly intense crucible of technological change, and the repurposing of military technologies and industries in the forging of a new post-war consumer [economy] is crucial [...]. Processes of technological bricolage turned the machines of war onto the natural world as global powers competed to cement their economic and imperial hegemony. In Great Britain’s post-war “groundnut scheme” in its East African territories (1946-51), this collision of nature, military hardware, and technical expertise was part of efforts to both produce more fats for the British diet and to demonstrate to the world (most importantly the United States) that, through a newly energized science-led developmentalism, British colonialism still had a “progressive” role to play in the postwar world.

The aim was to produce millions of tons of peanuts across Tanganyika using the latest methods of advanced scientific agriculture. The environmental conditions in the north, where the scheme was to begin, were known to be especially trying, not least the dry climate [...]. But faith in the power of mechanized agriculture was such that any natural limits were thought to be readily surmountable.

The groundnut scheme was to be, as its Director put it in an interview with the Tanganyika Standard, a “war” with nature, and an “economic Battle of Alamein” waged over some three million acres by an army of colonial technicians - many recruited from military ranks - and local laborers, for many of whom the scheme represented their first entry into the wage labor market.

But it wasn’t just the rhetoric of war that was repurposed.

Lancaster bombers were kitted out to survey and discover “new country” in East Africa for agricultural development. [...] [T]ractors and bulldozers from military surplus stores in Egypt proved unable to tackle the hard ground and tough vegetation, so the planners turned to a novel solution: repurposing surplus Sherman M4A2 tanks. The Vickers-Armstrong factory in Newcastle-Upon-Tyne set about rearranging key elements of the tanks’ construction [...]. The tractors, christened “Shervicks” for their hybrid origins, were [...] thought to be particularly suited to large-scale earth-moving and to the kind of heavy duty “bush clearing” that was required in Tanganyika.

Officials sought to dismiss concerns that large-scale bush clearing would have wider environmental consequences, using the well-worn colonial trope that any observed changes in local climate or erosion patterns were due to the “primitive” agricultural practices of the locals, not to the earth-moving practices of the colonists. [...] As the plants continued to wilt in the sun, [...] [t]he stakes were high. As [J.R.] of the Colonial Development Corporation put it in a letter: “Our standing as an Imperial power in Africa is to a substantial extent bound up with the future of this scheme. To abandon it would be a humiliating blow to our prestige everywhere.” The only option left was to try and bend the weather itself to the scheme’s will, by seeding the clouds for rain. [...] “Balloon bombs” (photographic film canisters tethered to weather balloons) and a repurposed Royal Navy flare gun were used to target individual clouds [...]. The scheme itself has survived as a cautionary tale of governmental hubris, but it is instructive too as a case study of how technologies of war have been turned against other foes.

---

All text above by: Martin Mahony. “The Enemy is Nature: Military Machines and Technological Bricolage in Britain’s ‘Great Agricultural Experiment.’“ Environment and Society Portal, Arcadia (Spring 2021), no. 11. Rachel Carson Center for Environment and Society. doi:10.5282/rcc/9191. [Bold emphasis and some paragraph breaks/contractions added by me. Images and their captions are shown unaltered as they originally appear in Mahony's article. Public Domain Mark 1.0 License for images: creativecommons dot org/publicdomain/mark/1.0/]

196 notes

·

View notes

Text

Dr. Quartero's note #4 the A.P.R.O part 1

<< First < Previouse Next part >

(Out of Character: Hey, just so you know, this entry is valid both for my comic Bright Blue Soul and my game The Anomaly Team as APRO, even if slightly different exists in both universes. Also yes, this is shamelessly inspired by SCP Foundation mythos)

Dr. Quatero here. Today, I will not be speaking of a single person or item, but an entire organization, the Anomaly Protection and Research Organization or APRO. The organization's origins are fuzzy at best. Despite being officially founded after the battle against the previous god of machines in 1807, now confidential reports reveal the organization has existed since at least the early 1700's. The founder is equally as mysterious, if he even exists, the elusive Administrator-0.

The organization's goal is officially to protect humanity from any anomaly or other existential dangers. They also study, develop, and produce a wide array of items, anything from civilian products to mass destruction weaponry.

APRO is also extremely politically and economically influential. They have contracts with every major military on the planet, even having some degree of influence over many governments, and they are also allied to the Quartero family. It is a little concerning how much power the organization has, but all investigations, including several from me, revealed no problematic actions. As long as they are on our side, I guess I shouldn't critique them too much.

The Organization is split into four main parts:

The International Anomaly Containment Operation or IACO also called the righteous right hand. IACO specializes in interventions, they're basically the muscles of the organization, taking care of the fieldwork. They include several hundred battalions of soldiers and specialized units ready to deal with anything from biological threats to reality warpers. They have extensive access to technology inaccessible by most of the public or the world's military like the F.F. portable reactors, the reality anchoring devices, and advanced artificial organs and limbs. Not only do they have a count of well-trained soldiers in the tens of thousands, they also possess tanks, fighter jets, missiles, and even a few nuclear weapons for last resort. The leader of this section of APRO is known as Administrator-1

The Internal Containment and Security Office or ICSO, sometimes called The left hand. ICSO is specialized in any internal security need. See them as the little brother of IACO, but instead of acting on the field, they keep entities contained and ensure that no military actions coming from the inside can hurt the organization. Take most of what I said for IACO, tone it down a little and you have the resume of what ICSO is. Their leader is Administrator-2

The Supply and Organization Wing or SOW, is sometimes called Red Heart. As the name may suggest they take care of organization and supplies. Hence why they are called the Heart, to some extent, the organization has been made to still function if one of its parts is destroyed, but SOW is probably the most important. APRO is an organization spanning across the globe, without an efficient administration and organization, it just couldn't work. They take care of most logistical needs, and also of industries controlled by APRO. Their leader is Administrator-4

The Research and Command Center or RCC, also called The Head That Knows. As its name may indicate, they are the head of the operations, and they also take care of research and observation. Their nickname comes from the fact that with their extensive amount of data, they know practically anything known to humanity. If you lost your keys this morning, they probably know where it is. Their leader is Administrator-3.

5 notes

·

View notes

Text

We are extremely pleased to announce the grand opening of our new state-of-the-art Meltingshop and Rolling Mill facility at Jalna, Maharashtra on 28th April 2023 which has brought us one step closer to fulfilling our vision of expanding our horizons to meet the ever growing demand and be the market leader while delivering quality TMT Rebars and focusing on customer satisfaction.

The inauguration of our new facility would be done by Smt. Ruchika Chaudhry Govil, Additional Secretary, Ministry of Steel and Hon’ble MP Raosaheb Patil Danve, Union Minister of State for Railways, Coal and Mines.

We are commited to serving our customers better by developing leading edge solutions in the technology, processes and products.

With our customer-first approach, innovative products, and continuous nurturing of our distribution channel, Rajuri Steel has emerged as a market leader in the Steel Rebar Industry with an evergrowing and strong PAN India dealer network.

We owe our success to all our dealers, customers, associates, and employees.

Thank you for your support and confidence in us and we assure you that Rajuri Steel is poised to achieve a lot of milestones in the future.

The Real Strength Of Togetherness!

#inauguration #steelplant #plantinauguration #rollingmill #openingceremony #growth #jalna #jalnaindustry #ministryofsteel #steelindustry #steel #RajuriSteel #TMTsteel #TMTbars #RCC #construction #architecture #building #TMTBar #TMT #Steelbar #TMTSariya #qualitysteel #TMTBarManufacturer #StrengthofTogetherness #InternationalQuality #GermanTechnology #33StrengtheningYears #Rajuri500 #Rajuri500DPlus #Rajuri550

3 notes

·

View notes

Text

Looking for an Industrial RCC Shed in IMT Manesar? We have a variety of options available to meet your business needs. Our Industrial RCC Shed in IMT Manesar offers spacious layouts, excellent structural integrity, and prime location advantages. Ideal for manufacturing and warehousing, these sheds provide a secure and efficient workspace for your operations. For more details, feel free to contact us at 8178749372 or 9910902063. Secure your industrial space today with Property4Sure!

#property4sure#industrial shed for rent in imt manesar#industrial rcc for rent#industrial rcc shed for rent

0 notes

Text

Top PEB Company in Greater Noida | Trusted Pre-Engineered Building Solutions

Introduction

With the increasing demand for efficient, cost-effective, and durable building solutions, Pre-Engineered Buildings (PEB) have emerged as the go-to choice for industrial, commercial, and institutional construction. PEB structures are designed for quick installation, superior strength, and long-term sustainability—making them an excellent alternative to traditional construction methods.

Greater Noida, a rapidly growing industrial hub, is home to several PEB manufacturers and construction companies. Among them, EPACK Prefab stands out as a leading PEB company in Greater Noida, offering innovative PEB construction solutions tailored to various industries.

What is a Pre-Engineered Building (PEB)?

A Pre-Engineered Building (PEB) is a factory-built structure that is transported to the site and assembled using bolted connections. Unlike traditional RCC (Reinforced Cement Concrete) buildings, PEB structures are:

✅ Cost-Effective: Reduces material wastage and labor costs. ✅ Faster to Construct: Pre-fabricated components significantly reduce on-site construction time. ✅ Durable & Strong: Made from high-quality steel and insulated panels for better longevity. ✅ Customizable: Designed based on project-specific needs with flexibility in size and layout. ✅ Energy-Efficient: Incorporates sustainable materials and insulation options to reduce energy consumption.

Why Choose PEB Structures?

1. Speedy Construction

PEB buildings are prefabricated at the manufacturing unit, allowing for quick installation at the site. This helps businesses meet project deadlines efficiently.

2. Cost Savings

Since most of the components are manufactured off-site, the cost of labor and raw materials is significantly reduced, making PEB construction a budget-friendly solution.

3. High Structural Strength

PEB structures use high-tensile steel, ensuring maximum strength, durability, and resistance to extreme weather conditions.

4. Sustainability & Energy Efficiency

Modern PEB construction techniques incorporate thermal insulation panels, skylights, and solar panels, making them an eco-friendly choice.

5. Versatility in Applications

PEB structures are widely used across multiple industries, including:

🏗 Industrial Sheds & Warehouses 🏢 Commercial Buildings & Offices 🏭 Manufacturing Plants & Factories 🏬 Retail Stores & Shopping Centers 🚧 Infrastructure & Airport Terminals

Best PEB Company in Greater Noida – EPACK Prefab

If you are looking for a trusted PEB manufacturer in Greater Noida, EPACK Prefab is a leader in pre-engineered building solutions. With years of expertise, EPACK Prefab specializes in customized, high-quality, and durable PEB structures.

Why EPACK Prefab?

🔹 State-of-the-Art Manufacturing – Our advanced production facility ensures precision-engineered PEB components. 🔹 Turnkey Solutions – From design, fabrication, and installation to after-sales service, we offer end-to-end solutions. 🔹 Custom-Built PEBs – Tailored to meet client-specific requirements with flexible dimensions and layouts. 🔹 Sustainable & Eco-Friendly – Incorporating energy-efficient designs and recyclable materials. 🔹 Timely Project Execution – Our streamlined approach ensures on-time delivery and cost efficiency.

youtube

EPACK Prefab’s PEB Solutions

EPACK Prefab specializes in manufacturing and installing PEB structures across multiple sectors, including:

✅ Industrial Sheds & Warehouses – Large-scale storage and production facilities. ✅ Factory Buildings – High-strength PEB structures for manufacturing units. ✅ Cold Storage Units – Thermally insulated buildings for temperature-controlled storage. ✅ Aircraft Hangars & Airport Terminals – Large-span steel structures for aviation facilities. ✅ Commercial & Institutional Buildings – Offices, shopping centers, and educational institutions.

Conclusion

The growing preference for Pre-Engineered Buildings (PEBs) is transforming the construction landscape. EPACK Prefab, a leading PEB company in Greater Noida, provides customized, cost-effective, and high-quality PEB solutions for diverse applications. Whether you need an industrial warehouse, a manufacturing unit, or a commercial building, EPACK Prefab ensures reliable, sustainable, and future-ready PEB structures.

Get in Touch with EPACK Prefab

📞 Call Us: +91-8130444466 📧 Email: [email protected] 🌐 Website: https://www.epack.in/

Build smarter, faster, and stronger with EPACK Prefab – Your Trusted PEB Partner in Greater Noida!

#PEBCompany#PreEngineeredBuildings#PEBConstruction#IndustrialBuildings#PEBManufacturers#SteelStructures#PrefabConstruction#EPACKPrefab#NoidaConstruction#WarehouseSolutions#Youtube

0 notes

Text

RCC Slab Cutting Services in Maharashtra | Cutting Services 9923437177

SB Demolition Offers Precise RCC Slab Cutting Contractors Services in Maharashtra. Ensure Safety And Quality For Your Construction Projects With Our Expert Team.

#RCC Slab Cutting Pune#RCC Slab Cutting Maharashtra near me#Concrete Slab cutting services#professional slab cutting in Maharashtra#RCC cutting experts in pune#construction slab cutting in Maharashtra#safe slab cutting services in pune#Slab cutting experts Pune Precision slab cutting#Safe RCC slab cutting#Construction slab cutting services#Industrial slab cutting#Residential slab cutting#Cost-effective slab cutting Pune#Concrete cutting contractors#Slab cutting for renovations#Quality RCC slab cutting services#RCC Slab Cutting Pune near me

0 notes

Text

Water Cooled Chilling Plants, Chiller, Chilling Plant Mfgr

Water Cooled Chilling Plants, Chilling Plant, Water Cooled Chiller, Chiller Supplier, Chilling Plant Exporter, Chilling Plant Manufacturer Mumbai, India.

Cooling Towers, Frp Cooling Towers, Pultruded Cooling Towers, Timber Cooling Towers, Rcc Cooling Towers, Ice Plant, Block Ice Plant, Ammonia Block Ice Plant, Freon Ice Plant, Flake Ice Plant, Tube Ice Plant, Chilling Plants, Air Cooled Chilling Plants, Water Cooled Chilling Plants, Brine Chilling Plants, Oil Chillers, Air Blast Coolers, Industrial Screw Chillers, Multi Compressor Chillers, Brine Process Cooling System, Water Process Cooling System, Water Cooled Screw Chillers, Atmospheric Type Condenser, Ammonia Cooling Coil, Trunk Coil, Ammonia Receiver, Ammonia Refrigerant Liquid Storing Tank, Ice Can, Cooling Tower Film Fills, Frp Fan Stack, Water Distribution System Frp Fan Stack, Drift Eliminators, Cooling Tower Services, Mumbai, India.

#Cooling Towers#Frp Cooling Towers#Pultruded Cooling Towers#Timber Cooling Towers#Rcc Cooling Towers#Ice Plant#Block Ice Plant#Ammonia Block Ice Plant#Freon Ice Plant#Flake Ice Plant#Tube Ice Plant#Chilling Plants#Air Cooled Chilling Plants#Water Cooled Chilling Plants#Brine Chilling Plants#Oil Chillers#Air Blast Coolers#Industrial Screw Chillers#Multi Compressor Chillers#Brine Process Cooling System#Water Process Cooling System#Water Cooled Screw Chillers#Atmospheric Type Condenser#Ammonia Cooling Coil#Trunk Coil#Ammonia Receiver#Ammonia Refrigerant Liquid Storing Tank#Ice Can#Cooling Tower Film Fills#Frp Fan Stack

0 notes

Text

How Can RCC Design and Detailing Training Enhance Your Civil Engineering Career?

Book your RCC Design and Detailing Training today with Conserve Academy and take the next step in your civil engineering career! Gain hands-on experience, industry-relevant skills, and expert guidance with the RCC design course in Chennai to excel in structural design. Learn advanced techniques, improve your detailing accuracy, and boost your job prospects in the construction industry. Don't miss this opportunity—secure your spot now and build a strong foundation for success!

#rccdesign#civilengineering#structuraldesign#rccdetailing#engineeringtraining#constructionindustry#rccdesigncourse#careerboost#chennaitraining#conserveacademy

0 notes

Text

Resin Coated Copper Foil (RCC) Market, Global Outlook and Forecast 2025-2032

Resin coated copper foil (RCC) is an advanced material used in the manufacturing of high-density interconnect (HDI) printed circuit boards (PCBs). RCC primarily utilizes electrolytic copper foil, coated with thermosetting insulating resin, which includes epoxy resin as the main component. Additionally, small amounts of high-performance resins such as BT (Bismaleimide Triazine), PPE (Polyphenylene Ether), and PI (Polyimide) are incorporated. Unlike traditional copper-clad laminates (CCLs), RCC eliminates the need for glass cloth reinforcement, reducing weight and thickness while enhancing electrical performance. This makes RCC particularly suitable for mobile phones, computers, cameras, and other compact electronic devices.

Market Size

Download FREE Sample of this Report @ https://www.24chemicalresearch.com/download-sample/286669/global-resin-coated-copper-foil-forecast-market-2025-2032-433

The global resin coated copper foil (RCC) market was valued at USD 5.70 million in 2023 and is projected to remain stable at USD 5.70 million by 2032, reflecting a CAGR of 0.00% over the forecast period.

Regional Market Insights:

North America: Market size was USD 1.49 million in 2023, maintaining a steady growth trajectory.

Asia-Pacific: The largest manufacturing hub for PCBs and electronic devices, Asia-Pacific is expected to hold a significant share due to its strong industrial base in China, Japan, and South Korea.

Europe, South America, and MEA: Moderate growth is expected as industries gradually adopt RCC for advanced PCB applications.

North America: Market size was USD 1.49 million in 2023, maintaining a steady growth trajectory.

Asia-Pacific: The largest manufacturing hub for PCBs and electronic devices, Asia-Pacific is expected to hold a significant share due to its strong industrial base in China, Japan, and South Korea.

Europe, South America, and MEA: Moderate growth is expected as industries gradually adopt RCC for advanced PCB applications.

Market Dynamics (Drivers, Restraints, Opportunities, and Challenges)

Drivers:

Increasing Demand for Miniaturized Electronics: The shift towards smaller, thinner, and more power-efficient devices drives demand for RCC in smartphones, tablets, and wearable technology.

Advancements in PCB Technology: The use of RCC in HDI PCBs improves electrical performance and signal integrity, supporting 5G networks, IoT, and AI-driven devices.

Eco-Friendly Manufacturing: RCC reduces the need for hazardous materials, aligning with global sustainability initiatives.

Increasing Demand for Miniaturized Electronics: The shift towards smaller, thinner, and more power-efficient devices drives demand for RCC in smartphones, tablets, and wearable technology.

Advancements in PCB Technology: The use of RCC in HDI PCBs improves electrical performance and signal integrity, supporting 5G networks, IoT, and AI-driven devices.

Eco-Friendly Manufacturing: RCC reduces the need for hazardous materials, aligning with global sustainability initiatives.

Restraints:

High Production Costs: The specialized manufacturing process and high-performance resins used in RCC production contribute to higher costs compared to traditional copper foils.

Limited Awareness and Adoption: Many PCB manufacturers still prefer traditional copper-clad laminates (CCLs), hindering RCC adoption.

High Production Costs: The specialized manufacturing process and high-performance resins used in RCC production contribute to higher costs compared to traditional copper foils.

Limited Awareness and Adoption: Many PCB manufacturers still prefer traditional copper-clad laminates (CCLs), hindering RCC adoption.

Opportunities:

Growth in the Semiconductor Industry: The increasing demand for high-speed, high-frequency circuits presents new growth avenues.

Expansion in 5G Infrastructure: The rise of 5G networks requires advanced PCB materials with superior signal transmission capabilities.

Integration in Automotive Electronics: The push towards electric vehicles (EVs) and autonomous driving increases demand for high-performance RCC materials.

Growth in the Semiconductor Industry: The increasing demand for high-speed, high-frequency circuits presents new growth avenues.

Expansion in 5G Infrastructure: The rise of 5G networks requires advanced PCB materials with superior signal transmission capabilities.

Integration in Automotive Electronics: The push towards electric vehicles (EVs) and autonomous driving increases demand for high-performance RCC materials.

Challenges:

Technological Barriers: RCC manufacturing requires specialized processing techniques, limiting mass adoption.

Competitive Pressure from Other PCB Materials: The market faces competition from flexible PCBs, liquid crystal polymer (LCP), and polyimide substrates.

Technological Barriers: RCC manufacturing requires specialized processing techniques, limiting mass adoption.

Competitive Pressure from Other PCB Materials: The market faces competition from flexible PCBs, liquid crystal polymer (LCP), and polyimide substrates.

Regional Analysis

North America:

Strong demand from aerospace, defense, and consumer electronics.

Leading companies investing in R&D for advanced PCB materials.

Strong demand from aerospace, defense, and consumer electronics.

Leading companies investing in R&D for advanced PCB materials.

Europe:

Focus on automotive electronics and telecommunications.

Stringent environmental regulations favor the adoption of eco-friendly RCC solutions.

Focus on automotive electronics and telecommunications.

Stringent environmental regulations favor the adoption of eco-friendly RCC solutions.

Asia-Pacific:

China, Japan, and South Korea dominate the RCC market due to high PCB production capacities.

India and Southeast Asia emerging as new manufacturing hubs.

China, Japan, and South Korea dominate the RCC market due to high PCB production capacities.

India and Southeast Asia emerging as new manufacturing hubs.

South America and MEA:

Gradual adoption of RCC in industrial automation and telecommunications.

Infrastructure development to boost regional demand.

Gradual adoption of RCC in industrial automation and telecommunications.

Infrastructure development to boost regional demand.

Competitor Analysis

Key players in the global RCC market include:

Panasonic – A leader in high-performance electronic materials.

RISHO KOGYO – Specializes in advanced resin-based copper foils.

ThinFlex Corporation – Focuses on flexible and lightweight PCB materials.

Elite Material – Supplies high-end copper-clad laminates and RCC solutions.

Guangdong Xiangsinm – Expanding its market presence in Asia-Pacific.

ITEQ CORPORATION – Known for HDI PCB material innovations.

Panasonic – A leader in high-performance electronic materials.

RISHO KOGYO – Specializes in advanced resin-based copper foils.

ThinFlex Corporation – Focuses on flexible and lightweight PCB materials.

Elite Material – Supplies high-end copper-clad laminates and RCC solutions.

Guangdong Xiangsinm – Expanding its market presence in Asia-Pacific.

ITEQ CORPORATION – Known for HDI PCB material innovations.

Market Segmentation (by Application)

HDI (High-Density Interconnect) PCBs

Increasing use in smartphones, tablets, and AI-powered devices.

Preferred for compact, high-speed electronic applications.

Increasing use in smartphones, tablets, and AI-powered devices.

Preferred for compact, high-speed electronic applications.

Metal Substrates

Utilized in heat dissipation applications for LED lighting and power electronics.

Utilized in heat dissipation applications for LED lighting and power electronics.

Other Applications

Includes flexible PCBs, RFID antennas, and high-frequency circuits.

Includes flexible PCBs, RFID antennas, and high-frequency circuits.

Market Segmentation (by Type)

12/18µm RCC

Standard thickness for general electronic applications.

Widely used in consumer electronics and industrial automation.

Standard thickness for general electronic applications.

Widely used in consumer electronics and industrial automation.

120µm and Above

Suitable for power electronics and high-frequency circuits.

Preferred in automotive and aerospace applications.

Suitable for power electronics and high-frequency circuits.

Preferred in automotive and aerospace applications.

Key Company

Panasonic

RISHO KOGYO

ThinFlex Corporation

Elite Material

Guangdong Xiangsinm

ITEQ CORPORATION

Panasonic

RISHO KOGYO

ThinFlex Corporation

Elite Material

Guangdong Xiangsinm

ITEQ CORPORATION

Geographic Segmentation

North America (USA, Canada, Mexico)

Europe (Germany, UK, France, Russia, Italy, Rest of Europe)

Asia-Pacific (China, Japan, South Korea, India, Southeast Asia, Rest of Asia-Pacific)

South America (Brazil, Argentina, Columbia, Rest of South America)

Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria, South Africa, Rest of MEA)

North America (USA, Canada, Mexico)

Europe (Germany, UK, France, Russia, Italy, Rest of Europe)

Asia-Pacific (China, Japan, South Korea, India, Southeast Asia, Rest of Asia-Pacific)

South America (Brazil, Argentina, Columbia, Rest of South America)

Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria, South Africa, Rest of MEA)

FAQ

What is the current market size of the Resin Coated Copper Foil (RCC) Market?

⣠As of 2023, the global RCC market was valued at USD 5.70 million and is projected to maintain stability through 2032.

Which are the key companies operating in the RCC Market?

⣠Major players include Panasonic, RISHO KOGYO, ThinFlex Corporation, Elite Material, Guangdong Xiangsinm, and ITEQ CORPORATION.

What are the key growth drivers in the RCC Market?

⣠Demand for miniaturized electronics

⣠Advancements in HDI PCB technology

⣠Growth of 5G and IoT applications

Which regions dominate the RCC Market?

⣠Asia-Pacific leads due to strong PCB manufacturing.

⣠North America and Europe see steady demand from telecom and automotive industries.

What are the emerging trends in the RCC Market?

⣠Adoption in high-frequency circuits and EVs

⣠Integration in AI-driven and IoT devices

⣠Advancements in flexible and stretchable PCBs

Industry drivers, restraints, and opportunities covered in the study

Neutral perspective on the market performance

Recent industry trends and developments

Competitive landscape & strategies of key players

Potential & niche segments and regions exhibiting promising growth covered

Historical, current, and projected market size, in terms of value

In-depth analysis of the Resin Coated Copper Foil (RCC) Market

Overview of the regional outlook of the Resin Coated Copper Foil (RCC) Market:

Key Reasons to Buy this Report:

Access to date statistics compiled by our researchers. These provide you with historical and forecast data, which is analyzed to tell you why your market is set to change

This enables you to anticipate market changes to remain ahead of your competitors

You will be able to copy data from the Excel spreadsheet straight into your marketing plans, business presentations, or other strategic documents

The concise analysis, clear graph, and table format will enable you to pinpoint the information you require quickly

Provision of market value (USD Billion) data for each segment and sub-segment

Indicates the region and segment that is expected to witness the fastest growth as well as to dominate the market

Analysis by geography highlighting the consumption of the product/service in the region as well as indicating the factors that are affecting the market within each region

Competitive landscape which incorporates the market ranking of the major players, along with new service/product launches, partnerships, business expansions, and acquisitions in the past five years of companies profiled

Extensive company profiles comprising of company overview, company insights, product benchmarking, and SWOT analysis for the major market players

The current as well as the future market outlook of the industry concerning recent developments which involve growth opportunities and drivers as well as challenges and restraints of both emerging as well as developed regions

Includes in-depth analysis of the market from various perspectives through Porter’s five forces analysis

Provides insight into the market through Value Chain

Market dynamics scenario, along with growth opportunities of the market in the years to come

6-month post-sales analyst support

In case of any queries or customization requirements, please connect with our sales team, who will ensure that your requirements are met.

Chapter Outline

Chapter 1 mainly introduces the statistical scope of the report, market division standards, and market research methods.

Chapter 2 is an executive summary of different market segments (by region, product type, application, etc), including the market size of each market segment, future development potential, and so on. It offers a high-level view of the current state of the Resin Coated Copper Foil (RCC) Market and its likely evolution in the short to mid-term, and long term.

Chapter 3 makes a detailed analysis of the market's competitive landscape of the market and provides the market share, capacity, output, price, latest development plan, merger, and acquisition information of the main manufacturers in the market.

Chapter 4 is the analysis of the whole market industrial chain, including the upstream and downstream of the industry, as well as Porter's five forces analysis.

Chapter 5 introduces the latest developments of the market, the driving factors and restrictive factors of the market, the challenges and risks faced by manufacturers in the industry, and the analysis of relevant policies in the industry.

Chapter 6 provides the analysis of various market segments according to product types, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different market segments.

Chapter 7 provides the analysis of various market segments according to application, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different downstream markets.

Chapter 8 provides a quantitative analysis of the market size and development potential of each region and its main countries and introduces the market development, future development prospects, market space, and capacity of each country in the world.

Chapter 9 introduces the basic situation of the main companies in the market in detail, including product sales revenue, sales volume, price, gross profit margin, market share, product introduction, recent development, etc.

Chapter 10 provides a quantitative analysis of the market size and development potential of each region in the next five years.

Chapter 11 provides a quantitative analysis of the market size and development potential of each market segment in the next five years.

Chapter 12 is the main points and conclusions of the report.

Get the Complete Report & TOC @ https://www.24chemicalresearch.com/reports/286669/global-resin-coated-copper-foil-forecast-market-2025-2032-433

Table of content

Table of Contents 1 Research Methodology and Statistical Scope 1.1 Market Definition and Statistical Scope of Resin Coated Copper Foil (RCC) 1.2 Key Market Segments 1.2.1 Resin Coated Copper Foil (RCC) Segment by Type 1.2.2 Resin Coated Copper Foil (RCC) Segment by Application 1.3 Methodology & Sources of Information 1.3.1 Research Methodology 1.3.2 Research Process 1.3.3 Market Breakdown and Data Triangulation 1.3.4 Base Year 1.3.5 Report Assumptions & Caveats 2 Resin Coated Copper Foil (RCC) Market Overview 2.1 Global Market Overview 2.1.1 Global Resin Coated Copper Foil (RCC) Market Size (M USD) Estimates and Forecasts (2019-2032) 2.1.2 Global Resin Coated Copper Foil (RCC) Sales Estimates and Forecasts (2019-2032) 2.2 Market Segment Executive Summary 2.3 Global Market Size by Region 3 Resin Coated Copper Foil (RCC) Market Competitive Landscape 3.1 Global Resin Coated Copper Foil (RCC) Sales by Manufacturers (2019-2025) 3.2 Global Resin Coated Copper Foil (RCC) Revenue Market Share by Manufacturers (2019-2025) 3.3 Resin Coated Copper Foil (RCC) Market Share by Company Type (Tier 1, Tier 2, and Tier 3) 3.4 Global Resin Coated Copper Foil (RCC) Average Price by Manufacturers (2019-2025) 3.5 Manufacturers Resin Coated Copper Foil (RCC) Sales Sites, Area Served, Product Type 3.6 Resin Coated Copper Foil (RCC) Market Competitive Situation and Trends 3.6.1 Resin Coated Copper Foil (RCC) Market Concentration Rate 3.6.2 Global 5 and 10 Largest Resin Coated Copper Foil (RCC) Player

Download FREE Sample of this Report @ https://www.24chemicalresearch.com/download-sample/286669/global-resin-coated-copper-foil-forecast-market-2025-2032-433

Follow Us On linkedin :- https://www.linkedin.com/company/24chemicalresearch/

0 notes