#Industrial Paints Singapore

Explore tagged Tumblr posts

Text

Walls That Stand the Test of Time

Discover Berger Paints' High-Quality Durable Wall Paints in Singapore. Our advanced formulations deliver exceptional durability, vibrant colors, and long-lasting performance, making them the perfect choice for residential and commercial projects alike.

#Paint Manufacturer Singapore#International Paint Singapore#Singapore Paint Supplier#Singapore Paint Distributor#Protective marine finishes#Aluminium Paint#Polyurethane paint in Singapore#Floor Coatings Singapore#Anti-Mould Paint Services#Interior Paints Singapore#Exterior Paints Singapore#Galvanized Paint#Industrial Paints Singapore#Buy Paint Singapore#Paint Shop Singapore#Paint Online Purchase

0 notes

Text

Exterior Excellence for Every Surface

Protect your exteriors with Berger Paints' Exterior Paints in Singapore. Our high-performance coatings offer superior weather resistance, color retention, and durability, ensuring your exteriors stay beautiful and protected.

#Paint Manufacturer Singapore#International Paint Singapore#Singapore Paint Supplier#Singapore Paint Distributor#Protective marine finishes#Aluminium Paint#Polyurethane paint in Singapore#Floor Coatings Singapore#Anti-Mould Paint Services#Interior Paints Singapore#Exterior Paints Singapore#Galvanized Paint#Industrial Paints Singapore#Buy Paint Singapore#Paint Shop Singapore#Paint Online Purchase

0 notes

Text

Top Paint Manufacturer for Premium Coatings in Singapore

Discover high-quality paint solutions from the leading paint manufacturer Singapore. We provide durable, vibrant coatings for residential, commercial, and industrial needs. Choose from eco-friendly and innovative options to suit your projects. Whether it's interior, exterior, or specialized coatings, our products guarantee exceptional performance and longevity. Enhance your spaces with our vast color palette and expert manufacturing standards.

2 notes

·

View notes

Text

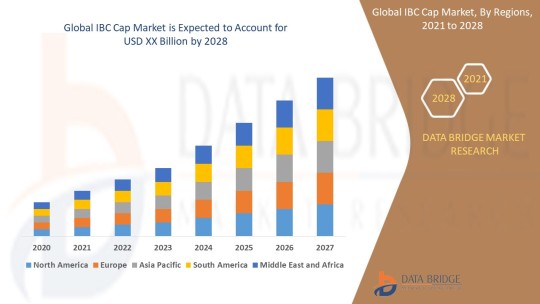

IBC Cap Market Size, Share, Trends, Growth and Competitive Analysis

"IBC Cap Market – Industry Trends and Forecast to 2028

Global IBC Cap Market, By Product Type (Flange, Plugs, Vent-in Plug, Vent-out Plug and Screw closure), Type (Plastic IBC, Metal IBC and Composite IBCs), Material Type (Plastics, Metal, Aluminium and Steel), End Use (Chemicals & Fertilizers, Petroleum & Lubricants, Paints, Inks & Dyes, Food & Beverage, Agriculture, Building & Construction, Healthcare & Pharmaceuticals and Mining), Application (Food And Drinks, Chemical Industry, Oil and Agriculture), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, U.A.E, Saudi Arabia, Egypt, South Africa, Israel, Rest of Middle East and Africa) Industry Trends and Forecast to 2028

Access Full 350 Pages PDF Report @

The global IBC cap market is expected to witness significant growth over the forecast period due to the increasing demand for intermediate bulk containers (IBCs) in various industries such as chemicals, food and beverages, pharmaceuticals, and others. The IBC caps play a crucial role in ensuring the safe storage and transportation of liquid products. The market growth is also being driven by technological advancements in IBC cap designs, such as tamper-evident seals and spouts for easy dispensing. Additionally, the growing focus on sustainability and recyclability of packaging materials is further boosting the adoption of IBC caps made from eco-friendly materials.

**Segments**

- Based on material type, the IBC cap market can be segmented into plastic, metal, and others. Plastic caps are widely used due to their lightweight nature and cost-effectiveness. - By cap type, the market can be categorized into screw caps, snap-on caps, and flip-top caps. Screw caps are preferred for their secure sealing properties. - On the basis of end-user industry, the market can be divided into chemicals, food and beverages, pharmaceuticals, and others. The chemicals segment is anticipated to hold a significant market share due to the widespread use of IBCs for storing chemical products.

**Market Players**

- TPS Industrial Srl - Schuetz GmbH & Co. KGaA - Mauser Packaging Solutions - Time Technoplast Ltd - Berry Global Inc. - THIELMANN UCON AG - Precision IBC, Inc. - Peninsula Packaging LLC

These market players are actively involved in strategic initiatives such as product launches, partnerships, and acquisitions to strengthen their market presence and expand their product offerings. The competitive landscape of the IBC cap market is characterized by intense competition, prompting companies to focus on innovation and quality to gain a competitive edge.

The Asia-Pacific region is expected to witness substantial growth in the IBC cap market, driven by the rapid industrialization and the increasing adoption of IBCsThe Asia-Pacific region represents a significant growth opportunity for the global IBC cap market due to several key factors. With rapid industrialization and the expanding manufacturing sector in countries like China, India, and Southeast Asia, there is a growing demand for efficient storage and transportation solutions, including IBCs and their associated caps. The increased focus on chemical production, food processing, and pharmaceutical manufacturing in the region further fuels the need for reliable packaging solutions like IBC caps. As these industries continue to grow, the adoption of IBC caps is expected to rise, driving market expansion in the Asia-Pacific region.

Moreover, the emphasis on enhancing safety standards and ensuring product integrity is a crucial factor contributing to the growth of the IBC cap market in Asia-Pacific. Regulations regarding the safe handling and transportation of hazardous chemicals and pharmaceuticals necessitate the use of high-quality caps that can effectively seal and protect the contents of IBCs. As companies in the region strive to comply with stringent regulatory requirements, the demand for advanced and secure IBC caps is projected to increase significantly.

Additionally, the shift towards sustainability and eco-friendly practices is another trend shaping the IBC cap market in Asia-Pacific. With growing environmental concerns and increasing awareness about plastic pollution, there is a rising preference for IBC caps made from recyclable and biodegradable materials. Market players in the region are focusing on developing sustainable packaging solutions to meet the evolving consumer demands and align with global sustainability goals. This shift towards eco-friendly IBC caps not only addresses environmental concerns but also presents market players with opportunities to differentiate their offerings and attract environmentally conscious customers.

Furthermore, the competitive landscape of the IBC cap market in Asia-Pacific is characterized by the presence of both local manufacturers and international players. Local companies often have a strong understanding of regional market dynamics and customer preferences, giving them a competitive advantage in catering to specific industry needs. On the other hand, multinational companies bring technological expertise and a wide product portfolio, which can appeal to a broader customer base seeking innovative and**Global IBC Cap Market, By Product Type**

- Flange - Plugs - Vent-in Plug - Vent-out Plug - Screw closure

**Type**

- Plastic IBC - Metal IBC - Composite IBCs

**Material Type**

- Plastics - Metal - Aluminium - Steel

**End Use**

- Chemicals & Fertilizers - Petroleum & Lubricants - Paints, Inks & Dyes - Food & Beverage - Agriculture - Building & Construction - Healthcare & Pharmaceuticals - Mining

**Application**

- Food And Drinks - Chemical Industry - Oil and Agriculture

The Global IBC Cap market is experiencing significant growth due to the rising demand for intermediate bulk containers across various industries. Plastic caps are increasingly preferred for their lightweight and cost-effective nature, driving market growth within the material type segment. Screw caps, known for their secure sealing properties, dominate the cap type category. The chemicals segment is anticipated to hold a substantial market share among end-user industries, attributed to the widespread use of IBCs for chemical storage. The market players in the industry are focusing on strategic initiatives like product launches and partnerships to enhance their market presence and offerings. The competitive landscape is intense, spurring companies to innovate and prioritize quality for a competitive advantage.

In Asia-Pacific, the IBC cap market is poised for robust growth fueled by rapid industrialization and the expanding manufacturing sector, particularly in countries like China,

Countries Studied:

North America (Argentina, Brazil, Canada, Chile, Colombia, Mexico, Peru, United States, Rest of Americas)

Europe (Austria, Belgium, Denmark, Finland, France, Germany, Italy, Netherlands, Norway, Poland, Russia, Spain, Sweden, Switzerland, United Kingdom, Rest of Europe)

Middle-East and Africa (Egypt, Israel, Qatar, Saudi Arabia, South Africa, United Arab Emirates, Rest of MEA)

Asia-Pacific (Australia, Bangladesh, China, India, Indonesia, Japan, Malaysia, Philippines, Singapore, South Korea, Sri Lanka, Thailand, Taiwan, Rest of Asia-Pacific)

Key Coverage in the IBC Cap Market Report:

Detailed analysis of IBC Cap Market by a thorough assessment of the technology, product type, application, and other key segments of the report

Qualitative and quantitative analysis of the market along with CAGR calculation for the forecast period

Investigative study of the market dynamics including drivers, opportunities, restraints, and limitations that can influence the market growth

Comprehensive analysis of the regions of the IBC Cap industry and their futuristic growth outlook

Competitive landscape benchmarking with key coverage of company profiles, product portfolio, and business expansion strategies

TABLE OF CONTENTS

Part 01: Executive Summary

Part 02: Scope of the Report

Part 03: Research Methodology

Part 04: Market Landscape

Part 05: Pipeline Analysis

Part 06: Market Sizing

Part 07: Five Forces Analysis

Part 08: Market Segmentation

Part 09: Customer Landscape

Part 10: Regional Landscape

Part 11: Decision Framework

Part 12: Drivers and Challenges

Part 13: Market Trends

Part 14: Vendor Landscape

Part 15: Vendor Analysis

Part 16: Appendix

Browse Trending Reports:

Calcium Glycinate Market Retinal Biologics Market Facial Fat Transfer Market Angio Suites Diagnostic Imaging Market Adoption Of Benelux Power Tools Market De Quervains Tenosynovitis Treatment Market Biodetectors And Accessories Market Colposcope Market Sports Medicine Market Automotive Adhesives Market Infrared Imaging Market Vapour Deposition Market Professional Diagnostics Market Ct Scanner Market Programmable Application Specific Integrated Circuit Asic Market Hospital Operating Room Or Products And Solutions Market Castor Oil Market Zika Virus Infection Drug Market Toluene Diisocynate Market Antibiotic Resistance Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: [email protected]"

2 notes

·

View notes

Text

Trumen Technologies Pvt. Ltd.” is an ISO 9001:2015 certified ,Indian based Manufacturer and Exporters of Level and Pressure sensing instruments. We at Trumen is a team of professionals having years of experience in Level and Pressure Instruments manufacturing who understands what customer needs, and try to fulfill those requirements in appropriate time with best Quality.

We have wide range of CE certified product like Radar Level Transmitters, Ultrasonic Level ,Vibrating fork solid level switch, Vibrating fork liquid level switch, Admittance point level switch, Capacitance point level switch, Vibrating rod point level switch, Conductivity point level switch, Capacitive continuous level transmitter, Hydrostatic continuous level transmitter, etc.

Our products used in different industrial applications in various industries like Power and Water, Oil and Gas, Petrochemical, Mining and Metal, Food and Beverages, Cement ,Pharmaceutical and many more. We are regularly supplying our products to NTPC, IOCL,BPCL, BORL, Cipla, Lupin, Cadila healthcare, Praj High Purity Systems , Ultratech Cement, Shree Cement ,Jindal Group ,TATA, Asian Paints, Procter & Gamble, Hindustan Unilever Ltd, Kirloskar, Vedanta, Nestle, Pepsi, BASF, Novartis and many more.

We are regularly exporting our products to USA, UK, South Korea, Italy ,Thailand, Taiwan, UAE, Tanzania, Turkey ,Sri Lanka ,Saudi Arabia , Kuwait ,Malaysia, Sweden, Canada, Egypt , Brazil ,Singapore etc.

Address: 39, Mangal Nagar, Behind Sai Ram Plaza, Near Rajeev Gandhi Circle, AB Road, Indore, Madhya Pradesh 452001

Web: https://trumen.in/

Contact: 0731 497 2065

#VibratingForkLevelSensor

#VibratingForkLevelSwitch

#VibratingRodPointLevelSwitch

#Vibratingrodpointlevelswitchmanufacturersinindia

#Vibratingrodpointlevelswitchsupplierinindia

#TuningForkPointLevelSwitch

#AdmittancePointLevelSwitch

#RotatingPaddleLevelSwitch

#RadarLeveltransmitter

#LevelSensor

#solidlevelswitch

#powderlevelswitch

#limestone

#coalbunker

#PVCpowder

#levelinstruments

#Levelswitch

#levelindicator

#leveltransmitter

#vibratingforklevelswitch#radarleveltransmitter#levelsensor#solidlevelswitch#capacitanceleveltransmitter#levelswitchinindia#levelindicator#rotatingpaddlelevelswitch#cementlevelsensor#vibratingforklevelsensor

2 notes

·

View notes

Text

Top 10 Commercial Painting Companies in Singapore

When it comes to choosing a commercial painting company in Singapore, the options can be overwhelming. Whether you're looking to spruce up your office space, retail store, or industrial facility, finding a reliable and skilled painting contractor is crucial. To help you narrow down your search, we've compiled a list of the top 10 commercial painting companies in Singapore that have garnered praise for their professionalism, quality of work, and customer satisfaction.

1. Best Painting Services Singapore

Best Painting Services Singapore is renowned for its comprehensive range of commercial painting solutions. With a commitment to quality and customer service, they offer tailored painting services that cater to various business needs.

2. Express Painting Services

Known for their efficiency and attention to detail, Express Painting Services has established itself as a trusted name in the commercial painting industry in Singapore.

3. Prime Painting Contractors

Specializing in large-scale commercial projects, Prime Painting Contractors is praised for their expertise in handling complex painting jobs with precision and professionalism.

4. Citywide Painting Solutions

Citywide Painting Solutions boasts a team of skilled painters who are dedicated to delivering high-quality results for commercial properties across Singapore.

5. ProPaint Services

With years of experience under their belt, ProPaint Services offers competitive pricing and top-notch painting services tailored to meet the unique needs of businesses in Singapore.

6. EcoPaint Contractors

Focused on sustainability, EcoPaint Contractors provides eco-friendly painting solutions without compromising on quality or performance.

7. Urban Painting Experts

Urban Painting Experts is known for their creativity and innovation in commercial painting, transforming spaces with their artistic touch.

8. Skyline Commercial Painters

Specializing in high-rise buildings and commercial complexes, Skyline Commercial Painters offers reliable painting services backed by extensive industry knowledge.

9. Precision Paintworks

Precision Paintworks prides itself on delivering precise and flawless painting finishes, making them a preferred choice for many commercial clients in Singapore.

10. Masterpiece Painters

With a reputation for excellence, Masterpiece Painters provides comprehensive painting solutions that exceed expectations, ensuring lasting impressions.

Choosing the right commercial painting company is essential for achieving superior results and maintaining the aesthetic appeal of your business premises. Whether you're looking for a company that specializes in office spaces, retail outlets, or industrial facilities, these top 10 commercial painting companies in Singapore are known for their professionalism, reliability, and commitment to quality.

For more information about each company and their services, visit their respective websites linked above.

Remember, investing in professional painting services not only enhances the appearance of your commercial property but also adds value and longevity to your investment. When it comes to commercial painting in Singapore, trust only the best.

2 notes

·

View notes

Text

Anyone who can make something of this piece is welcome to.

In one scenario highlighted by the Energy Market Authority in its 2050 committee report, nuclear energy could supply about 10 per cent of Singapore’s energy needs by 2050. This could potentially form a larger proportion of Singapore’s energy mix post-2050, once nuclear tech has been proven viable, said Prof Chung.

Electricity currently accounts for about 30% of Singapore’s energy consumption. Supplying two-thirds of that from fission within five years or so would seem to be entirely practicable, when we look at examples from Pickering to Barakah. It is difficult to see how the “viability” of atomic power there needs any proving which hasn’t been accomplished, for instance, by Finland, which has about the same population and also depends heavily on fuel imports.

In addition, newer nuclear power-plant designs like SMRs are being developed, and they have the potential to be much safer than many of the traditional power plants in operation today.

Claims that small modular reactors will be safer than existing nuclear generating units, like claims that extensive new research on atomic power safety is needed, are uselessly vague and even misleading without some illumination of just what deficiencies in safety are to be alleviated. What information is available seems to leave little doubt that fission is far and away the safest means of supplying energy on an industrial scale.

While severe nuclear accidents are few and far between, nuclear power has earned itself a bad reputation after disasters such as those in Fukushima and Chernobyl.

Must we reiterate that the Great East Japan Earthquake and Tsunami killed twenty thousand people? It is hard to understand why the damage to the reactors at Fukushima Daiichi is painted as the main story of that terrible day, except perhaps that it happened so much more slowly. The real “nuclear disaster” was the large-scale, long-lasting evacuation imposed, even though releases of radioactive materials from the stricken reactors were too small to justify (according to international standards) more than a “shelter in place” order.

We can certainly understand that the citizens of Singapore, with its small land area, would not want to risk losing any of that to something like the Chernobyl Exclusion Zone, but the Pickering accident of 1983 is proof positive that there are well-established power reactor designs available now that pose no such danger, and can be located without fear even in the environs of the largest cities.

2 notes

·

View notes

Text

Application of bitumen in building

Bitumen has numerous applications in the construction industry, primarily serving as an adhesive and waterproofing material. Its versatile properties make it indispensable in various building-related functions. Here are some key applications of bitumen in construction:

1. Roofing and Waterproofing:

Bitumen 60/70 is extensively used in roofing systems to provide waterproof membranes for flat roofs. Traditional bitumen roofing membranes consist of layers of bitumen sprayed with aggregate, with a carrier fabric made of polyester or glass in between. Polymer-modified bitumen sheets have become the standard for flat roof waterproofing. Bituminous roofing membranes can also be recycled easily, enhancing their sustainability.

2. Wall Sealing:

Bitumen 60/70 plays a crucial role in sealing walls, providing protection against water and moisture intrusion. It is applied to substrates such as bathrooms and toilets, which are constantly exposed to moisture, to prevent water penetration and safeguard the underlying structures.

3. Floor and Wall Insulation:

Bitumen 80/100 insulation is widely employed for building waterproofing, both horizontally and vertically. It effectively prevents water penetration into floorboards and walls, offering reliable protection. Bitumen's chemical and physical properties make it easy to work with and highly durable.

4. Sound Insulation:

Bitumen's sound-absorbing properties find applications beyond construction. It helps reduce noise transmission, such as the sound of footsteps under floor coverings. Special tar mats in cars and elevators utilize Bitumen 80/100 for sound insulation.

5. Electrical Cable Insulation:

Bitumen's low electrical conductivity makes it suitable for use as an insulating material for electrical cables. It helps protect the cables and prevent electrical hazards.

6. Other Uses:

Bitumen 80/100 & bitumen 60/70 finds application in various other areas, such as the paper industry and the manufacturing of paints and varnishes. Its thermal insulation properties are beneficial in different contexts.

From an ecological standpoint, bitumen is highly regarded for its long lifespan. It remains a popular construction material, with significant demand both domestically and in international markets. The producer of bitumen in Iran exports a large percentage of its production to other countries such as Singapore, Dubai, Panama.

In residential construction, plastic-modified bitumen (KMB) coatings are commonly used for insulation. They compete with bitumen-free FPD (Flexible Polymer Disc) seals, which are easier to apply and offer faster repair options.

Overall, the applications of bitumen in the construction industry are extensive, ranging from roofing and waterproofing to sound insulation and electrical cable insulation. Its versatility and durability make it a valuable material in various building-related functions.

Important Considerations Before Using Bitumen:

1. Surface Preparation:

Before applying bitumen, it is crucial to ensure that the surface is clean, dry, and free from any contaminants. Even the presence of dust, dirt, or grease can hinder the adhesion of the bitumen coating and compromise the effectiveness of the seal. Additionally, the surface should be free from frost. If there are old incompatible coatings, they must be removed. In the case of older buildings, previous applications of bituminous paints may not provide a suitable surface for polymer-modified bitumen (PMB) coatings.

2. Repairing Cracks and Unevenness:

Prior to applying bitumen, any cracks or unevenness on the surface should be repaired using appropriate materials like repair mortar or leveling compounds. This ensures a smooth and uniform surface, promoting better adhesion and a more effective seal.

3. Additional Preparatory Measures:

In some cases, additional preparatory measures may be necessary. One option is to use a layer of synthetic resin on the coarse-pored bed or to apply a sealing slurry. A sealing slurry is a waterproof mixture of cement and plastic that allows water vapor to pass through. The advantage of using a sealing slurry is that it can adhere well to old bituminous coatings, providing an ideal substrate for applying a thick new bituminous coating.

By following these steps and ensuring proper surface preparation, you can optimize the adhesion and effectiveness of bitumen coatings in various applications.

What are the suitable means for repairing cracks and unevenness on the surface before applying bitumen?

There are several suitable means for repairing cracks and unevenness on the surface before applying bitumen. The choice of repair method depends on the severity of the damage and the specific requirements of the project. Here are some common methods for repairing cracks and unevenness:

1. Crack Fillers and Sealants:

For smaller cracks, crack fillers or sealants can be used. These materials, such as asphalt-based crack fillers or specialized concrete crack sealants, are designed to fill and seal cracks, preventing water infiltration and further damage. They are typically applied using a caulk gun or trowel.

2. Repair Mortar:

Repair mortars are suitable for filling larger cracks, holes, or areas of unevenness. These mortars are made from a blend of cement, sand, and additives to enhance adhesion and strength. They can be mixed with water to create a workable paste and then applied to the damaged areas using a trowel or other appropriate tools. Repair mortars are commonly used for repairing concrete surfaces.

3. Leveling Compounds:

Leveling compounds, also known as self-leveling underlayments or floor levelers, are used to create a smooth and level surface. These compounds are typically made from a blend of cement, fine aggregates, and additives. They have a fluid consistency that allows them to flow and self-level over uneven areas. Leveling compounds are commonly used to repair uneven concrete or subfloor surfaces before applying flooring materials.

4. Patching Mixtures:

Patching mixtures, such as asphalt patching compounds or repair mixes, are specifically designed for repairing asphalt surfaces. They typically contain a combination of asphalt binder, aggregates, and additives. These mixtures can be applied to fill potholes, repair damaged areas, or smooth out unevenness in asphalt surfaces.

5. Resurfacing:

In cases where the damage or unevenness is more extensive, resurfacing the entire surface may be necessary. This involves applying a new layer of bitumen or asphalt mixture over the existing surface to create a smooth and uniform finish. Resurfacing can help address multiple issues, including cracks, potholes, and unevenness.

It's important to follow the manufacturer's instructions and best practices when using any repair materials. Additionally, proper surface preparation, including cleaning and removing loose debris, is essential before applying any repair method.

ATDM CO is a manufacturer and exporter of Bitumen 60/70, offering three different quality grades available in drums, bags, and bulk quantities. Our products are classified into premium, second, and third types, each with varying production costs and facilities. We provide a wide range of options to accommodate different customer needs and volume requirements.

#bitumen#bitumen 60/70#bitumen 80/100#bitumen 60/70 specs#bitumen penetration grade 60/70#bitumen 60/70 specification#bitumen 60 70#atdm co llc.

2 notes

·

View notes

Text

Unlock the Ultimate Shine with EA Detailer’s Paint Protection Coating

Your car is more than just a mode of transport—it's a reflection of your personality, taste, and lifestyle. At EA Detailer, we believe in elevating this reflection with cutting-edge paint protection coating that blends aesthetics with long-term durability. 💎

🧽 About Us – Where Passion Meets Precision

EA Detailer represents a distinctive voice in car paint surface treatment. With a devotion to detail and a passion for performance, we are Singapore’s trusted name for high-end vehicle care. From interior deep cleaning to exterior transformation, we go beyond the surface—literally and figuratively.

What sets us apart? 🧐 We merge avant-garde techniques with premium quality products to elevate your car’s condition and charisma. Whether you’re cruising the streets or turning heads at a car show, your vehicle will always shine bright with our expertise. 💫

🛡️ Our Services – Luxury Car Care at Its Finest

At EA Detailer, we offer a full suite of vehicle refinement solutions:

✅ Paint Protection Coating – Safeguard your paint from scratches, oxidation, and UV rays

✅ Ceramic Coating – We use only the best ceramic coating for cars, ensuring unmatched gloss and resistance

✅ Interior Deep Cleaning – Revitalize your car’s cabin with surgical-level cleanliness

✅ PPF (Paint Protection Film) – Ultimate shield against stone chips and surface damage

✅ Color Reinvention – Custom wrapping and paintwork to redefine your car’s look 🎨

With every treatment, we use the most respected detailing products in the industry, paired with masterful technique.

🎯 Our Mission – Excellence in Every Detail

Our mission is simple yet profound: To elevate car care into an art form, blending luxury, science, and precision. 🧪✨

We don’t just detail cars—we restore pride, revive paint, and reignite passion for driving. Our bespoke treatments are tailored to meet the unique needs of each client and vehicle. 💼🚘

🤩 Why Choose EA Detailer?

When it comes to paint protection coating, we aren’t just another detailing service—we’re a movement in automotive excellence. Here's why we're the first choice for car enthusiasts and professionals alike:

🔬 Cutting-Edge Technology

We implement the latest nanotechnology and ceramic innovations, giving your vehicle a hydrophobic shield that lasts for years. Water, dirt, and contaminants slide off like magic.

🏆 Industry-Leading Products

We only use the best ceramic coating for cars, ensuring your car gets nothing less than five-star treatment.

👨🔧 Experienced Craftsmen

Our detailing team are connoisseurs of car care, trained in both the science and artistry of surface refinement.

💎 Luxury Detailing Redefined

From paint enhancement to complete surface protection, we offer premium services with white-glove professionalism.

🌱 Eco-Conscious Detailing

We care for your car and the environment. Our techniques use eco-friendly and sustainable products that leave a minimal carbon footprint. 🌍💧

🔚 Conclusion – Preserve the Beauty, Drive with Confidence

A car is an investment—and like any valuable asset, it deserves long-lasting protection and care. At EA Detailer, we redefine what it means to take care of your vehicle. Our paint protection coating and best ceramic coating for cars are trusted by professionals, collectors, and luxury car lovers alike.

0 notes

Text

Professional Touch for Business Spaces

Trust Berger Paints for Professional Commercial Painting Services Singapore. Our expert team delivers impeccable results, enhancing the aesthetic appeal and longevity of commercial properties with precision and professionalism.

#Paint Manufacturer Singapore#International Paint Singapore#Singapore Paint Supplier#Singapore Paint Distributor#Protective marine finishes#Aluminium Paint#Polyurethane paint in Singapore#Floor Coatings Singapore#Anti-Mould Paint Services#Interior Paints Singapore#Exterior Paints Singapore#Galvanized Paint#Industrial Paints Singapore#Buy Paint Singapore#Paint Shop Singapore#Paint Online Purchase

0 notes

Text

Brilliant Sheen for Metal Surfaces

Protect your surfaces with Berger Paints' Aluminium Paint in Singapore. Our premium-quality coatings offer superior adhesion, corrosion resistance, and aesthetic appeal, ensuring your surfaces stay protected and looking great for years to come.

#Paint Manufacturer Singapore#International Paint Singapore#Singapore Paint Supplier#Singapore Paint Distributor#Protective marine finishes#Aluminium Paint#Polyurethane paint in Singapore#Floor Coatings Singapore#Anti-Mould Paint Services#Interior Paints Singapore#Exterior Paints Singapore#Galvanized Paint#Industrial Paints Singapore#Buy Paint Singapore#Paint Shop Singapore#Paint Online Purchase

0 notes

Text

From Vision to Reality: Junxin Engineering’s Trusted Construction Services in Singapore

Have a dream home or renovation project in mind but not sure where to start? At Junxin Engineering Pte. Ltd., we specialize in turning ideas into beautifully crafted spaces with our reliable and expert construction services in Singapore. Whether you're planning a complete overhaul or need targeted improvements, we are here to take your vision and turn it into reality—seamlessly, efficiently, and with unmatched quality.

Your Trusted Partner in Construction

Construction and home improvement projects can feel overwhelming. But with the right team by your side, the journey can be smooth and even enjoyable. That’s where Junxin Engineering Pte. Ltd. comes in.

We bring years of industry experience, a deep understanding of local building standards, and a passion for quality craftsmanship. Our clients choose us because we don’t just build structures—we build trust. From consultation to completion, we ensure transparency, open communication, and meticulous attention to detail in every project.

What We Offer

Our comprehensive construction services are tailored to meet the unique needs of every client. Whether you're upgrading your current space or starting fresh, we provide a wide range of solutions, including:

Residential Renovations (HDB, Condo, and Landed Homes)

Commercial Fit-Outs and Office Upgrades

Custom Design & Build Projects

Kitchen and Bathroom Makeovers

Tiling, Flooring & Painting

Structural Alterations & M&E Works

We use only high-quality materials and proven techniques, ensuring that every aspect of your project stands the test of time.

A Stress-Free Construction Experience

At Junxin Engineering Pte. Ltd., we believe in making your construction experience stress-free and enjoyable. Our process starts with understanding your goals, style preferences, and budget. From there, we create a clear project roadmap with timelines, materials, and design options, keeping you in the loop every step of the way.

Our project managers and skilled workers are hands-on, responsive, and committed to delivering top-notch results—on time and within budget. We’re proud to be known for our reliability and our ability to bring even the most ambitious visions to life.

Why Choose Junxin Engineering?

Experienced Team – Skilled professionals with deep industry knowledge Transparent Pricing – No hidden costs or surprises High-Quality Materials – Built to last with attention to detail Customer-Focused – We listen, we deliver, and we care End-to-End Service – From design consultation to final handover

Our satisfied clients across Singapore are a testament to our dedication, professionalism, and passion for excellence.

Let’s Build Something Great Together

Your dream space is closer than you think. Whether you're planning a renovation or a brand-new build, trust Junxin Engineering Pte. Ltd. to deliver beyond your expectations.

Contact Us Today: +65 9125 9885 Let’s take your vision from concept to reality—together.

0 notes

Text

Trumen Technologies Pvt. Ltd. is a renowned, ISO 9001:2015 certified Indian manufacturer and exporter specializing in advanced Level and Pressure sensing instruments. With years of expertise in the industry, Trumen’s dedicated team of professionals is committed to delivering high-quality products that meet the diverse needs of customers, ensuring timely delivery without compromising on quality.

We offer a broad range of CE-certified products, including:

Radar Level Transmitters

Ultrasonic Level Transmitters

Vibrating Fork Solid and Liquid Level Switches

Admittance Point Level Switches

Capacitance Point Level Switches

Vibrating Rod Point Level Switches

Conductivity Point Level Switches

Capacitive Continuous Level Transmitters

Hydrostatic Continuous Level Transmitters

Our instruments find application across various industries such as Power & Water, Oil & Gas, Petrochemical, Mining & Metals, Food & Beverages, Cement, Pharmaceuticals, and more. We are proud to serve major companies like NTPC, IOCL, BPCL, BORL, Cipla, Lupin, Cadila Healthcare, Praj High Purity Systems, Ultratech Cement, Shree Cement, Jindal Group, TATA, Asian Paints, Procter & Gamble, Hindustan Unilever, Kirloskar, Vedanta, Nestlé, Pepsi, BASF, Novartis, and many others.

Trumen Technologies is also a trusted supplier to international markets, exporting to countries including the USA, UK, South Korea, Italy, Thailand, Taiwan, UAE, Tanzania, Turkey, Sri Lanka, Saudi Arabia, Kuwait, Malaysia, Sweden, Canada, Egypt, Brazil, Singapore, and more.

Contact: 0731 497 2065

Contact Information: Address: 39, Mangal Nagar, Behind Sai Ram Plaza, Near Rajeev Gandhi Circle, AB Road, Indore, Madhya Pradesh 452001 Website: http://trumen.in/

1 note

·

View note

Text

Prefabricated Prefinished Volumetric Construction (PPVC): A Structural Engineer's Viewpoint in Singapore

In the face of rapid urbanisation and increasing demand for high-quality, cost-effective buildings, Singapore has witnessed a monumental shift in its construction methodologies. Prefabricated Prefinished Volumetric Construction (PPVC) is among the innovations revolutionising the construction industry. This cutting-edge approach offers significant speed, sustainability, and efficiency advantages—imperatives in the land-scarce city-state. To enhance productivity, the Building and Construction Authority (BCA) has been a driving force behind the widespread adoption of PPVC, advocating its use for various building types, from residential towers to commercial and public projects.

PPVC is more than just an innovative form of modular construction; it completely rethinks traditional construction practices. This article delves into the structural engineering perspective of PPVC in Singapore, discussing its unique features, challenges, and future potential while addressing the regulatory landscape and technological advancements shaping its future.

Understanding PPVC: A Game-Changer in Modern Construction

PPVC is often regarded as a transformative solution for urban construction, especially in cities with space constraints like Singapore. Unlike conventional prefabrication, where only parts of the building are constructed off-site, PPVC modules are fully pre-assembled, including walls, floors, ceilings, and interiors, before being transported and stacked on-site.

Key Features of PPVC

Off-Site Manufacturing: Modules are produced in high-precision factory settings, ensuring high-quality finishes and reducing the impact of on-site weather conditions.

Pre-Completed Interiors: Electrical systems, plumbing, and interior finishes are installed before the module is shipped, drastically cutting down the on-site labour needed.

Efficient Assembly Process: Modules are delivered and stacked in a pre-planned configuration, reducing construction time.

Minimal Wet Trades: Traditional construction methods involve extensive on-site work, including pouring concrete, plastering, and painting. PPVC dramatically cuts these processes down to a minimum.

PPVC is particularly suited for high-rise residential buildings, hotels, dormitories, and healthcare facilities—environments with premium space and repetitive layouts are common.

Structural Engineering Considerations for PPVC

While PPVC offers numerous benefits, it presents a unique engineering challenge. Structural engineers must consider several critical aspects to ensure the safety, stability, and longevity of PPVC buildings.

1. Load Transfer and Structural Integrity

PPVC modules are typically stacked to form multi-story structures. To ensure that these buildings remain safe and stable, engineers must design the modules to handle a variety of structural loads:

Gravity Loads include the weight of the building itself and any additional loads from occupants, furniture, and equipment. Engineers must ensure that each module can effectively transfer vertical loads down to the foundation and maintain this load distribution as the structure grows taller.

Lateral Loads: These forces, caused by wind, seismic activity, or other external factors, can place significant stress on a building. While Singapore is not as prone to large-scale seismic events, engineers must still account for lateral forces, especially for taller buildings. PPVC structures often incorporate reinforced concrete cores or steel-framed structures to resist these forces.

Differential Movement and Settlement: Singapore's soil conditions often involve soft clay and can result in differential settlement. Engineers must design foundations that accommodate settlement without compromising structural integrity, using techniques like post-tensioning or deep pile foundations to counteract the uneven settling of modules.

2. Material Selection for PPVC

The selection of appropriate materials is paramount in PPVC construction. Each material must contribute to the building's overall structural strength and durability while aligning with BCA regulations regarding fire safety, acoustic performance, and environmental sustainability.

Reinforced Concrete (RC): Used for its superior compressive strength and durability, reinforced concrete is often the material of choice for the core structure of PPVC modules.

Structural Steel: Steel offers a balance of strength and flexibility and is commonly used for module frameworks. It facilitates rapid assembly and enables lighter, more flexible structures.

Light Gauge Steel (LGS): LGS is a suitable option for buildings with less demanding load requirements, providing flexibility and ease of fabrication.

These materials must be engineered to meet stringent fire resistance standards, particularly for high-rise buildings, and ensure that acoustic performance meets expectations in terms of privacy and comfort.

3. Connection Systems and Modular Integration

One of the biggest challenges in PPVC is ensuring that the modular units integrate seamlessly once they are delivered to the site. The connection systems between these modules must be designed for both structural integrity and ease of assembly:

Bolted vs. Welded Joints: Engineers must decide whether bolted or welded joints are most suitable for the project. Bolted joints allow quicker assembly and disassembly, while welded joints offer enhanced stability.

Inter-Module Connections: These connections are vital for ensuring that all modules are securely integrated. Steel plates, grout pockets, and post-tensioning techniques are commonly used.

Waterproofing and Sealing: Preventing water ingress at module joints is critical for maintaining the building's durability and comfort. Advanced waterproofing membranes and sealing techniques ensure that moisture does not affect the internal spaces.

Regulatory Compliance and Standards for PPVC in Singapore

The Building and Construction Authority (BCA) plays a central role in regulating the use of PPVC in Singapore. The government's focus on construction productivity and sustainability means that PPVC projects must meet strict standards to ensure their success.

1. BCA's Guidelines for PPVC Implementation

To maintain safety and quality, the BCA enforces rigorous standards for PPVC:

Structural Robustness: PPVC projects must comply with the Eurocode 2 and 3 standards, which provide guidelines for the design of concrete and steel structures.

Fire Safety: Modules must meet fire safety codes, ensuring fire-resistant materials use and maintaining fire compartmentalisation throughout the building.

Acoustic Performance: Acoustic testing and compliance with BCA's acoustic performance standards are essential to maintaining privacy and comfort.

CONQUAS Compliance: The Construction Quality Assessment System (CONQUAS) evaluates construction quality, and PPVC projects are required to meet high-quality standards in both construction and finishes.

2. Government Incentives for Productivity

The BCA actively supports the use of PPVC through financial incentives and prioritisation of projects that incorporate Design for Manufacturing and Assembly (DfMA) principles. The government encourages builders and contractors to adopt more efficient construction methods by offering grants and tax incentives. Structural engineers play a critical role in ensuring compliance with these regulations while optimising the overall efficiency of PPVC projects.

Successful Case Studies of PPVC in Singapore

Several key projects in Singapore have already showcased the success of PPVC in transforming construction timelines, costs, and quality.

1. The Clement Canopy – Singapore's First High-Rise PPVC Residential Tower

Project Type: Residential (40-storey twin towers)

PPVC Strategy: Over 1,800 volumetric modules were prefabricated off-site and assembled on-site.

Results: The project saw a 25% reduction in construction time and improved quality control.

2. Jewel Changi Airport's YOTELAIR Hotel

Project Type: Hospitality (130 modular hotel rooms)

PPVC Strategy: Pre-assembled modular units were delivered and installed in record time.

Benefits: The project minimised disruption to airport operations and provided a high level of finish accuracy.

3. Tengah HDB Housing Development

Project Type: Public housing (Future Smart & Sustainable Town)

PPVC Strategy: Modular concrete units were extensively used to reduce construction time.

Impact: The project has provided faster delivery and sustainability benefits, serving as a model for future public housing in Singapore.

Looking Ahead: The Future of PPVC in Singapore

1. Digital Innovation in Design and Construction

Integrating Building Information Modeling (BIM) and Artificial Intelligence (AI) transforms PPVC design. Engineers can now simulate the structural performance of modules before fabrication, allowing for more precise error prediction and optimisation. These tools also enable the streamlining of supply chains and better coordination between architects, engineers, and contractors.

2. Sustainability and Circular Economy Practices

PPVC supports Singapore's Green Plan 2030, which aims to create more sustainable urban environments. Innovations in PPVC include solar-integrated facades and recyclable modular units, which contribute to a circular economy in which materials can be reused or repurposed.

3. The Future of Skyscrapers and Complex Structures

As PPVC technologies advance, constructing high-rise skyscrapers and complex structures through modular construction is becoming more feasible. The next frontier for PPVC may include 50-storey and taller buildings by utilising hybrid systems combining steel and concrete for enhanced load-bearing capacity.

Conclusion

PPVC is revolutionising the way buildings are constructed in Singapore. Providing faster, safer, and more sustainable construction solutions offers significant advantages over traditional methods. For structural engineers, adopting PPVC requires careful consideration of load distribution, material selection, and modular integration. With regulatory backing from the BCA and the integration of advanced technologies, PPVC has the potential to shape the future of urban construction in Singapore, leading to smarter, greener cities.

As Singapore continues its journey toward sustainable urbanisation, PPVC stands poised to play a central role in shaping the skyline of tomorrow.

1 note

·

View note

Text

Why Should You Remodel Your HDB Kitchen?

Renovating your HDB kitchen offers numerous benefits, including increased property value, enhanced functionality, and a fresh, modern aesthetic. A well-designed kitchen improves cooking efficiency, optimizes space, and incorporates energy-efficient appliances, reducing utility costs in the long run.

How Much Does an HDB Kitchen Renovation Cost in Singapore?

The cost of HDB kitchen remodeling varies based on size, materials, and complexity. On average:

Basic renovation (new cabinets, countertops, and flooring): SGD 10,000 - SGD 20,000

Mid-range renovation (custom cabinetry, premium countertops, upgraded appliances): SGD 20,000 - SGD 35,000

Luxury renovation (high-end materials, smart features, and extensive reconfiguration): SGD 35,000 - SGD 50,000+

What Should You Consider Before an HDB Kitchen Remodel?

Before starting your HDB kitchen renovation, keep these factors in mind:

Budget Planning: Set a realistic budget for the renovation.

Optimized Layout: Choose a design that maximizes space and efficiency.

Appliance Selection: Invest in energy-efficient and space-saving appliances.

Storage Solutions: Use smart storage options like pull-out drawers and overhead cabinets.

Material Durability: Opt for easy-to-maintain surfaces such as quartz or granite countertops.

Which Kitchen Layout Works Best for an HDB Flat?

Singapore’s HDB kitchens are often compact, making layout selection crucial. Consider these space-efficient designs:

Galley Kitchen: Ideal for narrow spaces with two parallel counters.

L-Shaped Kitchen: Maximizes corner space and offers flexibility.

U-Shaped Kitchen: Provides ample storage and counter space.

Open-Concept Kitchen: Seamlessly connects the kitchen with the living area.

What Are the Latest HDB Kitchen Design Trends?

Modern HDB kitchen designs blend aesthetics with practicality. Popular trends include:

Minimalist Designs: Clean lines, neutral colors, and sleek cabinetry.

Smart Kitchens: AI-powered appliances, touchless faucets, and automated lighting.

Eco-Friendly Features: Energy-efficient lighting, sustainable materials, and water-saving fixtures.

Industrial Chic: Matte black finishes, exposed brick, and metal accents.

What Common Mistakes Should You Avoid in an HDB Kitchen Remodel?

Avoid these costly errors during your HDB kitchen renovation:

Overcrowding: Stick to essential appliances and furniture to prevent clutter.

Poor Ventilation: Install a strong range hood to control smoke and odors.

Inadequate Lighting: Use layered lighting—ambient, task, and accent lighting.

Limited Storage: Plan sufficient cabinets, shelves, and organizers to maximize space.

How Long Does an HDB Kitchen Renovation Take?

The timeline for an HDB kitchen renovation depends on the complexity of the project:

Minor upgrades (painting, cabinet refacing): 1-2 weeks

Standard renovation (full cabinetry and countertop replacement): 4-6 weeks

Major overhaul (structural changes, plumbing, electrical work): 6-8 weeks

How to Choose the Best HDB Kitchen Renovation Contractor in Singapore?

Selecting a reliable contractor is key to a successful renovation. Consider these factors:

Check Reviews: Look at customer feedback and ratings.

Verify Licenses: Ensure the contractor is HDB-registered and BCA-certified.

Get Detailed Quotes: Compare multiple quotations before making a decision.

Inspect Previous Work: Visit completed projects to assess quality.

What Are the HDB Renovation Guidelines for Kitchen Remodeling?

HDB has strict renovation guidelines that must be followed, including:

Wall Hacking Restrictions: Structural walls cannot be removed.

Plumbing and Gas Rules: Relocating sinks and stoves requires HDB approval.

Electrical Work Compliance: Only HDB-licensed electricians can handle rewiring.

Noise Control: Loud work is restricted to 9 AM - 5 PM on weekdays.

How to Maximize Storage in a Small HDB Kitchen?

To maximize space in small HDB kitchens, implement these smart storage solutions:

Vertical Storage: Use wall-mounted shelves and cabinets.

Foldable Furniture: Opt for space-saving, multifunctional pieces.

Pull-Out Pantry: Utilize slim sliding racks for easy access.

Corner Storage: Install Lazy Susans or carousel shelves.

Final Thoughts on HDB Kitchen Remodeling in Singapore

A well-executed HDB kitchen renovation enhances both functionality and aesthetics. By carefully planning your layout, choosing the right materials, and hiring a trusted contractor, you can create a modern, efficient, and stylish kitchen space.

#singapore#architecture#interior design#home interior#interior decorating#interiors#kitchen renovators near me#kitchen design#kitchen renovation#kitchen

0 notes