#Industrial Lubricants Market Growth

Explore tagged Tumblr posts

Text

Industrial Lubricants Market Overview, Growth Analysis, Trends and Forecast By 2028

The Industrial Lubricants Market sector is undergoing rapid transformation, with significant growth and innovations expected by 2028. In-depth market research offers a thorough analysis of market size, share, and emerging trends, providing essential insights into its expansion potential. The report explores market segmentation and definitions, emphasizing key components and growth drivers. Through the use of SWOT and PESTEL analyses, it evaluates the sector’s strengths, weaknesses, opportunities, and threats, while considering political, economic, social, technological, environmental, and legal influences. Expert evaluations of competitor strategies and recent developments shed light on geographical trends and forecast the market’s future direction, creating a solid framework for strategic planning and investment decisions.

Brief Overview of the Industrial Lubricants Market:

The global Industrial Lubricants Market is expected to experience substantial growth between 2024 and 2031. Starting from a steady growth rate in 2023, the market is anticipated to accelerate due to increasing strategic initiatives by key market players throughout the forecast period.

Get a Sample PDF of Report - https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-industrial-lubricants-market

Which are the top companies operating in the Industrial Lubricants Market?

The report profiles noticeable organizations working in the water purifier showcase and the triumphant methodologies received by them. It likewise reveals insights about the share held by each organization and their contribution to the market's extension. This Global Industrial Lubricants Market report provides the information of the Top Companies in Industrial Lubricants Market in the market their business strategy, financial situation etc.

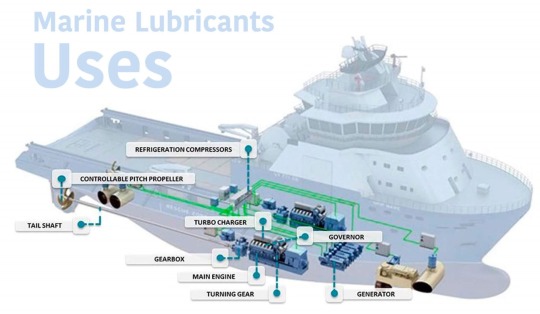

Shell group of companies, BP, Chevron Corporation., LUKOIL Marine Lubricants DMCC, Exxon Mobil Corporation., Eni S.p.A., Croda International Plc, Total Group, Synforce Lubricants., Valvoline LLC, Lubricon, Bailey’s Marine Fuels, Chevron Corporation., CASTROL LIMITED, China Petrochemical Corporation., Gulf Oil, Indian Oil Corporation Ltd, PETRONAS Lubricants International

Report Scope and Market Segmentation

Which are the driving factors of the Industrial Lubricants Market?

The driving factors of the Industrial Lubricants Market are multifaceted and crucial for its growth and development. Technological advancements play a significant role by enhancing product efficiency, reducing costs, and introducing innovative features that cater to evolving consumer demands. Rising consumer interest and demand for keyword-related products and services further fuel market expansion. Favorable economic conditions, including increased disposable incomes, enable higher consumer spending, which benefits the market. Supportive regulatory environments, with policies that provide incentives and subsidies, also encourage growth, while globalization opens new opportunities by expanding market reach and international trade.

Industrial Lubricants Market - Competitive and Segmentation Analysis:

**Segments**

- By Type: Mineral Oil Lubricants, Synthetic Lubricants, Bio-Based Lubricants - By Base Oil: Group I, Group II, Group III, Group IV, Group V - By End-Use Industry: Manufacturing, Automotive, Mining, Construction, Power Generation, Others

The global industrial lubricants market is projected to witness significant growth by the year 2028. The market is segmented by type into mineral oil lubricants, synthetic lubricants, and bio-based lubricants. Among these, the synthetic lubricants segment is expected to dominate due to their superior properties such as high performance in extreme temperatures and environments. Based on base oil, the market is classified into Group I, Group II, Group III, Group IV, and Group V. Group II base oil is anticipated to hold a substantial market share owing to its high viscosity index and low sulfur content. When considering end-use industries, the major sectors driving the demand for industrial lubricants include manufacturing, automotive, mining, construction, and power generation.

**Market Players**

- Exxon Mobil Corporation - Royal Dutch Shell Plc - TotalEnergies - Chevron Corporation - BP p.l.c. - FUCHS - Idemitsu Kosan Co., Ltd. - PetroChina Company Limited - Indian Oil Corporation Ltd. - Sinopec Corp.

The global industrial lubricants market is highly competitive with the presence of several key players driving market growth. Exxon Mobil Corporation, Royal Dutch Shell Plc, and TotalEnergies are among the leading companies in the market with a strong global presence and extensive product portfolios. Other prominent players such as Chevron Corporation, BP p.l.c., and FUCHS are also focusing on research and development activities to introduce innovative lubricant solutions catering to diverse industrial applications. Idemitsu Kosan Co., Ltd., PetroChina Company Limited, Indian Oil Corporation Ltd., and Sinopec Corp. are key players operating in regional markets, contributing toThe global industrial lubricants market is dynamic and highly competitive, characterized by the presence of key players such as Exxon Mobil Corporation, Royal Dutch Shell Plc, TotalEnergies, Chevron Corporation, and BP p.l.c., among others. These companies have a significant market share and a strong global presence, enabling them to maintain their competitive edge through continuous innovation and product development. Exxon Mobil Corporation, a global leader in the industry, is known for its extensive range of high-quality industrial lubricants catering to various sectors like manufacturing, automotive, and power generation. Royal Dutch Shell Plc, another major player, offers a diverse portfolio of synthetic and bio-based lubricants that meet the stringent requirements of modern industrial applications.

TotalEnergies is also a key player in the industrial lubricants market, focusing on sustainability and environmental-friendly solutions. The company's commitment to research and development has led to the introduction of innovative products that address evolving industry demands while minimizing environmental impact. Chevron Corporation and BP p.l.c. are renowned for their advanced lubricant technologies and strategic partnerships with industry stakeholders, positioning them as trusted suppliers in the market. FUCHS, a prominent player in the sector, emphasizes the development of specialty lubricants tailored to niche applications in sectors such as mining and construction.

Idemitsu Kosan Co., Ltd., PetroChina Company Limited, Indian Oil Corporation Ltd., and Sinopec Corp. play crucial roles in regional markets, offering localized expertise and tailored solutions to meet specific industry requirements. These companies leverage their regional presence to establish strong customer relationships and provide customized lubricant solutions that address local market needs effectively. With a focus on quality, reliability, and sustainability, these players contribute to the overall growth and innovation in the industrial lubricants market.

Emerging trends in the industrial lubricants market include a shift towards bio-based lubricants driven by environmental regulations and sustainability initiatives. Bio-based lubricants are gaining traction due to their biodegradability, lower toxicity, and renewable sourcing, making them attractive options**Market Players:**

- Shell group of companies - BP - Chevron Corporation - LUKOIL Marine Lubricants DMCC - Exxon Mobil Corporation - Eni S.p.A. - Croda International Plc - Total Group - Synforce Lubricants - Valvoline LLC - Lubricon - Bailey’s Marine Fuels - Chevron Corporation - CASTROL LIMITED - China Petrochemical Corporation - Gulf Oil - Indian Oil Corporation Ltd - PETRONAS Lubricants International

The industrial lubricants market is experiencing robust growth fueled by increasing industrialization across key sectors such as manufacturing, automotive, mining, and construction. The segmentation by type, base oil, and end-use industry provides a comprehensive view of the market dynamics and growth opportunities. Synthetic lubricants are gaining traction due to their superior performance characteristics, driving the dominance of this segment in the market. Group II base oil is expected to exhibit significant demand owing to its favorable viscosity index and low sulfur content. The manufacturing and automotive industries are major end-users of industrial lubricants, creating a steady demand for high-quality lubricant solutions.

Key market players such as Exxon Mobil Corporation, Royal Dutch Shell Plc, TotalEnergies, and Chevron Corporation are at the forefront of market competition, leveraging their technological expertise and global presence to maintain a competitive edge. These companies are actively involved in research and development activities to introduce innovative lubricant formulations that meet evolving industry requirements. The

North America, particularly the United States, will continue to exert significant influence that cannot be overlooked. Any shifts in the United States could impact the development trajectory of the Industrial Lubricants Market. The North American market is poised for substantial growth over the forecast period. The region benefits from widespread adoption of advanced technologies and the presence of major industry players, creating abundant growth opportunities.

Similarly, Europe plays a crucial role in the global Industrial Lubricants Market, expected to exhibit impressive growth in CAGR from 2024 to 2028.

Explore Further Details about This Research Industrial Lubricants Market Report https://www.databridgemarketresearch.com/reports/global-industrial-lubricants-market

Key Benefits for Industry Participants and Stakeholders: –

Industry drivers, trends, restraints, and opportunities are covered in the study.

Neutral perspective on the Industrial Lubricants Market scenario

Recent industry growth and new developments

Competitive landscape and strategies of key companies

The Historical, current, and estimated Industrial Lubricants Market size in terms of value and size

In-depth, comprehensive analysis and forecasting of the Industrial Lubricants Market

Geographically, the detailed analysis of consumption, revenue, market share and growth rate, historical data and forecast (2024-2031) of the following regions are covered in Chapters

The countries covered in the Industrial Lubricants Market report are U.S., Canada and Mexico in North America, Brazil, Argentina and Rest of South America as part of South America, Germany, Italy, U.K., France, Spain, Netherlands, Belgium, Switzerland, Turkey, Russia, Rest of Europe in Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA

Detailed TOC of Industrial Lubricants Market Insights and Forecast to 2028

Part 01: Executive Summary

Part 02: Scope Of The Report

Part 03: Research Methodology

Part 04: Industrial Lubricants Market Landscape

Part 05: Pipeline Analysis

Part 06: Industrial Lubricants Market Sizing

Part 07: Five Forces Analysis

Part 08: Industrial Lubricants Market Segmentation

Part 09: Customer Landscape

Part 10: Regional Landscape

Part 11: Decision Framework

Part 12: Drivers And Challenges

Part 13: Industrial Lubricants Market Trends

Part 14: Vendor Landscape

Part 15: Vendor Analysis

Part 16: Appendix

Browse More Reports:

Japan: https://www.databridgemarketresearch.com/jp/reports/global-industrial-lubricants-market

China: https://www.databridgemarketresearch.com/zh/reports/global-industrial-lubricants-market

Arabic: https://www.databridgemarketresearch.com/ar/reports/global-industrial-lubricants-market

Portuguese: https://www.databridgemarketresearch.com/pt/reports/global-industrial-lubricants-market

German: https://www.databridgemarketresearch.com/de/reports/global-industrial-lubricants-market

French: https://www.databridgemarketresearch.com/fr/reports/global-industrial-lubricants-market

Spanish: https://www.databridgemarketresearch.com/es/reports/global-industrial-lubricants-market

Korean: https://www.databridgemarketresearch.com/ko/reports/global-industrial-lubricants-market

Russian: https://www.databridgemarketresearch.com/ru/reports/global-industrial-lubricants-market

Data Bridge Market Research:

Today's trends are a great way to predict future events!

Data Bridge Market Research is a market research and consulting company that stands out for its innovative and distinctive approach, as well as its unmatched resilience and integrated methods. We are dedicated to identifying the best market opportunities, and providing insightful information that will help your business thrive in the marketplace. Data Bridge offers tailored solutions to complex business challenges. This facilitates a smooth decision-making process. Data Bridge was founded in Pune in 2015. It is the product of deep wisdom and experience.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC: +653 1251 2027

Email:- [email protected]

#Industrial Lubricants Market Size#Industrial Lubricants Market Shares#Industrial Lubricants Market Forecast#Industrial Lubricants Market Growth#Industrial Lubricants Market Demand

0 notes

Text

The global industrial lubricants market is on a steady rise, reaching an impressive $67.5 Billion in 2023. By 2032, it’s expected to grow to $90.3 Billion, thanks to innovations like bio-based lubricants and advanced industrial automation

0 notes

Text

#Electric Vehicle Fluids and Lubricants Market#Electric Vehicle Fluids and Lubricants Market Trends#Electric Vehicle Fluids and Lubricants Market Growth#Electric Vehicle Fluids and Lubricants Market Industry#Electric Vehicle Fluids and Lubricants Market Research#Electric Vehicle Fluids and Lubricants Market Report

0 notes

Text

The Aviation Lubricants Market is estimated at USD 804 Million in 2022 and is projected to reach USD 1,082 Million by 2027, at a CAGR of 6.1% from 2022 to 2027.

#Aviation Lubricant#Aviation Lubricant Market#Aviation Lubricant Industry#Aviation Lubricant Market Trends#Aviation Lubricant Market Report#Aviation Lubricant Market Value#Aviation Lubricant Market Forecast#Aviation Lubricant Market Growth

0 notes

Text

According to MarkNtel Advisors, the Global Fluid and Lubricants for Electric Vehicle Market is anticipated to grow at around 17.5% CAGR during the forecast period, i.e., 2021-26. The market growth primarily attributes to the rising inclination of consumers toward EVs as they are eco-friendly, sustainable, & help curb CO2 emissions, coupled with the burgeoning need for durable fluids for EVs and the introduction of various types of coolants & lubricants.

#Fluid and Lubricants for Electric Vehicle Market#Fluid and Lubricants for Electric Vehicle Market growth#Fluid and Lubricants for Electric Vehicle Market size#Fluid and Lubricants for Electric Vehicle Market industry

0 notes

Text

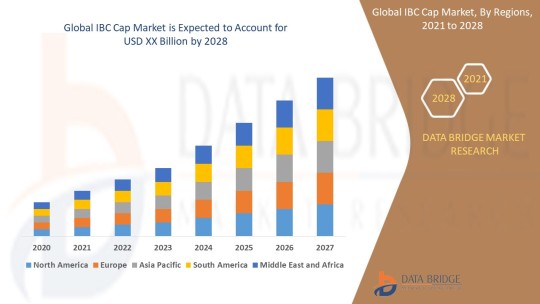

IBC Cap Market Size, Share, Trends, Growth and Competitive Analysis

"IBC Cap Market – Industry Trends and Forecast to 2028

Global IBC Cap Market, By Product Type (Flange, Plugs, Vent-in Plug, Vent-out Plug and Screw closure), Type (Plastic IBC, Metal IBC and Composite IBCs), Material Type (Plastics, Metal, Aluminium and Steel), End Use (Chemicals & Fertilizers, Petroleum & Lubricants, Paints, Inks & Dyes, Food & Beverage, Agriculture, Building & Construction, Healthcare & Pharmaceuticals and Mining), Application (Food And Drinks, Chemical Industry, Oil and Agriculture), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, U.A.E, Saudi Arabia, Egypt, South Africa, Israel, Rest of Middle East and Africa) Industry Trends and Forecast to 2028

Access Full 350 Pages PDF Report @

The global IBC cap market is expected to witness significant growth over the forecast period due to the increasing demand for intermediate bulk containers (IBCs) in various industries such as chemicals, food and beverages, pharmaceuticals, and others. The IBC caps play a crucial role in ensuring the safe storage and transportation of liquid products. The market growth is also being driven by technological advancements in IBC cap designs, such as tamper-evident seals and spouts for easy dispensing. Additionally, the growing focus on sustainability and recyclability of packaging materials is further boosting the adoption of IBC caps made from eco-friendly materials.

**Segments**

- Based on material type, the IBC cap market can be segmented into plastic, metal, and others. Plastic caps are widely used due to their lightweight nature and cost-effectiveness. - By cap type, the market can be categorized into screw caps, snap-on caps, and flip-top caps. Screw caps are preferred for their secure sealing properties. - On the basis of end-user industry, the market can be divided into chemicals, food and beverages, pharmaceuticals, and others. The chemicals segment is anticipated to hold a significant market share due to the widespread use of IBCs for storing chemical products.

**Market Players**

- TPS Industrial Srl - Schuetz GmbH & Co. KGaA - Mauser Packaging Solutions - Time Technoplast Ltd - Berry Global Inc. - THIELMANN UCON AG - Precision IBC, Inc. - Peninsula Packaging LLC

These market players are actively involved in strategic initiatives such as product launches, partnerships, and acquisitions to strengthen their market presence and expand their product offerings. The competitive landscape of the IBC cap market is characterized by intense competition, prompting companies to focus on innovation and quality to gain a competitive edge.

The Asia-Pacific region is expected to witness substantial growth in the IBC cap market, driven by the rapid industrialization and the increasing adoption of IBCsThe Asia-Pacific region represents a significant growth opportunity for the global IBC cap market due to several key factors. With rapid industrialization and the expanding manufacturing sector in countries like China, India, and Southeast Asia, there is a growing demand for efficient storage and transportation solutions, including IBCs and their associated caps. The increased focus on chemical production, food processing, and pharmaceutical manufacturing in the region further fuels the need for reliable packaging solutions like IBC caps. As these industries continue to grow, the adoption of IBC caps is expected to rise, driving market expansion in the Asia-Pacific region.

Moreover, the emphasis on enhancing safety standards and ensuring product integrity is a crucial factor contributing to the growth of the IBC cap market in Asia-Pacific. Regulations regarding the safe handling and transportation of hazardous chemicals and pharmaceuticals necessitate the use of high-quality caps that can effectively seal and protect the contents of IBCs. As companies in the region strive to comply with stringent regulatory requirements, the demand for advanced and secure IBC caps is projected to increase significantly.

Additionally, the shift towards sustainability and eco-friendly practices is another trend shaping the IBC cap market in Asia-Pacific. With growing environmental concerns and increasing awareness about plastic pollution, there is a rising preference for IBC caps made from recyclable and biodegradable materials. Market players in the region are focusing on developing sustainable packaging solutions to meet the evolving consumer demands and align with global sustainability goals. This shift towards eco-friendly IBC caps not only addresses environmental concerns but also presents market players with opportunities to differentiate their offerings and attract environmentally conscious customers.

Furthermore, the competitive landscape of the IBC cap market in Asia-Pacific is characterized by the presence of both local manufacturers and international players. Local companies often have a strong understanding of regional market dynamics and customer preferences, giving them a competitive advantage in catering to specific industry needs. On the other hand, multinational companies bring technological expertise and a wide product portfolio, which can appeal to a broader customer base seeking innovative and**Global IBC Cap Market, By Product Type**

- Flange - Plugs - Vent-in Plug - Vent-out Plug - Screw closure

**Type**

- Plastic IBC - Metal IBC - Composite IBCs

**Material Type**

- Plastics - Metal - Aluminium - Steel

**End Use**

- Chemicals & Fertilizers - Petroleum & Lubricants - Paints, Inks & Dyes - Food & Beverage - Agriculture - Building & Construction - Healthcare & Pharmaceuticals - Mining

**Application**

- Food And Drinks - Chemical Industry - Oil and Agriculture

The Global IBC Cap market is experiencing significant growth due to the rising demand for intermediate bulk containers across various industries. Plastic caps are increasingly preferred for their lightweight and cost-effective nature, driving market growth within the material type segment. Screw caps, known for their secure sealing properties, dominate the cap type category. The chemicals segment is anticipated to hold a substantial market share among end-user industries, attributed to the widespread use of IBCs for chemical storage. The market players in the industry are focusing on strategic initiatives like product launches and partnerships to enhance their market presence and offerings. The competitive landscape is intense, spurring companies to innovate and prioritize quality for a competitive advantage.

In Asia-Pacific, the IBC cap market is poised for robust growth fueled by rapid industrialization and the expanding manufacturing sector, particularly in countries like China,

Countries Studied:

North America (Argentina, Brazil, Canada, Chile, Colombia, Mexico, Peru, United States, Rest of Americas)

Europe (Austria, Belgium, Denmark, Finland, France, Germany, Italy, Netherlands, Norway, Poland, Russia, Spain, Sweden, Switzerland, United Kingdom, Rest of Europe)

Middle-East and Africa (Egypt, Israel, Qatar, Saudi Arabia, South Africa, United Arab Emirates, Rest of MEA)

Asia-Pacific (Australia, Bangladesh, China, India, Indonesia, Japan, Malaysia, Philippines, Singapore, South Korea, Sri Lanka, Thailand, Taiwan, Rest of Asia-Pacific)

Key Coverage in the IBC Cap Market Report:

Detailed analysis of IBC Cap Market by a thorough assessment of the technology, product type, application, and other key segments of the report

Qualitative and quantitative analysis of the market along with CAGR calculation for the forecast period

Investigative study of the market dynamics including drivers, opportunities, restraints, and limitations that can influence the market growth

Comprehensive analysis of the regions of the IBC Cap industry and their futuristic growth outlook

Competitive landscape benchmarking with key coverage of company profiles, product portfolio, and business expansion strategies

TABLE OF CONTENTS

Part 01: Executive Summary

Part 02: Scope of the Report

Part 03: Research Methodology

Part 04: Market Landscape

Part 05: Pipeline Analysis

Part 06: Market Sizing

Part 07: Five Forces Analysis

Part 08: Market Segmentation

Part 09: Customer Landscape

Part 10: Regional Landscape

Part 11: Decision Framework

Part 12: Drivers and Challenges

Part 13: Market Trends

Part 14: Vendor Landscape

Part 15: Vendor Analysis

Part 16: Appendix

Browse Trending Reports:

Calcium Glycinate Market Retinal Biologics Market Facial Fat Transfer Market Angio Suites Diagnostic Imaging Market Adoption Of Benelux Power Tools Market De Quervains Tenosynovitis Treatment Market Biodetectors And Accessories Market Colposcope Market Sports Medicine Market Automotive Adhesives Market Infrared Imaging Market Vapour Deposition Market Professional Diagnostics Market Ct Scanner Market Programmable Application Specific Integrated Circuit Asic Market Hospital Operating Room Or Products And Solutions Market Castor Oil Market Zika Virus Infection Drug Market Toluene Diisocynate Market Antibiotic Resistance Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: [email protected]"

2 notes

·

View notes

Text

Zero Friction Coatings Market: Charting the Course for Enhanced Performance and Sustainable Solutions

The global zero friction coatings market size is estimated to reach USD 1,346.00 million by 2030 according to a new report by Grand View Research, Inc. The market is expected to expand at a CAGR of 5.6% from 2022 to 2030. Growth can be attributed to the fact that these coatings reduce friction and wear resulting in low fuel consumption and less heat generation. According to the European Automobile Manufacturers' Association, 79.1 million motor vehicles were produced across the globe in 2021 which was up by 1.3% as compared to 2020. Zero friction coatings can extend the time between component maintenance and replacement, especially for machine parts that are expensive to manufacture.

Zero Friction Coatings Market Report Highlights

In 2021, molybdenum disulfide emerged as the dominant type segment by contributing around 50% of the revenue share. This is attributed to its properties such as low coefficient of friction at high loads, electrical insulation, and wide temperature range

The automobile & transportation was the dominating end-use segment accounting for a revenue share of more than 35% in 2021 due to the rapid growth of the automotive industry across the globe

The energy end-use segment is anticipated to grow at a CAGR of 5.7% in terms of revenue by 2030, owing to the excessive wear on the drill stem assembly and the well casing during the drilling operations in the oil and gas sector

In Asia Pacific, the market is projected to witness the highest CAGR of 5.8% over the predicted years owing to the presence of car manufacturing industries in the countries such as Japan, South Korea, and China

For More Details or Sample Copy please visit link @: Zero Friction Coatings Market Report

Several applications in the automobile industry use wear-resistant plastic seals that require zero tolerance for failure and lifetime service confidence. Increasing demand for the product from the automotive industry across the globe for various applications including fuel pumps, automatic transmissions, oil pumps, braking systems, and others is expected to drive its demand over the forecast period.

Low friction coatings can be used in extreme environments comprising high pressure, temperatures, and vacuums. These coatings can provide improved service life and performance thereby eliminating the need for wet lubricants in environments that require chemicals, heat, or clean room conditions. The product containing molybdenum disulfide (MoS2) are suitable for reinforced plastics while those free from MoS2 are suitable for non-reinforced plastics.

Zero friction coatings are paint-like products containing submicron-sized particles of solid lubricants dispersed through resin blends and solvents. The product can be applied using conventional painting techniques such as dipping, spraying, or brushing. The thickness of the film has a considerable influence on the anti-corrosion properties, coefficient of friction, and service life of the product. Its thickness should be greater than the surface roughness of the mating surfaces.

ZeroFrictionCoatingsMarket #FrictionlessTechnology #CoatingInnovations #IndustrialEfficiency #ZeroFrictionSolutions #AdvancedMaterials #SurfaceCoatings #ManufacturingAdvancements #GlobalIndustryTrends #InnovativeCoatings #PerformanceOptimization #MechanicalSystems #SustainableTechnology #IndustrialApplications #FutureTech #InnovationInMaterials #EfficiencySolutions #ZeroFrictionMarket #TechnologyInnovation #EngineeringMaterials

#Zero Friction Coatings Market#Frictionless Technology#Coating Innovations#Industrial Efficiency#Zero Friction Solutions#Advanced Materials#Surface Coatings#Manufacturing Advancements#Global Industry Trends#Innovative Coatings#Performance Optimization#Mechanical Systems#Sustainable Technology#Industrial Applications#Future Tech#Innovation In Materials#Efficiency Solutions#Zero Friction Market#Technology Innovation#Engineering Materials

2 notes

·

View notes

Text

This is why, so many people advised my generation (I'm about 40) "not to go to school if we didn't understand what we were getting out of it."

There were also many who were not aware of the price of tuition trend who advised me to go, working off nothing more than the average earning power of every level of education. (I'm not going to say some degrees are worthless, because that is not true. But some degrees are overrepresented compared to positions available and some are underrepresented.)

A surprising number of available positions are considered "High School Diploma required" but since many high schools have turned into college prep schools instead of high schools, and therefore no longer teach machine shop or welding or basic electrical work to the level of certification anymore. It's gotten to the point that there's no point in going to high school either.

Go down to your library, or used bookstore, (or amazon.com) and find some technical manuals in whatever subject you want jewellery making, or welding, or beekeeping. Or go down to your county courthouse and find the building inspector's office, and buy a copy of the building code, and just read it.

It won't give you practice doing any of the techniques, but you'll have an idea of the range of skills it would take to be competent in the field. Give you a lot more information about which fields you might want to get into or stay out of than you might get any other way. Then walk into a place of business like that, get a summer internship, look around for who's having the most fun, and find out what it takes to have that position, (education-wise, certification-wise, stress levels, work/life balance-wise, etc), whether you still want it / and think you can manage that. etc.

And the ridiculous part is that technical education(STEM) is exactly how we won the world wars and the Cold War, we know that's what it takes to keep the standard of living moving forward, but we've let two or three generations of youth see that banking and investing, instead of being a basic utility that is meant to lubricate industry for everyone, turn into a many-tentacled leach monster that is sucking it all dry. And when there weren't enough banking jobs available, and not enough people willing to say, investing (not speculating) is actually hard tedious work, but mostly just takes a lot of algebra, here's Securities Analysis 2nd Edition by Graham and Dodd. The Bible of Investing.

Or you can learn calculus and business communication and go into Engineering. Or statistics and go into biology. or both and go into Physics.

But no, of course not, you don't need to learn anything, just buy whatever feels right without doing market research on how you're going to help people with it and lose your shirt in crypto or college debt.

It's not the bank's fault that the car salesman is predatory, nor the car salesman's fault that banks are predatory, but together you cannot trust them.

Same with colleges and banks.

Colleges ought to be saying, Don't trust banks, use this worksheet to calculate the real cost of borrowing money, against the real cost of taking longer to finish your degree if you just take night school. Etc. (Do you already have a job that would allow you to take night school or whatever? How much is that salary?) How much farther ahead or behind will you be at the end of each year for ten years?

The speech I heard for my college orientation went like this: You are all here because you like learning, and you don't mind working, (or vice versa) and you've chosen one of the narrow ranges of fields that are currently growth fields. (smart choice)

But!

You won't get rich working.

Let me say that again.

You won't get rich working.

(Money comes to those who help people.)

You get more money by helping MORE people.

You will get wealthy by leveraging your own specialisation to better help more people. (Several examples to convince us that by the time we graduate, we should be hiring each other for each other's specialties, rather than trying to be independent generalists.)

Also, you can become wealthy by patiently leveraging your growing net worth to help more people help other people. (Which neatly includes, growing your business, investing in other people's businesses, and repairing and managing real estate.)

(A quick example of how he bought broken-down real estate, fixed it up, and found people who actually needed it, to sell it to.)

And then he wrapped up with a tour of the college and help getting our library cards.

They just want there to always be a class of people who are forever in debt. Whether it's chattel slavery, prison, student loan debt, medical debt, renters who will never be able to own a house, etc.

37K notes

·

View notes

Text

Rapeseed Oil Market Drivers and Challenges

The rapeseed oil market has witnessed substantial growth over the years, driven by its versatility, nutritional benefits, and widespread applications. As a vital vegetable oil used in food, industrial, and biofuel sectors, rapeseed oil continues to gain prominence globally. This article delves into the key factors influencing the rapeseed oil market, highlighting trends, challenges, and future growth opportunities.

Market Overview

Rapeseed oil is extracted from the seeds of the rapeseed plant and is highly regarded for its heart-healthy properties, including low saturated fat and high omega-3 fatty acid content. It is commonly used in cooking, food processing, and industrial applications such as lubricants, biofuels, and cosmetics. The global market has experienced consistent growth due to the rising awareness of healthy eating and the demand for sustainable biofuels.

Key Market Drivers

Rising Demand for Healthy Edible Oils Consumers are increasingly opting for healthier alternatives, driving demand for rapeseed oil in the food industry. Its low cholesterol content and nutritional benefits make it a preferred choice for health-conscious individuals.

Biofuel Industry Expansion The biofuel sector is a major contributor to rapeseed oil demand. Governments worldwide are promoting renewable energy sources, and rapeseed oil has emerged as a key feedstock for biodiesel production.

Growing Food Industry The processed food industry’s growth, particularly in emerging economies, has boosted the demand for rapeseed oil as a key ingredient in various food products.

Challenges in the Rapeseed Oil Market

Fluctuating Prices The rapeseed oil market is highly sensitive to price fluctuations, driven by changes in crop yields, weather conditions, and global trade dynamics.

Competition from Other Oils The market faces stiff competition from other edible oils like palm oil, sunflower oil, and soybean oil, which are often cheaper and more readily available.

Environmental Concerns While rapeseed oil is a renewable resource, its production and processing can have environmental impacts, such as deforestation and greenhouse gas emissions, which pose challenges to its sustainability image.

Emerging Trends

Organic and Non-GMO Products There is a growing demand for organic and non-GMO rapeseed oil, driven by consumer preference for natural and sustainably produced products.

Technological Advancements Innovations in processing and extraction techniques are enhancing the quality and shelf life of rapeseed oil, further boosting its market potential.

Sustainability Initiatives The push for sustainable agricultural practices is influencing the production and sourcing of rapeseed oil, making it more environmentally friendly and appealing to eco-conscious consumers.

Future Outlook

The rapeseed oil market is poised for steady growth, with increasing demand from the food, biofuel, and industrial sectors. Strategic investments in sustainable production practices and technological innovations will likely drive the market forward. However, addressing challenges such as price volatility and competition will be crucial for long-term success.

In conclusion, the rapeseed oil market presents significant opportunities for stakeholders. With the right strategies, the industry can overcome its challenges and capitalize on emerging trends to ensure sustainable growth.

Get Free Sample and ToC : https://www.pristinemarketinsights.com/get-free-sample-and-toc?rprtdtid=NzIz&RD=Rapeseed-Oil-Market-Report

0 notes

Text

Industrial Lubricants Market Trends, Opportunities and Forecast By 2028

The Industrial Lubricants Market sector is undergoing rapid transformation, with significant growth and innovations expected by 2028. In-depth market research offers a thorough analysis of market size, share, and emerging trends, providing essential insights into its expansion potential. The report explores market segmentation and definitions, emphasizing key components and growth drivers. Through the use of SWOT and PESTEL analyses, it evaluates the sector’s strengths, weaknesses, opportunities, and threats, while considering political, economic, social, technological, environmental, and legal influences. Expert evaluations of competitor strategies and recent developments shed light on geographical trends and forecast the market’s future direction, creating a solid framework for strategic planning and investment decisions.

Brief Overview of the Industrial Lubricants Market:

The global Industrial Lubricants Market is expected to experience substantial growth between 2024 and 2031. Starting from a steady growth rate in 2023, the market is anticipated to accelerate due to increasing strategic initiatives by key market players throughout the forecast period.

Get a Sample PDF of Report - https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-industrial-lubricants-market

Which are the top companies operating in the Industrial Lubricants Market?

The report profiles noticeable organizations working in the water purifier showcase and the triumphant methodologies received by them. It likewise reveals insights about the share held by each organization and their contribution to the market's extension. This Global Industrial Lubricants Market report provides the information of the Top Companies in Industrial Lubricants Market in the market their business strategy, financial situation etc.

Shell group of companies, BP, Chevron Corporation., LUKOIL Marine Lubricants DMCC, Exxon Mobil Corporation., Eni S.p.A., Croda International Plc, Total Group, Synforce Lubricants., Valvoline LLC, Lubricon, Bailey’s Marine Fuels, Chevron Corporation., CASTROL LIMITED, China Petrochemical Corporation., Gulf Oil, Indian Oil Corporation Ltd, PETRONAS Lubricants International

Report Scope and Market Segmentation

Which are the driving factors of the Industrial Lubricants Market?

The driving factors of the Industrial Lubricants Market are multifaceted and crucial for its growth and development. Technological advancements play a significant role by enhancing product efficiency, reducing costs, and introducing innovative features that cater to evolving consumer demands. Rising consumer interest and demand for keyword-related products and services further fuel market expansion. Favorable economic conditions, including increased disposable incomes, enable higher consumer spending, which benefits the market. Supportive regulatory environments, with policies that provide incentives and subsidies, also encourage growth, while globalization opens new opportunities by expanding market reach and international trade.

Industrial Lubricants Market - Competitive and Segmentation Analysis:

**Segments**

- **Type:** The global industrial lubricants market can be segmented based on type into gear oil, compressor oil, hydraulic oil, turbine oil, metalworking fluid, industrial engine oil, and others. The gear oil segment is expected to witness significant growth due to the increasing demand for efficient lubrication in various industrial applications to enhance equipment performance and longevity.

- **Base Oil:** On the basis of base oil, the market can be segmented into mineral oil, synthetic oil, bio-based oil, and semi-synthetic oil. The synthetic oil segment is anticipated to dominate the market as it offers superior properties such as high thermal stability, low volatility, and better lubrication performance compared to mineral-based oils.

- **End-Use Industry:** The industrial lubricants market can also be segmented by end-use industry, including manufacturing, automotive, energy, mining, construction, and others. The automotive industry is expected to be a key driver of market growth, with increasing vehicle production and the need for high-performance lubricants to improve fuel efficiency and reduce maintenance costs.

**Market Players**

- Exxon Mobil Corporation - Royal Dutch Shell plc - Chevron Corporation - BP plc - TotalEnergies SE - FUCHS - Idemitsu Kosan Co.,Ltd. - PetroChina Company Limited - Petroliam Nasional Berhad (PETRONAS) - Sinopec Corp

The global industrial lubricants market is projected to witness substantial growth during the forecast period, driven by the increasing demand from various end-use industries such as manufacturing, automotive, and energy. The rising need for efficient lubrication solutions to enhance equipment performance, reduce downtime, and minimize maintenance costs is expected to propel market growth. Factors such as technological advancements, stringent regulations promoting the use of environmentally friendly lubricants, and the expansion of industrial activities in emerging economies are also contributing to the market expansion. The shift towards synthetic and bio-based lubricants due to their superior properties and environmental advantages is anticipated to further boost market growth.

Key market players such as Exxon Mobil Corporation, Royal Dutch Shell plc, and Chevron Corporation are focusing on product innovations, strategic partnerships, and mergers and acquisitions to strengthen their market presence and expand their product portfolios. Collaboration with end-use industries to develop tailor-made lubricant solutions and investments in research and development activities to enhance product performance and sustainability are key strategies adopted by market players to gain a competitive edge.

For more insights, visit: https://www.databridgemarketresearch.com/reports/global-industrial-lubricants-marketThe global industrial lubricants market is experiencing significant growth, driven by various factors such as the increasing demand for efficient lubrication solutions across diverse industries like manufacturing, automotive, and energy. The emphasis on enhancing equipment performance, reducing downtime, and minimizing maintenance costs is fueling the adoption of industrial lubricants. Moreover, technological advancements in lubricant formulations are enabling the development of high-performance products that meet the specific needs of different industrial applications.

One of the key trends shaping the market is the growing focus on sustainability and environmental responsibility. Stringent regulations promoting the use of eco-friendly lubricants are pushing companies to invest in synthetic and bio-based options that offer superior performance while minimizing environmental impact. This shift towards sustainable lubricants is expected to create new growth opportunities in the market, particularly as companies strive to align with sustainability goals and reduce their carbon footprint.

In addition, the rapid industrialization in emerging economies is propelling the demand for industrial lubricants, driven by the expansion of manufacturing and construction activities. This presents a lucrative opportunity for market players to expand their presence in these regions and cater to the evolving needs of a growing industrial sector. Strategic collaborations with local partners, investment in distribution networks, and customization of lubricant solutions for specific regional requirements are key strategies that companies can employ to capitalize on this trend.

Furthermore, amid increasing competition in the market, innovation remains a crucial differentiator for market players. Companies such as Exxon Mobil Corporation, Royal Dutch Shell plc, and Chevron Corporation are investing in research and development to introduce advanced lubricant products with enhanced performance characteristics. By focusing on product differentiation and offering specialized solutions tailored to the unique challenges faced by different industries, these key players aim to maintain a competitive edge in the global industrial lubricants market.

Overall, the industrial lubricants market is poised for continued growth, driven by the convergence of factors such as technological advancements, sustainability initiatives, and the expansion of industrial activities in emerging economies. As companies navigate these trends and dynamics, strategic partnerships, product innovation, and a customer-centric approach will be vital for sustaining growth and competitive advantage in the evolving market landscape.**Segments:**

Global Industrial Lubricants Market, By Grade: - Group I - Group II - Group III - Group IV - Group V

Base Oil: - Bio-based - Mineral Oil - Synthetic and Semi-synthetic

Product Type: - Engine Oil - Compressor Lubricants - Turbine Lubricants - Transmission and Hydraulic Fluids - Metalworking Fluids - General Industrial Oils - Gear Oil - Greases - Process Oils - Other Product Types

End-Use Industry: - Marine - Automotive - Transportation - Textiles - Power Generation - Heavy Equipment - Metallurgy and Metal Working - Food and Beverage - Chemical Manufacturing - Other End-user Industries

Country: - U.S. - Canada - Mexico - Brazil - Argentina - Rest of South America - Germany - France - Italy - U.K. - Belgium - Spain - Russia - Turkey - Netherlands - Switzerland - Rest of Europe - Japan - China - India - South Korea - Australia - Singapore - Malaysia - Thailand - Indonesia - Philippines - Rest of Asia-Pacific - U.A.E - Saudi Arabia - Egypt - South Africa - Israel - Rest of Middle East and Africa

Industry Trends and Forecast to 2028

**Market Players:** - Shell group of companies - BP - Chevron Corporation - LUKOIL Marine Lubricants DMCC - Exxon Mobil Corporation - Eni S.p.A. - Croda International Plc - Total Group - Synforce Lubricants - Valvoline LLC - Lubricon - Bailey’s Marine Fuels - Chevron Corporation - CASTROL LIMITED - China Petrochemical Corporation - Gulf Oil - Indian Oil Corporation Ltd - PETRONAS Lubricants International

The global industrial lubricants market is a dynamic and rapidly evolving sector driven by various factors such as technological advancements, regulatory changes, and shifting consumer preferences. The market segmentation based on grade, base oil, product type, end-use industry, and geography offers a comprehensive view of the diverse landscape within the industry. The adoption of different grades of industrial lubricants, including Group I to Group V, reflects the varied performance requirements across industries, with increasing demand for higher-grade products with superior properties.

The choice of base oil, whether bio-based, mineral oil, or synthetic and semi-synthetic, plays a crucial role in determining the overall performance of industrial lubricants. Synthetic oils are gaining traction due to their superior characteristics such as thermal stability and lubrication efficiency, driving market growth in this segment. The wide range of product types available, including engine oils, greases, and metalworking fluids, cater to specific industrial applications, highlighting the diverse needs and preferences of end-users across different sectors.

End-use industries such as automotive, marine, power generation, and food and beverage are significant contributors to the demand for industrial lubricants, with each sector requiring specialized lubrication solutions tailored to their unique operational requirements. Geographic factors also influence market dynamics, with regions like Asia-Pacific experiencing rapid industrialization and driving market growth in countries like China and India. The industry trends and forecast provide valuable insights into future market developments, helping stakeholders make informed decisions and strategic investments.

Market players such as Shell group of companies, BP, and Chevron Corporation are at the forefront of industry innovation, leveraging their expertise to develop advanced lubricant products that meet the evolving needs of customers. Partnerships, acquisitions, and research and development initiatives are key strategies adopted by market players to enhance their competitive position and expand their market presence. With a strong focus on sustainability, product differentiation, and customer-centric approach, companies in the industrial lubricants market are poised for continued growth and success in the years to come.

North America, particularly the United States, will continue to exert significant influence that cannot be overlooked. Any shifts in the United States could impact the development trajectory of the Industrial Lubricants Market. The North American market is poised for substantial growth over the forecast period. The region benefits from widespread adoption of advanced technologies and the presence of major industry players, creating abundant growth opportunities.

Similarly, Europe plays a crucial role in the global Industrial Lubricants Market, expected to exhibit impressive growth in CAGR from 2024 to 2028.

Explore Further Details about This Research Industrial Lubricants Market Report https://www.databridgemarketresearch.com/reports/global-industrial-lubricants-market

Key Benefits for Industry Participants and Stakeholders: –

Industry drivers, trends, restraints, and opportunities are covered in the study.

Neutral perspective on the Industrial Lubricants Market scenario

Recent industry growth and new developments

Competitive landscape and strategies of key companies

The Historical, current, and estimated Industrial Lubricants Market size in terms of value and size

In-depth, comprehensive analysis and forecasting of the Industrial Lubricants Market

Geographically, the detailed analysis of consumption, revenue, market share and growth rate, historical data and forecast (2024-2031) of the following regions are covered in Chapters

The countries covered in the Industrial Lubricants Market report are U.S., Canada and Mexico in North America, Brazil, Argentina and Rest of South America as part of South America, Germany, Italy, U.K., France, Spain, Netherlands, Belgium, Switzerland, Turkey, Russia, Rest of Europe in Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA

Detailed TOC of Industrial Lubricants Market Insights and Forecast to 2028

Part 01: Executive Summary

Part 02: Scope Of The Report

Part 03: Research Methodology

Part 04: Industrial Lubricants Market Landscape

Part 05: Pipeline Analysis

Part 06: Industrial Lubricants Market Sizing

Part 07: Five Forces Analysis

Part 08: Industrial Lubricants Market Segmentation

Part 09: Customer Landscape

Part 10: Regional Landscape

Part 11: Decision Framework

Part 12: Drivers And Challenges

Part 13: Industrial Lubricants Market Trends

Part 14: Vendor Landscape

Part 15: Vendor Analysis

Part 16: Appendix

Browse More Reports:

Japan: https://www.databridgemarketresearch.com/jp/reports/global-industrial-lubricants-market

China: https://www.databridgemarketresearch.com/zh/reports/global-industrial-lubricants-market

Arabic: https://www.databridgemarketresearch.com/ar/reports/global-industrial-lubricants-market

Portuguese: https://www.databridgemarketresearch.com/pt/reports/global-industrial-lubricants-market

German: https://www.databridgemarketresearch.com/de/reports/global-industrial-lubricants-market

French: https://www.databridgemarketresearch.com/fr/reports/global-industrial-lubricants-market

Spanish: https://www.databridgemarketresearch.com/es/reports/global-industrial-lubricants-market

Korean: https://www.databridgemarketresearch.com/ko/reports/global-industrial-lubricants-market

Russian: https://www.databridgemarketresearch.com/ru/reports/global-industrial-lubricants-market

Data Bridge Market Research:

Today's trends are a great way to predict future events!

Data Bridge Market Research is a market research and consulting company that stands out for its innovative and distinctive approach, as well as its unmatched resilience and integrated methods. We are dedicated to identifying the best market opportunities, and providing insightful information that will help your business thrive in the marketplace. Data Bridge offers tailored solutions to complex business challenges. This facilitates a smooth decision-making process. Data Bridge was founded in Pune in 2015. It is the product of deep wisdom and experience.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC: +653 1251 1978

Email:- [email protected]

The Industrial Lubricants Market sector is undergoing rapid transformation, with significant growth and innovations expected by 2028. In-depth market research offers a thorough analysis of market size, share, and emerging trends, providing essential insights into its expansion potential. The report explores market segmentation and definitions, emphasizing key components and growth drivers. Through the use of SWOT and PESTEL analyses, it evaluates the sector’s strengths, weaknesses, opportunities, and threats, while considering political, economic, social, technological, environmental, and legal influences. Expert evaluations of competitor strategies and recent developments shed light on geographical trends and forecast the market’s future direction, creating a solid framework for strategic planning and investment decisions.

Brief Overview of the Industrial Lubricants Market:

The global Industrial Lubricants Market is expected to experience substantial growth between 2024 and 2031. Starting from a steady growth rate in 2023, the market is anticipated to accelerate due to increasing strategic initiatives by key market players throughout the forecast period.

Get a Sample PDF of Report - https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-industrial-lubricants-market

Which are the top companies operating in the Industrial Lubricants Market?

The report profiles noticeable organizations working in the water purifier showcase and the triumphant methodologies received by them. It likewise reveals insights about the share held by each organization and their contribution to the market's extension. This Global Industrial Lubricants Market report provides the information of the Top Companies in Industrial Lubricants Market in the market their business strategy, financial situation etc.

Shell group of companies, BP, Chevron Corporation., LUKOIL Marine Lubricants DMCC, Exxon Mobil Corporation., Eni S.p.A., Croda International Plc, Total Group, Synforce Lubricants., Valvoline LLC, Lubricon, Bailey’s Marine Fuels, Chevron Corporation., CASTROL LIMITED, China Petrochemical Corporation., Gulf Oil, Indian Oil Corporation Ltd, PETRONAS Lubricants International

Report Scope and Market Segmentation

Which are the driving factors of the Industrial Lubricants Market?

The driving factors of the Industrial Lubricants Market are multifaceted and crucial for its growth and development. Technological advancements play a significant role by enhancing product efficiency, reducing costs, and introducing innovative features that cater to evolving consumer demands. Rising consumer interest and demand for keyword-related products and services further fuel market expansion. Favorable economic conditions, including increased disposable incomes, enable higher consumer spending, which benefits the market. Supportive regulatory environments, with policies that provide incentives and subsidies, also encourage growth, while globalization opens new opportunities by expanding market reach and international trade.

Industrial Lubricants Market - Competitive and Segmentation Analysis:

**Segments**

- **Type:** The global industrial lubricants market can be segmented based on type into gear oil, compressor oil, hydraulic oil, turbine oil, metalworking fluid, industrial engine oil, and others. The gear oil segment is expected to witness significant growth due to the increasing demand for efficient lubrication in various industrial applications to enhance equipment performance and longevity.

- **Base Oil:** On the basis of base oil, the market can be segmented into mineral oil, synthetic oil, bio-based oil, and semi-synthetic oil. The synthetic oil segment is anticipated to dominate the market as it offers superior properties such as high thermal stability, low volatility, and better lubrication performance compared to mineral-based oils.

- **End-Use Industry:** The industrial lubricants market can also be segmented by end-use industry, including manufacturing, automotive, energy, mining, construction, and others. The automotive industry is expected to be a key driver of market growth, with increasing vehicle production and the need for high-performance lubricants to improve fuel efficiency and reduce maintenance costs.

**Market Players**

- Exxon Mobil Corporation - Royal Dutch Shell plc - Chevron Corporation - BP plc - TotalEnergies SE - FUCHS - Idemitsu Kosan Co.,Ltd. - PetroChina Company Limited - Petroliam Nasional Berhad (PETRONAS) - Sinopec Corp

The global industrial lubricants market is projected to witness substantial growth during the forecast period, driven by the increasing demand from various end-use industries such as manufacturing, automotive, and energy. The rising need for efficient lubrication solutions to enhance equipment performance, reduce downtime, and minimize maintenance costs is expected to propel market growth. Factors such as technological advancements, stringent regulations promoting the use of environmentally friendly lubricants, and the expansion of industrial activities in emerging economies are also contributing to the market expansion. The shift towards synthetic and bio-based lubricants due to their superior properties and environmental advantages is anticipated to further boost market growth.

Key market players such as Exxon Mobil Corporation, Royal Dutch Shell plc, and Chevron Corporation are focusing on product innovations, strategic partnerships, and mergers and acquisitions to strengthen their market presence and expand their product portfolios. Collaboration with end-use industries to develop tailor-made lubricant solutions and investments in research and development activities to enhance product performance and sustainability are key strategies adopted by market players to gain a competitive edge.

For more insights, visit: https://www.databridgemarketresearch.com/reports/global-industrial-lubricants-marketThe global industrial lubricants market is experiencing significant growth, driven by various factors such as the increasing demand for efficient lubrication solutions across diverse industries like manufacturing, automotive, and energy. The emphasis on enhancing equipment performance, reducing downtime, and minimizing maintenance costs is fueling the adoption of industrial lubricants. Moreover, technological advancements in lubricant formulations are enabling the development of high-performance products that meet the specific needs of different industrial applications.

One of the key trends shaping the market is the growing focus on sustainability and environmental responsibility. Stringent regulations promoting the use of eco-friendly lubricants are pushing companies to invest in synthetic and bio-based options that offer superior performance while minimizing environmental impact. This shift towards sustainable lubricants is expected to create new growth opportunities in the market, particularly as companies strive to align with sustainability goals and reduce their carbon footprint.

In addition, the rapid industrialization in emerging economies is propelling the demand for industrial lubricants, driven by the expansion of manufacturing and construction activities. This presents a lucrative opportunity for market players to expand their presence in these regions and cater to the evolving needs of a growing industrial sector. Strategic collaborations with local partners, investment in distribution networks, and customization of lubricant solutions for specific regional requirements are key strategies that companies can employ to capitalize on this trend.

Furthermore, amid increasing competition in the market, innovation remains a crucial differentiator for market players. Companies such as Exxon Mobil Corporation, Royal Dutch Shell plc, and Chevron Corporation are investing in research and development to introduce advanced lubricant products with enhanced performance characteristics. By focusing on product differentiation and offering specialized solutions tailored to the unique challenges faced by different industries, these key players aim to maintain a competitive edge in the global industrial lubricants market.

Overall, the industrial lubricants market is poised for continued growth, driven by the convergence of factors such as technological advancements, sustainability initiatives, and the expansion of industrial activities in emerging economies. As companies navigate these trends and dynamics, strategic partnerships, product innovation, and a customer-centric approach will be vital for sustaining growth and competitive advantage in the evolving market landscape.**Segments:**

Global Industrial Lubricants Market, By Grade: - Group I - Group II - Group III - Group IV - Group V

Base Oil: - Bio-based - Mineral Oil - Synthetic and Semi-synthetic

Product Type: - Engine Oil - Compressor Lubricants - Turbine Lubricants - Transmission and Hydraulic Fluids - Metalworking Fluids - General Industrial Oils - Gear Oil - Greases - Process Oils - Other Product Types

End-Use Industry: - Marine - Automotive - Transportation - Textiles - Power Generation - Heavy Equipment - Metallurgy and Metal Working - Food and Beverage - Chemical Manufacturing - Other End-user Industries

Country: - U.S. - Canada - Mexico - Brazil - Argentina - Rest of South America - Germany - France - Italy - U.K. - Belgium - Spain - Russia - Turkey - Netherlands - Switzerland - Rest of Europe - Japan - China - India - South Korea - Australia - Singapore - Malaysia - Thailand - Indonesia - Philippines - Rest of Asia-Pacific - U.A.E - Saudi Arabia - Egypt - South Africa - Israel - Rest of Middle East and Africa

Industry Trends and Forecast to 2028

**Market Players:** - Shell group of companies - BP - Chevron Corporation - LUKOIL Marine Lubricants DMCC - Exxon Mobil Corporation - Eni S.p.A. - Croda International Plc - Total Group - Synforce Lubricants - Valvoline LLC - Lubricon - Bailey’s Marine Fuels - Chevron Corporation - CASTROL LIMITED - China Petrochemical Corporation - Gulf Oil - Indian Oil Corporation Ltd - PETRONAS Lubricants International

The global industrial lubricants market is a dynamic and rapidly evolving sector driven by various factors such as technological advancements, regulatory changes, and shifting consumer preferences. The market segmentation based on grade, base oil, product type, end-use industry, and geography offers a comprehensive view of the diverse landscape within the industry. The adoption of different grades of industrial lubricants, including Group I to Group V, reflects the varied performance requirements across industries, with increasing demand for higher-grade products with superior properties.

The choice of base oil, whether bio-based, mineral oil, or synthetic and semi-synthetic, plays a crucial role in determining the overall performance of industrial lubricants. Synthetic oils are gaining traction due to their superior characteristics such as thermal stability and lubrication efficiency, driving market growth in this segment. The wide range of product types available, including engine oils, greases, and metalworking fluids, cater to specific industrial applications, highlighting the diverse needs and preferences of end-users across different sectors.

End-use industries such as automotive, marine, power generation, and food and beverage are significant contributors to the demand for industrial lubricants, with each sector requiring specialized lubrication solutions tailored to their unique operational requirements. Geographic factors also influence market dynamics, with regions like Asia-Pacific experiencing rapid industrialization and driving market growth in countries like China and India. The industry trends and forecast provide valuable insights into future market developments, helping stakeholders make informed decisions and strategic investments.

Market players such as Shell group of companies, BP, and Chevron Corporation are at the forefront of industry innovation, leveraging their expertise to develop advanced lubricant products that meet the evolving needs of customers. Partnerships, acquisitions, and research and development initiatives are key strategies adopted by market players to enhance their competitive position and expand their market presence. With a strong focus on sustainability, product differentiation, and customer-centric approach, companies in the industrial lubricants market are poised for continued growth and success in the years to come.

North America, particularly the United States, will continue to exert significant influence that cannot be overlooked. Any shifts in the United States could impact the development trajectory of the Industrial Lubricants Market. The North American market is poised for substantial growth over the forecast period. The region benefits from widespread adoption of advanced technologies and the presence of major industry players, creating abundant growth opportunities.

Similarly, Europe plays a crucial role in the global Industrial Lubricants Market, expected to exhibit impressive growth in CAGR from 2024 to 2028.

Explore Further Details about This Research Industrial Lubricants Market Report https://www.databridgemarketresearch.com/reports/global-industrial-lubricants-market

Key Benefits for Industry Participants and Stakeholders: –

Industry drivers, trends, restraints, and opportunities are covered in the study.

Neutral perspective on the Industrial Lubricants Market scenario

Recent industry growth and new developments

Competitive landscape and strategies of key companies

The Historical, current, and estimated Industrial Lubricants Market size in terms of value and size

In-depth, comprehensive analysis and forecasting of the Industrial Lubricants Market

Geographically, the detailed analysis of consumption, revenue, market share and growth rate, historical data and forecast (2024-2031) of the following regions are covered in Chapters

The countries covered in the Industrial Lubricants Market report are U.S., Canada and Mexico in North America, Brazil, Argentina and Rest of South America as part of South America, Germany, Italy, U.K., France, Spain, Netherlands, Belgium, Switzerland, Turkey, Russia, Rest of Europe in Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA

Detailed TOC of Industrial Lubricants Market Insights and Forecast to 2028

Part 01: Executive Summary

Part 02: Scope Of The Report

Part 03: Research Methodology

Part 04: Industrial Lubricants Market Landscape

Part 05: Pipeline Analysis

Part 06: Industrial Lubricants Market Sizing

Part 07: Five Forces Analysis

Part 08: Industrial Lubricants Market Segmentation

Part 09: Customer Landscape

Part 10: Regional Landscape

Part 11: Decision Framework

Part 12: Drivers And Challenges

Part 13: Industrial Lubricants Market Trends

Part 14: Vendor Landscape

Part 15: Vendor Analysis

Part 16: Appendix

Browse More Reports:

Japan: https://www.databridgemarketresearch.com/jp/reports/global-industrial-lubricants-market

China: https://www.databridgemarketresearch.com/zh/reports/global-industrial-lubricants-market

Arabic: https://www.databridgemarketresearch.com/ar/reports/global-industrial-lubricants-market

Portuguese: https://www.databridgemarketresearch.com/pt/reports/global-industrial-lubricants-market

German: https://www.databridgemarketresearch.com/de/reports/global-industrial-lubricants-market

French: https://www.databridgemarketresearch.com/fr/reports/global-industrial-lubricants-market

Spanish: https://www.databridgemarketresearch.com/es/reports/global-industrial-lubricants-market

Korean: https://www.databridgemarketresearch.com/ko/reports/global-industrial-lubricants-market

Russian: https://www.databridgemarketresearch.com/ru/reports/global-industrial-lubricants-market

Data Bridge Market Research:

Today's trends are a great way to predict future events!

Data Bridge Market Research is a market research and consulting company that stands out for its innovative and distinctive approach, as well as its unmatched resilience and integrated methods. We are dedicated to identifying the best market opportunities, and providing insightful information that will help your business thrive in the marketplace. Data Bridge offers tailored solutions to complex business challenges. This facilitates a smooth decision-making process. Data Bridge was founded in Pune in 2015. It is the product of deep wisdom and experience.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC: +653 1251 1978

Email:- [email protected]

#Industrial Lubricants Market Size#Industrial Lubricants Market Shares#Industrial Lubricants Market Forecast#Industrial Lubricants Market Growth#Industrial Lubricants Market Demand

0 notes

Text

Top 15 Market Players in Global Benzotriazole Derivatives Market

Top 15 Market Players in Global Benzotriazole Derivatives Market

Benzotriazole derivatives are critical additives used in corrosion inhibitors, UV stabilizers, and various industrial applications. The market is driven by their widespread utility in coatings, plastics, and automotive industries. Below are the top 15 players dominating the global benzotriazole derivatives market:

BASF SE BASF offers high-quality benzotriazole derivatives that are extensively used in industrial coatings, UV stabilizers, and automotive applications.

Clariant AG Clariant is a leading provider of specialty chemicals, including benzotriazole derivatives for advanced material protection and stabilization.

Songwon Industrial Co., Ltd. Songwon specializes in polymer stabilizers, including benzotriazole derivatives, for long-term material durability and UV resistance.

Evonik Industries AG Evonik delivers innovative benzotriazole derivatives that cater to diverse applications such as automotive, coatings, and electronics.

Adeka Corporation Adeka offers a wide portfolio of benzotriazole derivatives for advanced polymers and high-performance coatings.

Solvay S.A. Solvay focuses on producing benzotriazole derivatives that enhance the performance of lubricants, plastics, and construction materials.

Ashland Global Holdings Inc. Ashland provides specialized benzotriazole derivatives for use in corrosion inhibition and industrial water treatment.

Lanxess AG Lanxess manufactures advanced additives, including benzotriazole derivatives, for applications in construction, automotive, and industrial sectors.

Eastman Chemical Company Eastman offers benzotriazole derivatives designed for improved UV resistance and material longevity in polymers and coatings.

Valtris Specialty Chemicals Valtris focuses on cost-effective and high-performance benzotriazole derivatives for industrial and consumer applications.

Huntsman Corporation Huntsman produces benzotriazole derivatives for niche markets, including high-performance coatings and adhesives.

SABO S.p.A. SABO specializes in benzotriazole-based UV stabilizers and additives for plastics and polymer systems.

Mayzo, Inc. Mayzo provides benzotriazole derivatives for the plastics and coatings industries, emphasizing UV stabilization and corrosion protection.

The Lubrizol Corporation Lubrizol offers benzotriazole derivatives tailored for high-performance lubricant and metalworking applications.

Rianlon Corporation A key player in Asia, Rianlon produces benzotriazole derivatives for applications in plastics, coatings, and construction.

Request report sample at https://datavagyanik.com/reports/global-benzotriazole-derivatives-market-size-production-sales-average-product-price-market-share/

Top Winning Strategies in Benzotriazole Derivatives Market

The benzotriazole derivatives market is highly competitive, with key players leveraging various strategies to enhance their market presence and address evolving industry demands. Below are the top winning strategies:

Focus on Sustainability Manufacturers are investing in eco-friendly benzotriazole derivatives that comply with global environmental regulations, such as REACH and EPA guidelines.

Research and Development (R&D) Significant investments in R&D are enabling companies to develop high-performance derivatives with improved stability, UV resistance, and corrosion inhibition.

Expansion into Emerging Markets Companies are targeting high-growth regions like Asia-Pacific and Latin America, where industrial and automotive sectors are experiencing rapid expansion.

Partnerships and Collaborations Collaborations with raw material suppliers and end-users allow companies to streamline their supply chains and co-develop innovative products.

Product Diversification Expanding product portfolios with tailored benzotriazole derivatives for niche applications such as electronics, photovoltaics, and aerospace is a key strategy.

Regulatory Compliance and Certifications Meeting global quality and environmental standards has become essential to gaining customer trust and ensuring market expansion.

Adoption of Digital Technologies The integration of advanced digital tools, such as predictive analytics and AI, is helping companies optimize production processes and reduce operational costs.

Enhanced Supply Chain Resilience Strengthening supply chain networks and mitigating risks through diversified sourcing strategies are critical for uninterrupted production.

Cost Optimization Streamlining production and raw material sourcing processes has enabled companies to remain competitive in price-sensitive markets.

Development of High-Performance Derivatives Companies are focusing on formulating benzotriazole derivatives that offer superior thermal stability, UV resistance, and corrosion protection.

Strategic Mergers and Acquisitions Acquiring smaller, specialized players allows companies to expand their technological capabilities and market reach.

Focus on Long-Term Contracts Securing long-term contracts with major end-users ensures consistent demand and stable revenue streams.

Customer-Centric Solutions Providing customized benzotriazole derivatives and technical support helps manufacturers build strong relationships with end-users.

Marketing and Branding Efforts Targeted marketing campaigns and effective branding are enabling companies to enhance their visibility and attract a broader customer base.

Investments in Capacity Expansion Increasing production capacity to meet rising demand across industries is a critical strategy for market growth.

By implementing these strategies, companies in the benzotriazole derivatives market can strengthen their competitive position, capture new opportunities, and address the evolving needs of industries worldwide.

Request a free sample copy at https://datavagyanik.com/reports/global-benzotriazole-derivatives-market-size-production-sales-average-product-price-market-share/