#Industrial IoT gateway

Explore tagged Tumblr posts

Text

Industrial IoT Gateways and PLCs: Where OT Meets IIoT

PLCs (programmable logic controllers), which serve as the brain of factory floor automation systems and offer dependable and adaptable control methods for industrial control operations, have been at the center of these systems for the past few decades. However, new Industrial Internet of Things (IIoT) technologies are offering more sophisticated functionalities and effective solutions as a result of the rapid growth of IIoT technologies.

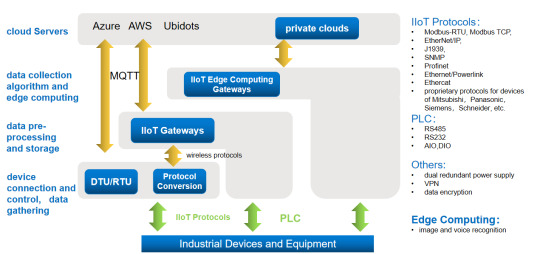

Industrial IoT gatewayᅠis a device based on Internet of Things technology, which can connect multiple sensors, instruments, controllers and other devices to realize real-time monitoring and management of various parameters in the industrial environment. More significantly, the industrial Internet of Things gateway may link OT and IIoT, facilitate information flow, and encourage equipment collaboration, all of which support the advancement of industrial automation.

This article will explore the synergy of industrial IoT gateways and PLCs in automated production, and and how they might work together to increase production efficiency, lower costs, and improve product quality.

What is PLC?

PLC, short for Programmable Logic Controller, is a device specially used for industrial automation control. In order to satisfy the demands of industrial production, it uses computer control technology and programming to accomplish real-time control, measurement, and execution duties. PLCs are essential for controlling complex industrial applications' production processes and enhancing output quality and efficiency.

Although PLCs can take on a variety of shapes and forms, their fundamental function—to fulfill the automatic control of industrial production—remains the same. PLC is used extensively throughout a range of industries, including manufacturing, electric power, transportation, mining, etc. It has grown to be an essential component of industrial automation.

PLC and the IIoT

PLC is a well-known type of industrial control system, with data contact usually takes place within the local area network, and system communication typically takes place in a workshop or factory. However, a greater variety of data exchange and remote management can be accomplished by integrating the PLC control system into the Industrial Internet of Things, further advancing the industrial automation process.

For instance, real-time production line running status can be obtained through remote PLC monitoring through the Internet. This allows for the early detection and resolution of issues, increasing the effectiveness and caliber of production. Additionally, the production process can be optimized and maintained in advance through data analysis and wise decision-making, which lowers production costs and resource usage even more.

PLC and an IIoT gateway

PLCs and IoT gateways both have significant contributions to make to industrial automation, but they operate in distinct ways.

PLC

PLCs are devices with some computer-like properties that are specifically made to control industrial equipment. They are capable of doing tasks like counting, timing, arithmetic computations, and sequence control. In order to achieve accurate control of the industrial machine, it modulates the output signal using the input signal.

Industrial IoT gateway

What is an industrial gateway?ᅠAn industrial IoT gateway, on the other hand, is a kind of IoT device that connects PLCs, sensors, instruments, industrial equipment, and other intelligent hardware with features including device networking, data collecting, and edge computing. It can simultaneously transfer the gathered data to local or cloud storage programs. In order to implement device interconnection, the IoT gateway can also be utilized as a connection point between the cloud platform and PLC controllers, sensors, or other industrial equipment.

The Convergence

In order to realize PLC data on the cloud, Dusun IoT's DSGW-081 Modbus RS485 CAN Bus I/O converter (WiFi/LTE 4G/Ethernet) has rich industrial control protocols and a variety of data interfaces embedded within it. This makes it compatible with more than 95% of common PLC devices currently available (Siemens, Mitsubishi, Omron, Schneider, Delta, AB, Beckhoff, Xinjie, Inovance, Panasonic, etc.). It is an effective and dependable option that promotes the growth of industrial automation.

IoT-based Remote Monitoring and Operation Solution Via IIoT Gateways And PLCs

Remote monitoring solution by IIoT gateway and PLCs are mainly composed of two major components:

Industrial gateways: interface with PLC or collector, gather data from industrial equipment, enable remote monitoring and intelligent control are the two parts of the solution.

Cloud platform for IIoT applications: stores, processes, and analyzes data that smart gateways upload to various locations; it can be displayed on a big screen to realize equipment management, maintenance work order management, remote operation and maintenance, big data analysis, etc.

In general, the industrial gateway may typically connect to and collect data from PLCs downlink, and transport data to clouds uplink to enable remote equipment administration and debugging.

Final Words

The Industrial Internet of Things has grown to be a significant force in the promotion of industrial automation as a result of the ongoing development of technology. In many industries, including equipment production, sewage treatment, animal husbandry, HVAC, refrigeration, transportation, etc., professional industrial IoT solutions are employed extensively. These technologies significantly increase equipment efficiency and reliability by enabling remote monitoring and administration of industrial equipment using PLC technology.

The Industrial Internet of Things will have to deal with more difficult and tough jobs in the future. It will increasingly rely on data analysis and artificial intelligence technology as the digital age progresses in order to achieve more intelligent and adaptive operation, maintenance, and management. Additionally, to respond to changing industrial surroundings and equipment, IIoT will need more adaptable and scalable solutions as industrial equipment keeps getting upgraded.

1 note

·

View note

Text

Discover the top 5 reasons why RS-485 IoT Gateways are essential for efficient and reliable industrial automation systems. Boost performance today!

#RS 485 IoT Gateway Solutions#Industrial IoT Gateway Solutions#industrial iot gateway devices#IOT gateway devices#IIoT gateway devices#MQTT IoT gateway#iot gateway manufacturers#Top IoT gateway companies#IoT gateway company#iot gateway solutions#modbus gateway#rs485 gateway#rs485 protocol#modbus rs485#modbus communication protocol#rs485 iot gateway#modbus protocol#iot gateway

0 notes

Text

Understanding CMSGP and the Role of Industrial IoT Gateway Devices

In the ever-evolving landscape of industrial automation and smart manufacturing, the Internet of Things (IoT) has emerged as a transformative force. Central to this transformation are Industrial IoT Gateway Devices, which play a crucial role in connecting machinery, sensors, and systems within an industrial environment. One entity at the forefront of this innovation is CMSGP (Connected Manufacturing Solutions for the Global Partnership), which focuses on enhancing operational efficiency through smart technology integration.

What are Industrial IoT Gateway Devices?

Industrial IoT Gateway Devices act as critical communication hubs that facilitate the seamless exchange of data between industrial equipment and cloud-based systems. These devices collect, process, and transmit data from various sensors and machines, enabling real-time monitoring and analysis. This capability is essential for industries looking to harness the power of data to improve productivity, enhance decision-making, and minimize downtime.

Key Features of Industrial IoT Gateway Devices

Data Aggregation: These devices gather data from multiple sources, including legacy equipment, and consolidate it for further analysis.

Protocol Translation: Industrial environments often employ a variety of communication protocols. IoT gateways can translate these protocols, ensuring compatibility and seamless communication across different systems.

Edge Computing: Many gateway devices come equipped with edge computing capabilities, allowing for data processing to occur locally. This reduces latency and bandwidth use while enabling real-time analytics.

Security: With increased connectivity comes heightened security risks. Industrial IoT gateways incorporate robust security features, such as encryption and secure authentication, to protect sensitive data.

Scalability: As industries grow, their IoT needs evolve. Gateway devices can be easily scaled to accommodate new sensors and equipment, making them a flexible solution for dynamic industrial environments.

The Role of CMSGP in Industrial IoT

CMSGP is dedicated to promoting connectivity and collaboration within the manufacturing sector. By leveraging Industrial IoT Gateway Devices, CMSGP enables businesses to integrate their operations into a cohesive smart manufacturing ecosystem. Here’s how CMSGP contributes to this advancement:

Enhancing Operational Efficiency

CMSGP’s focus on connected solutions allows organizations to monitor equipment health and performance in real time. By implementing IoT gateway devices, businesses can reduce unexpected downtimes and optimize maintenance schedules, leading to significant cost savings and improved operational efficiency.

Driving Data-Driven Decisions

With access to real-time data analytics, companies can make informed decisions based on accurate insights. CMSGP supports the integration of advanced analytics tools that work alongside IoT gateways, enabling predictive maintenance and proactive problem-solving.

Fostering Collaboration

CMSGP promotes a collaborative approach among manufacturers, technology providers, and other stakeholders. By standardizing communication protocols and integrating diverse systems through IoT gateways, CMSGP helps break down silos, fostering a more interconnected industrial environment.

Sustainability and Compliance

Industrial IoT solutions, including gateway devices, play a pivotal role in helping organizations meet sustainability goals and regulatory compliance. By optimizing resource use and minimizing waste through smart monitoring, businesses can operate more sustainably while adhering to industry standards.

Conclusion

As industries embrace the digital transformation brought about by the Internet of Things, the role of Industrial IoT Gateway Devices becomes increasingly vital. CMSGP stands at the forefront of this revolution, providing the tools and frameworks necessary for businesses to connect their operations effectively. By leveraging these gateway devices, companies can unlock new levels of efficiency, security, and sustainability in their industrial processes, paving the way for a smarter, more connected future.

In an age where data drives success, organizations must prioritize the integration of Industrial IoT Gateway Devices to remain competitive and responsive to the changing landscape of manufacturing.

0 notes

Text

IoT Gateway Comprehensive Study with Key Trends, Major Drivers and Challenges

IoT Gateway Market Overview

Global IoT Gateway Market Report 2024 presents critical information and factual data about the IoT Gateway Market, providing an overall statistical study of this market on the basis of market drivers, market limitations, and its future prospects. The widespread IoT Gateway market opportunities and trends are also taken into consideration in the industry. with growth trends, various stakeholders like investors, CEOs, traders, suppliers, research & media, the global manager, director, president, SWOT analysis, i.e., strengths, weaknesses, opportunities, and threats to the organization, and others.

According to Straits Research, the global IoT Gateway market size was valued at USD 1325 Million in 2021. It is projected to reach from USD XX Million in 2022 to USD 4200 Million by 2030, growing at a CAGR of 13.7% during the forecast period (2022–2030).

While studying the IoT Gateway market growth report, we completely studied the driving forces, development trends, restraints, obstacles, and profitable challenges to demonstrate the current and future market environment. Straits Research has given a thorough analysis that includes the key market strategies based on the most recent technologies, applications, and geographies around the world. The industry is predicted to grow significantly during the forecast period because to increased IoT Gateway market demand.

Competitive Landscape

Some of the prominent players operating in the IoT Gateway market are

Microchip Technology Inc.

Cisco Systems Inc

Advantech Co. Ltd

Dell Inc

Hewlett Packard Enterprise Development LP

Huawei Technologies Co. Ltd

Samsara Networks Inc.

and ADLINK Technology Inc.

Eurotech Inc

and Kontron S&T AG.

Get Free Request Sample Report @ https://straitsresearch.com/report/iot-gateway-market/request-sample

The report can help to know the market and strategize for business expansion accordingly. The strategy analysis, gives insights from market positioning and marketing channels to potential growth strategies, providing in-depth analysis for brand new entrants or existing competitors within the industry. Global IoT Gateway Market Report 2024 provides exclusive statistics, data, information, trends, and competitive landscape details during this niche sector.

Global IoT Gateway Market: Segmentation

As a result of the IoT Gateway market segmentation, the market is divided into sub-segments, the following are:

By Component

Processor

Sensor

Memory & Storage Device

Others

By Node

Smart Watch

Camera

RADAR

Thermostat

Actuator

Smart TV

Others

By Connectivity

Bluetooth

WiFi

ZigBee

Ethernet

Cellular

Others

By Deployment Model

On-Premise

Cloud-Based

By End-User

Automotive & Transportation

Healthcare

Industrial

Consumer Electronics

BFSI

Oil & Gas

Retail

Aerospace & Defense

Others

The report forecasts revenue growth at all geographic levels and provides an in-depth analysis of the latest industry trends and development patterns from 2024 to 2032 in each of the segments and sub-segments.

You can check In-depth Segmentation from here: https://straitsresearch.com/report/iot-gateway-market/segmentation

Stay ahead of the competition with our in-depth analysis of the market trends!

Buy Now @ https://straitsresearch.com/buy-now/iot-gateway-market

Key Highlights

The introduction, product type and application, market overview, market analysis by countries, market potential, market risk, and market driving forces are all used to explain the IoT Gateway Market.

Examining the manufacturers of the IoT Gateway Market in terms of their profile, main line of business, news, sales and price, revenue, and market share is the aim of this study.

In order to give a general picture of the competitive environment among the top manufacturers worldwide, including sales, revenue, and market share of IoT Gateway percent

To provide an example of the market segmented by kind and application, together with sales, pricing, revenue, market share, and growth rate for each segment.

To conduct an analysis of the main regions by manufacturers, categories, and applications, covering regions such as North America, Europe, Asia Pacific, the Middle East, and South America, with sales, revenue, and market share segmented by manufacturers, types, and applications.

To investigate the production costs, essential raw materials, production method, etc.

About Straits Research

Straits Research is dedicated to providing businesses with the highest quality market research services. With a team of experienced researchers and analysts, we strive to deliver insightful and actionable data that helps our clients make informed decisions about their industry and market. Our customized approach allows us to tailor our research to each client's specific needs and goals, ensuring that they receive the most relevant and valuable insights.

Contact Us

Email: [email protected]

Address: 825 3rd Avenue, New York, NY, USA, 10022

Tel: +1 6464807505, +44 203 318 2846

#IoT Gateway#IoT Gateway Industry#IoT Gateway Share#IoT Gateway Size#IoT Gateway Trends#IoT Gateway Regional Analysis#IoT Gateway Growth Rate

0 notes

Text

Design and enactment of an IoT gateway to build smart environments

Designing and implementing an IoT gateway for creating smart environments involves several crucial steps that ensure seamless integration and efficient data handling. This process is particularly impactful in applications like Smart Fire Monitoring, where real-time data and rapid response are critical.

Design Phase

Requirements Analysis

The first step in designing an IoT gateway is to understand the specific requirements of the smart environment. For Smart Fire Monitoring, this includes identifying the types of sensors (e.g., smoke detectors, temperature sensors, gas sensors) that need to be connected, the data they will generate, and the communication protocols they use (e.g., Zigbee, LoRaWAN, Wi-Fi).

Hardware Selection

Choosing the right hardware is essential for building a reliable Industrial IoT gateway. The gateway must support various communication protocols and have sufficient processing power to handle data aggregation and preliminary analysis. It should also have robust security features to protect data integrity and prevent unauthorized access.

Software Architecture

The software architecture of the IoT gateway must be designed to manage data flow efficiently. This includes implementing middleware that can handle protocol translation, data filtering, and local data storage. The gateway should also be capable of edge computing, allowing it to perform initial data processing and reduce the load on central servers.

Implementation Phase

Sensor Integration

The first step in implementation is integrating the sensors with the IoT gateway. This involves configuring the sensors to communicate with the gateway and ensuring that data from all sensors can be aggregated and processed. For Smart Fire Monitoring, the sensors must be placed strategically to cover all potential fire risk areas.

Data Management

Effective data management is crucial for the IoT gateway. This includes setting up data filtering to remove noise, data compression to save bandwidth, and local storage for temporary data holding. The gateway should be configured to transmit only relevant data to the cloud or central server, optimizing bandwidth usage and ensuring timely responses.

Security Measures

Implementing robust security measures is vital to protect the data being transmitted. This includes encrypting data at rest and in transit, using secure communication protocols, and ensuring that the gateway has built-in firewalls and intrusion detection systems.

Edge Computing

Incorporating edge computing capabilities allows the gateway to perform initial data analysis and make quick decisions without relying on cloud processing. For Smart Fire Monitoring, this means the gateway can trigger alarms or initiate fire suppression systems immediately upon detecting a fire risk, even if the internet connection is down.

Deployment and Testing

Once the IoT gateway is implemented, it needs to be thoroughly tested in a real-world environment. This involves validating that all sensors are accurately reporting data, the data is being processed correctly, and the gateway can handle the expected data load. Smart Fire Monitoring also includes testing the response times and ensuring that the system can reliably trigger alarms and notifications.

#iot gateway#industrial iot gateway devices#IIoT Gateway Devices#Industrial IoT Gateways & Devices#IIOT solution for manufacturing#iot in manufacturing industry

0 notes

Text

FMCG Challanges

#industrial iot#iot app development#iot development company#iot gateway#iot platform#fmcg#fmcgproducts#fmcg companies#fmcg industry#fmcg packaging market

1 note

·

View note

Text

Lantronix Expands Family of M110 Mobility Solutions With

New Post has been published on https://petn.ws/FmVh0

Lantronix Expands Family of M110 Mobility Solutions With

IRVINE, Calif., March 20, 2024 (GLOBE NEWSWIRE) — Lantronix Inc. (NASDAQ: LTRX), a global provider of compute and connectivity IoT solutions, today announced the addition of the new M114 CAT-1BIS modem to its family of M110 mobility solutions. Available now in EMEA markets, the M114 CAT-1BIS is a serial-to-cellular modem that comes pre-configured with Lantronix’s […]

See full article at https://petn.ws/FmVh0 #CatsNews #AdvancedIoTTechnology, #Inc, #IndustrialAutomation, #IoTCellularGateway, #Lantronix, #NasdaqLTRX, #SmartCities

#Advanced IoT Technology#inc.#Industrial Automation#IoT Cellular Gateway#Lantronix#Nasdaq:LTRX#Smart Cities#Cats News

0 notes

Text

BLIIoT| New Version BL120PM PLC to Modbus Gateway PLC Remote Upload and Download

Introduction

A PLC to Modbus gateway is a device that allows communication between a programmable logic controller (PLC) and a device or network that uses the Modbus communication protocol. The gateway acts as a bridge between the two systems, translating the data from one protocol to the other so that they can communicate with each other.

Product Description

BL120PM PLC to Modbus gateway can be used to connect a PLC to a Modbus device or network, enabling the exchange of data between them. The gateway can translate the data from the PLC's communication protocol to the Modbus protocol and vice versa, allowing the devices to communicate seamlessly with each other.

Product features

Supports PLC remote debugging upload and download.

Supports Siemens, Mitsubishi, Omron, Delta, Modbus RTU, Modbus TCP, Modbus cloud.

Supports connection to up to 50 devices and collection of 4,000 data points.

Supports 6 RS232/RS485 optional inputs.

It adopts embedded ARM MCU and is a product developed based on Linux OS system.

2 Ethernet ports (WAN port and LAN port).

Support 4G, WiFi, GPS.

Support OpenVPN, SNMPV1/V2.

It supports routing functions and cascade switch data collection to facilitate the collection of more industrial equipment data. The software has complete functions and covers most common application scenarios.

It integrates the humanized configuration interface that BLIIoT adheres to, as well as remote configuration, remote firmware upgrade and other functions. Users only need to make simple settings.

It adopts a fastening structure and has a power supply design with anti-reverse connection protection.

It adopts BLIIoT's patented rail buckle technology and supports standard DIN35 rail installation and wall-mounted installation.

Product Design

Model List

Application

PLC to Modbus gateways find applications in integrating Modbus devices into a PLC system, bridging the gap between legacy equipment and new PLCs, enabling remote monitoring and control, facilitating protocol conversion, and integrating devices from multiple vendors.

0 notes

Text

BLIIoT | New Multi-Protocol PLC Gateway BL104 Converts PLC to Cloud/Server for Remote Monitoring

Introduction

With the rapid development of Industry 4.0, it is deeply recognised that real-time, reliable and secure data transmission is crucial in industrial production and life. In this context, high-performance industrial automation PLC data transmission solutions - protocol conversion gateway came into being, widely used in industrial automation systems, PLC remote monitoring and IoT application environment.

BLIIoT always insists on the core of the user's needs, and constantly expands its applications in a variety of industrial fields. Recently, we have developed a new series of BLIIoT industrial PLC protocol gateways, which not only have excellent stability and anti-interference ability, but also explore the application of industry segments, aiming to bring users a new experience of industrial automation data acquisition and conversion.

Product Description

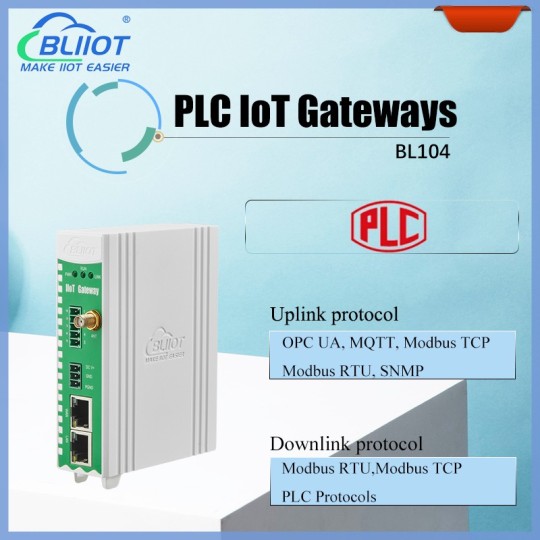

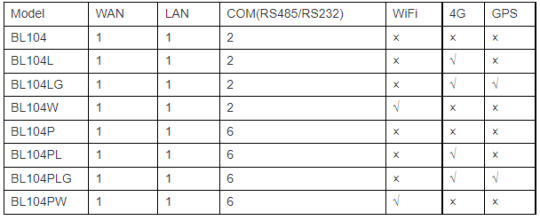

PLC Gateway BL104 is a specially developed for PLC connect MQTT and OPC UA system and remote PLC program uploading and downloading debugging.

The downlink protocol supports PLC protocols such as Mitsubishi, Siemens, Omron, Delta, Schneider, etc. and Modbus protocol.

The uplink protocol supports Modbus RTU, Modbus TCP, MQTT and OPC UA, access to Cloud, Server, SCADA, MES, ERP and other systems.

PLC Gateway BL104 hardware interfaces include 2 or 6 RS485/RS232 serial ports, 2 network ports and 1 WiFi wireless transmission interface, which realises seamless communication between PLC and OPC UA system.

The PLC gateway BL104 has an industrial-grade design to ensure reliability in harsh environments. BL104 is suitable for industrial automation systems, PLC remote monitoring and IoT applications.The PLC gateway BL104 connects to the future of the industry and provides users with a trusted, low-cost, stable and reliable PLC to Modbus, MQTT and OPC UA solution.

By using its own patented rail-clip technology, the installation process is simplified and the utility of the gateway is ensured.

Product features

Supported protocols: Downlink protocol: Modbus RTU, Modbus TCP, Mitsubishi, Siemens, Omron, Delta, Schneider and other mainstream PLC protocols.Uplink protocol: Modbus RTU, Modbus TCP, MQTT, SNMP and OPC UA.

Hardware interface: 6*RS485/RS232 serial ports: The serial ports are independent of each other. Each serial port parameter can be set to collect different protocols. The serial port can also set the master-slave relationship independently. It can be configured as either a master station or a slave station.2*network ports: used for data collection and forwarding. The LAN port has a routing function and provides a channel for other devices to connect to the external network.1*4G or WiFi wireless transmission interface: Provides diverse communication options to adapt to different industrial environment need

Data security:Support data TSL/SSL, X.509 certificate, SNMPV1/V2, key encryption and other security gateway functions.

Remote Configuration Support: Support remote PLC programming and program uploading and downloading, saving travelling costs and improving service response speed. Support remote configuration, providing users with convenient management and monitoring methods, no longer need to visit engineers, saving maintenance costs.

Product Size: L x W x H: 30 x 83 x 110mm

Safety and Stability:

Industrial-grade design: Durable shell material meets industrial environment requirements.

Stability: Efficient communication protocol conversion ensures stable operation of the system.

Environmental adaptation:

Operating temperature range: -40~80℃, adapting to various industrial environments. Protection grade: IP30, ensuring the reliability of the equipment in harsh environments.

Model List

Application scenarios

Meet the needs of PLC protocol to Modbus MQTT OPC UA in industrial automation and industrial IoT scenarios.

More information about BLIIoT New PLC to Modbus MQTT OPC UA Gateway BL104: https://www.bliiot.com/industrial-iot-gateway-p00415p1.html

#PLC Gateway#Industrial Automation#IoT#Modbus#MQTT#OPC UA#SNMP#Siemens#Omron#Schneider#Delta#mitsubishi

0 notes

Text

What is the Internet of Things (IoT) development?

Industrial IoT, often abbreviated as IIoT, is all about applying Internet of Things technology in industrial settings, especially when it comes to equipping sensors and devices with cloud-based capabilities. If you want a great example of how this works, take a look at the Titan use case PDF.

In recent times, industries have been making use of machine-to-machine communication, which is commonly known as M2M, to achieve wireless automation and control. However, things have gotten even more exciting with the rise of cloud technology and its companions, like analytics and machine learning. Thanks to these advancements, industries can now add a new layer of automation, leading to the creation of fresh revenue streams and entirely new business models.

Some folks even call this whole concept of the fourth wave of the industrial revolution, or Industry 4.0. It's a game-changer.

Here are some typical ways we put IoT to work:

Smart Manufacturing: Making our factories smarter and more efficient.

Connected Assets and preventive & Predictive Maintenance: Keeping an eye on equipment and predicting when maintenance is needed.

Smart Power Grids: Making our energy systems more intelligent and responsive.

Smart Cities: Creating cities that are more connected and responsive to the needs of their residents.

Connected Logistics: Improving the way we transport goods and track their progress.

Smart Digital Supply Chains: Revolutionizing the way we manage the flow of goods and information throughout the supply chain.

#iot#iotsolutions#iot applications#lorawan#lorawan gateway#lorawan sensors#lorawan devices#lorawan gateway manufacturers#industrial iot#iot connectivity

0 notes

Text

EtherCAT to EtherNet/IP IoT Gateway BL124EC

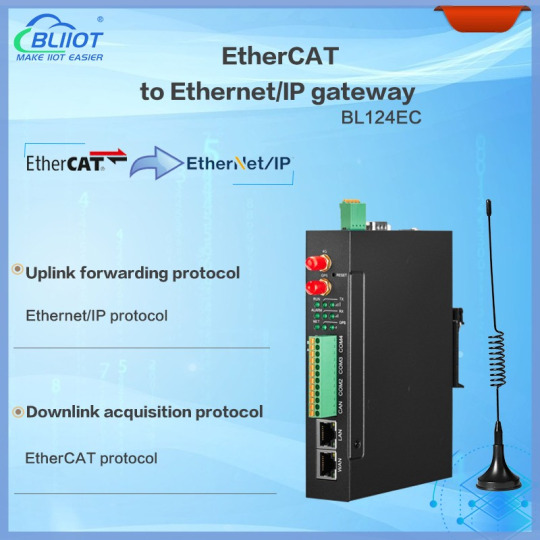

Introduction

BL124EC EtherCAT to EtherNet/IP Gateway establishes a connection between devices using the EtherCAT bus protocol and devices using the Ethernet/IP protocol. It receives data from EtherCAT devices and converts it into Ethernet/IP format for transmission. Likewise, it can receive data from Ethernet/IP devices and convert it into EtherCAT format. Therefore, BL124EC realizes interoperability and conversion between the two protocols.

The purpose of this protocol conversion gateway is to allow devices using different network protocols to work together seamlessly. It provides greater flexibility and interoperability for industrial control systems, improving the overall efficiency and performance of the production

Features

BL124EC EtherCAT to EtherNet/IP Gateway with high performance, stability and reliability, and supports fast data transmission and processing. It also has rich configuration options and flexible functions that can be customized and expanded according to actual needs. By using the BL124EC EtherCAT to Ethernet/IP gateway, industrial network communication becomes more convenient, efficient and reliable.

How to achieve EtherCAT to EtherNet/IP ?

In order to implement the conversion function, the BL124EC must be able to handle the protocol differences between EtherCAT and Ethernet/IP. Therefore, it uses advanced hardware and software mechanisms to effectively interpret and translate the differences between these two protocols

BL124EC reads data from the EtherCAT device through serial communication and packages it into data packets of the Ethernet/IP protocol. BL124EC sends the packaged Ethernet/IP data packets to the target Ethernet/IP device through the Ethernet interface.

At the same time, BL124EC can also receive data from the target Ethernet/IP device, decompress it into the correct EtherCAT message format, and then send it to the relevant device through the EtherCAT bus.

View more about IoT Gateway

#iot solutions#iot devices#datacollection#industrial automation#smartcities#EtherCAT to EtherNet/IP Gateway

0 notes

Text

IoT gateways play a crucial role in smart technology ecosystems by aggregating and processing data from various devices, ensuring seamless communication and interoperability.

#RS 485 IoT Gateway Solutions#Industrial IoT Gateway Solutions#industrial iot gateway devices#IOT gateway devices#IIoT gateway devices#MQTT IoT gateway#iot gateway manufacturers#Top IoT gateway companies#IoT gateway company#iot gateway solutions#modbus gateway#rs485 gateway#rs485 protocol#modbus rs485#modbus communication protocol#rs485 iot gateway#modbus protocol#iot gateway

0 notes

Text

Industrial IoT Edge Gateway: Enhancing Connectivity and Efficiency

In the dynamic landscape of industrial operations, the integration of IoT (Internet of Things) technologies has revolutionized efficiency, connectivity, and data-driven decision-making. At the forefront of this transformation stands the Industrial IoT Edge Gateway, a pivotal component empowering enterprises to harness the full potential of IoT.

Understanding the Industrial IoT Edge Gateway

The Industrial IoT Edge Gateway serves as a bridge between local IoT devices and the cloud or centralized data processing systems. Positioned at the edge of the network, these gateways facilitate real-time data collection, preprocessing, and secure transmission to centralized platforms. This functionality is crucial in environments where latency, bandwidth constraints, or data security are paramount concerns.

Key Features and Benefits

Real-time Data Processing: By enabling local data preprocessing, edge gateways reduce latency and optimize bandwidth usage. This capability ensures that critical insights are generated swiftly, supporting timely decision-making and operational responsiveness.

Enhanced Security: Edge gateways incorporate robust security protocols, safeguarding sensitive industrial data from external threats. They enable data encryption, access control, and threat detection mechanisms, mitigating risks associated with cyberattacks or unauthorized access.

Integration Flexibility: Designed to interface with diverse IoT protocols and devices, edge gateways facilitate seamless integration within existing industrial ecosystems. This interoperability supports scalability and future-proofing of IoT deployments.

Edge Computing Capabilities: Beyond data transmission, edge gateways often host edge computing functionalities. This empowers local processing of analytics, machine learning models, or predictive maintenance algorithms, enhancing operational autonomy and reducing dependency on cloud resources.

Cost Efficiency: By optimizing data traffic and reducing dependency on continuous cloud connectivity, edge gateways contribute to cost savings in terms of network bandwidth and cloud service usage. This makes IoT implementations economically viable across various industrial sectors.

Applications Across Industries

The versatility of Industrial IoT Edge Gateways extends across multiple sectors:

Manufacturing: Facilitates real-time monitoring of production lines, predictive maintenance of machinery, and quality control through sensor data integration.

Logistics and Supply Chain: Enables tracking of goods in transit, inventory management, and optimization of warehouse operations through RFID or GPS technologies.

Energy and Utilities: Supports remote monitoring of infrastructure, smart metering, and grid management for enhanced efficiency and reliability.

Healthcare: Enables remote patient monitoring, asset tracking in hospitals, and integration with medical devices to improve patient care and operational efficiency.

Future Outlook

As industries continue to embrace digital transformation, the role of Industrial IoT Edge Gateways is poised to expand. Advancements in edge computing, AI-driven analytics, and 5G connectivity will further enhance their capabilities, driving innovation and competitiveness across global markets.

Conclusion

In conclusion, the Industrial IoT Edge Gateway represents a pivotal technological advancement in industrial automation and connectivity. By enabling real-time data processing, enhancing security, and supporting diverse applications, these gateways empower enterprises to unlock new levels of operational efficiency, reliability, and agility in the digital age.

For enterprises seeking to harness the transformative potential of IoT, integrating an Industrial IoT Edge Gateway is not just a technological upgrade but a strategic imperative for sustainable growth and competitive advantage in today's interconnected world.

0 notes

Text

[381 Pages Report] The IoT node and gateway market was valued at USD 387.1 billion in 2020 and is projected to reach USD 566.4 billion by 2027; it is expected to grow at a compound annual growth rate (CAGR) of 6.7% from 2021 to 2027.

#IoT Node and Gateway Market#IoT Node and Gateway Industry Market#COVID 19 impact on IoT Node and Gateway Market

0 notes