#Industrial Garnet Market Share

Explore tagged Tumblr posts

Text

Industrial Garnet Market Analysis: Key Players and Growth Prospects

Origin and Properties of Industrial Garnet Garnet is a group of silicate minerals that forms through metamorphic processes deep within the earth. Their chemical composition makes them extremely hard and abrasion resistant. The garnet group includes almandine, spessartine, pyrope, grossular and uvarovite. Among these, almandine garnet which is an iron aluminium silicate mineral, is most commonly used for industrial applications due to its high hardness rating of 6.5–7.5 on Mohs scale. Other desirable properties of industrial garnet include chemical inertness, thermal stability and angular crystalline structure which allows it to perform well as an abrasive. Applications in Abrasive Blasting and Waterjet Cutting Garnet's hardness and angular crystalline shape make it ideally suited for abrasive blasting applications. Finely ground garnet is used as the abrasive media in various blasting processes like grit blasting, sand blasting and micro blasting. It is used to clean metal surfaces, degrease parts and prepares surfaces for painting or other coatings. In waterjet cutting, high pressure jets of water mixed with garnet abrasive are used to cut through even the hardest of metals like steel and titanium with extreme precision. Garnet isPreferred over other abrasives like silica and aluminum oxide for waterjet cutting as it is non-toxic and pose no health hazards. Role in Abrasive Powder and Paper Products Finely crushed garnet finds use in the manufacture of abrasive powders in varied grain sizes for uses like grinding, honing and polishing metal and stone surfaces. It is a key ingredient in manufacturing coated abrasives like sandpaper, grinding discs and belts etc. The angular structure and hardness of garnet particles provides the abrasiveness for removing material when used with coated abrasives. Garnet powder is also used as a filler in the manufacture of grinding wheels, cut-off wheels, grinding stones and honing sticks where it enhances their abrasiveness and performance. Use in Cleaning and Blast Finishing Due to their hardness and durability, garnet particles effectively remove dirt, stains, rust, coatings and even smooth rough surfaces. They are thus widely used in blast finishing of surfaces to achieve varied grades of roughness for applications like preparing metal surfaces for painting. Garnet particles are also used in cleaners for domestic and industrial applications to remove scale, stains and other dirt from surfaces like tiles, sanitary ware, glass, vehicle bodies etc. Their safety for the environment makes garnet an attractive alternative to other harmful abrasives for a host of cleaning purposes. Key Global Producer and Exporter - India India holds significant garnet reserves globally and is one of the leading producers and exporters of industrial garnet to markets across the world. Major garnet deposits are found in the states of Andhra Pradesh and Rajasthan which are mine to extract almandine-pyrope hybrid garnet variety. Stringent mining norms and emergence of organized players has ensured quality supply. India exports over 80% of its total refined garnet, primarily to the USA and Europe where it finds application in abrasives, waterjet cutting, drilling and surface preparation industries. With their unique abilities, garnet from India is poised to continue supporting key modern industries globally.

0 notes

Text

Industrial Garnet Market Odyssey: Pioneering Innovations in Ilmenite Processing Technologies

Global Industrial Garnet market was valued at US$ 652.7 Million in 2022, exhibiting a CAGR of 5.8 % in terms of revenue, over the forecast period (2023 to 2030) to reach US$ 1024.4 Million by 2030.

Garnets belong to the silicate mineral group and are one of the toughest minerals, which makes it ideal for use as an effective abrasive across various manufacturing facilities

0 notes

Text

Exploring the Growth of the Global Laser Cleaning Market

Exploring the Growth of the Global Laser Cleaning Market

The global Laser Cleaning Market is experiencing significant growth, driven by the increasing demand for efficient and environmentally friendly cleaning solutions across various industries. Valued at USD 0.66 billion in 2023, the market is projected to expand to USD 1.15 billion by 2032, achieving a CAGR of 6.36% during the forecast period from 2024 to 2032. Laser cleaning technology utilizes laser radiation to remove unwanted substances such as rust, paint, and contaminants from surfaces, offering a non-contact and non-abrasive method that minimizes damage to substrates while promoting sustainability.

Request Sample Link:https://straitsresearch.com/report/laser-cleaning-market/request-sample

Laser Cleaning Market Categorization

By Laser Type

Solid Laser

Yttrium Aluminum Garnet (YAG) Laser

Fiber Laser

Gas Lasers

Excimer Lasers

CO2 Laser

By Industry

General Manufacturing

Aerospace

Nuclear

Medical

Food and Beverage

By Application

Contaminant Cleaning

Coating Stripping

Mold Maintenance

Surface Cleaning

Adhesion Enhancement

Coating Life Extension

Sterilization

Weld Cleaning

Geographic Overview

The laser cleaning market exhibits varying trends across different regions:

North America: Dominated by the U.S., this region leads in market share due to advanced industrial infrastructure and a strong focus on sustainability initiatives, particularly in the aerospace and automotive sectors.

Europe: Countries like Germany and France are key players, leveraging laser cleaning technologies in manufacturing and restoration applications.

Asia-Pacific: Expected to be the fastest-growing region, with countries such as China, Japan, and South Korea driving demand for eco-friendly cleaning solutions in their robust manufacturing sectors.

Rest of the World: This category includes emerging markets where laser cleaning technology is gradually being adopted as industries mature.

Top Players in the Laser Cleaning Market

The competitive landscape of the laser cleaning market features several key players:

Coherent

Trumpf Group

Narran

Adapt Laser Systems LLC

Clean Laser Systeme GmbH

Advanced Laser Technology (ALT)

Anilox Roll Cleaning Systems

General Lasertronics

Laser Photonics

Laserax

White Lion Dry Ice & Laser Cleaning Technology

ARCS-ANILOX ROLL CLEANING SYSTEMS INC.

P-Laser

LASCAM

Andritz Powerlase.

These companies are at the forefront of innovation, continuously enhancing their technologies to meet the evolving needs of various industries.

Buy Now:https://straitsresearch.com/buy-now/laser-cleaning-market

Key Unit Economics for Businesses and Startups

For businesses and startups entering the laser cleaning market, understanding unit economics is crucial for sustainable growth:

The cost of laser cleaning equipment can vary significantly based on technology type and application.

Operating costs are generally lower than traditional methods due to reduced labor and material expenses.

The potential for high-margin services, particularly in specialized applications like aerospace and medical sterilization, presents lucrative opportunities.

Operational Factors Influencing the Market

Several operational factors contribute to the growth of the laser cleaning market:

The increasing emphasis on environmental sustainability is prompting industries to adopt cleaner technologies.

Advancements in laser technology enhance efficiency and effectiveness, making laser cleaning a preferred choice over traditional methods.

Regulatory pressures regarding emissions and waste disposal are driving companies toward eco-friendly solutions.

Why Straits Research?

Straits Research stands out as a leading provider of market intelligence in the laser cleaning sector due to its comprehensive analysis and insights into market trends, competitive landscapes, and growth opportunities across various segments and regions. Their reports are meticulously researched, providing stakeholders with valuable data to make informed decisions.

#Laser Cleaning Market#Laser Cleaning Market Share#Laser Cleaning Market Size#Laser Cleaning Market Research

0 notes

Text

Laser Cleaning Market Size, Business Revenue Forecast, Leading Competitors And Growth Trends

Laser Cleaning Market Key Players and Forecast Insights Through 2032

The latest ""Laser Cleaning Market"" Insight Report for 2024 offers a comprehensive analysis of the industry's key contributions, marketing strategies, and recent advancements by leading companies. This report provides a succinct overview of both historical and current performance metrics for major market players. It employs various analytical methods to deliver precise insights into the Laser Cleaning Market, with coverage across regions including North America, Europe, Asia Pacific, and more. The recent analysis also includes an in-depth review of the business strategies adopted by emerging industry players, along with detailed information on market segments, geographic coverage, product trends, and cost structures.

What are the growth projections for the Laser Cleaning Market?

According to Straits Research, the global Laser Cleaning Market size was valued at USD 685.38 Million in 2022. It is projected to reach from USD XX Million in 2023 to USD 992.83 Million by 2031, growing at a CAGR of 4.21% during the forecast period (2023–2031).

Get Free Request Sample Report @ https://straitsresearch.com/report/laser-cleaning-market/request-sample

Top Competitive Players of Laser Cleaning Market

Coherent

Trumpf Group

Narran

Adapt Laser Systems LLC

Clean Laser Systeme GmbH

Advanced Laser Technology (ALT)

Anilox Roll Cleaning Systems

General Lasertronics

Laser Photonics

Laserax

White Lion Dry Ice & Laser Cleaning Technology

ARCS-ANILOX ROLL CLEANING SYSTEMS INC.

P-Laser

LASCAM

Andritz Powerlase

Han's Laser

Suresh Indu Lasers (SIL)

SPI LASERS LIMITED

IPG Photonics Corporation.

What are the key trends within each segment of the Laser Cleaning Market?

By Laser Type

Solid Laser

Yttrium Aluminum Garnet (YAG) Laser

Fiber Laser

Gas Lasers

Excimer Lasers

Co2 Laser

By Industry

General Manufacturing

Aerospace

Nuclear

Medical

Food & Beverage

By Application

Contaminant Cleaning

Coating Stripping

Mold Maintenance

Surface Cleaning

Adhesion Enhancement

Coating Life Extension

Sterilization

Weld Cleaning

View the full report and table of contents here: https://straitsresearch.com/report/laser-cleaning-market/toc

The report forecasts revenue growth at all geographic levels and provides an in-depth analysis of the latest industry trends and development patterns from 2022 to 2030 in each of the segments and sub-segments. Some of the major geographies included in the market are given below:

North America (U.S., Canada)

Europe (U.K., Germany, France, Italy)

Asia Pacific (China, India, Japan, Singapore, Malaysia)

Latin America (Brazil, Mexico)

Middle East & Africa

This Report is available for purchase on Buy Laser Cleaning Market Report

Key Highlights

Provide a detailed explanation of various aspects including introduction, product types and applications, market overview, country-specific market analysis, opportunities, risks, and driving forces.

Examine manufacturers, including their profiles, primary business activities, recent news, sales and pricing, revenue, and market share.

Offer an overview of the competitive landscape, detailing sales, revenue, and market share among leading global manufacturers.

Present a detailed market breakdown by type and application, including sales, pricing, revenue, market share, and growth rates.

Analyze key regions—North America, Europe, Asia Pacific, the Middle East, and South America—covering sales, revenue, and market share segmented by manufacturers, types, and applications.

Investigate production costs, essential raw materials, and production methods.

Reasons to Buy:

In-depth analysis of market segmentation.

Country-specific insights alongside global demand and supply dynamics.

Examination of key players, including their products, financial performance, and strategies.

Insights into emerging market trends, opportunities, and challenges.

About Us:

StraitsResearch.com is a leading research and intelligence organization, specializing in research, analytics, and advisory services along with providing business insights & research reports.

Contact Us: Email: [email protected] Address: 825 3rd Avenue, New York, NY, USA, 10022 Tel: +1 6464807505, +44 203 318 2846

#Laser Cleaning Market#Laser Cleaning Market Share#Laser Cleaning Market Size#Laser Cleaning Market Research#Laser Cleaning Industry

0 notes

Text

Dry Sandpaper Market is valued at USD 2,624.69 million and is projected to grow at a compound annual growth rate (CAGR) of 4.82% over the forecast period, reaching approximately USD 3,825 million by 2032. Dry sandpaper, a fundamental abrasive material, plays a pivotal role across numerous industries, including automotive, woodworking, and construction. This market is poised for substantial growth, driven by increasing demand for smoother finishes, the rise in construction activities, and technological advancements in abrasives. In this article, we will explore the key factors contributing to the growth of the global dry sandpaper market, its segmentation, and the challenges and opportunities that shape its future.

Browse the full report at https://www.credenceresearch.com/report/dry-sandpaper-market

Market Overview

Sandpaper, also known as coated abrasive, consists of paper or fabric backing with abrasive materials like aluminum oxide, silicon carbide, or garnet attached to its surface. Dry sandpaper, specifically designed for dry sanding, is commonly used in automotive repairs, metalworking, and woodworking to smooth surfaces or remove material layers. With increasing demand from end-user industries such as automotive, aerospace, and construction, the global dry sandpaper market is experiencing notable growth.

The rise in DIY (Do-It-Yourself) projects, growing construction activities, and the emphasis on smoother and more refined finishes are significant factors that are expected to drive demand over the next decade. Additionally, the global trend toward more eco-friendly products has spurred innovation in sandpaper manufacturing, encouraging the production of biodegradable and reusable abrasives.

Key Drivers of Market Growth

1. Boom in Construction Activities: With rapid urbanization and infrastructure development in emerging economies, the demand for sandpaper in construction-related activities has seen consistent growth. In the construction industry, sandpaper is crucial for surface preparation, making it a necessary tool for painting, varnishing, and repairing surfaces.

2. Growing Automotive Industry: The automotive sector is another major driver of the dry sandpaper market. As manufacturers strive for precision and high-quality finishes in vehicle bodywork, sandpaper is an indispensable tool in painting, surface repair, and refinishing.

3. Increase in DIY Culture: The growing trend of DIY projects has led to a rise in demand for easy-to-use tools and equipment, with sandpaper being one of the essential items for woodworking and home improvement projects. Consumers are increasingly seeking cost-effective and user-friendly solutions, boosting demand in this segment.

4. Technological Advancements: Innovations in abrasives, including the development of more durable and versatile sandpaper products, have expanded the applications of dry sandpaper. Manufacturers are investing in research and development to create products that offer better performance, longer life, and lower environmental impact.

Challenges and Opportunities

Despite the positive outlook, the dry sandpaper market faces some challenges. The growing shift toward mechanized tools, such as power sanders and belt sanders, reduces the manual use of sandpaper in certain industries. Additionally, fluctuations in raw material prices, especially for aluminum oxide and silicon carbide, could impact profitability for manufacturers.

However, opportunities lie in the development of eco-friendly sandpaper products and the expansion of the market into emerging economies. The increasing awareness of sustainable practices is pushing companies to innovate, creating sandpaper that is biodegradable or made from recycled materials. Emerging markets with growing construction and automotive sectors present untapped potential for future expansion.

Key Player Analysis:

3M Company

Saint-Gobain Abrasives, Inc.

Klingspor AG

Mirka Ltd.

Sia Abrasives Industries AG

Carborundum Universal Limited

Kovax Corporation

Norton Abrasives (a brand of Saint-Gobain)

Flexovit USA, Inc.

Gator Finishing Products

Segmentation:

Based on Product Type:

Coated Sandpaper

Non-Woven Sandpaper

Others

Based on Material Type:

Aluminum Oxide

Silicon Carbide

Garnet

Emery

Others

Based on End-User:

Automotive

Woodworking

Metalworking

Other Sectors

Based on Geography:

North America

The U.S

Canada

Mexico

Europe

Germany

France

The U.K.

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of Middle East and Africa

Browse the full report at https://www.credenceresearch.com/report/dry-sandpaper-market

About Us:

Credence Research is committed to employee well-being and productivity. Following the COVID-19 pandemic, we have implemented a permanent work-from-home policy for all employees.

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

Website: www.credenceresearch.com

0 notes

Text

Industrial Garnet Market is ripe for emerging technologies by Smart Manufacturing

The industrial garnet market comprises products such as almandine, andradite, grossular uvarovite, pyrope and spessartine garnets that are formed by metamorphism. These garnets find wide applications owing to their unique physical and chemical properties including high density, hardness and resistance to wear and weathering. Industrial garnets are used as abrasive blasting media for surface preparation and finishing, water jet cutting, water filtration, abrasive powders for application such as abrasive powders in abrasive jets, collision and storage of energy. The Global Industrial Garnet Market is estimated to be valued at US$ 730.61 Mn in 2024 and is expected to exhibit a CAGR of 5.8% over the forecast period 2024 to 2031.

Industrial garnets are highly preferred for their cost effectiveness and environmental friendliness over toxic mediums like silica sand and steel grit. Also, the increasing adoption of garnet abrasives in water jet cutting and growing demand from the automotive and marine industries is propelling the market growth. Key Takeaways Key players operating in the industrial garnet market are GMA Garnet Group, Indian Ocean Garnet Sands Company Ltd., Trimex Sands Private Limited, Barton International, Zircon Mineral Co., Mohawk Garnet Inc., Opta Minerals Inc., V.V. Mineral Pvt. Ltd., Beach Minerals Company, and Rizhao Garnet Ltd. The key players are investing in advanced mining and sorting technologies to increase supply of higher quality industrial garnets. The growing demand for industrial garnets from various end-use industries like water filtration, abrasive blasting, water jet cutting etc. is expected to drive the market growth during the forecast period. The resistance to wear along with cost benefits over other substitutes makes industrial garnets irreplaceable for these applications. The global industrial garnet market is witnessing expansion in regions like Asia Pacific and North America attributed to growing industrial and infrastructure development activities. The availability of garnet reserves and growth of application industries in China, India and U.S. will boost the regional markets in coming years. Market Key Trends Adoption of smart manufacturing approaches is one of the key drivers gaining traction in the Industrial Garnet Market Trend. Various players are focusing on automation, Internet of Things (IoT) and use of analytics to enhance mining, processing, quality inspection and supply chain operations. This is helping players optimize operations, reduce costs and meetings the stringent quality standards of application industries.

Porter’s Analysis Threat of new entrants: New companies can enter the industrial garnet market by establishing manufacturing units and distribution network. However, significant capital investment and established manufacturers make the entry difficult. Bargaining power of buyers: The presence of numerous garnet mines and manufacturers gives buyers multiple options. However, specialized applications of garnet require long-term relationships and maintain consistency in garnet type and quality. Bargaining power of suppliers: The industrial garnet market has a concentration of suppliers as raw garnet sources are limited. The key suppliers have considerable influence over prices. Threat of new substitutes: Alternatives like aluminum oxide and silicon carbide are substitutes for certain abrasive and water jet cutting applications. However, garnet properties like density and hardness make it irreplaceable in major application areas. Competitive rivalry: The market has few leading global players and many medium and small manufacturers. Price-based competition is moderate due to product differentiation based on grade, chemistry and sizes. Geographical regions where the market value is concentrated include Asia Pacific and Europe. Asia Pacific accounts for over 45% share majorly due to growing abrasive, water jet cutting, and filtration applications in automotive, shipbuilding, aerospace and metal industries in China, India and other Asian countries. The fastest growing region is North America led by the US. Increasing usage of natural and eco-friendly garnet abrasives in metal cutting and waterjet cutting as well as growth in waterjet cutting machines is driving the demand up.

Get more insights on Industrial Garnet Market

About Author:

Ravina Pandya, Content Writer, has a strong foothold in the market research industry. She specializes in writing well-researched articles from different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. (https://www.linkedin.com/in/ravina-pandya-1a3984191)

0 notes

Text

Shot Peening Abrasive Material Market Size,Volume,Revenue Trends Analysis Report 2024-2030

On 2024-8-1 Global Info Research released【Global Shot Peening Abrasive Material Market 2024 by Manufacturers, Regions, Type and Application, Forecast to 2030】. This report includes an overview of the development of the Shot Peening Abrasive Material industry chain, the market status of Consumer Electronics (Nickel-Zinc Ferrite Core, Mn-Zn Ferrite Core), Household Appliances (Nickel-Zinc Ferrite Core, Mn-Zn Ferrite Core), and key enterprises in developed and developing market, and analysed the cutting-edge technology, patent, hot applications and market trends of Shot Peening Abrasive Material. Shot Peening Abrasive Materials are materials used in the shot peening process, which is a surface treatment technique designed to enhance the mechanical properties of metal components. This process involves bombarding the surface of a material with small spherical media, or "shots," at high velocity to induce compressive residual stresses. According to our (Global Info Research) latest study, the global Shot Peening Abrasive Material market size was valued at US$ million in 2023 and is forecast to a readjusted size of USD million by 2030 with a CAGR of %during review period. This report is a detailed and comprehensive analysis for global Shot Peening Abrasive Material market. Both quantitative and qualitative analyses are presented by manufacturers, by region & country, by Type and by Application. As the market is constantly changing, this report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across many markets. Company profiles and product examples of selected competitors, along with market share estimates of some of the selected leaders for the year 2024, are provided. Market segment by Type: Glass、Resin、Metal、Others Market segment by Application:Automotive、Aerospace、Others Major players covered: Abrasives Inc、Composition Materials、Sintokogio、Fuji Manufacturing、UJIDEN、NICCHU CO.,LTD.、Winoa、ITOH KIKOH、Opta Minerals、ABShot Tecnics、Advanced Finishing Technologies、AGSCO Corporation、SurfacePrep、Barton International、Synco Industries、Ervin Amasteel - UK、F.J. Brodmann、FROHN GmbH、Cym Materials、GMA Garnet、Ensio Resources、Naxos Diskus Schleifmittelwerke、Harsco Metals & Minerals、Prince Minerals、U.S Minerals、Blastrite、Saint-Gobain、K. C. Abrasive Company、Kramer Industries

Market segment by region, regional analysis covers: North America (United States, Canada and Mexico), Europe (Germany, France, United Kingdom, Russia, Italy, and Rest of Europe), Asia-Pacific (China, Japan, Korea, India, Southeast Asia, and Australia),South America (Brazil, Argentina, Colombia, and Rest of South America),Middle East & Africa (Saudi Arabia, UAE, Egypt, South Africa, and Rest of Middle East & Africa). The content of the study subjects, includes a total of 15 chapters: Chapter 1, to describe Shot Peening Abrasive Material product scope, market overview, market estimation caveats and base year. Chapter 2, to profile the top manufacturers of Shot Peening Abrasive Material, with price, sales, revenue and global market share of Shot Peening Abrasive Material from 2019 to 2024. Chapter 3, the Shot Peening Abrasive Material competitive situation, sales quantity, revenue and global market share of top manufacturers are analyzed emphatically by landscape contrast. Chapter 4, the Shot Peening Abrasive Material breakdown data are shown at the regional level, to show the sales quantity, consumption value and growth by regions, from 2019 to 2030. Chapter 5 and 6, to segment the sales by Type and application, with sales market share and growth rate by type, application, from 2019 to 2030. Chapter 7, 8, 9, 10 and 11, to break the sales data at the country level, with sales quantity, consumption value and market share for key countries in the world, from 2017 to 2023.and Shot Peening Abrasive Material market forecast, by regions, type and application, with sales and revenue, from 2025 to 2030. Chapter 12, market dynamics, drivers, restraints, trends and Porters Five Forces analysis. Chapter 13, the key raw materials and key suppliers, and industry chain of Shot Peening Abrasive Material. Chapter 14 and 15, to describe Shot Peening Abrasive Material sales channel, distributors, customers, research findings and conclusion.

Data Sources:

Via authorized organizations:customs statistics, industrial associations, relevant international societies, and academic publications etc.

Via trusted Internet sources.Such as industry news, publications on this industry, annual reports of public companies, Bloomberg Business, Wind Info, Hoovers, Factiva (Dow Jones & Company), Trading Economics, News Network, Statista, Federal Reserve Economic Data, BIS Statistics, ICIS, Companies House Documentsm, investor presentations, SEC filings of companies, etc.

Via interviews. Our interviewees includes manufacturers, related companies, industry experts, distributors, business (sales) staff, directors, CEO, marketing executives, executives from related industries/organizations, customers and raw material suppliers to obtain the latest information on the primary market;

Via data exchange. We have been consulting in this industry for 16 years and have collaborations with the players in this field. Thus, we get access to (part of) their unpublished data, by exchanging with them the data we have.

From our partners.We have information agencies as partners and they are located worldwide, thus we get (or purchase) the latest data from them.

Via our long-term tracking and gathering of data from this industry.We have a database that contains history data regarding the market.

Global Info Research is a company that digs deep into global industry information to support enterprises with market strategies and in-depth market development analysis reports. We provides market information consulting services in the global region to support enterprise strategic planning and official information reporting, and focuses on customized research, management consulting, IPO consulting, industry chain research, database and top industry services. At the same time, Global Info Research is also a report publisher, a customer and an interest-based suppliers, and is trusted by more than 30,000 companies around the world. We will always carry out all aspects of our business with excellent expertise and experience.

0 notes

Text

Understanding Multimedia Water Filters and Their Producers in Turkey

A multimedia water filter is a crucial component of many water purification systems, designed to remove a wide range of contaminants from drinking water. These filters typically use a combination of different filtration media, such as anthracite, sand, and garnet, to effectively trap particles and improve water quality. They are widely used in residential, commercial, and industrial settings due to their efficiency and versatility.

In Turkey, the production of multimedia water filter is an expanding industry, driven by the increasing demand for clean and safe drinking water. Several local manufacturers specialize in producing these filters, offering a variety of models and specifications to cater to different needs. These producers often incorporate innovative technologies to enhance the performance of their filters, ensuring high filtration efficiency and long-term durability.

One prominent multimedia water filter producer is known for its commitment to quality and customer satisfaction. They offer a range of products designed to meet the specific requirements of their clients, whether for home use or large-scale industrial applications. Their filters are engineered to comply with international standards and undergo rigorous testing to ensure reliability and effectiveness.

The multimedia water filter Turkey is competitive, with several companies vying for market share by offering competitive pricing and excellent service. This competition benefits consumers by providing them with a wide selection of filters to choose from, each offering unique features and benefits. Customers can select filters based on their water quality needs, budget considerations, and the size of their household or facility.

For those interested in purchasing multimedia water filters in Turkey, it's essential to consider factors such as the reputation of the manufacturer, the quality of materials used in the filter, and after-sales support. Many manufacturers offer warranty periods and maintenance services to ensure that their products continue to perform optimally over time.

0 notes

Text

Understanding Multimedia Water Filters and Their Producers in Turkey

A multimedia water filter is a crucial component of many water purification systems, designed to remove a wide range of contaminants from drinking water. These filters typically use a combination of different filtration media, such as anthracite, sand, and garnet, to effectively trap particles and improve water quality. They are widely used in residential, commercial, and industrial settings due to their efficiency and versatility.

In Turkey, the production of multimedia water filter is an expanding industry, driven by the increasing demand for clean and safe drinking water. Several local manufacturers specialize in producing these filters, offering a variety of models and specifications to cater to different needs. These producers often incorporate innovative technologies to enhance the performance of their filters, ensuring high filtration efficiency and long-term durability.

One prominent multimedia water filter producer is known for its commitment to quality and customer satisfaction. They offer a range of products designed to meet the specific requirements of their clients, whether for home use or large-scale industrial applications. Their filters are engineered to comply with international standards and undergo rigorous testing to ensure reliability and effectiveness.

The multimedia water filter Turkey is competitive, with several companies vying for market share by offering competitive pricing and excellent service. This competition benefits consumers by providing them with a wide selection of filters to choose from, each offering unique features and benefits. Customers can select filters based on their water quality needs, budget considerations, and the size of their household or facility.

For those interested in purchasing multimedia water filters in Turkey, it's essential to consider factors such as the reputation of the manufacturer, the quality of materials used in the filter, and after-sales support. Many manufacturers offer warranty periods and maintenance services to ensure that their products continue to perform optimally over time.

0 notes

Text

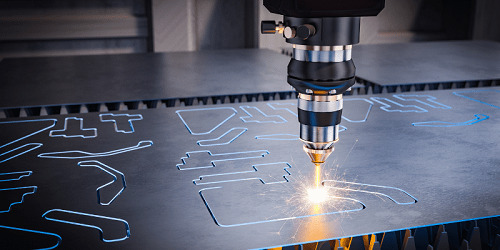

Laser Cutting Machine Market Evolution: Historical Analysis and Future Projections

The global laser cutting machines market size is expected to reach USD 10,351.0 billion by 2030, registering a CAGR of 5.5% over the forecast period, according to a study conducted by Grand View Research, Inc. Over the forecast period, it is anticipated that the growing trend of automation in the manufacturing sector and the rising demand for the end-use industry will increase demand for these machines. The growing application of CO2, fiber, and Yttrium Aluminum Garnet (YAG) lasers in various applications, such as industrial sectors and consumer electronics, is predicted to boost the demand for laser cutting machines. Industries such as consumer electronics are contributing to the market growth owing to the increasing use of lasers in material processing operations such as pruning, welding, and engraving. Furthermore, the requirement for high-power input and performance-based cutting tools drives demand and market growth for laser cutting machines over the forecast period.

Laser Cutting Machines Market Report Highlights

During the forecast period, the gas laser technology segment is expected to witness the highest CAGR of 6.1 %. The growth is attributed to the increasing demand for these lasers for better machine tools and equipment for laser printing, dye laser pumping, reading barcodes, and producing holograms

The fusion cutting is expected to register the highest CAGR of 6.1 % from 2023 to 2030. The advantage of fusion cutting is that it creates a cutting edge that is practically oxide-free and ideal for cutting thin sheets, which is expected to contribute to the growth of the segment

Over the course of the forecast period, the industrial sector is expected to dominate the laser cutting machine industry. It held a market share of 39.8 % in 2022. The need for laser cutting equipment is rising as industrial processes increasingly become automated. These tools consistently and quickly cut parts and patterns with precision

The rising GDP and quickening growth of the region's manufacturing sector, the Asia Pacific region is anticipated to continue growing. Additionally, businesses that use laser cutting to create semiconductors, consumer electronics, and automotive components are experiencing rapid regional growth. The need for laser cutting equipment in this area is rising along with the expansion of these industries

For More Details or Sample Copy please visit link @: Laser Cutting Machines Market Report

The development of innovative process lasers to maximize the manufacture of tailored three-dimensional glass elements, as well as a shift out of traditional semiconductor lasers and towards quantum cascade lasers, will likely drive up the demand for laser cutting machines. Continuous developments in laser technology enable manufacturers to engage in R&D to obtain a competitive advantage. Furthermore, due to the demand for high-speed and precision cutting and drilling the integration of the Internet of Things, Artificial Intelligence, and automation software with drilling machines is also supporting the laser cutting machine industry’s growth.

Major players are resorting to strategies such as product launches, mergers & acquisitions, and expansions to gain greater market shares. For instance, in May 2022, Yamazaki Mazak Pvt. Ltd. announced the launch of 3D based fiber laser cutting machine for cutting steel products- FG -400 NEO. The 3D laser is equipped with an efficient laser fiber oscillator which offers efficient energy conversion and enhanced productivity.

The laser is also compatible with cutting copper, brass, and aluminum. The laser is outfitted with a feature that enables users to easily modify the laser beam's diameter and form, enabling the cutting of sheets of different thicknesses. The oscillator's maximum output is limited to 4 kW, along with a rapid input rate on the X, Y, and Z axes is 60, 36, and 30 m/min, respectively. The continuous launch of advanced products is contributing to the laser cutting machine industry’s growth.

#LaserCuttingMachine#CuttingEquipment#CNCMachines#PrecisionCutting#MaterialProcessing#Metalworking#Fabrication#IndustryInsights#TechnologyTrends#MarketForecast#BusinessStrategy#InvestmentOpportunities#SupplyChain

0 notes

Text

Industrial Garnet Market Insights: Size, Share, and Growth Factors

Industrial Garnet: A Versatile Abrasive Mineral Garnet is an industrial mineral that plays a vital role in numerous manufacturing processes and consumer products. Though not as well-known as other gemstones, garnet has become indispensable in several modern industries due to its unique hardness and abrasive properties. Let's explore the many uses of garnet in greater detail. What is Garnet? Garnet refers to a group of silicate minerals that form in various crystalline structures. The three most common garnet varieties used industrially are almandine, spessartine, and pyrope. Garnet forms within metamorphic and igneous rocks under conditions of high temperature and pressure deep within the earth's crust. Major garnet deposits exist worldwide, with top producers including India, South Africa, and the United States. The defining attribute of garnet is its hardness of 6.5-7.5 on the Mohs hardness scale, which falls between quartz and topaz. This considerable hardness combined with its angular crystal structure makes garnet highly effective for grinding, blasting, water-jet cutting and other abrasive applications. Garnet's durability and chemical inertness further contribute to its versatility across industries. Applications in Abrasives Given garnet's hardness and durability, it sees widespread use as an abrasive material. Garnet accounts for over 90% of all industrial abrasives and over half of all mined garnet is processed for use in abrasives. - Abrasive Blasting: Garnet is the preferred mineral for abrasive blasting due to its sharp edges that efficiently remove paint, rust, and coatings from surfaces. It is used to prepare surfaces for painting or coating, clean industrial garnet equipment, shape stone and ceramic materials, and more. - Abrasive Powders: Crushed garnet is produced in precise mesh sizes for use in abrasive powders for sanding, grinding, cutting and polishing of metal, stone, wood and other hard materials. Its sharp crystals provide an optimum cutting effect. - Waterjet Cutting: Finely pulverized garnet is forced through ultra-high pressure water jets to precisely cut even very hard substances like titanium or composites. Due to garnet's durability, it produces long-lasting waterjets. - Abrasive Wheels: Bonded wheels containing garnet grit are used for cutoff and grinding of concrete, masonry as well as ferrous and non-ferrous metals. Garnet wheels ensure precise shaping and surface finishes. - Abrasive Paper/Cloth: Manufactured abrasive papers and cloths containing garnet are used for stock removal, polishing and deburring applications. Garnet's consistent grit helps produce scratch-free results. Industrial Filtration Garnet plays an important role in filtration processes across many industries: - Water Filtration: Its durable angular crystals serve as effective filters for municipal and industrial water treatment plants to remove particles and impurities from raw water sources. - Oil and Gas Filtration: Garnet filters protect sensitive drilling and pumping machinery from sediments and debris in oil/gas pipelines and reservoirs. It withstands high pressures and temperatures. - Food and Beverage Filtration: Finely ground garnet is used in cross-flow filtration systems to filter beer, wine, juices and other liquids to clarity without altering flavors. - Pharmaceutical Filtration: Its chemical inertness makes garnet suitable for precise micron-rated filtering of medical injections, vaccines and other pharmaceutical products. - Foundry Filtration: Garnet effectively filters slurries and removes inclusions from molten metals to improve cast part quality in foundries. Thanks to its hardness, precise sizing, and chemical stability, garnet remains the top choice mineral for critical filtration applications. Its reusability further adds to overall cost-effectiveness.

0 notes

Text

Gems and jewellery industries in Hyderabad are aggressively hiring staffs with good profile

The Gems & Jewellery Industry is one of the fastest growing segments in India. India is the largest consumer of gold in the world and consumes nearly 20% of the world consumption. India has an abundant supply of skilled manpower suited for designing and producing high volumes of exquisite jewellery at low labour costs. India is the largest diamond cutting and polishing centre in the world and globally enjoys a 60% share in value, 82 % share in cartage terms and 95% share in terms of pieces. Effectively, 9 out of 10 diamonds sold worldwide are processed in India. With a growing middle class, the market for branded jewellery is expanding substantially, with many of the large players in the industry are setting up retail chains of jewellery showrooms across India which market gold jewellery, fusion jewellery, diamonds etc. Gemstones have attracted humankind since ancient times, and have long been used for jewellery, gems were regarded by many civilizations as miraculous and endowed with mysterious powers. Since ancient times, gems of every hue have been imbued with significance and special powers by cultures around the world. They are one of the top Gems and Jewellery Recruitment Agency in Hyderabad.

Wearing gemstones is believed to be very beneficial. It bestows good physical and mental health to the wearer. It is said that gemstones balance the elements of the human body due to their unique natural mineral composition and inherent astrological properties. Wearing garnets increases energy levels and self-confidence and brings happiness to the wearer. Wearing rose quartz jewelry soothes the mind and heals the body of the wearer. It also brings peace to the wearer. Wearing amethyst jewellery reduces anxiety and calms the mind. It brings peace and increases the intuition power of the wearer. Wearing citrine jewellery cures insomnia and hearing problems, reduces inflammation and stomach problems. It also calms the mind and brings positive energy to the wearer. Wearing aquamarine jewellery increases communication skills. Wearing it also improves eye and tooth health and relieves digestive and stomach problems. Wearing sapphire jewellery improves the self-expression powers of the wearer. It also increases concentration and endurance levels. Wearing gold jewellery is believed to increase strength and resolve and build higher immunity levels. Best Gems and Jewellery Recruitment Agency in Hyderabad that support in consultancy.

Gems and jewellery industries in Hyderabad are aggressively hiring staffs with good profile. The jewellery industry is full of diverse and rewarding career options. From manufacturing to retail, design to valuing, there is a career path open to almost all interests and experience levels. Top Gems and Jewellery Recruitment Agency in Hyderabad gives services in placement. Gems and Jewelry sector forms an integral part of the Indian economy as it forms a major component of the export-led growth. The jewellery industry is a place where you can be curious, creative and commercial. You can help bring people together, make people feel empowered and celebrate life's true milestones. India possesses world's most competitive gems and jewellery market due to its low cost of production, highly skilled and best artisan force for designing and crafting jewellery.

The gems and jewellery industry plays a vital role in the Indian economy. The Government of India recently declared the gems and jewellery industry as a focal point for exports. India is considered a global hub for low costs and inexpensive skilled labour. Government policies support the polishing and gem cutting industry, making it the worlds largest. Experts have predicted that the industry will soon shine like a star and will sparkle like a precious diamond in the near future. The gemstone industry has greatly benefited from the rise of online retail and virtual shopping. Online retail has revolutionized the way gemstones are bought and sold. It has eliminated geographical barriers, allowing customers worldwide to access a wide variety of gemstones. Online retail provides a platform for small-scale gemstone businesses to reach a larger audience. This has led to increased market competition and innovation, benefiting both businesses and customers.

#GemsandJewelleryRecruitmentAgencyinHyderabad#BestGemsandJewelleryRecruitmentAgencyinHyderabad#TopGemsandJewelleryRecruitmentAgencyinHyderabad

0 notes

Text

Malaysia Abrasives Market Size, Trends and Growth opportunity , Competitive Market Share & Forecast, 2023 – 2030.

"

Malaysia Abrasives Market Size, Trends and Growth opportunity, By Raw Material (Synthetic (Metallic Abrasives, Aluminium Oxide, Silicon Carbide, Glass Fall, Others), Natural (Diamond, Garnet, Corundum, Quartz, Others), By Application (Polishing, Finishing, Cutting, Grinding, Drilling, Others), Regional Outlook, Competitive Market Share & Forecast, 2023 – 2030.

Malaysia Abrasives Market

The Malaysia Abrasives Market was valued at USD 4,869.00 million in 2022 and is expected to reach USD 7,699.00 million by 2030 at a CAGR of 5.26% from 2023-2030. The abrasives market covers a wide variety of materials used on large scale in various industries such as machinery, transportation, metal fabrication, and electronic equipment. The market for abrasives is experiencing an increasing trend known as abrasive recycling, which offers businesses the chance to provide recycling services and create new abrasive recycling technologies. Customers may save money because of this in addition to reducing waste.

Get a Sample PDF of the Report: https://analyticalmr.com/request-sample/Abrasives-Market/request-sample

Market Drivers

Malaysia's expanding manufacturing and construction sectors create a steady demand for abrasives. The growth in automotive, aerospace, electronics, and other manufacturing industries drives the need for precision cutting and finishing processes. The abrasives market in Malaysia is driven by the construction and manufacturing sectors` continuous growth. Abrasives are essential for material shaping, finishing, and polishing in various applications. The automotive industry is a major consumer of abrasives for various applications, including grinding, polishing, and surface preparation. Malaysia's growing automotive sector, including vehicle assembly and parts manufacturing, will contribute to the demand for abrasives. Abrasives are essential in metal fabrication for tasks like cutting, grinding, deburring, and surface finishing. As Malaysia's metalworking industry grows, the demand for abrasives will rise. Governments and oversight organizations have begun implementing strict safety rules for those who work at heights. To comply with safety regulations, several companies choose aerial work platforms as a safer alternative to ladders and scaffolding.

Market Restraints

Abrasives might rely on raw materials sourced from various countries. Disruptions in global supply chains, caused by factors like geopolitical tensions or natural disasters, can lead to shortages and impact the production of abrasive products. Fluctuations in the economy can impact industries' spending on manufacturing and construction activities, directly affecting the demand for abrasives. Economic downturns can lead to reduced production and investment in various sectors. Alternative technologies and materials that can replace traditional abrasive methods might impact the demand for abrasive products. For instance, advanced machining techniques and laser cutting could reduce the need for traditional abrasive processes in some applications. Abrasives might be subject to international trade, and fluctuations in currency exchange rates can impact the cost of imports and exports, potentially affecting market competitiveness and pricing. The production processes for abrasives can be energy-intensive. Fluctuating energy costs can impact the overall production costs of abrasive products, potentially affecting pricing and profitability.

Impact Of COVID-19 On Market

The pandemic led to disruptions in global supply chains due to lockdowns, travel restrictions, and factory closures. This affected the availability of raw materials and components for abrasive manufacturing, leading to potential production delays and supply shortages. Many industries that are major consumers of abrasives, such as automotive, construction, and manufacturing, experienced decreased demand as lockdowns and restrictions led to project delays and reduced consumer spending. The abrasives market in Malaysia faced challenges during the pandemic due to decreased industrial activities and disruptions in the supply chain. Reduced demand from sectors like manufacturing and construction influenced sales. However, increased focus on cleaning and maintenance products led to higher demand for abrasives. Economic uncertainties and shifts in industrial priorities further influenced market dynamics. The overall economic uncertainty caused by the pandemic led to cautious spending and investment decisions, which impacted various industries' procurement of abrasive products.

Impact of Russia-Ukraine Conflict on Malaysia Abrasives Market

If any part of the global supply chain for abrasives, including raw materials or finished products, runs through the conflict-affected region, disruptions could occur due to border closures, transportation interruptions, or other logistical challenges. If Ukraine is a significant supplier of raw materials used in abrasives production, such as minerals or metals, disruptions in supply could lead to higher prices and potential shortages. Some industries, such as manufacturing, construction, and automotive, could be more directly affected by disruptions in the global supply chain. These industries are also major consumers of abrasive products. Geopolitical tensions can lead to reduced business confidence and uncertainty, affecting investment decisions and potentially leading to decreased demand for abrasive products. Geopolitical events can lead to changes in trade agreements, tariffs, and regulations. These changes can impact the cost of doing business and affect the competitiveness of abrasive products.

Market Segmentation

The Malaysia Abrasives Market is segmented into Raw Material, and Application. Based on raw materials, the synthetic category held the greatest market share in 2022. This is because the Malaysian government has pushed the use of synthetic abrasives to reduce the negative environmental consequences of the business. As a result, the demand for synthetic abrasives has increased across the country.

Regional Analysis

Based on country, Malaysia had the most share in 2022, and by 2030, it is anticipated to have the highest CAGR in the market for abrasives. Malaysia serves as a major hub for the manufacturing of autos and electronics, just like in Southeast Asia. Due to the growth of these industries, abrasives which are used in several operations like polishing, grinding, and cutting are in great demand. The continued development of the abrasives business has also been aided by the application of cutting-edge technologies like nanotechnology and biotechnology. These new technologies enable the creation of abrasive products that are more effective and efficient. Malaysia accounted for 9.04% of the market in 2022, as there are various abrasives manufacturers in Malaysia, both domestic and foreign. These manufacturers produce a wide range of abrasives, including coated, bonded, and super abrasives. Malaysia is becoming a prominent provider of abrasives in the region due to the presence of various producers.

Key Players

Various key players are discussed into the Malaysia Abrasives Market Report including: BlastOne Malaysia, FACO Abrasive Industrial Sdn. Bhd., Schmidt Abrasive Blasting Sdn Bhd, Sundisc Abrasives South East Asia Sdn Bhd, Robert Bosch Sdn Bhd, 3M Malaysia Sdn Bhd, KOVAX (Malaysia) Sdn., Bhd, Badak Abrasive Sdn Bhd, VISTA ABRASIVE SDN. BHD., Aim Marketing Sdn Bhd.

Market Taxonomy

By Raw Material • Synthetic o Metallic Abrasives o Aluminium Oxide o Silicon Carbide o Glass Fall o Others • Natural o Diamond o Garnet o Corundum o Quartz o Others By Application • Polishing • Finishing • Cutting • Grinding • Drilling • Others By Region • Asia Pacific o Malaysia

"

0 notes

Text

Dental Equipment Market Size, Share & Revenue Forecast 2030

Dental Equipment Market Growth & Trends

The global dental equipment market size is expected to reach USD 17.06 billion by 2030, according to a new report by Grand View Research, Inc., registering a CAGR of 6.2% over the forecast period. These tools help with an oral health diagnosis, care, and maintenance and allow practitioners to plan a precise course of action. The introduction of supportive government efforts for oral health, an increase in medical tourism for dental operations, and the incidence of dental problems all contribute to the industry's growth. In addition, manufacturers like Planmeca are always introducing fresh computer-aided technology to the market.

Request a free sample copy or view report summary: https://www.grandviewresearch.com/industry-analysis/dental-equipment-market

For instance, the industry demand is being driven by the company's March 2019 launch of the Planmeca Creo C5, an innovative 3D printer created to deliver chairside CAD/CAM dentistry and restorative dental treatments in a single visit.According to the estimates published by the United Nations in 2019, there were 703 million people aged over 65 years globally, and the number of older individuals is projected to double to 1.5 billion by 2050. The rising prevalence of various oral conditions in the geriatric population is likely to increase the demand for preventive, restorative, and surgical services in the future. According to the American Dental Association, 85% of individuals in the United States, value dental health and consider it an essential aspect of overall care.

The realization of the importance and maintenance of oral health combined with better access to advanced dental services will help in the growth of the industry. However, the “emergency-only” mode of dental care delivery due to the COVID-19 pandemic had a rippling effect and the industry witnessed an imminent increase in availing cost of dental care. According to the Journal of Contemporary Dental Practice, dental services were among the last to relaunch in post-pandemic relaxations since dental procedures are at high risk of transmission. This resulted in serious financial problems and revenue loss for the overall dental market.

Dental Equipment Market Report Highlights

Dental systems and parts emerged as the largest product segment in 2022 as these equipment are used for digital imaging and diagnosis of dental ailments

The dental lasers segment is expected to witness the highest CAGR during the forecast period. This is owing to its increasing application in surgical and teeth-whitening procedures.

North America dominated the global industry in 2022 owing to the high demand for new technologies & the prevalence of dental disorders and the presence of a large pool of key players & advanced healthcare infrastructure

Asia Pacific, on the other hand, is expected to register the highest CAGR over the forecast period

Dental Equipment Market Segmentation

Grand View Research has segmented the global dental equipment market on the basis of product type and region:

Dental Equipment Product Type (Revenue, USD Million, 2018 - 2030)

Dental Radiology Equipment

Intra-Oral

Digital X-ray Units

Digital Sensors

Extra-Oral

Digital Units

Analog Units

Dental Lasers

Diode Lasers

Quantum well lasers

Distributed feedback lasers

Vertical cavity surface emitting lasers

Heterostructure lasers

Quantum cascade lasers

Separate confinement heterostructure lasers

Vertical external cavity surface emitting lasers

Carbon Dioxide Lasers

Yttrium Aluminium Garnet Lasers

Systems & Parts

Instrument Delivery systems

Vacuums & Compressors

Cone Beam CT Systems

Cast Machine

Furnace and Ovens

Electrosurgical Equipment

Other System and Parts

CAD/CAM

Laboratory Machines

Ceramic Furnaces

Hydraulic Press

Electronic Waxer

Suction Unit

Micro Motor

Hygiene Maintenance Devices

Sterilizers

Air Purification & Filters

Hypodermic Needle Incinerator

Other Equipment

Chairs

Hand Piece

Light Cure

Scaling Unit

Regional Insights

North America dominated the global industry in 2022 with a market share of more than 38.35% and is expected to showcase a significant CAGR over the forecast period. This is attributed to the rising geriatric population, strong medical infrastructure, well-established reimbursement policies, the existence of key players, and advancement in preventive and restorative dental treatments. Moreover, according to the American Dental Association, 85% of individuals in the United States truly value dental health and consider oral health an essential aspect of overall care. The combination of all these factors will make North America the most promising regional market over the forecast period.

The APAC region is expected to witness the highest CAGR over the forecast period. China, Japan, and India are emerging economies with well-developed healthcare infrastructure & facilities and are now more focused on leading on the basis of R&D activities. They have suitable infrastructure and fundings for the same. A total of 43.6% of the spending is expected to emanate from Asia with countries like China, Japan, and India being the topmost to spend on R&D activities.

Attributes like favorable government policies, the rising geriatric population, the presence of key players, and the rise in the demand for dental procedures are paving way for the market in the Asia Pacific region. Moreover, medical tourism in the region is rapidly increasing due to shorter patient waiting times, low-cost treatment, availability of a large pool of skilled dental practitioners & high-end technology, and the presence of tourist destinations & quality accommodations. These aforementioned factors will assist in the market growth in the region.

List of Key Players of Dental Equipment Market

A-Dec Inc.

Planmeca Oy

Dentsply Sirona

Patterson Companies Inc.

Straumann

GC Corp.

Carestream Health Inc.

Biolase Inc.

Danaher Corp.

3M EPSE

Authoritative Research: https://www.grandviewresearch.com/industry-analysis/dental-equipment-market

#Dental Equipment Market#Dental Equipment Market Size#Dental Equipment Market Share#Dental Equipment Market Growth

0 notes

Link

0 notes

Text

Fiber Laser Market Analysis, Key Players, Industry Segments & Forecast to 2031

The global fibre laser market is anticipated to be valued US$ 3.1 billion in 2021, with a CAGR of 11.1% between 2021 and 2031.

Erbium, neodymium, ytterbium, praseodymium, thulium, dysprosium, and holmium are examples of rare earth elements found in fibre lasers. Previously, carbon dioxide or helium-neon were utilised in gas lasers. Solid state lasers built of neodymium-doped yttrium aluminium garnet, on the other hand, are used in a range of laser-related procedures. The advantages include ease of use, greater reliability, no maintenance, high stability, and integration possibilities.

Fibre lasers are used in medicine for hair removal, cosmetics, laser tattoo removal, skin conditions, dentistry, and aesthetic plastic surgery. According to the American Society for Aesthetic Plastic Surgery, liposuction and eyelid surgery account for more than half of total costs. Non-surgical procedures represent 44% of the market.

Download a Sample Copy of this Report @ https://www.futuremarketinsights.com/reports/sample/rep-gb-8174

Material processing makes use of high beam for cutting, welding, and etching. These days, fiber lasers are preferred in barcodes, traceable labels, scientific research, diamond industry, 3D printing, and semi-conductor industries. High power fiber laser is being used in metal cutting operations as an outcome of the unparalleled combination of productivity and precision with higher cost-effectiveness. Future Market Insights has enlisted these facts with insights in its latest market study entitled ‘Fiber Laser Market’.

Key Takeaways from Fiber Laser Market

North America is expected to witness a CAGR of 10.9% in the fiber laser market due to the US being a hub of automotives and consumer electronics.

Coming to Europe, Germany leads from the front due to an ever-increasing demand for ICs and semiconductors. It is also subject to fast adoption of compact laser cutting and welding machines. Also, as per Federal Motor Transport Authority, over 394,000 electric cars were registered in Germany in the year 2020 alone. Modern automotives are also seen using LiDAR system.

The Asia-Pacific is expected to grow at the fastest rate in the fiber laser market, led by Japan. The country is emphasizing on usage of fiber lasers to produce body panels.

Continuous wave fiber laser holds the largest market share and is expected to continue with its winning streak (~70%) in the near future.

“With flourishing material processing vertical, the global fiber laser market is bound to grow on an astonishing note in the near future”, says an analyst from Future Market Insights.

Competitive Landscape

IPG Photonics Corporation, in November 2018, announced releasing next generation high power lasers. They do come with multi-year service-free operation and claim to be having the least weight.

Videojet Technologies, in March 2021, tabled ‘Lightfoot’ fiber laser solution to facilitate high speed beverage canning. It does combine standard reliability on the part of videojet fiber laser and dual Lightfoot marking heads’ high speed for meeting every need pertaining to beverage production and canning.

LVD, in November 2020, came up with a novel large-format fiber laser cutting machine termed as ‘Taurus’, which is particularly designed to suffice extra-large sheet metal cutting capacity. In other words, machine is able to laser cut a broad range of parts, thereby optimizing usage of material and increasing productivity.

Coherent, in June 2020, tabled a novel 4000 w ‘Highlight FL4000CSM-ARM’ fiber laser conducive to automotive applications. The system paves the way for advanced welding capabilities to cater to tough metals and also aligns to the welding needs for energy storage, e-mobility, and general electric connections comprising dissimilar materials.

What does the Report Cover?

Future Market Insights offers an exclusive perspective and various real-time insights on the fiber laser market in its latest study, presenting historical demand assessment of 2016 – 2020 and projections for 2021 – 2031.

The research study is based on laser type (continuous wave lasers, pulsed lasers, and Quasi Continuous Wave Laser), by output power (low power (up to 100 W), medium power (100 – 2,000 W), and high power (more than 2,000 W)), and by application (cutting, welding & other high power applications, marking, fine & micro processing, communications and advanced applications, and medical).

Get Full Access of this Report @ https://www.futuremarketinsights.com/reports/fiber-laser-market

Key Segments Covered In Fiber laser Market Study:

By Laser Type:

Continuous Wave Lasers

Pulsed Lasers

Quasi Continuous Wave Laser

Output Power:

Low Power (Up to 100 Watts)

Medium Power (100W-2,000W)

High Power (More than 2,000 W)

Application:

Cutting

Welding & Other High Power Applications

Marking

Fine & Micro Processing

Communications and Advanced Applications

Medical

Region:

North America

Latin America

Europe

China

Asia Pacific

Middle East and Africa

0 notes