#Industrial Air Compressor Manufacturers

Explore tagged Tumblr posts

Text

8 Essential way to Improve Air Compressor Safety

An air compressor is essential in various industries, powering machinery and tools that make everyday tasks more efficient. However, with great power comes great responsibility. Using an air compressor machine can pose significant safety risks if not handled correctly. Whether you’re working with a portable air compressor or a large-scale industrial air compressor, it’s essential to prioritise safety to protect your employees, equipment, and environment. In this guide, we’ll explore eight essential ways to improve air compressor safety, ensuring a safe and efficient process at all times.

Effective tips for improving air compressor safety

Conduct regular maintenance and inspections.

A well-maintained air compressor runs more efficiently, lasts longer, and reduces the possibility of hazardous situations. Regular maintenance is the key to avoiding safety risks caused by malfunctioning parts.

Why regular maintenance is required:

Air compressors are complex machines that require routine checks to ensure they are working at optimal performance. An inadequately maintained air compressor could produce leaks, damaged parts, or overheating issues—leading to dangerous accidents. Always inspect essential parts like belts, air filters, pressure gauges, and safety valves.

Tip: Work with industrial air compressor manufacturers to induct a customised maintenance schedule that suits your specific model and industry needs. Don’t forget to document inspections to stay on top of necessary repairs.

Train operators Effectively

Proper training is one of the essential factors of air compressor safety. Operators should be well-trained in the correct handling, emergency procedures, and safety protocols for the air compressor machine they’re using.

Training should cover the following:

Pressure settings: Operators must understand the recommended pressure levels and how to adjust them based on the task.

Emergency protocols: Train employees on how to handle a malfunctioning compressor, including turning off the machine and venting excess pressure.

Safety gear: Operators should know the importance of wearing personal protective equipment (PPE) to safeguard against injuries.

Tip: Ensure that training is refreshed periodically and customised to meet the specific needs of your industry. A well-trained workforce is the foundation of a safe working environment.

Monitor correct air pressure settings.

Maintaining the proper pressure settings is important to prevent over-pressurisation, which can lead to system failure and accidents.

Why pressure control is important:

An air compressor machine that exceeds its pressure limits can cause parts to fail, resulting in leaks, breakdowns, or even explosions. Always check the pressure meters and ensure they remember the correct settings for your specific industrial needs. Regularly monitor and maintain pressure levels within industrial air compressor manufacturers‘ guidelines.

Tip: Invest in a pressure relief valve that automatically releases excess pressure to ensure the system works within safe limits, preventing destructive failures.

Install safety valves and pressure relief tools.

Installing safety valves and pressure relief tools is one of the best ways to protect an air compressor from dangerous pressure buildup.

The role of safety valves:

These valves are designed to release excess pressure, preventing the air compressor from exceeding its rated capacity. If the internal pressure rises too much, the valve will open to allow air to exit safely. This essential feature helps prevent equipment damage or explosions.

Tip: Regularly test the safety valves to ensure they are working correctly. If they fail, the air compressor could become a significant safety hazard.

Provide personal protective equipment:

While the air compressor is a powerful tool, it can also be a source of potential hazards. Personal protective equipment (PPE) is necessary to shield employees from noise, flying debris, and potential accidents.

Essential PPE for working with air compressors:

Hearing protection: An air compressor machine can generate high noise levels, which can cause hearing damage over time. Use earplugs or earmuffs.

Safety goggles: Eye protection is crucial to avoid injury from high-pressure air or flying debris.

Work gloves: Gloves will protect workers from cuts, abrasions, and burns.

Tip: Regularly inspect PPE for wear and tear and replace damaged equipment immediately to maintain safety standards.

Ensure proper ventilation

An air compressor, especially large industrial models, generates heat and may release exhaust fumes. Proper ventilation is necessary to keep the air compressor operating safely and effectively.

Why ventilation matters:

Without adequate airflow, compressors can overheat, leading to potential breakdowns or fires. Moreover, toxic gases like carbon monoxide can be stashed in poorly ventilated areas, posing health risks to workers. Ensure the compressor room is well-ventilated or use exhaust systems to remove dangerous fumes.

Tip: Install air filtration systems or exhaust fans to keep air quality high and maintain a safe working environment.

Clear the area around the compressor.

A clean, clutter-free environment is necessary for air compressor safety. Obstructions can cause accidents or hinder the effective functioning of the air compressor machine.

Why keeping the area clean is important:

Clutter around the air compressor can block airflow, damage hoses, or create tripping hazards. In an emergency, a blocked exit or inaccessible emergency stop button could pose a significant risk to workers. Keep the area around the air compressor clear of unnecessary items, and ensure all components are easily accessible for maintenance or emergency response.

Tip: Use cable management systems and organise hoses to keep them tidy and out of the way, ensuring easy access and safe operation.

Handle compressed air properly.

Compressed air is a powerful tool that needs to be handled with caution. Improper handling

or storage of air hoses and equipment can lead to accidents, leaks, or bursts.

How to handle compressed air safely:

Inspect hoses and fittings: Regularly check hoses and fittings for cracks or wear, which could cause air leaks or bursts.

Proper storage: Store hoses and equipment in a dry, clean area to prevent damage from dirt, moisture, or rust.

Secure connections: Ensure all air compressor fittings are properly secured before starting the machine.

Tip: When transporting or storing the air compressor, ensure that it is securely attached to prevent damage during transit.

Summary:

Air compressor safety is a top priority for industrial air compressor manufacturers. Following these eight essential safety tips, regular maintenance, effective trfaining, correct pressure settings, safety valves, PPE, ventilation, a clear workspace, and proper air handling can minimise the risks associated with air compressor operations. Keeping your workplace safe is not just about compliance; it’s about ensuring the well-being of your employees and the longevity of your equipment. Reach out to www.indoair.com today to learn more about how we can help you improve safety and efficiency in your operations.

#industrial air compressor manufacturers#air compressors#air compressor#air compressor manufacturers in india

0 notes

Text

Top Air Compressor Supplier

At BOGE America, Inc., we are a leading air compressor supplier specializing in industrial-grade solutions. As top industrial air compressor manufacturers, we offer a wide range of high-performance compressors designed for various applications. Our commitment to quality ensures reliable and efficient operation for your business. Trust BOGE for innovative and durable air compression technologies. Explore our products and find the perfect fit for your needs.

#Air Compressor Supplier#Industrial Air Compressor Manufacturers#Industrial air compressor suppliers

0 notes

Text

Discover Parth Compressor, a trusted name among air compressor manufacturers in India. Our cutting-edge technology, reliable performance, and commitment to excellence redefine industry standards. From industrial to commercial applications, we deliver compressed air solutions that power your success.

#air compressor manufacturers in India#air compressor manufacturers in Ahmedabad#industrial air compressor manufacturers

1 note

·

View note

Text

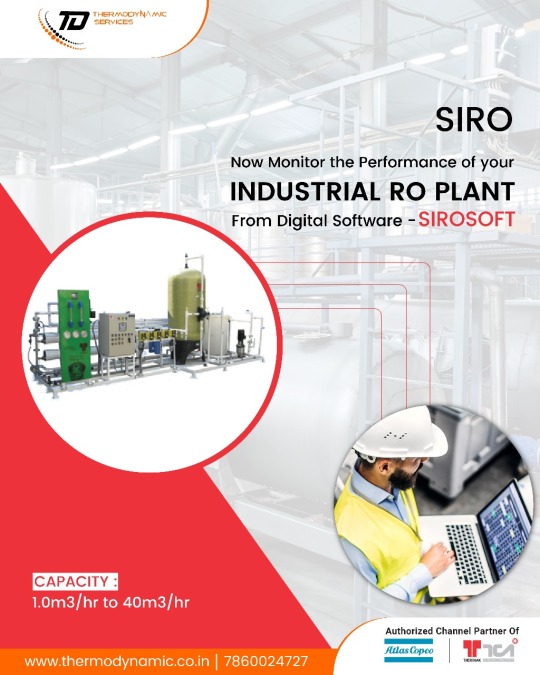

Atlas Copco Air Compressor Dealer in Uttar Pradesh - Thermodynamic Services

Welcome to Thermodynamic Services, your trusted partner for top-notch industrial air compressors and compressed air solutions in Uttar Pradesh. As the premier Atlas Copco dealer in the region, we take pride in delivering cutting-edge technology and reliable products to meet your diverse compressed air needs.

Atlas Copco Air Compressors in Uttar Pradesh:

At Thermodynamic Services, we specialize in offering a comprehensive range of Atlas Copco air compressors in Uttar Pradesh. Our commitment to quality and efficiency ensures that your industrial operations run smoothly with the most advanced and reliable compressed air solutions.

Atlas Copco Dealer in Kanpur:

If you are based in Kanpur and searching for a reliable Atlas Copco dealer, look no further than Thermodynamic Services. We bring you the latest models of Atlas Copco air compressors, combining innovation and durability to enhance your industrial processes.

Industrial Air Compressor Manufacturer & Supplier in Kanpur:

As a leading industrial air compressor manufacturer and supplier in Kanpur, Thermodynamic Services provides customized solutions tailored to meet the unique requirements of your business. Our state-of-the-art compressors are designed to optimize energy efficiency and minimize downtime.

Atlas Copco Compressed Air Dryer Dealer in Uttar Pradesh:

Thermodynamic Services is your go-to Atlas Copco compressed air dryer dealer in Uttar Pradesh. Our range of air dryers ensures that your compressed air is free from moisture, contaminants, and impurities, guaranteeing the longevity and efficiency of your equipment.

Unmatched Quality and Reliability:

When you choose Thermodynamic Services, you invest in unparalleled quality and reliability. Our partnership with Atlas Copco, a global leader in compressed air technology, ensures that you receive products that adhere to the highest industry standards.

Customer-Centric Approach:

At Thermodynamic Services, customer satisfaction is our priority. Our team of experienced professionals is dedicated to understanding your specific needs and providing tailored solutions. We believe in building lasting relationships with our clients through exceptional service and support.

Conclusion:

For all your industrial air compressor needs in Uttar Pradesh, Thermodynamic Services stands as the preferred choice. As the foremost Atlas Copco dealer in the region, we guarantee top-quality products, unmatched reliability, and a customer-centric approach. Elevate your industrial processes with Thermodynamic Services – your trusted partner for compressed air solutions.

conatct us on 91 78600 24711

#industrial air compressor dealer in uttar pradesh#Atlas Copco Air Compressor#Atlas Copco Air Compressors in Uttar Pradesh:#Atlas Copco Dealer in Kanpur#Industrial Air Compressor Manufacturer & Supplier in Kanpur:#Atlas Copco Compressed Air Dryer Dealer in Uttar Pradesh:#industrial air compressor needs in Uttar Pradesh

5 notes

·

View notes

Text

Top Benefits of Choosing Blower Rental Fort Worth TX for Outdoor Maintenance

Keeping your property clean and well-maintained is essential, especially in Fort Worth, TX, where seasonal changes can bring everything from fallen leaves to dust and debris. For those looking to save time and effort, renting a high-quality blower is a smart choice. EZ Equipment Rental provides an efficient solution with their Blower Rental Fort Worth TX service, catering to both residential and commercial needs.

Why Rent a Blower?

Blowers are versatile tools designed to make outdoor cleaning quick and easy. From blowing away leaves in the fall to clearing debris after a storm, a powerful blower can save you hours of labor. Renting a blower gives you access to commercial-grade equipment without the cost of purchasing and maintaining one yourself.

Benefits of Blower Rental in Fort Worth, TX

Cost Efficiency: Buying a high-performance blower can be expensive, especially if you only need it for occasional use. Renting from EZ Equipment Rental is a cost-effective alternative, allowing you to access top-quality equipment when needed without a hefty price tag.

Time-Saving Tool: Using a blower significantly reduces the time it takes to clean outdoor spaces compared to manual methods. Whether it's a residential yard or a commercial parking lot, a rented blower can handle the task efficiently, freeing up your time for other activities.

Versatility and Power: Blowers come in various sizes and power levels. By renting, you can choose the ideal model for your specific job, whether it's light leaf removal or heavy-duty debris clearing. EZ Equipment Rental offers a range of blowers suitable for different tasks, ensuring you get the right tool for the job.

EZ Equipment Rental in Fort Worth, TX

EZ Equipment Rental is known for providing quality and reliability in the Fort Worth area. Their Blower Rental Fort Worth TX service stands out due to their commitment to customer satisfaction and their wide selection of high-performance blowers. Whether you need a handheld blower for a small yard or a backpack blower for a more extensive area, they have you covered.

Hassle-Free Rental Experience

Renting a blower from EZ Equipment Rental is simple and convenient. You can easily browse their equipment online or visit the store to get personalized advice. Their friendly staff is always ready to recommend the best blower based on your specific needs, ensuring you get effective results every time.

Why Choose EZ Equipment Rental?

• Wide Selection: A variety of blowers for different tasks and power levels. • Affordable Pricing: Competitive rates to fit any budget. • Convenient Rentals: Flexible rental periods, from daily to weekly options. • Expert Advice: Knowledgeable staff to guide you in choosing the right blower.

Conclusion

For anyone in Fort Worth looking to maintain their outdoor spaces, Blower Rental Fort Worth TX from EZ Equipment Rental is the ideal solution. With quality equipment, competitive pricing, and a commitment to customer service, they provide everything you need to keep your property clean and tidy.

Renting a blower from EZ Equipment Rental is a smart and economical choice, giving you access to the right equipment for any job, big or small, without the hassle of ownership.

#industrial equipment#equipment rental#manufacturing#dump trailer#trailers rental#forklift rental#sandblasting#construction#air compressor

0 notes

Text

Digoma Enterprise is an experienced leader in manufacturing industrial shafts in India. Knowledge of the highest standards through sophisticated technology enables us to design shafts. Our team of efficient professionals takes great care in providing precision and durability in making these shafts. With insight into the specific demands of industries, we offer customized solutions according to the different types of machines. Digoma Enterprise has years of experience, and that expertise helps us deliver excellent products every time. Our clients trust us for commitment to quality and reliability. If you want expert industrial shaft manufacturers in India, Digoma Enterprise is the right place for you.

#best air compressor spare parts#best supplier#best quality crankshafts#quality products#handcrafted#3d printing#machine learning#best crankshafts#resources#best air compressors#expert industrial shaft manufacturers in India

0 notes

Text

0 notes

Text

Dasset Engineering: Your Trusted Partner for High-Performance Crankshafts in India

Crankshafts are a critical engine component, serving as the backbone of power transmission and converting linear piston motion into rotational motion. Whether you’re running an automotive engine, stationary machinery, marine engines, or agricultural equipment, the quality of the crankshaft can significantly impact performance, efficiency, and reliability. At Dasset Engineering, we specialize in providing top-tier crankshafts tailored to meet the diverse needs of various industries, making us the best crankshafts manufacturer and supplier in India.

Why Choose High-Quality Crankshafts?

The crankshaft is subjected to immense pressure, high temperatures, and constant motion. Therefore, it must be designed with the utmost precision and constructed from high-quality materials to withstand these stresses. A well-engineered crankshaft minimizes vibrations, reduces engine wear, and ensures optimal performance. That’s where Dasset Engineering comes in, offering a wide range of forged and cast crankshafts to suit every requirement.

Our Crankshaft Solutions: Forged and Cast Crankshafts

At Dasset Engineering, we pride ourselves on delivering high-performance crankshafts that cater to a broad spectrum of applications:

Forged Crankshafts: Forged crankshafts are manufactured through a process that compresses and molds the metal, resulting in a denser, more durable component. These crankshafts are ideal for high-performance engines, such as those in race cars, heavy-duty trucks, and industrial machinery, where strength and resistance to fatigue are paramount. The forging process ensures minimal internal defects, offering excellent structural integrity and superior tensile strength.

Cast Crankshafts: Cast crankshafts are produced by pouring molten metal into a mold, allowing it to cool and solidify into shape. They are suitable for applications where moderate performance and cost-effectiveness are essential. Our advanced casting techniques produce crankshafts with uniformity, precision, and a smooth surface finish. Cast crankshafts are often used in standard automotive engines, air compressors, and other moderate-duty applications.

Both types of crankshafts are available in fully finished or semi-finished conditions. This flexibility allows us to cater to your specific needs, whether you require a crankshaft ready for installation or one that can be customized further to fit unique engine requirements.

Applications of Dasset Engineering Crankshafts

Our crankshafts are designed to deliver optimal performance across various industries and applications:

Automotive Engines: Our crankshafts provide the strength and balance necessary for passenger cars, commercial vehicles, and racing engines, ensuring smooth operation and longevity.

Stationary Engines: For generators, pumps, and industrial equipment, we supply crankshafts that deliver consistent power and reliability.

Marine Engines: In harsh marine environments, our crankshafts offer superior corrosion resistance and durability.

Agricultural and Industrial Engines: Used in tractors, earthmovers, and heavy machinery, our crankshafts are built to handle tough conditions with ease.

Air and Refrigeration Compressors: We provide crankshafts for compressors that demand high precision and balance to maintain performance and reduce vibration.

Why Dasset Engineering Stands Out

Dasset Engineering has earned a reputation as the best crankshaft manufacturer and supplier in India for several reasons:

Commitment to Quality: We use only the finest materials and the latest technologies to produce crankshafts that meet international quality standards.

Expert Engineering: Our team of skilled engineers ensures each crankshaft is meticulously designed and manufactured to deliver peak performance.

Customization Options: We provide both standard and custom solutions to fit the specific needs of our clients, offering flexibility in terms of design, materials, and finishes.

Stringent Testing: Every crankshaft undergoes rigorous quality control tests to ensure it meets our high standards for durability, performance, and reliability.

Conclusion

Dasset Engineering is your trusted partner for high-performance crankshafts in India. Whether you need forged crankshafts for a high-power application or cast crankshafts for cost-effective solutions, we provide products that promise quality, performance, and longevity. Our crankshafts are designed to drive efficiency and reliability, making us the preferred choice for automotive, marine, industrial, and agricultural applications.

Choose Dasset Engineering for all your crankshaft needs and experience unmatched quality and service. Contact us today to learn more about our offerings and how we can support your business!

#Best crankshaft manufacturer in India#High-performance crankshafts for automotive engines#Forged crankshafts supplier for industrial engines#Cast crankshafts for marine and agricultural applications#Crankshaft manufacturer for air compressors in India#Top crankshaft suppliers for tractors and earthmovers#Buy high-quality forged crankshafts in India#Custom crankshafts for industrial and stationary engines#Durable crankshafts for refrigeration compressors#Crankshafts for heavy machinery engines in India#High-strength crankshafts for race cars and heavy-duty trucks#Fully finished and semi-finished crankshafts suppliers#Affordable cast crankshafts for automotive applications#Leading supplier of crankshafts for agricultural equipment#Customized crankshaft manufacturing services in India

0 notes

Text

15-300 HP Air Compressors | From ELGi USA

15 HP – 300 HP EG SERIES

REQUEST A QUOTEDOWNLOAD BROCHURE

ELGi’s EG Series oil-lubricated screw air compressors offer a robust compressed air solution for many industries including manufacturing, aerospace, chemical, and packaging . The EG Series ranges from 15 hp to 300 hp and are designed with the end-users in mind. ELGi’s industrial air compressors are equipped with our unique air end design offering reliability and efficiency. The EG Series industrial screw compressor are engineered to deliver high performance and energy efficiency to save operating expenses while maintaining air quality. The ELGi EG Series’ advanced package design not only minimizes system losses to maximize energy savings, but also offers ease of service and low noise levels. ELGi is the only air compressor manufacturer to offer a life-time air end warranty and a five-year compressor package warranty.*

*Terms and conditions apply

WHY ELGi's EG SERIES SCREW AIR COMPRESSOR?

Highly Efficient Airend - Superior Energy Efficiency At the heart of ELGi's EG Series oil-lubricated screw air compressor lies a unique air end equipped with proprietary η-V profile rotors featuring a 4/5 lobe combination. ELGi’s industrial compressor’s air ends operate at low speeds, maximizing energy efficiency. The EG Series air ends come with a life time warranty. ELGi’s life time air end warranty extends to the entire range of EG Series air compressors, ranging from 15 HP to 300 HP.

Best-in-class Maintenance and Operation Cost The EG Series screw air compressor comes with ELGi's next-generation technology of oil-injected screw rotors, designed for easy access, with a hinged panel design, stainless control lines, and O-ring flanged faces that eliminate leaks. A filtered cabinet extends the life of components. As a result, they provide high-quality compressed air even in extreme environmental conditions and offer long and trouble-free life with low operation costs. The EG Series industrial compressor’s package is designed to ensure ease of maintenance saving you money on your routine service.

Advanced Package Design - Functional and Aesthetic Our package is configured with subsystems designed to minimize energy losses, making it a highly energy-efficient solution. In addition, it offers ease of service, and maintains low noise levels, ensuring smooth operations.

Reliable and Efficient Motels The TEFC severe duty motors in the ELGi's EG air compressors are built with a larger core and increased windings, offering reliability and efficiency. Their direct coupling with the air end enhances energy efficiency, while high ambient ratings make them a reliable choice for all industrial applications.

Lowest Oil Carryover in the Industry (< 1ppm) ELGi has developed a unique OSBIC process (Oil Separation by Impact and Centrifugal action) to separate air and oil with minimum pressure drop. This process involves removing oil in three stages, delivering consistent low oil carryover in the compressed air, reducing the oil discharged into the environment. This efficient method also increases the life of the air-oil separation filter.

Efficient Cooling System - Large Cooler and Optimized Fan The oversized and bolted cooler design eliminates thermal stresses, extends the compressor's life, lowers power consumption, and maintains low discharged compressed air temperatures, reducing the load on downstream equipment.

Best-in-Class Warranty Program ELGi offers a best-in-class warranty on its products and components, ensuring they provide complete peace of mind. The EG Series rotary screw air compressor comes with a lifetime air end warranty and a five-year package warranty, providing customers with best-in-class compressed air products and industry-leading warranty coverage.

Reliability Under Extreme Conditions - Robust and Reliable The EG Series industrial air compressors are designed to perform in extreme conditions, from cold to hot and from dry to highly humid environments, with ambient temperatures reaching up to 115°F. Optional outdoor modifications and low ambient designs are also available to ensure maximum running time throughout the year.

Optional Variable Speed Drives for Energy Efficiency Maximize energy savings with the optional Variable Frequency Drives (VFD). ELGi’s integrated VFD matches the compressor output with the demand by varying the motor speed. This results in reduced power consumption following the reduced demand, thus eliminating the frequent load-unload cycle, and offering an energy-efficient solution with low operating speed, low maintenance and low sound level.

Operating Data and Safety Measures The EG industrial air compressors are equipped with high-pressure trips, high-temperature trips, pressure relief valves, low-voltage trips, single-phase preventers, and reverse rotation prevention mechanisms, to ensure the highest level of safety.

youtube

WHY CHOOSE THE ELGi EG SERIES SCREW COMPRESSOR?

Watch the video to learn how the EG Series air compressors lead in maintenance, cost of ownership, and quality.

To know more, watch the video Read More Contact us

Elgi Compressors USA, INC 4610 Entrance Drive, Suite A Charlotte, NC 28273 USA

Tel : 704-448-2510 Email : [email protected]

#air compressor accessories#industrial air compressors#portable air compressors#oil free air compressor#185 cfm air compressor#air compressor parts#air compressor manufacturer#air compressor usa#air compressor#Youtube

0 notes

Text

Comprehensive Solutions in Thermodynamic Services: A Leading Partner in Uttar Pradesh

Introduction: In the bustling industrial landscape of Uttar Pradesh, Thermodynamic Services emerges as a beacon of excellence, catering to a diverse range of thermodynamic needs. With a rich history of collaboration with industry giants like Thermax Limited, Atlas Copco (India) Limited, and Buhler India Pvt. Limited, Thermodynamic Services stands as a trusted partner offering comprehensive solutions. Specializing in industrial air compressors, compressed air dryers, thermic fluid heaters, industrial water treatment plants, STP plants for hospitals, and ETP plants for industrial use in Kanpur and beyond, Thermodynamic Services is committed to addressing the most challenging issues in heat, energy, air, water, solar, and grain processing.

Industrial Air Compressor Manufacturer & Supplier in Kanpur: As a premier industrial air compressor manufacturer and supplier in Kanpur, Thermodynamic Services delivers top-of-the-line equipment tailored to meet the rigorous demands of modern industries. Drawing from years of expertise and partnerships with leading manufacturers, we provide cutting-edge solutions that ensure optimal performance and efficiency for our clients' operations.

Compressed Air Dryer / Refrigerated Air Dryer Supplier in Kanpur: Recognizing the critical importance of quality compressed air in industrial processes, Thermodynamic Services offers premium compressed air dryers and refrigerated air dryers. Our products guarantee the delivery of clean, dry air, free from moisture and contaminants, thereby safeguarding the integrity of our clients' operations and prolonging the lifespan of their equipment.

Thermic Fluid Heater Supplier/Manufacturer in Uttar Pradesh: In the realm of thermic fluid heating systems, Thermodynamic Services stands as a distinguished supplier and manufacturer in Uttar Pradesh. Our thermic fluid heaters are engineered to deliver efficient heat transfer, ensuring consistent performance and reliability across various industrial applications. With a focus on innovation and quality, we empower our clients to optimize their processes while minimizing energy consumption.

Industrial Water Treatment Plants Supplier/Manufacturer in Uttar Pradesh: Water is a precious resource, and Thermodynamic Services is committed to its responsible management through advanced water treatment solutions. As a leading supplier and manufacturer of industrial water treatment plants in Uttar Pradesh, we offer customized systems designed to meet the unique needs of each client. From filtration to purification, our solutions ensure the availability of clean water for industrial processes, enhancing productivity and sustainability.

STP Plant for Hospitals: Ensuring safe and sustainable wastewater management is imperative for healthcare facilities, and Thermodynamic Services provides tailored solutions with our STP (Sewage Treatment Plant) plants for hospitals. Compliant with regulatory standards and designed for efficiency, our STP plants effectively treat wastewater, mitigating environmental risks and promoting a healthier community.

ETP Plant for Industrial Use in Kanpur: Industries in Kanpur rely on efficient wastewater treatment, and Thermodynamic Services meets this demand with our ETP (Effluent Treatment Plant) plants for industrial use. Through advanced technologies and expert engineering, our ETP plants efficiently remove pollutants from industrial effluents, ensuring compliance with environmental regulations and fostering sustainable industrial practices.

Conclusion: Thermodynamic Services stands as a testament to excellence in thermodynamic solutions, driven by a commitment to innovation, quality, and customer satisfaction. With a proven track record of serving esteemed clients and addressing complex challenges, we continue to be the preferred partner for industries across Uttar Pradesh. Whether it's industrial air compressors, compressed air dryers, thermic fluid heaters, water treatment plants, or wastewater management solutions, Thermodynamic Services remains at the forefront, empowering industries to thrive in an ever-evolving landscape.

#Industrial air compressor manufacturer & supplier in kanpur#Air compressor dealers in Kanpur/ Uttar Pradesh#compressed air dryer / refrigerated air dryer supplier in kanpur#STP plant for hospitals#ETP Plant for industrial use in kanpur

0 notes

Text

One of the Famous Industrial Air Compressor Manufacturers in India - Essar Pneumatics & Equipment

Introduction

Essar Pneumatics & Equipment is a prominent industrial air compressor manufacturer in India, catering to a wide range of industries. From its establishment, the company has steadily grown to become a reliable source for high-quality compressed air solutions. If you are looking for compressors in Kolhapur, then Essar Pneumatics & Equipment is undoubtedly the best place for you.

Company Overview

Essar Pneumatics & Equipment has been in the market since 1987. The company is in the field of Air Compressors, Garage Equipments, Pneumatic Piping Systems, Lubricants and Specialized Hand Tools. The company operates in Goa, Kolhapur, Satara, Sangli, Ratnagiri and Sindhudurg. It has a strength of 40+ subordinates. Its head office is situated in Kolhapur.

One-Stop Solution for Compressed Air Needs

Essar Pneumatics & Equipment’s comprehensive one-stop solution is tailored to meet all your industry requirements. From procurement to production, they have got you covered. Experience seamless operations, optimized workflows, and cost-effective solutions with Essar Pneumatics & Equipment.

Essar Pneumatics & Equipment stands as a reputable industrial air compressor provider in India, known for its commitment to quality, innovation, and customer satisfaction. As the company continues to evolve and expand its market presence, it remains a key player in the competitive landscape of air compressor manufacturing.

Compressed Air Solutions

Compressed air solutions play a crucial role in various industries, providing a versatile and efficient power source for a wide range of applications. From manufacturing and construction to healthcare and food processing, compressed air is utilized in numerous processes. Essar Pneumatics & Equipment provide versatile compressed air solutions for the various requirements. Check out our Compressed Air Solutions Products.

Piping Solutions

Piping solutions are a critical component of various industries, providing a network for the transportation of fluids, gasses, and other materials within a facility or from one location to another. The design, materials, and installation of piping systems are crucial to ensure the efficient and safe conveyance of substances. Essar Pneumatics & Equipment provide different piping solutions for the various requirements. Check out our Industrial Piping Solutions Products.

Pneumatic Components Pneumatic components play a crucial role in various industries by harnessing compressed air to perform mechanical work. These components are part of pneumatic systems that use compressed air to generate power and motion. Check out our Pneumatic Components.

0 notes

Text

How Can I Control Contaminants in My Industrial Air Compressor System?

Maintaining a clean and contaminant free industrial air compressor system is essential for ensuring efficiency, extending equipment lifespan, and maintaining product quality. Contaminants in compressed air can harm your business in more ways than one. They reduce product quality, damage manufacturing equipment, and even pose health risks to customers and end users. The good news? You can control these harmful particles before they impact safety or your bottom line. But first, let’s explore what these contaminants are, where they come from, and the problems they cause—so you can tackle them effectively.

Common contaminants in industrial air compressors

Several contaminants can enter an industrial air compressor system, affecting its performance. The most common include:

Moisture (Water vapour and condensation)

Moisture is the number one enemy of compressed air systems. Condensed water and aerosols can rust pipes, reduce efficiency, and increase maintenance costs. Without proper drying and filtration, your system’s performance takes a hit. If not removed, this moisture can lead to:

Corrosion of pipes and system components

Growth of bacteria and mold

Reduced efficiency of pneumatic tools

Particulates (Dust, dirt, and debris)

Rust, pipe scale, dust, and microorganisms slink into your system despite filtration. These tiny particles wear down components, damage equipment, and shorten the lifespan of an industrial air compressor. These contaminants can:

Block filters and valves

Damage moving parts inside the industrial air compressor

Contaminate end products in sensitive industries (e.g., food and pharmaceuticals)

Oil contamination

Many India compressor use oil for lubrication, cooling, or sealing. But when oil enters the system as a vapour, aerosol, or liquid, it mixes with moisture, turning acidic. This leads to rust, potential system failures, and even product contamination., leading to:

Damage to air-operated tools and machinery

Health hazards when used in breathing air applications

Reduced efficiency of pneumatic processes

Microorganisms and bacteria

Warm and humid environments inside air compressors create a breeding ground for bacteria, fungi, and mould. These can:

Contaminate production processes

Cause foul odors in compressed air output

Lead to product spoilage in food and beverage industries

Effective strategies to control contaminants in industrial air compressor

Use High-quality air filters:

Air filters are the first line of defence against airborne contaminants. Air compressor manufacturers can use different types of filters to remove specific pollutants:

Particulate filters: Catch dust, dirt, and solid debris.

Coalescing filters: Remove oil aerosols and fine particles.

Activated carbon filters: Absorb oil vapours and odors for higher air purity.

Best methods for air filters:

Inspect and replace filters regularly.

Use multiple filters in sequence for enhanced protection.

Ensure filters match the required air purity standards for your industry.

Execute air dryers to remove moisture:

Moisture is one of the most damaging contaminants in a compressed air system. Installing air dryers can help control excess water.

Types of air dryers:

Refrigerated dryers: Cool the air to condense and remove moisture.

Desiccant dryers: Absorb moisture using chemical desiccants.

Membrane dryers: Use selective permeable membranes to dry compressed air.

Install automatic drain valves:

Even with air dryers, condensation can collect in the system. Automatic drain valves help remove this moisture from an industrial air compressor, tanks, and filters.

Drain valve guidance:

Use electronic or timer-based drain valves for automatic moisture removal.

Install drains at multiple points, including air tanks and low-lying sections.

Maintain oil-free compressed air where necessary:

In industries such as food processing and medical applications, oil-free air is necessary. Using oil-free compressors or advanced filtration can ensure minimal oil contamination.

Oil-free solutions:

Use oil-free air compressors if the application requires pure air.

Install oil removal filters and coalescing filters in oil-lubricated systems.

Monitor and maintain system components regularly:

Routine maintenance plays an essential role in controlling contaminants. Regular inspections and servicing prevent buildup and maintain system efficiency.

Key maintenance tips:

Check and replace filters, dryers, and drain valves regularly.

Inspect air lines for leaks and corrosion.

Conduct regular audits to monitor air quality and performance.

Ensure proper air intake placement:

Where the air compressor removes air from affects contamination levels. Placing the intake in a clean, dry area away from dust, fumes, and pollutants minimizes contamination.

Air intake placement tips:

Keep air intake away from exhaust fumes and chemical storage areas.

Install pre-filters if the air source contains excessive dust.

Summary:

Controlling contaminants in industrial air compressor systems is essential for optimizing efficiency, ensuring product quality, and extending equipment life. By executing proper filtration, drying techniques, regular maintenance, and following industry standards, you can significantly reduce the risk of contamination. Choosing high-quality air compressor manufacturers and reliable filtration solutions will also enhance system performance and safety. With the right strategies in place, you can maintain clean, high-quality compressed air that meets the demands of your industry.

#compressed air#air compressor manufacturers#industrial air compressor#air compressors#air compressor manufacturers in india

0 notes

Text

Choosing the Right Breathing Air Compressor System Manufacturer: Key Considerations

Introduction

The demand for high-quality breathing air compressor systems is rising in various industrial sectors. These critical systems ensure a safe and reliable supply of breathable air to workers in hazardous environments. However, selecting the right breathing air compressor system manufacturer is crucial to guaranteeing the system's performance, durability, and compliance with safety standards. In this blog, we will explore the key considerations to help you make an informed decision when choosing a manufacturer for your industrial breathing air systems.

Industry Expertise and Reputation

When it comes to life-saving equipment like breathing air compressor systems, experience matters. Look for manufacturers with a proven track record in designing and producing reliable industrial breathing air systems. A reputable manufacturer will have a long-standing presence in the industry and a strong reputation for delivering top-notch products. Seek testimonials and reviews from other businesses or industries using their systems to gauge customer satisfaction and reliability.

Compliance with Safety Standards

The safety of your workforce is paramount. Ensure the breathing air compressor system manufacturer meets stringent safety standards and certifications. Manufacturers should comply with regulations set forth by organizations like OSHA (Occupational Safety and Health Administration), NFPA (National Fire Protection Association), and CGA (Compressed Gas Association). These certifications guarantee that the systems meet the necessary safety requirements and are suitable for industrial use.

Customization and System Flexibility

Industrial environments vary significantly, and a one-size-fits-all approach may not always suit your needs. Look for a manufacturer that offers customized breathing air compressor systems tailored to your industry's requirements. A flexible manufacturer can provide options for different configurations, capacities, and additional features to ensure the system seamlessly integrates into your existing setup.

Quality of Components and Construction

A reliable breathing air compressor system relies on top-notch components and robust construction. Inquire about the quality of materials used in the system's construction and the reputation of the manufacturer's suppliers. Durable materials and construction ensure the system can withstand harsh industrial conditions and perform consistently over time, reducing downtime and maintenance costs.

After-Sales Support and Service

The relationship with the manufacturer continues after the purchase. Evaluate the after-sales support and service the breathing air compressor system manufacturer offers. A reputable manufacturer should provide maintenance services, spare parts availability, and technical assistance to keep your system operating optimally. Prompt and efficient support is essential to minimize any disruptions to your operations.

Energy Efficiency and Environmental Impact

In today's eco-conscious world, energy efficiency and environmental impact are significant factors. Choose a manufacturer that prioritizes energy-efficient designs and incorporates eco-friendly features in their breathing air compressor systems. An energy-efficient system reduces operational costs and contributes to sustainability efforts, demonstrating your commitment to environmental responsibility.

Product Testing and Certification

Before finalizing your decision, inquire about the manufacturer's product testing procedures. Rigorous testing ensures the breathing air compressor system meets high-quality standards and performs as expected under varying conditions. Ask for information on reliability tests, performance evaluations, and safety certifications to confirm the system's overall reliability and efficiency.

Conclusion

Selecting the right breathing air compressor system manufacturer is a crucial step in ensuring the safety and well-being of your workforce in industrial environments. Consider the manufacturer's industry expertise, reputation, compliance with safety standards, and customization options. Evaluate the quality of components, construction, and after-sales support, and keep energy efficiency and environmental impact in mind.

At Trident Pneumatics, we take pride in our extensive experience as trusted breathing air compressor system manufacturers. Our industrial breathing air systems are designed to deliver uncompromising safety, reliability, and performance for various industrial applications. With a commitment to quality, compliance, and customer satisfaction, we stand ready to cater to your unique needs and contribute to the success of your operations.

0 notes

Text

Discover the indispensable world of air compressors with 'Unlocking the Power of Air.' This beginner's guide demystifies the workings of these versatile tools, unveiling their applications in various industries. From inflating tires to powering pneumatic tools, delve into the fundamentals of air compressors, empowering yourself with essential knowledge to harness the potential of compressed air for a multitude of practical tasks.

#air compressor#air compressors#air compressor manufacturer#industrial air compressor#air compressor manufacturers in India#air compressor manufacturers in Ahmedabad

0 notes

Text

STP Plant for Hotels/Hospitals and ETP Plant for Industrial Use

Welcome to Thermodynamic Services, your trusted partner for industrial air compressor solutions, air compressor installation services, Thermax products, industrial steam boilers, steam system engineering, hot water generators, STP plants for hotels and hospitals, ETP plants for industrial use, and RO plants for hotels and hospitals in Uttar Pradesh. We are your authorized dealer for top-notch Atlast Copco and Thermax products. Our commitment is to provide reliable and efficient solutions for your industrial needs.

Industrial Air Compressor and Installation Services:

At Thermodynamic Services, we offer a comprehensive range of industrial air compressors and professional installation services throughout Uttar Pradesh. Our team ensures that your air compressor system is installed efficiently, optimizing your production processes while reducing energy consumption.

Thermax Dealer in Varanasi and Lucknow:

As the authorized Thermax dealer in Varanasi and Lucknow, we bring you cutting-edge solutions for heating, cooling, and power generation. Our Thermax products are renowned for their quality and efficiency, ensuring that your industrial processes run smoothly.

Industrial Steam Boiler Manufacturer in Uttar Pradesh:

Our state-of-the-art industrial steam boilers are designed to meet the highest standards in performance and safety. We are the top industrial steam boiler manufacturer in Uttar Pradesh, offering tailored solutions for your specific requirements.

Steam System Engineering Services:

Thermodynamic Services specializes in steam system engineering services. Our team of experts will analyze, design, and implement the most efficient and cost-effective steam systems for your industrial operations in Uttar Pradesh.

Hot Water Generators for Hospitals & Hotels:

For hospitals and hotels in Uttar Pradesh, we provide high-quality hot water generators. These systems ensure a continuous and reliable supply of hot water, meeting the demands of your customers and patients.

STP Plant for Hotels/Hospitals and ETP Plant for Industrial Use:

We offer sustainable solutions for waste management with STP (Sewage Treatment Plant) and ETP (Effluent Treatment Plant) installations. Ensure your business is environmentally responsible and compliant with regulations.

RO Plant for Hotels and Hospitals:

Our RO (Reverse Osmosis) plants are ideal for hotels and hospitals, providing clean and safe drinking water. We prioritize the health and well-being of your guests and patients.

Conclusion:

Thermodynamic Services is your one-stop solution for all industrial needs in Uttar Pradesh. We pride ourselves on offering top-quality products and services that enhance your industrial operations. Partner with us to ensure efficiency, compliance, and sustainability. Contact us today for all your industrial requirements and enjoy the benefits of our trusted solutions.

conatct us on 91 78600 24711 or https://thermodynamic.co.in/

#Air Compressor Installation Services in Uttar Pradesh#Thermax Dealer in Varanasi#Thermax Dealer in Lucknow#Industrial Steam Boiler Manufacturer in Uttar Pradesh#Steam System Engineering Services in Uttar Pradesh#Hot Water Generator for Hospitals & Hotels#STP Plant for Hotels/Hospitals#ETP Plant for Industrial Use#RO Plant for Hotels and Hospitals

0 notes

Text

Why Choose Zero Turn Mower Rental Irving TX for Your Landscaping Needs?

When you need professional-grade lawn care, renting a zero-turn mower can make a significant difference. For residents and businesses in Texas, finding the right equipment to maintain your landscape is essential. EZ Equipment Rental in Irving, TX, offers a reliable solution with their Zero Turn Mower Rental Irving TX service.

Why Choose a Zero Turn Mower?

Zero-turn mowers are designed to provide high efficiency and precision. Unlike traditional mowers, they have a unique design that allows for sharper, faster turns, enabling you to maneuver around obstacles effortlessly. This agility reduces mowing time, making them an ideal choice for both residential and commercial properties.

Benefits of Zero Turn Mower Rental in Irving, TX

Cost-Effective Solution: Investing in a high-quality zero-turn mower can be costly. Renting gives you access to the latest models without the upfront expense. EZ Equipment Rental provides competitive rates, making it affordable for homeowners and businesses to achieve a well-maintained lawn.

High Performance and Speed: Zero-turn mowers are known for their speed and efficiency. Their powerful engines and precise controls allow for faster mowing compared to standard mowers. This makes them perfect for larger properties or those with intricate landscaping.

Professional Finish: These mowers offer a cleaner, more professional cut. Their advanced deck design ensures even grass cutting, giving your lawn a polished look every time. For those seeking a beautifully manicured yard, renting a zero-turn mower can make all the difference.

EZ Equipment Rental in Irving, TX

EZ Equipment Rental stands out as a top choice for Zero Turn Mower Rental Irving TX due to their excellent customer service and quality equipment. They understand that every lawn is different, and they offer a range of models to suit various needs. Whether you’re maintaining a small backyard or a large commercial space, they have the right equipment to get the job done.

Convenient and Reliable Service

EZ Equipment Rental makes the rental process easy and convenient. With a straightforward booking system, you can reserve your mower online or by phone, ensuring that the equipment is ready when you need it. Their knowledgeable staff can provide guidance on the best mower for your specific requirements, ensuring optimal performance and satisfaction.

Why Rent From EZ Equipment Rental?

• Quality Equipment: They offer top-of-the-line zero-turn mowers, ensuring you get the best performance. • Affordable Rates: Flexible rental options to fit any budget. • Expert Support: Friendly and knowledgeable staff to assist with your rental needs. • Convenience: Easy pick-up and delivery options available.

Conclusion

For anyone in need of professional lawn care solutions, Zero Turn Mower Rental Irving TX from EZ Equipment Rental is the go-to choice. Their high-quality equipment, affordable rates, and excellent customer service make them a trusted provider in the area. Whether you’re a homeowner aiming for a perfect lawn or a business maintaining a large property, renting a zero-turn mower from EZ Equipment Rental can help you achieve impressive results.

Choosing EZ Equipment Rental ensures you have the tools needed to keep your lawn looking its best without breaking the bank.

#industrial equipment#equipment rental#manufacturing#dump trailer#trailers rental#construction#air compressor#forklift rental

0 notes