#Hydraulic Filtration Systems

Text

How to Prevent Common Failures in Hydraulic Filtration Systems

If you're in the industrial or manufacturing sector, you're likely familiar with the critical role that hydraulic filtration systems play in keeping your machinery operating smoothly. These systems are the unsung heroes, quietly working behind the scenes to ensure that contaminants are kept at bay and your equipment operates at peak performance.

However, like any complex machinery, hydraulic filtration systems are susceptible to failures if not properly maintained.

Understanding the Importance of Hydraulic Filtration Systems

Before diving into how to prevent common failures, let's take a moment to understand why hydraulic filtration systems are so crucial.

These systems are responsible for filtering out contaminants such as dirt, debris, and moisture from hydraulic fluid, which is essential for ensuring the proper functioning of hydraulic equipment.

Without effective filtration, these contaminants can wreak havoc on machinery, leading to increased wear and tear, reduced efficiency, and even costly breakdowns.

Common Failures and Their Causes

Now that we understand the importance of hydraulic filtration systems let's explore some of the common failures that can occur and their underlying causes.

One of the most prevalent issues is filter clogging, which can occur when contaminants build up over time, reducing the flow of hydraulic fluid and putting strain on the system.

Other common failures include bypass valve malfunction, seal leaks, and pump damage, all of which can be attributed to inadequate filtration or poor maintenance practices.

Tips for Preventing Failures

Preventing failures in hydraulic filtration systems requires a proactive approach to maintenance and regular inspections.

Here are some tips to help keep your systems running smoothly:

1. Regular Filter Inspections: Make it a habit to inspect your filters regularly for signs of clogging or damage. Replace filters as needed to prevent contaminants from bypassing the filtration system.

2. Use High-Quality Filters: Invest in high-quality filters that are designed to withstand the rigours of industrial applications. Cheap, inferior filters may save you money upfront but can end up costing you more in the long run due to increased maintenance and downtime.

3. Monitor Fluid Contamination Levels: Keep a close eye on fluid contamination levels and invest in monitoring equipment to detect any changes early on. This proactive approach can help prevent costly damage to your machinery.

4. Follow Manufacturer Recommendations: Always follow the manufacturer's recommendations for filter replacement intervals and maintenance procedures. These guidelines are designed to optimise the performance and longevity of your hydraulic filtration systems.

5. Maintain Proper Fluid Levels: Ensure that your hydraulic fluid levels are maintained at the recommended levels to prevent air from entering the system, which can lead to cavitation and other issues.

6. Keep External Contaminants at Bay: Take steps to minimise the ingress of external contaminants, such as dust and moisture, by sealing off hydraulic filtration systems and implementing proper housekeeping practices in your facility.

7. Train Personnel: Provide training for your staff on proper maintenance procedures and the importance of hydraulic filtration systems. A well-trained team is essential for ensuring that maintenance tasks are carried out effectively and consistently.

Conclusion

In conclusion, hydraulic filtration systems are an indispensable component of industrial machinery, and preventing failures requires a proactive approach to maintenance and proper care.

By following the tips outlined above and staying vigilant in your inspections, you can minimise the risk of downtime and costly repairs, keeping your operations running smoothly for years.

Remember, a little prevention goes a long way regarding hydraulic filtration systems.

Source URL: https://hydraulicfilterau.blogspot.com/2024/03/how-to-prevent-common-failures-in.html

0 notes

Text

Importance of Filter Carts and how to select the right one?

A lubricant filter cart is an important tool that can be used in many ways. From filtering all types of new and used oil to taking samples and transferring oil, filter carts are considered to be a must-have for an effective lubrication program. Oil filter carts have many benefits; they can be customized to fit any plant as per the uses and specifications. If designed, it can also give a warning if the unit needs servicing.

The uses and importance of filter carts are as follows

For cleaning the lubricants stored

For transferring the filtered oil to a machine or containers

For reconditioning of oil (currently in use)

For flushing (power, line, wand, etc.)

For contamination control functions (hose cleaning)

For meeting cleanliness standards

Subscribe to our Website Blog for more insightful Articles and Case Studies: Click Here

How to select the right filter cart?

If you don’t want your money to get wasted, select the right filter cart considering the below check-points:

Check the type of oil before buying a filter cart because carts are designed as per the viscosity levels. If a plant uses different types of oil then multiple filter carts are to be used.

Choose a filter cart that can be carried easily to the place of its application. Here, you have to consider the source of power as well.

Knowing your oil cleanliness target is very important before you buy filter carts. Don’t depend on the ISO standards entirely to evaluate used oil. Considering the specification of the type of oil is vital. We know that when viscosity increases, the cleanliness level decreases.

Check the oil flow rate. Powerful carts will cost you more, so it’s very important to know the filter’s flow rate before buying.

Customization of filter cart can be done, check before you buy if it matches your requirements or not. For example, the installation of bypass valves, dual filters, etc.

It is always better to take a second opinion than to stick with a single thought. It’s advisable to have a discussion with your filter distributor or manufacturer to find the best option. Remember that the filter cart must be chosen carefully and effectively to meet the cleanliness goals.

Reach us anytime to find the right Filter cart for your Plant - [email protected] or +91 70309 01267

#minimac systems#contact minimac#Oil Purification Systems#oil flushing#filer skid#filter replacements#Condition Monitoring#contract & services#oil purification machine#frf#lvdh#transformer oil cleaning#lube oil#hydraulic oil#chemical cleaning#oil filtration#filter machine#oil cleaning machine

2 notes

·

View notes

Text

#Turbine Oil Cleaning System#Oil Cleaning Machines#Turbine Oil Cleaning Systems#Oil Filtration Plant#Gear Oil Filtration Systems#Industrial Oil Filter Machine#Oil Filtration Systems#Double Stage Oil Transformer Machine#Oil Filtration Elements#Oil Filtration Machine#Oil Filtration & Cleaning Systems#Thermic Oil Filtration Systems#On Site Oil Testing#Online Oil Cleaning Systems#Hydraulic Oil Online Filters#Mobile Oil Filtration Plant#Portable Oil Filtration Plant#Portable Oil Filtration System#Turbine Oil Filtration Plant#Turbine Oil Filtration Machine#Transformer Oil Filtration System#Transformer Oil Cleaning Systems#Evacuation System for Transformers#Transformer Oil Filtration Plant#Two Stage Transformer Oil Filtration Plant#Transformer Evacuation System#Transformer Oil Filtration Machine#Transformer Oil Filter Machine#Turbine Oil Flushing System#Centrifugal Oil Cleaner

0 notes

Text

Keep Your Hydraulics Running Smoothly with Sumesh Petroleum

Ensure optimal performance and extend the life of your hydraulic systems with top-notch filtration machines from Sumesh Petroleum. We offer a comprehensive range of machines designed to remove contaminants, improve oil quality, and minimize downtime. Contact us today to discuss your specific needs and discover how Sumesh Petroleum can keep your hydraulics running smoothly. If you are interested then tap on the link hydraulic oil filtration machine manufacturers.

#Online Transformer Oil Filtration System Manufacturers#hydraulic oil filtration machine manufacturers

0 notes

Photo

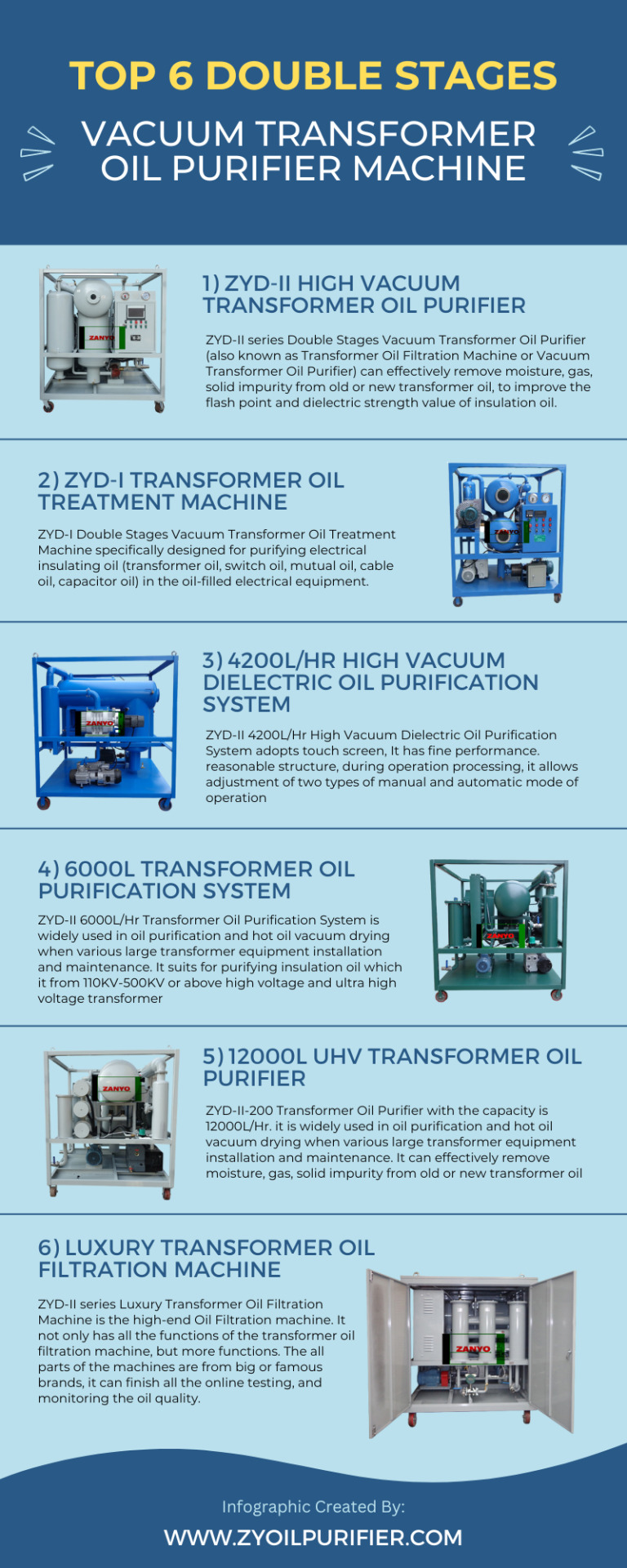

ZANYO manufacturer quality Online & Offline Transformer Oil Filtration Treatment System for sale. Top rate oil purifier machine at affordable price, free service and support in 2023.

Double stage vacuum transformer oil purifier machine is also called transformer oil dehydration machine and transformer oil filtering machine.

Double Stage Vacuum Transformer Oil Purifier is designed for purifying new or aged transformer oil, cable oil, super high -voltage transformer oil, switch oil, capacitor oil and different insulating oils.

For more information about Vacuum Transformer Oil Purifier, visit here: https://www.zyoilpurifier.com/double-stages-vacuum-transformer-oil-purifier/

#Double Stage Vacuum Transformer Oil Purifier#Vacuum Transformer Oil Purifier#oil purification#oil purifier#transformer oil filtration#transformer oil purification#transformer oil purifier#Turbo Oil Purifier#Zanyo Turbo-Flash Turbo Oil Purifier#Turbine Oil Purifier#ZYE Insulation Oil Vacuum Injector#ZYV Vacuum Extraction System#ZYK Fire Resistant Oil Filtration Machine#ZYL Hydraulic Oil Purification System#zyl lubricating oil filtration machine

1 note

·

View note

Link

Hydraulic filters are important components of hydraulic circuits of modern equipment.Working pressure and flow rate of the hydraulic system: Filters are designed based on these two basic factors. Unless these are specified one can not select filter properly.Once type of filters are finalized based on location, other important aspects such as pressure drop allowed, micron rating, beta ratio and filtering efficiency, seals, effective flow rate, servicing facilities, interval of replacement etc. are to be considered.

Filter choking indicators are available to be attached to filters . They are visual , electric options, buzzers etc. is available to indicate filter element is chocked Or pressure drop achieved. Other gauges are like level indicators etc. to be selected .

0 notes

Note

I rarely see any TFP Soundwave love here, let’s fix that shall we?

TFP Soundwave developing an obsession for the Autobots new human, a girl with hacking abilities so good she has best Soundwave at his own game of my than one occasion, is unable to read her mind despite him being telepathic, and has saved and cared from Laserbeak due to outside forces without the Autobots knowing.

*Soundwave, tilting his head to the side with a question mark popping up on his visor: “Query: (Y/N); prime mommy material?”

Cause let’s me honest, you’d get the hots too if a chick smaller and daintier than you kicked your ass on more than one occasion and cared for your kid despite being enemies.

(In total agreement. I love me some TFP!SW and this is most likely a slight crossover with Elsewhere University or a Magic!AU since you earned a boon to shield yourself from mental abilities.)

You’re difficult to locate and it’s galling.

Unlike the other Autobot pets, taken and secluded away by their guards and shielded base, you actually have a life outside of them, and it seems that you have no set ‘bot for some meager protection.

Instead of an easy target to snatch away -so eye-catching with that ridiculously bright-green hoodie with flopping audials- Soundwave digs and digs and digs for your whereabouts…

And you’re not there. The most he could find was your birth records, a few newspaper scans of the sparkling-equivalent of basic education, and then you drop from the face of the planet after high school. You reappear after five years and hop across the world with no rhyme or rhythm and at an impossible speed with the current technology on Earth.

Annoyance turns into begrudging respect for your efficient work. You have a talent for finding even the most inconsequential recordings of their presence and you cleanly wipe away the evidence.

If anything you do break the monotony of his work, especially with the little notes of “Better luck next time, Slenderman” or sad cat memes replacing the conspiracy posts of Cybertronian presence on Earth…

And then, Laserbeak completely disappears for a week without a hint of her status. No activity. No locator. Not even a life signal.

Soundwave searched everywhere. Remaining at the consoles, letting the massive amount of data flow into his systems, and refining his queries. When that amounted to nothing, he locked his hydraulics and set himself into the Nemesis itself, supplying his frame from the ship’s flow, overriding his own filtration because needed its power. He has to know. There must be absolute proof. He cannot stare into the ceiling of an empty room and do nothing but scramble after hope-

When Laserbeak suddenly reappeared, Soundwave disconnected from the warship and checked himself into Knock Out’s care, dismissing the accumulated complaints because he still had done all the necessary work and more during his locked state.

He weighed the necessary systems flush for the accumulated slag and joint stress as an acceptable tradeoff.

“Aren’t you a lucky girl? Count your stars that I do actually have standards, pretty bird.” In the memory loop, he feels the ghost of your touch, gentle and searching as you repair the damaged circuitry and clamp the sparking wires. A gloved hand resting upon the still wing and he can feel the phantom of your own biochemistry. Unique in its chaotic not-patterns and near-repetitive beats that clash and reform and clash again.

And you were right. Laserbeak was truly lucky that the shot didn’t stray to the left and the compromised seams. Otherwise, she would be gone as well. Laserbeak pings her active status over the bond as if she’s not currently docked on him.

“Sorry, birdy, you gotta stay like this.” Beneath the tease, there are apologetic notes as you keep Laserbeak immobilized by unknown means. In an off-placed mirror, he sees the outline of dark goggles and a facemask underneath that absurd hoodie, the screens of monitors, a toolbox, and, of all the things, Energon crystals.

“And tell your master that there’s no point coming here. I’ll be long gone and elsewhere.”

Something in your tone spoke of a private inside joke.

And true to your word, the suburban dwelling used to treat her is completely empty. It stands empty and unoccupied and without a trace of your once presence. Not even the security cameras, both public and private, could find one hint of a person living there. Only the vehicle with darkly-tinted windows drove and entered the garage, the doors closed without anyone stepping out.

And you purposely leave that hint.

That car -the very one used to transport Laserbeak -was found abandoned and hollowed out by fire, erasing physical evidence of yourself and her.

:: ‘Tor. I like that one. :: Laserbeak hums with a pulse of warmth. Not quite affection, but close enough.

His lips twitch to a near smile beneath the visor as it traces the digital records of the license plate. It leads to a second-hand purchase by a dead human.

He’s starting to like you, too.

#ask#transformers#transformers prime#tfp#soundwave#reader insert#magic#cybertronian biology#laserbeak#maccadam#my writing#arson falls under Decepticon appreciation and love language#Or more like Soundwave's#You wear a GIR hoodie all the time#that thing has powerful protection#injury

111 notes

·

View notes

Note

Cuz that’s the thing with Viktor, there’s not much that’s beyond his control these days, and that’s by design (...) you can’t do that forever. It’ll eat you alive.

Jayce learns the hard way when Viktor is about to implode. His movements become more stiff, with random bursts of gear grinding and jolts. The shimmer injectors working iust little more than usua. He goes almost mute, but when he talks the modulator sound even raspier. He doesn't take off the mask.

I was just gunna answer this with some more meta or analysis but you know what… this one deserves a little ficlet. Let’s call it Overheated.

Overheated

Jayce knew something was wrong the moment he stepped foot inside Viktor’s lab. Sure, the air was stifling from the myriad of running machines and clouds of puffy steam… but it was the subtle little in-between things that tipped Jayce off; like a single snagged thread pulling at a compromised seam. It was the why that mattered.

It was stifling and hot because something was throwing off Viktor’s usual protocols. Something was clouding his typically routine-oriented mind, keeping him from noticing the abnormally warm and hazy state of his lab. He was fixated on something, fixated hard enough that the best interest of his gadgets was slipping his mind.

Jayce could hear him before he could see him—loudly tinkering away around the corner in what stood for a measly bedroom. And there was a shortness, a tension to said tinkering that didn’t usually plague Viktor’s work. Usually, he was precise and careful to a fault; his work so clean, well… a machine might as well have done it.

And while Viktor’s moods were wholly different nowadays, given the emotional suppressor, Jayce was beginning to re-learn them. He’d once likened it to putting a diamond under a hydraulic press—it would be tough, it would be fortified. It could withstand more pressure than almost any other substance on the planet. But eventually something would give. And it wouldn’t go quietly, either; no, it would be explosive.

So rather than injecting himself into that maelstrom, Jayce steered clear of his former partner for now and instead went about doing what he knew he could to help—wandering quietly into the workshop proper and flipping the switch to power on Viktor’s air filtration system. If they’d been in Piltover, he could have just popped a few windows open, but down here in Zaun, that would just pollute the air further.

So next he went for the cooling fans over in the corner where Blitzcrank’s charging bay sat empty, and angled them toward Viktor’s bedroom before flipping those on as well. And finally, after listening for a moment and hearing only a loud crash and litany of mumbled bilingual curses, Jayce went for the small kitchen counter, rinsed the sole mug that didn’t have cracks in it, and poured a healthy amount of sweetmilk.

Then it was just a matter of wrangling this particular runaway train. So Jayce steeled himself, clutching the mug close to his chest as he meandered into Viktor’s bedroom.

It was immediately clear where the steam had come from—not the many running machines, though those were noticeably hot even from several feet away—no, it was Viktor himself.

The vents in his neck were set at an extreme angle, letting out puff after puff of heavy, thick steam that occasionally turned black when Viktor released a particularly strained breath. There was loud, chaotic rattling resonating from points of tension all over his mechanical body—his neck, his chest, his left arm and leg. And beneath it all, the subtle little hiss of the Shimmer injectors as they delivered micro doses like clockwork to combat his visibly agitated state.

That was the thing about suppressing his emotions… suppress them long enough, and they’re bound to recoil. It was simple physics—and while Jayce could have mentioned this, could have piped up about I warned you this would happen, that this isn’t healthy, and now look what it’s done to you, that would just be throwing gasoline onto the fire, and that was the last thing Viktor needed. So Jayce went a different route.

He cautiously stepped forward, patting Viktor on the back once to announce his presence before leaning past him and setting the mug down in the only mess-less corner he could find.

“You, uh… you wanna talk about it?” he asked, cringing at the mother-hen inflection.

Viktor did not answer—instead taking a single step to the side and deliberately turning his back on Jayce. The vents in his neck sent out another huff of black, and Jayce took this for what it was; don’t mother me, it’s insulting.

But Jayce wasn’t deterred—after all, why was a little mothering such a bad thing? Some care, some consideration, some warmth and doting? Everyone could use that every once in a while. Yes, even the infallible Machine Herald. Especially the infallible Machine Herald.

“V?” he prodded, his hand hovering at Viktor’s back as he tried to decide if touching was the best idea right now.

“No,” Viktor snapped, and even just from that one word alone, Jayce could hear the stress on the voice modulator—low and raspy, as if he’d recently spent a significant amount of time raising his voice.

“Okay,” Jayce agreed, retracting his hand and taking a step away—just freeing up Viktor’s space so he wouldn’t feel so constricted.

Instead, Jayce peered down at the project Viktor had been angrily funneling his not-very-suppressed emotions into. It appeared to be a modification for Blitzcrank’s revolving gadget arm; replacing several busted or outmoded gadgets and rewiring the entire thing to make switching between options a quicker and more seamless operation.

So without another word, Jayce pulled up a stool, grabbed Viktor’s spare pliers, and went to work—removing and rewiring the attachment ports, thus freeing Viktor up to focus on the gadgets themselves.

And for the longest time, they simply worked—shoulders bumping every so often as they just shared in the silence, in the heady weight of each other’s company. They worked, as they always had, like a well-oiled machine; wordlessly passing tools to each other and reading the other’s needs as if it were their own. And slowly but surely, the rattling within Viktor’s chest began to go quiet, the hissing tempo of his overworking injectors steadily slowed and eventually stopped. And Jayce could hear it more than see it when the tension in those rigid metal shoulders relaxed—a creak and a groan like hot metal plunged into an ice bath.

Finally, after Gods knew how long, Viktor’s movements ceased entirely—his hands stalling where they were turning a bolt on the wrist rotator and a single, long sigh leaving the voice modulator like struck glass.

Jayce mimicked it, stilling his hands and turning his head to peer at the flat, unreadable surface of Viktor’s mask with eyes that hopefully said are you okay now? That’s all I wanted, all that mattered—that you’re okay.

And he wasn’t sure how, but he could just tell Viktor was giving him a withering, grateful grin under that mask.

“Thank you, sluníčko,” he said, voice even and harmonic like morning church bells.

Jayce offered up a proud, toothy smile before leaning in and placing a quick, chaste kiss to the mask, right where Viktor’s lips would be—silently communicating that I know you feel like you have to keep it on sometimes, that you don’t like what you’re feeling, and you don’t want anyone to see that, even me. And that’s ok. Keep it on, if that’s what makes you comfortable. I can love you with it on just the same.

A new series of whirs and clicks went off in Viktor’s neck, followed by a short burst of steam, but this time Jayce knew them to be a good sign—the Machine Herald’s version of a blush.

25 notes

·

View notes

Text

Let’s make a horrible TTRPG setting

Been absorbing way too much post apocalyptic and TTRPG stuff lately, so of course I'm working on a setting:

Glasslands

Named after the huge swaths of land which have been blasted by nuclear fire, Glasslands is a setting in which people have spent generations building and customizing family- and community-owned mechanical hardsuits.

Hardsuits

Hardsuits are not susceptible to radiation or cosmic rays because they're heavily shielded and rely mainly on purely mechanical systems rather than electronics to move the limbs and equipment. Most hardsuits use high pressure hydraulics pumped by their engines, and use complex gearboxes and pumping mechanisms similar to a car's power steering to drive them.

Over many generations of customization, repair, and new users, the hardsuits gain a sort of familial identity which sets each one apart from any other. Every hardsuit looks different, has different features, and is designed to fit different people.

Hardsuits are often powered by petroleum-based fuels, though some have been converted to work on alcohol, coal, or even burning wood. Many hardsuits use crude petroleum, and are often visible from long distances because of their exhaust columns. Larger mechanical mecha-type machines can use nuclear or steam power depending on who is running them, and each one is completely unique from all the rest.

The Glasslands

The glasslands themselves are huge swaths of land which have been glassed by atmospheric nuclear detonations, turning large areas into radioactive deadzones that look similar to wide expanses of obsidian or fields of cooled lava. Nothing grows in the glasslands, and they're extremely dangerous to traverse because they're highly irradiated and leave you visible for miles.

When traversing the glasslands, most groups will have spotters on designated watch rotations who ride a hardsuit and keep their eyes peeled in all directions. Because even the best hardsuit has extremely limited, tank-like visibility, it's important for their drivers to have spotters who can call out potential threats or obstacles that may not be visible through the tiny slot, aperture, or periscope available to them.

Travel

When traveling in groups, there are never enough hardsuits for more than one or two people, so anyone not in a hardsuit is carried in lead-lined tents on trailers, or sometimes in human-sized bags which hang off the outside of hardsuits. Whole families are sometimes carried slung in leaden bags which hang off a hardsuit like saddlebags on a horse.

The lead lined bodybags that hold a driver's companions are usually equipped with small interior lights, attached water reserves, waste catchers, and various air filtration systems. With enough rations, a person can live for a week or two in a bodybag, though that type of span is usually only for long-distance travel. Before exiting a bodybag, you should always check your external Geiger counter to make sure you're not going to turn into soup.

Carbon Forests

Stands of trees or tall buildings directly under the air bursts of atmospheric nuclear detonations result in hazardous areas called carbon forests. Because the energy from the blast is going straight down, perfectly vertical structures remain standing even in completely carbonized form, and are a great place to ambush or be ambushed.

Carbon forests are especially common along the west coast of the continental US and Canada where chains of nuclear detonations turned the redwoods and sierras into raging firestorms that lasted months. Areas like Los Angeles and the farmlands of the California Central Valley alternate between glasslands and carbon forests where population centers and huge farm communities were obliterated.

9 notes

·

View notes

Text

Fluid Recycling: Enhancing Efficiency and Sustainability

Fluid recycling is an essential process in modern industrial operations. It involves the collection, filtration, and reuse of fluids, such as cutting oils, coolants, and hydraulic fluids, reducing waste, lowering operational costs, and enhancing sustainability. Fluid recycling systems are often integrated with filtration technologies to maximize the reuse potential of fluids, promoting a circular economy.

The concept of fluid filtration & recycling addresses two key challenges faced by industries: resource conservation and waste management. By reusing fluids that would otherwise be disposed of, businesses reduce the demand for new raw materials, such as oil or water, thereby conserving resources. Additionally, recycling reduces the volume of hazardous waste generated during industrial processes, lowering disposal costs and environmental risks.

Fluid recycling systems vary depending on the type of fluid and contaminants present. In most cases, recycling involves multi-stage filtration processes that remove both solid particulates and emulsified oils. Coolants, for instance, are often contaminated with metal chips, dirt, and bacteria after use. A coolant recycling system typically includes a filtration stage to remove solid debris, followed by chemical treatments to restore the fluid's pH balance and effectiveness.

Industries such as automotive manufacturing and metalworking, where large volumes of fluids are used daily, are the biggest beneficiaries of fluid recycling. These operations save significant costs by extending the life of their working fluids and reducing the need for frequent fluid replacement. Additionally, recycling systems help companies comply with increasingly stringent environmental regulations by limiting fluid waste.

In conclusion, fluid recycling offers numerous benefits: operational efficiency, cost savings, environmental sustainability, and regulatory compliance. By integrating advanced filtration and recycling systems, industries can minimize their environmental footprint while optimizing resource use. This dual approach of filtration and recycling ensures that fluids remain clean, effective, and less harmful to the environment throughout their lifecycle.

1 note

·

View note

Text

Troubleshooting Common Issues with Hydraulic Filtration Systems: Tips and Solutions

Hydraulic filtration systems are an integral part of hydraulic equipment, ensuring the efficiency and longevity of the machinery they support. Understanding the common issues that can arise with these systems and how to troubleshoot them effectively is crucial.

In this blog, we'll delve into the definition of hydraulic filtration systems, emphasise the importance of proper maintenance, and provide tips and solutions for addressing common issues.

Definition of Hydraulic Filtration Systems

Hydraulic filtration systems are designed to remove contaminants from hydraulic fluid, ensuring the fluid remains clean and free from particles that can damage system components. These systems typically consist of filters, pumps, and reservoirs, working together to maintain the cleanliness and proper functioning of the hydraulic fluid.

Importance of Proper Maintenance

Proper maintenance of hydraulic filtration systems is essential for hydraulic equipment's overall performance and longevity. Regular maintenance helps prevent contamination build-up, pressure drop, fluid overheating, and component wear and tear, which can lead to costly repairs and downtime. By understanding and addressing common issues, you can ensure the smooth operation of your hydraulic systems.

This blog aims to provide valuable insights into troubleshooting common issues with hydraulic filtration systems. We offer tips and solutions to empower individuals and businesses to effectively maintain their hydraulic equipment, minimise downtime, and maximise operational efficiency.

Understanding Common Issues

Contamination Build-Up

Contamination build-up occurs when particles and debris accumulate within the hydraulic fluid, potentially leading to blockages and component damage.

Pressure Drop

Pressure drop is a decrease in hydraulic pressure within the system, often caused by restricted flow due to clogged filters or other blockages.

Fluid Overheating

Fluid overheating can occur when the hydraulic fluid exceeds recommended temperature levels, reducing lubrication and potentially damaging system components.

Component Wear and Tear

Component wear and tear can result from prolonged exposure to contaminated fluid, inadequate lubrication, or excessive stress on system components.

Troubleshooting Tips and Solutions

Contamination Build-Up

Regular Filter Replacement: Replacing hydraulic filters is crucial to prevent contamination build-up. Over time, filters become saturated with contaminants and lose their effectiveness, so adhering to a scheduled replacement routine is essential.

Use of High-Quality Filters: Investing in high-quality filters can significantly reduce the risk of contamination build-up. Quality filters are designed to capture and retain particles more effectively, promoting cleaner hydraulic fluid.

Pressure Drop

Checking for Blockages or Restrictions: Regularly inspecting the system for blockages or restrictions, such as clogged filters or debris in the lines, can help identify and address issues causing pressure drop.

Adjusting Pump Settings: Fine-tuning pump settings can help optimise hydraulic pressure and flow, addressing pressure drop issues and ensuring efficient system operation.

Fluid Overheating

Monitoring Temperature Levels: Installing temperature sensors and regularly monitoring fluid temperature levels can help identify potential overheating issues before they escalate, allowing for proactive intervention.

Upgrading Cooling Systems: Upgrading cooling systems, such as adding additional heat exchangers or improving ventilation, can help dissipate heat more effectively, preventing fluid overheating.

Component Wear and Tear

Inspecting Components for Damage: Regularly inspecting system components for signs of wear, corrosion, or damage can help identify issues early and prevent further damage.

Upgrading to High-Quality Hydraulic Filter Products: Upgrading to high-quality hydraulic filter products, including filters, fluid, and additives, can improve lubrication and overall system performance, reducing the risk of component wear and tear.

Importance of Professional Assistance

When to Seek Professional Help

While many common issues can be addressed through regular maintenance and troubleshooting, there are instances where professional assistance is necessary. Complex problems, system malfunctions, or specialised maintenance requirements may warrant the expertise of hydraulic professionals.

Benefits of Partnering with Experts

Partnering with hydraulic experts offers several benefits, including access to specialised knowledge, advanced diagnostic tools, and tailored maintenance solutions. Professional assistance can help optimise system performance, minimise downtime, and extend the lifespan of hydraulic equipment.

Conclusion

In conclusion, proactive maintenance and promptly addressing common issues are essential for the optimal performance of hydraulic filtration systems you have. By understanding the common problems associated with these systems and implementing practical troubleshooting tips and solutions, individuals and businesses can ensure the smooth operation of their hydraulic equipment. Regular maintenance, including filter replacement, system inspections, and temperature monitoring, is critical to preventing contamination build-up, pressure drop, fluid overheating, and component wear and tear. For complex issues or specialised maintenance needs, seeking professional assistance can further enhance the reliability and efficiency of hydraulic systems.

0 notes

Text

#Turbine Oil Cleaning System#Oil Cleaning Machines#Turbine Oil Cleaning Systems#Oil Filtration Plant#Gear Oil Filtration Systems#Industrial Oil Filter Machine#Oil Filtration Systems#Double Stage Oil Transformer Machine#Oil Filtration Elements#Oil Filtration Machine#Oil Filtration & Cleaning Systems#Thermic Oil Filtration Systems#On Site Oil Testing#Online Oil Cleaning Systems#Hydraulic Oil Online Filters#Mobile Oil Filtration Plant#Portable Oil Filtration Plant#Portable Oil Filtration System#Turbine Oil Filtration Plant#Turbine Oil Filtration Machine#Transformer Oil Filtration System#Transformer Oil Cleaning Systems#Evacuation System for Transformers#Transformer Oil Filtration Plant#Two Stage Transformer Oil Filtration Plant#Transformer Evacuation System#Transformer Oil Filtration Machine#Transformer Oil Filter Machine#Turbine Oil Flushing System#Centrifugal Oil Cleaner

0 notes

Text

Find the Perfect Fit: Online Oil Filtration System Manufacturers

Keeping your oil clean is crucial for efficient operation and extended equipment life. Online oil filtration systems manufacturers continuously remove contaminants, improving oil quality and reducing maintenance costs. But with numerous manufacturers, selecting the right one can be overwhelming.

This guide explores reputable online oil filtration system manufacturers to help you find the perfect solution for your needs. We'll delve into factors like system types, filtration capacities, and compatibility to ensure a smooth and successful purchase.

0 notes

Photo

Transformers are used to transfer electrical energy between circuits and are essential components in power systems. To ensure proper operation, transformer oils need to be regularly filtered to remove any impurities that can reduce the transformer’s effectiveness. ZYOilPurifier offers a range of transformer oil filtration products designed to help keep your transformers working reliably. Let's take a look at why transformer oil filtration is so important and how it can benefit your business.

Media Contact

Company Name: Chongqing Zanyo Electromechanical And Machinery CO., Ltd.

Contact Name: Robine

Contact Phone: Mobile/wahtsapp: 8615683638961

Address Jiulong Industrial Park,Jiulongpo District, Chongqing,China,400039

Email: [email protected]

Visit Our Website: https://www.zyoilpurifier.com/how-is-the-transformer-oil-purifier-machine-process/

#transformer oil filtration#oil purification#oil purifier#transformer oil purification#transformer oil purifier#zyl lubricating oil filtration machine#oil filtration#Turbo Oil Purifier#Zanyo Turbo-Flash Turbo Oil Purifier#Turbine Oil Purifier#ZYE Insulation Oil Vacuum Injector#ZYV Vacuum Extraction System#ZYK Fire Resistant Oil Filtration Machine#ZYL Hydraulic Oil Purification System

1 note

·

View note

Text

Hydraulic machine manufacturers in India

We are one of the leading brand in hydraulic machine manufacturers in india, innovative Hydraulic manufacturing enabling customers to compete in the market. Our company was consecrated in 2009 offers engineering services and is a pioneering manufacturer, supplier, and distributor with an exemplary range of Hydraulic cylinder, Hydraulic Power unit, Critical for manifold block, Pump motor station, filtration system.

Our experts and technology efficiency made us one of the most prolific companies in the manufacturing field. With the consistent innovation for every custom requirement help us attaining the product perfection with loyal customers.

0 notes