#Hoist crane

Explore tagged Tumblr posts

Text

Overhead Cranes, Hoists, and Expert Services: A Guide to Material Handling

Shin Guan's indelible imprint on material handling crystallizes through its holistic modus operandi. From the conception of overhead cranes' blueprints to the craftsmanship imbued within hoists and the symphony of maintenance services, Shin Guan's prowess encapsulates the essence of industrial harmony. The ebb and flow of heavy loads cease to be mere operational tasks; they metamorphose into a tapestry of efficiency and security. As industries navigate complex currents and strive for zeniths of performance, Shin Guan emerges as a luminary, illuminating the path with innovative solutions that empower businesses to ascend the pinnacles of material handling prowess.

#Wire rope hoist#Overhead crane#Overhead travelling crane#Hoist Crane#Single girder overhead crane#Crane Servicing#Crane Maintenance#Repair Crane#Crane Load Testing#Chain Hoist#Monorail Crane#Crane Relocation#Dismantle Crane

0 notes

Text

27 notes

·

View notes

Text

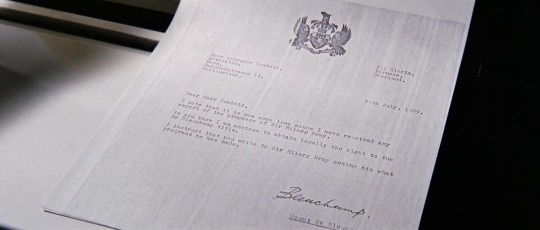

Ohhhh, it's a safe cracker and a copier/printer! Take that Canon All-in-One!!

#The nozzle fits over the combination lock#now he did have to have someone hoist it in on a construction crane to him while no one was looking but it fits inside a steamer trunk....#so canon wins on portability I guess#wonder what kind of ink cartridge it takes#On Her Majesty's Secret Service#On Her Majesty's Secret Service Rewatch#Bond-a-Thon#Bond a Thon

7 notes

·

View notes

Text

Sandy is fated to be Picked Up it seems. Like I'm realizing how many cranes are in her family/friendship circle. Cranky is her dad, Carly is her sister, she's Victor's apprentice so she hangs around Kevin at times, she's probably chatted up with Beresford now and again, and she's maybe KINDA acquaintances with Tess. And when she was a baby she was the perfect size and weight for a strong enough adult human to lift her up.

#ttte#all engines go#ttte au#ttte aeg#all engines go au#my au#Children of Sodor Au#she's very holdable! no longer perfect for humans to hold but just perfect for small cranes to lift up and bigger cranes to lift Carly up-#-when she's lifting Sandy up.#if big cranes want to get eye-level with Sandy they have to get Carly involved because the hooks are too big to safely hoist a rail speeder

6 notes

·

View notes

Text

15 Ton Overhead Cranes For Steel Slabs Handling

IntroductionManufacturing Process of Double Girder Overhead CranesUtilization of Double Girder Overhead Cranes in the Steel IndustryHow to Determine the Price of Your Crane ProjectConclusion Introduction In the world of industrial logistics, efficiency, strength, and reliability are the key characteristics that dictate the quality of equipment. We’re excited to bring forth a prime illustration…

View On WordPress

#coil handling#coil industry cranes#coil lifting#coil loading cranes#coil transport#crane design#crane manufacturing#crane operations#crane safety#girder cranes#heavy-duty cranes#high-capacity crane#hoisting equipment#industrial cranes#load management#material handling#overhead cranes#steel coil production#steel coil storage#steel coils

2 notes

·

View notes

Text

Lifting Equipments In UAE

We're excited to announce that TradersFind has added a new category: Lifting Equipments! 🌟

Looking for reliable and efficient lifting equipment in UAE? Discover a wide range of top-quality solution providers on our website. From cranes to hoists, find the perfect equipment to boost your productivity. Explore now and elevate your operations!

🔗 Visit our website: https://www.tradersfind.com/category/lifting-equipments or enquire now on WhatsApp: +971 569773623

#liftingequipment#uae#heavyequipment#industrialequipment#constructionequipment#materialhandling#logistics#supplychain#manufacturing#warehouse#forklift#crane#hoist#safetyfirst#qualityassurance

0 notes

Text

The Versatility and Benefits of Electric Hoists for Material Handling - Hes Cranes

Electric hoists are essential tools in industries that require heavy lifting and precise material handling. These devices are engineered to reduce manual labor and increase safety while enhancing productivity. Whether used in warehouses, construction sites, or manufacturing facilities, electric hoists are invaluable for efficient and reliable operations. Here's a closer look at their features, advantages, and applications.

What is an Electric Hoist?

An electric hoist is a motorized lifting device that uses electrical power to lift, lower, and position heavy loads. It typically consists of a motor, drum or lift wheel, and a rope or chain for load handling. Available in a variety of models, electric hoists can cater to different weight capacities and lifting heights.

Key Benefits of Using Electric Hoists

Enhanced Safety

Electric hoists are designed with safety features such as emergency stop buttons, overload protection, and braking systems that reduce the risk of workplace injuries.

Automated lifting minimizes the physical strain on workers, reducing the chances of musculoskeletal injuries.

Increased Efficiency

These devices significantly boost productivity by enabling faster and more precise lifting of heavy materials compared to manual methods or manual hoists.

The automation allows workers to focus on other tasks, optimizing the overall workflow.

Precision in Handling

Modern electric hoists come equipped with variable speed controls, which provide accurate movement and positioning of loads.

This precision helps prevent damage to delicate or high-value items during lifting and transport.

Versatility

Electric hoists are adaptable and can be used for a wide range of applications, from construction and industrial tasks to smaller-scale projects in workshops.

They can be mounted on cranes, overhead beams, or fixed positions, making them suitable for various types of facilities.

Common Features of Electric Hoists

Durable Construction

Built with high-quality materials such as alloy steel and heavy-duty cast iron, electric hoists are made to withstand rigorous use and harsh conditions.

Their robust design ensures longevity and consistent performance.

Load Capacity Range

Electric hoists come in different capacities, typically ranging from small models suitable for a few hundred kilograms to heavy-duty hoists capable of handling several tons.

Choosing the right capacity for your needs is essential to maximize safety and functionality.

User-Friendly Controls

Intuitive control systems, often with remote or push-button operation, make electric hoists easy to use.

Remote controls enhance operational flexibility, allowing operators to stand at a safe distance while maneuvering loads.

Applications of Electric Hoists

Warehouses and Storage Facilities

Electric hoists streamline the process of lifting and stacking heavy materials, making them perfect for warehouse environments.

Manufacturing Plants

They facilitate the movement of machinery and raw materials, ensuring seamless production processes.

Construction Sites

Electric hoists play a pivotal role in moving construction materials to different levels safely and efficiently.

Workshops and Garages

Smaller electric hoists are ideal for handling car engines or heavy equipment in repair shops.

Choosing the Right Electric Hoist

When selecting an electric hoist, consider the following:

Load Capacity

Ensure the hoist can handle the maximum weight of the loads you intend to lift.

Lift Height

Measure the distance the hoist needs to travel and match it with the specifications of the equipment.

Operational Environment

Choose a hoist that suits the conditions of your workspace, whether indoor, outdoor, or in a high-dust environment.

Power Requirements

Electric hoists come in various power types, including single-phase and three-phase options. Ensure compatibility with your facility's electrical setup.

Maintenance Tips for Longevity

Regular Inspections

Frequent checks help identify and address any signs of wear or damage before they turn into major issues.

Lubrication

Proper lubrication of moving parts ensures smooth operation and prolongs the lifespan of the hoist.

Clean and Dry Storage

When not in use, store the hoist in a clean, dry area to prevent rust and corrosion.

Final Thoughts

Electric hoists are integral to modern material handling, providing a blend of safety, efficiency, and precision. With proper selection and maintenance, they can be a long-term asset in various industrial and commercial applications. By investing in a reliable electric hoist, companies can enhance their operational capabilities while ensuring a safer work environment.

For More:

Ph: 1800 437 272

Mail id: [email protected]

Working Time: Monday to Friday 9.00am - 5.30 pm Saturday and Sunday Open 24 hours.

Visit us: https://hescranes.com.au/

0 notes

Text

Improving Vessel Performance and Profitability with Variable Frequency Drives (VFDs)

Cut your energy consumption on fans, pumps and compressors by as much as 60% when integrating VFDs. The IP55/NEMA12 and IP66/NEMA4X rated enclosures for the Optidrive P2 High Performance series are ready to operate in marine environments straight out of the box with no additional enclosures required.

For your onboard winches, the Optidrive P2 features Auto Tension Control which maintains the correct level of winch tension in all operating conditions. The VFDs provide precise and responsive control of thruster systems, enhancing the vessel maneuverability. VFDs will also significantly reduce the maintenance costs associated with hydraulic oil leakages and oil change.

The VFD Exchange

#vfd#variablefrequencydrives#inverter#acdrives#thrustercontrol#wheelhousecontrol#electrical#controls#automation#marine#maritime#ships#fpso#fso#thrusters#winches#crane#hoist#pump#compressor#fans#hvac#engineering#vfds#variablefrequencydrive#acmotors#invertek#optidrive#ams#pms

0 notes

Text

The Indispensable Role of Goliath Cranes in Heavy-Duty Industrial Operations

Introduction: The Need for Goliath Cranes in Today's Industries

In today’s fast-paced industrial landscape, the ability to move heavy loads efficiently and safely can make or break your operations. Enter Goliath cranes—the heavy-duty champions designed to tackle the toughest lifting tasks in sectors like shipbuilding, steel manufacturing, and large-scale construction. If you're in the market for reliable material handling solutions, look no further than the innovative offerings from Double Girder EOT Crane Manufacturers in India. Their cutting-edge technology ensures that you have the best equipment to streamline your operations and boost productivity.

What Sets Goliath Cranes Apart?

A Goliath crane, often referred to as a portal crane, is engineered for strength and efficiency. With its two vertical supports and a robust horizontal beam, it can navigate large spaces with ease, lifting loads that weigh tons. If you’re handling oversized components or conducting outdoor operations, you need a crane that can rise to the occasion. Goliath cranes can handle everything from massive ship parts to industrial machinery, making them a vital asset in any heavy-duty operation.

Why You Must Invest in Goliath Cranes Now

Unmatched Heavy Load Handling: Goliath cranes are built to carry incredibly heavy loads, ensuring your industrial operations run smoothly and efficiently. If you're dealing with materials that weigh hundreds of tons, you cannot afford to compromise on quality.

Versatility for Any Environment: Unlike traditional cranes that may be confined to indoor settings, Goliath cranes thrive both indoors and outdoors. Whether you're in a bustling shipyard or a sprawling construction site, these cranes can adapt to your needs.

Cost-Effective Solutions: By eliminating the need for dedicated runway structures, Goliath cranes save you both time and money. Don’t let unnecessary infrastructure costs weigh you down; invest in a crane that can stand alone and deliver results.

Custom Solutions Tailored for You: Every industrial operation is unique, and Goliath cranes can be customized to meet your specific requirements. Whether you need a crane with a particular lifting capacity or specialized movement capabilities, manufacturers in India have you covered.

Applications Where Goliath Cranes Shine

When it comes to lifting heavy materials, Goliath cranes are simply unbeatable. Here are the industries where they truly excel:

Shipyards: If you’re involved in shipbuilding, you know how crucial it is to handle large components with precision. Goliath cranes ensure that your operations run seamlessly, allowing you to meet deadlines and client expectations.

Steel Plants: In steel manufacturing, efficiency is key. Goliath cranes help in transporting massive volumes of raw materials and finished products, significantly boosting productivity.

Construction Sites: Are you managing a large construction project? Goliath cranes are ideal for moving prefabricated sections, ensuring that your project stays on schedule and within budget.

With a rising demand for Goliath cranes, it’s essential to choose a reputable Goliath Crane Manufacturer in India that can provide you with the quality and reliability you need to thrive.

Goliath Cranes vs. EOT Cranes: The Clear Choice

While both Goliath and EOT (Electric Overhead Travel) cranes have their place in industrial settings, the choice is clear when heavy-duty lifting is involved:

EOT Cranes: Best suited for indoor operations, these cranes excel at precise movements but may lack the versatility required for heavy outdoor tasks.

Goliath Cranes: These are your go-to cranes for any challenging lifting scenario. Their ability to operate in open environments makes them invaluable in heavy-duty industries.

The Future is Bright for Goliath Cranes

As industries worldwide gear up for a new era of growth, the need for reliable and efficient material handling solutions will only increase. Goliath cranes are at the forefront of this evolution, incorporating innovative technologies that enhance safety and efficiency. Now is the time to ensure your operations are equipped for the future.

Conclusion: Don’t Miss Out on the Advantages of Goliath Cranes

The message is clear: investing in Goliath cranes can transform your industrial operations, providing you with the efficiency and reliability needed to succeed in today’s competitive landscape. Don’t let your competitors get ahead—partner with the best Goliath Crane Manufacturers in India and Overhead EOT Crane Manufacturers in Delhi to secure your place at the forefront of your industry.

Make the smart choice today, and experience the unparalleled advantages that Goliath cranes bring to your heavy-duty operations. The future of your business depends on it!

#Over Head EOT Crane Manufacturers in India#Hot Metal Crane Manufacturers in India#Goliath Crane Manufacturers in India#Electric Wire Rope Hoists in India#Double Girder EOT Crane Manufacturers in India

0 notes

Text

How to Ensure Safe Gantry Crane Operations at Night

Operating gantry cranes at night or in low-light environments can be challenging. Without proper precautions, the risks of accidents and equipment malfunction increase significantly. To ensure safety during nighttime crane operations, it’s crucial to focus on both equipment and environment.

The first step is setting up sufficient lighting. Poor visibility can lead to errors and accidents, so using appropriate lighting like tungsten iodide lamps for outdoor work is essential. Operators should also have emergency tools, such as flashlights, on hand to handle unexpected lighting failures.

Additionally, gantry crane control circuits must be checked thoroughly before nighttime use. Ensuring the proper functioning of control circuits and the solenoid system can prevent unexpected shutdowns, which can be dangerous during critical lifts.

To learn more about safe gantry crane operation during nighttime shifts and the importance of lighting, control systems, and emergency preparedness, check out our comprehensive guide.

0 notes

Text

Electric Wire Rope Crane At Best Price In India

Electric Wire Rope Crane At Best Price In India Tecon Crane System LLP offers wide a range of services, including Electric Wire Rope Crane products.

0 notes

Text

Chain hoists are indispensable tools in various industries, from construction and manufacturing to warehousing and logistics.

0 notes

Text

How Are Konecranes Shaping the Crane and Hoist Market? Strategies, Innovations, and Developments

Introduction:

Konecranes, a leading global provider of lifting equipment and services, is at the forefront of shaping the Crane and Hoist Market through its strategic initiatives, emerging innovations, and recent developments. As the industry evolves, Konecranes is leveraging its expertise and technological advancements to address the changing needs of various sectors. This article explores how Konecranes is influencing the crane and hoist market with its strategies, innovations, and key developments.

Download FREE Sample: https://www.nextmsc.com/crane-and-hoist-market/request-sample

Strategic Focus on Digitalization and Smart Technologies

Konecranes has made digitalization a cornerstone of its strategy, focusing on integrating smart technologies into its crane and hoist solutions. The company’s commitment to innovation is evident in its development of the Konecranes TRUCONNECT® Remote Monitoring system. This technology enables real-time monitoring and diagnostics of lifting equipment, providing customers with valuable insights into equipment performance and maintenance needs. By utilizing IoT (Internet of Things) and data analytics, Konecranes helps businesses optimize their operations, reduce downtime, and extend the lifespan of their equipment.

The company's emphasis on digitalization also includes advancements in control systems and automation. For instance, Konecranes has introduced Konecranes CXT® Smart technology, which offers enhanced precision and ease of use through automated features and advanced control interfaces. This focus on smart technology aligns with industry trends toward increased automation and efficiency in lifting operations.

Pioneering Innovations in Safety and Efficiency

Safety and efficiency are paramount in the crane and hoist market, and Konecranes is leading the way with its innovative solutions. The company has developed a range of safety features designed to enhance the protection of personnel and equipment. For example, Konecranes’ Active Load Control system ensures stable and controlled lifting, reducing the risk of accidents and equipment damage. Additionally, the Sway Control feature minimizes load sway, improving accuracy and safety during operation.

Konecranes is also investing in energy-efficient solutions to address the growing demand for sustainability. The company’s Konecranes ECO Service focuses on optimizing energy consumption and reducing environmental impact. By offering energy-efficient cranes and hoists, Konecranes supports customers in achieving their sustainability goals while also benefiting from lower operational costs.

Expanding Service Offerings and Global Reach

Konecranes is strategically expanding its service offerings to cater to a broader range of customer needs. The company’s Lifting Equipment Service (LES) provides comprehensive maintenance, repair, and modernization services, ensuring that equipment remains in peak condition throughout its lifecycle. Konecranes’ service network spans globally, enabling the company to support customers across various regions with localized expertise and rapid response times.

Recent developments in Konecranes’ service offerings include the expansion of Konecranes Smart Features, which integrate predictive maintenance and remote diagnostics into their service packages. This proactive approach helps customers prevent potential issues before they escalate, enhancing overall operational efficiency and minimizing downtime.

Strategic Partnerships and Acquisitions

To strengthen its market position and enhance its technological capabilities, Konecranes has engaged in strategic partnerships and acquisitions. One notable example is the acquisition of Mammoet, a leading provider of engineered heavy lifting and transportation services. This acquisition has expanded Konecranes’ service portfolio and geographical reach, positioning the company as a more comprehensive solutions provider in the lifting and transportation sector.

Additionally, Konecranes has formed partnerships with technology companies to accelerate innovation in lifting solutions. Collaborations with tech firms have enabled Konecranes to integrate cutting-edge technologies such as AI (Artificial Intelligence) and machine learning into its products and services. These partnerships contribute to the development of smarter, more efficient lifting equipment that meets the evolving needs of the market.

Commitment to Sustainability and Green Technologies

Sustainability is a key focus for Konecranes, reflecting the broader industry trend toward environmentally friendly practices. The company is dedicated to reducing its environmental footprint through the development of green technologies and sustainable practices. Konecranes’ EcoCrane series, for instance, features energy-efficient designs and eco-friendly components that align with global sustainability standards.

Recent advancements include the introduction of electric and hybrid cranes, which offer significant reductions in energy consumption and emissions compared to traditional diesel-powered models. By prioritizing sustainability, Konecranes not only meets regulatory requirements but also supports customers in achieving their own environmental goals.

Inquire before buying: https://www.nextmsc.com/crane-and-hoist-market/inquire-before-buying

Innovations in Customization and Flexibility

Recognizing that different industries have unique requirements, Konecranes has focused on providing customizable and flexible solutions. The company offers a wide range of crane and hoist configurations tailored to specific industry needs, including bespoke designs for challenging applications. Recent innovations in customization include modular crane systems and adjustable hoists, which provide customers with the ability to adapt their equipment to changing operational demands.

Konecranes’ commitment to flexibility is also evident in its approach to product development and customer service. The company’s Tailor-Made Solutions program allows customers to work closely with Konecranes engineers to design and implement equipment that meets their precise specifications. This level of customization enhances the efficiency and effectiveness of lifting operations across various industries.

Conclusion

Konecranes is a significant player in the crane and hoist market, driving change through its strategic focus on digitalization, innovation, and customer service. The company’s advancements in smart technologies, safety features, and sustainability are setting new standards for the industry. Through strategic partnerships, acquisitions, and a commitment to customization, Konecranes is positioning itself as a leader in the evolving crane and hoist market.

As the industry continues to develop, Konecranes’ proactive approach to technology and service will likely influence future trends and shape the market’s direction. Stakeholders and customers alike can expect continued innovation and excellence from Konecranes as it navigates the challenges and opportunities of the crane and hoist sector.

0 notes

Video

youtube

Versatile Applications of NYBON Machinery Cranes and Winches in Key Indu...

#youtube#NYBON Machinery is a professional manufacturer based in China specializing in cranes and hoisting equipment. We produce a diverse range of p#www.nybonlift.com#www.nyboncrane.com#www.nybonchina.com#electric winches#hydraulic winches#gantry cranes#overheadranes

0 notes

Text

Monkey Lift Mini Crane Manufacturer and Supplier in India

Weber Construction Machinery is a top manufacturer of monkey lift mini crane and monkey hoist that is perfect for lifting materials in construction projects. The monkey lift mini crane machine offers easy operation, robust performance, and enhanced safety features, ideal for small to medium-scale construction sites.

#mini crane manufacturer#monkey lift manufacturers#monkey hoist manufacturer#monkey lift mini crane#Mini Monkey Lift Machine#mini crane machine for construction#mini crane lift#monkey hoist crane#monkey hoist machine#mini monkey crane#mini monkey hoist

0 notes

Text

Get the best result in terms of performance and safety by using our overhead crane maintenance services through our maintenance programs. A team of experienced mobile crane operators checks for the safety of the structure, tests the equipment for malfunctions, applies the necessary disengagements, and then carries on with their work. We also should get your equipment checked periodically, so let our specialists handle it because proper care prolongs the equipment period of time to the maximum limit.

0 notes