#High-Quality TMT Bar Cutting Machine

Explore tagged Tumblr posts

Text

Reliable TMT Bar Cutting Machine for Construction |Iri equipment

Your trusted source for Construction Equipment Supplier and Industrial Machinery. We offer Reliable TMT Bar Cutting Machines for construction uses. Our High-Quality TMT Bar Cutting Machines are engineered for enduring performance. Contact Iri equipment today for top-notch metalworking tools!

#construction equipment#suspended rope platform#buy suspended rope platform#suspended rope platform for plastering#Reliable TMT Bar Cutting Machine#High-Quality TMT Bar Cutting Machine#Affordable TMT Bar Cutting Machine#High-Performance TMT Bar Cutting machine

1 note

·

View note

Text

The Evolution and Process of Steel-Making: From Ancient Methods to Modern Techniques

Steel is a cornerstone of modern construction, tool manufacturing, automotive industries, and numerous other applications. As an alloy primarily consisting of iron and elements like chromium, steel has a storied history and an essential role in the global economy. Although steel production dates back centuries, its large-scale commercialization began in the 19th century. Revolutionary advancements in steel-making processes transformed it into a mainstream industry. Today, ongoing technological innovations continue to enhance steel-making efficiency, making it integral to our daily lives. At Agni Steels, we take pride in producing some of the best 550D TMT bars, reflecting our commitment to quality and excellence.

The Historical Context of Steel-Making

The ancient methods of steel-making involved bloomery furnaces and crucibles, which were labor-intensive and yielded limited quantities of steel. The Industrial Revolution marked a significant turning point, with the 1850s and 1860s introducing transformative techniques that enabled large-scale steel production. These advancements, coupled with improved injection technology and process control, laid the foundation for modern steel-making. Today, steel production is vital to the global economy, supporting infrastructure, manufacturing, and more.

The Modern Steel-Making Process

Steel-making today combines traditional raw materials with recycled components and utilizes advanced methods to produce various grades of steel, including the best 550D TMT bars. The process typically involves six key steps:

1. Iron-Making

The initial step involves melting raw materials—iron ore, coal, and limestone—in a blast furnace. This results in molten iron, or "hot metal," which still contains 4-4.5% carbon and other impurities, making it brittle. These impurities must be removed to produce high-quality steel.

2. Primary Steel Making

The impurities in the molten iron are removed through two main methods:

Basic Oxygen Steelmaking (BOS): Recycled or scrap steel is added to the molten iron in a converter. Oxygen is blown through the metal at high temperatures, reducing the carbon content to about 0-1.5%. This process is essential for producing the best 550D TMT bars.

Electric Arc Furnace (EAF): Scrap steel is melted using high-power electric arcs. This method is efficient and ideal for producing high-quality steel.

At the end of this stage, the steel produced is known as raw steel.

3. Secondary Steel Making

Raw steel is further treated to achieve specific grades, including the best 550D TMT bars. Techniques applied may include:

Stirring: To ensure uniform composition.

Temperature Adjustment: To achieve desired properties.

Ladle Injection: For precise alloying.

Gas Removal: To eliminate unwanted gases.

CAS-OB: For advanced processing.

These steps tailor the steel to meet particular performance and quality standards.

4. Continuous Casting

In this step, molten steel is cast into cooled molds, allowing it to harden. Guided rollers draw the steel from the molds while it is still hot, and then it cools completely. The steel is cut to required lengths for various applications, including beams, slabs, billets, and high-strength 550D TMT bars.

5. Primary Forging

Cut steel is shaped through primary forging, typically by hot rolling. This process eliminates casting defects and provides the steel with a desirable shape and surface quality. Products such as seamless tubing, long products, and flat products are created in this stage, including the robust 550D TMT bars.

6. Secondary Forming

The final step involves secondary forming, which imparts the steel’s final shape and properties. Techniques used include:

Heat Treatment (Tempering): To enhance mechanical properties.

Joining (Welding): For creating complex structures.

Shaping (Cold Rolling): To achieve precise dimensions.

Coating (Galvanizing): To prevent corrosion.

Machining (Drilling): For detailed components.

Surface Treatment (Carburizing): To improve surface hardness.

Our Commitment to Quality

At Agni Steels, we are dedicated to maintaining the highest standards of quality, integrity, efficiency, and responsibility in all our operations. Our rigorous processes and advanced technology ensure that we produce some of the best 550D TMT bars available, meeting the highest performance and safety standards.

We are committed to delivering excellence in every piece of steel we produce.

Conclusion

Steel-making has evolved dramatically from its ancient origins. With modern techniques and a focus on producing the best 550D TMT bars, the industry continues to innovate and meet the demands of today’s world. At Agni Steels, we are proud to be at the forefront of this dynamic industry, providing top-quality steel products that support infrastructure and development across the globe.

0 notes

Text

Exploring Tata Tiscon Price List 2024: Your Comprehensive Guide

Introduction

In the realm of construction, Tata Tiscon stands as a prominent manufacturer of high-quality steel rebars in India. The brand's extensive product line caters to the diverse needs of infrastructure, housing, commercial complexes, and industrial construction projects across the country.

Tata Tiscon TMT Bar: A Symbol of Trust

Tata Tiscon TMT Bar, also known as Sariya, adheres to the latest Indian Standards and is available in Fe415, Fe500, Fe550, 550SD, and Fe600 grade versions. These superior-grade rebars boast impressive strength and ductility, meeting the stringent quality standards set by Tata Steel.

Features of Tata Tiscon 550SD

A noteworthy addition to Tata Tiscon's offerings is the Super Ductile Tata Tiscon 550SD. This revolutionary rebar is India’s first GreenPro certified and is produced using cutting-edge automation, ensuring unmatched quality. Made from virgin iron ore and pure steel, each rebar offers enhanced load-carrying capacity, supreme strength, and improved earthquake resistance.

Tata Tiscon Superlinks: Reinforcement Simplified

In the realm of construction, stirrups play a crucial role in providing lateral support to the main structure. Tata Tiscon Superlinks, made from high-strength ribbed TMT rebars, serve this purpose effectively. These readymade stirrups, manufactured with precision and quality control, ensure consistency, accuracy, and reliability in every project.

Tata Tiscon Ultima GFX Coated Superlinks: Corrosion-Resistant Innovation

Introducing Tata Tiscon Ultima GFX Coated Superlinks – the new standard in corrosion-resistant construction. Crafted from high-strength Tata Tiscon 550SD rebars through advanced machines, GFX Coated Superlinks come with a special GFX coating, ideal for homes in coastal and sea-side areas. Elevate the bonding strength of your dream home with Tiscon Ultima Superlinks.

Tata Steel Aashiyana: Your One-Stop Solution

Experience a complete transformation with the Super Ductile Tata Tiscon 550SD, available for online purchase on Tata Steel Aashiyana. This platform offers more than just products; it provides total home building support under one roof. From detailed home building guides to a diverse range of home, gate, and roof designs, as well as an easy online material estimator, Tata Steel Aashiyana is your ultimate home building One-Stop-Shop.

Tata Tiscon Price List Today 2023

To facilitate informed decisions, Tata Tiscon offers a comprehensive price list. This list, varying across Indian states, provides the latest prices for TMT bars. Let's explore the price range for different Tata Tiscon TMT Bar sizes as of 2023:TMT Bar SizeMin Price (Per Piece)Max Price (Per Piece)6 mmRs. 210Rs. 2408 mmRs. 355Rs. 41010 mmRs. 540Rs. 62512 mmRs. 760Rs. 88516 mmRs. 1355Rs. 157520 mmRs. 2125Rs. 246025 mmRs. 3310Rs. 3835

Tata Tiscon Price List Today in Different States

Let's delve into the state-wise Tata Tiscon Price List as of 2023:

1. Andhra Pradesh

TMT Bar SizePrice (Per Piece)6 mmRs. 2258 mmRs. 37510 mmRs. 56212 mmRs. 80516 mmRs. 143020 mmRs. 223525 mmRs. 3480

2. Assam

TMT Bar SizePrice (Per Piece)6 mmRs. 2258 mmRs. 38010 mmRs. 57812 mmRs. 81516 mmRs. 145020 mmRs. 226525 mmRs. 3532

3. Bihar

TMT Bar SizePrice (Per Piece)6 mmRs. 2258 mmRs. 37710 mmRs. 57512 mmRs. 81216 mmRs. 144320 mmRs. 225725 mmRs. 3518

4. Chhattisgarh

TMT Bar SizePrice (Per Piece)6 mmRs. 2158 mmRs. 36510 mmRs. 55812 mmRs. 78916 mmRs. 140020 mmRs. 219025 mmRs. 3415

5. Delhi

TMT Bar SizePrice (Per Piece)6 mmRs. 2168 mmRs. 36610 mmRs. 55712 mmRs. 78716 mmRs. 140020 mmRs. 218825 mmRs. 3411

6. Goa

TMT Bar SizePrice (Per Piece)6 mmRs. 2138 mmRs. 35810 mmRs. 54512 mmRs. 76716 mmRs. 136220 mmRs. 212825 mmRs. 3317

7. Gujarat

TMT Bar SizePrice (Per Piece)6 mmRs. 2128 mmRs. 35910 mmRs. 54512 mmRs. 76216 mmRs. 136020 mmRs. 213225 mmRs. 3320

8. Haryana

TMT Bar SizePrice (Per Piece)6 mmRs. 2188 mmRs. 36810 mmRs. 55912 mmRs. 78916 mmRs. 140220 mmRs. 219025 mmRs. 3412

9. Himachal Pradesh

TMT Bar SizePrice (Per Piece)6 mmRs. 2208 mmRs. 37110 mmRs. 56212 mmRs. 79216 mmRs. 140620 mmRs. 219725 mmRs. 3424

0 notes

Link

TMT means Thermo Mechanical Treatment, which is a thermomechanical process; These TMT steel bars are generally used material in construction for enhanced protection against earthquakes and another type of natural disasters. To ensure safety for your structure TMT steel bars should be resistant to corrosion which helps to obtain a longer life to your structure.

The manufacturing process of TMT Bars

First, carefully selected high-quality raw materials are charged into the furnace and heated up to 1600o C. The heated steel is then treated with an inert gas to release any dissolved gasses present in the metal. The liquid steel is cast into steel billets which are apparently the most modern method of casting steel. These billets are then subjected to preheating and are re-sized according to the required diameter. The further manufacturing process of TMT bars involves 3 distinct steps which are as follows:

Quenching

In this step, the finished diameter bars are treated to give the desired properties. The red-hot steel rod is sent to a chamber where water is continuously sprayed onto the incoming bar. This results a rapid change in temperature in the outer layer of the steel rod whereas the temperature on the inner core remains the same.

Tempering

The temperature of the outer layer suddenly decreases from 900oC to 280oC and the temperature on the inner core of the bar remains the same. Therefore, the inner layer tempers the outer layer. The bar now reaches an equalization temperature of 575oC – 625oC depending upon the grade of steel chosen.

Cooling

The bars are then cut according to the desired length and sent to a cooling bed to attain the equalization temperature. This process results in the formation of a hard outer layer that keeps the bar strong and a soft inner layer to provide ductility to the bar.

Testing of TMT Bars

Once the TMT bar of desired grade and diameter is manufactured, it is subjected to finishing to a fine look. Various tests are conducted to check the quality of the bar. There are quite a number of TMT bar manufacturing companies out in the market. But not all of them provide the best quality of steel. Hence, testing the bar before buying it is of prime importance. The tests are conducted to check the following properties:

Chemical composition

The chemical composition must be in accordance with the IS Specification. It must be right to get the desired properties and grade of steel. A spectrometer is an instrument used for testing the chemical composition of TMT Bar. It gives the chemical composition of the tested bar in terms of 32 elements and also ensuring the IS specifications are strictly maintained.

Strength

The bar strength is tested by the Universal Testing Machine, also known as UTM. TMT bar is placed in between the plates of the UTM and pressure is applied to it. If the bar breaks before the characteristic value for yield strength, it should be sent back.

Flexibility & Bending

The test conducted to check the flexibility of the TMT bar is called the bending and re-bending test. In this test, the bar is bent to 1350 and kept in boiling water for about 30 minutes. It is the re-bent to approximately 157.50. If the bar is designed for the right amount of strength and flexibility, it should bend easily without any appearance of surface cracks along the bends.

Dytron Steel being one of the best TMT bar manufacturers in West Bengal, they are a company with years of experience in this field.

1 note

·

View note

Link

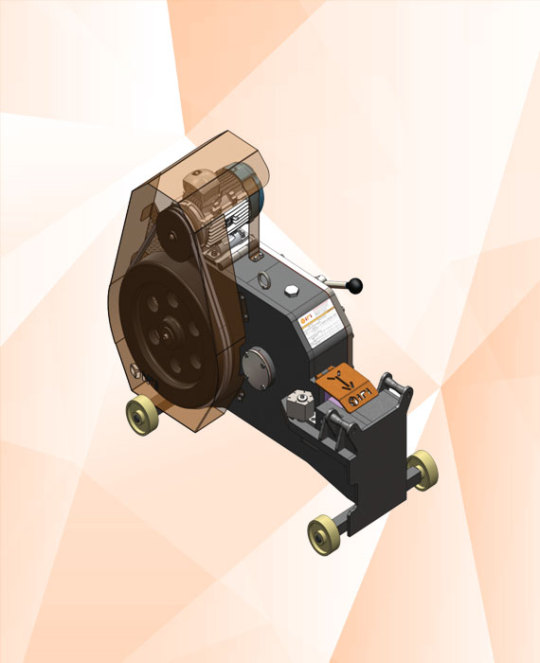

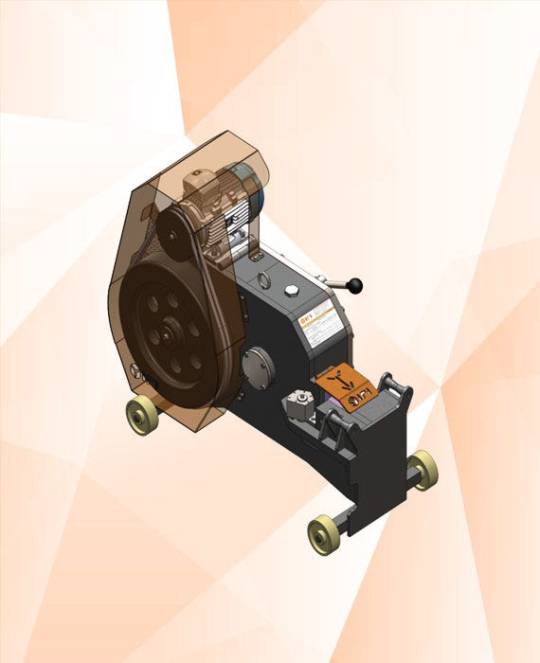

We are Surat based supplier of high quality Bar processing machineries, Construction Machineries and Scaffolding equipment. We deal in all kind of Construction Machineries like Bar Processing Machines, Cement Processing Machines, Concrete Testing Equipment, Lift and hoists equipment's, Scrap Bar Straightening Machines, Automatic Stirrup Ring Making Machines etc. Smit corporation is the leading manufacturer in the filed of construction equipment, We offer Highly Productive and Accurate which requires minimum Maintenance. We offer various models of Bar processing Machines like Bar Bending Machine/TMT bar bending machine, Scrap Bar Straightening Machine, Automatic Rebar Stirrup Machine, Rebar Threading Machine, Bar Cutting Machine, Stirrup Ring Making Machine, Rebar Thread Chaser/ Bar Threading Machine/Rebar Thread Chaser, Bar Decoiling Machine, TMT Bar Cold Forging, Rebar Wire Twister, Rebar Coupler. Please contact smit corporation for Bar Bending Machinery. Please visit https://www.smit-corp.com/shop/ for more details.

#smit corporation: Suspended Rope Platform suppliers in Gujarat#smit corporation: Suspended Rope Platform suppliers#smit corporation: Suspended Rope Platform suppliers in surat#smit corporation: Suspended Rope Platform suppliers in india#smit corporation: Suspended Rope Platform seller#smit corporation: Suspended Rope Platform manufacturer#smit corporation: Suspended Rope Platform#best smit corporation: Suspended Rope Platform suppliers#smit corporation: S#Suspended Rope Platform suppliers in Gujarat#Suspended Rope Platform suppliers in india#Suspended Rope Platform suppliers#Suspended Rope Platform#Suspended Rope Platform seller in gujarat#Suspended Rope Platform manufacturer

1 note

·

View note

Text

Ribbed Wire: A New Technology Looking to Replace TMT Bars

The advancement of technology has delivered many things to us. One such thing is ribbed wires which is a type of high-strength steel. But many people often think the ribbed wire is a complete TMT bar replacement. But this is not true, as you can consider it a partial replacement.

The ribbed wire manufacturers in India produce this product by controlling the cold twisting of hot rolled bars. These wires have projections or ribs on their outer surface.

They also come with various diameters varying from 6 mm to 50 mm. The most outstanding thing about the ribbed wires is that they have the exact strength and durability of TMT bars.

The Usage of Ribbed Wires

You can use the wires created by the top ribbed wire manufacturers in India in cement-based prefabricated structures like mean windows, construction boundaries, and others. Ribbed wires create better bonding with concrete. Some of the uses of ribbed wire include:

Building structures like high-rise houses and buildings, stadiums, hollow floor board, nuclear power plants, and wall boards

Reinforcing structures such as dams or any other rock soil anchoring project

Prefabricated concrete structures such as cement concrete pipes or pressure pipes

Bridge and road structures like subways, railway sleepers, highways, and others

Other uses like cement poles, mines, tubular piles, girders, double T-board, crane beams, panels, free-cutting steel, TV towers, and many more.

Different Types of Ribbed Wire

These are some of the types of ribbed wires;

Helical Ribbed Wire

The main characteristics of helical ribbed wire are the rolling out procedure. It deals with semi-finished products after the last drawing or plastic deformation. Thus, the wire created on the four convex-shaped consecutive ribs is excellent in feature compared to strand or plain steel wire.

Helical Ribbed Strand Wire

The wire includes 3 to 6 convex-shaped consecutive ribs on the surface. The primary advantage of this type of ribbed wire is strengthening the bond between the concrete and the wire. Thus, it improves the product’s performance and also extends its life.

Cold Drawn Ribbed Wire

Companies chiefly use it for concrete reinforcement like bars after the strengthening procedure. It is one of the most efficient construction materials with high strength, holding, capability, and many other qualities.

The primary applications of cold-drawn ribbed wire are precast reinforcement steel, concrete reinforcement wire, and many more.

Features of Ribbed Wire

Ribbed wires include the following features.

High bonding force

Wide range of application

Low relaxation and high tensile strength

Advanced production line, examination equipment, and necessary facility

Things to Remember While Choosing Ribbed Wires

While selecting the ribbed wires, remember a few things to get the best one. To help you with this, here we have penned down the most significant factors to help you to choose the best-ribbed wire.

Rib Pattern

As you might know, each ribbed wire comes with a specific pattern on its outer surface. It is called the ribbed pattern. But these patterns have different variations. That is why it is crucial to think while selecting one.

You need to pick the pattern by considering how you will use the ribbed wire. In this way, you can ensure the wire will offer increased strength and durability.

Pattern Formation Techniques

The ribbed wire manufacturers in India create the pattern and the formation of the ribbed wires in a way that you can use them for various purposes. Besides this, the best manufacturers use advanced CNC machines to ensure uniformity in ribbed wire manufacturing.

Importance of Ribbed Wires

Unlike TMT bars, ribbed wires offer enhanced bonding strength to concrete structures. The structure can withstand an earthquake or flood as it provides an extra layer of structure safety.

Additionally, ribbed wires can distribute the load evenly across the entire structure and build a better grip on concrete. It also decreases the slipping issue during construction. On top of all, due to the excellent welding ability and bonding, the upkeep cost is marginally low.

The benefit of using ribbed wire is that it can strengthen the combination between concrete and wire. Ribbed wires are used in hollow slabs, water pipes, telegraph poles, and many more.

Benefits of Ribbed Wires

By reading the above segments, you can more or less understand the importance of ribbed wires in today’s world. Many people are now using these wires to get multiple benefits. Let us take a look at some of those.

You can bend ribbed wires 360 degrees without cracks or fractures on their outer surface. It is beneficial to execute different and complex projects.

By using ribbed wires, you can get enough strength and durability.

By using these wires, you can also make the weight of the structure much less.

Ribbed wires are much more economical than TMT bars. These wires significantly reduce the expense of reinforcement by up to 30 to 40 percent.

Ribbed wires support welding. You can weld them by using electric flash butt welding or arc welding.

The structural properties of ribbed wires are more enhanced than the ordinary plain round bars.

You can use ribbed wires for every prominent type of reinforced concrete structure.

These wires are rust-proof and highly flexible.

The handling and fixing are also quite simple. As a result, if you use ribbed wires, you can significantly reduce labor costs.

You can also implement ribbed wires in casting the floors of building construction.

Beneficial for seismic-prone regions as ribbed wires offer structural integrity

Provides lower friction

Final Words

To sum up, it is needless to say that ribbed wires are a new invention that works perfectly as a partial replacement for TMT bars. By using these wires, you will get several benefits and also save your money significantly.

But while selecting ribbed wires, you must choose the products manufactured by the best-ribbed wire manufacturer in India, like Group Nirmal. Group Nirmal supplies different varieties of ribbed wires with diameters ranging from 4mm to 11.9 mm.

0 notes

Text

Stainless Steel Production and Processing

We have manufactured steel for a thousand years, yet stainless steel is a relative newcomer. It was developed in 1913 by a Harry Brearley, a British metallurgist. Physicists, designers, and materials researchers have been testing from that point forward. As a rust proof combination, it can offer similar material properties as steel with the imperviousness to rust of composites, for example, aluminum, however at a lesser cost. From the outset, Stainless steel was utilized generally in little applications, as parts for water meters or siphons, just as being brilliant cutlery. Nowadays, it is additionally being utilized as a primary structure material, in a lot bigger amounts.

There are two different ways a spotless article can be made: An item may be produced using crude steel pieces that are pounded, rolled, and joined. Or then again it very well may be produced using liquid steel filled a form molded like the eventual outcome. Which is the more proficient treated steel creation strategy relies upon what the item is and what it very well may be utilized for.

THE STAINLESS STEEL PRODUCTION PROCESS

Stainless steel creation is a multi-step measure: steel scrap is dissolved, projected in a strong shape, heat treated, cleaned, and cleaned.

Dissolving and projecting

Framing

Warmth treatment

Descaling

Work solidifying

Cutting or machining

Wrapping up

Softening and projecting

Steel and alloying metals are stacked into an electric curve heater. Once in the heater, the metal is warmed to a particular temperature over its dissolving point, normally in abundance of 2800°F. Because of the outrageous temperatures, accuracy, and enormous volumes required, the softening stage by and large requires 8–12 hours. All through this stage, steel experts consistently check the shower temperature and synthetic arrangement.

After the steel amalgam is totally liquefied, the combination is refined. Argon gas and oxygen are siphoned into the heater, where they convert pollutions to gas and make others structure slag for simple expulsion. For most applications, the refined steel is projected into structures including blossoms, billet, sections, poles, and cylinder adjusts. These will be utilized as the crude materials for created items. Foundries can project stainless steel into its last expected shape by making a form to that plan. This shape may go through some machining as a completing advance instead of an assembling step.

Shaping

Most cast steel is shaped by hot rolling—the section, sprout, or billet is warmed and gone through enormous rollers, loosening up the steel into a more drawn out, more slender structure. Hot moving happens over the recrystallization temperature of the steel. Every section is shaped into a sheet, plate, or strip, while sprouts and billets are framed into wires and bars.

Stainless steel blossom creation

Stainless steel is projected into blossoms, and afterward hot folding changes them into wires or bars.

Cold moving is utilized when more exact measurements or an unrivaled surface sparkle are required. It happens underneath the recrystallization temperature of the steel. Cold moving uses little breadth wheels with a progression of supporting wheels to make smooth, wide sheets of treated steel to close resiliences.

Warmth treatment

Warmth treatment fortifies moved Stainless steel by recrystallizing the twisted microstructure. Most tempered steel is heat treated by strengthening. The Stainless steel is warmed to a careful temperature over its crystallization temperature, and gradually cooled under controlled conditions. This cycle assuages inside burdens and relax the hardened steel. The toughening temperature, time, and cooling rate all effect the properties of the total steel.

Descaling

A moved bit of Stainless steel procures a layer of oxidized "factory scale," which should be washed away to reestablish a glossy surface completion. Plant scale is generally eliminated through compound methods like electro-cleaning and pickling. In pickling, the Stainless steel is lowered in a shower of nitric-hydrofluoric corrosive. Electro-cleaning utilizes a cathode and phosphoric corrosive to pass a current onto the Stainless steel surface. The de-scaled metal is done off with a high-pressure water wash, leaving a brilliant, sparkling completion.

Work solidifying

Work solidifying is the way toward fortifying material through twisting. Stainless steels solidify rapidly generally speaking, with the specific rate dictated by the particular evaluation. Austenitic prepares solidify more promptly than different evaluations.

Cutting or machining

Stainless steel is sliced to a predefined shape and size. The Stainless steel can be sheared with round blades, sawed with rapid cutting edges, or blanked with punches. Elective techniques, for example, fire, plasma, and waterjet cutting are some of the time utilized.

For objects cast in a foundry to effectively be near conclusive structure, this cutting/machining stage may simply be to clean join lines, carry estimations to exact resiliences, or make a surface completion.

Wrapping up

Stainless steels can be made with a wide assortment of surface completions. The picked surface completion isn't absolutely tasteful. Certain completions make Stainless steel more impervious to erosion, simpler to clean, or all the more promptly utilized in assembling. The kind of finish is controlled by the expected application.

Surface completions are the consolidated consequence of creation cycles and completing strategies. Hot moving, strengthening, and de-scaling produce a dull completion. Hot moving followed by chilly moving on cleaning rolls creating a splendid completion. A mix of cold moving, toughening, and polishing with a fine surface makes an intelligent surface. A variety of pounding, cleaning, polishing, and sandblasting gear is utilized in completing Stainless steel surfaces.

Stainless steel bicycle rack finish

Stainless steel surface completions meet both stylish and utilitarian purposes by making the material more impervious to erosion and simpler to clean with a splendid completion.

QUALITY CONTROL AND INSPECTION

Albeit in-measure controls exist all through the assembling and manufacture of Stainless steels, they are ordinarily insufficient to satisfy worldwide quality guidelines. Prior to being sent, each cluster of Stainless steel must go through compound and mechanical testing to guarantee that it meets the ideal particulars.

Mechanical testing

Mechanical testing estimates the actual capacity of a Stainless steel to withstand loads, stresses, and effects. Mechanical tests incorporate the ductile, Brinell, and durability tests depicted above in mechanical properties.

Substance testing

Substance tests check the specific science of an example prior to guaranteeing the hardened steel grade. Compound tests are typically completed by non-ruinous spectrochemical examination. Consumption opposition is of specific significance for Stainless steels. Steel plants test and measure erosion opposition with salt shower testing—the more drawn out the steel stays stainless by consumption after presentation to salt splash, the higher the erosion obstruction.

OVERALL PRODUCTION OF STAINLESS STEEL

After Stainless steel was designed, specialists and creators immediately discovered applications for it. Cutlery was underway five years after Brearley understood his chromium-steel was rust proof. By 1926, when Stainless steel was thirteen, it began being utilized in careful inserts. 1935 saw the principal Stainless steel clad plane. War endeavors helped increment producing limit with respect to pure.

Somewhere in the range of 2005 and 2018,Stainless steel creation multiplied, to an overall yield of 50.7 million metric tons. China is the world's greatest maker of the metal.

As an overall newcomer in building supplies, Stainless steel is a material with even more prospects. Advancements like duplex Stainless steel are as yet happening. As new sciences are investigated, it's conceivable that new evaluations of Stainless steel will keep on being found, for applications we have not yet envisioned.

You can also checkout ksteel. They are the primary steel dealers in Bangalore. They provide most of the SAIL material at discount. They are offering products in SAIL TMT Bars, Rebars, HR and CR steel, GC galvanized steel sheets, MS angles, Vsp steel, Crs Grade TMT, Steel plates and more..

Resource : https://ksteels.blogspot.com/2020/12/stainless-steel-production-and.html

0 notes

Text

Quality of Radha 550 TMT Bars: A Detailed Analysis

Thermo Mechanically Treated Bars, widely known as TMT bars, are strong reinforcement bars having a tough outer core and a soft inner core. While the hard outer core strengthens a structure and provides supportive framework, the soft inner safeguards the structures from seismic activities.

TMT bars are the backbone of the construction industry. The strength and robustness of the TMT bars make them essential for all construction works. According to engineers and builders, the super-premium, high-strength TMT bars are extensively used in the residential and commercial projects to protect concrete structures from earthquakes and natural calamities.

However, it’s evident that TMT bars serve their purpose only if they are of high-quality. Radha TMT - a derivative of Radha Group, established under the leadership of industry veteran Late Shri Radheshyam Saraf in the 1960s, takes pride in being the best TMT bar company in India.

Here’s a detailed guide on Radha TMT bar manufacturing process and the quality of Radha 550 TMT bars.

Radha TMT Bar Manufacturing Process

The first step of manufacturing TMT bars involves passing high-quality steel billets through a 12-Mega-Watt, 30-Mega-Tonne furnace and then through a spectrometer. Next, they’re passed through a 6/11 Continuous Casting Machine and Billet Cooling Bed. Then, the Hot Conueyar for billet is passed through Roughing Chamber followed by Rib Cutting Machine, THERMAX and TMT Cooling bed. Freshly obtained TMT bars are then collected in TMT stockyard.

Quality of Radha 550 TMT Bars

Radha 500-grade TMT bars are known for its exceptional quality. Here are some of its core features -

Bonding Strength - The external ribs that run across the entire length of Radha 550 TMT Bars provide superior bonding strength between the bar and concrete in accordance with IS: 456/78 and IS: 1786/85.

Malleable - The high flexibility of the Radha TMT bars make it a preferred choice of engineers and builders across India.

Corrosion Resistant - Controlled water-cooling during the THERMEX TMT process prevents the formation of coarse carbides that are responsible for making the bars prone to corrosion. Additionally, Radha TMT bars don’t have surface stresses that are caused by the cold twisting process.

Earthquake Resistant - The soft ferrite-pearlite core helps the bar to bear dynamic and seismic loading. Additionally, Radha TMT bars display higher fatigue resistance to Dynamic/Seismic loads due to their superior ductility.

Fine Welding Features - Low carbon content of Radha 550 TMT Bars makes it easy for engineers to weld joints without reducing the strength of the bars.

Fire Resistant - Radha TMT bars have high thermal stability and are highly capable of withstanding temperatures of 400-6000 degrees centigrade.

Formability - Radha TMT bars have high elongation values and provide excellent workability and bendability.

Easy To Work - Radha 550 TMT Bars reduce construction and fabrication time by providing better ductility and bendability.

Here was a complete guide on Radha TMT bar manufacturing process and its qualities that make it the best

TMT bar company in India

Ensure that the TMT bar you are purchasing are always of high-quality and are manufactured by a trusted manufacturer to ensure maximum protection from seismic activities, corrosion and harsh weather conditions.

0 notes

Text

Are You Looking for Wire Cutting machine?

Veer Machinery is a well recognized firm in the market offering top quality Wire cutting machine. We strive to manufacture nothing but best quality product by finest quality raw materials. Our aim is to fulfill the short term and long term needs of clients within a budget which is affordable to them. As the name suggests, our wire straightening and cutting machine is well equipped to cut the wire effectively. It has the ability to mold the wire as per desired size and shape. Wire Straightening & Cutting Machine's Manufacturer and Exporter in Ahmedabad, Mumbai, Ghaziabad, Delhi, and Ludhiana in India.

We introduce our self as the leading manufacturer of wire straightening machinery, we rigidly believe in delivering quality product as it is a culture at veer machinery, we have been in this field for quite a long time and have evolved since then according to our customers requirements We have done business with many reputed customers which are truly satisfied with us.

We feel immense pleasure to introduce ourselves as the leading manufacturers of Wire cutting machine manufacturer Gujarat for TMT / Plain Wire. Since last one decade we have successfully installed the said machines at works of no. of clients belonging to various industries in India and overseas. The machines are manufactured under very strict quality control policy adapted by the company and hence receiving the repeat orders has now become a tradition at VEER MACHINERY.

We have catered to the needs of the following industry and more:

· Automobile sector

· Metal processing sector

· Electrical industry

· Fabrication activities

We have these machineries available in varying capacities based on the type of use. The wire thickness, speed, weight, and wire length to be cut manually and automatically may vary. Our experts strive to come with purest series of products. Our machines are required to serve the multiple needs of Electrode industry with precision quality and maximum output.

The machine consists of straightening wheels out of which only a limited numbers are powered. It has enough strength to impose the pressure upon steel bar by rotating handle. As a result, internal force gets eliminated while the steel bar is straightened. A certain power motor based pressure unit will just be convenient with the uniform landing and lifting.

We are offering a complete line of Wire Straightening & Cutting Machine to deal with different types of wire. Thus, it would be really easy for you to prepare cut length rods from the coils. It comes into use whenever a wire is processed in rods form and where proper straightening of coiled wire by clean cut is required. A modern design, low maintenance, and high productivity are other characteristics of our heavy duty machinery.

For More Information Visit: http://www.veermachinery.in/

#Wire cutting machine#Wire cutting machine manufacturer#Wire Straightening & Cutting Machine's Manufacturer and Exporter

0 notes

Text

A Trusted Construction Equipment Manufacturer and Supplier in India : IRI EQUIPMENT INDIA PVT. LTD.

IRI Equipment India Pvt. Ltd. stands as a reputable construction equipment manufacturer and supplier in India, carving a niche in the industry with a commitment to quality and innovation. Specializing in a range of construction solutions, IRI Equipment has become a trusted name for builders and contractors alike.

At Iri Equipment, we specialize in creating high-grade equipment like Suspended Rope Platforms, TMT Bar Bending Machines, TMT Bar Cutting Machines, and Mini Cranes. Our focus is on providing innovative and reliable solutions that cater to our customers’ evolving requirements.

Our commitment revolves around ensuring each piece of equipment meets stringent quality standards, promising reliability and satisfaction. From small-scale projects to large construction endeavors, Iri Equipment stands as your trusted partner, providing the tools essential for success.

Our Product

Suspended rope platform Bar bending machine TMT bar cutting machine Mini Crane Machine

Suspended Rope Platform

For vertical construction challenges, IRI Equipment provides the secure Suspended Rope Platform, a reliable solution for accessing elevated areas during construction and maintenance tasks. This platform ensures the safety and convenience of workers while facilitating work at height.

Bar Bending Machine

At the forefront of their product lineup is the high quality Bar Bending Machine, a precision tool designed to efficiently bend reinforcing bars with accuracy and speed. This crucial equipment ensures the seamless shaping of bars, contributing to the structural integrity of buildings and infrastructure projects.

Bar Cutting Machine

Our high power Bar Cutting Machine, another cornerstone in IRI Equipment’s portfolio. Engineered for precision cutting, this machine provide the accurate sizing of reinforcing bars, ensuring they meet the exact specifications required for diverse construction applications.

Mini Crane Machine

In addition , IRI Equipment India Pvt. Ltd. extends its expertise to the Mini Crane Machine, a versatile lifting solution designed to navigate confined spaces and handle varying loads efficiently. The Mini Crane machine enhances on-site logistics, contributing to a smoother construction process.

Driven by a commitment to excellence, IRI Equipment India Pvt. Ltd. consistently delivers high-quality products that meet the stringent demands of the construction industry. Their focus on technological advancement and customer satisfaction solidifies their position as a leading player in the realm of construction equipment manufacturing and supply.

#construction equipment#suspended rope platform for plastering#buy suspended rope platform#bar bending machine#suspended rope platform#machinery#IRI EQUIPMENT INDIA PVT. LTD.#reputable construction equipment manufacturer and supplier

1 note

·

View note

Text

Wire Straightening and Cutting Machines in India

Strong Star Machine Tools is one of the main organizations in the market to give you the best quality CNC, PLC, Fully Automatic, Wire Straightening Machine of Coil, Pipe Polishing, Tube, Square, TMT, Bar Polishing, Buffing Apparatus, High Speed Wire Straightening and Cutting Machines in India. We are the outstanding and all around prestigious maker, exporters and providers of such items. We make the best quality item with the whole finest and regular quality items. We generally satisfy the necessities and requests of our customers by offering them the best according to their prerequisite and under their financial plan moreover. Since, 2001 we are submitted in offering the best quality results of this in the market and due to this our customers are likewise happy with our administrations. We generally give you the best quality item in the market and at extremely sensible rates. We generally utilized the most recent innovation gear for the make of these items.

Best Wire Straightening and Cutting Equipment: We are mfrs of wire fixing and cutting apparatus. These advancements are utilized to straight wire from curl frame and afterward cut consequently according to wanted length. Different sorts of materials i.e. Gentle steel, EN8, SS 316, SS 304, SS 202, Aluminum, Brass, Copper, Rebar and Spring steels can be fixed and consequently cut. No scratch, No checking and No burr are key highlights of our gear. These advances give high creation with idealize length and precise fixing. These device are accessible in both manual and mechanized models. Read More...

#Wire Straightening and Cutting Machines in India#wire straightening machine#Wire Straightening Cutting#Pipe polishing machine

0 notes

Text

Tenders for Hardware Materials

Tender for Purchase Of Various Trade Related Raw Materials – Hardware, Electrical, Electronics, Tailoring And Stationery

TRN : 10395744 | Central Government/Public Sector | Education And Research Institutes

Ahmedabad - Gujarat | Last Date : 13 Feb, 2017 | Tender Value NA

| Get Help | Liaison Service |

Tender for Supply Of Lan Materials -Cat6 Utp 4 Pair Cable, Cat6 I/O, Face Plate Single & Back Box Set, Cat6 24 Port Jack Panel Loaded, Cat6 Patch Cord 1 Mtr. For Rack End, Cat6 Patch Cord 2 Mtr For User End, 24 Port Switch 10/100 Base Unmanaged, 9U Rack With Pdu, Cable Manager, Hardware Nut, Fan

TRN : 10373859 | Central Government/Public Sector | Services

Kolkata - West Bengal | Last Date : 21 Jan, 2017 | Tender Value NA

| Get Help | Liaison Service |

Tender for Supply Of Iron Materials, General Hardware, Stationery Materials, Automobile Row Materials, Chemical Row Materials,

TRN : 10340615 | State Government | Education And Research Institutes

Vadodara - Gujarat | Last Date : 27 Jan, 2017 | Tender Value NA

| Get Help | Liaison Service |

Tender for Tender For Supply Of Stores Against Local Service Local Purchase Annual Contract For Packing Materials –Hilton Sheet, Hdpe Sheet Pp Sheet, Fabric Woven, Polythene Sheet, Cleaning Materials, Electric & Electronic Items, Computer Peripherals, Hardware, Consumables Repairs, Mt Spares Repairs, Clothing Item, Foot Wears, Stitching Of Uniforms, Paints, Thinner, Hygiene Chemicals, Minor Fire Fighting Equipment Material Handling Equipment, Hiring Of Trucks & Hiring Of Car Passengers

TRN : 10278061 | Central Government/Public Sector | Security Services

Nasikcity - Maharashtra | Last Date : 28 Jan, 2017 | Tender Value NA

| Get Help | Liaison Service |

Tender for Supply Of Inconel Forgings For Valves, Inconal Fittings, Carbon Steel Forgings Sa105 For Drum Nozzles, Malleable Iron Castings, Special Stainless Steel, Carbon Steel Cut Flats, Special Alloy Steel Rounds For Hp Lp Valves, Flame Scanner Head Assy Test Kit, Pressure Switch For Electromatic Releif Valve, Purge Meter, Flow Switch In High Pr. Steam Line, Micro Switch For Gravimetric Feeder, Name Plates, Accessories For Hea Ignitor, Vfd Controller, Wired Modular Panel, Ash Level Switch, Electrode For Electronic Water Level Indicator, Furnace Flame Viewing Camera System, Fibre Optic Cable And Lens Barrel Assy, Decibel Scanner, Proximity Switch, Solenoid For Hp Bypass Valves, Regulating Duty Electrical Actuator, Pneumatic Actuator, Cable Dressing Materials, Cable Tags, Cable Lugs, Flame Scanner Head, Modular Type Cabinet, Electrical Accessories, Gravimetric Feeder Control Modules, Signal Isolator, Passenger And Goods Elevator, Digital Tachometer, Feeder Belt, Sonic Tube, Electronic Water Level Indicators, Fluegas Analyzers, Mill Seal Air Filter Assembly, Limitswitch Lightduty, Feeder Light Fittings, Springs, Plug Valves, Circlips For Feeders, Flow Beam For Oil Field Equpment, Sump Pump Motor Assembly, Speed Regulator, Graphite Alloy Damper Bearing And Bushings 400 Deg C Operation, Gaskets For Coupling, Variable Orifice, Heat Resistent Glass, Gravimetric Feeder Components, Mobile Platform, Head Pulley Bush, Strainers Duplex, Link Chains, Tadpole Tape, Glass Globe / Light Fitting For Feeder, Portable Instrument For In-Situ Tube, Thickness Measurement, Hardware & Software For Tube Life, Assessment System, Gun Metal Valve, Nitrogen Blanket System, Hydro Test Pump, Special Bearing For Oil Field Equipment, Feed Back Transmiter, Mandrel Flow Adaptor, Non - Metallic End Covers, Pre Formed Gaskets For Quick Closing Non, Return Valves, Special Packing Set For Full Bore Valves, Sintered Bronze Bush, Special Tools For Oil Field Equipments, Hp Fill & Purge Filter Assembly, Intrascope, High Pressure Startup Control Valve, Insulation: Calcium Silicate, Slab/Block/Pipe, Sealing Compound, Solenoid Valves, Light Duty Limit Switches, Gear Pump With Motor Drain Oil, Steam Trap, Neoprene Hoses, Oil Accumalator Fuel Oil, Rockwell/Sleeve Couplings, Victaulic/Pipe Couplings, Gravimetric Feeder Assembly, Furnace Maintenance Platform, Handling Equipment: Manually Operated, Quick Erect Scaffolding System - Steel, Anti Seize, Spray/Thread/Lubricant/Adhesive Sealants, Feeder Components, Gasket Eliminator/Sealant, Fuel Oil Triple Screw Pump, Sintered Flange Bronze Bushes, Slip On Pipe Coupling, Corrugated Al Sheet, Gear Box And Clean Out Conveyor Drive, Self Cleaning Rotary Valve, Rotary Feeder, Air Lock Feeder, Actuator For Full Bore Valve, Spring Washers, High Pressure Filter, Gear Box For Valves, Non Asbesters Packing For Valves, Drive Belts Pulleys For Temperature Probe, Swagelock Fittings, Teflon O-Rings, Packing Rings Etc, Ss Wiremesh Rope, Dynamic Shaft Seals, Ptfe Seated Plug Vales, Masterfuel Tripvalve, Ball Type Control Valve & Accessories, Self Actuating Valves, Mica Shield For Water Level Guage, Throttle Device For Hydraulic Power Unit, Mpgfc Cpu, Weighing Module, Soft Starter -Dc Scanner Air Fan Motor, Critical Application Pressure Gauges, Lighting Arrestors, Critical Application Pressure Switches, Annular Cutter New, 2 Side Adhisive Tape, Disc Slitting Wheels, Steel Measuring Tapes, Hacksaw Blades, Tube Expanders, Boring And Facing Heads, Boring Holders And, Facing Holders, Api Gauges, Carbide Burrs, Carbide Tipped Circular Saw, Grinding Wheels, Shelf Life Grinding Wheels, Alloy Steel Flats, Spiral Fin Tubes, Flux Cored Wire E91t1-B3, Flux Cored Wire E316lt1-1, Saw Flux For Sa335p92, Smaw Electrode Jis Z3211 D4316, Gtaw Wire For T92, Gmawwire Ernicrfe-7A, Saw Wire For Sa335p92, Gtaw Rod - T92 / P92, Gtaw Rod Super 304H, Smaw Elecd - T92/P92, Flux Cored Wire E309t0-1, Smaw Electrode Ecocr-E, Smaw Electrodes - E310-16, Smaw Electrodes - E316l-16, Smaw Electrode 253Ma, Saw Wire Eb3, Saw Wire Ea4, Hayness Alloy 25 Ha-25 Filler Rod, Hayness Alloy 21 Ha-21 Filler Rod, Er 309 Saw Wire, Er 347 Saw Wire, Fused Saw Flux For Drum Welding, Fused Saw Flux For Tube To Fin Welding, Gmaw Wire, Bulkpack, Smaw Electrode, Cast: Aluminium, Forged Finned Elbow, Nickel Based Castings, Non Ferrous Castings 0.5 To 200, Closed Die Forged Components, Sg Iron Castings, Socket Welded Forged Fittings, Investment Castings, Coal Nozzles Sg Iron Castings Up, Kgs, Hemi-Spherical Dished Ends, Open Forgings F91, F92, Non-Ferrous Castings For Feeder, Cast Iron Castings For Windbox, Feeder, Formed Fittings, Investment Castings For Connectors, Windbox, Steel Castings, Sg Iron Machined Castings For Coal Nozzles, Split Collar For Wind Box, Formed Fittings, Close Die Forgings, Formed Fittings, Forged Flanges, Open Forgings - Carbon, Alloy And Stainless Steel, Open Forgings For Hp Bypass Valves: Carbon And Alloy Steel, H.R. Aluminium Paints, Stainless Steel Pipes, Seamles P91/P92 Pipe, Alloy Steel Plates, Parallel Flange Beam, Carbon Steel Rounds For Valves, Carbon Steel Plates Boiler Quality, Tmt Bars, Frp Junction Box, Local Instrument, Pressure & Dp Swithces, Transmitter Pressure, Panels, Brass Cable Gland, Cctv System, Motor Control, Airfilter Regulator, Dp Gauges, Electrical Accessories For Valves, Electrical Panels, Sheet Steel Junction Boxes, Earthing System, Fluegas Analyzers, Pressure Gauges, Limit Switches, Orifice Plate Assy, Flow Nozzles, Pvc Insulated Copper Control Cable, Xlpe Insulated Lt Power Cable, Direct Water Level Gauge, Hea Ignitor Assy, Isolation Valves, Scanner Air Fan, Scanner Air Filter Elements, Non Metallic Expansion, Coal Valves Clad Roller, Felt Rings, High Pressure Rubber Hoses, Drum Saddle Slide Bearing Plate, Drum Saddle Slide Bearing Plate, Disc Springs, Refractory For Cfbc Boiler, Ceramic Wool, Burner, Blowers, Cbd & Ibd Tanks, Chains For Soot Blowers, Plc Panels For Soot Blower, Oil Cylinder For Quick Closing Nrv, Elastomers For Oil Field Equipment, Gear Box With Motor For Soot Blowers, Accumulatars Accessories, Soot Blower Sprocket, Soft Iron Gaskets & Sealing Rings, Spiralwound Gasket, Coil Springs For Safety Valves With, Sealing Rings, Retainer Rings, Drive, Water Level Gauge Rings & Washers, Oil Supply Unit For Hp Bypass System, Valves Elec Actuators, Hydraulic Power Unit, Proportional Valve, Valves Special Iq Actuators, Cfbc Refractory For Modification, Steel Glazed Windows, Strainers: Simplex, Boiler Circulating Water Pumps, Teflon Hose Ss Braided, Flexible, Gaskets, Start-Up Burner, Drag Link Chain Feeder, Machined Components For Valves, Spl Fasteners For Oil Field Equipment, Accumulator Manifold, Hydraulic Actuators Components, Fuel Oil Control & Trip Valves, Y Type Strainers, Butterfly Valves Wafer Design, Metallic Expansion Bellows, Oil Seals, Ss Spiral Wound Gasket, Air Cylinder Open/Close, Retractor, Assembly, Teflon Slide Bearing Plate, Dosing System, Supply Of Power Assisted Safety Valves, Safety Valves For Supercritical Boiler, Isolating Ball Valves, Component: Stellite Weld Seat & Disk, Fabricator Metal Component, O-Rings & Oil Seals, Tunguston Carbide Balls, Bearings, Washers And Circlips, Pourable Insulation, Woven Wire Cloth-Stainless Steel, Ss Flexible Hoses, Assembly Fittings Like Male Stud Olive Coupling, Pressure Relieving Valves, Forged Valves, Special Glass For Water Level Gauge, Limit Switches For Quick Closing Nrv, Ring Joint Gasket, Valve Diaphragm Actuator, Floor Grills & Step Treads, Galvanised/Painted - Manual Welded, Pre-Painted Galvanised Sheets For Boiler Roof, Aluminium Sheet, Ball Valves, Soot Blower Pressure Reducing Valve, Fire Bricks, Trip Valves, Bearings, Coil Springs For Safety Valves, Keys, Pins, Washers, Control Valve, Wool Mattress, Spiral Wound Gaskets, O Rings, High Tensile Fasteners, Conventional Valves, Damper And Damper Components, Solenoid Valve, Boiler Water Recirculating Pump, Cast Aluminium Junction Box, Localvibration Monitor, Galvanised Sheet Steel Junction Box, Stainless Steel Junction Boxes, Process Thermocouples & Rtds With, Thermowell, Coated Abbrasives, Hss Circular Saw, Hss Cutting Tools, Letter And Number Punchs, Spade Drills, Straight Edges, Tapping Attachments, Wrenches, Zircon Belts, Absf Cutters, Carbide Tips, Diamond Tools, Gear Cutting Tools, Symmetrical Carbide Drills, Indexable Carbide Drills, Adaptors, Bta Tools, Thread Gauges, High Q Carbide Cutting Tools, Measurnig Instruments, Spiral Fluted Tap, Threading Taps, Thread Rollers, Carbide Tipped Tools, Hand Tools, Special Cutters, Stellite Turning Inserts, Threading Tools, Vdi Holders, Fine Boring Tools, Bi-Metal Band Saw Blades, Carbide Cutting Tools, Carbon Steel Flats, Rifle Tubes, Stainless Steel Tubes, Gmaw Wire, Gtaw Rod Tig, Fcaw Wire, Gmaw Wire, Flux Cored Wire, Smaw Electrodes, Weldwire Saw, Saw Flux Struct.

TRN : 10199343 | Central Government/Public Sector | Electrical Products

Trichy - Tamil Nadu | Last Date : 19 May, 2017 | Tender Value NA

| Get Help | Liaison Service |

Tender for Empanelment Of Vendors - Supply Of Raw Materials - Die Steel Rods Din:1.2550, Steel En Series, Mild Steel, Tool Steel, Austenitic Ss 310, Copper Sheet, Brass Sheet, Fss Coils, Bimetallic Coin Blanks, Ni-Br Sheets ., All Non – Ferrous Alloys, Sand, Cement, Bricks, Stone Chips Etc., Paint, Putty Etc, Tar, Tarpaulin, Asbestos / G.I. Sheet Etc, Scaffolding Material, Laddles Etc, Plumbing Raw Materials., Machineries Equipments Spare Parts, Computers, Peripherals, Printers, Software, Hardware, Networking. Ht & Lt Sub Station Equipments Electrical Spares Material Handling Equipments, Measuring & Testing Equipments, Balances & Weighing Scales, Comparators Etc. Pump Sets Fire Fighting Equipments Telecom Equipments A.C Spares Pallet Truck, Fork Lift Truck, Stacker Spare Parts, Annual Rate Contract / Services, Manpower Hiring On Outsourcing Basis, Skilled, Unskilled, Transport Services Hiring Of Vehicles Viz Cars, Forklifts, Pallette Trucks, Stackers Etc. House Keeping Horticulture Sanitation Packaged Drinking Water, Catering Services. Auditing/ Consulting Services. Rodent / Pest Control. Advertising Transit Insurance, Vehicle Insurance, Annual Maintenance Contract / Repairing / Supply Of Spare Parts, Electric Motor Rewinding Computers, Computer Peripherals, Printers, Xerox Machines, Software, Hardware, Air Conditioners, Ac Plant, Water Coolers Air Compressor System Dg Sets 500 Kva Fork Lift Trucks, Pallet Trucks, Stackers Voltage Stabilisers 125Kva-400Kva Air Ventilation System Fire Fighting Equipments Safety & Security Items Rolling Shutters, Photo Copiers Epabx System Biometric Control System. Metal Detectors, Hand Held & Door Frame Cctv Siemen - Ac, Dc Drives, Plcs, Pcbs Machinery And Mechanical Items Civil Work In Factory & Townships All Electrical & Electronics Work In Factory & Townships, Machined Fabricated Materials, Ms Drums, Containers Ms / Wooden Pallets Machine Parts Collars Tc& D2, Dial Indexing Plates Industrial Items Plastic Moulded Jobs Cast Iron Box & Trays, Job Works, Consultancy Heavy Labour Jobs, Erection & Commissioning. Fabrication, Welding, Brazing, Grinding Etc Automation Engineering Heat Treatment Job Testing, Analysis Civil Maintenance, Painting & Plumbing Radiator Cleaning Testing & Certification Of Cranes, Lifting Tackles, Pr. Vessels Etc. Testing & Calibration Of Measuring Instruments Packaging Of Medals And Commemorative Coins Manufacturing Of Medal Blanks Structural Audit / Survey Civil/Labour Contractor Re-Filling Of Cartridges., Production Consumables, Ldpe Film Rolls / Bags Thermal Transfer Ribbons Thermal Transfer Printer Label Rolls Printing Ink Polycarbonate / Acrylic Sheets, Moulded / Acrylic Inserts. Lubricant Oils, Cutting/Coolant Oil, Quenching Oil, Hydraulic Oil. All Industrial Oils Grease Charcoal Hosiery Cleaning Cloth & Rags. Cotton Waste Cleaning Cloth. Cotton Hand Gloves Machine Cleaning Material Pickling & Polishing Compound T.C Dies And Punches For Blanking Tool Corn Cob All Chemicals Production And Laboratory Satellite Balls Cotton Waste Fine Crucibles For Melting, Mechanical Items, Bearings Of All Types. Belts Of All Types Nuts, Bolts, Screws, Springs, Pins Straight & Taper, Washers Etc Rubber Rolls Gears, Shafts, Pulleys And Other Spare Parts Of Various, Machinery. Loctite, Grease Sevogem Cutting Tools, Drills, Milling Cutters, Tool Tips, Cnc Working Tools, Taps & Dies Etc. Hacksaw Blades Of All Sizes, Knifes Grinding Wheels/Mounted Wheels, Tips/ Dressers, Hand Grinding Wheels / Cutters Etc. All Files Emery Paper And Emery Cloth, Oil Stone Etc. Polishing Mobs Diamond Lapping Compound Glass Balls, Hammer Balls Pressure Gauges & Regulators Gaskets, Valves Etc. Filters – Air & Oil Ms Wire Hardware, Paints, Plumbing, Carpentry Items Plastic Bins Grease Gun And Oil Gun Pneumatic System Components Lubrication System Components Hydraulic System Components All Types Of Wood, Ply Wood, Sal Wood Polish & Resins Industrial Adhesives All Nails, Electrical & Electronics Items, Lightings, Switches, Fans, Coolers, Room Heaters, Geyser, Air Conditioners, Water Coolers, Industrial Fans, Exhaust Fans Control Panel Items-Relays, Contactors, Timers, Plc Modules, Micro Switches, Semiconductors, Fuses, Connectors Etc. Heating Elements, Nichrome – For Furnace, Plastic Sealing Electrical Motors Printed Electronic Cards & Modules, Electronic Items Solenoid Coils/Valves, Optical Sensors Etc. Cables – Electrical, Telephone, Fiber Optic Power Backup Systems Motor Winding Materials Transformers Ac & Refrigeration Dg & Compressor Electrical Appliances Coffee & Tea Premix & Vending Machines Telecom Equipments Computer, Printer And Peripherals, - Computer Software, Tools & Tackles, Mechanical Maintenance Tools Electrical & Electronic Measuring & Maintenance Tools Hand Tools, Drilling Machines, Blower, Grinder Etc Plumbing Tools Carpentry Tools Civil Tools Horticulture Tools Painting Tools Welding Tools, Office Stationery - A4 / A3 Size Xerox Machine Paper Computer Stationary Continuous With Perforation On Both Sides Registers, Writing Pads Diaries, Calendars, Pens, Pencils Etc Box Files, Office Files Etc Printer Cartridges Muster Rolls Fax Rolls Other Office Related Stationery.Pens, Pencils Etc Box Files, Office Files Etc Printer Cartridges Muster Rolls Fax Rolls Other Office Related Stationery., Packaging Items, Rubber Bands Corrugated Boxes Hdpe Woven Sacks Bopp Tape/ Cello Tape Cotton Tape, Cotton Yarn Plastic String With Metal Clip Shrink Wrapping Film Wooden Packing Boxes Polythene Bags, Ldpe Film Etc Medal Cases, Stands, Acrylic Cases, Acrylic Stands, Blister Pack, Ribbon For Medal And Other Packing Material Jute Bags / Gunny Bag, Jute Long, Jute Rope Stickers, Labels, Printed Materials T.T.Ribbons Thermal Transfer, Furniture, Canteen Items, Office Furniture Industrial Furniture Canteen And Other Furniture Vegetable Cooking Oil Atta Wheat Flour Rice Pulses & Cereals Milk In Pouches Sugar Tea Cutlery Canteen Utensils Kitchen Appliances All Canteen Provisions, Safety Equipments Items, General Safety Fire Safety And Fire Fighting Equipments Electrical Safety Protective Clothing Safety Shoes, Ordinary Shoes & Socks Ear Plugs Nose Masks, Respirators Hand Gloves Rubber/Cotton Helmets Eye Safety / Eye Protection Safety Gadgets, General Items, Uniform Cloth / Protective Cloth Uniform – Men And Women Toiletries Soaps And Detergent Powder Sanitary Items Towels Banian Bits, Pocket Less Underwear, Hosiery Cloth & Rags Medicines, Gases And Petroleum, Lpg Gas Nitrogen, Argon, Acetylene, Oxygen Etc Refrigerant R22, R134a Etc. Petrol, Diesel, H.S Diesel, Kerosene, Brushes Chalk Pencil, Chalk Powder Etc Cotton Duster Cutleries And Others

TRN : 10161958 | Corporations/Associations/Others | Printing Work

Hyderabad - Andhra Pradesh | Last Date : 09 Feb, 2017 | Tender Value NA

| Get Help | Liaison Service |

For More Information About Hardware Materials Tenders Just Click Here

0 notes

Text

Roll of Structural Steel and Plate Fabrications in Major Industries

Steel is known for its high elasticity and ease. It is in the establishment of pretty much every industry and significant segment utilized in structures, foundation, instruments, ships, cars, machines, apparatuses, and weapons. Alongside that, Steel assumes an extremely essential function in manufacture businesses. All significant business areas, for example, Heavy Steel, Petrochemical, Construction, Mining, Food and Dairy, Power Supply and Distribution include Steel creation either in their everyday activity or have utilized it during their underlying arrangement. Thinking about the high strength of steel, we require innovative instruments, for example, laser slicing billboard which is utilized to deal with the crude steel items into something helpful, for example, auxiliary steel radiates, segments, steel lines, areas, and bars.

Let’s look at how these different industries are involved in the entire steel fabricating process.

Substantial Industry

Weighty basic steel creation organizations doing the manufacture cycle for some private, business and mechanical tasks.

Substantial steel structure produced using developed areas, for example, scaffolds and crane supports which can be created by various machines like SAW developed segment.

The auxiliary steel is additionally ordinarily utilized in the development of skyscraper business structures. Different shafts, for example, H-radiates, I-bars, and T-radiates are manufactured at these enterprises.

These structures are utilized as burden bearing individuals.

Weighty Structural Steel Fabrication

Basic Steel Fabrication Construction

Development Industry

Industry Structural Steel Fabrication for Construction Industry is generally thought about as it's the most savvy building asset. In the development business, reasonable material, for example, steel permits structures to be constructed rapidly at a low cost. Since steel comes in different compounds and structures, it very well may be intended to satisfy the needs of each task.

Steel upgrades underway add to the coming of the elevated structure, just as the development of railroads everywhere on the world

The strength and sturdiness of houses, vehicle parks, schools and high rises, most structures all depend on steel. The development business is subject to steel for the correct foundation needs of non-industrial nations by permitting wind-safe and defensive seaside plans.

Petrochemical Industry

Petrochemical Industry Steel Plate Fabrication – There has been an expanded worldwide dependence on worth added ideas particularly in the Petrochemical Industry that has been utilizing Steel Plate Fabrication.

This industry requires changing worth crude materials like oil and gas into different materials that are thusly the crude materials which are utilized in numerous different enterprises.

The classes of prepares utilized here are impeccable, high-strength, carbon, and miniature alloyed. These assistance in the creation of the hardware like pipelines and seaward stages. Such properties of steel help in the energy anticipates for the forthcoming requesting conditions.

Steel Plate Fabrication for Petrochemical

Steel Fabrication for Mining Industry

Mining Industry

Steel Fabrication for Mining Industry – In the Mining Industry Steel Fabrication is very helpful. The primary mining measure includes numerous apparatus and devices that are framed utilizing steel creation.

Mining Industry utilizes entirely different hardware like transports, lifts, lifts. The entirety of this hardware requires strength and adaptability, which no one but steel can give.

Quality manufacture of transport lines ensures toughness and execution for the whole system.

Digging organizations use steel for a more grounded hold in more profound mines where the parallel weight is more prominent.

Being one of the most adaptable metals, a wide scope of surface medicines like hot plunge arousing, powder covering, and painting should be possible with it.

Food and Dairy Industry

Steel Plate Fabrication in Food Industry is generally utilized as it is required for some, designing plan administrations.

A wide scope of food and dairy holders and creation gear are finished by the steel business.

As Stainless steel needs item contact surface surfaces it is generally utilized for food industry manufacture ventures. Its capacity to effectively dismantle the hardware for cleaning and examination gives further advantages to food industry clients.

Protected Metal Feed Storage Fabrication

Steel Fabrication for Power Industry

Power Supply and Distribution Industry

The Steel Fabrication work in Power Supply and Distribution Industry

It can give power plants that are created metals, reactor internals, regulation parts, pressure vessels, tanks, heat exchangers, funneling frameworks, wet stockpiling racks, spent fuel holders, auxiliary backings, and lifting rigs.

Laser Cutting Sign Board Industry

Likewise, on the off chance that we talk about Laser Cut Sign Board, these can be handily produced using acrylic laser cutting and metal laser cutting in aluminum, steel, hardened steel, metal, and copper up to 1mm.

Steel can undoubtedly make a little or gigantic billboard utilized for business purposes

Structural steel is alluded to as the main green basic development material that expands energy productivity and related ecological issues. It is the most favored metal in the development business as it is recyclable and truth be told, has a high stake in the market of mechanical and business structures.

Primary steel dealers in Bangalore are selling the products at quite a reasonable price for their products, compared to the others. They are offering products in SAIL TMT Bars, Rebars, HR and CR sheets, GC galvanized steel sheets,GI Pipes,Steel plates, MS angles, Vsp steel and more.

Resource : https://ksteels.blogspot.com/2020/11/roll-of-structural-steel-and-plate.html

0 notes

Photo

smit corporation: Suspended Rope Platform suppliers in Gujarat We are Surat based supplier of high quality Bar processing machineries, Construction Machineries and Scaffolding equipment. We deal in all kind of Construction Machineries like Bar Processing Machines, Cement Processing Machines, Concrete Testing Equipment, Lift and hoists equipment's, Scrap Bar Straightening Machines, Automatic Stirrup Ring Making Machines etc. Smit corporation is the leading manufacturer in the filed of construction equipment, We offer Highly Productive and Accurate which requires minimum Maintenance. We offer various models of Bar processing Machines like Bar Bending Machine/TMT bar bending machine, Scrap Bar Straightening Machine, Automatic Rebar Stirrup Machine, Rebar Threading Machine, Bar Cutting Machine, Stirrup Ring Making Machine, Rebar Thread Chaser/ Bar Threading Machine/Rebar Thread Chaser, Bar Decoiling Machine, TMT Bar Cold Forging, Rebar Wire Twister, Rebar Coupler. Please contact smit corporation for Bar Bending Machinery. Please visit https://www.smit-corp.com/shop/ for more details.

#Suspended Rope Platform suppliers in Gujarat#Suspended Rope Platform suppliers in india#Suspended Rope Platform suppliers#Suspended Rope Platform suppliers in surat

0 notes

Photo

Suspended Rope Platform suppliers in Gujarat We are Surat based supplier of high quality Bar processing machineries, Construction Machineries and Scaffolding equipment. We deal in all kind of Construction Machineries like Bar Processing Machines, Cement Processing Machines, Concrete Testing Equipment, Lift and hoists equipment's, Scrap Bar Straightening Machines, Automatic Stirrup Ring Making Machines etc. Smit corporation is the leading manufacturer in the filed of construction equipment, We offer Highly Productive and Accurate which requires minimum Maintenance. We offer various models of Bar processing Machines like Bar Bending Machine/TMT bar bending machine, Scrap Bar Straightening Machine, Automatic Rebar Stirrup Machine, Rebar Threading Machine, Bar Cutting Machine, Stirrup Ring Making Machine, Rebar Thread Chaser/ Bar Threading Machine/Rebar Thread Chaser, Bar Decoiling Machine, TMT Bar Cold Forging, Rebar Wire Twister, Rebar Coupler. Please contact smit corporation for Bar Bending Machinery. Please visit https://www.smit-corp.com/shop/ for more details.

0 notes

Text

smit corporation: Suspended Rope Platform suppliers in Gujarat

We are Surat based supplier of high quality Bar processing machineries, Construction Machineries and Scaffolding equipment. We deal in all kind of Construction Machineries like Bar Processing Machines, Cement Processing Machines, Concrete Testing Equipment, Lift and hoists equipment's, Scrap Bar Straightening Machines, Automatic Stirrup Ring Making Machines etc. Smit corporation is the leading manufacturer in the filed of construction equipment, We offer Highly Productive and Accurate which requires minimum Maintenance. We offer various models of Bar processing Machines like Bar Bending Machine/TMT bar bending machine, Scrap Bar Straightening Machine, Automatic Rebar Stirrup Machine, Rebar Threading Machine, Bar Cutting Machine, Stirrup Ring Making Machine, Rebar Thread Chaser/ Bar Threading Machine/Rebar Thread Chaser, Bar Decoiling Machine, TMT Bar Cold Forging, Rebar Wire Twister, Rebar Coupler. Please contact smit corporation for Bar Bending Machinery. Please visit https://www.smit-corp.com/shop/ for more details.

0 notes