#High-Pressure Slurry Pump

Explore tagged Tumblr posts

Text

So you’ve written that our attention is getting fracked. What do you mean by that?

D. GRAHAM BURNETT: Fracking. I suspect most of your listeners have heard that term. Fracking is mostly associated with this idea of getting petroleum resources out of the earth. But it’s a new technology for doing that. In the old days, pre major exploitation of petroleum resources, there were these big, juicy zits of high-value crude oil just sitting there in the earth, waiting to geyser up if you tapped them. Drill a hole — whew, gusher.

We’ve tapped all that out. The only way you can get the remaining petroleum and natural gas resources out of the deep earth is to pump down in there high pressure, high volume detergent, which forces up to the surface this kind of slurry, mixture of natural gas, crude oil, leftover detergent, and juice and nasty stuff, which you then separate out, and you get your monetizable crude.

This is a precise analogy to what’s happening to us in our contemporary attention economy. We have a, depending on who you ask, $500 billion, $3 trillion, $7 trillion industry, which, to get the money value of our attention out of us, is continuously pumping into our faces high-pressure, high-value detergent in the form of social media and non-stop content that holds us on our devices. And that pumping brings to the surface that spume, that foam of our attention, which can be aggregated and sold off to the highest bidder.

— D. Graham Burnett, from “Ezra Klein Interviews D. Graham Burnett” (NY Times, May 31, 2024)

22 notes

·

View notes

Text

Smells like Team Spirit

Written for Femslash February 2025

Day 3. Fracture

Series: Glitter Puffs

Title: Smells Like Team Spirit

Ship: Nozomi/Rin

Fandom: Yes Pretty Cure 5

Word Count: 1,749

Rating: T

Warning: None

Tags: Fluff, Established Relationship, Kissing, Slight Injury

“Go Rin, yeah, go, go!” Nozomi yelled from the side of the field.

Rin and her fellow futsal players were out in the grass, beat down by a harsh, summer heat and locked in a passionate tussle with their opponents. Despite these intense conditions, they were playing the best game of their lives. A well oiled machine, drenched in sweat and built up by weeks of practice.

Now, finally, here it was: the semi-finals. Whoever triumphed over the other would be sent straight to the finals and from there? Victory was within their grasp. All they needed was to overcome the currently tied scoreboard. The referees whistled and pointed, the crowd roared as the junior athletes raced across the field.

The formations were tight and well coordinated. Pressure was clearly mounting on both sides. It was all but a stalemate as the soccer ball went back and forth in triangular motions, pummeled by swift, strong kicks and in the instances of the goalie, amazing feats of throwing.

Nozomi was dazzled and she was, by far and large, the number one fangirl on the sidelines. Why wouldn’t she be? Her girlfriend was the extraordinarily capable and fiery ace of the team.

Rin was, without a shadow of a doubt on such a searing day, the MVP by a country mile. Even the opposing team and coach had a gleam of respect and admiration for her in their eyes. Her number coming up the most in shouted advice from the players in green.

Nozomi couldn’t be prouder. She knew Rin and the other girls on her team had worked really hard for this and here it came. The climax of the game. How exciting! Nozomi held her breath and bit her tongue, yet all that amazement had to go somewhere. She thrashed a silent cheer, her pigtails bouncing and her fists flailing, as she tried not to disrupt Rin’s concentration.

Sweat beaded down the side of her face. Rin’s eyes narrowed as she glanced between options, possible ways forward. She ran. Hard. Hard enough to kick up dirt and grass in her wake. She kept consistent with her off-siders, their trusting glances in wait of what Rin was going to do, they would fall her lead off a cliff if they had to.

Rin would never, of course, but it was do or die as time ticked by.

They couldn’t stall. It was now or never.

So Rin took her shot.

It was risky but risk was all they had. She swiped her arms out, to give her as much room from the opposing players as possible. The formation made her feel like an eagle as she lined up the shot in instant speed. She was so far out. Stupidly far out for this kind of kick but Rin didn’t care. Her blood thrummed inside of her as instinct took over and she knew that this was not going to be luck. This was going to be culmination of all her hard work.

Assuming the risk paid off as time all but slowed within Rin’s mind and her perception of the field. The sun must have fried her brain as its rays on her scalp was all she could feel. Everything else melted away in the boiling hot conditions. All that Rin was left was the slurry of what she had to do to get this soccer ball into the rival goal.

The power, the timing, the strength she needed. Rin could feel it in her readied body, adrenaline pumping. All she could see were these calculations across the green grass and the white goal. The metal poles glinted, the net fluttered in the slight breeze and then.

Rin kicked the ball.

It went soaring high. Higher than the players, higher than the crowds. Birds - swallows, Nozomi would think - swooped low and into the blades of grass just to avoid the ball. It spun and it flipped, its shape obscured even that of the sun as everyone watched in awe of Rin’s shoot.

Everyone except the rival goalie.

Her heart must have dropped as she launched herself up, heavy gear and all. Only… to miss.

The ball grazed the top of her armoured head and hit the ground behind her.

“Goal!” the Referee bellowed, a whistle punctuating the announcement - only to blend the sound of the timer being up.

The siren rang through the skies. Birds scattered and people cheered. Rin’s jaw dropped. She did it. She had beaten the buzzer and put the final score on the board. It was changed manually by an opposing team’s manager.

“Point to Cinq Lumières.” the Referee added.

As though it needed to be said at all as celebration erupted on the field. Rin could hardly believe it as people yelled not just for her team but her alone. The other two girls jogged over and patted her on the back. They grinned and slapped hard. Their rivals slow clapped them out, shook hands with them and Rin managed to return such sentiments of true sportsmanship.

All whilst in this stupor of hers. It wasn’t even the finals, yes, but they were within sight - and possibility. What would it be like to win real big and take home the trophy? Rin’s heart seized as she was too humble to explore such possibilities. Her ears rang with tinnitus as she stood, dumbfounded, with her disbelief as more formalities were wrung out over the loudspeaker and such.

It only became real to her when Nozomi bounded over, clumsy and happy as a puppy dog.

“Rin, Rin, Rin!” Nozomi squealed. “I’m so proud of you!”

She flung herself in pride at Rin and Rin managed to catch her. Thankfully. She held her girlfriend around her waist whilst Nozomi continued to launch herself like a missile. Rin had to bend backwards just to make sure Rin didn’t sent them both flying - or worse, crashing.

Nozomi nuzzled against Rin’s cheek. She didn’t mind one bit that Rin stank and was slick with sweat. It was all to the wayside as Nozomi cheered and celebrated.

“Woohoo, you are the greatest, Rin!” Nozomi cheered as she peeled herself back off Rin.

“Not yet I’m not.” Rin chuckled.

“Yes, you are, gimmie a hip, gimmie a hooray, gimmie a… hip-hip hooray!” Nozomi shouted.

All but in Rin’s ears but Nozomi had gotten too carried away in her overbearing joy for Rin. She wobbled on her spot, bent down low and tried to do what she had seen in the movies. She tried to scoop Rin up from her midsection. Her arms slid underneath her, her legs bowed.

She got, maybe, Rin’s right foot off the ground but that was about it. Rin laughed awkwardly whilst Nozomi stretched and strained. To inevitably buckle under her weight - and what she had taken on of Rin’s. Rin was pure muscle despite being such a small size and Nozomi couldn’t handle that at all.

Nozomi went down like a sack of potatoes, head over bum and collapsed. She brought Rin down with her, too. It was ungraceful and klutsy and had them both seeing stars for a minute.

Rin moaned slightly, “A-Are you okay, Nozomi?” She was probably fine. Nozomi had broken her fall and Nozomi had broken her own with her butt but still.

Not a single good noise came out of Nozomi’s mouth.

Rin was in her lap, their legs were entangled. They looked like they should have been in the middle of a gamer of twister, not after a futsal match/ It was so cliche but they had ended up in such a compromising position but not an impossible one. Rin would know, she had all kinds of bumps, bruises, scratches and scrapes thanks to sports injuries.

Which… by the way… now was definitely not the time to get even the slightest graze!

“I… I think I…” Nozomi’s voice was breathy and panicked.

Rin turned her head and saw how Nozomi’s chest went up and down. Her big inhales and even bigger exhales. All of it just to explode in tears.

“I think I broke my ankle!” Nozomi screamed. “I-It really hurts, Rin!”

Rin sighed. “Let me take a look…”

She wriggled out of Nozomi’s lap and turned herself onto her knees. She smiled, sympathetic, at Nozomi as she had a poke and prod. She pushed down Nozomi’s socks, not even a lump or some redness.

“Your all right, Nozomi, not even a fracture. Maybe you just sprained it?” Rin suggested through Nozomi’s hysterics.

Nozomi’s chin turned a strawberry and she had a frantic look of worry in her eyes. She wasn’t sure if she believed Rin or not but surely some as big as her, Cure Dream, should be right as rain because of something as small as falling over on a football field.

Rin picked up Nozomi by the foot. She was all too easy to swing around, being light as a feather and breakable as a stick, apparently. She cupped it and leaned into Nozomi’s leg, felt the prickle of her haphazardly shaved calf and smiled. She pecked Nozomi’s ankle, right where she feared it hurt the most.

Nozomi winced but her expression became a bashful appreciation.

“See? I kissed your booboo all better, c’mon, let’s get up an’ at ‘em.” Rin said.

“Okay.” Nozomi replied, her voice soft and quiet, a scant blush across her face.

Nozomi moved her leg off Rin’s shoulder at her own volition and let Rin get up first. She sported a hefty - and exaggerated - grunt as she all but did a burpee, to express just how fine she felt despite the accidental tumble. Then, Rin offered her hand to Nozomi.

Nozomi accepted it and Rin gave it her all to hold her. Nozomi’s heart fluttered as she felt the tight squeeze of Rin’s calloused hand against her soft palm. Rin grunted and Nozomi almost toppled frontwards this time but Rin eased her back onto the balls of her feet. Only for Nozomi to simper and seethe, ever so slightly under her breath to at least pretend to put on a brave face.

Though just as both expected, Nozomi was ginger on both feet once Rin had her up on them. Rin sighed and shook her head. She let Nozomi use her as a crutch, bringing them both closer, cheek to cheek, as Nozomi hobbled off the field so Rin could go and join her teammates. They had caused quite a scene as it was.

#femslash#femslashfeb2025#femslash february 2025#nozorin#nozomi yumehara#yumehara nozomi#rin natsuki#natsuki rin#yes precure 5#yes precure 5 gogo#writing tag#smells like team spirit#glitter puffs#glitter puffs 2025

3 notes

·

View notes

Note

Hiiiii 🫶 I am so intrigued by Mashal in the best way. If I may, can I ask for an info dump on his ~workings~? Like his systems, what they effect, what happens if something goes wrong? Does he require special upkeep?

You have the wildest, most creative OCs I cannot stress that enough.

Eeee, Sable you make my day <333

To preface, I don't know shit or fuck about mechanical stuff. Changing a car tire is about the upper limit of my expertise. So anything I say about Mashal's hardware came probably exclusively from a google search or some basic assumptions about how pressure works.

But let's start with the basics! Mashal's mind (maybe soul?) is contained within his heart rune. This is a piece of glass tubing arranged into a rough figure-eight shaped rune. An alchemical slurry of brain matter, sorcerous enzymes, and a certain species of magically mutated bacteria flow through this tubing in a constantly circulating closed circuit. All of this is contained in a little box in the center of his chest. Really, this heart rune is all that Mashal is. His metallic body can take all sort of damage, but the heart rune is self-contained, so as long as it remains undamaged, he'll live. Aside from actually breaking the rune, one of the few things Mashal is susceptible to is high temperatures, as the cells will start to denature. Cold, he tolerates a little easier, but excessive heat will kill him or at least fry his brain a bit. He tends to get kind of loopy once the outside temp hits around 110°F. Astra is working on a cooling system to solve this problem, however, it's pretty difficult to introduce new runes to the casing of his heart rune when she barely knows how the heart rune works.

His heart rune is connected to a central hydraulic pump by way of some linkage runes (these are more traditionally etched runes. Actually, his heart rune with its alchemical tubing is really weird so far as magic goes.) That central hydraulic pump powers the rest of his body by not only fluid mechanics, but also by using the presence of hydraulic fluid as an activation condition for even more runes, mainly sensory and gravitation. The gravitation specifically makes him a bit lighter, so his mechanical bits don't have to work as hard. Gravitation runes also keep his central hydraulic pump constantly moving without the need for an outside fuel source.

On to upkeep! Mashal has bigger fish to fry over the course of the couple of months the Mortal God series takes place in, so he's not the best about this, but he does need a good deal of upkeep to function. Fluid quality is a big one, since unwanted precipitates in the hydraulic fluid can scratch runes and make them unusable. This is one area Astra has to help him in, as for a full oil change, he'll essentially be disconnected from his body. Any other maintenance that has to be done on a hydraulic system, he probably has to do a few times a year. The only major difference is that he also has to re-etch all his runes once a year or so, just to make sure there are no cracks or rust that might interrupt the shape. Thankfully, his heart rune is designed to function indefinitely without interference, so he doesn't have to mess with that one too much.

As for if something goes wrong, that sort of depends on the something. I already mentioned the heat thing, but if he's low on hydraulic fluid, his movements will be sluggish and he'll have blackout moments where his vision and hearing cuts out. Actually, now that I mention senses, Mashal really only has hearing and sight. He's got a rudimentary pressure sensor so he doesn't crush everything he grabs, but that doesn't do anything for texture or tactile sensation. Astra built him a rudimentary temperature sensor, but that's more like a little HUD that tells him how hot an object he's touching is. He can't feel pain or exhaustion, though his mind remembers being human enough that he can feel phantom pain.

As for how Mashal feels about this... He honestly really hates doing upkeep on his body. It feels like admitting he'll be stuck in it forever, and he doesn't like to think about being a machine if he doesn't have to. He's perturbed also by the fact that, if he does proper upkeep, he's effectively immortal, at least in terms of aging. Thankfully, Astra's always there to talk him through things. She's incredibly adamant about keeping him in good working order and takes pride in teaching him how to do his own repairs. She also does frequently try to talk him into letting her do crazy mods on him, like a retractable sword arm or hidden recorder or built-in heelies. So far, only the sword arm has made it in, but she'll keep trying.

Ok I think this has gotten long enough, mayhaps, but please let me know if you have any questions! And thanks so much for the ask :)

6 notes

·

View notes

Text

A farmer in Edinburgh, Scotland is understandably rather angry after around 1,000 cars were parked on his field without permission. Around 200 vehicles were left in the field overnight, and Farmer Willie got little support from local Police.

Apparently, the same thing happened in 2019. Why the hell did the farmer not learn from this previous experience? As I see it, he had two possible options... Either make the field inaccessible by strengthening fences and gates, and/or digging a trench. Or, take the opportunity to make some extra money by advertising the field as "additional parking", and charging vehicles to use it.

Farmer Willie did not want risk confrontation by blocking the illegally parked vehicles, but, he could have punished the crop-destroying drivers by deploying a cow poo cannon... I mean, muck spraying the field that evening!

I had a small problem on my Dorset farm in 2019, when Bottom Pasture (the field furthest from any of the farm buildings) was advertised on social media as being the location of an illegal rave.

I was alerted to this by my cyber team in the City of London (who removed the ad from the internet). Dorset Police showed little (if any) interest... so I set up my own security arrangements. I replaced the wooden gate with a heavy metal one, set up temporary security cameras and, my secret weapon: The Cow Poo Cannon... an 18,000 litre tanker with a high-pressure pump and hose, filled with cow slurry, strategically positioned.

On the advertised date of the illegal rave it was very wet and windy. Nothing happened, except the security cameras being knocked out of position. We moved the Cow Poo Cannon back to a more secure area closer to farm buildings, and breathed a sigh of relief.

I think it was four days later, a neighbour alerted me that around 40 cars were blocking the narrow lane outside Bottom Pasture. (I think he exaggerated the number of cars.)

I phoned Dorset Police... Estimated response time: 2 hours... Advice: Do not intervene. Fools!

My two Czech farmhands took a tractor out to drag the Cow Poo Cannon back into position, Farmer Frank took a tractor out onto the road to block the narrow lane, and I drove the Land Rover over the fields.

I got there first. There were only six cars that I could see... but, as soon as they saw me approaching the revellers tried to get away. Two cars managed to escape before Frank blocked the road, one crashed into a wall and another tried to escape by driving across a field before being abandoned when it got stuck in the mud.

I had had a drink or two, so I didn't risk taking the Land Rover down the steep hill... instead, I ran towards the little gits shouting, aggressively!

Two Police cars turned up (much quicker than expected) before I got to confront any of the intruders face-to-face. I was restrained by two Police Officers, one of them a Sergeant. I was officially cautioned and bundled into the back of a Police car after I made remark questioning the Sergeant's intellect and parentage!

Only eight arrests were made that night (not including me), and only three were charged... 2 with drug related offences, and 1 for carrying a knife. (The two abandoned cars were both stolen vehicles.)

Unfortunately, my two devoted Czech farmhands had been on the Vodka that night... so it took them a little longer than it should have done to hook up the Cow Poo Cannon to the tractor... I would have loved to see them cover the Police cars with muck!

10 notes

·

View notes

Text

Center Enamel – China's Premier Epoxy Coated Steel Desalinated Water Tanks Manufacturer

Innovating Desalinated Water Storage Solutions: Center Enamel – China's Premier Epoxy Coated Steel Desalinated Water Tanks Manufacturer

In today's rapidly evolving water management landscape, efficient and sustainable storage solutions for desalinated water are not just a necessity—they are a critical component in addressing global water scarcity and quality challenges. At Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel), we are redefining industry standards as China's leading manufacturer of epoxy coated steel desalinated water tanks. Our forward-thinking approach and commitment to questioning conventional practices enable us to deliver products that are as resilient as they are innovative.

As a leading storage tank manufacturer worldwide. Center Enamel can provide Glass-Fused-to-Steel (GFS) tanks, fusion bonded epoxy tanks, stainless steel tanks, galvanized steel tanks and aluminum geodesic dome roofs, Wastewater and Biogas Project Equipments for global customers.

Configuration of Customized Storage Tanks

Storage tanks

Volume

Roofs

Application

Design Requirements

GFS Tanks

SS Tanks

Fusion Bonded Epoxy Tanks

Galvanized Steel Tanks

Welded Steel Tanks

<1000m³

1000-10000m³

10000-20000m³

20000-25000m³

>25000m³

ADR Roof

GFS Roof

Membrane Roof

FRP Roof

Trough Deck Roof

Wastewater Treatment Project

Drinking Water Project

Municipal Sewage Project

Biogas Project

Fire Water Storage Project

Oil Storage Project

Water Supply & Drainage System

Seismic Design

Wind Resistant Design

Lightning Protection Design

Tank Insulation Design

WasteWater Treatment Project Equipment Supply

Pretreatment Equipment

Resource Utilization System

Sludge Treatment System

Other Equipment

Mechanical Bar Screen

Solid-liquid Separator

Submersible Mixer

Gas Holder

Boiler System

Boost Fan

Biogas Generator

Torch System

Dehydration and Desulfurization Tank

PAM Integration Dosing Device

Screw Sludge Dewatering Machine

Slurry Separation Centrifuge

Sewage Pump

Mud Scraper

Submersible Sewage Pump

Three-phases Separator

Advanced Epoxy Coated Steel Technology

Our state-of-the-art epoxy coated steel tanks are engineered using cutting-edge fusion-bonded epoxy technology. This innovative process ensures:

Superior Corrosion Resistance: The advanced epoxy coating creates a durable barrier that protects steel from the harsh effects of desalinated water, significantly extending the lifespan of each tank.

Uniform, Defect-Free Coatings: Every tank undergoes rigorous testing—including high-voltage evaluations—to guarantee a consistent, defect-free finish that meets the highest industry benchmarks.

Enhanced Structural Integrity: By combining robust steel construction with a high-performance epoxy coating, our tanks deliver unmatched strength and reliability even under extreme operating conditions.

At Center Enamel, we continually ask: How can we further improve the durability of our coatings to meet the demands of tomorrow's water storage challenges?

Uncompromising Quality Control and International Compliance

Quality is the cornerstone of our manufacturing process. Our epoxy coated steel desalinated water tanks are subject to 100% factory testing and stringent quality inspections, ensuring full compliance with international standards such as ISO 28765:2016 and AWWA D103-19. This rigorous quality control framework inspires confidence that every tank we produce is built to last and perform under pressure.

Key Quality Assurance Features Include:

Comprehensive Testing Protocols: Each tank is meticulously evaluated to detect even the slightest imperfections, ensuring zero defects before leaving our facility.

Third-Party Validation: We actively seek independent assessments to confirm that our products not only meet but exceed global safety and environmental standards.

Continuous Improvement: By questioning traditional testing paradigms and embracing innovative methodologies, we ensure our quality control processes evolve with industry demands.

Customizable Solutions for Diverse Global Needs

Desalinated water storage requirements vary widely—from municipal water treatment facilities to industrial applications and agricultural uses. Recognizing this diversity, Center Enamel offers customizable tank designs tailored to the specific needs of our customers.

Our Customization Capabilities Include:

Variable Sizes and Capacities: Whether for large-scale municipal projects or specialized industrial applications, our tanks can be designed to fit any capacity requirement.

Flexible Configurations: From standard to bespoke configurations, our engineering team collaborates with clients to optimize tank design for operational efficiency and ease of maintenance.

Adaptability to Environmental Conditions: Our tanks are engineered to perform reliably in a range of environmental conditions, ensuring robust performance regardless of geographical location or climate challenges.

By challenging the one-size-fits-all approach, we are pioneering solutions that are as versatile as they are dependable.

A Commitment to Sustainability and Eco-Friendly Design

In an era where environmental sustainability is paramount, Center Enamel is dedicated to creating products that contribute to a greener future. Our epoxy coated steel desalinated water tanks are designed not only for superior performance but also for minimal environmental impact.

Sustainability Initiatives:

Reduced Maintenance Footprint: The corrosion-resistant properties of our tanks lead to lower maintenance requirements and longer service life, reducing resource consumption over time.

Eco-Friendly Manufacturing Practices: We continually refine our production processes to minimize waste and energy usage, ensuring our operations are as sustainable as our products.

Future-Ready Innovation: We are proactive in anticipating evolving environmental regulations and integrating eco-friendly innovations into every stage of our manufacturing process.

We remain critically inquisitive—always exploring how our technologies can further reduce environmental impacts and promote sustainable water management practices.

Future-Proofing Through Continuous Innovation

At Center Enamel, we understand that standing still is not an option in a fast-changing world. Our commitment to continuous research and development means we are always seeking better ways to design, test, and refine our products.

Our Vision for the Future Includes:

Adapting to Emerging Challenges: We actively engage with industry experts and regulatory bodies to anticipate and address future water storage challenges.

Investing in Next-Generation Materials: By exploring new materials and coating techniques, we aim to further enhance the performance and longevity of our tanks.

Embracing a Culture of Questioning: We encourage a healthy skepticism of the status quo, constantly asking critical questions to drive innovation and maintain our competitive edge.

This relentless pursuit of excellence ensures that Center Enamel remains at the forefront of the desalinated water storage industry, ready to meet the demands of an ever-evolving market.

Building a Sustainable, Resilient Future Together

As the global water crisis intensifies, the need for reliable, sustainable storage solutions becomes ever more critical. Center Enamel stands ready to lead the way with our advanced epoxy coated steel desalinated water tanks—products designed with precision, built with quality, and continually refined through innovation.

We invite industry leaders, partners, and forward-thinking customers to join us on a journey towards a more resilient and sustainable water management future. Together, we can challenge current limitations, embrace new possibilities, and ensure a reliable water supply for generations to come.

0 notes

Text

Choosing the Right Pump for Your Industry: Ace Lobe Pump vs. Rotary Lobe Pump

In industrial fluid handling, selecting the appropriate pump is crucial for maintaining efficiency and ensuring the longevity of the system. Pumps are designed to transport a variety of liquids, from viscous substances to those containing solids, and they must operate reliably under demanding conditions. The Ace Lobe Pump and the Rotary Lobe Pump are two popular options that stand out for their precision and versatility. This article will explore their unique features, helping industries determine which pump best meets their needs.

Understanding the Ace Lobe Pump

The Ace Lobe Pump is a type of positive displacement pump that uses rotating lobes to transfer liquids efficiently. Its design makes it ideal for handling viscous or shear-sensitive fluids, such as those found in the food, cosmetic, and pharmaceutical industries. The Ace Lobe Pump offers a gentle pumping action that helps preserve the integrity of the liquid being transferred, making it perfect for delicate substances like creams, sauces, and pastes. Its ability to maintain consistent flow with minimal pulsation ensures smooth operations, which is crucial for industries that prioritize quality and consistency in their products.

Why Choose the Ace Lobe Pump?

One of the major advantages of theAce Lobe Pump is its versatility in handling various fluid types. From low-viscosity liquids to thick, viscous materials, this pump can handle them with ease. Its positive displacement technology ensures that a consistent volume of fluid is pumped at each cycle, preventing fluctuations in pressure and maintaining flow rates. This makes the Ace Lobe Pump a reliable option for industries that require precise fluid management. The ability to handle shear-sensitive liquids without causing damage further adds to its appeal, ensuring that sensitive products maintain their integrity throughout the pumping process.

The Rotary Lobe Pump: Robust and Reliable

On the other hand, the Rotary Lobe Pump is known for its robust construction and high-performance capabilities, especially when dealing with more challenging fluids. This pump uses two or more rotating lobes inside the pump chamber to move fluids. It is ideal for applications where the pumped liquid is abrasive, contains solids, or has high viscosity. The Rotary Lobe Pump excels in environments where other pumps might struggle, as it can handle thicker, more complex fluids with ease. Its ability to manage a wide range of substances, from slurries to chemicals, makes it a versatile and durable option for many industries.

Advantages of the Rotary Lobe Pump

The Rotary Lobe Pump stands out in situations where high suction capabilities and minimal pulsation are required. The design allows it to efficiently handle abrasive fluids and those containing high solids content, making it a go-to choice for industries like wastewater treatment, mining, and chemical processing. Its low-maintenance nature and ability to run at high pressures also contribute to its efficiency in harsh conditions. With its minimal pulsation and high suction capabilities, the Rotary Lobe Pump ensures a steady and consistent flow, even under difficult operational circumstances.

Choosing Between the Ace Lobe Pump and Rotary Lobe Pump

When selecting between the Ace Lobe Pump and the Rotary Lobe Pump, industries must consider the specific needs of their fluid systems. The Ace Lobe Pump is ideal for handling shear-sensitive, delicate fluids that require a gentle and consistent flow, making it perfect for food and pharmaceutical applications. Meanwhile, the Rotary Lobe Pump is better suited for industries that deal with more challenging materials, such as abrasive liquids, slurries, or those with solid particles. Both pumps offer significant advantages, but the key lies in understanding the nature of the fluid being pumped and the overall system requirements.

Conclusion

In conclusion, both the Ace Lobe Pump and the Rotary Lobe Pump offer exceptional performance, but their suitability depends on the specific fluid handling needs of a given industry. For gentle, precise pumping of delicate liquids, the Ace Lobe Pump is an excellent choice. On the other hand, for more demanding fluids, the Rotary Lobe Pump provides the necessary robustness and versatility. For more information on these pumps and their applications, visit Acelobepump.com, where more details and solutions are available.

0 notes

Text

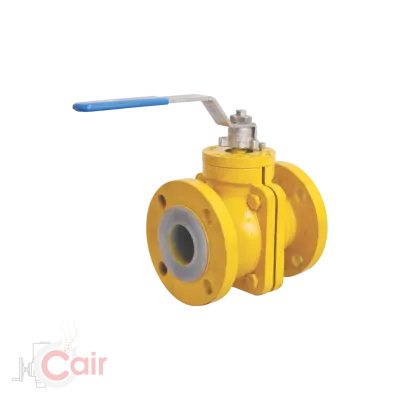

What Is a Ball Valve? A Complete Guide to Its Function and Uses

Ball valves are one of the most commonly used types of valves in industries worldwide. Their design and versatility make them ideal for controlling the flow of various fluids and gases. This comprehensive guide will explore what a ball valve is, how it functions, and its various applications, along with insights into the ball valve manufacturing industry in India.

What is a Ball Valve?

A ball valve is a type of valve that uses a spherical ball to control the flow of media (liquids, gases, or slurries) through a pipe or system. The ball has a hole or port through the center, which aligns with the flow path when the valve is open. When the valve is closed, the ball rotates 90 degrees, blocking the flow path and preventing the passage of the media.

The simplicity of this design allows for quick and efficient operation. Ball valves are known for their durability, reliability, and ability to maintain a tight seal even after long periods of use.

How Does a Ball Valve Work?

A ball valve consists of several key components, including the body, the ball, the stem, and the handle or actuator. The ball is mounted inside the valve body, with the hole or port aligned with the flow path when the valve is open. When the valve handle is turned, the stem rotates the ball, either opening or closing the valve.

The flow direction and the valve's status (open or closed) are determined by the orientation of the ball. In the open position, the flow passes through the hole in the ball, allowing the fluid or gas to move through the valve. In the closed position, the ball rotates 90 degrees, blocking the flow entirely.

One of the key features of ball valves is their ability to create a tight seal. The design ensures minimal leakage, even in high-pressure applications, making them highly reliable in various industries.

Types of Ball Valves

There are different types of ball valves, each suited for specific applications. The most common types include:

Standard Ball Valve: This is the most basic type of ball valve, ideal for simple on/off applications.

V-Port Ball Valve: This valve has a V-shaped ball, which allows for precise flow control, making it suitable for throttling applications.

Multi-Port Ball Valve: These valves have multiple ports, allowing for directional flow control and bypassing multiple channels. They are used when more complex flow control is needed.

Trunnion Ball Valve: A trunnion ball valve has a ball that is supported by bearings, allowing for larger sizes and higher-pressure applications.

Uses of Ball Valves

Ball valves are widely used across different industries due to their efficiency and reliability. Some of the key applications include:

Oil and Gas: Ball valves are essential in oil and gas systems for controlling the flow of crude oil, natural gas, and other fluids. Their ability to withstand high pressures and temperatures makes them ideal for this industry.

Water Treatment: In water treatment plants, ball valves are used to control the flow of water and chemicals. They are often found in filtration systems, distribution lines, and pumping stations.

Chemical Processing: Chemical plants use ball valves to manage the flow of various chemicals, ensuring safe and controlled operations. The tight seal offered by ball valves minimizes leaks and contamination.

HVAC Systems: In heating, ventilation, and air conditioning (HVAC) systems, ball valves regulate the flow of fluids used for heating and cooling purposes.

Food and Beverage: In the food and beverage industry, ball valves ensure the smooth flow of ingredients, liquids, and gases, as well as maintain hygienic conditions.

Pharmaceuticals: Ball valves are also critical in the pharmaceutical industry, where cleanliness and precise flow control are required for producing medicines and vaccines.

Why Choose Ball Valves?

There are several reasons why ball valves are favored in various industries:

Durability: Ball valves are highly durable and can withstand harsh operating conditions, such as extreme temperatures and high pressures.

Leak-Proof Performance: Ball valves are designed to provide a tight seal, preventing leaks even in demanding applications.

Ease of Operation: With a simple 90-degree turn, ball valves are easy to operate and provide quick response times.

Versatility: They can be used for a wide range of applications, from small-scale systems to large industrial plants.

Low Maintenance: Due to their robust design and minimal moving parts, ball valves require little maintenance compared to other types of valves.

India has become a significant player in the global valve manufacturing industry, with many reputable ball valve manufacturers producing high-quality valves. A ball valve manufacturer in India is equipped with advanced technology and expertise to meet the growing demand for industrial valves in various sectors.

These manufacturers use state-of-the-art materials and rigorous quality control processes to ensure that their products meet international standards. As a result, India's ball valve manufacturers are well-positioned to cater to both domestic and international markets, offering products that are durable, reliable, and cost-effective.

Conclusion

Ball valves are essential components in many industries, offering excellent control and reliability in fluid and gas handling systems. Their simple design, combined with a tight seal, makes them an ideal choice for various applications. Whether in oil and gas, water treatment, or pharmaceuticals, ball valves continue to play a crucial role in ensuring smooth and safe operations. As the demand for high-quality valves grows, ball valve manufacturers in India are playing a crucial role in supplying the global market with reliable and durable valves to meet diverse industry needs.

0 notes

Text

The Power of Cast Elastomers in Rugged Industries

In industries that operate under harsh conditions—such as Oil & Gas, Mining, Automotive, and heavy-duty manufacturing—finding materials that can endure relentless wear and tear is a critical challenge. Traditional materials often fall short, leading to frequent replacements, increased downtime, and higher operational costs. Enter cast elastomers: a versatile solution that combines durability, flexibility, and exceptional resistance to extreme environments. These materials are transforming how businesses approach efficiency and longevity, proving to be a game-changer across various sectors.

What Are Cast Elastomers?

Cast elastomers are a specialized type of polyurethane material created by combining polyols and isocyanates through a casting process. This method allows for precision customization, enabling manufacturers to tailor the material’s properties to meet specific requirements. Cast elastomers can be engineered for shock absorption, abrasion resistance, chemical durability, and more. They are designed to thrive in environments where traditional materials often fail, making them an ideal choice for industries that demand resilience and reliability.

Why Are Cast Elastomers

The global cast elastomer market was valued at USD 1.4 billion in 2023 and is projected to reach USD 1.8 billion in 2028, growing at 5.0% cagr from 2023 to 2028. The market is mainly led by the significant usage of cast elastomers in various end-use industries. The increasing industrialization and manufacturing activities in emerging economies coupled with the superior advantage of cast elastomers over conventional materials are driving the market for cast elastomers.

The significance of cast elastomers lies in their versatility and performance in extreme conditions. Let’s explore how they are making an impact across key sectors:

1. Oil & Gas: Built for the Tough Stuff

The Oil & Gas industry operates in some of the most punishing environments imaginable. Drilling rigs, pipelines, and offshore operations face high pressures, extreme temperatures, and corrosive chemicals daily. Cast elastomers are particularly suited for these applications due to their ability to withstand such harsh conditions.

Common uses include seals, gaskets, and pipeline linings—components that are critical for safety and operational efficiency. For instance, cast elastomers play a vital role in blowout preventers (BOPs), which are essential safety devices on oil rigs. Their durability ensures reliability under immense stress, leading to fewer breakdowns and enhanced safety measures. This translates to less downtime and significant cost savings for operators.

2. Mining: Taking a Beating Day After Day

Mining operations are synonymous with brute force and constant abrasion. Equipment like conveyor systems, slurry pumps, and screening machinery endure relentless wear as they process materials. Cast elastomers excel in this environment by offering exceptional resistance to wear and tear.

For mining companies, switching to cast elastomers often means fewer equipment replacements and reduced maintenance costs. These materials can absorb impacts and resist abrasions effectively, allowing them to take the beating that comes with heavy-duty operations. This durability not only saves money but also minimizes disruptions in production schedules.

3. Automotive & Transportation: Comfort Meets Strength

In the automotive industry, cast elastomers play a crucial role in enhancing vehicle performance and comfort. From suspension systems to engine seals, these materials contribute significantly to the overall functionality of vehicles.

Their shock-absorbing qualities improve ride comfort by reducing vibrations while driving. Additionally, cast elastomers resist oils, greases, and other fluids commonly encountered in automotive applications, ensuring that components last longer without degradation. Heavy-duty vehicles like trucks and buses particularly benefit from these properties as they endure constant vibrations and heavy loads without cracking or failing.

4. Industrial Manufacturing: Keeping the Line Moving

In manufacturing environments where efficiency is paramount, downtime can be detrimental. Cast elastomers help keep production lines running smoothly by powering conveyor belts, rollers, and wheels. Their ability to resist abrasion means less frequent repairs and maintenance.

Moreover, cast elastomers are used in vibration-dampening applications that protect expensive machinery from wear caused by constant motion. For industrial operations looking for reliability and cost-effectiveness, integrating cast elastomers into their processes is a strategic choice.

What Makes Cast Elastomers Stand Out?

Several key attributes set cast elastomers apart from traditional materials:

Unbeatable Durability: Designed to last in the most punishing environments.

Customizable Properties: Manufacturers can tailor hardness levels, softness, heat resistance, and other characteristics based on specific needs.

Chemical Resistance: They withstand exposure to oils, fuels, and harsh chemicals without degrading.

Cost-Effectiveness: Their longevity translates into savings on replacements and repairs.

Extreme Environment Ready: Capable of performing well in both scorching heat and freezing cold conditions.

The future looks promising for cast elastomers as manufacturers continue to innovate. There is a growing trend toward sustainable options such as bio-based elastomers to meet increasing environmental demands. Additionally, advancements in 3D printing technology may unlock new possibilities for precision manufacturing with cast elastomers.

These innovations mean even more opportunities for industries reliant on high-performance materials to maximize efficiency while reducing costs.

Download PDF Report Insights :

For businesses operating in Oil & Gas, Mining, Automotive, or Industrial sectors, investing in cast elastomers could be the upgrade you've been waiting for. These materials offer more than just durability; they provide solutions that can improve your bottom line by enhancing efficiency and extending equipment life.

In an era where every dollar counts, choosing a material as tough and reliable as cast elastomers makes perfect sense. By embracing these resilient powerhouses, you can tackle your toughest challenges head-on while future-proofing your business against the ever-changing demands of the industrial landscape.

In summary, while cast elastomers may not be the most glamorous material on the market, their impact across industries is undeniable. They deliver reliability and adaptability—exactly what is needed in demanding sectors like Oil & Gas, Mining, Automotive, and Industrial manufacturing—making them an essential consideration for any business looking to thrive in challenging environments.

#CastElastomers#IndustrialMaterials#DurableSolutions#OilAndGas#MiningIndustry#AutomotiveComponents#IndustrialApplications#MaterialScience#RuggedIndustries#WearResistance#PolyurethaneSolutions#EngineeringMaterials#HeavyDutyApplications#CustomElastomers#IndustryInnovation

0 notes

Text

Meghmani Metal Industries is a Prominent Stainless Steel Flexible Hose Pipe Supplier in Uttar Pradesh. Our manufacturing unit is in Ahmedabad, Gujarat, India. We offers high-quality stainless steel flexible hose pipe solutions to meet the needs of various industries. Meghmani Metal Industries is known for delivering reliable, durable, and cost-effective products with excellence and innovation. We deliver cost-effective solutions without compromising on quality, making our products ideal for optimizing operations. Features of Our Hose Pipes: Durability: Made from high-quality materials like PVC, rubber, and stainless steel, our hose pipes are built to withstand high pressure, temperature variations, and rough conditions.Flexibility: We design our stainless steel flexible hose pipe to bend and maneuver easily, making them ideal for complex setups and spaces. Corrosion Resistance: Our stainless steel flexible hoses are resistant to corrosion, ensuring longevity even in harsh environments. Weather Resistance: Resistant to UV rays, ozone, and extreme weather conditions, making them perfect for both outdoor and indoor applications. Leak-proof Design: Our stainless steel flexible hose pipes feature leak-proof connections and fittings to ensure a safe and secure flow. Applications of Hose Pipes: Chemical Industry: Transferring chemicals, oils, and other hazardous materials. Agriculture: Used in irrigation systems, liquid fertilizer delivery, and pesticide spraying. Automotive: Cooling systems, fuel, and air transfer systems in vehicles. Construction: For pumping water, transporting sand, and other construction materials. Food & Beverage: Transferring liquids like water, juice, milk, or oils in the food processing industry. Mining: Used for slurry handling and fluid transfer in mining operations. FAQs: What is the maximum pressure capacity of your hose pipes?We design our stainless steel flexible hose pipes to handle high-pressure conditions, with capacity varying by material type. Rubber and stainless steel hoses can withstand pressures up to 5000 psi. Are your hose pipes resistant to extreme temperatures?Yes, we design our stainless steel flexible hose pipe to withstand a wide range of temperatures, from extremely cold to high-temperature environments. Meghmani Metal Industries is Stainless Steel Flexible Hose Pipe in Uttar Pradesh, India Including Agra, Aligarh, Amroha, Ayodhya, Azamgarh, Bahraich, Ballia, Banda, Bara Banki, Bareilly, Basti, Bijnor, Bithur, Budaun, Bulandshahr, Deoria, Etah, Etawah, Faizabad, Farrukhabad-cum-Fatehgarh, Fatehpur, Fatehpur Sikri, Ghaziabad, Ghazipur, Gonda, Gorakhpur, Hamirpur, Hardoi, Hathras, Jalaun, Jaunpur, Jhansi, Kannauj, Kanpur, Lakhimpur, Lalitpur, Lucknow, Mainpuri, Mathura, Meerut, Mirzapur-Vindhyachal, Moradabad, Muzaffarnagar, Partapgarh, Pilibhit, Prayagraj, Rae Bareli, Rampur, Saharanpur, Sambhal, Shahjahanpur, Sitapur, Sultanpur, Tehri, Varanasi. For more information or to place an order, contact Meghmani Metal Industries today! View Product: Click Here Read the full article

0 notes

Text

Biogas in Kerala: Purification, Enrichment, and Utilization

Kerala, renowned for its commitment to sustainability, has been at the forefront of renewable energy initiatives. Among these, biogas technology has emerged as a crucial solution for waste management and energy generation. In this article, we explore biogas purification, enrichment, and utilization, emphasizing its transformative potential in Kerala.

What is Biogas?

Biogas is a renewable energy source produced through the anaerobic digestion of organic waste such as agricultural residues, kitchen waste, and animal manure. Composed primarily of methane (CH4) and carbon dioxide (CO2), biogas can be used for cooking, heating, and electricity generation. However, to maximize its utility, biogas requires purification and enrichment.

Biogas Purification

Raw biogas contains impurities like carbon dioxide, hydrogen sulfide (H2S), and water vapor, which can corrode equipment and reduce energy efficiency. Purification is essential for enhancing its quality and usability. The key steps in biogas purification include:

H2S Removal: Hydrogen sulfide is toxic and corrosive. Techniques such as activated carbon filters or iron oxide scrubbers are used to eliminate H2S.

CO2 Separation: Carbon dioxide reduces the calorific value of biogas. Membrane separation and pressure swing adsorption (PSA) are popular methods to remove CO2.

Dehumidification: Moisture in biogas can lead to pipeline blockages and equipment damage. Condensers and drying agents are employed to reduce water content.

Biogas Enrichment

Biogas enrichment involves increasing its methane concentration to achieve properties similar to natural gas. Enriched biogas, also known as biomethane, has a methane content of over 90%, making it suitable for applications like:

Compressed Biogas (CBG): Biomethane can be compressed and used as an alternative to CNG (Compressed Natural Gas) in vehicles.

Grid Injection: Enriched biogas can be injected into natural gas pipelines, expanding its accessibility.

Utilization of Biogas in Kerala

Kerala’s abundant organic waste offers immense potential for biogas production. With the state’s focus on decentralized waste management and clean energy, biogas plants are being set up across urban and rural areas. Here are some key utilization scenarios:

Household Applications:

Biogas generated from kitchen waste is widely used for cooking, reducing dependence on LPG.

Agricultural Use:

Farmers utilize biogas for powering irrigation pumps and other agricultural machinery.

The slurry from biogas plants serves as a nutrient-rich organic fertilizer.

Commercial and Industrial Use:

Hotels, hospitals, and industries in Kerala are adopting biogas systems for waste management and energy needs.

Transport Sector:

The state is exploring the potential of CBG as a sustainable fuel for public and private transportation.

Challenges and the Way Forward

While Kerala has made significant strides in biogas adoption, challenges such as high initial investment, lack of technical expertise, and maintenance issues remain. To overcome these barriers, the following measures can be taken:

Government Support: Subsidies, tax incentives, and awareness campaigns can encourage wider adoption.

Technological Advancements: Innovations in biogas purification and enrichment technologies can reduce costs and enhance efficiency.

Training and Capacity Building: Educating stakeholders about biogas plant operation and maintenance is crucial for long-term success.

Conclusion

Biogas in Kerala holds immense promise for addressing waste management challenges and promoting clean energy. By focusing on purification, enrichment, and efficient utilization, the state can set an example for sustainable energy practices. Embracing biogas technology not only contributes to environmental conservation but also paves the way for energy self-reliance.

#biogas in kerala#biogas plant for home#incinerator manufacturers in kerala#biogas#kerala#portable biogas plant for home#incinerators in kerala

0 notes

Text

Microlite : The Ultimate Low-Density Filler for High-Strength Oilfield Applications

Microlite, a type of glass microsphere, is a groundbreaking material known for its lightweight, high strength properties. These hollow spheres are extensively utilized in the oil and gas industry to enhance drilling fluid performance, reduce wellbore stress, and improve cementing efficiency. Their low-density structure minimizes hydrostatic pressure during drilling, enabling safer and more effective operations in deep and challenging reservoirs. Additionally, microlite contributes to better thermal insulation and increased durability of materials, making it an indispensable component in modern oilfield applications. As the leading suppliers of glass microspheres in Indiaand suppliers of glass microspheres across the globe, we take pride in delivering unparalleled quality and precision with every product. Recognized as one of the leading sellers of glass microspheres, we consistently deliver solutions that redefine standards, combining advanced technology with customer-focused service. Whether you are seeking cutting-edge materials for industrial applications or high-performance microspheres for specialized needs, Petra Microlite is your go-to partner.

MICROLITE GM 40 and GM 46, our premium hollow glass microspheres, and their crushing strength makes them the optimal choice for cementing slurry applications in oil and gas operations.

Why Crushing Strength Matters:

The crushing strength of Microlite GM 40 and GM 46 is a defining feature, making them ideal for the most demanding cementing applications.

MICROLITE GM 40:

Compressive Strength: 28/4000 psi

This ensures that GM 40 remains intact even in medium-pressure environments, where alternatives like cenospheres or perlite may collapse, leading to slurry performance issues.

MICROLITE GM 46:

Compressive Strength: 41/6000 psi

With even higher strength, GM 46 is engineered for high-pressure and high-temperature (HPHT) zones, ensuring it maintains its structural integrity and performance under extreme conditions.

Precise Advantages of GM’s Crushing Strength:

Enhanced Durability:

The high crushing strength of Microlite GM microspheres ensures they do not collapse under pressure, unlike cheaper fillers. This results in more stable slurry performance, even in deep wells or HPHT environments.

Improved Operational Reliability:

Crushing strength allows Microlite GM 40 and GM 46 to endure the intense pumping and mixing pressures without losing their integrity. This means fewer failures and reduced risk of costly rework due to compromised slurry.

Better Slurry Control:

The microspheres' durability helps maintain a consistent slurry density, which is essential for optimal cementing results. This leads to better fluid flow and reduces risks like lost circulation or poor zonal isolation.

Examples Where GM Excels:

HPHT Environments:

In challenging high-pressure zones, MICROLITE GM 46 provides superior strength, unlike alternative fillers that may fail, ensuring both the stability of the cement and the overall well integrity.

High-Risk Cementing Applications:

For weak or fractured formations, MICROLITE's high crushing strength ensures that slurry remains stable during pumping and placement, reducing the risk of lost circulation or gas migration.

Improved Well Integrity:

The durability of Microlite GM 40 and GM 46 ensures enhanced zonal isolation, leading to better long-term well integrity, which directly translates into higher ROI through better production and reduced repair costs.

CONCLUSION:

As the leading suppliers of glass microspheres in India and across the globe, we take pride in delivering unparalleled quality and precision with every product. At PETRA INDUSTRIES, we combine innovation and expertise to meet the diverse needs of industries worldwide, ensuring exceptional performance and reliability. Our commitment to excellence has established us as trusted sellers of glass microspheres, offering solutions that empower businesses to achieve their goals. Choose Microlite for superior quality, unmatched service, and a proven reputation as the preferred glass microsphere supplier in India and beyond. Experience the difference with Microlite – where quality meets innovation.

youtube

0 notes

Text

High Flow High Head Pump Solutions in the UAE: Revolutionizing Industrial Efficiency

In industries across the UAE, reliable pump systems are critical for ensuring smooth operations, especially in high-pressure environments. High Flow High Head Pumps are becoming increasingly popular in industries where high efficiency and effective fluid transfer are paramount. Whether used for water treatment, agriculture, or industrial applications, these pumps are designed to handle high-flow, high-pressure situations with ease. If you are looking for cutting-edge solutions, investing in these pumps is a step toward boosting productivity and ensuring operational reliability.

Why Choose High Flow High Head Pumps for Your Industrial Needs?

The High Flow High Head Pump UAE is known for its versatility and robust design, making it a great fit for a variety of industries. These pumps are specifically engineered to handle high-pressure and high-flow applications. They provide an unmatched level of efficiency in transferring liquids, even under extreme conditions. Whether for lifting water from deep reservoirs, pumping heavy liquids, or transferring fluids at great distances, these pumps offer outstanding performance that meets the demands of industrial sectors.

The robust materials used in these pumps ensure longevity and durability, minimizing downtime and maintenance needs. Furthermore, these pumps are energy-efficient, reducing operational costs while maintaining high performance.

Applications of High Flow High Head Pumps in the UAE

The UAE’s diverse industrial landscape requires specialized pump systems for many critical applications. High Flow High Head Pumps are widely used in:

Water Treatment Plants: These pumps are ideal for moving water over long distances or raising water from deep wells, ensuring that water treatment plants run smoothly and efficiently.

Agriculture: In regions where irrigation is crucial, these pumps provide the necessary pressure to distribute water evenly across large agricultural fields.

Mining and Construction: For handling slurry or dewatering tasks in harsh environments, these pumps offer unparalleled efficiency and reliability.

Vacuum Assisted Centrifugal Dewatering Pumps: A Key Component in Modern Industry

In addition to High Flow High Head Pumps, another essential technology in industrial pumping is the Vacuum Assisted Centrifugal Dewatering Pump UAE. These pumps are engineered for high-efficiency dewatering applications, particularly in construction, mining, and wastewater treatment industries.

Vacuum Assisted Centrifugal Dewatering Pumps combine centrifugal force with vacuum technology to effectively remove water from slurry or other fluids. This technology is crucial in reducing moisture content in materials, ensuring better processing and reducing operational costs.

Efficient Fluid Transfer for All Industries

Both High Flow High Head Pumps and Vacuum Assisted Centrifugal Dewatering Pumps are essential tools for industries requiring advanced pumping solutions. With growing demand in sectors like construction, wastewater management, and mining, the need for such efficient pumping systems in the UAE continues to rise.

For top-notch High Flow High Head Pumps UAE and other industrial pumping solutions, you can explore more options and detailed product specifications here. With cutting-edge pump systems tailored to meet high-pressure needs, these pumps offer unparalleled performance and durability.

Conclusion

When looking for the best pumping systems for high-pressure and high-flow applications in the UAE, High Flow High Head Pumps and Vacuum Assisted Centrifugal Dewatering Pumps are the solutions to turn to. Their advanced technology, energy efficiency, and adaptability make them invaluable assets for industries across the region. By investing in these systems, companies can ensure a more reliable and cost-effective approach to fluid transfer and dewatering, contributing to a more efficient and sustainable future in the UAE.

Explore more about how these pumps can improve your operations by visiting the High Head Pump page.

0 notes

Text

Pioneering Excellence in Industrial Valve Manufacturing Since 1977

Introduction

Prime Industrial Valves Mfg. Co., established in 1977, is a premier manufacturer of industrial valves, headquartered in Ahmedabad, India. Over the years, the company has emerged as a leader in the industrial valve sector, known for its commitment to quality, innovation, and customer satisfaction. With a robust infrastructure, dedicated R&D capabilities, and a highly skilled workforce, Prime Industrial Valves Mfg. Co. continues to set benchmarks in the industry.

Vision and Mission

Vision: To be a globally recognized leader in the industrial valve manufacturing industry, delivering innovative solutions tailored to the evolving needs of our clients.

Mission: To provide high-quality, cost-effective, and timely solutions while ensuring superior customer satisfaction and environmental sustainability.

Infrastructure and Certifications

Prime Industrial Valves Mfg. Co. operates a state-of-the-art manufacturing facility in Ahmedabad, equipped with cutting-edge technology. The facility boasts an in-house casting unit renowned for its precision and excellence. A dedicated R&D unit drives innovation and continuous improvement, enabling the company to stay ahead in the competitive market.

The company’s commitment to quality and efficiency is validated by prestigious certifications, including:

ISO 9001: For adhering to international quality management standards.

NSIC Certification: Demonstrating our capabilities as a trusted MSME partner.

IBR Certification: Ensuring compliance with the Indian Boiler Regulations.

Product Portfolio

Prime Industrial Valves Mfg. Co. offers a comprehensive range of valves and related products, tailored to meet the diverse needs of industries worldwide. Each product is manufactured from high-quality materials such as Forged Steel, Alloy Steel, Stainless Steel Valve, and Duplex Steel. Here’s an overview of the product range:

1. Gate Valves

Used in water and sewage systems, oil and gas industries, and various industrial processes, gate valves ensure reliable flow control.

2. Globe Valves

Ideal for water and wastewater systems, chemical processing, oil and gas applications, and power plants. Globe valves are designed to regulate flow effectively and withstand challenging environments.

3. Ball Valves

Widely used in water and wastewater treatment, HVAC systems, oil and gas industries, and chemical processing, Ball valves offer durability and precise control. With advanced sealing technologies, they ensure leak-proof operation.

4. Butterfly Valves

Designed for water and wastewater treatment, industrial processes, and pipelines, Butterfly Valves provide efficient flow regulation and are available in various configurations to meet specific needs.

5. Check Valves

Preventing backflow, Check valves are essential for water distribution systems, pumping stations, and fire protection systems. Their robust design ensures long-term reliability.

6. Strainers

Used in water systems, HVAC systems, industrial processes, marine applications, and petrochemicals, strainers ensure the removal of debris and particles, protecting downstream equipment.

7. Needle Valves

Perfect for laboratories, hydraulic systems, fuel systems, and aerospace industries, needle valves provide precise flow control, ensuring accuracy in critical operations.

8. Piston Valves

Used in hydraulic and pneumatic systems, chemical processing, and water treatment, Piston valves are known for their reliability and ability to handle high-pressure environments.

9. Pressure Reducing Valves

Designed for water, gas, steam, and hydraulic systems, Pressure Reducing valves regulate pressure effectively, enhancing system efficiency and safety.

10. Knife Edge Gate Valves

Ideal for wastewater treatment, mining, pulp and paper, and chemical processing, Knife Edge Gate Valves are built for rugged environments and can handle slurry and viscous media efficiently.

11. Specialized Products

Moisture Separators: For steam systems and compressed air applications, ensuring dryness and efficiency.

Blow Down Valves: For boilers and pressure vessels, helping in the effective removal of impurities.

Flush Bottom Valves: Facilitating cleaning and maintenance in industrial processes, ideal for reactors and tanks.

Steam Traps: Enhancing efficiency in heating systems, steam boilers, and autoclaves.

2-3 Way Motorized, Cylinder & Pneumatic Control Valves: Offering precision control in automation systems, designed for advanced industrial needs.

Industries Served

Prime Industrial Valves Mfg. Co. caters to a wide array of industries, ensuring customized solutions for each sector’s unique requirements. Key industries include:

Oil and Gas: Valves designed to handle high pressure and corrosive environments.

Chemical Processing: Specialized valves for handling aggressive chemicals and high temperatures.

Water and Wastewater: Solutions for efficient water management and distribution systems.

Power Generation: High-performance valves for power plants and energy systems.

HVAC Systems: Components ensuring optimal flow and temperature control.

Food and Beverage: Hygienic and durable valves for stringent industry standards.

Marine and Petrochemicals: Robust valves designed for challenging environments.

Operational Philosophy

Prime Industrial Valves Mfg. Co. operates on the philosophy of "QUALITY, COST, and DELIVERY." This ensures that every product not only meets stringent quality standards but is also cost-efficient and delivered on time to exceed customer expectations. The focus on maintaining high standards across all operations has solidified the company’s reputation for excellence.

Research and Development

Innovation is the cornerstone of Prime Industrial Valves Mfg. Co. The R&D unit is equipped with the latest technology and software tools, enabling the design and development of advanced valve solutions. Recent innovations include high-efficiency sealing systems, corrosion-resistant materials, and automation-compatible valves. Continuous research helps the company introduce new products and improve existing ones, ensuring alignment with global industry trends.

Commitment to Sustainability

As a socially responsible organization, Prime Industrial Valves Mfg. Co. is committed to environmental sustainability. The company employs eco-friendly manufacturing practices and materials, minimizing its environmental footprint while maximizing operational efficiency. Initiatives such as energy-efficient production processes and recycling programs reflect the company’s dedication to a greener future.

Global Reach and Export Capabilities

Prime Industrial Valves Mfg. Co. has established a strong presence in both domestic and international markets. Key export regions include the Middle East, Southeast Asia, Africa, and Europe. By maintaining high-quality standards and offering competitive pricing, the company has successfully built lasting relationships with clients worldwide. Customized solutions and efficient logistics ensure timely delivery, enhancing customer satisfaction.

Conclusion

Prime Industrial Valves Mfg. Co. stands as a testament to excellence in the industrial valve manufacturing industry. With a legacy of over four decades, the company has consistently demonstrated its expertise in delivering high-quality, innovative, and cost-effective solutions. Guided by its core values of quality, efficiency, and customer focus, Prime Industrial Valves Mfg. Co. is poised to continue its journey of excellence and innovation in the years to come.

youtube

0 notes

Text

Understanding the Importance of Material Selection in Lobe Pump Construction

When selecting a lobe pump for an industrial application, understanding the power range is essential for ensuring optimal performance. Lobe pumps come in a wide power lobe pumps range, from smaller models at 0.75KW to high-capacity models at 95KW. Each power level is suited to different operational requirements.

Small-Power Lobe Pumps: Ideal for Low-Volume Applications Lobe pumps with a power rating of 0.75KW to 3KW are ideal for smaller applications with low-volume fluid transfer needs. These pumps are typically used in laboratories, small-scale food production, and other low-capacity systems. Despite their smaller size, they offer excellent precision and reliability for less demanding operations.

Medium-Power Lobe Pumps: Versatile for a Range of Industries Medium-power lobe pumps, typically ranging from 4KW to 20KW, are widely used in industries like food processing, pharmaceuticals, and chemicals. These pumps handle moderate flow rates and pressure requirements, making them perfect for versatile applications. They offer a balance of efficiency, reliability, and cost-effectiveness in medium-scale operations.

High-Power Lobe Pumps: Perfect for Heavy-Duty Applications High-power lobe pumps, from 30KW to 95KW, are designed for heavy-duty applications that require high flow rates and pressure. These pumps are commonly used in large-scale industrial processes, such as oil and gas, wastewater treatment, and chemical processing. Their powerful design ensures reliable performance even under demanding conditions.

Selecting the Right Power for Your System Choosing the right power level for your lobe pump depends on your system's specific needs. Consider factors like flow rate, fluid viscosity, and pressure requirements. Smaller pumps are suitable for low-volume, low-pressure applications, while larger pumps are better suited for high-flow, high-pressure environments with more challenging fluids.

Energy Efficiency Across Power Ranges Energy efficiency is a key consideration across all power ranges of lobe pumps. Even high-power models are designed with energy-saving technologies to reduce electricity consumption. By choosing the right pump for your needs, you can ensure that your system operates efficiently, reducing energy costs while maintaining optimal performance.

Customizing Pump Power for Unique Applications For specialized applications, custom lobe pumps can be designed to meet specific power and performance needs. Manufacturers can tailor pump power, materials, and features to suit unique operating conditions, ensuring that your system is perfectly aligned with your requirements. Custom solutions provide maximum efficiency and effectiveness for complex processes.

Impact of Power on Pump Lifespan and Maintenance The power rating of a lobe pump affects its durability and maintenance requirements. High-power pumps typically undergo more stress, which can lead to increased wear over time. Regular maintenance and appropriate usage can extend the lifespan of these pumps. Understanding your power requirements ensures that your pump operates efficiently and lasts longer.

The Role of Power in Fluid Handling Capabilities The power of a lobe pump directly influences its ability to handle challenging fluids, such as viscous liquids, slurries, or abrasive materials. Higher power pumps can move thicker fluids with ease, while smaller pumps are better suited for handling lighter, less viscous substances. Select a pump power level based on the fluid type.

Adaptability to Different Industrial Environments Lobe pumps across the entire power range offer adaptability to various industrial environments. Whether you're working in food production, pharmaceuticals, or chemicals, there's a lobe pump suited for the job. Understanding your industry’s unique demands ensures that you select the most suitable pump to maximize productivity and efficiency.

Conclusion: Matching Power to Performance for Maximum Efficiency Choosing the correct power range for your lobe pump ensures that it meets your operational needs while providing lobe pumps long-term efficiency and durability. From small pumps at 0.75KW to powerful units at 95KW, selecting the right power level optimizes performance and reduces energy consumption. Understanding these factors helps you make an informed, cost-effective decision.

0 notes

Text

Understanding Hydraulic Dredge Pumps and Their Critical Role

Hydraulic dredge pumps are essential components in dredging operations, designed to efficiently move large volumes of water and solid materials, such as sand, gravel, and sediment, through pipelines. These robust pumps operate by creating a suction that draws the material from underwater or other locations and transfers it to designated areas for processing or disposal. They play a critical role in maintaining waterways, harbor deepening, land reclamation, and mining. Hydraulic dredge pumps are highly versatile, with designs tailored to handle abrasive materials and varying densities. Their performance is influenced by factors such as pump size, impeller design, and operational conditions. Understanding their functionality and applications is vital for optimizing dredging efficiency, minimizing environmental impacts, and ensuring long-term operational success.

Introduction to Hydraulic Dredge Pumps

Hydraulic dredge pumps are essential components used in dredging operations to remove sediment, debris, or other materials from bodies of water. These pumps operate by harnessing the power of hydraulic systems to transport slurry (a mixture of water and sediment) from the dredge site to disposal areas. They play a crucial role in maintaining waterways, harbors, and ports, ensuring that vessels can navigate through shallow or obstructed areas. The technology behind hydraulic dredge pumps is constantly evolving to meet the demands of modern dredging projects, making them an invaluable tool in various industries such as construction, mining, and environmental management.

The Basics of Hydraulic Dredge Pump Operation

Hydraulic dredge pumps operate by converting hydraulic energy into mechanical energy to move slurry. The pump is powered by a hydraulic motor, which is usually driven by a diesel engine or other power sources. The pump's components include an impeller or rotor that draws the slurry into the pump, and a casing that directs it to the discharge outlet. The hydraulic pressure and flow are adjusted to control the suction, discharge, and pressure conditions of the pump. The efficiency of the pump depends on factors such as pump size, design, and the type of slurry being dredged.

Types of Hydraulic Dredge Pumps

There are several types of hydraulic dredge pumps, each designed for specific dredging tasks. The most common types include centrifugal pumps, diaphragm pumps, and piston pumps. Centrifugal pumps are widely used due to their high capacity and ability to handle large volumes of slurry. Diaphragm pumps are preferred for handling thicker slurries with higher viscosity, while piston pumps are known for their ability to pump abrasive materials. The selection of the right pump type depends on the nature of the dredging project, the type of material being dredged, and the environmental conditions.

Key Benefits of Hydraulic Dredge Pumps

Hydraulic dredge pumps offer several advantages over other types of dredging equipment. One of the primary benefits is their efficiency in moving large volumes of slurry. They are capable of dredging both fine and coarse materials, including sand, silt, clay, and gravel. Hydraulic dredge pumps are also highly versatile, as they can be adjusted to accommodate different flow rates, pressures, and material types. Their ability to operate in challenging environments, such as deep water or areas with strong currents, makes them ideal for both offshore and inland dredging projects. Additionally, hydraulic systems allow for precise control over pump performance, reducing wear and tear on the pump components.

Challenges in Hydraulic Dredge Pump Operations