#High speed voltage amplifier

Explore tagged Tumblr posts

Text

https://www.futureelectronics.com/p/semiconductors--analog--amplifiers--general-purpose/ts393idt-stmicroelectronics-4394615

Amplifiers, General Purpose Amplifiers, TS393IDT, STMicroelectronics

TS393 Series 16 V 600 pA SMT Micropower Dual CMOS Voltage Comparator - SOP-8

#Amplifiers#General Purpose Amplifiers#TS393IDT#STMicroelectronics#power op amp#High-gain electronic#Op amp circuits#High speed voltage amplifier#a chip#applications#Operational amplifier circuit#analog devices op amps

1 note

·

View note

Text

High speed op amps, general purpose op amps, voltage amplifying device

LM Series 0.6 V/us 32 V SMT Single Supply Quad Operational Amplifier - SOIC-14

#Amplifiers#Operational#General Purpose Amplifiers#LM2902DR2G#Onsemi#high speed op amps#general purpose op amps#voltage amplifying device#low-voltage#general-purpose#op amps#what is General Purpose Amplifiers#Op amp circuits#high speed op amp

2 notes

·

View notes

Text

https://www.futureelectronics.com/p/semiconductors--analog--amplifiers--general-purpose/ts393idt-stmicroelectronics-2252658

OP amp circuits, electronic voltage amplifier, Operational amplifier circuit

TS393 Series 16 V 600 pA SMT Micropower Dual CMOS Voltage Comparator - SOP-8

#STMicroelectronics#TS393IDT#Amplifiers#General Purpose Amplifiers#op amp circuits#electronic voltage amplifier#Power operational amplifier#High-Performance#High-speed voltage amplifier#voltage divider

1 note

·

View note

Text

BOSS - CE-1 Chorus Ensemble

"... yeah, there’s a reason why they occupy so much Cabinet real estate. The company created the “first” of a variety of effects, and was certainly the first to offer many types in compact boxes. However, one such pedal is a stone-cold all-time classic despite never being offered in Boss’s trademark compact enclosure. That pedal is the CE-1 Chorus Ensemble.

Released one year after parent company Roland’s flagship Jazz Chorus amplifiers, Boss did what was once considered the unthinkable. Following the rapid and perhaps unexpected success of the aforementioned amp series, Roland wasted no time with ripping a circuit straight from them and putting them in a floor unit. In fact, this circuit ended up being the first pedal to bear the Boss name, and what a first it was.

Back when the CE-1 was conceptualized, the idea of mains-powered pedals was pretty commonplace. Mu-Tron effects used them, and so did MXR on some of its more ambitious models. Onboard and oftentimes custom-wound transformers ensured that voltages would be stepped down at precisely the right increments in order to preserve tonal integrity and headroom.

Of course, most pedals of the time also ran on nine-volt batteries, establishing a standard that continues today. But before these standards were established, the idea of grandiose effects thrived under the usage of mains power. Such a boundless canvas allowed companies like Boss to rip entire hunks of circuitry straight from larger silicon conglomerates and put them right at a player’s feet. These days, very few manufacturers offer such exacting circuitry, and the few that do charge exorbitant prices.

The CE-1 is one particularly exceptional example of this practice, because it expands on the original circuit, with the added bonus that you can play it through an actual tube amplifier. It also adds an extra functionality that the Jazz Chorus just couldn’t match. The Jazz Chorus gives players both Chorus and Vibrato modes, and to that end, serves up three knobs, of which Speed and Depth are two. The third knob is actually a rotary switch that chooses either mode. While the JC-120 offers a footswitch input to toggle the effect on and off, the CE-1 does one better and converts the rotary switch into a stompable button, meaning you don’t have to do the Angus Young duckwalk back to your amp mid-set to change modes. Nobody wants to do this.

Roland’s Jazz Chorus—and thusly the CE-1—couldn’t have come at a better time for end-users or commerce. Californian semiconductor company Reticon developed the first bucket-brigade device (BBD) and distributed them through the usual suspects, including Radio Shack under the store’s in-house Archer brand. The only problem—again for end-users and commerce—was that each one cost a crazy amount of 1970s dollars. Even at wholesale prices, Reticon’s SAD series of BBD chips made effects a bit on the expensive side.

Shortly after in Japan, Matsushita released the genesis of the Japanese BBD boom that ended up sinking Reticon and all pedals that relied on it. The first chip off the Matsushita line was the MN3002 and found its way into the CE-1 tout de suite. With the combination of the relatively inexpensive BBD and the full-strength brawn of the circuit itself, the CE-1 made a splash in the effects world and primed the pump for Boss’s compact series to take the effects world by storm.

The most unsung piece of the CE-1 puzzle is the onboard preamp that preps the signal for its impending modulation. While many effects and amplifiers (especially of this era) features “high” and “low” inputs, they usually correspond to a brute force approach that swaps out resistors in the signal path. However, the CE-1 preamp section starts with an op-amp preamp circuit that sweetens the signal, and switching over to high mode inserts a transistorized gain stage between the input and the op-amp section. This adds a velvety gloss to the signal before it ever sniffs the BBD chip, catapulting your tone into heights unreached by lesser devices.

It’s not often that almost 50 years later, no effect of a given type has surpassed the first one ever created, but such is the case with the CE-1. Its combination of unsurpassed tonal brilliance, component count and wacky power requirements has cemented its place in the effects hall of fame, leaving even the most modern refinements squarely in the rear-view mirror."

cred: catalinbread.com/blogs/kulas-cabinet/boss-ce-1-chorus-ensemble

47 notes

·

View notes

Note

re: talk of Burn, do you have any idea why Yang's aura clearly broke when Neo struck her in V8 (right after activating Burn)? my theory is that perhaps activating her semblance does something like Tock's where it makes her aura manifest more solidly on her body (which is how it can make her hair light on fire) and therefore also, like Tock, means that her aura is more vulnerable. to me this would also explain why Yang would use it as a finisher at first; using it when she's already going to run out of aura makes it, in a sense, less dangerous because she's already gotten most of the other uses out of her aura that she can get.

would love to know if you think this is accurate, or what you actually think is going on with yang's semblance on a mechanical level (if you're interested in that anyway)

first, a general point about aura and aura breaking. the characters’ use of meters has led to a sort of popular fanon that aura works like hit points in a video game, where you have this many and taking damage reduces your HP by a certain number until you hit zero and then your aura breaks; (dark souls splash screen voice) YOU DIED.

i do not think it works that way.

from world of remnant:

aura is a manifestation of the soul, a life force that runs through every living creature on remnant—whether they are a meager shopkeep or a renowned knight. however, what sets true warriors apart from all others is their ability to amplify and control their aura.

aura is the power of one’s soul. it’s guided by emotion, self-knowledge, and spirituality. in its purest form, it becomes a semblance.

defensive aura is not a passive effect. we know this for a fact. in V5, oscar finds it physically exhausting to engage his aura in this way and ren tells him that’s normal—it requires intense concentration at first, then becomes second nature with practice. in V7, jaune’s aura-training demonstrates that recovery, regaining aura once it has been depleted, is a conscious action that can be improved through practice. this is because the “aura level” tracked by those meters is not a measurement of how much aura you have in the tank, as it were, but something like the density of the aura-field you’re pushing outward, or speed of flow, or something along those lines.

(the way i’m handling it in TDT is there’s a hard upper bound to how much aura you can hold in your skin, like a sponge not being able to absorb more water, and what auraleric gauges attempt to measure is % of maximum saturation because everyone’s aura will break around 5-10% saturation even though the amount of aura you have at 100% varies. anything you push out above that threshold is projected as transient bursts of energy and that’s where you start getting into offensive techniques.)

hazel’s phenomenal endurance is noted to derive from his rapid recovery, not the basal amount of aura he has. (he even just shrugs off being impaled.) i believe his semblance gives him an edge here, because it requires concentration to amplify one’s aura and hazel can’t be distracted by physical pain.

which brings me to aura-breaking. it doesn’t happen when the proverbial tank is empty. auras break when you can’t sustain the mental effort of generating enough aura; this might happen because the well you’re drawing from really has run dry (<- think this is what happened to nora with the high voltage door), but it might also be because you’re too tired, or you took a really painful or unexpected hit that shattered your focus, because you’re panicking or furious.

i think tock’s semblance is in the same ‘family’ as hazel’s and ironwood’s in that it puts her into a state of intense focus by blocking out anything that might shake her—with hers being far, far more potent than theirs but so potent she can’t maintain it for longer than sixty seconds, and possibly needs the ticking clock to ‘anchor’ her focus.

(fic stuff again, because tock’s alive in TDT for butterfly wing flaps reasons: sixty seconds is not a hard limit of her semblance; she can and on one occasion did go for much longer. to project an aura field you draw aura out of your reserve, which is the aura that naturally ‘pools’ around your soul; if that runs dry and you’re desperate enough, pushing hard enough, you can wring more aura out of your soul. blood from a stone. it hurts a lot, it will mess you up, and it can do permanent damage similar to what the aura transfer machines do to pietro. sixty seconds is how long it takes for tock’s semblance to drain her aura reserve, rounded down to allow for a margin of error.)

so. yang.

i think, mechanically, when the average person with aura training gets hit, their aura burns up to disperse most of that energy. (<- when they’re swatting gunfire away, the bullets bounce; the energy is reflected.)

but yang’s semblance absorbs energy—which is to say, if you had a ball throwing machine shoot a tennis ball at yang and someone else with equivalent training from the same distance, it would hit yang harder because her aura is less reflective; more of the ball’s kinetic energy flows into her body. then, like a battery, her aura converts that energy into some other form that can be stored.

sort of like dust, in fact. dust has a lot of potential energy, which is released when the material reacts with aura. given the literally explosive firepower yang gains from burn, i think that she’s storing this absorbed energy in the same form as occurs naturally in dust, which would put burn in the same ‘family’ as coco’s hype or arrastra’s equilibrium…

…and would also mean that this statement:

some prefer to use dust in its raw form: elegant, yet destructive. those who choose to wield dust in this state must possess a certain level of discipline to ensure that their resulting powers do not break free of their control.

is true of burn, too. and that tracks with who yang is and how she uses her semblance—even in V1-3, yang takes a more head-on approach to fights and tends to soak up more damage before exploding bigger vs her increasingly nimble and even acrobatic style post-beacon, but her control over those massive volcanic eruptions is immaculate.

the way burn works in general requires that yang be very, very in control of her aura at all times because she needs to balance between absorbing energy to charge up her semblance while reflecting enough to prevent injury, and this is one reason why i think yang is probably the best out of the cast when it comes to using aura. ren might have her beat on the more spiritual, extra-sensory perception side of things, but yang has to keep her focus while getting hit harder than anyone else Because Physics.

and that brings us to neo one-shotting yang’s aura. here is what happens: cinder is gloating from atop a pillar of fire while people scream and run in a panic all around them, and out of the corner of her eye, yang sees a glint of steel and realizes that neo is about to stab her unsuspecting baby sister in the back, she’s too far away, she can’t get there fast enough—burn is, in that moment, a reflex. instinct. she panics and hurls herself in between neo and ruby without even thinking about it because the only thing in her mind is GET TO RUBY NOW.

and that’s why her aura just shatters. it requires concentration—you practice until it becomes instinctive, until you don’t need to think about it, muscle memory. but it still takes focus. intention. yang has incredible self-control and thus incredible control of her aura, but everyone has limits, and hers are “holy fuck that guy stabbed blake” and “neo is going to kill ruby go go go.”

her semblance in itself doesn’t make her defense any weaker—but when she’s terrified enough for burn to activate reflexively like this, her aura will break if she gets hit because she’s freaking out.

46 notes

·

View notes

Text

The Truth the Whole Truth

But nothing is the truth.

I have been meditating on the eternal dichotomy of tubes versus transistors. In my opinion the big difference is in power amplifiers.

Small signal devices as in preamplifiers in class A operation are not so different in either glass or solid state. But in power amplifiers the difference is significant and is the cause behind the wars between the tribes.

First up is for high quality devices the differences are small. And neither is best. Though I do lean towards solid state for being more accurate.

So I meditate on nanoseconds and feedback. No device is free from distortion. That is just another way of saying they are not perfect. An excellent method to reduce distortion is feedback, or if you like to stand on your head feed forward.

The idea is simple. Compare what you get at the output to the input. If there is a difference other than magnitude subtract it (negative feedback) or add the inverse by way of a perfect small signal amplifier. (feed forward see that THX patent or the old QUAD amp) Either way is a correction signal. Fix the error.

Some people fret over the idea that if you correct an input that passes through the same imperfect device it is never right. Some people will claim that making a device with no correction signal is an obvious choice. It only has to be perfect.

All of my power amps have negative feedback. All told I have 4 of those. 3 are solid state and 1 is tube. Just in terms of wire and the speed of light it takes about a bit over a nanosecond for the correction signal to get from the output to the input. A nanosecond is a billionth of a second. That inverts to a frequency of gigahertz. None of my amps go to gigahertz so that gap would get lost no? It is effectively no delay at all.

A tube amp is special though. All production tube amps have output transformers. Small signal class A devices do not need output transformers so they are not that different. Power Tubes are high voltage and speakers are low voltage (except for electrostatics) so you need an impedance matching device, a transformer. And 99 times out of 100 the correction signal is pulled off the secondary winding which is many feet of wire and loops of magnetic flux away from the power tube. As magnetic flux is involved and all sorts of black magic and differential equations you also get phase issues as well as other things which makes the feedback a bit weird and always off a bit. Oh the test instruments show things as better, but not quite right to human ears.

I can hear the effect. My high end tube amp masks tiny little details my brute of a transistor amp is quite happy to reveal. BUT the tube amp paints lovely colors over the signal. I do mean lovely, rich, and very attractive textures. It is a shame they are not real, but I like them. That in the end is the difference. I know they are not real. I know those tiny sounds are there under the nice colors.

That is why the transistor amp is more accurate. The tube amp is prettier sounding. If both were perfect they would sound exactly the same.

I have the advantage of not adhering to either side of the hostile argument. I have both. Also when I put the black Franken-Amp back in service as the weather warms up it saves the tubes in the glass beast. Rather than one or two years service I should get double whatever is due.

2 notes

·

View notes

Text

Bypass Capacitors: Essential Components in Electronic Circuits

Introduction to Bypass Capacitors

A bypass capacitor is a vital component used in electronic circuits to stabilize voltage and filter out noise. Positioned parallel to the power supply, it "bypasses" unwanted high-frequency signals, allowing only the desired DC or low-frequency signals to pass through. This prevents fluctuations that could disrupt the proper functioning of sensitive components such as microcontrollers, amplifiers, and analog sensors.

Functionality of Bypass Capacitors

Bypass capacitors smooth out voltage levels by providing a low-impedance path for high-frequency signals to ground. When a power supply has noise or transients, the capacitor acts as a short circuit to these signals, diverting them away from the critical parts of the circuit. This results in cleaner power and reduced electromagnetic interference (EMI).

Types of Bypass Capacitors

There are several types of bypass capacitors, with ceramic capacitors being the most commonly used for this purpose due to their low cost and wide availability. Electrolytic capacitors may be used for larger values of capacitance, typically in power supply filtering. Each type offers different performance characteristics, such as stability, response time, and size, making it important to select the appropriate type for the circuit’s needs.

Selecting the Right Bypass Capacitor

Choosing the right value for a bypass capacitor involves considering factors like the circuit’s operating frequency, current, and noise level. Typically, small ceramic capacitors (0.1µF to 1µF) are used for high-frequency noise filtering, while larger values (10µF to 100µF) might be necessary for low-frequency smoothing. The capacitor’s voltage rating should exceed the maximum operating voltage to ensure reliability.

Importance in High-Speed and High-Frequency Circuits

Bypass capacitors are especially crucial in high-speed digital circuits and RF systems where noise and signal integrity are critical. In such applications, even minute voltage fluctuations can cause malfunction or degradation in performance. By placing multiple capacitors of varying values near power pins of integrated circuits, designers can achieve optimal filtering across a broad range of frequencies, enhancing overall system stability.

0 notes

Text

Studiomaster PA Series: The Benchmark in Professional Amplifiers

When it comes to professional audio amplification, the Studiomaster PA series stands out as a powerhouse lineup designed for exceptional performance, durability, and reliability. Each model within this series delivers cutting-edge technology combined with meticulous engineering to meet the demands of audio professionals. Let's dive into the details of each model in the PA series, ranging from the compact PA 1.5 to the flagship PA 10.0.

Studiomaster PA 1.5: Compact yet Powerful

The PA 1.5 is the ideal choice for setups requiring high-quality sound and efficient performance in a compact form. With its combination of switch mode and linear power supplies, the PA 1.5 ensures smooth operation even in environments with fluctuating voltage levels as low as 130V. a

Key Features:

Input Options: Balanced XLR and 1/4” Stereo Jack.

Modes: Stereo, Mono, and Bridge for versatile application.

Cooling: Intelligent low-noise variable-speed fans with efficient heatsinks.

Transformers: High-current toroidal transformers with high-grade cores for greater transient response and low noise, even at 2 Ohms.

Indicators: Mute, Signal, Clip, and Fault LEDs for performance monitoring.

Operational Efficiency: Rated for 2Ω operation with a sensitivity switch (+4 dB or 0 dB).

Additional Protection: Low-cut and Limiter switches for optimal speaker performance.

PCB Design: High-quality glass epoxy, double-sided PTH PCBs, and high-grade components ensure reliability even in tough ambient environments.

Slightly more powerful than the PA 1.5, the PA 2.0 delivers enhanced audio performance while retaining the reliability and flexibility synonymous with the PA series.

Key Features:

Durable Construction: High-quality glass epoxy, double-sided PTH PCBs with high-grade components ensure reliability even in tough ambient environments.

Versatile Input: Supports both Balanced XLR and 1/4” Stereo Jack.

Flexible Modes: Stereo, Mono, and Bridge modes for varied setups.

Cooling Mechanism: Advanced heat management with noise-controlled fans.

Protection Mechanisms: Switchable Low-cut and Limiter switches.

Performance Monitoring: Comprehensive LED indicators.

Transformers: High-current radial transformers with high-grade cores for low noise and excellent transient response.

Studiomaster PA 3.0: For Medium to Large Venues

The PA 3.0 amplifier is designed for medium to large scale audio setups. It offers superior sound quality and robust power output, making it a popular choice among audio professionals.

Key Features:

High Efficiency: Switch mode and linear power supplies for seamless performance.

Cooling System: Low noise fans and optimized heat sinks for reliability.

Enhanced Inputs: Balanced XLR and 1/4” Stereo Jack.

Operational Modes: Stereo, Mono, and Bridge for various applications.

Durability: Built with high-quality glass epoxy PCBs and premium components.

Protection & Monitoring: Equipped with Low-cut and Limiter switches along with comprehensive LED indicators.

Advanced Transformers: High-current toroidal transformers ensure consistent performance and reduced noise.

Studiomaster PA 4.5: Versatility Meets Power

The PA 4.5 is a step up in terms of power and features, making it a versatile solution for professional audio requirements. It’s built to withstand demanding conditions while delivering exceptional audio clarity.

Key Features:

Robust Design: High-grade components and durable construction ensure longevity.

Cooling Efficiency: Intelligent fans with heat management systems.

Flexible Modes: Operates in Stereo, Mono, and Bridge modes.

Comprehensive Monitoring: Mute, Signal, Clip, and Fault LED indicators.

Protection Features: Low-cut and Limiter switches for speaker safety.

Enhanced Connectivity: Balanced XLR and 1/4” Stereo Jack inputs.

Reliable PCB: Glass epoxy, double-sided PTH PCBs for durability in tough environments.

Studiomaster PA 6.0: Professional Power Amplification

The PA 6.0 delivers professional grade audio performance, making it a reliable choice for larger venues and events. Its advanced cooling and power management features ensure consistent output even under demanding conditions.

The PA 6.0 delivers professional grade audio performance, making it a reliable choice for larger venues and events. Its advanced cooling and power management features ensure consistent output even under demanding conditions.

Key Features:

Power Supply: Combination of switch mode and linear power supplies.

Durability: Built with glass epoxy PCBs and premium grade components.

Connectivity: Balanced XLR and 1/4” Stereo Jack inputs.

Cooling System: Variable speed fans and direct mounted heat sinks.

Operational Flexibility: Stereo, Mono, and Bridge modes.

Additional Features: Low-cut and Limiter switches for optimal performance.

Transformers: High-current toroidal transformers with high-grade cores provide superior transient response and low noise.

Studiomaster PA 7.5: High-End Power Amplifier

The PA 7.5 is designed for professional applications requiring high power and uncompromising audio quality. It’s ideal for concerts, large auditoriums, and high energy events.

Key Features:

High Power Output: Suitable for demanding audio setups.

Advanced Cooling: Low noise fans and efficient heat dissipation.

Operational Versatility: Stereo, Mono, and Bridge modes.

Durable Build: High-quality components and robust construction.

Protection: Includes Low-cut and Limiter switches.

Monitoring Indicators: Comprehensive LED status indicators.

Reliable Transformers: High-current toroidal transformers deliver consistent performance with low noise.

Studiomaster PA 10.0: The Ultimate Powerhouse

As the flagship model, the PA 10.0 represents the pinnacle of Studiomaster’s engineering excellence. It combines high power output with unparalleled sound clarity, making it the go to amplifier for the most demanding professional audio scenarios.

Key Features:

Unmatched Power: Delivers exceptional sound quality at high power levels.

Cooling Technology: Intelligent cooling system with variable speed fans.

Operational Modes: Stereo, Mono, and Bridge modes for diverse applications.

Input & Output: Balanced XLR, 1/4” Stereo Jack, and Speak-on output connectors.

Advanced Monitoring: Mute, Signal, Limiter, and Temperature LED indicators.

Protection Mechanisms: Equipped with Low-cut and Limiter switches for speaker safety.

PCB & Transformers: High-quality glass epoxy PTH PCBs and toroidal transformers ensure reliability and superior performance.

Conclusion : The Studiomaster PA series offers a range of amplifiers catering to every professional audio need. From the compact PA 1.5 for smaller setups to the PA 10.0 for high powered events, each model guarantees exceptional sound quality, operational reliability, and user friendly features. Whether you’re an audio enthusiast or a seasoned professional, the PA series has an amplifier that fits your needs perfectly. Explore the Studiomaster PA series and elevate your audio experience to the next level!

0 notes

Text

Maximize the Performance of Your NAU7802SGI

The NAU7802SGI is a game-changing analog-to-digital converter (ADC) that bridges the gap between precision and ease of use. If you’re here, chances are you’re looking to unlock its full potential. Whether you’re working on a DIY project or an industrial application, we’ll guide you step by step on how to make the most of this incredible chip.

Introduction to the NAU7802SGI

Imagine having a digital scale that reads not just grams but even the tiniest fractions with flawless precision. That’s the kind of accuracy the NAU7802SGI delivers. It’s more than just an ADC; it’s a tool that transforms raw sensor data into reliable, usable insights.

This guide will take you on a journey, from understanding the basics to fine-tuning your setup for peak performance.

Why Choose the NAU7802SGI?

The NAU7802SGI is not just another ADC. It’s a well-rounded solution designed to cater to applications where accuracy and ease of use are paramount. But why should you consider it for your project?

Versatility: Works with a range of sensors.

Simplicity: Integrates easily with microcontrollers via I²C.

Affordability: High performance without a hefty price tag.

Key Features of the NAU7802SGI

Let’s highlight what makes this ADC shine:

24-bit Resolution: Perfect for precise measurements.

On-Chip Amplifier: Reduces external components.

Low Power Consumption: Ideal for portable and battery-powered devices.

Wide Operating Range: Suitable for diverse environments.

These features make it a reliable choice for both beginners and professionals.

Applications of the NAU7802SGI

The NAU7802SGI is a favorite in many fields:

Digital Scales: Ensures precise weight measurements.

IoT Devices: Used in smart sensors and home automation.

Healthcare Equipment: Powers devices like blood pressure monitors.

Industrial Tools: Ideal for strain gauges and force measurement.

Setting Up the NAU7802SGI

Getting started is simple:

Power It Up: Ensure a stable power supply (2.7V to 5.5V).

Connect the Inputs: Attach your sensor to the differential input pins.

I²C Communication: Use SDA and SCL lines to interface with your microcontroller.

Run Initial Tests: Verify the setup with basic readings.

Calibrating the NAU7802SGI

Calibration is key to unlocking the NAU7802SGI’s full potential. Think of it like tuning a musical instrument—precision is everything. Follow these steps:

Zero Calibration: Adjust for baseline readings.

Gain Calibration: Fine-tune amplification for accurate outputs.

Periodic Recalibration: Maintain accuracy over time.

Optimizing Noise Performance

Noise can be a challenge, but it’s manageable with these tips:

Proper Grounding: Connect all grounds to a common point.

Shielding: Use metal cases or enclosures to block interference.

Low-Pass Filters: Filter out unwanted high-frequency signals.

Power Management Tips

Efficient power management enhances performance:

Sleep Modes: Utilize the chip’s low-power modes during inactivity.

Stable Supply: Use capacitors to smooth voltage fluctuations.

Battery Considerations: Choose batteries with consistent output.

Best Practices for I²C Communication

To avoid hiccups in communication:

Pull-Up Resistors: Use appropriate resistor values for SDA and SCL lines.

Clock Speed: Match the I²C clock frequency with your microcontroller.

Error Handling: Program for retries in case of communication failures.

Enhancing Accuracy in Load Cell Systems

When using the NAU7802SGI with load cells:

Choose Quality Load Cells: Precision load cells yield better results.

Stable Mounting: Ensure the load cell is securely mounted.

Environmental Factors: Compensate for temperature and vibration effects.

NAU7802SGI Firmware Integration

Seamless integration with your firmware ensures a smooth workflow:

Drivers: Use pre-built libraries or write custom drivers.

Data Processing: Filter and average readings for stability.

Debugging: Test each step to identify and resolve issues early.

Common Challenges and Solutions

Here are a few hurdles and how to tackle them:

Drifting Readings: Check for temperature effects and recalibrate.

Interference: Implement proper shielding and grounding.

Inconsistent Power Supply: Use voltage regulators for stability.

Comparing the NAU7802SGI with Competitors

Why does the NAU7802SGI outshine others?

Built-In Features: Reduces the need for external components.

Affordability: High performance at a lower cost.

Ease of Use: Simple setup and calibration process.

Conclusion

The NAU7802SGI is more than just an ADC—it’s a tool that empowers precise measurements across various applications. By following the tips and insights in this guide, you’ll be equipped to maximize its performance, whether for a hobby project or a professional system.

Ready to unlock the full potential of your NAU7802SGI? Start experimenting today and let this marvel of engineering elevate your next project!

0 notes

Text

U.S. Motor Vehicle Sensor Market to Double by 2033, Reaching $7.2 Billion at a 7.5% CAGR

U.S. Motor Vehicle Sensor Market is rapidly expanding, fueled by advancements in autonomous driving, electric vehicles (EVs), and connected car technologies. Sensors play a pivotal role in enhancing vehicle safety, performance, and efficiency by monitoring critical parameters like speed, temperature, pressure, and proximity. Applications such as advanced driver assistance systems (ADAS), lane departure warnings, and collision avoidance systems are increasingly dependent on sophisticated sensor networks, ensuring safer and smarter driving experiences. As regulatory bodies push for higher safety standards, the adoption of motor vehicle sensors is accelerating across conventional and electric vehicle platforms.

To Request Sample Report : https://www.globalinsightservices.com/request-sample/?id=GIS32539 &utm_source=SnehaPatil&utm_medium=Article

Moreover, the shift toward sustainability and energy efficiency in the automotive industry has amplified the demand for high-precision sensors that optimize fuel consumption and emissions control. Electric vehicles particularly benefit from innovations in battery management sensors, which monitor voltage, temperature, and charge levels to extend battery life and ensure optimal performance. With U.S. automakers heavily investing in R&D, the market for motor vehicle sensors is set to witness exponential growth, paving the way for a connected, automated, and sustainable future in transportation.

#MotorVehicleSensors #AutomotiveInnovation #ADAS #ElectricVehicles #SustainableTransport #ConnectedCars #VehicleSafety #AutonomousDriving #EVTechnology

0 notes

Text

GF302 MULTIFUNCTION THREE PHASE PORTABLE POWER & ENERGY CALIBRATOR

GF302 portable power& energy calibrator is suitable for power plant and power grid companies for the following function: measuring and testing department and instrumentation classes, national levels measuring and testing institutions, railway, petroleum, chemical industry and other large industrial and mining enterprises, scientific research units, etc. The core technology function with digital signal processor (DSP) and 16 high-speed digital converters composed of high precision work frequency communication terminal. The signal source is DSP and 16 high-speed digital-to-analog converters, it can control the sine wave and distortion wave signal source. It can be used as a concentration electrical laboratory.

APPLICATION ■ Power plant; ■ Universities; ■ Research institutes; ■ Electrical testing center; ■ Panel meter manufacturers; ■ Transducer manufacturers; ■ Pointer meter manufacturers; ■ Digital meter manufacturers; ■ Power meter manufacturers; ■ Railway electrical department; ■ ISO17025 Electrical laboratory; ■ Power engineering commissioning company; ■ Electricity power bureau & power company; ■ Electrical Department of industrial and mining enterprises;

FUNCTIONS & FEATURES ■ 6.4 inch big screen color display and English interface; ■ Testing AC sample device, RTU & measurement device error; ■ With USB port, it can connect computer for data management or controlled by PC ■ For the software calibration, you don't need to open the case, it's stable and reliable; ■ With automatic failure detection function, shows fault part, the convenience users check line; ■ Test single-phase, three-phase electronic, mechanical watt-hour meter or energy meter/ kWh meter error; ■ As one voltage source, current source and power source with high precision and high stability standard resource; ■ Voltage output terminal with short circuit, current output terminal open protection and power amplifier overheating protection function; ■ The built-in electric measurement transducer, electric measurement instrument and meter instructions of verification program, fully automatic or semi-automatic for verification, and save 10000 group test data; ■ Check all kinds of electric measurement indicating meter, including AC/DC voltmeter, AC/DC ammeter, frequency meter, phase angle meter, single & three-phase ac active power meter, three-phase ac reactive power meter & synchronous meter etc; ■ All kinds of electric measurement transducer can be tested, including AC/DC voltage transducer, AC/DC current transducer, frequency transducer, phase transducer, single/ three-phase AC active power transducer, three-phase reactive power transducers;

1 note

·

View note

Text

The Role of Amplifiers in Industrial Automation: Enhancing Signal Strength and Precision

Introduction:

In industrial automation, a high quality amplifier ensures boosting of such signals across various control systems for transmitting data accurately without loss. A high-quality amplifier in amplifying weak signals from sensors and controllers provides the most necessary action of sending it over long distances without degrading. This is particularly crucial in high-noise electrical environments, where a quality amplifier would filter out interference from signals and maintain the clarity of signals to achieve sharp operations. From motor control to sensor data conditioning, high-quality amplifiers enhance the efficiency, accuracy, and stability of the system and are therefore an essential part of modern automated processes.

What is an Amplifier?

An amplifier is an electronic device that increases the strength, or amplitude, of a signal, be it a voltage, current, or power signal. This means that an amplifier can take a very weak input signal to a stronger output signal while maintaining all its characteristics at a greater magnitude. General-purpose amplifiers are used in most audio systems for low-level sound signal amplification, in communication systems for boosting signals over long distances, and for boosting control signals for motors, sensors, and other automated equipment.

Amplitude amplifiers are utilized significantly in industrial automation because they ensure that the signal would not degrade in integrity over long cable lengths or where electrical noise may get superimposed over it, resulting in distortion. It ensures the precise control and accurate reading, which plays an important role in the reliable automation and systems’ efficiency in achieving their objectives.

Types of Amplifiers:

Operational Amplifiers (Op-Amps): These are high-gain voltage amplifiers with differential inputs used for many functions, which include amplification, filtering, and signal conditioning. The operational amplifier amplifies the difference between two input signals and can be very versatile in electronics.

Power Amplifiers: These are designed to offer high power output to drive large loads, such as speakers or motors, through boosting both current and voltage.

Servo Amplifiers: Control servo motors where the position, speed and torque are controlled according to feedback from the system through dynamic modification of power to offer high precision motion control.

Current Amplifiers: Ample signal with negligibly small alteration in its voltage for such applications demanding a high current.

Instrumentation Amplifiers: Low noise, high precision and high output amplifiers to preserve the integrity of the signal in sensitive applications.

Audio Amplifiers: Amplifies the audio signals to the frequency within the audible range; they allow the provision of a high fidelity audio output with negligible distortion.

RF Amplifiers: They amplify the frequency between MHz and GHz in RF frequency to be used for various applications such as wireless communications, broadcasting, etc. It is used for several applications of radar.

Voltage Amplifiers: Amplifiers used to increase the level of voltage in a signal that will be used in some form of further processing or applied as driving power in another circuit.

Key Functions of Amplifiers:

Amplification: Amplifiers strengthen the weak signal so that it can be transmitted through the automated systems for long distances without loss of signal. This feature is required in order to maintain the clarity of transmission among sensors, controllers, and actuators in the vast industrial environment.

Noise Suppression: Electrical noise is a problem in industrial environments because it adversely affects signal accuracy. Amplifiers eliminate noise so that signals are cleaned and clear for reliable data transmittance and control.

Stabilization and Control: Amplifiers stabilize signals, thus preventing fluctuations that could disrupt operations. In specific applications involving motor speed, position, or torque control, this stability is crucial as consistent signals ensure smooth and accurate machine performance.

Power Adjustment: Amplifiers control power levels to meet the requirements of various components. For instance, power amplifiers offer high output power to drive motors or actuators, thus ensuring that these devices receive enough power to function effectively.

Signal Conditioning: In sensor systems, amplifiers condition and enhance signals so that they can be processed. Through signal amplitude alteration and filtering out anomalies, amplifiers ensure that proper data acquisition and processing are made possible.

Support for Long-Distance Transmission: Amplifiers ensure that the signal strength is not affected even if a long cable run is involved, and thus data or control commands are not lost on their way to destinations. This is a function of high importance in large industrial environments where signals need to cover large distances.

Precise Measurement: Amplifiers, particularly instrumentation amplifiers, amplify weak sensor signals in measurement applications to enhance the accuracy of monitoring temperature, pressure, or other critical parameters in industrial processes.

0 notes

Text

Applications of VBA2412 and VB2355 MOSFETs in Vehicle Communication Control: Enhancing System Reliability and Data Transmission Security

Vehicle Communication Control The vehicle communication control system is responsible for receiving, processing, and managing various data streams within and outside the vehicle. These include driver identification, real-time vehicle status monitoring, accident information recording and transmission, remote fault diagnosis, and onboard navigation. The efficient and stable operation of vehicle communication control directly impacts vehicle safety and intelligence. In this context, MOSFETs play a crucial role in enhancing system reliability and data transmission security.

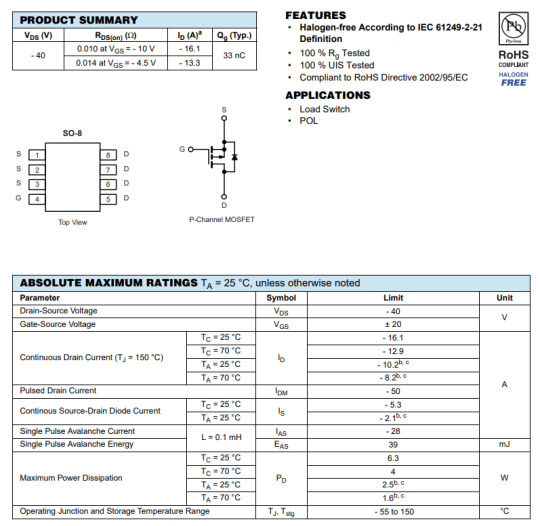

Product Specifications

VBA2412:

Operating Voltage (VDS): -40V

Maximum Tolerance Voltage (VGS): 20V

Threshold Voltage (Vth): -2V

On-Resistance at VGS=4.5V: 14mΩ

On-Resistance at VGS=10V: 10mΩ

Maximum Drain Current (ID): 16.1A

VB2355:

Polarity: Single P-Channel

VDS: -30V

Maximum Tolerance Voltage (VGS): 20V

Threshold Voltage (Vth): -1.7V

On-Resistance at VGS=4.5V: 54mΩ

On-Resistance at VGS=10V: 46mΩ

Maximum Drain Current (ID): -5.6A

Technology: Trench

Package: SOT23-3

Application Scenarios

Signal Amplification and Filtering MOSFETs can amplify weak signals, ensuring clear and interference-resistant sensor data transmission.

VBA2412: With low on-resistance (14mΩ at VGS=4.5V, 10mΩ at VGS=10V), it is suitable for high-current signal amplification, enhancing stability.

VB2355: Its higher on-resistance is ideal for low-power signals, performing well in fine data transmission.

High-Speed Switching Control MOSFETs provide rapid switching performance, ensuring real-time response in high-frequency applications.

VBA2412: Its fast response and 16.1A drain current make it suitable for high-frequency, high-power switching, ensuring data transmission in real-time.

VB2355: Designed for low-power, high-speed signal switching, it’s ideal for signal processing in small modules.

Power Management MOSFETs manage power supply according to module requirements, providing stable current and saving energy.

VBA2412: High current capacity supports power management in high-power modules.

VB2355: Performs well in energy-saving mode for small communication modules.

Overcurrent Protection MOSFETs can detect abnormal currents and quickly cut power to prevent communication module damage.

VBA2412: Suitable for overcurrent protection in high-current conditions.

VB2355: Protects low-power devices, preventing damage to small equipment.

Low Power Control MOSFETs reduce energy consumption in low-power modes, extending system standby time.

VBA2412: Ideal for sustained power supply modules with low-power performance in high-power operations.

VB2355: Extends standby time in small systems during low-power mode.

Advantages and Focus of VBA2412 and VB2355 The VBA2412 is more suitable for high-power, high-frequency applications such as signal amplification, fast switching, and overcurrent protection. The VB2355, on the other hand, excels in low-power, low-noise applications, ideal for signal isolation and low-power control. Together, they complement each other in vehicle communication control applications.

The VBA2412 and VB2355 MOSFETs provide robust support for vehicle communication control in modern intelligent connected vehicles, optimizing data processing and power management. They improve system stability and response speed, ensuring effective power and signal management and protection. These components play a crucial role in enhancing the reliability and energy efficiency of communication modules, laying a foundation for communication control in future smart vehicles.

1 note

·

View note

Text

Acousto-Optic Drivers: Operation Principles and Key Specifications

Acousto-optic (AO) technology enables precise control of light through the manipulation of sound waves, playing a significant role in laser modulation, optical communications, and spectroscopy. At the heart of this technology is the acousto-optic driver, a device responsible for generating the radio frequency (RF) signals that control AO modulators. In this article, we dive into how acousto-optic drivers operate, the key specifications that define their performance, and their applications in different fields.

How Acousto-Optic Drivers Work

An acousto-optic driver controls an AO modulator by converting electrical input signals into RF signals, which generate acoustic waves within the AO modulator. These acoustic waves interact with the light beam passing through the modulator, altering its properties, such as direction or intensity, through a process known as the acousto-optic effect.

The basic steps of an acousto-optic driver’s operation are as follows:

Input Signal: The driver receives an electrical input signal that determines how the light beam should be modulated. This signal can be analog, digital, or pulsed, depending on the required modulation type.

Signal Processing: Inside the driver, the input signal is processed, filtered, and amplified. This processing ensures the signal is clean and strong enough to generate the required acoustic waves.

RF Generation: The processed signal is converted into an RF signal using a voltage-controlled oscillator (VCO). The frequency and shape of the RF signal depend on the type of input and modulation required.

Driving the AO Modulator: The generated RF signal is then amplified to a level sufficient to drive the piezoelectric transducer in the AOM modulator. The transducer converts the RF signal into an acoustic wave, which creates periodic changes in the modulator's refractive index, enabling precise control of the light beam.

Key Specifications to Consider

Choosing the right acousto-optic driver requires understanding several key specifications, as they directly impact performance and system compatibility. These include:

Operating Frequency: The RF range must match the acoustic resonance of the AO modulator.

Output Power: The amount of power delivered to the piezoelectric transducer determines the intensity of the generated sound waves.

Modulation Type: Drivers can offer analog, digital, or pulsed modulation options, depending on how the light beam needs to be manipulated.

Rise Time: This measures how quickly the light beam transitions between on and off states, which is crucial for applications requiring precise timing.

Impedance Matching: Proper input and output impedance ensures efficient signal transfer and minimizes power losses.

Applications of Acousto-Optic Drivers

AOM drivers are widely used in various fields that require precise control of light:

Laser Modulation: AOM drivers are essential in controlling the intensity and direction of laser beams, making them critical in applications like material processing, laser printing, and telecommunications.

Optical Communication: AOM drivers enable high-speed modulation of optical signals in fiber optic communication systems, ensuring fast and reliable data transmission.

Spectroscopy: In scientific research, AOM drivers are used to manipulate light in spectrometers for analyzing the composition of materials.

Conclusion

Acousto-optic drivers are indispensable for controlling light in many optical applications. By converting electrical signals into RF signals, these devices enable precise light manipulation through the acousto-optic effect. Understanding key specifications, such as frequency range, output power, and modulation type, helps in selecting the appropriate driver for any optical system, ensuring optimal performance and system integration.

0 notes

Text

How to adjust the dip switch of the stepper motor driver

1.Explanation of stepper motor driver The stepper motor driver is an actuator that converts electrical pulses into angular displacement, which is mainly used to control the rotation and movement of the stepper motor. It realizes the drive of the motor by converting the control signal into the drive signal of the motor. The stepper motor driver is generally composed of a pulse generator, a power module, a signal decoder and a drive module. The pulse generator is used to generate a control signal (pulse signal) to control the movement of the motor; the power module provides power to the motor so that the motor can operate normally; the signal decoder converts the pulse signal into a motor drive signal to control the operation of the motor; the drive module is used to amplify the motor drive signal to provide sufficient power to drive the motor.

2.Classification of stepper motor drivers 1.Voltage driver: It controls the speed and position of the stepper motor by changing the drive voltage. This driver is characterized by simple structure and low cost, but poor dynamic performance, easy to heat up and lose step. 2.Constant current driver: It drives the stepper motor by controlling the current to ensure that the current of the motor remains constant during operation. This type of driver is characterized by good dynamic performance and low heat generation, but the structure is relatively complex and the cost is high. 3.Microstep driver: It is a high-precision drive method that achieves more detailed position control by dividing the basic step of the stepper motor. This driver has the characteristics of high precision, low vibration and low noise, and is suitable for application scenarios with high precision requirements. 4.Closed-loop driver: By adding an encoder or other sensor to achieve real-time feedback on the position of the stepper motor, high-precision position control is achieved. This driver has the characteristics of high precision, high dynamic performance and low step loss rate, but the structure is relatively complex and the cost is high.

3.Reasons for stepper motor driver alarm 1.Power supply problems are one of the common reasons for stepper motor driver alarms. This includes unstable power supply voltage, too high or too low power supply voltage, poor power supply line contact, and power switch failure. Solutions to these problems include checking whether the power supply voltage meets the requirements, adjusting the power supply voltage in time, repairing or replacing the power supply line contact, and checking and replacing the power switch. 2.Motor problems may also cause stepper motor driver alarms, including motor damage, poor contact between the rotor and stator, and winding short circuit. Solutions to motor failures may include checking whether the motor is overheating and whether it needs to be replaced or maintained, such as cleaning and lubrication. 3.Control signal problems are also an important factor, including poor contact of the control signal line, controller failure, and unstable control signal voltage. Solutions to these problems may involve repairing or replacing the control signal line, checking and replacing the controller, and adjusting the control signal voltage. 4.Problems with the driver itself, such as a damaged or improperly adjusted driver, can also cause alarms. Solving these problems may require replacing the driver or adjusting the driver settings.

4.How to adjust the stepper motor driver dip switch 1.Understand the basic principles of stepper motor drivers A stepper motor driver is an electronic device used to control stepper motors. It converts current into signals that the stepper motor can understand, thereby driving the motor to rotate precisely. Before adjusting the dip switch, you need to understand the basic principles of the stepper motor driver. 2.Determine the working mode and parameter settings Before adjusting the dip switch of the stepper motor driver, you first need to determine the working mode and parameter settings. The working mode can be full-step mode, half-step mode or micro-step mode; parameter settings include step angle, acceleration, drive current, etc. 3.Consult the instruction manual of the stepper motor driver Stepper motor drivers are usually equipped with an instruction manual, which contains detailed parameter settings and information about the dip switches. Before making adjustments, read the instruction manual carefully to understand the location and corresponding functions of the dip switches. 4.Locate and adjust the dip switches According to the instruction manual of the stepper motor driver, locate the dip switches on the driver. Dip switches are usually a row of small switches that can be set to different functions and parameters by toggling. Before adjusting the dip switches, it is recommended to turn off the power supply to avoid short circuits or other damage to the circuit. 5.Adjust the dip switches as needed Adjust the dip switches from one position to another as needed. When adjusting the dip switches, carefully check the information in the instruction manual to ensure that they are adjusted to the correct position. Some dip switches may have multiple options, while others may only have two options (on/off). 6.Start and test the stepper motor driver After the adjustment is completed, reconnect the power supply and start the stepper motor driver. According to the working mode and parameter settings of the driver, perform corresponding tests to ensure that the motor can rotate as expected. If other parameters need to be adjusted, you can refer to the instruction manual again and repeat the above steps. 7.Test and application of the adjusted stepper motor driver Once the dip switches of the stepper motor driver are successfully adjusted, some tests and practical applications can be performed. In the test, you can verify whether the set working mode and parameters are as expected. In the application, you can connect the stepper motor driver to the corresponding equipment or system to achieve the desired functions and performance.

Source:https://www.steppernews.com/2024/09/how-to-adjust-dip-switch-of-stepper.html

0 notes

Text

Gallium Nitride Market Soars: Driven by Automotive Electrification, Consumer Electronics Advancements, and Government Support

According to the UnivDatos Market Insights analysis, automotive electrification, advancements in consumer electronics, and substantial government support and investment will drive the global scenario of the Gallium Nitride market. As per their “Gallium Nitride Market” report, the global market was valued at USD 276.2 Million in 2023, growing at a CAGR of 24.3% during the forecast period from 2024 - 2032 to reach USD XX Million by 2032.

Gallium Nitride is rapidly emerging as a critical material in the semiconductor market, renowned for its superior electronic properties compared to traditional silicon. Gallium Nitride is celebrated for its high electron mobility, thermal conductivity, and efficiency, making it ideal for high-power and high-frequency applications. These characteristics have driven its adoption in various industries, including telecommunications, automotive, and consumer electronics. The demand for Gallium Nitride is particularly strong in the development of power electronics, RF amplifiers, and LEDs, where its ability to operate at higher voltages and temperatures without degradation offers significant performance improvements. As industries continue to push the boundaries of technological innovation, Gallium Nitride is poised to play a pivotal role in the next generation of electronic devices, contributing to energy efficiency and enhanced performance.

The Gallium Nitride market is primarily driven by its superior material properties that enable high-performance applications across various sectors. One significant driver is the increasing demand for energy-efficient and high-power electronics. Gallium Nitride's high electron mobility and thermal conductivity allow for smaller, more efficient power devices that can handle higher voltages and frequencies than traditional silicon-based components. This makes Gallium Nitride an attractive option for power converters, RF amplifiers, and LEDs, leading to significant adoption in the automotive, telecommunications, and consumer electronics industries. The growing trend towards electrification in vehicles, coupled with the need for efficient power management solutions in consumer devices, is further propelling the demand for Gallium Nitride-based technologies.

Another critical driver is the rising investment in 5G infrastructure and advanced communication systems. Gallium Nitride's ability to operate at higher frequencies with greater efficiency makes it ideal for 5G base stations and other RF applications. As telecom companies globally roll out 5G networks, the need for Gallium Nitride components, which can provide better performance and reliability in high-frequency operations, is becoming more pronounced. Additionally, the defense and aerospace sectors are increasingly adopting Gallium Nitride technology for radar and satellite communications due to its robustness and ability to deliver high power density. These combined factors underscore the strategic importance of Gallium Nitride in driving innovation and efficiency across various high-tech industries.

Automotive Electrification

The shift towards electric vehicles (EVs) is significantly driving the demand for Gallium Nitride-based power electronics. Gallium Nitride transistors offer higher efficiency, faster switching speeds, and reduced heat generation compared to silicon-based counterparts. These advantages are critical in EV applications where power efficiency directly translates to longer driving ranges, faster charging times, and overall better performance.

For Instance: Toyota, a leading automotive manufacturer, has been integrating Gallium Nitride technology into its power converters and inverters for electric vehicles. By utilizing Gallium Nitride transistors, Toyota achieves higher efficiency in power management systems, which helps extend the driving range of its EVs and reduces the overall energy consumption. This adoption aligns with the broader industry trend of enhancing vehicle performance while promoting sustainability.

Consumer Electronics Advancements

The consumer electronics market is increasingly adopting Gallium Nitride technology to develop smaller, more efficient power supplies and chargers. Gallium Nitride's high electron mobility and thermal conductivity allow for compact designs with better performance metrics, making it ideal for fast chargers, power adapters, and other portable electronic devices.

For Instance: Anker, a popular brand in the consumer electronics space, has launched a series of Gallium Nitride-based fast chargers that are significantly smaller and more efficient than traditional silicon-based chargers. These Gallium Nitride chargers offer faster charging times and better heat dissipation, enhancing user convenience and device safety. The success of Anker's Gallium Nitride chargers underscores the growing consumer preference for compact and high-performance electronic accessories.

Request Free Sample Pages with Graphs and Figures Here https://univdatos.com/get-a-free-sample-form-php/?product_id=64189

Government Support and Investment

Government initiatives and funding for semiconductor research and manufacturing are crucial drivers for the Gallium Nitride market. Various governments, particularly in the Asia-Pacific region, are investing heavily in the development of advanced semiconductor technologies to support domestic industries and reduce reliance on imports. Policies promoting renewable energy, electric vehicles, and advanced communication infrastructure further boost the demand for Gallium Nitride technology.

For Instance: The Chinese government has been actively investing in the semiconductor sector, including Gallium Nitride technology, through initiatives like the Made in China 2025 plan. This plan aims to boost domestic production capabilities and technological advancements in high-tech industries. Significant funding and subsidies are directed towards research and development of Gallium Nitride semiconductors, facilitating their adoption in various applications from renewable energy systems to telecommunications.

Conclusion

The Gallium Nitride market is experiencing robust growth driven by automotive electrification, advancements in consumer electronics, and substantial government support and investment. Gallium Nitride's superior efficiency and performance make it a key component in electric vehicles, as seen with Toyota's implementation, and in consumer electronics, highlighted by Anker's innovative chargers. Furthermore, government initiatives, particularly in China, underscore the strategic importance of Gallium Nitride technology in advancing national high-tech capabilities. These drivers collectively highlight the critical role of Gallium Nitride in transforming power management and electronic systems across diverse industries.

Contact Us:

UnivDatos Market Insights

Email - [email protected]

Contact Number - +1 9782263411

Website -www.univdatos.com

0 notes