#High Pressure Hoses Manufacturers

Explore tagged Tumblr posts

Text

Parker High Pressure Hoses: An In-Depth Review of Key Features and Specifications

In fluid power systems, where precision and reliability are paramount, Parker high pressure hoses are a testament to cutting-edge engineering and unwavering performance. As an industry leader, Flexotech has consistently delivered top-notch solutions, and their high-pressure hoses are no exception. This in-depth review will explore the key features and specifications that make Parker high pressure hoses a preferred choice across various industries.

A commitment to material innovation lies at the core of Parker's high-pressure hoses. These hoses are crafted from advanced materials that ensure durability, flexibility, and resistance to wear and tear, even in the most demanding applications. High-quality materials make Parker hoses ideal for conveying fluids under high pressure with minimal risk of leaks or failures.

Parker high pressure hoses are engineered to cater to various applications, from hydraulic systems in heavy machinery to critical processes in manufacturing plants. The versatility of these hoses makes them indispensable in the construction, agriculture, aerospace, and automotive industries. Whether it's transmitting hydraulic fluids, oils, or gases, Parker high pressure hoses provide a reliable and efficient solution.

One of the standout features of Parker high pressure hoses is their impressive pressure ratings. These hoses are designed to withstand extreme pressure conditions and ensure optimal performance and safety in high-pressure applications. The availability of a wide range of sizes allows users to select hoses that precisely match their system requirements, providing flexibility in system design and installation.

Parker high pressure hoses excel not only in handling extreme pressure but also in adapting to temperature variations. These hoses are designed to perform flawlessly in a broad temperature range, from sub-zero to elevated temperatures. This adaptability is crucial for applications where the temperature environment can fluctuate significantly, ensuring consistent performance in all conditions.

Parker employs advanced construction techniques and reinforcement methods to enhance the strength and longevity of their high-pressure hoses. The layers of reinforcement, often comprising high-tensile steel wires or synthetic fibers, provide structural integrity and prevent hose deformation under pressure. The robust construction of Parker hoses contributes to their resistance against abrasion and chemical degradation.

In complex hydraulic systems, the ability of hoses to bend and flex without compromising performance is crucial. Parker high pressure hoses are designed flexibly, allowing for easy installation and routing in confined spaces. The specified bend radius ensures the hoses maintain structural integrity even when subjected to sharp bends, enhancing their overall reliability.

Parker understands the diverse nature of fluid conveyance applications, and as such, their high-pressure hoses are engineered for compatibility with various hydraulic fluids and chemicals. This feature ensures that the hoses remain resilient and effective, even when exposed to various substances commonly encountered in industrial operations.

Flexotech upholds stringent quality control measures to ensure that every high-pressure hose that bears its name meets or exceeds industry standards. Rigorous testing procedures, including pressure testing, leak detection, and material analysis, are integral to manufacturing. This commitment to quality assurance instils confidence in users, assuring them of the reliability and performance of Parker high-pressure hoses.

Parker's global presence ensures that their high-pressure hoses are readily available to customers worldwide. This extensive network is complemented by dedicated customer support, technical assistance, and a wealth of resources that empower users to make informed decisions about their fluid power systems.

In conclusion, Parker's high pressure hoses epitomize excellence in fluid power solutions. From their innovative use of materials to their versatility, pressure ratings, and global support, these hoses consistently meet and exceed the demanding requirements of various industries. Whether you are navigating the challenges of heavy-duty machinery or seeking reliability in critical manufacturing processes, Parker high pressure hoses emerge as a reliable and robust choice.

0 notes

Text

Top High Pressure Hose Pipe Suppliers In India - Mcneil Instrument

Mcneil Instrument is a leading manufacturer, exporter, and supplier of high-pressure hose pipes in India, We specialize in producing and distributing hoses capable of withstanding and conveying fluids under high pressure. The new industrial power hose Mcneil was created specifically for high-pressure applications. The hose that has longitudinal parts that have been strengthened is the Mcneil high-pressure hose. For uses like air, pneumatics, heavy-duty suction and delivery of water and chemicals, it demonstrates its versatility as a hose. A high-pressure hose is a specialized type of hose designed to safely and efficiently transport fluids or gases under extremely high pressure. Constructed from premium materials like stainless steel, these hoses feature a robust design with heavier wall thickness and hydro-formed construction to ensure durability and resistance to harsh environments.

0 notes

Text

#Hydraulic Hoses#PTFE Hoses#PTFE Tubes#Convoluted PTFE Hose Manufacturers#Convoluted Hoses#High Pressure PTFE Hose#Threaded Pipe Connector#Threaded Connector#SS Wire Braided Convoluted Hoses#PTFE Hoses Aerospace#PTFE Plain Hoses#Two Axis Pipe Connector#Fixed Flange Connector#Copper Ended Connector#Dash 2 PTFE Hoses

1 note

·

View note

Note

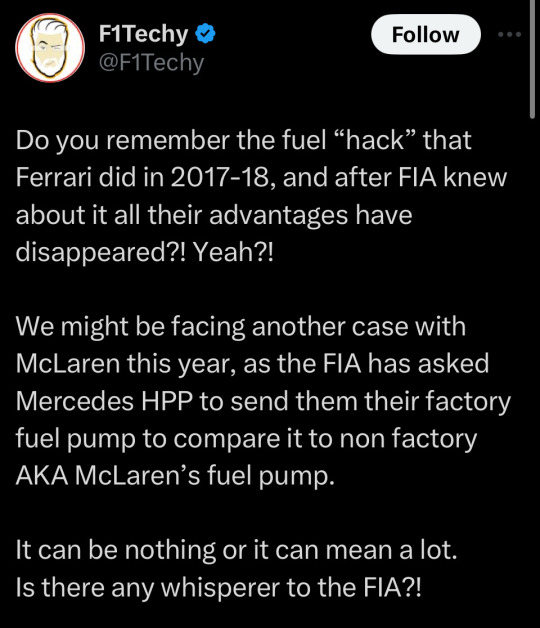

https://x.com/F1Techy/status/1797338007860662614

is this real?

Nope, whoever this person is, they are way off and they have no sources so don’t believe a word they say

In fact Mercedes don’t make their own fuel pumps, let alone McLaren’s. No team has made their own fuel pumps since 2021.

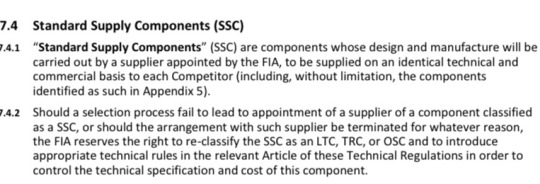

Fuel pumps are categorised as a Standard Supply Component which means that they are designed and manufactured by a third party designated by the FIA.

This means that the same company makes all of the fuel pumps for all of the teams on the grid, so if there was anything going on with a fuel pump they would be going back to this third party not Mercedes.

Just because someone has a blue tick, doesn’t mean that they know what they are saying.

Full list of SSC parts below (from FIA regulations)

Wheel covers

• Clutch shaft torque

• Wheel rims

• Tyre pressure sensor (TPMS)

• Tyres

• Fuel system primer pumps, and flexible pipes and hoses

• Power unit energy store current/voltage sensor

• Fuel flow meter

• Power unit pressure and temperature sensors

• High-pressure fuel pump

• Car to team telemetry

• Driver radio

• Accident data recorder (ADR)

• High-speed camera

• In-ear accelerometer

• Biometric gloves

• Marshalling system

• Timing transponders

• TV cameras

• Wheel display panel

• Standard ECU

• Standard ECU FIA applications

• Rear lights

69 notes

·

View notes

Text

RV Maintenance Tips for Traveling Through Crawfordville, Georgia

Traveling through Georgia, especially near areas like Crawfordville, offers picturesque views, tranquil surroundings, and the ultimate escape into nature. As you journey, it’s crucial to ensure your RV is in tip-top shape. Whether you’re staying at Sunrise River RV Park or passing through RV parks near Augusta, GA, maintaining your RV is vital to ensure a smooth and enjoyable trip. Below are some essential RV maintenance tips to keep in mind as you explore this beautiful region.

1. Regular Tire Inspections

One of the most critical aspects of RV maintenance is tire care. Before heading to any RV park near Augusta, GA, check your tires for proper inflation, wear, and tear. The varied terrain in Georgia, from highways to forest trails, can strain your tires. Ensure they are inflated to the manufacturer's recommended pressure. Also, inspect the treads for any signs of excessive wear, and replace tires if necessary. A blowout on the road can be dangerous and inconvenient, so this simple check can save you a lot of trouble.

2. Check and Maintain Brakes

Given the hilly landscapes around Crawfordville, ensuring your brakes are in excellent condition is essential. Regularly check the brake pads, rotors, and fluid levels. If you notice any squeaking, grinding, or decreased braking efficiency, get them serviced immediately. The peace of mind knowing your brakes are functioning correctly will make your travel through Georgia’s scenic routes much safer.

3. Inspect Roof Seals and Vents

Georgia’s climate can be unpredictable, with sudden rain showers even in sunny conditions. To avoid leaks and water damage, inspect the seals around your RV's roof, windows, and vents. Look for any cracks or deteriorated seals, and reapply sealant if necessary. This small step can prevent costly repairs later, especially if you're planning to stay at Sunrise River RV Park, where the natural surroundings are best enjoyed dry and leak-free!

4. Keep the Electrical System in Check

Your RV’s electrical system is its lifeline, powering everything from the refrigerator to the air conditioning. Before you park at any RV park near Augusta, GA, inspect your batteries, wires, and connections. Make sure your batteries are fully charged and in good condition. Test your generator to ensure it’s functioning properly, especially if you plan to camp in more remote areas like Crawfordville. Keeping a multimeter handy can help you diagnose any electrical issues that may arise on the road.

5. Monitor Your Water System

Georgia’s humidity and temperatures can lead to unique challenges for your RV’s water system. Regularly check your freshwater, gray, and black water tanks for leaks or signs of wear. Ensure that the hoses are in good condition and securely connected. If you plan on staying at Sunrise River RV Park, you’ll appreciate having a fully functional water system for showers and kitchen use. Additionally, consider investing in a water pressure regulator to prevent high-pressure water at certain campsites from damaging your RV’s plumbing.

6. Keep Your HVAC System Clean

The summer heat in Georgia can be intense, making your RV’s HVAC system essential for comfort. Clean the filters regularly and ensure that the air conditioning unit is functioning properly. If you're visiting Crawfordville during the warmer months, you’ll want to stay cool and comfortable after a day of exploring. Routine maintenance of your HVAC system will keep you and your family comfortable throughout your journey.

7. Stock Up on Essential Supplies

Crawfordville offers natural beauty and serenity, but it’s also essential to be prepared for any situation. Ensure you have a well-stocked toolkit that includes wrenches, screwdrivers, pliers, and any other tools specific to your RV model. Carry spare fuses, bulbs, and essential fluids like oil, coolant, and windshield washer fluid. Being prepared will ensure that minor issues don’t escalate into significant problems, allowing you to enjoy your stay at any RV park near Augusta, GA, or beyond.

8. Plan for Waste Disposal

Responsible waste management is vital for the environment and the longevity of your RV’s sanitation system. Before arriving at Sunrise River RV Park, familiarize yourself with the park's waste disposal facilities. Ensure that your black and gray water tanks are emptied and clean. Carry appropriate chemicals to treat your tanks, reducing odors and buildup. Keeping your waste management system in top shape ensures a pleasant experience for you and your fellow campers.

9. Check Your Propane System

Propane is essential for cooking, heating, and refrigeration in many RVs. Before embarking on your journey through Georgia, inspect your propane tanks and lines for leaks. Make sure your tanks are securely mounted and that your regulator is functioning correctly. It’s also wise to keep a carbon monoxide detector in your RV for safety. Regularly inspecting your propane system will allow you to enjoy meals and hot showers without worry during your stay.

10. Protect Against Pests

Crawfordville, with its lush landscapes and natural beauty, can also be a haven for insects and small animals. To protect your RV from unwanted guests, seal any gaps or cracks where pests might enter. Regularly clean your RV’s interior, removing food crumbs and trash that could attract pests. If you’re staying at Sunrise River RV Park, you’ll want to focus on the natural beauty of the area, not on dealing with ants or mice inside your RV!

11. Keep Your RV Clean

Traveling through Georgia can expose your RV to dust, dirt, and debris. Regularly wash your RV to maintain its appearance and protect its exterior from damage. Pay special attention to the undercarriage, especially after traveling on dirt roads or through muddy areas. Cleaning your RV not only keeps it looking good but also helps prevent rust and corrosion, ensuring it stays in excellent condition for years to come.

12. Stay Informed About Local Road Conditions

As you travel through Georgia, staying informed about local road conditions can help you avoid unexpected delays or hazards. Check weather forecasts and road reports, especially during the rainy season, when roads can become slick or flooded. Knowing the conditions ahead of time allows you to plan your route and adjust your driving to ensure a safe journey to Sunrise River RV Park or any other destination in the area.

Conclusion

Maintaining your RV is essential to ensure a safe, comfortable, and enjoyable journey through Crawfordville and the surrounding areas of Georgia. Whether you’re heading to Sunrise River RV Park or exploring RV parks near Augusta, GA, following these maintenance tips will keep your RV in top condition, allowing you to focus on the adventure ahead.

From regular tire checks to ensuring your water and electrical systems are functioning properly, taking the time to maintain your RV will enhance your travel experience. By being proactive with your maintenance routine, you can enjoy the natural beauty and serene landscapes of Crawfordville, Georgia, without worry. Safe travels!

2 notes

·

View notes

Text

360-Degree Freedom: Exploring the Benefits of Hose Swivel Fittings

Hose swivel fittings are essential components that revolutionize the way hoses are used in various applications. With their ability to rotate freely, these fittings provide increased flexibility, reduce tangling and kinking, and improve overall efficiency.

For More Information Please visit, https://www.superklean.com/our-products/standard-swivel-fittings/

In this infographic, we will explore the key features and benefits of hose swivel fittings.

360-Degree Rotation:

Hose swivel fittings enable a full 360-degree rotation, allowing hoses to move freely without restrictions. This rotation eliminates twists and tangles, ensuring a smooth flow of water or other fluids. It enhances maneuverability, making it easier to reach different angles and corners, even in tight spaces.

Seamless Connections:

Hose swivel fittings offer seamless connections between hoses and various attachments. They provide a rotating joint that allows for easy attachment and detachment without twisting or kinking the hose. This feature simplifies the process of connecting sprinklers, nozzles, and other accessories, saving time and effort.

Improved Durability:

By reducing strain on hose connections, swivel fittings help extend the lifespan of hoses. The rotating action minimizes wear and tear, preventing leaks, cracks, and premature failure. With enhanced durability, you can rely on your hoses for longer periods, reducing replacement costs.

Versatility:

Hose swivel fittings are available in various sizes and configurations, making them compatible with different hose types and applications. Whether you have a garden hose, high-pressure hose, or specialized industrial hose, there is a swivel fitting to suit your needs. This versatility ensures that you can optimize your hose setup for a wide range of tasks.

Enhanced Safety:

Tangled or kinked hoses can pose safety risks, leading to tripping hazards or sudden bursts of water pressure. Hose swivel fittings mitigate these risks by promoting a tangle-free and secure hose connection. They allow for smooth hose movement, minimizing accidents and creating a safer working environment.

Increased Efficiency:

Hose swivel fittings significantly improve efficiency by reducing the time spent untangling hoses and ensuring a continuous flow of fluids. With easy maneuverability, you can complete tasks faster and more effectively. This increased efficiency translates into enhanced productivity, whether you're gardening, cleaning, or conducting industrial operations.

Cost Savings:

Investing in hose swivel fittings offers long-term cost savings. By prolonging the lifespan of your hoses and reducing the need for frequent replacements, swivel fittings help you save money in the long run. Additionally, the efficiency and productivity gains achieved through the use of swivel fittings can contribute to overall cost reductions.

Conclusion:

Hose swivel fittings are game-changers when it comes to optimizing hose usage. With their ability to provide unrestricted rotation, seamless connections, improved durability, versatility, enhanced safety, increased efficiency, and cost savings, they are indispensable tools for homeowners, professionals, and industries alike. Incorporating hose swivel fittings into your hose setup will transform your experience, making hose-related tasks easier, safer, and more efficient.

2 notes

·

View notes

Text

SuperKlean's High-Temperature Hose: The Ultimate Solution for Industrial Hot Water Delivery

SuperKlean, a leading provider of industrial cleaning equipment, is proud to offer their heavy duty hot water hose. This high-quality hose is designed to withstand the demands of industrial applications, providing users with a reliable and efficient way to deliver hot water in a range of settings.

SuperKlean's heavy duty hot water hose is constructed from high-quality materials, making it durable and long-lasting. The hose is designed to handle high temperatures and high pressures, ensuring that it can deliver hot water even in the most demanding environments. This makes it an ideal solution for a wide range of industries, including manufacturing, food processing, and more.

For More Information Please visit, epdm hot water hose

In addition to its durability, SuperKlean's heavy duty hot water hose is also highly flexible, making it easy to maneuver and use in tight spaces. The hose features a rugged cover that resists abrasions and punctures, as well as a smooth inner tube that helps to minimize flow resistance and maximize the flow of hot water.

One of the key benefits of SuperKlean's heavy duty hot water hose is its resistance to kinking. Unlike many other hoses, which can easily become kinked and damaged, this hose is designed to remain flexible and kink-free, even in challenging conditions. This helps to minimize downtime and reduce the need for frequent hose replacements.

SuperKlean's heavy duty hot water hose also features a range of safety features, designed to protect users and equipment from accidents and damage. For example, the hose features a durable brass fitting that helps to prevent leaks and spills. Additionally, the hose is designed to be easy to handle, with a comfortable grip that reduces the risk of hand fatigue and injury.

Overall, SuperKlean's heavy duty hot water hose is a reliable and efficient solution for delivering hot water in industrial settings. With its durable construction, high flexibility, and range of safety features, this hose is sure to meet the needs of a wide range of industries. Whether you're looking for a hose for food processing, manufacturing, or other applications, SuperKlean has the right solution for you.

2 notes

·

View notes

Text

How to Maintain Your Home’s Exterior Paint Over Time

Exterior paint is an essential layer of protection and beauty for your home. It shields the structure from harsh weather, moisture, and sunlight while enhancing curb appeal. Proper maintenance can extend the life of your exterior painting, saving time and money in the long run. Below is a detailed guide to help you keep your home’s exterior paint looking fresh and durable over time.

1. Inspect Your Exterior Regularly

Frequent inspections help spot issues early before they escalate.

Walk Around Your Home Twice a Year Check for cracks, peeling, or fading paint.

Focus on Vulnerable Areas Pay extra attention to window frames, doors, and shaded areas prone to moisture.

2. Clean the Surface Annually

Dirt, grime, and mold can degrade paint over time.

Wash With a Garden Hose or Pressure Washer Use mild soap and water to remove dust and stains.

Target Mold and Mildew Scrub affected areas with a mixture of water and bleach to prevent damage.

Avoid Harsh Chemicals Opt for gentle cleaning solutions to protect the paint’s finish.

3. Address Minor Repairs Promptly

Small issues can grow into major problems if ignored.

Seal Cracks and Gaps Use caulk to seal any small cracks around windows, doors, and siding.

Fix Chipped Paint Sand and repaint areas with peeling or chipped paint to prevent further damage.

Repair Damaged Wood or Siding Replace rotten wood or cracked siding to maintain the paint’s integrity.

4. Protect Paint From Moisture

Water can cause blistering, peeling, and mold growth.

Check Gutters and Downspouts Ensure they direct water away from your walls and foundation.

Trim Nearby Trees and Shrubs Prevent branches from touching your walls, which can trap moisture.

Inspect Caulking Around Openings Replace deteriorated caulking to keep water out.

5. Touch-Up Faded or Damaged Areas

Touching up small areas can prevent the need for a complete repaint.

Match Paint Colors Carefully Use leftover paint or color-matched options for consistency.

Apply Thin Layers Use a brush or roller to blend new paint with existing areas seamlessly.

6. Protect Paint From Sun Damage

Excessive sun exposure can fade and weaken paint over time.

Choose UV-Resistant Paint Opt for paints designed to resist fading from sunlight.

Add Shading Elements Install awnings or plant trees to protect walls from direct sunlight.

Repaint When Necessary Dark and vibrant colors may require repainting sooner due to faster fading.

7. Repaint Every 5–10 Years

Even with excellent maintenance, repainting is inevitable.

Follow Manufacturer’s Guidelines Check your paint’s warranty and recommended lifespan.

Choose High-Quality Paint Investing in premium paint ensures better durability and protection.

Prepare the Surface Properly Sand, clean, and prime before repainting for the best results.

8. Prevent Insect Damage

Insects like termites can damage wood and cause paint to crack.

Inspect for Signs of Pests Look for holes, wood dust, or other signs of insect activity.

Apply Protective Coatings Use insect-repellent paints or treatments to safeguard your home.

Hire a Pest Control Professional Address infestations immediately to prevent structural damage.

9. Seasonal Maintenance Tips

Different weather conditions require specific care.

Spring: Clean and inspect your exterior after winter weather.

Summer: Focus on sun protection and touch-ups.

Fall: Remove debris and prepare for rain or snow.

Winter: Check for ice dams and water pooling around the house.

10. Hire Professional Help When Needed

Certain tasks are best handled by experts.

Schedule Routine Inspections A professional can identify potential issues early.

Hire Painters for Large Repairs Professionals ensure smooth and durable repairs.

Consider Annual Maintenance Plans Many companies offer packages for regular upkeep.

Benefits of Maintaining Exterior Paint

Enhances Curb Appeal A well-maintained exterior boosts your home’s appearance.

Extends Paint Lifespan Proper care reduces the need for frequent repainting.

Protects Against Structural Damage Prevents water and pest issues that can weaken your home.

Saves Money Regular maintenance is more cost-effective than major repairs.

Conclusion

Maintaining your home’s exterior paint requires regular inspections, cleaning, and minor repairs. Protecting against moisture, sunlight, and insects helps preserve the paint’s integrity and appearance. By following these simple steps, you can ensure your home looks beautiful and remains protected for years to come.

If you’re unsure where to start or need assistance, don’t hesitate to contact a professional exterior painting service. A little maintenance today can save you from costly repairs tomorrow!

0 notes

Text

Every business majorly involving in the industrial & manufacturing segment faces situations where there is an immediate requirement for a compressor. With 25 years of rental air compressor industry excellence, Pioneer India offers portable air compressor rental in and around Bangalore, we have a wide variety of compressor products to support air tools for high demanding jobs. Our rental air compressor equipment is from the best brands in the market, equipped with ISO standards, Fast set-up and a cost- and energy-effective installation depending on the delivery location in/around Bangalore. Trusted by 4000+ Happy Clients, our other offerings involve auxiliary equipment like air dryers, oil-water separator, high-pressure hoses, storage tanks, customized to specific needs & demands of clients.

0 notes

Link

Construction: CR – Synthetic rubber at the core, covered in CR synthetic rubber on the outside, reinforced with four spiral steel wires

Poly High Pressure Hose Manufacturers In Bangalore

Under the same working temperature, these hose have a higher working pressure. The hose has the best resistance to abrasion and impulse fatigue thanks to its four layers of high-tensile spiral wire. Oil field services, paving and road maintenance, construction, ground and building maintenance, material handling, and construction all make use of these hoses.

0 notes

Text

High Pressure Water Pipe for Car Wash

A high-pressure hose is a specialized type of hose designed to safely and efficiently transport fluids or gases under extremely high pressure. Constructed from premium materials like stainless steel, these hoses feature a robust design with heavier wall thickness and hydro-formed construction to ensure durability and resistance to harsh environments. This makes them ideal for car wash applications, where high-pressure water is needed to effectively clean vehicles.

Key Features of Mcneil Instrument High Pressure Hose 1. Materials and Construction: Crafted from premium stainless steel with a durable outer cover, our hoses are resistant to oil, abrasion, corrosion, ozone, and aging, ensuring longevity and reliability. 2. Inner Core Design: The smooth inner core minimizes pressure drop, while high-tensile spiraled wire construction enhances durability, kink resistance, and longevity. 3. Temperature and Flexibility: Capable of operating in temperatures ranging from 40°F to 250°F, our hoses offer flexibility and require less installation space. 4. Performance Benefits: Low volumetric expansion ensures rapid response times in hydraulic systems, making them ideal for applications requiring tight routing and high-pressure conditions. 5. Chemical Resistance: Our hoses maintain flexibility and resilience in challenging environments, remaining resistant to chemicals throughout their service life. Mcneil Instrument is a leading manufacturer, exporter, and supplier of high-pressure hose pipes in India, We specialize in producing and distributing hoses capable of withstanding and conveying fluids under high pressure. The new industrial power hose Mcneil was created specifically for high-pressure applications. The hose that has longitudinal parts that have been strengthened is the McNeil high-pressure hose. For uses like air, pneumatics, heavy-duty suction and delivery of water and chemicals, it demonstrates its versatility as a hose.

0 notes

Text

How Is Calcium Carbonate Used in the Production of Rubber?

Rubber production is a complex process that involves combining various materials to achieve desired properties like durability, flexibility, and strength. Among these materials, calcium carbonate plays a crucial role in improving the quality and cost-efficiency of rubber products. This naturally occurring substance has unique properties that make it ideal for use in the rubber industry.

Enhancing Rubber Properties

Calcium carbonate is widely used in rubber manufacturing because it enhances several key properties of the final product. When added, it increases the strength and elasticity of rubber, making it more resistant to wear and tear. Additionally, it improves the surface finish of rubber products, giving them a smooth and appealing texture. These qualities are essential for products like tires, belts, and hoses that require both durability and aesthetic appeal.

Reducing Production Costs

One of the main advantages of using calcium carbonate powder in rubber production is its ability to reduce manufacturing costs. As a cost-effective filler material, it replaces a portion of the more expensive rubber compound without compromising quality. This substitution not only cuts costs but also reduces the environmental impact by minimizing the amount of raw rubber needed.

Supporting Manufacturing Processes

Calcium carbonate also contributes to the efficiency of the production process. Its fine particles improve the flow and processing characteristics of rubber compounds during mixing and molding. This ensures uniformity in the material, making the production process smoother and faster. Manufacturers can produce high-quality rubber products with fewer defects, enhancing overall productivity.

Improving Heat Resistance and Longevity

In addition to its structural benefits, calcium carbonate enhances the heat resistance of rubber. This makes the material suitable for applications in high-temperature environments, such as automotive and industrial machinery parts. Moreover, it increases the lifespan of rubber products by reducing the rate of wear and degradation over time.

Common Applications in the Rubber Industry

Calcium carbonate powder is used in a variety of rubber products, including:

Tires: Provides strength and reduces wear.

Conveyor Belts: Enhances durability and flexibility.

Hoses: Improves resistance to pressure and heat.

Footwear: Adds strength and a smooth finish to soles.

These applications showcase the versatility of calcium carbonate in creating products that meet specific industrial requirements.

Conclusion

Calcium carbonate is an indispensable component in the production of rubber, offering numerous benefits such as enhanced durability, improved manufacturing efficiency, and cost reduction. By incorporating calcium carbonate powder into rubber compounds, manufacturers can create high-quality products that meet the demands of various industries. Its contribution to the rubber industry highlights the importance of this material in modern manufacturing processes.

0 notes

Text

Our Experience with the Washing Machine Service Centre in Palavakkam

Looking for reliable washing machine services in Palavakkam? Our washing machine service center offers expert solutions for all types of washing machine problems, ensuring quick and efficient repairs. With years of experience and a team of certified technicians, we provide hassle-free services for both top-loading and front-loading machines.

Our Services:

Repair Washing Machine Regardless of the nature of the malfunction-be it related to the motor, drum, electrical components, or internal wiring-we can manage every mechanical or electrical breakdown. Our specialities lie in speedy detection and precise fixing.

Installation and Setup: Need help installing your new washing machine? Our experts ensure your machine is correctly set up, connected to the water supply, and tested to avoid any issues after installation. We handle both in-home and commercial setups.

Regular Maintenance and Servicing: Proper maintenance will lengthen the lifespan of your washing machine, so we offer preventive maintenance services to clean the machine and check for any matters for further adjustments, thus giving you an exemption from sudden breakdowns.

Unclogging and Drainage Problems: A clogged drainage system can prevent your washing machine from working properly. Our technicians are experts in unclogging blocked drain pipes, fixing faulty pumps, and solving water drainage problems to ensure your machine is running smoothly.

Leakage and Water Supply Issues: Leakage is a common problem with washing machines. Our experts are adept at finding and fixing leaks from the water inlet, hoses, or the drum. We also resolve low water pressure issues to ensure smooth operation.

Spin Cycle and Noise Repair: If your washing machine is not spinning properly or is noisy, it could be due to imbalanced loads or faulty parts. We diagnose and fix spin cycle malfunctions, reduce noise, and repair unbalanced drum issues to restore the machine's efficiency.

Replacing of Parts: We give the customer authentic parts in case a particular part fails. The belts, motors, bearings, seals, and filters all come from genuine manufacturers who will guarantee to produce long-lasting compatible parts with your machine.

Diagnostic Service: Diagnostic service is an entire diagnostic analysis given to trace out the precise problem that affects the functioning of the washing machine. Once diagnosed, we find a suitable solution according to our customers' convenience.

Conclusion

Our washing machine service center in Palavakkam provides excellent and efficient repair and maintenance services for all leading brands. Our skilled technicians, along with our high-quality service, ensure your washing machine is running smoothly. Contact us today for prompt professional assistance!

0 notes

Text

How do you troubleshoot common problems in the Range Rover Engine 3.0?

The Range Rover 3.0 is an engine widely lauded for its outstanding performance and innovative design. These day's market has seen the luxury SUV gaining much market share; however, after some time, even such high-performance engines experience certain issues. Correct troubleshooting helps minor problems not develop into a costly repair. These are especially important for users of reconditioned engines, which, although reliable, can have characteristics that differ from the new. We delves into some common problems associated with the Range Rover engines 3.0 and offers practical troubleshooting tips to keep the vehicle running at its best.

Identifying Common Oil Leaks in the Range Rover 3.0 Engine

Oil leaks are a frequent issue in Range Rover engines, particularly in older or reconditioned engines. Common causes include degraded gaskets, damaged seals, or loose drain plugs. Symptoms may include visible oil puddles under the vehicle or a burning oil smell. First, check the oil pan, valve cover gasket, and oil filter housing for leaks. Use a flashlight to spot any wet or oily areas. Tighten loose components and replace any worn gaskets or seals. Regular oil changes and using the manufacturer-recommended oil grade can also prevent future leaks. For persistent issues, a professional diagnostic scan is advisable, especially for reconditioned engines where previous repairs might influence performance.

Overheating Diagnosis in Range Rover 3.0

Overheating can cause severe engine damage. Common reasons for overheating in the Range Rover 3.0 are coolant leaks, a faulty thermostat, or failure of the water pump. Inspect the coolant level and look for visible leaks from hoses and at the radiator. Test the thermostat by feeling the upper radiator hose; it should warm up slowly. A cold hose could indicate a stuck thermostat. Check the water pump for wear, including leaks or unusual noises. In rebuilt engines, the cooling system parts should have been inspected as part of the rebuild. Regularly flushing the cooling system and keeping coolant at the recommended level will eliminate overheating once and for all.

Fuel System Malfunctions in the Range Rover 3.0 Engine

Poor engine performance or stall is caused by a malfunctioning fuel system, among other reasons. It may involve clogged fuel injectors, the fuel pump starting to fail, or contaminated fuel. Troubleshooting involves observing for signs of clogging through uneven engine performance or misfire. Minor clogs can be solved by adding a fuel injector cleaner. Another step is testing the fuel pump pressure with the use of a gauge to meet manufacturer specifications. Replacement of the fuel filter is an imperative so that no debris reaches the engine. Reconditioned engines require recheck on fuel systems to confirm the calibration upon reinstallation. Sufficient-quality fuel should always be used in maintaining the system.

Clearing Noises from Timing Chain in the Range Rover 3.0 Engine

A noisy timing chain is another common problem that is seen often in high-mileage Range Rover engines. The causes can range from failure of the chain tensioner to worn-out chain guides. Begin by listening for rattling noises during engine startup, especially when the engine is cold. Inspect the timing chain and its components for wear. Replace the chain, tensioners, and guides if necessary. For reconditioned engines, ensure that the timing chain assembly was replaced or inspected during reconditioning. Regular oil changes using the recommended oil grade help maintain the timing chain's longevity and reduce noise.

How to Troubleshoot Electrical System Malfunctions of the Range Rover 3.0 Engine

Range Rovers mainly employ electronic systems that fail or become faulty at times. These include malfunctioning sensors, faulty wiring, or even software errors. The OBD-II scanner is used to scan for any error codes related to the engine. Visible damage or loose connections in the wiring harnesses are inspected. Sensors like the crankshaft position sensor and oxygen sensors are checked for proper functionality. Software updates may be needed if the problems persist. The ECU, or Engine Control Unit, in a reconditioned engine must be compatible and properly programmed. Regular diagnostic checks ensure that electrical issues are detected early and resolved quickly.

Turbocharger faults in the 3.0 Range Rover engine

The turbocharger improves engine performance but often malfunctions through low boost pressure or excessive smoke from the exhaust. Causes can be oil contamination, worn bearings, or broken turbo fins. Inspect the turbocharger for oil leaks and excessive play in the shaft. Check the intercooler and related hoses for blockages or leaks. Clean or replace the air filter regularly to prevent debris from damaging the turbo. Reconditioned engines may have replaced or refurbished turbochargers; ensure these components meet OEM standards. Timely oil changes and using high-quality engine oil can prolong turbocharger life.

Diagnosis of Exhaust System Problems in Range Rover 3.0

Exhaust system problems, for instance, high emissions or unusual noises can affect an engine's performance. The more common causes are likely to be a failing catalytic converter, exhaust leaks, or mufflers that have been damaged. Check the exhaust system for any visible damage, rust, or leaks. Listen for unusual noises, especially during acceleration. Use an emissions tester to determine if the catalytic converter is working correctly. For reconditioned engines, ensure that the exhaust system complies with emission standards and vehicle specifications. Regular maintenance and prompt repairs can prevent long-term exhaust system damage.

Low Oil Pressure in the Range Rover 3.0 Engine

Low oil pressure can cause severe damage if not addressed promptly. Common causes include a failing oil pump, clogged oil passages, or insufficient oil levels. Keep track of the oil pressure gauge for irregular readings. Examine the oil pump and all its associated parts for wear. Flush the engine to remove sludge that might be clogging oil passages. Refill with the type and amount of oil recommended. On reconditioned engines, make sure the oil pump was checked or replaced as part of the rebuild. Routine oil changes and checking oil levels can prevent pressure-related issues. Read the full article

0 notes

Text

CPAP Machine is Making Noise: Troubleshooting and Solutions

Continuous Positive Airway Pressure (CPAP) machines are lifesaving devices for individuals with sleep apnea. However, like any electronic device, they can develop issues over time. One of the most common concerns users face is excessive noise. A noisy CPAP machine can disrupt sleep, causing discomfort to the user and their bed partner. This blog will help you identify the causes of CPAP noise and guide you in resolving the problem effectively.

Understanding the Source of CPAP Noise

Machine Motor CPAP machines generate air pressure through a motor. Over time, wear and tear or mechanical issues can cause the motor to produce unusual sounds.

Hose or Tubing Cracks, kinks, or loose connections in the CPAP hose can lead to air leaks, creating whistling or hissing sounds.

Mask Fit An improperly fitted mask may cause air to escape, leading to noise and reduced therapy effectiveness.

Filters Dirty or clogged filters can force the motor to work harder, increasing the noise level.

Humidifier Chamber Vibrations or improper alignment of the humidifier chamber can result in a rattling or humming sound.

Environmental Factors Vibrations from a hard surface or interference from other devices may amplify the sound.

How to Troubleshoot a Noisy CPAP Machine

Inspect the Machine

Ensure that the CPAP machine is on a stable, padded surface to minimize vibrations.

Check for any visible damage to the machine.

Check the Tubing

Look for cracks, holes, or kinks in the hose.

Secure the hose connections at both the machine and the mask.

Adjust the Mask

Ensure the mask fits snugly to avoid air leaks.

Replace worn-out cushions or straps as they may affect the seal.

Clean and Replace Filters

Wash reusable filters regularly as per the manufacturer’s guidelines.

Replace disposable filters every month or as recommended.

Inspect the Humidifier

Check for proper alignment of the humidifier chamber.

Ensure there is enough water in the chamber to prevent a dry motor sound.

Update or Replace Components

Replace old tubing, masks, and filters.

If the machine motor itself is noisy, contact the manufacturer or supplier for repair or replacement options.

Reduce Environmental Noise

Use a CPAP machine cover or noise-reducing mat.

Place the machine in a drawer or box with sufficient ventilation to muffle sound.

Preventing Noise Issues in the Future

Regular Maintenance Cleaning and maintaining your CPAP machine according to the manufacturer’s instructions is crucial.

Use Quality Accessories Invest in high-quality CPAP accessories to ensure durability and performance.

Service the Machine Periodically Schedule annual checkups with your supplier or manufacturer to ensure the machine is functioning optimally.

Opt for Quiet Models If noise persists, consider upgrading to a quieter CPAP machine. Many modern models are designed for silent operation.

When to Seek Professional Help

If troubleshooting does not resolve the issue, it may be time to seek expert assistance. Contact your CPAP supplier or the manufacturer for professional inspection or repair. You may also consider renting or purchasing a new machine if your current one is outdated or beyond repair.

Conclusion

A noisy CPAP machine can disrupt the therapy process and affect your sleep quality. Identifying the source of the noise and applying the troubleshooting steps outlined in this blog can help resolve most issues. Regular maintenance and timely component replacement are essential for ensuring the long-term performance of your device.

At Healthy Jeena Sikho, we provide a wide range of CPAP machines and accessories for purchase and rental. If your CPAP machine is making noise and needs servicing or replacement, our team is here to assist you. Explore our website for quality products and expert support.

FAQs

Why is my CPAP machine whistling? Whistling is often caused by air leaks in the tubing or mask. Inspect and secure all connections.

Can I fix a noisy CPAP machine myself? Minor issues like loose connections or dirty filters can be fixed at home. For major problems, seek professional help.

How often should I replace my CPAP machine filters? Replace disposable filters every month and clean reusable ones weekly.

Does the surface affect CPAP machine noise? Yes, placing the machine on a hard surface can amplify vibrations and noise.

What are the quietest CPAP machine models? Brands like ResMed and Philips offer ultra-quiet CPAP models.

Why is my CPAP motor making a humming sound? This could be due to wear and tear or an unclean filter.

Can I use a noise cover for my CPAP machine? Yes, noise-reducing covers can help muffle sounds.

Is it safe to use a CPAP machine in a drawer? Only if the drawer is well-ventilated to prevent overheating.

How do I know if my CPAP machine needs servicing? Unusual noise, reduced pressure, or error messages indicate the need for servicing.

Where can I find affordable CPAP machine options? Visit Healthy Jeena Sikho for a wide selection of CPAP machines for rent or sale at competitive prices.

For expert advice and quality CPAP machines, visit Healthy Jeena Sikho. We’re here to help you breathe easy!

0 notes

Text

Industrial Hose Pipe Couplings: Ensuring Efficiency and Safety in Industrial Operations

In the modern industrial landscape, reliable connections for fluid transfer are crucial for smooth operations. Industrial hose pipe couplings play a pivotal role in this domain, ensuring the secure and efficient flow of various liquids and gases. Whether for high-pressure applications, chemical handling, or general industrial use, choosing the right hose coupling is essential for both safety and performance.

What Are Industrial Hose Pipe Couplings?

Industrial hose pipe couplings are connectors used to join hoses to pipes or other hoses. They are widely used in various industries, including chemical, petroleum, agriculture, and manufacturing. These couplings are designed to provide a secure connection that prevents leaks, ensuring that operations run smoothly while minimizing risks of fluid loss or accidents.

Why Choose High-Quality Industrial Hose Pipe Couplings?

The choice of hose coupling impacts both the safety and efficiency of your operations. High-quality industrial hose pipe couplings can withstand extreme pressures, resist corrosion, and offer quick assembly and disassembly for ease of maintenance. Manxpower is a leading industrial hose clamps supplier, offering products designed to handle even the most demanding environments.

Key Features of Industrial Hose Pipe Couplings:

Durability: Made from high-grade materials like stainless steel or brass to withstand pressure and corrosive elements.

Safety: Engineered to prevent leaks and ensure secure connections, reducing the risk of accidents.

Versatility: Suitable for a wide range of applications, from firefighting equipment to chemical transfer systems.

Ease of Installation and Maintenance: Many of these couplings are designed for quick connection and disconnection, reducing downtime.

At Manxpower, we provide top-of-the-line industrial hose pipe couplings that are known for their durability and performance. As an experienced industrial hose clamps supplier, we also offer various other solutions to complement our hose coupling products, ensuring that you have everything needed for optimal system functionality.

Other Solutions for Industrial and Fire Safety:

In addition to hose couplings, we supply a variety of essential fire and safety equipment, such as:

(1) Commercial Fire Sprinkler Supplier: Protect your industrial space with reliable fire suppression systems.

(2) Wall Mount for Fire Extinguisher: Keep your fire safety equipment easily accessible and in place with sturdy mounts.

(3) Pressure Gauge for Fire Safety: Monitor pressure levels in fire safety systems to ensure their effectiveness.

(4) Conventional Fire Alarm Systems: We provide high-quality, conventional fire alarm systems for early detection and prevention.

About Manxpower:

Manxpower is a leading supplier of industrial hose pipe couplings, clamps, and fire safety equipment. Located in the heart of Delhi, our company has built a reputation for providing reliable and efficient products tailored to the needs of industries across the region.

Contact Information:

Phone: +91–7428115550

Email: [email protected]

Address: 3963/9, Ground Floor, City Market, Ajmeri Gate, Delhi 110006

We are committed to ensuring your operations run smoothly with high-quality products designed to meet the highest standards of safety and performance. Get in touch with us today to learn more about our industrial hose pipe couplings and other products!

0 notes