#Heavy Duty Pipe Cutters SUPPLIER

Explore tagged Tumblr posts

Text

#Heavy Duty Pipe Cutters SUPPLIER#Pipe Cold Cutting Machine IN UAE#Pipe Cutting and Beveling Tools in Middle East#Pipe Cutting and Beveling Tools stockist#Fire Retardant Door Supplier in UAE#Fire Blanket supplier in UAE#Tests and Measuring Instruments dealer in UAE#Tests and Measuring Instruments supplier in Dubai#Full range of PPE supplier UAE

0 notes

Text

Safety and HDPE Sheets: Best Practices for Handling and Usage

High-Density Polyethylene (HDPE) sheets have become an indispensable material across various industries due to their durability, flexibility, and cost-effectiveness. However, like all industrial materials, the safe handling and proper usage of HDPE sheets are paramount to ensuring both safety and efficiency in operations. This guide delves into the best practices for handling and using HDPE sheets, addressing critical considerations such as HDPE sheet price, suppliers, and thickness.

Understanding HDPE Sheets

HDPE sheets are a type of thermoplastic polymer known for their high strength-to-density ratio. This material is used in a myriad of applications, from piping and geomembranes to packaging and consumer goods. The intrinsic properties of HDPE, such as its resistance to impact and chemicals, make it a preferred choice in environments requiring robust and durable materials. When considering HDPE sheet price, it's important to recognize that this material provides excellent value over time due to its longevity and resilience.

Choosing the Right HDPE Sheet

Selecting the appropriate HDPE sheet thickness is crucial for the intended application. The thickness of HDPE sheets can vary significantly, typically ranging from thin films of a few millimeters to thick slabs of several inches. The choice of thickness impacts not only the performance but also the cost. Thinner sheets are often used for lightweight applications like packaging, while thicker sheets are suitable for heavy-duty uses such as industrial flooring or tank linings. Consulting with HDPE sheet suppliers can provide valuable insights into selecting the right thickness for specific needs.

Importance of HDPE Sheet Suppliers

Reliable HDPE sheet suppliers play a vital role in ensuring the quality and consistency of the material. Suppliers with a proven track record can provide certifications and quality guarantees, which are crucial for industries that require stringent material standards. Building a relationship with reputable suppliers can also facilitate better pricing and access to a wider range of products. When assessing HDPE sheet suppliers, consider their ability to offer customized solutions, including varying sizes, colors, and thicknesses, to meet unique project requirements.

Safe Handling of HDPE Sheets

Here are some best practices for handling HDPE sheets:

1. Personal Protective Equipment (PPE) Wearing appropriate PPE is the first step in safe handling. This includes gloves to protect hands from sharp edges, safety goggles to shield eyes from potential splinters, and steel-toed boots for foot protection in case of sheet slippage.

2. Lifting and Transportation Given their size and weight, HDPE sheets should be handled by multiple workers or with the aid of lifting equipment such as forklifts or cranes. Sheets should be lifted and transported in a manner that prevents bending or dropping, which could lead to damage or injury.

3. Storage Store HDPE sheets in a clean, dry environment to prevent contamination and warping. Sheets should be stored flat and stacked evenly to avoid any pressure points that might cause deformation. If stored outdoors, they should be covered to protect them from UV radiation and weather elements, which can degrade the material over time.

Cutting and Shaping HDPE Sheets

Cutting and shaping HDPE sheets require precision and the right tools. Here are some guidelines to follow:

1. Tools and Equipment Use tools specifically designed for cutting plastics, such as circular saws with fine-toothed blades, routers, or hot wire cutters. Ensure that all equipment is in good condition to achieve clean cuts and reduce the risk of accidents.

2. Cutting Techniques Secure the HDPE sheet firmly before cutting to prevent movement. Mark the cut lines clearly using a marker and a straight edge. Perform the cutting at a steady, controlled pace to ensure smooth edges and reduce the generation of heat, which can cause melting or warping.

3. Post-Cutting Handling Sand down any rough edges to prevent injury and ensure a smooth finish. Clean the work area to remove any plastic debris that could pose slip hazards or contaminate other materials.

Joining and Welding HDPE Sheets

In many applications, HDPE sheets need to be joined or welded. Here are best practices for these processes:

1. Welding Methods Common welding methods for HDPE include butt welding, extrusion welding, and hot gas welding. For example, butt welding is ideal for joining large, flat sheets, while extrusion welding is suitable for more complex shapes and repairs.

2. Surface Preparation Use a degreaser if necessary and allow the surfaces to dry completely. Proper surface preparation is critical to achieving a strong, reliable weld.

3. Welding Procedure Follow the recommended welding parameters for temperature, speed, and pressure as specified by the HDPE sheet suppliers. Improper welding conditions can lead to weak joints or material degradation. Allow the welded joints to cool naturally without applying any external force to ensure they set correctly.

Maintenance and Inspection

Regular maintenance and inspection of HDPE sheets are essential for prolonged service life and safety. Here are some tips:

1. Routine Inspections Conduct regular inspections for signs of wear and tear, such as cracks, warping, or discoloration. Early detection of issues can prevent more significant problems and extend the material's lifespan.

2. Cleaning Clean HDPE sheets with mild detergents and water. Avoid harsh chemicals or abrasive cleaners that could damage the surface. For stubborn stains or residues, consult with HDPE sheet suppliers for recommended cleaning solutions.

3. Repair and Replacement Address any damage promptly to prevent it from worsening. Minor scratches or gouges can often be repaired using plastic welding techniques. For more severe damage, it may be necessary to replace the affected sections.

Cost Considerations:

The price of HDPE sheets can vary based on several factors, including thickness, size, and supplier. While cost is an important consideration, it should not be the sole determining factor. Investing in high-quality HDPE sheets from reputable suppliers ensures better performance and longevity, ultimately offering better value for money. Comparing prices from different HDPE sheet suppliers and considering bulk purchase discounts can also help manage costs effectively.

Conclusion

HDPE sheets are a versatile and durable material widely used across industries. By adhering to best practices for handling, cutting, welding, and maintaining HDPE sheets, users can ensure safety and maximize the material's performance. Key considerations such as selecting the appropriate HDPE sheet thickness, choosing reliable suppliers, and understanding the factors affecting HDPE sheet price are crucial for making informed decisions. Prioritizing safety and quality in the handling and usage of HDPE sheets will lead to more efficient operations and long-lasting applications.

FAQs

Can HDPE sheets be used outdoors? Yes, HDPE sheets can be used outdoors. However, it’s essential to choose UV-stabilized sheets to prevent degradation from prolonged exposure to sunlight.

What are the safety measures for handling HDPE sheets? Always wear appropriate PPE, use the correct cutting tools, and ensure proper ventilation when machining or thermoforming HDPE sheets to prevent accidents and exposure to harmful fumes.

How do I maintain and clean HDPE sheets? Clean HDPE sheets with mild detergents and avoid abrasive cleaners. Regular maintenance and inspections can help prolong the life of the sheets and ensure they remain in good condition.

0 notes

Text

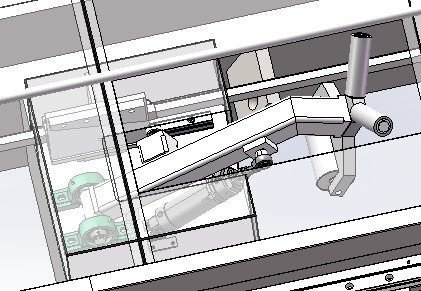

Remcor technology is a global supplier for the turnkey fiber laser cutting lines, which have around 18 years experiences, 5000 sets installations globally. No matter what type what size and how thickness your sheet material is, we can provide you the suitable equipment. Pipe Fiber laser cutting machine mainly been applied in metal pipes and tubes fabrications, with the character of fast speed, high precision or accuracy, environmental friendly, low power consumption, low table cost, and low maintenance cost. which is widely applied in fast cutting metal pipes of steel, stainless steel, carbon steel, aluminum, copper, galvanized steel, titanium alloy, gold, silver and other material. OEM ODM services are available.

Heavy Duty bed, apply the fully plate welding bed, with higher rigidity and durable use.

Compared with two chuck clamping or traditional metal pipes cutter. Three chucks equipment can realize the real zero tailing .processing details as the following descriptio.

More flexible for pipe cutting processing especially for extra heavy duty pipes or tubes, less swing or shake.Perfect accuracy and precision.

Heavy duty type load longer tailing material avaliable.

Apollo AK Two-chuck Tube Laser Cutting Machine 1000w-6000w Parameter Details

APOLLO BK SERIES-3 Chucks

Type

6020-BK

7025-BK

9025-BK

9034-BK

Power Range

1500-6000W

Chuck Structure

3 chucks

Tube Size

Round Type: 15-200mm Square

Round Type:15- 245mm

Round Type:15- 245mm Square

Round Type:15- 330mm Square

Type:15- 140mm

Square Type:15- 175mm

Type:15- 175mm

Type:15- 230mm

Positioning accuracy of X& Y

土0.05mm/m

Max Positioning speed X&Y

100m/min

80m/min

Max cutting length

6000mm

7000mm

9000mm

9000mm

Tail length

2 0mm

Max weight single tube

135KG

260KG

260KG

500KG

Max loading length

6000mm

7000mm

9000mm

9000mm

Fully Annealed Table

The bed body adapts the segmented rectangular tube welding bed with fully annealed treatment at over 600⁰. After tempering, the strength, rigidity and stability are guaranteed, the precision would be tested and debugged which can make sure the precision can be maintained for a long time. The table is equipped with automatic lubrication device, which ensure the moving parts operate in good condition and improve the service life of guide rails, gears and rack.

Follower Support

The follower support device will be optional. The follower support is mainly to assist in controlling the excessive deformation of cutting longer pipes (pipes with smaller diameter), and the servo motor drives the up and down movement of the pallet assembly. When the chuck moves to the corresponding position, the auxiliary support automatically drops for avoidance.

Smart Auto Focus Laser Head

Standard auto focus function, no need focus adjustment while changing sheet; Automatic tracking and accurately adjusting the focus according to the material thickness to ensure the best cutting effect of the whole board. Shorter perforation time, better perforation quality, high-speed cutting, saving time.

Intelligent CNC Operating System

It simplifies complex CNC machine operation and integrates CAD, Nest and CAM modules in one. From drawing, nesting to workpiece cutting all can be finished by a few clicks on big IPAD Screen. Realize the intelligent diagnosis, multi-threading operation, three-level perforation, laser energy control, adaptive edge-finding, automatic corner acceleration and deceleration, flight cutting, switching worktables, mechanical accuracy compensation etc.

Pneumatic Clamp Chucks

Pneumatic clamp design on both sides. The dual-chucks help reduce tube vibration to a minimum, guaranteeing high accuracy in even complex tube configurations at high cutting speed. Suitable for cutting a range of tube diameters from Ø20 mm to Ø220 mm and various wall thicknesses.

Front chuck

tube laser cutting machine front chuck

Back chuck

tube laser cutting machine back chuck

Fractional Automatic Support Technology

Applies the intelligent tube support design, which can solve the deformation problems in the process of long tube cutting.

Equipped with two sets of variable-diameter support structures, which are automatically lifted by the cylinder to avoid the rear chuck in processing. When processing profiles with different diameters, manually turn the variable-diameter wheels to achieve fit and support for different-sized profiles. The variable-diameter wheels It can be supported every two degrees of rotation to reduce the diameter of the circumscribed circular tube by 2mm

0 notes

Text

Tubing Notchers Specialists | The Best in the Business

At Baileigh Industrial we've got over 20 years of experience. Therefore, we can offer the best products and service in the industry. We have state of the art machines, and our tubing notchers are no exception. Our high performance tube notchers assure precision and flexibility and can be used for a variety of applications. They are particularly prominent in the motor sport industry. We are a key sponsor of Team Dynamics British Touring Car Championship (BTCC) Team. As a result, our equipment is recognised as world-class quality. We are proud to provide the best tube notcher and tube bending equipment that’s available on the market.

Tube Notcher Varieties at Baileigh Industrial

We have a wide range of tubing notchers, and with so many variations to choose from, you can be sure to find exactly what you need with us. Our extensive tube notcher range in the UK includes manual, holesaw, abrasive and eccentric mill type notchers. As far as quality goes, it doesn’t get any better than a Baileigh pipe notcher.

Quality Every Time

We are delighted to be a key supplier to the motorsport industry. Our tubing notchers are used to create half moons, fish mouths, and scallop type notches. These help to allow the tubes to be neatly joined together and then nicely welded. Our quality tube notchers join the tubes seamlessly together for a faultless finish. Our equipment helps meets regulating standards as outlined in The Motorsport UK Yearbook, commonly known as the Blue Book of British racing standards.

Save Time and Increase ROI

We are very committed to providing quality tools and equipment, which enable you to optimise productivity, and increase ROI. Our pipe notcher machines are leaders in the industry. Baileigh's high performing, heavy-duty metalworking tube and pipe notchers will help you save time, as well as increasing your profits. Here at Baileigh industrial we provide a vast variety of pipe and tube notchers in varying capacities. All of our notchers are capable of creating notches in pipes and tubes. Plus, certain notchers can be used with a variety of electrical and battery powered drills. Depending upon the model, they can also be operated with a variety of hole saws, round cutters, and milling bits.

Baileigh Industrial | Call Us Today!

If you have any tube notcher or pipe notcher requirements then head to our website today. Or, call +44 (0)24 7661 9267 to speak to a member of our helpful and friendly team. If you’d like to check our more of our products and what we offer at Baileigh Industrial then have a read of our previous blog on metal guillotines. Read the full article

0 notes

Text

Tubing Notcher Specialists | The best In The Business

At Baileigh Industrial we've got over 20 years of experience and this means we can offer the best products and service in the industry. We have state of the art machines, and our tubing notchers are no exception. Our high performance tube notchers assure precision and flexibility and can be used for a variety of applications. They are particularly prominent in the motor sport industry. We're a key sponsor of Team Dynamics British Touring Car Championship (BTCC) Team which means our equipment is recognised as world-class quality. We're proud to provide the best tube notcher and tube bending equipment that’s available on the market.

Tube Notcher varieties at Baileigh Industrial

We have a wide range of tubing notchers, and with so many variations to choose from, you can be sure to find exactly what you need with us. Our extensive tube notcher range in the UK includes manual, holesaw, abrasive and eccentric mill type notchers. As far as quality goes it doesn’t get any better than a Baileigh pipe notcher.

Quality every time

We're delighted to be a key supplier to the motorsport industry. Our tubing notchers are used to create half moons, fish mouths, and scallop type notches. These help to allow the tubes to be neatly joined together and then nicely welded. Our quality tube notchers join the tubes seamlessly together for a faultless finish. Our equipment helps meets regulating standards as outlined in The Motorsport UK Yearbook, commonly known as the Blue Book of British racing standards.

Save time and increase ROI

We're very committed to providing quality tools and equipment, which enable you to optimise productivity, and increase ROI. Our pipe notcher machines are leaders in the industry. Baileigh high performing, heavy-duty metalworking tube and pipe notchers will help you save time and increase your profits. Here at Baileigh industrial we provide a vast variety of pipe and tube notchers in varying capacities. All of our notchers are capable of creating notches in pipes and tubes. Plus, certain notchers can be used with a variety of electrical and battery powered drills. Depending upon the model, they can also be operated with a variety of hole saws, round cutters, and milling bits.

Baileigh Industrial | call us today!

If you have any tube notcher or pipe notcher requirements then head to our website today. Or, call +44 (0)24 7661 9267 to speak to a member of our helpful and friendly team. If you’d like to check our more of our products and what we offer at Baileigh Industrial then have a read of our previous blog on metal guillotines. Read the full article

0 notes