#Heating Polyester Yarn

Explore tagged Tumblr posts

Text

Heating Polyester Yarn

Heating Polyester Yarn Specification

30-500D/36-576F

Test standard: GB/30127-2013 Test index: Far infrared emissivity ≥ 0.88 Far infrared radiation temperature rise ≥ 1.7 ° C

Measured value: far infrared emissivity is 0.92/far infrared radiation temperature rise 2.6 ° C

Application fields:bed sheets,underwear,down jacket,socks

Contact us Email: [email protected] Tel: 86-57585510907

0 notes

Text

That is the very high-end, luxury cotton

Sea Island Yarn

Sea Island Yarn is usually a high-end, luxury yarn manufactured from the extra-long staple fibers belonging to the Gossypium barbadense cotton plant that is grown exclusively for the West Indies islands. The long, silky fibers on this special cotton are prized therefore to their strength, luster, along with softness. They are sometimes blended with other fibers for instance silk or cashmere to generate even more high quality textiles.

In the hands of any skilled spinner, that silky fiber can easily yield exquisitely good, cool-to-the-touch fabrics along with yarns. Fine lawns as well as handkerchief cottons are among the most used and recognizable products of the special variety with cotton. 36-576F Heating Polyester Yarn Manufacturers This type of cotton is used to make heirloom quality cargo area linens and clothing along with other fine fabric goods for instance handbags and gloves.

The heirloom quality of this sort of cotton is on account of several factors, most of all the exceptionally much time staple lengths belonging to the plant. The regular staple length connected with Sea Island cotton is 4. 26 inches, which is over twice providing the average staple time-span of other commercial cotton varieties. The particular longer fibers generate the cotton a lot easier to spin, plus the resulting yarn will be smoother and stronger than some others of cotton.

Longer staple plans also reduce how much twist in that resulting yarn, and also this produces a smoother plus much more silky finish. Which allows the yarn to be easily dyed in addition to gives it a nice sheen that some others of cotton are not able to match.

Sea Island cotton is a very rare commodity, which is only available in small quantities by several growers around the globe. The quality on this specialty cotton is so outstanding that it is a sought after diet material for high-end manner and apparel brands, manufacturers of high class linens, and other producers of extravagance textiles.

In truth, this type regarding cotton is coveted a whole lot that it is actually protected under this trademark laws connected with some countries. Additionally it is highly regulated to ensure the proper raising practices are adopted, and that only the best possible examples of this special different cotton are used in the production of Sea Island Yarn.

That is the very high-end, luxury cotton that is certainly often sold throughout blends with other fibers to form higher-end products, and it really is quite expensive. But to the dedicated knitter who will be willing to spend the amount of money on this pretty special and rare kind of cotton, it is often worth the expense.

If you choose to try this exquisite yarn by yourself, we are pleased to make available it at Inventive Ewe. Enter the value VeryPink at checkout to be handed a 25% discount on your own order of just about any of our Sea Island yarns in the end of February.

0 notes

Text

HEY guess what you can do with wool? That's right!

DYE IT

With food coloring and kool-aid!! And also acid dyes, which are designed for this, but acid dyes can't be used with cookware you put food in, and Kool-Aid packets are 50 cents.

.. did they go up in price? Didn't they used to be 20 cents? Anyway

Tbh a big part of the allure of spinning my own yarn is dying either the fibers or the final product. I just like the sense of independence that comes from going "ah, I need a color, and I have a lot of white and a handful of dyes!". I did this a lot with my posable critters too, though acrylic and polyester are a lot more strict about what dyes will actually work.

(Though tbh? Soaking acrylic faux fur in watered down acrylic paint, waiting for it to dry, and then taking a slicker brush and brushing out the clumps will get you pretty far!)

The evidence of crimes past with that paint permanently on there. I think this fucker is almost old enough to make its own Tumblr account (but not in Australia 8()

I digress! Because I haven't been dyeing acrylic, but KERATIN!

I did actually try dyeing a chunk with the same semi-permanant magenta dye I use on my own hair, cos like. Hair is also keratin.

Actually, it was supposed to be a bisexual gradient from pink to blue, but when it came time to heat set the color, the manic panic blue just fucking vanished.

Lesson learned: Ion Color Brilliance is a good brand, Manic Panic is not.

My bestie has inquired about me spinning the yarn and knitting them a scarf, so I wanted to make what was basically a mockup of the different ways you can spin the fibers to get different colors effects. And also I got Kool-Aid this past grocery visit and have been chomping at the bit to use it.

@sivilityy enables me <3

BEHOLD, MY CHILDREN!

Dyeing wool with kool-aid or food coloring is very easy!

Step 1: Soak wool in warm to hot water with about a 1/3rd of a cup of white vinegar for 15 to 45min. The vinegar is a mordant, something that helps the fibers take up the dye.

Step 2: Mix your dye of choice into a pot of warm to hot water, close in temperature to the soaking bath. The more kool-aid or food coloring, the stronger the color. I was going for pastels, so I used half a pack for the blue and pink, and a single drop of yellow food coloring for the yellow. The purple... 8') We won't talk about the purple.

Step 3: Fish your wool out of its soak, give it a gentle squeeze, then plop it into the pot. I like to scoop out some of the vinegar water and pour it into the pot as well. For insurance!

Step 4: Heat your pot to just below boiling. You want steam, but little to no bubbles. Agitation + heat or sudden temperature changes = felt. You can't spin felt. If you want to to make felt, though, now you know.

Step 5: leave your wool at simmering for around 30 min. How do you know when its done?

it fucking sucks all the color out of the water. How sick is that?! In the few batches I've done, I haven't always gotten it to be clear like that but don't stress it. About 30 min seems to be good even if there's still some color in the water.

Turn off the burner and let your creations cool down in their soup. Or, if you're impatient like me, run your hottest tap water into a different pot, then pour your wool into the slightly cooler but still hot water, so it doesn't get a HUGE temperature shock. Don't use cold water, or you're gonna get felt! Give em a rinse in the hot water to get any extra color out.

Let 'em hang and dry, and you're done!

So far all of mine have felted a little bit? Which hasn't been so bad, I've just needed to fluff them up a little once they're dry. I want to try indirect heat with a steamer basket and see if that helps, but I only got the one basket and 4 colors this time, so I used the pots.

SCIENCE

#Technically art#Hey butters how is chapter 19 coming along#*flips water pitcher* YARN#If you want to try this yourself please look up a tutorial that wasn't written on a phone on Tumblr#I haven't skipped any steps but I didn't elaborate as much as I could have#Tbh I just wanted to show off how the color got complete sucked out of the water#But then my Adderall kicked in

17 notes

·

View notes

Text

SO! You might be wondering what I've been doing while I was on hiatus! Outside of working, of course. That one is a given.

Well, I haven't really been writing, unfortunately. I have, of course, been continuing to post Stolen Child. Decided I'm going to do a double update on the 8th to celebrate getting older.

Mainly thought?

I have been going absolutely crazy dyeing yarn!

I've been shifting back into a natural dye phase, as I do from time to time, and was bemoaning the fact I don't really use wool yarn much (wool moths? In my house? ...just a couple...) and that most of the knitting Mum and I do these days is for a charity that doesn't insists on using synthetic yarns anyway because they need something warm - which cotton, silk, and such aren't - and will not give the poor kids with wool allergies a massive rash when suddenly it hit me!

I have a cupboard full of RitDyemore that I got for dyeing dolls, synthetic wigs, etc!

I CAN DYE SYNTHETIC YARN!

Along with allowing me to make colours that just aren't popular in stores at the moment (I guess green is out?), I can dye various types of yarn colours that they normally just...aren't! Ombré metallics! Jewel toned baby yarn! TIE DYE!

Needless to say I was very shortly at JoAnn selecting things to play with. I went with Big Twist, because Mum is going to be the one working with this, and she likes that brand. Then I added Big Twist Metallic, because I like shiny things, Bernat Pipsqueak, because I like soft things, and Caron Simply Soft, because really nice finish! I wanted to try Lionbrand Re-Spun, but they didn't have any in parchment, which is the closest they get to white. Bummer. Have to try that later.

Some of my more interesting findings are as follows:

They all took the dye nicely, but varied in which colours they absorbed from the bath!

The Pipsqueak tended to dye duller colours than the others, although they could still be nice and strong.

While the Pipsqueak (100% Polyester) retained it's super soft, fluffy texture when dyed, the acrylic yarns would up feeling like cotton? Not a bad thing, but kind of interesting. It's obviously something to do with the heat required for using Dyemore.

Getting a super even dye job is near impossible. There are too many factors that result in light patches. The good news is that the variation makes the yarn more interesting!

I have found multiple ways to make ombré and other variegated yarn. They are all fun. I think my favorite is to ball the yarn and then dye it.

Tie dyeing yarn does not work like you'd think it would! Basically the places where the yarn is tied are white, but they don't scrunch the surrounding strands together enough to cause fading or spidering or anything like that...which is ironic since not getting dye between the strands is one of the things that causes uneven dyeing and light spots? The end result is yarn with random white speckles through it, which is still super cool! (See the dark blue-green hank of Pipsqueak)

And that's what I've got for now! Most of these have been exhaust dyed (I've dyed multiple batches in the same dye bath, so they get progressively lighter), with the occasional variation. I'm planning on getting another skein of the Big Twist Metallic and just exhaust dyeing the entire thing with the same formula to see how consistent I can get. And, of course, hoping for some parchment Re-Spun. It'll be very interesting to see what the texture does on that one, given that is also 100% Polyester, but not fluffy and recycled. Does it make a difference?

...and definitely more variegated yarns in the future! Hands down my favorite!

And I have some wool, so I can play with natural dyes!

#diy#yarn#yarn dyeing#big twist yarn#pipsqueak yarn#simply soft yarn#rit dye#rit dyemore#hand dyed yarn

4 notes

·

View notes

Text

Exploring the Cost Dynamics: Non-Woven Fabric vs. Traditional Woven Fabric

Non-woven fabric has emerged as a popular choice in various industries due to its versatility, durability, and cost-effectiveness. As a leading provider of fabric solutions, Mavazi Fabrics understands the importance of cost considerations for our clients. In this article, we'll explore how the cost of non woven fabric manufacturer

compares to traditional woven fabric and the factors that influence this comparison.

1. Production Process

One of the primary factors influencing the cost of non woven fabric manufactureris the production process. Non-woven fabrics are manufactured using a process that does not involve weaving or knitting yarns together. Instead, fibers are bonded together mechanically, chemically, or thermally. This results in a simpler and more streamlined manufacturing process compared to traditional woven fabric, which requires yarn spinning, weaving, and finishing. The reduced complexity of the production process often translates to lower production costs for non woven fabric manufacturer.

2. Raw Material Costs

The cost of raw materials also plays a significant role in determining the overall cost of non-woven fabric. Non-woven fabrics can be made from a variety of materials, including natural fibers such as cotton and wool, synthetic fibers such as polyester and polypropylene, and recycled materials. The availability and cost of these raw materials can vary depending on factors such as market demand, production capacity, and geographical location. In general, non woven fabric manufacturer made from synthetic fibers tend to be more cost-effective compared to those made from natural fibers.

3. Labor Costs

Labor costs are another important consideration when comparing the cost of non woven fabric manufacturer to traditional woven fabric. Non-woven fabric manufacturing typically requires less labor compared to weaving or knitting processes. This is because non-woven fabrics can be produced using automated machinery and require fewer manual interventions. As a result, labor costs associated with non woven fabric manufacturer production are often lower, contributing to overall cost savings.

4. Energy Consumption

Energy consumption during the manufacturing process is another factor that influences the cost of non-woven fabric. Non-woven fabric production generally requires less energy compared to traditional weaving or knitting processes. This is because non-woven fabric manufacturing involves fewer mechanical motions and heating processes. As a result, non woven fabric manufacturer production can be more energy-efficient, leading to lower operating costs and reduced environmental impact.

5. Customization and Versatility

Non-woven fabrics offer greater customization and versatility compared to traditional woven fabrics. They can be engineered to meet specific performance requirements, such as strength, absorbency, and filtration efficiency. This customization capability allows non-woven fabric manufacturers to tailor their products to the unique needs of their clients, potentially adding value and justifying higher costs compared to traditional woven fabrics.

In conclusion, the cost of non woven fabric manufacturer compared to traditional woven fabric depends on various factors, including the production process, raw material costs, labor costs, energy consumption, and customization capabilities. While non-woven fabrics often offer cost advantages due to their simpler production process and lower labor and energy costs, the final cost comparison may vary depending on specific requirements and market conditions. As a trusted provider of fabric solutions, Mavazi Fabrics offers a wide range of non-woven fabrics tailored to meet the diverse needs of our clients while ensuring cost-effectiveness and quality.

#nonwovenfabric#manufacturer#fabricengineer#innovativematerials#textileindustry#sustainableproducts#technicaltextiles#manufacturingexcellence#madeinUSA#materialsourcing#productionprocesses#ecofriendlytechnology#qualityassurance#industrialmaterials#textiledesigns#nonwovenmaterials#advancedmanufacturing#productionefficiency#environmentallyfriendlyinfos .

2 notes

·

View notes

Text

Clothing & Wearing Magic – Part 2

Part 1: Location.

Part 2: Materials

Just as it is emphasized that wood, an amethyst, salt, and sugar have different spiritual properties due to their physical and chemical capabilities, clothing and accessories can also have different properties based on the material they are made of.

In this post I previously talked about metals, so I won't go into details, other than remembering that a silver ring and an aluminum ring have different properties to take into account. So everything that is jewelry is included there. But it also includes belt buckles, metal buttons on jeans, zippers on clothes, and everything that is metallic. If metal exists, it can be enchanted based on its specific properties.

Materials:

All the plant-based materials, like yarn, hemp, cotton, bamboo, jute, linen and their derivations, are a pure Earth element, are part of a plant that grows from the ground, fed by the Sun. That alone brings the properties of both elements and will be beneficed by spells related to both, like protection. The most commons to find in a normal cloth are cotton and linen.

Cotton: Is a soft, fluffy staple fiber that grows in a boll and is covered with thorns. The white color of the fiber gives its characteristic association of cleanliness and purity, just as the ability to retain vibrations, help protect from negative energies (the thorns add more aggression to it) and is known for represent simplicity and harvest. It also has properties as being static electricity resistant, absorbs water and “breathes”, can withstand heat, detergents, and bleach, so naturally act like a barrier.

Linen: Is made from the fibers of a plant, but in this case, from the “inner bark” and since is hard to make, it is also more expensive, that’s why is related to elegance, luxury and sophistication. Used by members of high class, usually priests, got the idea of be linked to the righteousness and purity, and the common use to sheets, made it corresponded to the rest. It is the second strongest fabric after the silk and also static electricity resistant.

Wool, leather and silk, on the other hand, come from animal sources, which also add the Fire component to the equation, adding the life force and energy of said element.

Wool: A textile fiber obtained from sheep and other mammals, especially goats, rabbits, and camelids, with the characteristic to be insulating, temperature regulating, mold resistant and flame resistant. Since the wool grow back each season is linked to the hope and renewal, durability, comfort and warmth. Each type of wools can also bring the energy and characteristics of the specific animal to which come from, so can be useful to focus in these features at the moment to enchant it.

Leather: At difference of the wool, the leather doesn’t grow back, is the result of the death of the animal, which brings even more Fire element to the equation, just as the instinct and strength of the animal to which come from. Can be completely waterproof and hard to burn, which bring extra protection.

Silk: Is the strongest natural textile in the world, a natural protein fiber, composed mainly of fibroin and is produced by certain insect larvae to form cocoons. The process is time-consuming and delicate, which explains the high cost of this fabric but also brings the correspondence of being a symbol of wealth, luxury and prestige. In certain lighting conditions, silk produces a shimmering optical effect, which is due to the triangular prism-like structure of silk fibers. These prisms reflect light at various angles, which results in the subtle rainbow hue that has made silk so famous, which add the capacity of the transformation and magical insulation.

Within the synthetic fibers you can find lycra, polyamide, neoprene, polyester, and many other mixtures of synthetic origin, most of which are derivatives of plastic. Despite the fact that it is an “artificial” product and that the environmental effects it produces are devastating, its origins remain natural in some way. But rather than focusing on where it comes from, in this case it is useful to ask the physical abilities when giving it an occult correspondence. It is waterproof and can completely nullify electricity (that ability to be completely null could be an excellent shield against magical energies, since it doesn't react at all), it can be molded into any shape (perfect for transformation spells), it doesn't oxidizes and can last thousands of years (long-term resistance). It may be the least interesting, but a good witch sees opportunity in even such a thing.

In some clothes, especially excellent level jackets, we can also find an insulating feather padding, which is a primordial Air element, associated with freedom, escape, spirituality, wisdom, power, strength, trust, honor, lightness, dryness, the heavens, height, and speed.

Some garments may also have wooden buttons, a powerful Earth element from which any witch can deduce its properties.

Knowing now what material a garment is made of, this knowledge can be used when potentiating enchantments, and even more if the color of said item is taken into account.

Part 3: Designs and Colors.

#witchcraft#witches#witch#witchy#correspondences#cloths#material#pagan#paganism#baby witch#New Witch#witch beginner

19 notes

·

View notes

Text

Joe Burrow Shirt, Vintage Joe Burrow T-Shirt, Joe Burrow Football Shirt

Important Notes: 1/ Please note that the mockup images and product titles displayed are for illustrative purposes only. We offer a diverse range of custom products, and it is crucial for customers to select the appropriate shirt style based on their specific requirements. 2/ If you want to wear oversized, please up to 1-2 sizes. 3/ We have many other colors. Please contact us directly for advice. We also have Gildan, Bella Canvas and Comfort Colors fabric. * Color of Comfort Colors Fabric: Army, Azalea, Banana, Bay, Berry, Blue Jean, Carolia Blue, Chalky Mint, Charcoal, Forest, Granite, Grape, Graphite, Gray, Heliconia, Hemp, Hot Pink, Ice Blue, Ivory, Kelly, Lavender, Light Green, Lime, Maroon, Moss, Natural, Peachy, Pepper, Royal Caribe, Sandstone, Sapphire, Texas Orange, Turquoise, Violet, Washed Denim, Water Melon **Color of Bella Canvas fabric: Heather Red, Lilac, Heather, Orange, Berry, Heather Maroon, Cherry Red, Cardinal, Olive, Natural, Chestnut, Pink,Storm, Silver, Mauve, Aqua, Army, Asphalt, Atlantic, Autumn, Baby Blue, Brown, Burnt Orange, Canvas Red, Charity Pink, Citron, Clay, Columbia Blue, Cool Blue, Coral, Dark Lavender, Dark Olive, Deep Teal, Dust, Dusty Blue, Electric Blue, Evergreen, Fuchsia, Kelly, Lavender Blue, Lavender Dust. MATERIALS: *Gildan Unisex Shirt GL5000: – 99% cotton (fiber content may vary for different colors) – Medium fabric (5.3 oz/yd² (180 g/m²)) – Classic fit – Tear-away label – Runs true to size *Gildan Sweatshirt GL 18000: – 50% Cotton 50% Polyester Runs true to size – 50% cotton: Made with special yarn spun into a very durable and smooth fabric, perfect for printing – 50% Polyester: Extremely strong polyester yarn, resistant to most chemicals, stretching and shrinking. Viscose added Pleated and soft great for shirts *Gildan Unisex Hoodie GL 18500: – 50% cotton, 50% polyester – Medium-heavy fabric (8.0 oz/yd² (271 g/m²)) – Classic fit – Tear-away label – Runs true to size Tank Top Unisex: – 99% Airlume combed and ring-spun cotton (fiber content may vary for different colors) – Extra Light fabric (3.8 oz/yd² (110 g/m²)) – Retail fit – Sewn in label – Runs true to size Youth T-Shirt: - 5.3 oz./yd² (US) 8.8 oz./L yd (CA), 100% cotton, 20 singles - Ash Grey is 99/1 cotton/polyester - Sport Grey is 90/10 cotton/polyester - Dark Heather, Graphite Heather, Heather, Neon & Safety Colors are 50/50 cotton/polyester - Safety Green is compliant with ANSI / ISEA 107 high-visibility standards - Classic fit - Classic width, rib collar - Taped neck and shoulders for comfort and durability - Tear away label - CPSIA Tracking Label Compliant - Proud member of the U.S. Cotton Trust Protocol - Made with OEKO-TEX certified low-impact dyes Youth Sweatshirt: - 8 oz./yd² (US) 13.3 oz./L yd (CA), 50/50 cotton/polyester, 20 singles - Classic fit - 1x1 rib with spandex for enhanced stretch and recovery - Tear away label - CPSIA Tracking Label Compliant - Proud member of the U.S. Cotton Trust Protocol - Made with OEKO-TEX certified low-impact dyes. Youth Hoodie: - 8 oz./yd² (US) 13.5 oz./L yd (CA), 50/50 cotton/polyester, 20 singles - Heather colors are 60/40 polyester/cotton - Classic fit - Double-lined hood - 1 x 1 rib with spandex for enhanced stretch and recovery - Pouch pocket - Tear away label - CPSIA Tracking Label Compliant - Proud member of the U.S. Cotton Trust Protocol - Made with OEKO-TEX certified low-impact dyes CARE INSTRUCTIONS: – Machine wash in cold water – Do not use bleach – Tumble dry low – Iron on low heat with shirt inside-out – Never iron directly over design EXCHANGE POLICY : Due to the custom nature of our products, unless the item arrives damaged or defective due to printing errors. We do not accept returns or exchanges that: – Customers do not clearly mention the customization requirements. – Customers set wrong sizes and styles (Every item is custom printed on demand as you order them. Please be sure to check size charts and measurements for the best fit. ) Should you need assistance please contact us prior to purchasing so that we can help you achieve that perfect fit. We are always happy (and quick!) to help answer any sizing and fit questions you may have CARE INSTRUCTIONS: – Machine wash in cold water – Do not use bleach – Tumble dry low – Iron on low heat with shirt inside-out – Never iron directly over design EXCHANGE POLICY ( please read carefully!) Due to the custom nature of our products, unless the item arrives damaged or defective due to printing errors. We do not accept returns or exchanges that: – Customers do not clearly mention the customization requirements. – Customers set wrong sizes and styles (Every item is custom printed on demand as you order them. Please be sure to check size charts and measurements for the best fit. ) Should you need assistance please contact us prior to purchasing so that we can help you achieve that perfect fit. We are always happy (and quick!) to help answer any sizing and fit questions you may have Read the full article

4 notes

·

View notes

Text

It can often feel like you need a PhD in material science just to understand the textiles that appear on garment care labels. While natural fibres including wool and cotton are pretty easy to identify, synthetics such as polyester and viscose can be harder to decode.

Generally speaking, human-made materials fall into one of two categories: those derived from fossil fuels and those derived from chemically processed cellulose (the building block of plants).

Fossil fuel-based fibres

Polyester

Polyester is the most common fibre on the planet, making up over half of the overall fibre market. It is a type of plastic called polyethylene terephthalate or PET which is moulded into yarn then woven into a fabric.

Dr Georgia McCorkill, a fashion lecturer at RMIT, says fossil fuels are the basis of the chemicals that make PET, so from an environmental and sustainability standpoint, their origins are already problematic. Since plastic does not so much biodegrade as split into smaller and smaller pieces (it was only invented last century, so we can’t really know how long it will hang around), polyester is also problematic when it is washed, as it can shed microplastics into waterways and at the end of a garment’s life.

“In an ideal world [polyester] would exist in a closed-loop system where it would be perpetually melted down and reformed into new fabrics,” says McCorkill. “However the design, production and waste recovery systems required to make this a reality don’t exist.”

Recently, there has been a push towards recycled polyester – which uses plastic bottles as an input – instead of virgin resources. While recycled polyester has a lower carbon footprint than conventional polyester, it is not a perfect solution. Turning plastic bottles into new plastic bottles is more efficient than recycling them into polyester, and it can be done on a loop. Current methods for turning plastic into polyester at scale do not result in a material that can be recycled again post-use.

McCorkill says polyester is an extremely strong material and can be necessary in activewear, sportswear or outdoor gear. But, she says, “polyester can get very smelly over time and become unwearable”. This is because it clings to odour and stains, making them impossible to remove.

Nylon

Like polyester, nylon is also a plastic derived from fossil fuels but it is more expensive to make and therefore used less frequently. It makes up about 11% of the clothing fibre market. Since nylon is stretchier and stronger than polyester, it is often found in swimwear and yoga gear.

Manufacturing nylon releases nitrous oxide into the atmosphere, contributing to global heating, and because nylon is a plastic it won’t biodegrade. The founder of Cloth & Co, Caroline Poiner, suggests looking for recycled alternatives such as Econyl that are made with recovered waste products, including fishing lines and other waste pulled from the ocean.

Unlike recycled polyester, recycled nylon can be regenerated into new nylon more than once, provided it has not been blended with other fibre types.

Elastane

The other fossil fuel-based fibre you’ll often encounter on a garment care label is elastane (also called spandex or Lycra). It is commonly blended with other fibres to provide added stretch (it can expand and recover up to five times its own length).

This elasticity makes it similar to rubber. But while natural rubber or elastic is derived from trees, elastane is derived from polyurethane and will not biodegrade. While elastane’s capacity for stretch and recovery makes it very useful in athletic gear and underwear, when exposed to heat or too much strain, its elasticity will degrade over time.

Man-made cellulosic fibres

Viscose rayon is the umbrella term for fibres manufactured from cellulose, but as many fibres fall into this broad category, it can be very confusing. The list includes rayon, viscose, modal, lyocell, acetate, bamboo and cupro. Aside from cupro, which is made from cotton waste, all of these materials are derived from wood pulp.

Poiner warns that although bamboo and the like are often marketed on their eco credentials, it can be “comparable to synthetic fibres in its impact on the environment and also the health and wellbeing of workers."

Sourcing viscose rayon has historically been linked to deforestation, and even now the environmental not-for-profit Canopy estimates that of the 200m trees cut down each year to make viscose, at least half come from ancient or endangered forests. If you want to be sure these fabrics have been sustainably sourced, look for FSC or PEFC certifications.

The process of turning wood or cotton waste into a fabric “requires highly toxic chemicals in its production”, says Poiner, who notes some manufacturers choose factory sites where they can avoid strict health and safety regulations.

Less harmful cellulose fabrics are manufactured using a closed-loop system, that recovers and reuses toxic solvents. EcoVero and Tencel are types of lyocell, trademarked by fabric giant Lenzing, which are made using best practice pulp-sourcing and chemical management during the production process.

There are also exciting innovations in this space, with new types of viscose rayon made using agricultural, food or clothing waste as a source material instead of trees, however these are not yet widely available.

7 notes

·

View notes

Text

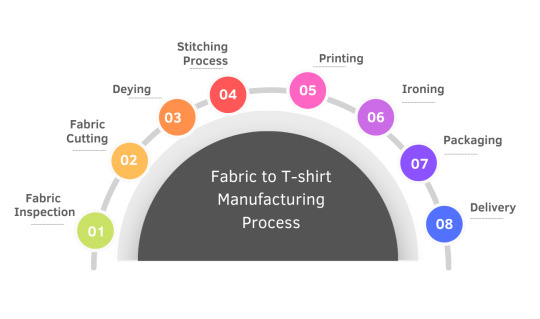

Have you wonder how a t-shirt is manufactured? Learn about t-shirt manufacturing process

The first t-shirt was manufactured in 1920. There are a huge variety of t-shirts manufactured all around the world starting with different types of neckband such as crew neck, V-neck, scoop neck and tank top. There are variations in sleeves such as full sleeves, half sleeves, capped, raglan and yoked. Raw materials used in the t-shirt manufacturing process are cotton and polyester. The neckband is made with a fabric named twill. A particular thread is used for stitching and sewing.

T-shirt Manufacturing Process

Cotton Farming: T-shirt manufacturing process starts from procuring cottons from farmers. Cottons are then converted into bales and transported to Ginning mills.

Ginning Mill: This is the place where cotton fiber and cotton seeds are separated. The cotton fiber is then used in manufacturing garments and cotton seeds are used in manufacturing vegetable oil.

Spinning : The cotton fibers are now separated and in this unit they are cleaned and cotton yarns are made out of it. Spinning unit involves many steps starting with Blow room → Combing → Carding → Drawing → Roving → Spinning.

Dyeing: The yarn is dyed using three dyeing processes: package dyeing, hank dyeing and warp dyeing. Package dyeing is the most popular dyeing process where yarn rolls are heated together with dye inorder to dye the yarn.

Knitting: Yarn enters the knitting machine as a raw material. There are various yarn inserted into the circular knitting machine, various yarn are intertwined together to make a sheet of fabric.

Inspection: Once the fabric is purchased by a garment manufacturer it is inspected by them in order to check any defectiveness or to check any shade variation. If the shade variation is found the cutting process is done accordingly.

Cutting: Many layers of the fabric are stacked together in this process and then using a bend knife cutting machine they are cut into different dimensions like front, back, sleeves, neckband and pocket if any.

Stitching: Different dimensions of fabric are stitched in this step using 2 methods of stitching overlock and superimposed. First front and back part are stitched then sleeves then neckband and at last the hem of the t-shirt.

Printing: Printing is done to the t-shirt to make it stylish. There are several types of printing. Screen-printing, digital printing, heat embossing and spray printing. Then these bulk printed t-shirts are transferred to the stitching department.

Finishing: This process is divided into 2 parts. Firstly, t-shirts are ironed in order to give it a finishing and appealing look and secondly, the tagging and packaging takes place. Then wholesalers and retailers offered to buy t-shirts in bulk.

#textile#textiles#dyeing#pattern#fiber art#fiber#fabric#knitting#sewing#patterns#business#clothing#manufacturing

2 notes

·

View notes

Text

TEXTILE DESIGN IN 2023-24

Overview of top textile importer, exporter countries & manufacturing industries. Textile design is the art of creating designs for woven, knitted, or printed fabrics. It is an integral part of the textile industry, which encompasses the production of fibers, yarns, fabrics, and finished textile products. Textile design is a vast field that encompasses a wide range of techniques and processes, including drawing, painting, printing, weaving, and embroidery. In this article, we will explore the history of textile design, the various techniques used in textile design, and the current trends in the field. History of Textile Design Textile design has a long and rich history that dates back to prehistoric times. The first textiles were made by hand using natural fibers such as flax, cotton, and wool. These fibers were spun into yarn and woven into fabrics using simple looms. Textiles were used for clothing, bedding, and household items such as curtains and tablecloths. Over time, textile design became more complex as new techniques and materials were developed. The introduction of the spinning wheel in the Middle Ages allowed for the production of finer and more even yarns. The invention of the Jacquard loom in the 18th century enabled the production of intricate patterns and designs. The Industrial Revolution in the 19th century brought about significant changes in the textile industry, with the introduction of mechanized production methods. In the 20th century, textile design became an art form in its own right. The development of new synthetic fibers such as nylon and polyester allowed for new possibilities in textile design. The Bauhaus school, founded in Germany in 1919, played a significant role in the development of modern textile design. The school's emphasis on functional design and the use of new materials and techniques had a profound influence on the field. Techniques Used in Textile Design Textile design encompasses a wide range of techniques and processes. Some of the most common techniques used in textile design include: Drawing and Painting: Many textile designs begin as drawings or paintings. Designers use a variety of media, including pencil, pen, ink, and watercolor, to create designs that are then transferred to fabric. Printing: Printing is a common technique used in textile design. Designs are created on paper using a variety of techniques, such as block printing, screen printing, and digital printing. The designs are then transferred onto fabric using heat or pressure. Weaving: Weaving is the process of interlacing two or more sets of yarns or threads at right angles to create a fabric. Weaving can be done by hand on a loom or by machine. Knitting: Knitting is a technique used to create fabrics by interlocking loops of yarn. Knitting can be done by hand or by machine. Embroidery: Embroidery is the art of decorating fabric or other materials with needle and thread. It is often used to add texture and dimension to textile designs. Current Trends in Textile Design Textile design is a constantly evolving field, with new techniques and materials being developed all the time. Some of the current trends in textile design include: Sustainability: The textile industry is one of the most polluting industries in the world, and there is a growing trend towards sustainable textile design. This includes the use of organic and recycled materials, as well as the development of eco-friendly production methods. Digital Printing: Digital printing is a relatively new technique in textile design that allows designers to create complex designs with a high level of detail. It is also more environmentally friendly than traditional printing methods, as it uses less water and produces less waste. 3D Printing: 3D printing is a cutting-edge technology that is being used in textile design to create innovative fabrics with a variety of textures and shapes. Smart Textiles: Smart textiles are fabrics that are designed to be interactive and responsive. Smart Textiles: Smart textiles are fabrics that are designed to be interactive and responsive. They incorporate electronic components such as sensors, actuators, and microcontrollers to enable the fabric to sense and respond to its environment. Smart textiles can be used in a wide range of applications, from fashion to medical devices. For example, smart textiles can be used in clothing to monitor vital signs and adjust temperature, or in bedding to monitor sleep patterns and adjust the bed's firmness. Innovation in Materials: There is a growing trend towards innovation in materials in textile design. Designers are exploring new materials, such as sustainable and bio-based materials, to create fabrics with unique properties. For example, fabrics made from bamboo, soy, or hemp are becoming more popular due to their sustainable and eco-friendly properties. Mixing of Textures and Prints: There is a trend towards mixing different textures and prints in textile design. Designers are using contrasting textures and prints to create bold and visually striking designs. This trend is evident in fashion, where designers are using a combination of textures such as silk and velvet or prints such as stripes and florals to create unique and eye-catching garments. Digital Fabrication: Digital fabrication is the use of digital tools such as computer-aided design (CAD) and 3D printing to create textiles. This technique allows designers to create complex designs with a high degree of precision and accuracy. Digital fabrication is particularly useful for creating one-of-a-kind textiles or small production runs. Collaboration and Interdisciplinary Work: Collaboration and interdisciplinary work are becoming increasingly important in textile design. Designers are working with scientists, engineers, and other professionals to develop new materials and technologies. This collaborative approach is leading to innovative solutions and new possibilities in textile design. Textile design is a dynamic and constantly evolving field. From the early hand-woven textiles to the cutting-edge smart textiles of today, textile design has come a long way. The field encompasses a wide range of techniques and processes, from drawing and painting to digital fabrication and smart textiles. With the growing focus on sustainability and innovation, textile design is poised to continue to evolve and shape the future of fashion, interior design, and other related industries. TOP TEXTIL EXPORTER COUNTRY The textile industry is a global industry, with many countries producing and exporting textiles. The top textile exporting countries in the world are: - China: China is the world's largest exporter of textiles, accounting for around 35% of global textile exports. The country has a strong manufacturing base and is known for its production of cotton, silk, and woolen textiles. - India: India is the second-largest exporter of textiles in the world, with a share of around 12% of global textile exports. The country is known for its production of cotton textiles, including handloom textiles, and is also a significant exporter of silk and woolen textiles. - Bangladesh: Bangladesh is the third-largest exporter of textiles, with a share of around 6% of global textile exports. The country is known for its production of low-cost cotton textiles and is a major supplier to many western clothing brands. - Vietnam: Vietnam is the fourth-largest exporter of textiles, accounting for around 5% of global textile exports. The country has a growing textile industry and is known for its production of cotton and synthetic textiles. - Turkey: Turkey is the fifth-largest exporter of textiles, with a share of around 4% of global textile exports. The country has a well-established textile industry and is known for its production of high-quality cotton textiles and home textiles. Other significant textile exporting countries include Pakistan, Italy, Germany, Indonesia, and the United States. The textile industry plays an important role in the economies of these countries, providing employment opportunities and contributing to the overall economic growth. TOP TEXTILE IMPORTER COUNTRIES The global textile trade is driven by demand from textile importing countries that rely on textile imports to meet their domestic demand. The top textile importing countries in the world are: - United States: The United States is the world's largest textile importer, accounting for around 16% of global textile imports. The country has a significant textile industry but also relies on imports to meet the demand for a wide range of textile products. - Germany: Germany is the second-largest textile importer, with a share of around 9% of global textile imports. The country has a well-established textile industry but also imports a significant amount of textiles to meet the demand for high-quality fabrics. - Japan: Japan is the third-largest textile importer, accounting for around 8% of global textile imports. The country has a significant textile industry but also imports textiles to meet the demand for a wide range of consumer products, including clothing and home textiles. - United Kingdom: The United Kingdom is the fourth-largest textile importer, with a share of around 6% of global textile imports. The country has a significant textile industry but also imports a significant amount of textiles to meet the demand for a wide range of products. - France: France is the fifth-largest textile importer, accounting for around 4% of global textile imports. The country has a significant textile industry but also imports textiles to meet the demand for high-quality fabrics and luxury goods. Other significant textile importing countries include Italy, Spain, Canada, Russia, and China. The textile industry plays an important role in the economies of these countries, providing employment opportunities and contributing to the overall economic growth. TOP TEXTIL MANUFACTURING COMPANY The textile manufacturing industry is a highly competitive industry with many companies vying for market share. The top textile manufacturing companies in the world are: - China National Textile and Apparel Council (CNTAC): CNTAC is the world's largest textile manufacturing company. It is a state-owned enterprise that has a dominant position in the Chinese textile industry. CNTAC operates a large number of textile mills and produces a wide range of textile products, including cotton, silk, wool, and synthetic fabrics. - Indorama Ventures: Indorama Ventures is a global chemical and textile manufacturing company with a presence in more than 30 countries. The company produces a wide range of textile products, including polyester, nylon, and spandex fabrics. - Luthai Textile: Luthai Textile is a leading textile manufacturing company based in China. The company produces a wide range of cotton and polyester fabrics, including high-quality shirting fabrics. - Vardhman Textiles: Vardhman Textiles is one of the largest textile manufacturing companies in India. The company produces a wide range of cotton and synthetic fabrics, including home textiles, garments, and yarns. - Hyosung Corporation: Hyosung Corporation is a South Korean company that produces a wide range of textile products, including polyester, nylon, and spandex fabrics. The company has a significant global presence and operates textile mills in several countries. Other significant textile manufacturing companies include Toray Industries, Inc., Teijin Limited, Milliken & Company, and Arvind Limited. These companies are known for their high-quality textile products, innovative technologies, and sustainable manufacturing practices. TOP 10 BEST DIGITAL TEXTILE DESIGN COMPANIES The textile industry has rapidly adopted digital technologies, leading to the emergence of several digital textile design companies. The top 11 best digital textile design companies are:

- Mahashankh Design: Mahashankh Design is a India-based company that offers world most complex & convertible digital designs services in two format 1. Shared Design : in Shared Design copyright of design will remains to mahashankh design before the payment & After the payment only they have right to use in personal projects. 2. Dedicated Design : in Dedicated Design all rights will be goes to customer after payment . - Spoonflower: Spoonflower is a US-based company that offers digital printing services for custom fabric, wallpaper, and gift wrap designs. The company's platform allows customers to upload their designs and have them printed on a range of fabrics. - Printful: Printful is a Latvian-based company that offers on-demand printing and fulfillment services for custom apparel, home decor, and accessories. The company's platform allows customers to upload their designs and have them printed on a range of products. - Patternbank: Patternbank is a UK-based company that provides trend forecasting and digital textile design services to the fashion and textile industries. The company's platform offers a range of design tools and resources to help designers create unique and innovative designs. - Kornit Digital: Kornit Digital is an Israeli-based company that offers digital printing solutions for the textile industry. The company's platform includes a range of printers and software tools designed to help textile manufacturers and designers create high-quality digital prints. - Lectra: Lectra is a French-based company that offers software and hardware solutions for the fashion and textile industries. The company's platform includes design software, cutting machines, and automation tools designed to help manufacturers improve their production efficiency. - Epson: Epson is a Japanese-based company that offers digital printing solutions for the textile industry. The company's platform includes a range of printers and software tools designed to help textile manufacturers and designers create high-quality digital prints. - EFI: EFI is a US-based company that offers software and hardware solutions for the textile industry. The company's platform includes design software, printers, and automation tools designed to help manufacturers improve their production efficiency. - AVA CAD/CAM Group: AVA CAD/CAM Group is a UK-based company that provides digital textile design and print solutions to the fashion and textile industries. The company's platform includes design software, color management tools, and production planning tools designed to help textile manufacturers and designers improve their efficiency. - Mutoh: Mutoh is a Japanese-based company that offers digital printing solutions for the textile industry. The company's platform includes a range of printers and software tools designed to help textile manufacturers and designers create high-quality digital prints. - HP: HP is a US-based company that offers digital printing solutions for the textile industry. The company's platform includes a range of printers and software tools designed to help textile manufacturers and designers create high-quality digital prints. These digital textile design companies are known for their innovative solutions and their ability to help designers and manufacturers create unique and high-quality textile products. Read the full article

3 notes

·

View notes

Text

Polyester DTY Brown Series ZN0085 FM

Polyester DTY Brown Series refers to a group of polyester yarns in various sunglasses of brown. This collection gives a variety of brown colours, consisting of chestnut, chocolate, caramel, and mahogany. Polyester DTY, or Draw Textured Yarn, is thought for its strength, sturdiness, and resistance to wrinkles and shrinking. The brown shade adds a sense of heat and richness to textile products, making them suitable for loads of programs, such as clothing, upholstery, and home textiles.

0 notes

Text

TFC Athletic Track Suit Trousers | TFC-Sp-TS-02 TFC Athletic Track Suit Trousers TFC Athletic brought Everything you need in a track suit Trouser light and warm. Suitable for active wear , running , gym wear and casual wear. Fitted: Next-to-skin without the squeeze thermo-conductive inner brushed coating to absorb & retain body heat. Durable, bonded 2- layer material has a quiet outer layer & comfort stretch. Secure, zip front and trouser with zip locked pockets. Description: Trouser: Two side Pockets with zips Draw cord Adjustment Waist Belt Open hem Bottom Fabric DNA: Combed Yarn brushed fleece Brushed (inside) Fleece Composition: 100% Polyester GSM 300 Care Hand wash separately Do not twist Flat dry https://tfcoutfits.com/tfc-athletic-track-suit-trousers/?feed_id=308&_unique_id=67aad904ce35c #uniform #sportswear #football #fashion #basketball #sports #uniforms #seragam #ww #hoodies #usa #military #embroidery #tshirt #army #soccer #workwear #tracksuit #clothing #apparel #teamwear #cabincrew #jersey #sublimation #follow #americanfootball #konveksi #aviation #socceruniform #instagram

0 notes

Text

Understanding Polyester Filament Yarn Prices: Key Factors and Market Trends

Polyester filament yarn (PFY) is a critical component in the textile industry, widely used for weaving, knitting, and manufacturing various fabrics, including apparel, home textiles, and industrial products. As one of the most consumed synthetic fibers in the world, polyester filament yarn plays a significant role in global textile markets. The prices of polyester filament yarn, however, are influenced by a variety of factors that fluctuate due to market demand, raw material costs, energy prices, and technological advancements. Understanding the key drivers behind polyester filament yarn prices can help manufacturers, suppliers, and consumers navigate market trends more effectively.

What is Polyester Filament Yarn?

Polyester filament yarn is made from polyester polymer, which is produced through a process called extrusion. The polymer is melted and then drawn into long continuous fibers. These fibers can be used in their natural form or further processed to meet specific applications. Polyester filament yarn is known for its strength, durability, low moisture absorption, and ease of maintenance, which makes it a popular choice in both fashion and functional textiles.

Factors Influencing Polyester Filament Yarn Prices

Raw Material Costs The primary raw materials used to produce polyester filament yarn are purified terephthalic acid (PTA) and monoethylene glycol (MEG). The prices of these raw materials are highly sensitive to global oil prices. Since both PTA and MEG are derived from petroleum, any fluctuations in oil prices can directly affect the cost of polyester filament yarn. When oil prices rise, the cost of polyester production increases, leading to a hike in PFY prices.

Global Supply and Demand Like any other commodity, the prices of polyester filament yarn are subject to the dynamics of supply and demand. When demand for textile products increases globally—especially from large markets like China, India, and Europe—there is upward pressure on yarn prices. Conversely, during periods of reduced demand or when there is an oversupply in the market, prices may fall. The COVID-19 pandemic, for example, significantly disrupted both demand and supply chains, leading to volatility in textile production and, consequently, polyester filament yarn prices.

Energy Costs The production of polyester filament yarn is energy-intensive, particularly during the extrusion and heating processes. The cost of energy (natural gas, electricity, etc.) plays a significant role in the overall price of PFY. In regions where energy prices are high, the cost of production increases, which can result in higher prices for consumers. Energy shortages or price hikes in key regions also exacerbate this issue.

Labor and Operational Costs Labor and operational costs are important contributors to the price of polyester filament yarn. The cost of labor varies by country and is influenced by factors such as minimum wage laws, labor union demands, and availability of skilled workers. Countries with lower labor costs, such as Southeast Asia, often have a cost advantage in polyester filament yarn production. Conversely, countries with higher labor costs (such as the United States or Western European nations) may experience higher PFY prices.

Technological Advancements and Production Efficiency Improvements in textile production technology can affect PFY prices. Innovations such as better extrusion techniques, more energy-efficient machinery, or new chemical treatments can help reduce production costs. Producers who invest in modern, more efficient manufacturing processes can potentially offer lower prices, especially if they gain a competitive edge in operational costs.

Exchange Rate Volatility Since polyester filament yarn is traded internationally, fluctuations in currency exchange rates can also impact prices. For instance, when a country’s currency weakens against the dollar, imported raw materials or finished polyester yarn can become more expensive, leading to higher overall costs.

Environmental Considerations and Sustainability Trends Sustainability has become a growing concern in the textile industry, and this has an impact on polyester filament yarn prices. As demand increases for recycled polyester, bio-based polyester, or more sustainable production methods, manufacturers may face higher costs due to the advanced technology required. These costs may be passed on to consumers in the form of higher prices for eco-friendly yarns. Additionally, regulatory pressures in different countries to reduce the environmental impact of synthetic fibers may lead to changes in production methods and the costs associated with compliance.

Global Market Trends and Regional Price Variations

Asia-Pacific Region: Asia, particularly China and India, dominates the global production and consumption of polyester filament yarn. The demand for PFY in this region is driven by the burgeoning textile and garment industries. In India and Southeast Asia, polyester yarn is relatively affordable due to lower production costs, making these regions attractive for both local and international buyers.

North America and Europe: In contrast to Asia, production costs in North America and Europe are higher due to labor costs, regulatory standards, and energy prices. As a result, polyester filament yarn in these regions tends to be more expensive. However, high-quality standards and an increasing demand for sustainable products are pushing suppliers to invest in more advanced production technologies.

>> 𝐁𝐨𝐨𝐤 𝐚 𝐝𝐞𝐦𝐨 𝐭𝐨 𝐠𝐞𝐭 𝐫𝐞𝐚𝐥-𝐭𝐢𝐦𝐞 𝐢𝐧𝐬𝐢𝐠𝐡𝐭𝐬: https://www.price-watch.ai/book-a-demo/

Price Forecasts and Outlook

In the coming years, several factors will continue to affect polyester filament yarn prices:

Post-pandemic Recovery: As global economies recover from the pandemic, the demand for textiles, particularly for fashion and industrial applications, is expected to rise. This could result in increased pressure on polyester filament yarn prices.

Raw Material Price Volatility: Ongoing fluctuations in oil prices, and in particular, the cost of PTA and MEG, will continue to be a key determinant of PFY pricing trends. The global energy crisis, ongoing geopolitical tensions, and supply chain disruptions could exacerbate price volatility.

Sustainability Focus: With growing concerns about environmental impact, the demand for sustainable and recycled polyester filament yarn is likely to increase. As these products typically require more advanced and energy-intensive production processes, this could contribute to higher prices.

Technological Innovations: As the industry continues to adopt new production methods and technologies that enhance efficiency and reduce environmental impact, we could see a shift in price dynamics, depending on how widespread these advancements become.

Polyester filament yarn prices are influenced by a complex interplay of factors, including raw material costs, global supply and demand, technological advancements, energy prices, and labor costs you can outreach pricewatch to get real time pricing insights. The industry must remain adaptable to shifting market conditions, such as fluctuations in oil prices or changes in consumer demand for more sustainable products. By staying attuned to these market trends, stakeholders in the textile and polyester filament yarn industry can make more informed decisions, ensuring competitiveness and sustainability in a dynamic market environment.

#commodity market#commodities#price intelligence#business intelligence#market research#data driven decisions#strategic insights#competitive analysis

1 note

·

View note

Text

While I'm not overly familiar with superwash wool, I looked up some stuff and I think I understand what the Reddit comment was referring to.

Superwash refers to a special way of treating natural fibers, usually wool, so that it can go through a machine washer and dryer which would make untreated wool shrink. Wool fibres are naturally course and have a scaly surface (imagine a hair under a microscope but less smooth) which is why it can itch and also why it shrinks. When these little scales rub against one another (like in a dryer), they get caught and the fibres get tangled and felt together and thus shrink. The process of superwash treating wool smoothes these scales so the wool doesn't catch and thus won't shrink as much. This also gives superwash wool a shinier look and smoother feel.

The issue the Redditor is likely referring to is that, according to my research, the traditional way of superwash treating is a chemical treatment called the Hercosett method that uses harsh chlorinated chemicals that, yes, do make the wool washer and dryer safe, but are also harmful to the environment and cover the surface of the wool in a thin layer of synthetic material which ruins wools natural moisture and heat regulating properties. This effectly renders it an expensive substitute for polyester so you might as well pay half the price for a product that has the same properties.

But I also found out that there are newer treatment methods that don't include harsh chemicals are supposedly work just as well to make the wool not shrink. I don't understand it fully, I'll have to research more, but it's a physical process where the wool is exposed to electrodes and the coated in plasma. I don't know if the wool's natural properties (beyond shrinkage) are kept intact.

But anyway, I think the Redditor was referring to the Hercosett method which, yeah, is basically making the wool as effective as polyester in terms of fibre properties. I'll personally say that superwash wool is still much nicer to the touch than your average acrylic yarn but in terms of what you get for your money, even nice acrylic yarn will usually be less than merino, superwash or no. So if I had to pick, I'd go for the non-superwash or at least make sure it wasn't treated with the Hercosett method. Though as someone who's particularly fond of wool and works with it regularly, I might be biased.

#this was really interesting to research#thank you for the question i learned a lot#and i hope you got a satisfactory answer#reblog#fibre arts

82K notes

·

View notes

Text

Textile Manufacturers in India [Top Companies]

1. Loyal Group: Started by South Indian visionary industrialist Karumuttu Thiagarajan Chettiar, the initial credentials of this mill were a spinning and weaving mill, which used old machines and retrenched labour.

Loyal Group comprises of four spinning mills, two weaving units, one knitting unit, one dyeing house, seven garment manufacturing units, one trading cum retail company and a joint venture trading company in Italy.

Being one of the top garment manufacturers, it has an unwavering obsession with quality.

The major subsidiaries are Loyal IRV Textiles, Loyal International Sourcing Private Limited and Sri Chintamani Textile Mills Limited.

Original Source: https://knowledgekablog.wixsite.com/knowledgekablog/post/textile-manufacturers-in-india-top-companies

2. Mandhana Industries: It is headquartered in Mumbai and has various manufacturing units located in various locations like Tarapur, Bengaluru and Baramati.

It is an integrated textile and apparel company with a global presence across a number of fashion brands.

With state-of-the-art designs, statistical quality control techniques, superior technology and marketing capabilities, it has become a pioneer in the modern textile revolution.

The company is capable of yarn dyeing, printing, processing, designing and garment manufacturing.

3. Bombay Rayon Fashions Ltd.: It is India's largest shirt manufacturing company.

It manufactures a wide range of fabrics, including cotton, polyester, tencel, modal, lycra, wool and various blends. Yarn-dyed fabrics, printing techniques, finishing, processing, knitting and stitching, all combine to make it a complete package of textile engineering.

With manufacturing facilities of 100 million metres per annum, garment manufacturing facilities of 60 million pieces per annum which is being expanded to 90 million pieces per annum, it has made its presence felt in the global market.

4. Nahar Group of Companies: Started as a small woollen spinning machine and hosiery manufacturer, the group has grown to become a leading textile giant in Northern India. The group now represents Oswal Woollen Mills Ltd., Nahar Spinning Mills Ltd., Monte Carlo Fashions Ltd., Cotton County Retail Ltd. and others.

Currently, the group is responsible for the production of the following materials:

Woollen products such as pullovers, cardigans, shirts, coats, baby suits, mufflers, shawls, blankets, woollen knits

Cotton/blended/knitted hosiery, pullovers, t-shirts, baby suits, ladies tops, winter thermals, tracksuits, jackets, hoodies

All types of yarns such as woollen, woollen blended, cotton, polyester-cotton, other blends, compact yarns, mercerised gassed yarns, organic cotton yarns

Knitted fabric for shirts, trousers and denim.

5. Rupa & Co. Ltd.: It is one of the largest knitwear companies in India. It was founded by the Agarwal brothers as Binod Hosiery. There are many brands under the family like Frontline, Softline, Softline Leggings, Euro, Bumchums, Torido, Thermocot, Macroman, Frontline, John. Rupa family supplies many products such as

Men's Clothing: Vests, Briefs, Drawers, Bermudas, Capris, T-shirts, Loungewear, Boxer Shorts and Sleepwear.

Women's Clothing: Bras, Panties, Camisoles and Leggings.

Children's Clothing: Baba suits, Bloomers and slips for infants/toddlers, Lounge-wear, Bermudas and T-shirts.

Winter Clothing: Many thermal clothing for both men and women.

Clothing and Us:

Along with the evolution of mankind, human needs have also changed accordingly. There was a time when we desperately needed clothes to protect us from heat, cold, rain and storms. In the medieval times, it became an essential item of dignity for some and luxury for very few. Now, it is limited to comfort, design, style and fashion. But be it any era or civilization, clothes have always represented personality, culture and tradition. And, textile manufacturers have always tried their best to meet the needs and demands of the people in India.

Note: Choose 77Data as your data provider company in India. Get all types of industry and business data at best price. Download data list in just one click, given below.

manufacturing company list in india | pune manufacturing company list | company list in gurgaon

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] Product Description SMOOTH SILK LIKE FABRIC Blackout curtains are silky faux material that is made of 100 percent polyester. These silky, soft drapery are thick & very pleasant to touch when compared to other curtains. TRIPLE WEAVE TECHNOLOGY Blackout curtains are interwoven by top fabric layer, high density black yarn and back fabric layer with advanced triple weave technology which helps block out 85 to 99 percent sunlight. ROOM DARKENING EFFECT Our room darkening curtains have a special coating that blocks light from shining through, which is effective at keeping out both, drafts in the winter and heat in the summer. BLACKOUT COLOR SHADE CHART The darker the colors the more the blackout effect, while the lighter the colors the blackout effect tends to fade. But overall the blackout effect tends to vary from all different color ranges. PRIVACY PROTECTION These blackout drapery & curtains will stop the outside world from creeping into your private moments so you can enjoy the privacy with family members and friends to the utmost. NOISE REDUCTION The solid blackout curtains ensure that even if you are a light sleeper you will not be disturbed by the sound on the streets or the outside hustle bustle. It helps you sleep peacefully like a baby. COZY THEATER ATMOSPHERE

Enjoy a home theater effect with the solid blackout curtains which helps create a room darkening effect suitable for binge watchers & movie buffs. Create a great entertainment feel right at your home. ENERGY SAVERS Our curtains have the ability to keep warm air from penetrating the house & help tremendously with maintaining an optimal room temperature which helps you save on bills. The video showcases the product in use.The video guides you through product setup.The video compares multiple products.The video shows the product being unpacked. Why Choose Our Blackout Curtains? Our Blackout curtains offer a multitude of compelling reasons to be the preferred choice for many homeowners and individuals seeking enhanced comfort and functionality within their living spaces. Beyond their light-blocking capabilities, they also provide an added layer of privacy, shielding the interiors from prying eyes during the evening when indoor lights are on. They offer aesthetic appeal & also come in various colors, and sizes like Door | Window | Long Door Package Contents : 2 Piece of Blackout Semi Long Door Curtains | Dimension (Size) : 116 x 242 cm or 46 x 95 inches, 300 GSM, Pattern : Solid, Material : Faux Silk, Color : Green | Story@Home blackout curtains 8 feet semi long door ensure 100% opacity, making them ideal dark curtains for bedroom no light, enhancing your sleep quality and providing complete privacy, ideal use of curtains for living room decoration, office curtains, curtains 8 feet long & home decoration items for living room These blackout curtains 8 feet for long door block most sunlight, allowing only a hint of light to create a softly lit space while ensuring complete privacy. Full blackout green curtains also act as protective barriers, shielding your interior from outdoor elements, dust, and light breezes, enhancing both comfort and cleanliness. Perfect for creating a cozy and peaceful atmosphere, these curtain 8 feet set of 2 combine functionality and style to suit any room Care Instructions: Before machine washing your door curtains 8 feet set of 2, remove plastic eyelets. Wash with cold water only and avoid tumble drying, bleaching, or dry cleaning to preserve the quality. Transform your bedroom into a serene sanctuary with our blackout curtains. Designed to fit curtain rod pipe systems, these curtains for bedroom block out light and reduce noise, ensuring a peaceful night's sleep Our blackout curtain : perfect for various spaces such as home, hall, bedroom, living room, studio, office, cafe, hotel, hospital, theater, and hostel. These Blackout Curtains 8 feet for semi long door seamlessly combine functionality and style, making them ideal for enhancing any room. Suitable for both doors and large windows, they offer excellent blackout and noise-reducing properties, ensuring comfort throughout your home. With superior insulation against summer heat and winter cold These effective room darkening elevate any interior decor and serve as an excellent backdrop decoration for home. Fancy curtains for living room is ideal for gifting on occasions like Diwali, Dussehra, Durga Puja, New Year, Christmas, weddings, and baby showers, they make a thoughtful and appreciated gift. With their versatility and elegance, these 8 ft curtain for living room are the perfect choice for any special celebration

[ad_2]

0 notes