#Heat Exchanger tubes

Explore tagged Tumblr posts

Text

Shell and Tube Heat Exchanger vs. Plate Heat Exchanger: Key Differences

When choosing the right heat exchanger for your system, understanding the differences between shell and tube heat exchangers and plate heat exchangers is crucial. These two types cater to varied applications, each offering unique advantages in performance, design, and maintenance. Read on to make an informed decision for your specific needs.

Design and Structure

Shell and Tube Heat Exchangers

These exchangers consist of a cylindrical shell housing a bundle of tubes. Fluids flow through the tubes and around the shell to transfer heat. Their robust design makes them suitable for handling high pressures and temperatures, often seen in industrial and power generation applications.

Plate Heat Exchangers

Plate heat exchangers feature a series of thin, corrugated plates stacked together. Fluids pass through alternating plates to exchange heat. Compact and modular, they are perfect for applications with space constraints or low to medium pressure requirements.

Working Mechanism

Shell and Tube Heat Exchangers

Heat transfer occurs as one fluid flows through the tubes and another fluid flows over the tube bundle within the shell. This setup provides excellent thermal efficiency and can handle a wide range of operating conditions.

Plate Heat Exchangers

In this design, heat transfer takes place as fluids flow across thin plates. The large surface area of the plates ensures efficient heat exchange, even at lower flow rates.

Efficiency and Performance

Shell and Tube Heat Exchangers

Renowned for their durability, they perform well in extreme conditions. However, their efficiency might be lower compared to plate heat exchangers in low-pressure systems.

Plate Heat Exchangers

With a larger heat transfer area per unit volume, plate heat exchangers offer superior thermal efficiency. They are ideal for applications requiring precise temperature control.

Size and Space Requirements

Shell and Tube Heat Exchangers

These exchangers are typically larger and require more space for installation. They are best suited for industrial setups where space is not a constraint.

Plate Heat Exchangers

Compact and lightweight, plate heat exchangers are an excellent choice for setups with limited space, such as HVAC systems or small-scale industrial plants.

Maintenance and Cleaning

Shell and Tube Heat Exchangers

Cleaning can be labor-intensive as it often requires disassembly. Regular maintenance is essential to prevent fouling and ensure longevity.

Plate Heat Exchangers

Easy to disassemble, plate heat exchangers facilitate quick cleaning and maintenance. This feature makes them ideal for industries like food and beverage, where hygiene is critical.

Cost and Durability

Shell and Tube Heat Exchangers

While they have a higher upfront cost, their robust construction ensures long-term durability and reliability, making them a cost-effective option for heavy-duty applications.

Plate Heat Exchangers

Typically more affordable upfront, they are less durable than shell and tube exchangers. Their components may need frequent replacement in high-pressure or high-temperature settings.

Applications and Industry Use

Shell and Tube Heat Exchangers

Commonly used in petrochemical plants, power generation, and marine applications, where high pressure and temperature conditions prevail.

Plate Heat Exchangers

Widely employed in HVAC systems, refrigeration, and the food and beverage industry due to their compact design and high efficiency.

Key Takeaway

Selecting between a shell and tube heat exchanger and a plate heat exchanger depends on your specific requirements, such as operating conditions, space availability, and budget. While shell and tube exchangers are ideal for heavy-duty applications, plate exchangers shine in compact, low-pressure setups.

Enhance Your Heat Exchanger Efficiency with High-Quality Seamless Pipes

The performance of your heat exchanger also relies on the quality of its components. At Anand Seamless, we provide premium seamless pipes designed for optimal heat transfer and durability.

Explore our range of products and services to enhance the efficiency of your heat exchangers today!

Read More: Shell and Tube vs. Plate Heat Exchanger: Key Differences

0 notes

Text

#Graphite#Graphite Heat Exchanger#Graphite Condensers#Graphite Cooler#Cubic Block Graphite Heat Exchanger#Cylindrical Block Graphite Heat Exchanger#Shell & Tube Graphite Heat Exchanger#Graphite Reboilers

2 notes

·

View notes

Text

Shell and Tube Heat Exchanger: An Introduction

Are you familiar with the concept of a heat exchanger? It's a device that transfers thermal energy between two fluids. And if you're particularly interested in this technology, then you've likely come across Shell and Tube Heat Exchangers. These types of heat exchangers have been around for over 150 years, but they're still widely used today due to their effectiveness and reliability. If you're looking to learn more about these amazing machines, then keep reading! This blog post is your definitive guide to the fascinating world of shell and tube heat exchangers - an introduction like no other.

What is a Shell and Tube Heat Exchanger?

A shell and tube heat exchanger is a type of heat exchanger that is commonly used in industrial applications. It consists of a shell, which is a large cylindrical vessel, and a bundle of tubes that run through the shell. Heat is transferred between two fluids that flow through the shell and the tubes, respectively.

How Does a Shell and Tube Heat Exchanger Work?

In a shell and tube heat exchanger, the two fluids flow in opposite directions. The fluid that needs to be heated or cooled flows through the tubes, while the other fluid flows through the shell. As the fluids flow through the tubes and the shell, heat is transferred from one fluid to the other through the walls of the tubes.

Types of Shell and Tube Heat Exchangers

There are several types of shell and tube heat exchangers, including:

Fixed Tube Sheet Heat Exchanger: This is the simplest type of shell and tube heat exchanger, where the tube sheet is fixed and cannot be removed.

U-Tube Heat Exchanger: In this type of heat exchanger, the tube bundle is bent into a U-shape, allowing for easy maintenance and cleaning.

Floating Head Heat Exchanger: In a floating head heat exchanger, the tube bundle is removable, making it easy to clean and maintain.

Applications of Shell and Tube Heat Exchangers

Shell and tube heat exchangers are commonly used in a variety of industrial applications, including:

Chemical Processing: Shell and tube heat exchangers are commonly used in chemical processing plants to heat or cool fluids.

Oil and Gas: Shell and tube heat exchangers are used in oil refineries and gas processing plants to transfer heat between fluids.

HVAC: Shell and tube heat exchangers are used in HVAC systems to transfer heat between air and water.

Advantages of Shell and Tube Heat Exchangers

Efficient heat transfer

Can handle high-pressure applications

Can handle a wide range of fluids and temperatures

Conclusion

Why use a shell and tube heat exchanger? Shell and tube heat exchangers are an important component in many industrial applications. They provide efficient heat transfer between two fluids, making them ideal for use in chemical processing, oil and gas, and HVAC systems. While they can be expensive to manufacture and install and can be difficult to clean and maintain, the advantages of shell and tube heat exchangers make them a valuable asset in many industrial settings. So, whether you're designing a new industrial process or looking to improve an existing one, consider the benefits of a shell and tube heat exchanger.

4 notes

·

View notes

Text

Inconel Alloy

Inconel Alloy is a high-performance material known for its exceptional strength, corrosion resistance, and ability to withstand extreme temperatures. Composed primarily of nickel and chromium, Inconel is ideal for applications in industries like aerospace, chemical processing, power generation, and marine engineering.

#Inconel alloy#capillary tubes#Manufacturer of U Tubes#Stainless Steel Pipe Suppliers#Coil Formed Tubes Manufacturing Process#Capillary Tubes Manufacturer#Heat Exchanger Tubes Manufacturer#Seamless Tube Suppliers#Seamless Heat Exchanger Tube

0 notes

Text

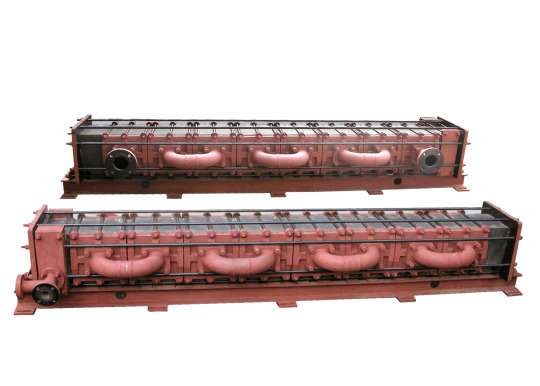

Efficient Shell & Tube Heat Exchangers | Goel Scientific | Canada

Explore efficient shell and tube heat exchangers from Goel Scientific, engineered for superior performance in industrial applications. Contact us today!

#heat exchanger shell tube in canada#best heat exchanger shell tube in canada#top heat exchanger shell tube in canada#heat exchanger shell tube Manufacture in canada#Industrial Glassware manufacture in USA#best Industrial Glassware manufacture in canada

0 notes

Text

Efficient Cooling with Shell & Tube Heat Exchangers

Discover how shell & tube heat exchangers boost industries' efficiency, durability, and thermal performance. Learn more today!

0 notes

Text

Role of Shell and Tube Heat Exchanger in Versatile Industries

A shell and tube heat exchanger consists of a series of tubes where one fluid flows through the tubes and another flows around them in the shell. This design efficiently transfers heat between the two fluids. These heat exchangers are durable and used in industries like oil, gas, and chemical processing.

0 notes

Text

#Stainless Steel 904L Heat Exchanger Tubes#Stainless Steel 904L Heat Exchanger Tubes Manufacturers#Stainless Steel 904L Heat Exchanger Tubes Suppliers#Stainless Steel 904L Heat Exchanger Tubes Stockists#Stainless Steel 904L Heat Exchanger Tubes Exporters

0 notes

Text

The Science Diaries of S. Sunkavally, page 336.

#oedema#vitamin B deficiency#folic acid deficiency#neural tube defect#pulmonary oedema#gas exchange#diffusion distance#filaria#lymph nodes#thiamine destruction by heat#brain size#evolution#discovery of fire#acetylcholine#tendon reflex#excitatory neurotransmitters#epilepsy#reticular activating system#glutamate#aspartate#spinal cord reflex#lumbar puncture#migraine#stapes#perforated eardrum#gentamicin#deafness#rustling leaves#sound level

0 notes

Text

At Valutech, we excel in complex thermal transfer through our advanced shell and tube heat exchanger operation. Our meticulously engineered systems are designed to deliver high-performance solutions that address critical industrial applications with precision and reliability.

0 notes

Text

Shell and Tube Heat Exchanger: A Comprehensive Guide

Shell and tube heat exchangers are essential components in thermal processing systems, designed to transfer heat between fluids efficiently. heat exchangers are widely used in oil refining, chemical processing, and power generation industries.

This guide will explore how shell and tube heat exchangers work, their design features, applications, key advantages, and important maintenance considerations to ensure optimal performance and longevity.

What is a Shell and Tube Heat Exchanger?

A shell and tube heat exchanger is a device used to transfer heat between two fluids. It has a large outer shell with several tubes inside. One fluid flows through the tubes, while the other flows around them inside the shell. This design helps exchange heat efficiently. These heat exchanger tubes are widely used because they are effective and can be customized for different needs.

Shell and tube heat exchangers are popular because of their simple design and efficient heat transfer. They work by moving fluid or steam through the shell, which heats the tubes inside. For the best performance, the fluid is usually passed through the tubes four times, which ensures effective heat transfer.

Understanding Shell and Tube Heat Exchanger Design

Shell & tube heat exchanger designs are among the most versatile and widely used devices for heat transfer in industrial processes. Their design, ability to handle high pressures, and adaptability across multiple applications make them a preferred choice in various industries. Let’s delve into their operating principles, key applications, advantages, and maintenance requirements.

Operating Principles of Shell and Tube Heat Exchangers

Shell and tube heat exchangers operate by transferring heat between two fluids. One fluid flows through the tubes (tube side), while the other flows around the tubes inside the shell (shell side). Depending on the flow pattern, these heat exchangers can work in two configurations:

Counterflow: Fluids move in opposite directions, ensuring maximum temperature difference and higher heat transfer efficiency.

Parallel Flow: Fluids flow in the same direction, offering less efficient heat transfer compared to counterflow.

Shell and Tube Heat Exchanger Applications Across Industries

Shell and tube heat exchangers are indispensable in industries due to their ability to manage diverse temperature and pressure conditions. Shell and Tube Heat Exchanger Applications include:

Petrochemical Industry: Vital for refining processes like condensation, distillation, and heating of fluids.

HVAC Systems: Used to regulate air temperature and humidity in heating, ventilation, and air conditioning systems.

Power Generation: Essential in boilers, condensers, and cooling systems for heat transfer between steam and water.

Food Processing: Widely used for pasteurization, sterilization, and cooling in the dairy, beverage, and pharmaceutical industries

Why Choose Shell and Tube Heat Exchangers from Amardeep Steel?

Amardeep Steel is a leading supplier of high-quality shell and tube heat exchangers designed to meet the diverse needs of industries worldwide. With expertise in manufacturing and sourcing premium materials, Amardeep Steel ensures durability, efficiency, and performance in every product. Whether you need custom-built designs or standard configurations, their solutions cater to all industrial requirements.

Maintenance Tips for Optimal Performance

To ensure the longevity and efficiency of shell and tube heat exchangers:

Regular Cleaning: Prevents fouling and maintains heat transfer efficiency.

Inspect Tubes Regularly: Check for leaks, corrosion, or damage to avoid system failures.

Monitor Performance: Keep track of temperature differentials and flow rates to identify and address issues early.

Conclusion

Shell and tube heat exchangers are vital for efficient heat transfer in numerous industries. With their durability, adaptability, and high performance, they are a reliable solution for complex thermal processes. For premium-quality heat exchangers and exceptional service, shell and tube heat exchanger manufacturers trust Amardeep Steel, a leader in delivering solutions to meet your industrial needs.

0 notes

Text

What Distinguishes a Custom-Solution Heat Exchanger Manufacturer?

Selecting the right heat exchanger manufacturer is crucial for industries where heat transfer is vital. Custom-solution heat exchangers offer tailored systems designed to meet specific operational demands, providing a competitive edge through enhanced functionality, reliability, and longevity.

In-Depth Understanding of Client Needs

A leading heat exchanger manufacturer prioritizes understanding the intricate needs of its clients. Unlike off-the-shelf solutions, custom heat exchangers are designed to integrate seamlessly with a business’s existing systems. This requires a deep dive into the operational environment, focusing on specific challenges such as handling extreme temperatures, corrosive materials, or energy efficiency demands. By analyzing these factors, manufacturers can identify gaps in standard equipment and develop solutions that enhance productivity while minimizing downtime and maintenance costs.

Collaboration with Clients for Precise Requirements

Customisation thrives on collaboration. The best heat exchanger manufacturers actively involve clients at every stage of development. From the initial consultation to design finalization, manufacturers maintain open communication channels to incorporate client feedback and suggestions. This collaborative approach ensures that the final product not only meets but exceeds client expectations, leading to long-term satisfaction and performance reliability.

Engineering Expertise and Innovation

Engineering expertise is the backbone of any heat exchanger manufacturer delivering custom solutions. Advanced design capabilities, supported by state-of-the-art design software and simulation tools, enable manufacturers to create highly efficient heat exchanger models. These tools allow engineers to predict performance under various operating conditions, ensuring optimal functionality before manufacturing begins. Innovative designs might include enhanced tube configurations, improved flow patterns, or optimized heat transfer surfaces, which can significantly improve efficiency and performance.

Manufacturing Precision

Precision in manufacturing is essential for custom heat exchangers. Utilizing advanced manufacturing techniques and quality control processes ensures that each component meets stringent standards. This attention to detail results in heat exchangers that perform reliably under specified conditions, contributing to the overall efficiency and longevity of the equipment.

Custom Testing and Validation

Before deployment, custom heat exchangers undergo rigorous testing and validation. This process includes performance testing under simulated operating conditions to ensure the heat exchanger meets all specified requirements. Such thorough testing guarantees that the final product will perform as expected, reducing the risk of operational issues and enhancing reliability.

Flexibility in Design and Production

A custom heat exchanger manufacturer offers flexibility in design and production, accommodating unique specifications and requirements. This adaptability allows for the creation of heat exchangers that fit within specific space constraints, handle unique operational conditions, and comply with industry-specific standards. Such flexibility ensures that the heat exchanger integrates seamlessly into existing systems, providing optimal performance.

Comprehensive Maintenance Plans

To ensure the longevity and optimal performance of custom heat exchangers, manufacturers often provide comprehensive maintenance plans. These plans include regular inspections, preventive maintenance, and prompt support services, helping to identify and address potential issues before they lead to significant problems. Such proactive maintenance contributes to the overall efficiency and reliability of the equipment.

Sustainability and Energy Efficiency

Custom heat exchangers are designed with sustainability and energy efficiency in mind. By optimizing heat transfer processes and reducing energy consumption, these heat exchangers contribute to lower operational costs and a reduced environmental footprint. This focus on sustainability aligns with global efforts to promote energy efficiency and environmental responsibility.

Contact a Reliable Heat Exchanger Manufacturer in India

For industries seeking custom heat exchanger solutions, partnering with a reliable manufacturer is essential. In India, companies like Anand Seamless Ltd. specialize in manufacturing and exporting various types of cold-drawn carbon steel and alloy steel seamless tubes, finned tubes, and heat exchangers. Their expertise in custom solutions ensures that clients receive products tailored to their specific operational needs.

In conclusion, choosing a custom-solution heat exchanger manufacturer offers numerous advantages, including a deep understanding of client needs, collaborative design processes, engineering expertise, manufacturing precision, comprehensive testing, design flexibility, maintenance support, and a focus on sustainability. These factors collectively contribute to enhanced performance, reliability, and efficiency in heat transfer applications.

Read More: What Distinguishes a Custom-Solution Heat Exchanger Manufacturer?

0 notes

Text

Top Features and Benefits of Shell and Tube Heat Exchanger

Shell and tube heat exchangers are essential in industrial heat transfer, featuring a cylindrical design with tube bundles. Commonly used in the food, chemical, gas, and oil sectors for cooling, heating, and heat recovery, they operate in parallel or counterflow configurations. Read in detail here about "Shell and Tube Heat Exchangers: Introduction, Principle, and Benefits".

0 notes

Text

Stainless Steel 304 Heat Exchanger Tubes Exporters In India

Metinox Overseas stands tall as one of the eminent manufacturers, suppliers, stockists, and exporters of Stainless Steel 304 Heat Exchanger Tubes.

#Stainless Steel 304 Heat Exchanger Tubes Stockists#Stainless Steel 304 Heat Exchanger Tubes Exporters#Stainless Steel 304 Heat Exchanger Tubes Manufacturers In India#Stainless Steel 304 Heat Exchanger Tubes Suppliers In India#Stainless Steel 304 Heat Exchanger Tubes Stockists In India#Stainless Steel 304 Heat Exchanger Tubes Exporters In India#Stainless Steel 304 Heat Exchanger Tubes Manufacturers In Mumbai#Stainless Steel 304 Heat Exchanger Tubes Suppliers In Mumbai#Stainless Steel 304 Heat Exchanger Tubes Stockists In Mumbai

0 notes

Text

Capillary Tubes

Capillary Tubes are thin, precision-engineered tubes designed for applications requiring the controlled flow of liquids and gases. Made from high-quality materials like stainless steel or copper, these tubes offer excellent corrosion resistance, durability, and dimensional accuracy. Commonly used in industries such as refrigeration, medical devices, and chemical processing, capillary tubes ensure precise fluid regulation in critical systems.

#stainless steel seamless tubes#buy seamless tubes and pipes#coil formed tubes manufacturing process#heat exchanger tubes manufacturer#manufacturer of coil formed tubes#manufacturer of stainless tubes and pipes#manufacturer of u tubes#buy coil formed tubes#manufacturer of instrumentation tubes#manufacturer of stainless steel pipe#seamless tube suppliers

0 notes

Text

Shell and Tube Heat Exchanger Parts and Functions

#basic concepts#thermodynamics#allinfoche#chemical engineering#chemical engineer#HeatExchanger#HeatTransfer#shell and tube heat exchanger

0 notes