#Grade B8M Bolt

Explore tagged Tumblr posts

Text

#ASME SA320 Grade L7 Bolt#Grade B8M Bolt#Grade A320 Flange Head Bolt#ASTM A320 B8 Hex Head Bolt#ASME SA320 Grade Eye Bolt#A320 Grade Stud Bolt.

0 notes

Text

Guide to Grade B8M Heavy Hex Bolts

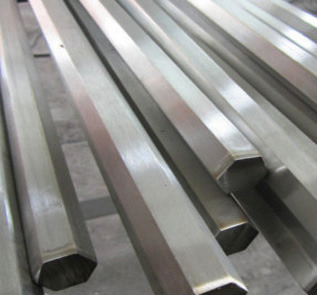

What Are Grade B8M Heavy Hex Bolts?

Grade B8M heavy hex bolts are made from stainless steel alloy of the highest quality. This type of bolt is designed with six sides, which allows it to provide more surface area for the nut or other fastener to hold onto. The advantage of this design is that it offers superior strength and stability compared to other types of bolts.

Additionally, Grade B8M Heavy Hex Bolts are corrosion-resistant, making them ideal for use in environments where humidity or moisture is present.

Applications of Grade B8M Heavy Hex Bolts

Grade B8M heavy hex bolts can be used in a variety of different industries and applications. They are commonly used in the construction industry as they provide superior stability when connecting structural components together such as beams or columns.

They are also often used in the marine industry due to their corrosion-resistant properties. In addition, these bolts can be used in medical equipment, machine tools, aircraft engines, and even for automobile repairs.

Benefits of Grade B8M Heavy Hex Bolts

Grade B8M heavy hex bolts offer several benefits over other types of fasteners. For one thing, they require less torque than standard nuts and bolts due to their unique shape which means less effort is required when tightening them down during installation. Additionally, grade B8M heavy hex bolts have excellent tensile strength which ensures that they won’t fail under pressure or vibration like some other types of fasteners can do over time.

Furthermore, these bolts have a higher resistance to corrosion meaning they will last longer than traditional steel fasteners in moist or humid environments. Finally, grade B8M heavy hex bolts are often available in custom sizes which makes them perfect for any application where standard sizes don’t fit properly.

#Benefits of Grade B8M Heavy Hex Bolts#Applications of Grade B8M Heavy Hex Bolts#Guide to Grade B8M Heavy Hex Bolts#What Are Grade B8M Heavy Hex Bolts

0 notes

Text

ASTM A193 Grade B8 Bolts, Nuts, and Washers: A Comprehensive Guide

Introduction

The ASTM A193 Grade B8 specification is widely recognized in the fastener industry for its exceptional performance in high-temperature and corrosive environments. Grade B8 fasteners, made from austenitic stainless steel (typically Type 304), are essential components in various industries, including petrochemical, power generation, and marine applications. This blog explores the characteristics, chemical and mechanical composition, applications, and manufacturing details of Grade B8 bolts, nuts, and washers.

What is ASTM A193 Grade B8?

ASTM A193 Grade B8 refers to a standard specification for austenitic stainless steel bolts, nuts, and washers designed for high-pressure or high-temperature services. These fasteners are made from stainless steel Type 304, offering excellent corrosion resistance, durability, and strength.

Characteristics of Grade B8 Fasteners

Corrosion Resistance: Grade B8 fasteners exhibit excellent resistance to corrosion and oxidation, making them suitable for harsh environments.

High-Temperature Strength: These fasteners retain their mechanical properties at elevated temperatures, making them ideal for high-temperature applications.

Durability: The material’s austenitic structure enhances toughness and longevity.

Non-Magnetic Properties: While Grade B8 fasteners are generally non-magnetic, slight magnetism may develop due to cold working.

Chemical Composition

The chemical composition of Grade B8 fasteners aligns with Type 304 stainless steel. The primary elements include:

Carbon (C): Max 0.08%

Manganese (Mn): Max 2.00%

Phosphorus (P): Max 0.045%

Sulfur (S): Max 0.030%

Silicon (Si): Max 1.00%

Chromium (Cr): 18.00 - 20.00%

Nickel (Ni): 8.00 - 11.00%

Iron (Fe): Balance

Mechanical Properties

Grade B8 fasteners provide the following mechanical properties:

Tensile Strength: Min 75 ksi (515 MPa)

Yield Strength (0.2% Offset): Min 30 ksi (205 MPa)

Elongation: Min 30%

Hardness: Max 223 HB or 96 HRB

Applications of Grade B8 Fasteners

Grade B8 bolts, nuts, and washers are employed in various industries, such as:

Petrochemical Industry: Used in piping systems, heat exchangers, and pressure vessels.

Power Generation: Ideal for boilers, turbines, and high-temperature equipment.

Marine Applications: Suitable for shipbuilding and offshore platforms due to their corrosion resistance.

Construction: Utilized in structural components exposed to corrosive environments.

Manufacturing and Processing

Grade B8 fasteners are manufactured using high-quality Type 304 stainless steel. The process includes:

Cold Working: To enhance mechanical properties such as tensile strength.

Threading: Rolled threads ensure smooth installation and removal.

Heat Treatment: Some Grade B8 fasteners may undergo heat treatment to achieve specific mechanical properties.

Surface Finishing: Options include passivation or electro-polishing to improve corrosion resistance.

Benefits of ASTM A193 Grade B8 Fasteners

Long-lasting performance in challenging environments.

Resistance to rust and oxidation.

High strength-to-weight ratio.

Versatility in various industrial applications.

Conclusion

ASTM A193 Grade B8 bolts, nuts, and washers are a reliable choice for industries requiring durable and corrosion-resistant fasteners. Their superior mechanical and chemical properties make them suitable for demanding applications, ensuring longevity and performance under challenging conditions.

When sourcing Grade B8 fasteners, partnering with a reputable manufacturer ensures compliance with international standards and consistent quality. Ananka Group is a trusted name in the fastener industry, offering a wide range of Grade B8 fasteners tailored to meet specific industrial needs.

Frequently Asked Questions (FAQ)

1. What is the difference between Grade B8 and Grade B8M?

Grade B8 fasteners are made from Type 304 stainless steel, while Grade B8M fasteners are manufactured using Type 316 stainless steel, offering enhanced corrosion resistance due to the addition of molybdenum.

2. Are Grade B8 fasteners suitable for marine applications?

Yes, Grade B8 fasteners exhibit excellent corrosion resistance, making them suitable for certain marine applications, though Grade B8M may be preferred for environments with high chloride exposure.

3. What is the temperature range for Grade B8 fasteners?

Grade B8 fasteners can withstand temperatures up to 815°C (1500°F), making them ideal for high-temperature applications.

4. Can Grade B8 fasteners be used in acidic environments?

Grade B8 fasteners resist corrosion in mildly acidic environments. For highly acidic conditions, consider using fasteners made from Type 316 or other specialized alloys.

5. Why choose Ananka Group for Grade B8 fasteners?

Ananka Group is a leading manufacturer and supplier of Grade B8 fasteners, ensuring high-quality products that meet international standards and cater to diverse industrial requirements.

#gradeb8#b8grade#gradeb8bolts#bolts#b8gradebolts#boltmanufacturer#Ananka#Anankafasteners#fasteners#fastenersmanufacturer#Article#blog#manufacturer#supplier#tumblr#blog tumblr#articles

0 notes

Text

Fasteners Manufacturer in Azerbaijan - Sachiya Steel International

Fasteners are crucial components in industrial manufacturing, providing the necessary connections and security between parts across various sectors. These mechanical devices, which include bolts, nuts, screws, washers, and rivets, are essential for maintaining the structural integrity and functionality of countless applications. Sachiya Steel International Private Limited of India is renowned for its high-quality fasteners, and its presence in Azerbaijan highlights its commitment to global excellence.

Understanding Fasteners

Fasteners are an extensive array of mechanical components used to join or fasten materials together. Each type of fastener serves a different function depending on factors like material type, load-bearing capacity, and environmental conditions.

Types of Fasteners

Bolts

Nuts

Screws

Washers

Rivets

Fastener Selection

Selecting high-quality fasteners is crucial for maintaining structural integrity, safety, and longevity across various applications. Industries such as construction, automotive, aerospace, and marine manufacturing rely on reliable fastening solutions to meet specific operational challenges.

Sachiya Steel International: Building Excellence

With decades of experience and a cutting-edge manufacturing facility in India, Sachiya Steel International has become an industry leader. Their commitment to precision engineering, superior quality products, and customer satisfaction have earned them global praise.

Product Range and Specializations

Sachiya Steel International offers an extensive portfolio of fasteners to meet the diverse needs of industries worldwide. Their product range includes:

Bolts: High-tensile bolts, hex bolts, socket head bolts, foundation bolts.

Nuts: Hex nuts, lock nuts, wing nuts, square nuts.

Screws: Machine screws, self-tapping screws, wood screws, drywall screws.

Washers: Flat washers, spring washers, toothed lock washers.

Rivets: Blind rivets, solid rivets, pop rivets.

Each product undergoes rigorous quality checks and adheres to international standards such as DIN, ANSI, ASTM, and ISO, ensuring reliability and performance excellence.

Grades of Fasteners Offered

Construction Grade

Specifications: ASTM A307, ASTM F1554 (Grade 36, 55, 105)

Application: Structural applications requiring high strength and durability.

Automotive Grade

Specifications: Grade 8.8, Grade 10.9, Grade 12.9

Application: Automotive assembly, ensuring reliable performance under high stress and vibration conditions.

Aerospace Grade

Specifications: ASTM F568, ASTM F2281

Application: Aerospace and defense applications, meeting stringent safety and reliability standards.

Industrial Grade

Specifications: ASTM A193 (B7, B8, B8M), ASTM A320 (L7, B8, B8M)

Application: General industrial use, offering corrosion resistance and durability in harsh environments.

Global Footprint and Market Reach

Sachiya Steel International has expanded its operations to meet Azerbaijan’s growing demand for premium fasteners. Their distribution network and optimized logistics ensure prompt delivery and excellent customer support.

Customization Capabilities

Sachiya Steel International understands the importance of offering customized solutions. They provide options to customize dimensions, materials (including stainless steel, carbon steel, and alloy steel), finishes (plain, zinc-plated, hot-dip galvanized), and coatings (phosphate, black oxide) to meet specific project needs with flexibility and precision.

Environmental Responsibility and Sustainability

Sachiya Steel International prioritizes sustainability in its manufacturing processes. They invest in eco-friendly technologies, waste reduction initiatives, and energy-saving practices to minimize environmental impact while contributing to global conservation efforts.

Conclusion

Sachiya Steel International Private Limited stands out as the go-to choice for high-quality fasteners in Azerbaijan and beyond. With a legacy built on innovation, reliability, and customer-centricity, Sachiya Steel continues to set standards in the global fastener industry. Whether for large-scale industrial projects or niche applications, Sachiya Steel is ready to offer unparalleled quality and service excellence.

Read More: Fasteners Manufacturer in Azerbaijan

0 notes

Text

Importance of Material Grade in Heavy Hex Bolts | Roll Fast

Roll Fast is a renowned manufacturer and exporter of heavy hex bolts for the construction of petrochemical industries. Heavy Hex Bolts are designed for use in a variety of high-temperature, high-strength industrial applications, such as steel fabrication and general construction. We also offer heavy hex bolts to structural grade ASTM a307, a325, and a490 specifications. They feature a thicker head than standard or regular hex bolts and offer a greater bearing surface that distributes the clamping load over a wider area. Heavy hex bolts are heavy profile hexagon bolts with large widths across flats and high head height. Also known as heavy hex head bolts or heavy hex structural bolts, these heavy hex bolts are commonly manufactured in high tensile grade 5, 8, 8.8, 10.9, 12.9, a193 grade b7, b7m, b8, b8m, b16, a320 grade l7, l7m, stainless steel, and other material.

visit source url : https://www.roll-fast.com/industries-served/petrochemical-industries/heavy-hex-bolts.html

0 notes

Text

ASTM A193 Gr-B8M C1 fasteners Manufacturer & Exporter | BigBoltNut

Bigboltnut are a manufacturer of Grade B8M C1 and C2 Fasteners used for Alloy and Stainless Steel Bolting Materials for High Temperature or High-Pressure Service in petrochemical & chemical Construction Applications. This specification includes fasteners intended for use in pressure vessels, valves, flanges, and fittings. Although, this material is often available in national coarse (UNC) thread pitches, if being used in traditional applications, threads are specified 8 threads per inch (tpi) for diameters above one inch.

Source Url: https://www.bigboltnut.com/product/astm-a193-gr-b8m-c2.html

0 notes

Text

What is a Stud Bolt? Types, Grades, and Standards

Delta Fitt Inc., your dependable Stud Bolts Manufacturers in India, Welcome to the realm of precise fasteners. We are well-known for our attention to quality and perfection, and we specialise in creating stud bolts, which serve as the foundation of solid connections in a range of sectors. Consider Delta Fitt Inc, where each bolt is a testament to great engineering.

What is a Stud Bolt?

Stud bolts are specialist fasteners used to provide secure and long-lasting connections in a variety of applications. These threaded rods include bolts at both ends and a unique design that includes an unthreaded centre part. Stud bolts are key structural components in the construction, oil & gas, petrochemical, and power generation industries, due to their high tensile strength and ease of installation.

Their threaded design enables for simple installation, making them useful in situations needing frequent disassembly. Stud bolts are dependable components in the fastener landscape, helping to maintain structural and mechanical stability.

Types of Stud Bolts

Fully Threaded Stud Bolts:

Ideal for applications requiring maximum thread engagement. Commonly used in scenarios where both ends need to be screwed into different components.

Double-End Stud Bolts:

Threaded on both ends, allowing for versatile applications.Used when components need to be tightened from both ends simultaneously.

Tap-End Stud Bolts:

Features threads on one end and a chamfered point on the other. Useful in situations where quick alignment and engagement are necessary.

Continuous Thread Stud Bolts:

Uninterrupted threading for the entire length.Suitable for heavy-duty applications where strength is paramount.

Top 3 ASTM Standard Stud Bolt Grades

ASTM A193 Grade B7 Stud Bolts:

B7 stud bolts, known for their high tensile strength and durability, are integral in critical applications. As reputable B7 Stud Bolts Manufacturers in India,We assure precision engineering and provide sturdy solutions for sectors where secure fastening is critical. Deltafitt Inc can supply B7 stud bolts that fulfill high quality requirements, assuring reliability in a variety of industrial environments.

ASTM A193 Grade B8 Stud Bolts:

B8 stud bolts, synonymous with corrosion resistance and exceptional performance, play a crucial role in demanding environments. As leading B8 Stud Bolts Manufacturers in India, Delta Fitt specializes in producing these bolts with precise engineering, providing dependable solutions for industries that require corrosion-resistant fastening. Count on us to supply high-quality B8 stud bolts that satisfy demanding quality requirements, assuring longevity and consistent performance in a wide range of industrial applications.

ASTM A193 Grade B8M Stud Bolts:

B8M stud bolts are known for their corrosion resistance, making them perfect for use in harsh situations. We excel in producing these bolts with precision engineering as a trusted B8M stud bolts manufacturer in India. Our B8M stud bolts are reliable solutions for industries that require corrosion protection, offering endurance and consistent performance across a wide range of industrial applications. Count on us for high-quality B8M stud bolts that exceed stringent quality requirements while delivering long-lasting fastening solutions.

Visit Delta Fitt for Choosing the Best Stud Bolts

Finally, Stud bolts are hidden fastener shining examples, securing structures and components across a wide range of industries. From construction to oil and gas, the kinds, selection criteria, and adherence to standards are critical for their successful usage. Understanding the subtleties of stud bolts enables industries to assure project safety, dependability, and lifespan.

Delta fitt, obtained the best stud bolts by top Stud Bolt Manufacturer in India, takes centre stage. Learn about their competitive advantages, manufacturing strategies, and market position. Examine the benefits, emphasise key aspects, and learn about industry challenges. Consider the future danger of stud bolt expansion. Choose best quality stud bolts like B7 & B8 Stud Bolts reliability for secure projects. Make the right choice for lasting reliability. Choosing these stud bolts from trusted B8 and B7 Stud Bolts suppliers in India creates a construction cooperation.

As a Stud Bolt Suppliers in India, Elevate your projects with the robust reliability of Stud Bolts. Secure success now!

#stud bolt manufacturers in india#B7 Stud Bolts Manufacturer in India#B8 Stud Bolts Manufacturers in India#stud bolt manufacturers

0 notes

Text

Purpose of choosing ASTM A193 grade strength

Alloy steel bolting materials meeting ASTM A193 Grade B16 criteria are the norm for strain vessels, valves, flanges, and fittings meant to face up to excessive temperatures and pressures. The maximum frequent users of these applications are the petrochemical, oil & gas, and power generation fields.

The chemical make-up of grade B16 bolts is as follows: silicon (0.15-zero.35%), chromium, manganese, phosphorus, sulfur, vanadium, and carbon. Grade B16 bolts are the maximum broadly used sort of alloy metal amongst numerous versions. These bolts' precise composition offers them with exquisite resistance to oxidation and sulfidation in addition to excessive temperature power.

To make certain that Grade B16 bolts are suitable and reliable for use in excessive-temperature and high-strain settings, the ASTM A193 widespread specifies necessities for his or her manufacturing, warmth treatment, and testing.

Could you explain the differences between B16 and B7 bolts?

While B7 and B16 bolts have similar features, what sincerely distinguishes them are their mechanical houses and material composition.

Enterprises coping with accelerated temperatures and pressures regularly make use of bolts with the B7 and B16 classifications. This is specially actual for the petrochemical, power era, and oil and gasoline sectors.

In order to achieve the required hardness and electricity, the medium carbon alloy metallic (4140) used to create B7 bolts and ASTM A193 B8 Bolts is often heated to the best temperature and then tempered. They have minimal yield and tensile strengths of 105 ksi and 125 ksi, respectively.

But the metal used to make B16 bolts is a higher alloy metal with molybdenum, chromium, and vanadium combined collectively. B16 bolts are stronger and extra proof against oxidation and sulfidation in warm conditions way to those additives. Moreover, B16 bolts have minimal yield and tensile strengths which can be corresponding to B7 bolts.

Use B7 bolts for packages desiring high energy and mild temperature resistance; use B16 bolts for packages requiring better energy and stronger resistance to oxidation and sulfidation at immoderate temperatures. B7 bolts are the endorsed desire while some diploma of heat resistance is vital.

Materials that are comparable to ASTM A193 Grade B16 consist of:

DIN EN 10269 1.4980:

European standard addresses bolts composed of a robust and heat-resistant chromium-molybdenum alloy steel.

ISO 898-1 class 10.9:

For bolts composed of alloy steels comparable to ASTM A193 Grade B16, International Standard ISO 898-1 class 10.9 provides mechanical criteria.

BS 1501-640B:

One can use British standard BS 1501-640B to fabricate fastening materials with characteristics comparable to ASTM A193 B8C bolts and ASTM A193 Grade B16. This general applies to high-power steel plates which have gone through heat remedy.

JIS SCM 4:

This Japanese business well-known specifies what to do with low-alloyed steels which have mechanical characteristics and chemical compositions equivalent to ASTM A193 Grade B16 and ASTM A193 B8M Stud Bolt.

It's vital to hold in mind that at the same time as the chemical composition and mechanical traits of numerous materials may be equal, their manufacturing methods, warmth remedy methods, and trying out requirements may additionally range. These variations may have an impact on the materials' performance for particular applications. It is advisable to study the pertinent material requirements and get advice from an experienced engineer or metallurgist when selecting bolting materials for applications involving high temperatures and pressures.

0 notes

Text

Detailed knowledge of stainless steel manufacturing techniques.

Steel has become one of the most often used building materials because of its capacity to withstand wear and tear, its strength, and its malleability. Steel fabrication appears to be the name given to the process of shaping steel into various forms that have practical use. Fabricators shape steel into bespoke shapes by cutting, grinding, burning, and welding it using cutting-edge technologies. The type of steel that is utilized is determined by the features that are required for the task.

Alloy steels are one of the many forms of steel that can be fashioned, and they receive their name from the fact that they include many elements whose mechanical qualities were intentionally chosen by the manufacturer. There are many other types of steel that may be fashioned as well. The following is a list of some of the most frequent ways that steel may be classed. The most ideal size can be found Inconel pipe suppliers.

There are a variety of tool steel grades available, including those with water hardening, colder-working, shock resistance, hot-working, greater speed, and special purpose. The fundamental level of toughness and hardness may be altered by altering the quantity of components used, such as carbon, manganese, molybdenum, and silicon. Finding Inconel Flanges Company to handle your project is a breeze.

It appears that weathering steel, a type of steel used in construction that does not need painting and, when weathered, takes on an especially stable, rusty aspect, is a type of steel utilized in the industry. Indeed, Singapore is the top metal supplier. Steel fabricators have relied on this method for making weapons and other items for centuries. Inconel pipe fittings are reliable.

When bent or twisted, spring steel will immediately return to its original shape due to its unique composition. This steel often has a high silicon content. It is used to create tools that can be bent and then quickly return to their original shape, such as stage swords, lock picks, spring clamps, springs, and antennas. A wide variety of Inconel round bar can be found online.

Grades 304 and 304l are widely utilized because to their mechanical qualities and strong corrosion resistance, mainly in chemical equipment, but also in nuclear and perhaps cryogenic containers. In addition, the corrosion resistance of 304 stainless plates in particular makes these metals excellent for producing equipment used in industries like the food industry, where cleanliness and the prevention of product contamination are of the utmost importance. Many folks prefer using Inconel forged fittings.

316l is chemically equivalent to 316 stainless but contains less carbon, therefore its characteristics are the same. The addition of molybdenum to austenitic steel makes 316L plates equally as strong as A320 L7 bolts, but significantly more resistant to corrosion in both chemical and marine environments. These services are preferred by many since they can usually be relied upon. These services are available at affordable rates. The usage of alloy steels in steel building systems is widespread. To obtain A193 B8m bolts, you need speak with a metals broker or a construction company.

0 notes

Text

Petrochemical Nuts And Bolts

The standard refers to the American ASTM or ASME standard with new and unique technical clauses added, which is suitable for a type of petrochemical fasteners used in high temperature and high-pressure environments, including bolts, studs, nuts, etc.

The mechanical properties and materials specified in GB/T3098/8 "Mechanical Properties of Carbon Steel Fasteners Part VIII Heat-resistant Threaded Connections" are suitable for fasteners that can withstand high temperature, alternating loads, and to a greater extent. Be sure to tighten the axial force.

High temperature and high-pressure petrochemical fasteners - commodity fasteners and special fasteners

Common Commodity wind energy fasteners: ●The type and size of hexagon head bolts meet the requirements of GB/T5782, A and B grades. The mechanical properties of these petrochemical fasteners refer to the performance grades of carbon steel bolts according to GB/T3098/1 standard: A2-50, A4-50, A2-70, A4-70;

●The nut type conforms to GB/T6170 I-type nut and special nut (pipe flange nut). Its mechanical properties refer to the performance grades of carbon steel according to the GB/T3098/2 standard: grades 6 and 8; the performance grades of stainless steel nuts of GB/T3098/15 are A2-50, A4-50, A2-70, A4-70 ;

Special Petrochemical Fasteners: ●In order to be suitable for the conditions of high-temperature resistance, low-temperature resistance, and environmental corrosion resistance, formulate suitable special fasteners, such as full-threaded studs for pipe flanges, in accordance with the provisions of GB/T901. The dimensions of hexagon head bolts and nuts shall be carried out according to national standards.

●Selected materials (grades) include medium carbon alloy steels: 35CrMo (applicable temperature +100-525℃); 25Cr2MoV (applicable temperature>-20--575℃); 42 CrMo (applicable temperature +100-525℃). The strength is between 690~890Mpa, that is to say, the medium carbon alloy steel is tempered at high temperature (550℃<=tempering temperature<=600℃) to obtain comprehensive mechanical properties to meet the service of high-temperature environment.

●Stainless steel materials selected are: 0Cr18Mi9 (applicable temperature -196--800 ℃); 0Cr17Mi12Mo2 (applicable temperature +196--800 ℃); the strength of stainless steel material obtained by solution treatment is between 690~890Mpa, and the performance level is A2- 70 A4-50 A4-80 grade.

●Using American standards, using stainless steel grades and materials: ASTM A193 B8 CL.2 (for temperature +196-525℃); A193 B8M CL.2 (for temperature +196-525℃); A453660 (for temperature +29- 525℃); also includes A320L7 suitable for low temperature and high-pressure environment (applicable temperature -100℃).

●Special grade nut material (grade) can choose medium carbon alloy steel: 30CrMo, 35CrMo; guaranteed load

0 notes

Text

#A193 Grade B8M Allen Bolt#B8M Grade Flange Bolt#SA193 Class 1 B8M Anchor Bolt#Class 1 Grade B8M Hex Bolt#B8M Grade ASME SA193 Eye Bolt#ASTM A193 B8M Hex Bolt#B8M Class 1 Stud Bolt#ASME SA193 B8M U Bolt.

0 notes

Text

A320 Grade B8M Bolts – Fastener for Low Temperature Application

Apparently, drawing comparisons between A193 and A320 grade comes naturally. Thanks to a majority of common attributes, these two grades are held quite similarly to their mechanical and chemical requirements. However, these two aren’t alike in all cases. Precisely, the grade A193 bolts are needed in high temperate and high pressure applications, whereas A320 is meant for cryogenic range.

Basically, a customer looking for A320 grade B8M bolts would have classic requirements for cold temperature applications. The AISI 304 type comprises this category of for class 1 Stainless Steel where it is carbide solution treated for delivering high-quality performances. The mechanical and chemical properties may rarely see a fluctuation due to the given order of manufacturing.

Both class 1 and class 2 of A320 grade B8 bolts are carbide solution treated. However, in class 2, these bolts are strain annealed to achieve additional results. Since ASTM A320 specially covered the bolts and fasteners for low temperature applications, the most common applications used to be in valves, flanges, vessels, and fittings. Excluding a few, the ASTM A320 specifications recommend a Charpy impact test for all grades. Definitely, it is held in order to test the toughness of a material. Nevertheless, carbide solution treated and strain hardened grades like B8 and B8M would not be required.

Unless one settles for one brand irrespective of the quotes they offer, there should be an all and out competition between suppliers and manufacturers to deliver the best quality products to the customers or clients.

0 notes

Text

Premium Stud Bolts Manufacturer, Supplier & Exporter

Introduction

Stud Bolts are one of the versatile fasteners widely used in all industries like oil & gas, petrochemical, power plants, construction, and marine applications. It is designed to have critical fastening. Ananka Group is a leading manufacturer, supplier, and exporter of Stud Bolts; it ensures top quality precision, and reliability in all its products.

The premium stud bolts that manufacture, supply, and export in high-quality and precision commitment in the fastener industry. We as a manufacturer use advanced materials and cutting-edge technology to produce stud bolts that meet the stringent industry standards for durability and reliability in applications ranging from construction to automotive sectors. Focus on superior craftsmanship and strict quality control processes, thus giving products not only make structures safer but also increase efficiency.

Additionally, capability to satisfy different customers through customization also indicates a commitment to customer satisfaction. Being trusted suppliers in the global market, these manufacturers have become the link between industries and premium fastening solutions that have withstood time. As a way of giving credit to their hard work, we acknowledge the important role these premium stud bolts play in driving innovation and excellence in many sectors.

About Stud Bolts

Stud bolts are long threaded rods with threads on both ends, or sometimes throughout the rod. They are primarily used to clamp flanges or other equipment together, ensuring a tight, leak-free seal. Unlike traditional bolts, stud bolts do not have heads and rely on nuts for fastening.

Types of Stud Bolts

Fully Threaded Stud Bolts: Threads run across the entire length of the stud.

Tap-End Stud Bolts: Threads on both ends, but the lengths of the threads differ.

Double-End Stud Bolts: Threads of equal length at both ends.

Reduced Shank Stud Bolts: Feature a reduced diameter in the unthreaded section to improve flexibility.

Stud Bolts Specifications

Standards: ASTM A193, ASTM A320, ASME SA193, ISO, DIN, and other international standards.

Sizes: From M6 to M64 or custom sizes as per client requirements.

Thread Types: Coarse, fine, or special threads based on the application.

Finish: Plain, galvanized, or coated with PTFE, zinc, or other protective materials.

Stud Bolts Sizes & Standards

Stud Bolts Materials / Grades & Sizes

Carbon Steel Stud Bolts

Grades: ASTM A193 Grade B7, ASTM A320 Grade L7

Applications: High-temperature and pressure environments.

Stainless Steel Stud Bolts

Grades: ASTM A193 Grade B8, B8M

Applications: Corrosion-resistant environments like marine and chemical industries.

Alloy Steel Stud Bolts

Grades: ASTM A193 Grade B16

Applications: High-strength requirements and elevated temperatures.

Nickel Alloy Stud Bolts

Grades: Inconel, Monel, Hastelloy

Applications: Extreme temperatures and highly corrosive environments.

Exotic Material Stud Bolts

Materials: Titanium, Duplex, Super Duplex

Applications: Specialized industries like aerospace and medical.

Why Choose Ananka Group for Stud Bolts?

Uncompromising Quality: Manufactured as per international standards with precise tolerances.

Material Versatility: Offering a wide range of materials to suit varied applications.

Customization: Tailor-made solutions for specific project requirements.

Global Reach: Exporting to countries across Europe, Asia, America, and Africa.

Conclusion

Stud bolts are indispensable in industries requiring high-strength and secure fasteners for critical applications. With Ananka Group, you are assured of the best quality products, backed by extensive expertise, advanced manufacturing facilities, and a commitment to excellence.

FAQs

Q1. What are stud bolts used for?A: Stud bolts are primarily used in applications requiring secure fastening, such as connecting flanges, pipelines, and machinery.

Q2. What materials are stud bolts made of?A: Common materials include carbon steel, stainless steel, alloy steel, and nickel alloys.

Q3. Can stud bolts be customized?A: Yes, stud bolts can be tailored to specific sizes, materials, coatings, and thread types.

Q4. How to choose the right stud bolts?A: The choice depends on the application requirements, such as temperature, pressure, corrosion resistance, and strength.

Q5. Do you provide international shipping?A: Yes, we export our stud bolts to various countries worldwide.

#AnankaFasteners#Fasteners#StudBolts#BoltManufacturing#Manufacturing#Linkedin#Article#StudboltMaking#FastenersManufacturing#manufacturer#ananka#supplier#hex#bolt#mumbai#uk

0 notes

Text

Know All About the A193 B8m -A prefect Stainless steel

A193 B8m specifications are used in oil and chemical structure applications. ASTM standards cover high-temperature or high-pressure stainless steel and alloy steel such as B7 bars. STM A193 carbonless and stainless steel rods and bolts are used to connect flanges, valves, pressure vessels, and fittings to high temperature and high-pressure services.In 1936, specificationA193 B8m was approved. This specification is commonly utilized in structural applications in the petroleum and chemical industries. Fasteners for pressure vessels, valves, flanges, and fittings are included in this specification. This material is often available at thread pitches, but for use in conventional applications, threads larger than 1 inch are specified as eight threads per TPI).There are several grades to the A193 specification with different chemical compositions, mechanical properties, and high temperature properties. The most common grade in the A193 specification is Class B7, but there are several others.Fasteners based on Spec A193 are commonly specified, manufactured, and supplied as heavy hexagon bolts or threaded rods and bolts (weekend thread bolts). The carbon steel flanges manufacturers in india offer a series of bent bolts (U, L, or J), threaded rods at one or both ends, and heavy, non-hexagonal head bolts. All screws, rods, and bolts must be flushed.ASTM A962 is a related standard that covers a set of general requirements related to A193. Section 13 of the A962 specification corresponds to the shape and class of the wire. The threads must be in accordance with ASME B1.1, Class 2A, and can be cutting or coil type. If the diameter is 1 inch or less, the National Unified Coarse (UNC) thread chain is used, and if the diameter is larger than 1 inch, the 8UN (8UN) thread chain is used unless otherwise stated.CoatingCertain grades of fasteners made with ASTM A193 (hot-dip galvanized, mechanically galvanised) or F1941 (mechanically galvanized) can be galvanized (cold or electro-galvanized). Teflon, xylan, and PTFE coatings are also often utilized with A193V, in addition to cadmium coatings.Product labelThe quality code and the stainless steel carriage bolt manufacturers‘ identification information both apply to the screw head and one end of the threaded rod and bolt. Section 17 of the A193 B8m specification describes the omission of product marks on the fasteners and the tolerance for marking very small diameters elsewhere, but rarely the work. Dual grade marks are permitted as long as the fasteners meet all the requirements of both specifications.Dimension exampleUnless otherwise stated, plug screws must be dimensional heavy hexagons covered with A193 B8m. A193 rods and bolts are typically measured from first thread to first thread instead of full length, including the sloping ends.The high tensile fasteners manufacturers in india can manufacture all kinds of fasteners such as studs, hex bolts, flange bolts, flat nuts and washers, flange nuts and spring washers, non-standard products.Durable and strong fasteners for customers at the most competitive market prices in the world. The stainless steel flanges manufacturers in india manufactured a wide range of hex nuts and bolts under the best guidance and gained the highest reputation.

0 notes

Text

ASTM A193 Grade B7M Bolts, Stud Bolts | Roll Fast

Roll Fast is a manufacturer, supplier, and exporter of ASTM A193 Grade-B7M bolts and stud bolts in India. It includes alloy and stainless steel bolting for pressure vessels, valves, flanges, and fittings used in high-temperature or high-pressure applications, as well as other special applications. ASTM A193 grade B7M includes chromium-molybdenum alloy steel fasteners covered in this basic material specification. These high-tensile fasteners are in high demand in chemical and petroleum construction applications. There are many grades covered, including ferritic steels and austenitic stainless steels with designations such as B5, B6, B7, B8, B8M, and so on.

visit source URL: https://www.roll-fast.com/astm-a193-grade-b7m.html

0 notes

Text

Threaded Rods and Bars Manufacturer, Supplier and Exporter India | BigBoltNut

We are a leading Manufacturer of threaded rods and bars in India. These Rods are generally provided with double nuts and often with 4 nuts depending upon the application and requirements. Available in 8.8, 10.9, B7, B7M, L7, L7M, B8, B8M Class 1 and Class 2 grades. Full threaded Rods are non headed bolts, these are in form of a rod and have threads from end to end. These Rods are generally provided with double nuts and often with 4 nuts depending upon the application and requirements of the project or customer. Threaded rods are generally used in civil construction; they find their use in joining ducting and other uses where ever necessary.

0 notes